Mychef FSSB22G2, iSENSOR, TTSB06G2, FSSB2UG2, FSSB2LG2 Installation, Operation And Maintenance Manual

...

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

iSENSOR

1

Index

1. INTRODUCTION ..................................................................................................................... 3

2. TECHNICAL CHARACTERISTICS .............................................................................................. 3

2.1 Functional equipment ................................................................................................... 3

2.2 Constructive features .................................................................................................... 3

2.3 General tabletop model sizes ........................................................................................ 4

2.4 General floor standing model sizes ............................................................................... 5

3. GENERAL SAFETY AND ACCIDENT PREVENTION REGULATIONS ........................................... 6

3.1 Operating personnel of the machine ............................................................................ 6

Personnel must be familiar with the safety regulations and instructions for use. ................... 6

3.2 Electrical hazard ............................................................................................................ 6

3.3 Thermal hazard ............................................................................................................. 6

3.4 Hazard arising from the use of gas ................................................................................ 6

This machine is not designed for the use of Oxygen O2 or other flammable gases. .................... 6

4. INSTALLATION ....................................................................................................................... 6

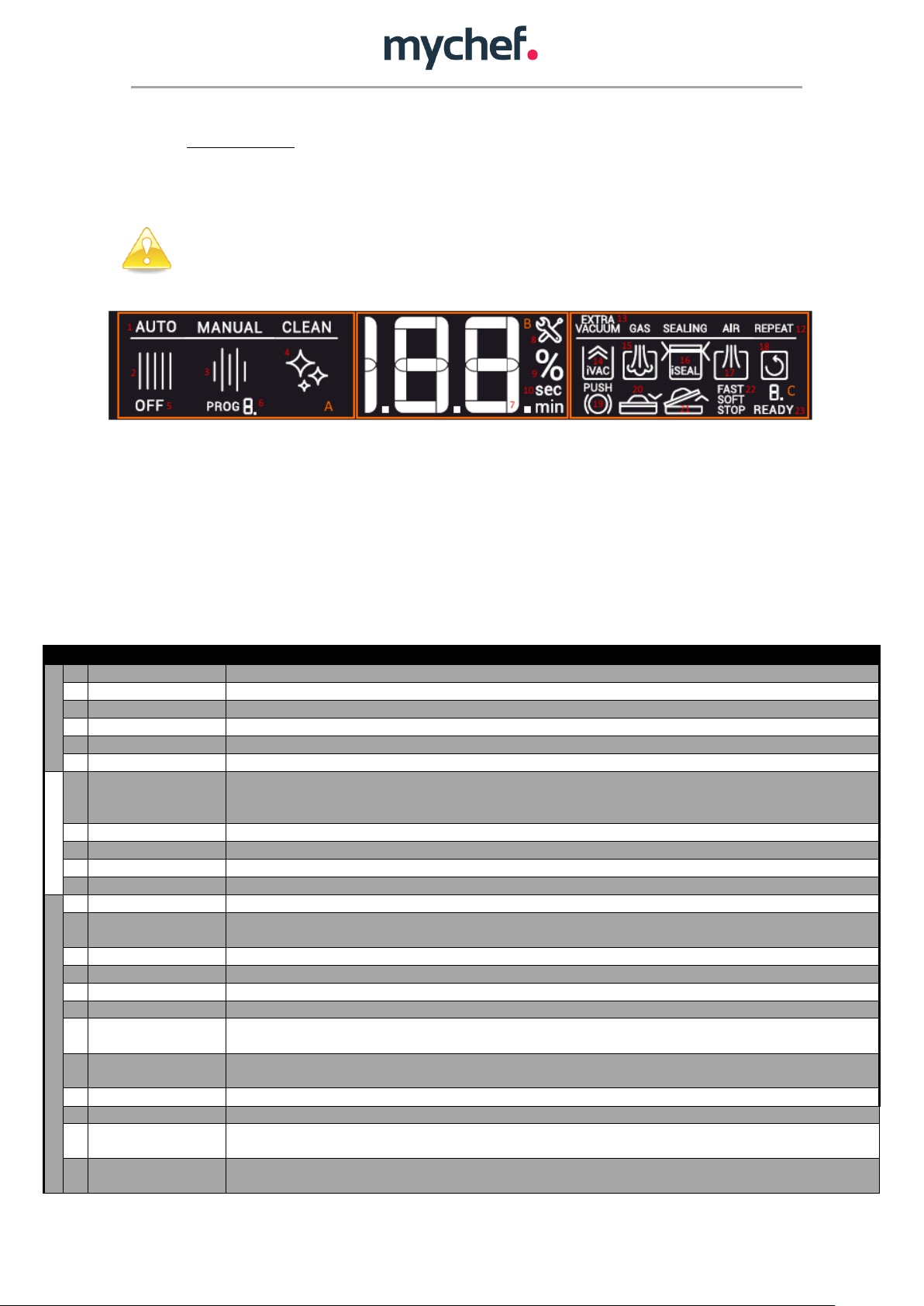

5. CONTROL PANEL.................................................................................................................... 7

6. CALIBRATION ......................................................................................................................... 8

6.1 Self Calibration system SCS ........................................................................................... 8

7. OPERATION ........................................................................................................................... 9

7.1 Powering and switching on the machine ...................................................................... 9

7.2 Inert gas injection ........................................................................................................ 10

7.3 Operating modes ......................................................................................................... 10

7.3.1 Automatic mode .................................................................................................. 10

7.3.2 Manual mode ...................................................................................................... 11

7.3.3 Autoclean ............................................................................................................ 13

7.4 Packaging ..................................................................................................................... 13

8. ERRORS ................................................................................................................................ 15

9. MAINTENANCE .................................................................................................................... 16

9.1 Cleaning ....................................................................................................................... 16

9.2 Vaccum pumb oil ......................................................................................................... 16

9.3 Welding bar ................................................................................................................. 16

