C OMBI OVEN

U S ER MANUAL MYC HEF C ONC EPT

Index

1. INTRODUCTION ............................................................................................................. 6

2. MYCHEF CONCEPT ....................................................................................................... 7

2.1 Control .................................................................................................................... 7

2.1.1 Switching on the equipment ........................................................................ 11

2.1.2 Rotary knob LED indicator ........................................................................... 11

2.1.3 Cooking programs ........................................................................................ 12

2.1.4 Cooking mode .............................................................................................. 13

2.1.5 Cooking control ............................................................................................ 15

2.1.6 Programs edition .......................................................................................... 18

2.1.7 Step Edition ................................................................................................... 19

2.1.8 Starting the cooking cycle ........................................................................... 20

2.1.9 End of step .................................................................................................... 20

2.1.10 Fast cooling .................................................................................................. 20

2.1.11 Speed selection ............................................................................................ 21

2.1.12 HACCP data recording ................................................................................. 21

2.2 Cleaning the cooking chamber ........................................................................... 22

2.2.1 Manually assisted cleaning ......................................................................... 22

2.2.2 Self-Cleaning System ................................................................................... 23

2.3 Configuration menu ............................................................................................. 28

All records are presented below: ................................................................................ 29

2.3.1 Block P1, oven configuration ....................................................................... 29

2.3.2 Block P2, Date and time ............................................................................... 30

2.3.3 Block P3, Configuration SAT ....................................................................... 31

2.3.4 Block P4, Probe ............................................................................................ 33

2.3.5 Block P5, Statistics ....................................................................................... 33

2.3.6 Block P6, Errors ............................................................................................ 34

2.4 Errors y alarms ..................................................................................................... 34

5

Before carrying out any intervention or use of the equipment, it is necessary

to read this manual carefully and completely.

The manufacturer shall disclaim any liability for problems caused by

improper installation, modification, use or improper maintenance.

1. INTRODUCTION

This manual has been carefully prepared and checked to provide reliable and helpful

information for proper installation, use and maintenance that will ensure proper

operation and prolong the life of the oven. This manual is divided into two parts, the

first part dedicated to the installation of the equipment at the working point, and the

second part focused on cleaning and maintenance of the oven.

The manufacturer disclaims any implied or explicit liability for any errors or omissions

it may contain.

- The oven may not be used by personnel who have not received any kind

of training, and who do not have the necessary skills or experience for

the correct operation of the equipment. Do not allow children to use or

play with the equipment.

- The owner of the equipment has the obligation to have this manual read

to the personnel in charge of its use and maintenance, and to keep this

manual in a safe place so that it can be used by all users of the

equipment and for future reference. If the equipment is sold to other

people, this manual must be given to them.

- This oven may only be used for the purpose for which it was designed, i.

e. cooking, heating, regenerating or dehydrating food. Any other use

may be hazardous and may result in personal injury and damage to

property.

- The equipment is shipped from the factory once it has been calibrated

and passed rigorous quality and safety tests to ensure correct

operation.

6

Block

Function

Description

A

ON/OFF switch

Oven on/off switch

B

Connection slot

Slot for connecting the multipoint or sousvide probe

C

Program button PROG

Button for selecting and editing cooking programs.

D

STEP phase button

Button for selecting and editing the cooking program phases.

E

CLEAN self-cleaning button

Button for selecting self-cleaning programs.

