C OMBI OVEN

INSTALLATION MANUAL

INDICE

1. INTRODUCTION ............................................................................................................. 6

2. TECHNICAL CHARACTERISTICS .................................................................................. 7

2.1 Main characteristics MyChef S ............................................................................. 7

2.2 Main characteristics MyChef L ............................................................................. 7

3. GENERAL SAFETY AND ACCIDENT PREVENTION REGULATIONS............................ 8

3.1 Personnel responsible for using the equipment .................................................. 8

3.2 Electrical hazard ..................................................................................................... 8

3.3 Thermal hazard ...................................................................................................... 8

3.4 Corrosion hazard.................................................................................................... 8

4. RECEPTION, TRANSPORT AND POSITIONING .......................................................... 10

4.1 Reception .............................................................................................................. 10

4.2 Transport .............................................................................................................. 10

4.3 Positioning ............................................................................................................ 10

5. INSTALATION .............................................................................................................. 12

5.1 Electrical connection ........................................................................................... 12

5.1.1 Three phase connection 400V 3L+N .......................................................... 14

5.1.2 Three phase 230V 3L ................................................................................... 15

5.1.3 Single phase 230V L+N ................................................................................ 17

5.2 Water connection ................................................................................................. 19

5.2.1 Water input .................................................................................................... 19

5.2.2 Drain .............................................................................................................. 19

5.3 Vapour condensation hood ................................................................................. 19

6. GENERAL ELECTRICAL DIAGRAM.............................................................................. 21

6.1 Power MyChef S ................................................................................................... 21

6.2 Relés MyChef L .................................................................................................... 22

6.3 Control MyChef S and MyChef L ......................................................................... 23

5

1. INTRODUCTION

Before carrying out any intervention or use of the equipment, it is necessary

to read this manual carefully and completely.

The manufacturer shall disclaim any liability for problems caused by

improper installation, modification, use or improper maintenance.

This manual has been carefully prepared and checked to provide reliable and helpful

information for proper installation, use and maintenance that will ensure proper

operation and prolong the life of the furnace. This manual is divided into two parts, the

first part dedicated to the installation of the equipment at the working point, and the

second part focused on cleaning and maintenance of the oven.

The manufacturer disclaims any implied or explicit liability for any errors or omissions

it may contain.

- The furnace may not be used by personnel who have not received any kind of

training, and who do not have the necessary skills or experience for the correct

operation of the equipment. Do not allow children to use or play with the

computer.

- The owner of the equipment has the obligation to have this manual read to the

personnel in charge of its use and maintenance, and to keep this manual in a

safe place so that it can be used by all users of the equipment and for future

reference. If the equipment is sold to other people, this manual must be given

to them.

- This oven may only be used for the purpose for which it was designed, i. e.

cooking, heating, regenerating or dehydrating foodstuffs. Any other use may be

hazardous and may result in personal injury and damage to property.

- The equipment is shipped from the factory once it has been calibrated and

passed rigorous quality and safety tests to ensure its correct operation.