9.4 Lid gasket ..................................................................................................................... 16

10. MAINTENANCE SCHEDULE .............................................................................................. 17

10.1 Check the oil level ....................................................................................................... 17

10.2 Changing the pump oil ................................................................................................ 18

2

10.2.1 Table top models ................................................................................................. 18

10.2.2 Fool standing models .......................................................................................... 22

10.3 Other maintenance operations ................................................................................... 23

10.4 Owner’s liability ........................................................................................................... 23

11. SPECIFICATIONS............................................................................................................... 24

11.1 General wiring diagram iSensor Tabletop SMALL, MEDIUM Y LARGE ........................ 25

11.1.2 General wiring diagram iSensor Floor standing SMALL, MEDIUM Y LARGE ........... 26

11.2 Pneumatic diagram ..................................................................................................... 27

1. INTRODUCTION

Removable solder bar without

connections.

Possibility of programming up to 9 work

cycles.

Optional inert gas inlet on all models.

External vacuum accessory for all iSensor

tabletop models (optional).

Progressive pressure recovery to avoid

damage to the bag caused by spines,

bones, etc....

Polyethylene plate inside the chamber,

which increases the vacuum speed and

regulates the working height.

Controlled visualization of all process

steps.

Vacuum control by sensor.

Auto-calibration system

Vacuum plus vacuum to force air out of

porous products.

Intelligent mode for packaging liquids

and porous products (iVac).

AUTO-CLEAN OIL process, self-cleaning

oil system.

Standard external vacuum for all tabletop

models.

Double sealing 2x3 mm for iSensor

tabletop packaging machines.

Double welding 2x4 mm for iSensor floor

standing packers.

Built in stainless steel.

The tank has rounded edges for easy

cleaning.

Transparent methacrylate lid to visualize

the element to be packed.

For standing models, 4 wheels two with

brake for easy mobility.

Rear oil level indicator

For floor standing models, it is possible to

choose the sealing shape:

This document has been prepared and to provide reliable and helpful information for the use

of the equipment. The manufacturer disclaims any implied or explicit liability for any errors or

omissions it may contain.

Before carrying out any intervention or use of the machine, it is recommended to read

this manual carefully and completely.

The owner of the equipment is obliged to have this manual read by the personnel in

charge of its operation and maintenance.

2. TECHNICAL CHARACTERISTICS

2.1 Functional equipment

3

NOTE: The floor standing models are factory wired to 400V with 3 phases plus a neutral, if you

want the 230V voltage with 3 phases will be provided a technical note for a specialized SAT to

make the change.

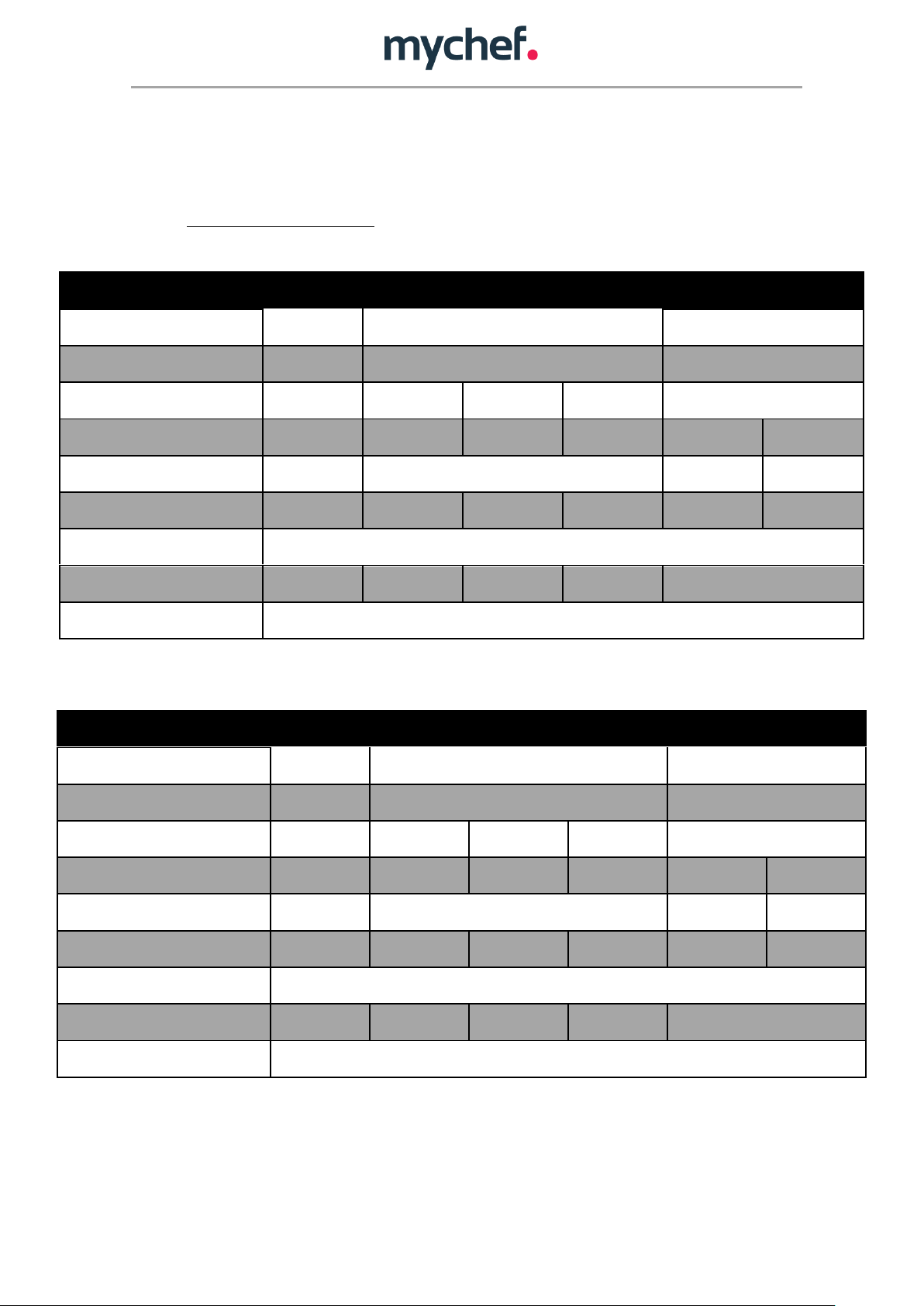

2.2 Constructive features

REFERENCE

TTSB06G2

TTMB10G2

TTMB16G2

TTMB20G2

TTLB21G2

TTLB22G2

External dimensions (mm)

388x491x382

475x561x454

620x571x469

Internal dimensions (mm)

328x385x162

412x453x200

560x465x210

Pump capacity (m3/h)

6

10

16

20

20

Machine cycle (S)

40

41

30

28

40

35

Sealing bar length (mm)

315

405

455

455 x2

Approximate weight (kg)

28

38

39

40

43

45

Voltage

230/1/50-60Hz

Power (kW)

0,25

0.30

0,55

0,75

0.75

Lubricant

Synthetic food grade oil SAE 10 VSL 32

REFERENCE

TTSB06E2

TTMB10E2

TTMB16E2

TTMB20E2

TTLB21E2

TTLB22E2

External dimensions (mm)

388x491x382

475x561x454

620x571x469

Internal dimensions (mm)

328x385x162

412x453x200

560x465x210

Pump capacity (m3/h)

6

10

16

20

20

Machine cycle (S)

38

40

28

26

38

33

Sealing bar length (mm)

315

405

455

455 x2

Approximate weight (kg)

28

38

39

40

43

45

Voltage

230/1/50-60Hz

Power (kW)

0.25

0.30

0,55

0,75

0.75

Lubricant

Synthetic food grade oil SAE 10 VSL 32

2.3 General tabletop model sizes

iSensor tabletop models with inert gas:

4

iSensor models for tabletop without inert gas:

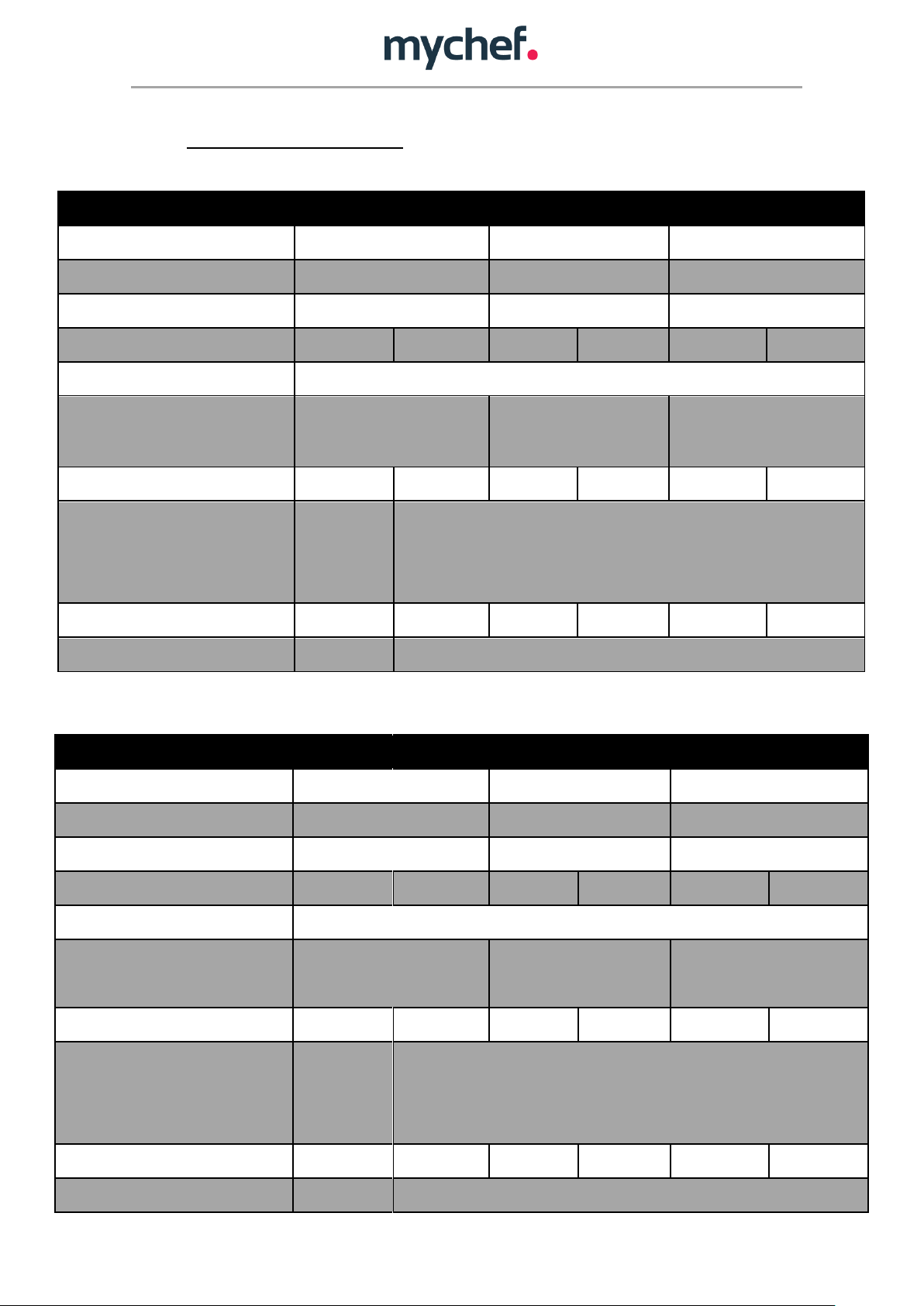

2.4 General floor standing model size

REFERENCE

FSSB2*G2

FSSB4*G2

FSMB4*G2

FSMB6*G2

FSLB6*G2

FSLB1*G2

External dimensions (mm)