6

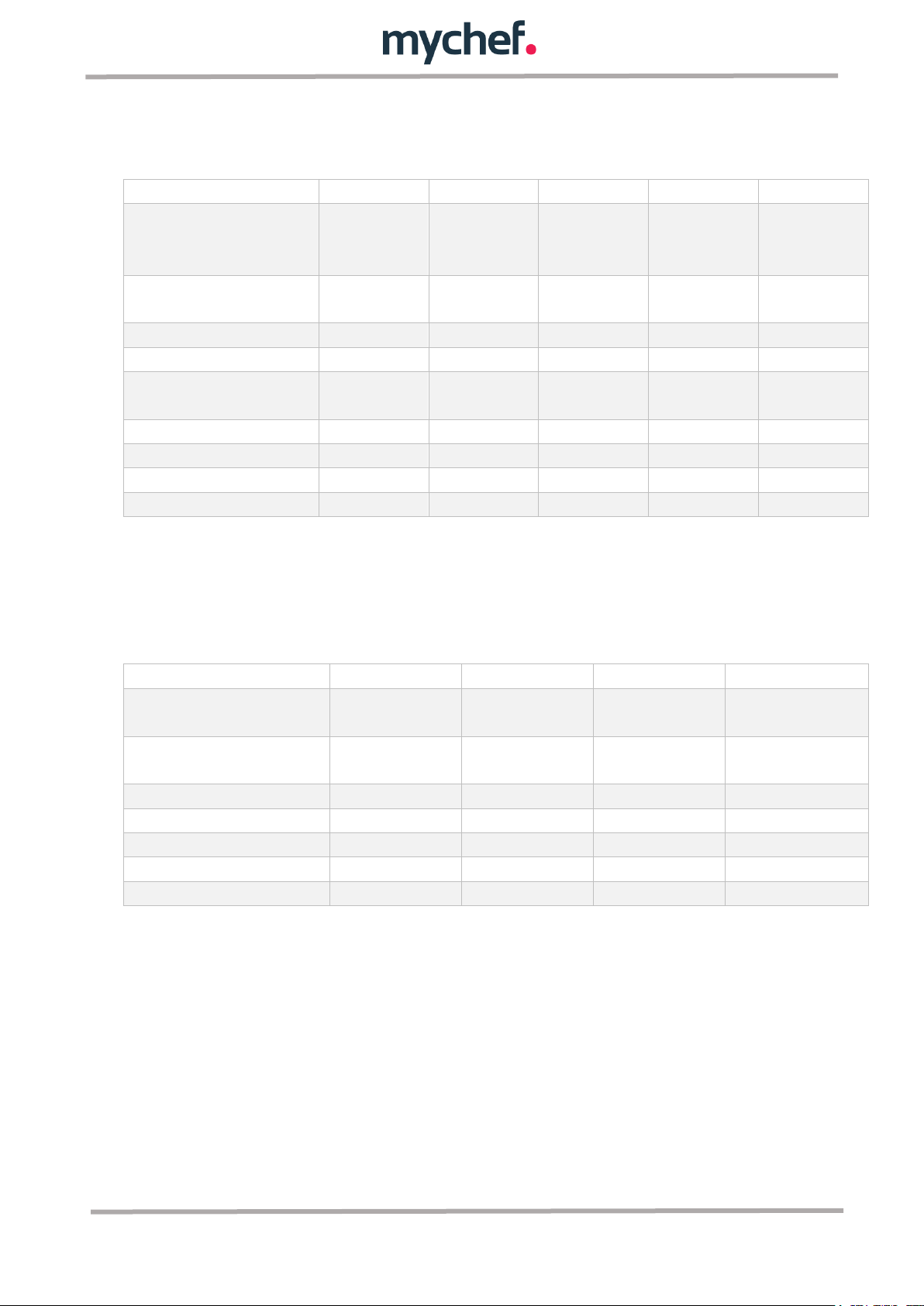

4GN 1/1

6GN 2/3

6GN 1/1

6GN 1/1 T

9GN 1/1

External dimensions

(Width x Depth x

Height)

520 x 800 x

662mm

520 x 623 x

662mm

520 x 800 x

662mm

760 x 595 x

662mm

520 x 800 x

822mm

Capacity

4 GN 1/1

40mm

6 GN 2/3

40mm

6 GN 1/1

40mm

6 GN 2/3

40mm

10GN 1/1

40mm

Power (1L+N)

2,9/5,6kW

2,9/5,6kW

- - -

Power (3L, 3L+N)

5,6kW

5,6kW

7kW

7kW

10,4kW

Distance between

trays

62mm

54mm

54mm

54mm

54mm

Meals/day

20-80

20-80

30-100

30-100

50-150

Currant (1L+N)

13/24A

13/24A

- - -

Current (3L, 3L+N)

12A

12A

15A

15A

23A

Cable section

2.5mm2

2.5mm2

2.5mm2

2.5mm2

2.5mm2

6GN 1/1

6GN 2/1

10GN 1/1

10GN 2/1

External dimensions

(Width x Depth x Height)

760 x 700 x

822mm

760 x 950 x

822mm

760 x 700 x

1122mm

760 x 950 x

1122mm

Capacity

6 GN 2/3

40mm

6 GN 1/1

40mm

6 GN 2/3

40mm

10GN 1/1

40mm

Power (1L+N)

10.7kW

17.2kW

18.4kW

34.4kW

Power (3L, 3L+N)

73mm

73mm

73mm

73mm

Distance between trays

40-110

60-180

80-160

150-300

Meals/day

16A

25A

27A

50A

Currant (1L+N)

2.5mm2

4mm2

4mm2

10mm2

2. TECHNICAL CHARACTERISTICS

2.1 Main characteristics MyChef S

Table 1: Main features of MyChef S ovens.

The maximum recommended load of food per GN 1/1 40mm tray is 3.5 Kg and 2Kg for

GN 2/3 trays.

2.2 Main characteristics MyChef L

Table 2: Main features of MyChef L ovens.

The maximum recommended load of food per GN 1/1 65mm tray is 5 Kg and 3.5Kg for

GN 2/3 trays.

7

3. GENERAL SAFETY AND ACCIDENT PREVENTION REGULATIONS

Personnel performing any action on the furnace, whether it be use, cleaning,

installation, handling, etc. must be familiar with the safety regulations and

instructions for use.

Do not allow unauthorized personnel to use, handle, or clean equipment.