853x537x1032

930x607x1046

1136x707x1050

Vacuum chamber dimensions (mm)

700x430x180

800X500X200

1000x600x200

Dimensions with packaging (mm)

925x665x1300

1002x735x1314

1208x835x1318

Pump capacity (m3/h)

20

40

40

63

63

100

Machine cycle (S)

25-60 segundos

Sealing bar length (mm)

*410 + 410 mm

* 410 + 630 mm

* 410 + 410 + 580 mm

*460 + 460 mm

* 460 + 730 mm

* 460 + 460 + 680 mm

* 560 + 560 mm

* 560 + 880 mm

* 560 + 560 + 880 mm

Approximate weight (kg)

147

157

197

215

247

265

Voltage

230 V / 1L +

N/50Hz

400V / 3L + N / 50Hz

230V / 3L /50 Hz

Power (kW)

0,75

1,125

1,125

1,5

1,5

2,25

Lubricant

SAE 10 VSL 32

SAE 30 VSL100

REFERENCE

FSSB2*G2

FSSB4*G2

FSMB4*G2

FSMB6*G2

FSLB6*G2

FSLB1*G2

External dimensions (mm)

853x537x1032

930x607x1046

1136x707x1050

Vacuum chamber dimensions (mm)

700x430x180

800X500X200

1000x600x200

Dimensions with packaging (mm)

925x665x1300

1002x735x1314

1208x835x1318

Pump capacity (m3/h)

20

40

40

63

63

100

Machine cycle (S)

25-60 segundos

Sealing bar length (mm)

*410 + 410 mm

* 410 + 630 mm

* 410 + 410 + 580 mm

*460 + 460 mm

* 460 + 730 mm

* 460 + 460 + 680 mm

* 560 + 560 mm

* 560 + 880 mm

* 560 + 560 + 880 mm

Approximate weight (kg)

147

157

197

215

247

265

Voltage

230 V / 1L +

N/50Hz

400V / 3L + N / 50Hz

230V / 3L /50 Hz

Power (kW)

0,75

1,125

1,125

1,5

1,5

2,25

Lubricant

SAE 10 VSL 32

SAE 30 VSL100

* replace the asterisk with the desired sealing setting (2, L, U)

iSensor floor standing models with inert gas:

5

iSensor floor standing models without inert gas:

3. GENERAL SAFETY AND ACCIDENT PREVENTION REGULATIONS

3.1 Operating personnel of the machine

The use of the machine is reserved for trained personnel.

Personnel must be familiar with the safety regulations and instructions for use.

3.2 Electrical hazard

Work on the power supply and access to live parts is permitted only by qualified

personnel and at their own risk. In any case, this access must be done with the device

disconnected from the mains supply.

3.3 Thermal hazard

Keep ventilation openings clear of obstacles.

Do not install the machine in the vicinity of flammable products.

6

3.4 Hazard arising from the use of gas

The use of gas for controlled atmosphere packaging is restricted to the use of N2

nitrogen or CO2 carbon dioxide or mixtures of both.

This machine is not designed for the use of Oxygen O2 or other flammable gases.

4. INSTALLATION

Once the equipment has been received, the packaging will be carefully removed by checking

with the label (located on the back left) that it is the requested equipment. Once the

equipment has been checked, read this "Installation, use and maintenance manual" taking into

account the following precautions:

a) Personnel responsible for installation must be qualified in the installation of

machinery.

b) Check that the supply voltage/current is that required by the equipment.

c) Grounding is mandatory.

d) Check that the components of the equipment are correctly placed and undamaged

due to transport

Place the equipment on a flat surface and check that the machine is level.

The equipment must be positioned in such a way that it is protected against splashing water

and dirt.

Before starting up the equipment, check through the rear sight glass that the oil level is

between the MAX and MIN marks. If it is below the minimum, it must be filled in (see section

10 Maintenance).

7

Function

Description

A

1

Modes

Labels of the 3 operating modes: Automatic, Manual and Self Cleaning.

2

“AUTO ”Icon

Automatic mode indicator.

3

“MANUAL” Icon

Operation mode indicator Manual.

4

“CLEAN” Icon

Self-cleaning mode indicator.

5

“OFF” Icon

Indicator of the packer shutdown process.

6

Program indicator

Program display in the Manual mode. The numeric display shows the number of the selected program.

B

7

Numerical display

Shows integers from 0 to 199 or with a decimal from 0.0 to 99.9. This display shows all the numerical parameters

required during the vacuum cycle or the configuration of the packaging machine; from the vacuum level in % to

sealing times, self-cleaning, etc., passing through the error number or program selection in manual mode.

8

Error Icon

Error indicator, shows that the central numerical display shows an error value.

9

% of vacuum

Icon indicating that the central numeric display shows a value in %.

10

Seconds Icon

Icon indicating that the central numeric display shows a value in seconds.

11

Minute Icon

Icon indicating that the central numeric display shows a value in minutes.

C

12

States

Labels of the 5 operating cycle states of Vacuum, Gas, Sealing, Air and Repeat.

13

Extra vacuum

indicator

Indicator of the Extra Vacuum status, where the packer maintains 100% vacuum for a certain period of time.

14

Vacuum Icon

Vacuum status indicator. Indicates that the chamber is being vacuumed. (Pump running)

15

Gas Icon

Gas status indicator. Indicates that gas is being injected into the chamber.

16

Sealing Icon

Sealing status indicator. Indicates that the vacuum bag is being sealed.

17

Air Icon

Air status indicator. Indicates that atmospheric pressure in the chamber is recovering.

18

Cycles Icon

Repeat status indicator. Indicates the vacuum cycle repeat number and recovery in manual mode. If a multicycle

mode is set, the numeric display below the icon indicates the current cycle number in countdown.

19

Encoder push button

icon

Indicates that the cover can be closed to start operation.

20

Closed lid icon

Indicates that the cover can be closed to start operation.

21

Open lid icon

Indicates that the lid can be opened.

22

Type of air icon

Indicates the selected air inlet mode: Soft (progressive air inlet), Fast (normal air inlet) and Stop (blocking of the

vacuum percentage in the chamber for making marinades, etc.).

23

“Ready” icon

Indicates whether the machine is ready to start a new packaging cycle. If this icon flashes, the machine will be

ready after opening the filler cap.

5. CONTROL PANEL

MyChef iSensor packaging machines consist of an LCD display and a rotary encoder with a

central button.

Do not clean the screen surface of the packaging machine with liquids containing

alcohol, solvents, acids or detergents that may damage the screen surface and affect

its visualization.

Figure 1. LCD Screen with the whole segments

Each zone contains a series of icons and text elements that describe at all times the state of

operation of the packaging machine and allow the user to interact with the machine, changing

the packaging parameters to suit each use. The role of each of them is explained below:

The LCD display is structured in three main zones:

- The left zone or operating mode zone(A in Figure 1)

- The central zone or zone of vacuum percentage level and error indicator (B in Figure 1)

- The right zone or status zone (C in Figure 1)

Table 1. Control board indicators, displays and buttons

8

6. CALIBRATION

6.1 Self Calibration system SCS

The iSensor tabletop and floor-standing packers have a fully automatic calibration system, Self

Calibration System (SCS), patented by myChef. As a result of this automatic recalibration

algorithm of the vacuum percentage, we have the following advantages:

Calibration without user intervention

The vacuum packer automatically detects optimal calibration conditions and can be

calibrated autonomously based on the following physical changes:

Automatic adaptation to temperature variations

Automatic adaptation to climatic variations

Automatic adaptation to height variations

Automatic adaptation to changes in oil properties.

The machine is capable of detecting both increases and decreases in the differential

pressure of the atmosphere, recalibrating accordingly.

Greater accuracy in vacuum measurement

When calibrated constantly and automatically, the values used to calculate the vacuum

percentage are dynamically updated. Therefore, the percentage of vacuum selected by the

user has a lower error than if calibration was not performed dynamically.

9

7. OPERATION

7.1 Powering and switching on the machine

When the machine is turned on, a start-up process takes place where all internal values are

initialized and safety and control checks are carried out to ensure optimum control of the

packaging. This will be displayed on the screen with all segments flashing simultaneously for a

few seconds.

During this blinking, technical control parameters can be called up by pressing the encoder

button. These parameters may be relevant for maintenance purposes. Specifically, it will show

two parameters:

- Vacuum pump operating hours.

- Number of vacuum cycles performed.

The first value displayed is the operating hours of the vacuum pump. This will be identified by

the "Vacuum" icon, which will light up in the right-hand block of the screen. The digits of the

number will be shown on the central display cyclically by marking the end of the digits with an

"H". For example, if the pump motor has been running for 20991 hours, the display will

show:"2 - 0 - 9 - 9 - 9 - 1 - H", looped.

Figure 2. Display of vacuum pump operating hours

By pressing the push-button while the number of pump operating hours is displayed, the filler

will go on to show the number of complete vacuum cycles it has completed. The value will be

displayed using the same method, changing the "H" that identifies the end of the number of

operating hours to a "C" for packaging cycles. In this case the value will be identified by the

"Repeat" icon.

Figure 3. Displaying the number of vacuum cycles performed

Press the central button again to finish displaying this value and continue the machine start

process.

Once the packaging machine is connected and the initialization process is completed (whether

or not the status values of the pump are consulted), it will be switched off, waiting for the user

to switch it on to start working.

The machine can be switched on in three different ways:

- Using the encoder push button.

- Rotating the encoder in any direction.

10

- Opening the lid.

Any interaction will start it in automatic mode so that with only one more movement of the lid

it can start to pack.

¡WARNING! The Manufacturer shall not be liable for any injury to persons or animals

and damage to components resulting from improper use and not in conformity with

the machine.

7.2 Inert gas injection

In some foods, it may be interesting or advisable to use antioxidant gas to improve the

preservation of the same or also mixtures of gas to avoid crushing the packaged product. This

option is available with all myChef iSensor vacuum packers’ machines

The following is a description of the precautions to be taken into account when carrying out

vacuum packaging in a protective atmosphere:

NEVER USE FLAMMABLE GASES OR MIXTURES IN WHICH THERE IS TOO MUCH

OXYGEN, THE OXYGEN CAUSES THE FLAMMABILITY POINT OF THE MATERIALS TO

DROP AND THERE IS A RISK OF EXPLOSION.

THE INSTALLATION MUST BE DONE BY A SPECIALIZED TECHNICIAN.

GAS TANKS MUST BE SECURELY FASTENED.

THE GAS OUTPUT PRESSURE OF THE PUMP SHOULD NOT EXCEED 1 bar BECAUSE A

HIGHER PRESSURE MAY DAMAGE THE COMPENENTS OF THE PACKAGING MACHINE

ONCE THE LAST GAS OPERATION HAS BEEN MADE, CLOSE THE STOPCOCK OF THE GAS

TANKS.

TO CONNECT THE GAS INPUT TO THE PACKAGING MACHINE A FLEXIBLE 10mm

ØINTERIOR TUBE THAT SUPPORTS PRESSURE AND SECURES THE CONNECTOR WITH A

METALLIC FLANGE WILL BE NEEDED TO BE CONNECTED.

7.3 Operating modes

ISensor packers have three different operating modes: Automatic mode, Manual mode and

Self-Cleaning mode. The operating mode is selected by rotating the encoder until the

corresponding icon is highlighted in the left menu of the LCD screen.