Keep ventilation openings clear of obstacles. Do not install the equipment in

the vicinity of flammable products. Avoid positioning the oven near sources

of heat such as stoves, irons, fryers, etc. Check the safety distances in

chapter ¡Error! No se encuentra el origen de la referencia..

DANGER OF ACCIDENT! Use caution when using food containers in the oven

when the top tray is 160 cm or higher. There is a risk of injury from the hot

contents of GN trays.

While the furnace is in operation, avoid touching metal parts and the glass of

the door as they can exceed 60°C. Touch only the handle and control panel.

3.1 Personnel responsible for using the equipment

Use of the equipment is reserved for trained personnel.

3.2 Electrical hazard

Work on the power supply and access to live parts is permitted only by qualified

personnel and at their own risk. In any case, this access must be done with the

equipment disconnected from the mains supply.

If the appliance is placed on a trolley or on tables that have some mobility, do not allow

it to move while connected to the power source to avoid possible damage to the wiring,

drain pipes or water inlet pipes. In case you want to move or change the position of the

unit, disconnect the cables and drains and water pipes.

3.3 Thermal hazard

When the appliance is in operation, open the door slowly and carefully to avoid possible

burns from the steam or hot air that may come out of the cooking chamber.

3.4 Corrosion hazard

When using cleaning products, special care and appropriate safety measures should be

taken to handle these products. Always read the safety data sheets of the different

chemicals before using them and follow their instructions for use. These products, in

8

Use MyCare cleanduo in ovens equipped with automatic washing system,

and DA21 in ovens with semi-automatic washing system. Use of other

products voids warranty.

contact with any part of the body, are abrasive and can produce skin and eye irritations

and caustications.

During the cleaning process of the combi steamer and in case of aerosol or mist

formation during handling of the cleaning products, wear a facemask with particle filter

type P2 / P3, panoramic splash glasses and/or spray masks and chemical protective

gloves.

MyCare cleanduo and DA21 cleaning products have been specially formulated for the

correct cleaning and protection of MyChef ovens with automatic and semi-automatic

washing respectively. Both products contain, in addition to detergent, polish for a

perfect finish. The use of these detergents in MyChef ovens is mandatory.

9

4. RECEPTION, TRANSPORT AND POSITIONING

Before carrying out the installation, the dimensions of the site where the equipment is

to be installed and the electrical and water connections must be checked, and it must

be verified that they are within the parameters detailed in the installation sheet.

4.1 Reception

Once the furnace has been received, check that the model purchased corresponds to

the order.

Check that the packaging is undamaged during transport and that there are no missing

parts or pieces of equipment. If any anomalies or problems are detected, please

contact your dealer immediately.

4.2 Transport

The equipment must be transported in its original packaging to the place closest to the

point of installation to avoid damage as much as possible. It is recommended that the

original packaging be stored until the equipment is properly installed and operating.

To move the equipment and place it in your workspace, consider the following

observations:

- The dimensions of the different models to be taken into account when passing

through narrow spaces (passageways, doors, narrow spaces). See Table 1 and

Table 2.

- The manipulation must be done with the necessary personnel to move the load

of the furniture taking into account the regulations in force regarding work

safety at the place of installation.

- During the movement of the oven, it must always be in a vertical position. It

must be lifted perpendicular to the ground and transported parallel to it.

- Make sure that during transport it does not tip over and does not hit any

objects.

4.3 Positioning

- Place the oven at a convenient distance from the wall to make the electrical and

water connections. There must be a minimum separation from the parts of the

furnace so that it can be properly ventilated and cooled. This minimum distance

is:

o 50mm on the left and right sides

o 100mm from the rear part

o 500mm at the top

10

For the installation of stacked MyChef ovens, follow the instructions

supplied with the corresponding stacking kit.

500m

100mm

50mm

1000m

50mm

- The unit must be placed on a MyChef support table or wall mount.

- If there are heat sources near the equipment (burners, grills, grill, fryer, etc.),

these must be at a distance of more than 1 metre.

- Once it is placed in the workspace, check that it is level.

- Never block the underside of the front water collector.

Figure 1: Example of suitable installation location.

11

5. INSTALATION

Connection to an equipotential bonding system ensures additional safety in

the event of simultaneous ground fault and differential failure.

Observe the applicable regulations for connecting the equipment to the lowvoltage mains supply.

5.1 Electrical connection

Check that the voltage at the point where the furnace is to be connected matches the

operating voltage of the equipment.

Before carrying out any electrical work, make sure that there is no electric current at the

equipment connection point.

The equipment must be connected to the mains by means of an omnipolar cut-off

switch and with a contact opening distance of more than 3 mm. Also install a class A

differential device and overcurrent protection.

Always guarantee an efficient earthing system.