7.3.1 Automatic mode

The automatic mode of operation is designed so that the user can pack perfectly and

efficiently without having to configure any parameters. This mode performs a complete

packaging cycle without the need for monitoring: it produces vacuum in the pouch by

controlling the vacuum percentage with the intelligent iVAC algorithm, seals it hermetically by

regulating the seal duration with the iSeal algorithm and automatically recovers atmospheric

pressure in the chamber.

11

Figure 4. Automatic mode.

MyChef patented iVAC control algorithm automatically detects and completes the vacuum

process depending on the type of food and its conditions. It is particularly suitable for the

packaging of porous foods and liquids as it prevents them from boiling and overflowing out of

the bag.

On the other hand, the iSeal algorithm regulates the sealing time of each cycle to avoid

overheating in the bar and thus avoid burning the bag. This allows the bar temperature to be

adjusted to each seal, extending the service life of all bar components and guaranteeing

perfect seals regardless of the number of cycles previously performed.

To start it, just select the automatic mode by rotating the encoder and lower the cover once

the "AUTO" icon is on.

7.3.2 Manual mode:

The manual mode allows the user to fully control the packaging parameters and access special

features such as repeat vacuum cycles or extra sealing times.

Figure 5. Manual mode.

Once the "MANUAL" icon has been selected, the "PROG" icon at the bottom left of the screen

will light up and the digit next to it will indicate the selected program. By default this will be 0.

By pressing the button, the program icon will blink, allowing you to select the different

programs when rotating the encoder.

This mode is organized in 10 packaging programs, from 0 to 9. These allow you to configure

packaging parameters for a specific purpose such as making marinades or vacuuming products

with bones or pieces that may damage the bag. The programs allow you to save these

parameters and load them quickly every time you want to pack with the same characteristics.

These values do not have to be edited and entered each time, making it easy to perform

specific packaging processes multiple times over.

To edit the parameter values, press the encoder button with the selected program to be

modified. On the right size of the LCD screen, the icon related to the parameter to be modified

will start flashing; for example, if the vacuum level to be reached is changed, the "VACUUM"

icon will start flashing (later all the parameters and their relationship with the LCD screen icons

are presented). Then by rotating the encoder, you can modify the parameter value and

pressing it again saves it and jumps to the next value to be set. This process will be repeated

until all parameters are modified and saved, returning to the manual mode starting point.

If you want to use a previously configured and saved program without editing any options, you

can close the cover once you have selected the program in question. The packaging machine

enters the manual vacuum cycle according to the parameters stored in the memory without

any modification or confirmation of each value.

Figure 6. Parameters that the user can modify

All parameters are described below in configuration order:

- Vacuum percentage:

This parameter sets a vacuum value per cent, once this value is reached the pump will

switch off and jump to the next state. Once the value "Int" has been selected, the

vacuum percentage control is delegated to the iVAC algorithm explained in the

automatic mode. The icon that identifies it is the "VACUUM" icon.

- Vacuum extra time:

The extra vacuum time marks a time in seconds during which the vacuum pump is kept

turned on. This bonus is used to guarantee vacuum in very porous foods. For proper

operation this time can only be set when 100% vacuum is selected. The icon that

identifies it is the "EXTRA" icon.

12

- Gas percentage:

This parameter determines the value of the percentage of gas with which the chamber

will be filled. This value is conditioned by the percentage of vacuum selected in the

previous parameter; The vacuum level minus the gas level must be at least 50%. The

icon that identifies it is the "GAS" icon.

- Sealing time:

This time value specifies the seal time of the bag. It marks the duration of electrical

contact on the sealing bars and must be adjusted to each type of bag. In order to know

the ideal time it is recommended to consult with the bag supplier. As in the selection

of the vacuum percentage, selecting the "Int" value delegates’ control of the sealing

time to the iSeal algorithm that will regulate this time automatically. The icon that

identifies it is the "SEALING" icon.

- Atmospheric pressure recovery mode:

This parameter allows the selection of 3 types of air inlet:

1. FAST: The atmospheric pressure recovery in FAST mode allows the air to be blown in

by opening the inlet valve until the atmospheric pressure inside the chamber recovers.

It is the quickest and most suitable way in most cases.

2. SOFT: The pressure recovery in SOFT mode allows the air to enter intermittently,

controlling the deformation of the bag. This mode is useful for slowly restoring

atmospheric pressure so that the packaged food is properly molded to the pouch and

preventing sharp objects from breaking it.

3. STOP: This mode allows the pump to stop at a certain vacuum value by pressing the

encoder button or until it reaches the value determined by the vacuum percentage

parameter. The vacuum packer will hold this vacuum until the button is pressed again.

This process can be useful for marinating meat or fish or for extracting air from sauces.

13

The icon that identifies it is the "AIR" icon and selecting each type of recovery is done using the

icons below it: "FAST","SOFT" and "STOP".

- Repeat multiple vacuum cycles:

It is possible to program series of repetitions of the same vacuum cycle, i. e. it allows

the vacuum to be carried out and the atmospheric pressure in the packaging machine

to be restored cyclically. In each repetition, the packer reaches the vacuum value set in

the "Vacuum percentage" parameter. If this is 100% and an extra vacuum time is set,

this time is also completed within each repetition. The atmospheric pressure inside the

chamber is then recovered. This recovery is not fully completed as a small percentage

of vacuum is kept in the chamber to avoid opening the lid, allowing another repetition

to start automatically.

This process will perform as many repetitions as defined in this value, with a maximum

of 9. The icon that identifies it is the "REPEAT" icon and the digit below it marks the

number of repetitions remaining.

The gas injection is compatible with the cycle repeat mode, although it should be

noted that the gas will be injected only at the last repetition, in the same way that it is

injected when sealing is performed.

7.3.3 Autoclean:

When the oil in the vacuum pump has become whitish due to water condensation, this can be

removed with this mode. This process helps the water in the oil to evaporate due to

temperature.

These water particles can cause rust particles to appear in internal pump components.

Every 200 vacuum cycles, the vacuum packer will alert the user to perform a self-cleaning

process. This will happen when the machine is connected or switched on. If the lid is

closed during this period the "AUTO-CLEAN OIL" process will start automatically.

If you don't want to do the AUTOCLEAN at the time of the warning, you can rotate the

encoder to navigate through the menu and perform the cycle of your choice.

An AUTOCLEAN cycle can be performed whenever desired by entering the AUTOCLEAN mode

manually in the operating mode selection menu. The maximum duration of the AUTO-CLEAN

mode is 20 minutes, although it can be stopped by pressing the encoder button.

7.4 Packaging

In order to pack a product, the bag (suitable for vacuum packaging) must be placed correctly

on top of the polyethylene plate, the entire bag width must be above the sealing area. Make

sure that there is no product on the sealing bar. Then lower the lid of the packaging machine.

It is important to remember that a packaging process cannot be started while the manual

mode parameters are being set.

NOTE: It is recommended to use the safety latch on each packaging cycle, at this point the

active mode or program is started and the indicators of the processes to be carried out

14

(vacuum, extra vacuum, gas injection, sealing, progressive air inlet, repetitions) are illuminated

continuously:

- The vacuum process (VACUUM) extracts the air from the chamber and the central

display shows the percentage of vacuum achieved so far.

- The vacuum plus process (EXTRA VACUUM) keeps the vacuum pump running during

the programmed seconds. This is used to extract air from very porous food. The

central display shows the elapsed seconds.

- The gas injection (GAS) fills the chamber with the percentage of gas specified in the

program. The percentage of gas entered is also shown on the central display.

- The seal consists of three phases. The first is the lifting of the cylinders. During this

phase, the fixed value of the sealing duration in seconds is shown in the central

display. The second is resistance heating. In this phase the SEAL display will

progressively decrease from the previous value. The third phase, which lasts five

seconds, is the cooling of the bag and in it the SEAL display increases progressively up

to 5.0 seconds.

- The last phase is the recovery of atmospheric pressure (AIR). The display will show the

percentage of vacuum in the chamber decreasing. During this phase, the selected type

of atmospheric recovery will also illuminate; SOFT or FAST.

The active process is signalled by the associated indicator light. Once the process is complete,

the indicator will turn off.

If repetitions of packaging cycles (REPEAT) have been set up, they will be done at the start of

packaging. The "REPEAT" icon will light up and the "VACUUM","EXTRA VACUUM" or "AIR" icon

will also light up, depending on whether vacuum in the chamber, extra vacuum time or

atmospheric pressure is being recovered. Each time a repetition is made, the digit below the

"REPEAT" icon will decrease its value until it is passed to the last packaging cycle.

All processes except pressure recovery in the vacuum chamber can be cancelled by pressing

the encoder button while running. This will take you to the next step in the cycle until you

reach the air inlet where it will end.

If the vacuum is not correctly performed, the machine will display an error (see 8).

3-minute rest periods are recommended between cycle.

15

Error

Descripción

Solución

E01

Lowered lid

Open the lid. If the error persists, call your service technician indicating the

error code.

E02

Vacuum system failure

The system has detected that the vacuum pump has been running too long to

reach a certain vacuum level. Perform a system calibration. If the calibration is

successful, perform the test again. If not, call for service. The maximum running

time is 2 minutes.

E03

Fault in the vacuum sensor

(minimum)

Check the connection tube to the vacuum sensor for leaks or poor connection.

If you think everything is OK, call the service department indicating the error

code and the value of the central display just before the error.

E04

Fault in the vacuum sensor

(maximum)

Check the connection tube to the vacuum sensor for leaks or poor connection.

If you think everything is OK, call the service department indicating the error

code and the value of the central display just before the error.

E05

Internal Error

The control board has detected an internal error. Call your service

representative indicating the error code.

8. ERRORS

The machine has algorithms that allow the detection of anomalous situations that can lead to

a malfunction of the machine. These situations are reported to the user via an error screen as

shown below:

Figure 7. Errors display

The table below shows the errors and possible solutions:

Table 2. Errors and possible solutions

Due to automatic checks the machine can be turned off to avoid serious failure. Switch it on

normally.

In case of an error in the packaging machine, please contact the technical service.

9. MAINTENANCE

After any handling for cleaning, maintenance or repair, the equipment must be

disconnected from the mains supply.

If the power cord is damaged, it must be replaced by the manufacturer, its service

department or similarly qualified personnel in order to avoid danger.

9.1 Cleaning

Clean the vacuum packer regularly and carefully.

Cleaning the packer with high pressure cleaning equipment is HARMFUL to the

equipment and could result in breakage of the equipment and could result in loss of

the bottler's WARRANTY.

For the stainless steel housing, use a cloth dampened with water and detergent.

The lid must be cleaned with a cloth dampened with water and neutral detergent. DO

NOT USE ANY LIQUIDS CONTAINING ALCOHOL, ACID, DETERGENTS, SOLVENTS OR

EQUIVALENT FOR CLEANING THE LID.

16

Failure to comply with these instructions may cause the lid to break and will result in loss of

warranty on the lid.

9.2 Oil vacuum pump

Carry out periodic oil level checks, possibly complete if necessary, respecting the maximum

and minimum levels.

Use the type of oil recommended by the manufacturer of the vacuum pump (depending on the

model).

An oil in good condition must have a transparent colour. If it becomes white, this means that it

has acquired water due to condensation of the sucked in humid air, which would mean that it

has lost its characteristics and needs to be replaced.

The oil may also acquire a darker shade because it has sucked in dirt, which would mean that it

has lost its properties and needs to be replaced.