Connect the equipment to an equipotential bonding system using the specially

designed contact for this purpose (see equipotential sign on the lower left side of the

equipment). In the case of two stacked equipment, both must be connected to the

equipotential bonding system.

Wiring and other safety devices used for electrical installation must have the

appropriate cross-section for the equipment in question.

Before starting the electrical installation, verify that the electrical requirements of the

furnace and mains supply are the same.

For correct connection after positioning, you will need a cable with a length that allows

you to reach the connection point plus about 20cm, to make the connection on the

back of the equipment. Remove the rear plate from the equipment. Insert the cable

through the cable gland in the lower left-hand side of the furnace (see rear panel).

Some MyChef ovens can be connected to different voltages and configurations at the

time of installation. To make the correct connection, use the terminal blocks supplied

with the equipment according to the instructions in the following subchapters. These

terminal strips are located between contacts 4 and 5 of the terminal block.

12

Figure 2: Terminal junction strips.

Figure 3: Entrada de cable y bornero.

Never connect a phase to neutral or ground. Check that the installation

voltages correspond to those of the equipment.

Check, once the connection has been made, that no cable is loose and they are all

firmly fastened. Also secure the cable gland.

The following subchapters show the three types of possible connections for MyChef

ovens.

13

5.1.1 Three phase connection 400V 3L+N

Figure 4: Three phase 400V 3L+N.

Figure 5: Three phase 400V 3L+N.

Color

Cable

Connector

■

Brown

L1

1 ■ Black

L2

2 ■ Grey

L3

3

■

Blue

Neutral

4

■

Green-yellow

Ground

Ground

Table 3: Three phase cable 400V 3L+N.

14

Figure 6: Three phase 230V 3L.

Figure 7: Three phase 230V 3L.

Color

Cable

Connector

■

Brown

L1

1

■

Black

L2

2,3

■

Grey

L3

4 ■ Green-yellow

Ground

Ground

5.1.2 Three phase 230V 3L

5.1.2.1 MyChef

Table 4: Three phase cable 230V 3L MyChef.

To connect terminal block positions 2-3, use the connecting plate supplied with your

MyChef oven.

15

5.1.2.2 MyChef L

Figure 8: Three phase 230V 3L.

Figure 9: Three phase 230V 3L.

Cable

Cable

Connector

■

Brown

L1

1 ■ Black

L2

2,4

■

Grey

L3

3

■

Green-yellow

Ground

Ground

Table 5: Three phase cable 230V 3L MyChef L.

In this type of connection, the triangular convection resistors must be rewired (Delta).

Figure 10: Star and triangle (Delta) connections

16

Figure 11: Single phase half power.

Figure 12 Single phase half power.

Figure 13: Single phase full power

Figure 14: Single phase full power.

5.1.3 Single phase 230V L+N

This type of connection is only valid for MyChef ovens S 4GN1/1 and MyChef S

6GN2/3.

17

Color

Cable

Connector

■

Brown

L1

1,2,31

■

Blue

Neutral

4 ■ Green-yellow

Ground

Ground

1

Table 6: Single phase cable 230V L+N.

Use the connecting plates supplied with your MyChef furnace to connect positions 1-2

and 2-3 of the terminal block.

Connection in position 3 is made at full power.

18

If it is a new installation, the water should be allowed to run until the

connection is completely purified. This operation must be repeated each

time work or repairs are carried out on the water supply to the furnace

A

B

5.2 Water connection

5.2.1 Water input

Cold water (max. 30°C) ¾’’ from 150 to 400 kPa of dynamic flow pressure.

Potable quality water with the following characteristics:

- Hardness between 3º y 6º FH

- PH between 6,5 y 8,5

- Chlorides lower than 30ppm

Use of water softener and filter is mandatory.

The furnace has two dedicated water inlets on the back of the furnace, one for soft

water (A) used for steam generation and one for untreated water (B) for self-cleaning

processes.

Figure 15: Soft (A) and untreated (B) water inlets.

5.2.2 Drain

For proper operation of the steam system of the furnace, the equipment must be

connected to a drainage system of 40mm nominal diameter (DN40) through a heatresistant pipe. The MyChef oven incorporates an internal odour blocking system that

can come from the drainpipe.

For correct operation, keep in mind that the pipe must have a constant minimum slope

of 5º.

5.3 Vapour condensation hood

Refer to the installation manual supplied with the vapour condensing hood for

installation.

19

The steam condensing hood is optional equipment. The hood can be

installed after the furnace has been installed.

20

6. GENERAL ELECTRICAL DIAGRAM

6.1 Power MyChef S

Figure 16: Electrical drawing MyChef S.

21

6.2 Relés MyChef L

Figure 17: Electrical drawing MyChef L.

22

6.3 Control MyChef S and MyChef L

Figure 18: Human interface.

23

Loading...

Loading...