The vacuum pump used by this equipment is not designed to operate in extremely cold or

extremely hot environments. Operating temperature range 12/35°C.

9.3 Welding bar

Periodically check the condition of Teflon adhesive tape and sealing tape. These must be in

perfect condition and without knocks.

9.4 Lid gasket

Periodically check the condition of the sealing gasket on the cover. This one has to be in

perfect condition.

10. MAINTENANCE SCHEDULE

First 100 hours of operation

Change oil in the vacuum pump

Weekly or when the CLN message appears

on the packaging machine

Performing an auto-cleaning program

Check oil level

Check sealing bar condition

Check seal gasket lid condition

Semi-annually or every 500 hours of

operation

Change oil in the vacuum pump

Every 1000 operating hours

Change oil filter

Annually

Check for leaks in the vacuum circuit

It is recommended that maintenance work be carried out by a qualified person

or by your dealer or service technician.

10.1 Check the oil level

17

Table 3. Maintenance schedule

The rear cover does not need to be removed to check the oil level of the pump.

Illustration 1. Oil level indicator

10.2 Changing the pump oil

Caution: Before disassembling any components, make sure that the equipment is

disconnected from the mains supply and the inert gas connection.

Material required for oil change:

Material: Synthetic food grade oil SAE 10 VSL32 (table-top models ") Synthetic oil

SAE 30 VSL 100 (Floor standing models).

18

Illustration 2. Oil replacement kit

Tools:

o Allen screwdriver 3.

o Universal wrench.

10.2.1 Table top models

Step 1Unscrew the two rear screws

Unscrew, with the aid of the Allen key 3, the two screws on the back of the sides (Do not

disassemble the two front screws, the bowl pivots on them). Once these two have been

removed, loosen the central screw on the back with the same screwdriver (it is not necessary

to remove it completely).

Illustration 4. Hinged opening system

Illustration 3. Rear screws

Rear lateral part

Rear part

(Only loosen)

19

Step 2 Opening of the hinged system

Like the hood of a car, lift the rear of the packer until it stops.

Step 3 Open the cap to drain the pump

Illustration 5. Remove the oil drain plug

Using a universal wrench remove the oil drain plug from the pump.

20

Place a container under the hole so that the oil drains into it and does not contaminate the

floor of the packer.

Illustration 6. Oil drain

When all the oil has come out, put the cap back on.

Step 4 Open the oil filler cap.

With the help of the universal wrench we open the oil filler cap and, helping us, from a funnel

we pour the oil to the maximum of the packaging machine.

21

Illustration 7. Remove the oil filler cap and refill with new oil.

The oil level must be between the MIN and MAX limits indicated by the sight glass on the

pump.

Step 5 We close the filler oil cap

With the help of the universal wrench we close the oil filler cap and proceed to reverse process

to leave the machine operational.

10.2.2 Floor standing models

Illustration 8. Remove the 6 screws at the back

Illustration 9. Position of the drain plug

Position of the 6 screws

Drain stopper

Step 1: Unscrew the 6 screws at the rear with the Allen key 3.

22

Step 2 Remove the back cover and locate the pump.

Step 3 Open the cap to drain the pump

For the standing models, all pump plugs are located on the rear side as shown in Illustration 9.

Once the emptying plug has been located, proceed as in step 3 of section 10.2.1.

Step 4 Open the oil filler cap.

For models with 20 m3/h and 40 m3/h pumps, the fill plug is located at the top of the pump,

while for 63 m3/h and 100 m3/h models, the plug is on the right side just above the oil sight

glass.

Now with the help of a funnel we fill the pump until the oil level is between the MAX and MIN

marks that appear as a reference in the oil sight glass.

23

Step 5 Close the oil filler cap

With the help of the universal wrench we close the oil filler cap and proceed to reverse process

to leave the machine operational.

Step 6 We close the back of the packaging machine

With the help of the Allen wrench we replace the rear cover and the oil change will be

complete.

10.3 Other maintenance operations

Other maintenance operations, such as changing the oil filter, must be carried out by qualified

technicians or by your dealer or service personnel.

10.4 Owner’s liability

IT IS THE RESPONSIBILITY OF THE OWNER TO PERFORM REGULAR MAINTENANCE. IT MUST

BE POSSIBLE TO CHECK THAT THE MAINTENANCE HAS BEEN CARRIED OUT.

If the vacuum packing machine is subjected to harsh conditions, such as low temperatures

(below 12-15°C) or frequent short operating periods, checks must be carried out more

frequently.

11. SPECIFICATIONS

DISTFORM, SL. (SPAIN) CIF: B-25262726

Año: 2010

Modelo: TTMB20G2

Nº serie: 111111/001

Tensión: 230 Vac Frecuencia: 50HZ

Potencia: 750 W Gas: --

GIP: 65 Carga gas: --

The packaging machine has a type plate with the following specifications and references:

Manufacturer: Distform, S.L.

Carrer Tramontana, s/n

25123 Torrefarrera (Lleida)

Model

Serial number

Electrical characteristics

Year of manufacture

24

This packaging machine has been manufactured according to the following standards:

- UNE-EN 60335-1

- UNE-EN 60335-2-64

- EN 12100-1

- EN 12100-2

-

And it complies with the low voltage (2006/95/CE), electromagnetic compatibility

(2004/108/EC) and machinery (2006/42/EC) directives.

It is forbidden to damage, remove, modify, cover or alter the type/identification plate

of the equipment and must always remain visible. The alteration or removal of the

same may result in loss of warranty.

11.1 General wiring diagram iSensor tabletop SMALL, MEDIUM Y LARGE

25

26

11.1.2 General Standard wiring diagram iSensor floor standing SMALL, MEDIUM Y LARGE

2

1

2

1

2

1

VACUUM PACKAGE

M

GAS IN

Gas models only

ATMOSPHERE IN

CYLINDERS

11.2 Pneumatic diagram

27

Loading...

Loading...