A

B

D

C

E

F

A1

G H I J K L M N O P Q R S T U V W X

Y

Z

2. MYCHEF CONCEPT

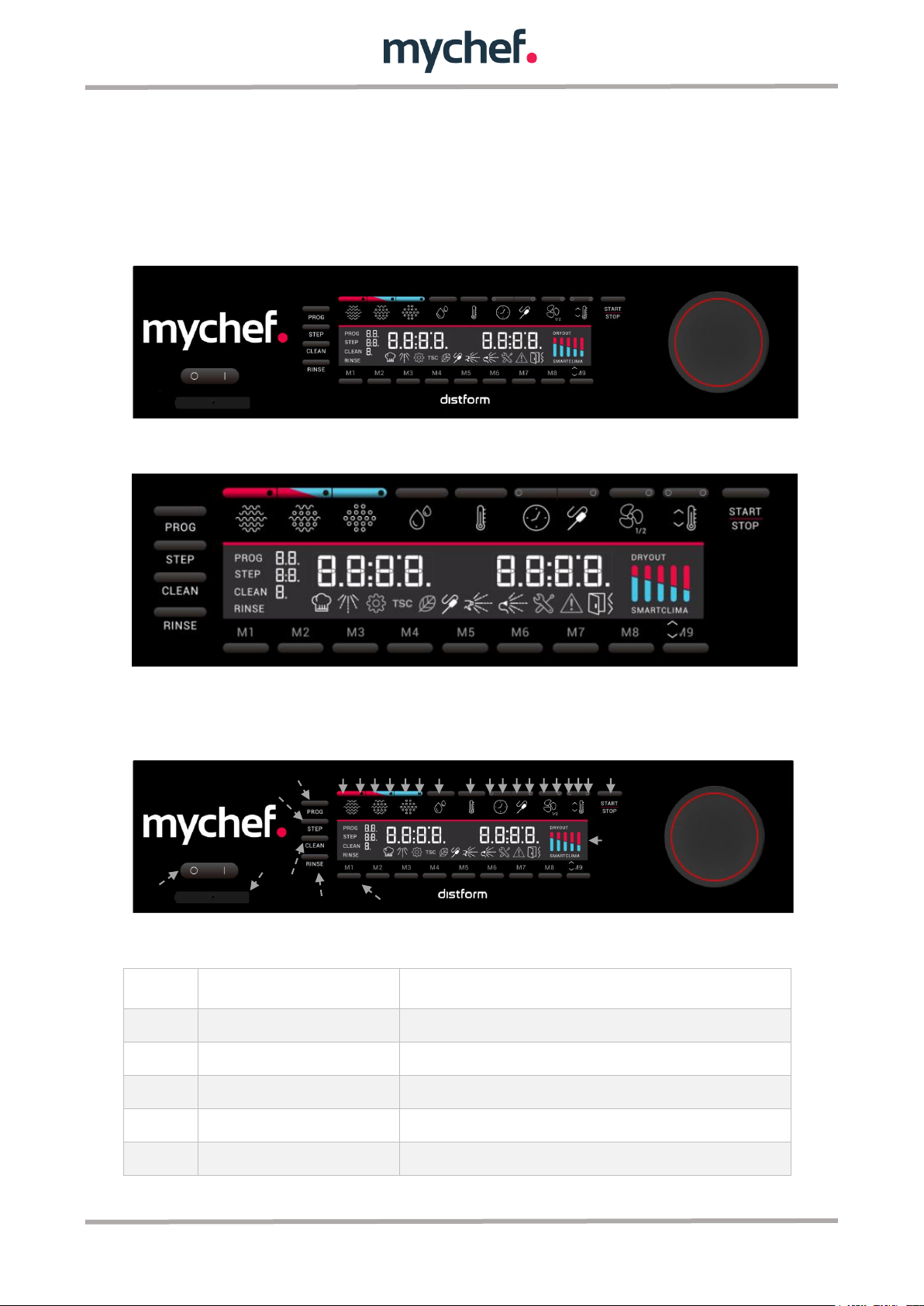

2.1 Control

The figure below shows the control panel of a MyChef Concept oven. It consists of a

central LCD screen with different elements such as displays and icons, buttons, a

rotary knob and visual indicators of different colours.

Figure 1. Control panel.

Figure 2. Control panel detail.

The functionality of each of them is explained below:

Figure 3: Control panel description.

7

F

Rinse button RINSE

Convection mode selection button.

G

Convection button

Select the selected mode.

H

Convection mode indicator

Mixed mode selection button.

I

Mixed button for convection and

steam

Select the selected mode.

J

Mixed mode indicator

Steam mode selection button.

K

Steam button

Select the selected mode.

L

Steam mode indicator

Moisture percentage selection button. Only active in mixed mode.

M

Moisture button

Temperature selection button. In operation, the temperature can be

displayed by pressing this button.

N

Temperature button

Indicates the time firing selection.

O

Time indicator

Time selection button.

P

Time button

Convection mode selection button.

Q

Core probe temperature button

Select the heart probe cooking mode by pressing briefly.

Allows the core probe temperature to be read when performing a

long press.

R

Core probe indicator

Indicates the heart probe firing selection.

S

Fan speed button

Fan speed selection button. Each press changes the speed. There

are three speeds: maximum and reduced, and pressed.

The reduced speed is automatically selected at low temperatures.

The pulsed speed is automatically selected at very low

temperatures.

T

Fan speed indicator

Indicates whether the convection fan is at reduced speed, either

pressed or continues. If it is turned off the speed of the convection

fan will be maximum.

U

Cooling indicator

Indicates that cooling will take place or is taking place. If the

indicator flashes, cooling will take place when the temperature

adjustment button is pressed. If it is fixed, cooling is being carried

out.

V

Temperature adjustment knob

(preheating or cooling)

Allows you to start cooking with a cooling or preheating cycle

depending on the current chamber temperature and the desired

cooking temperature.

W

Preheating indicator

Indicates that a preheating is being or will be performed. If the

indicator flashes, a preheating will take place when the temperature

adjustment button is pressed. If it is fixed, this preheating is being

carried out.

X

START/STOP button

Oven start/stop button.

If the oven is on but not cooking, pressing lightly will start the

cooking cycle.

If the oven is on and cooking, pressing lightly will cancel the cooking

cycle.

8

Y

LCD display

LCD screen containing all the icons and displays needed to show

the status and allow user interaction with the oven.

Z

Rotary control

Used to edit values and navigate through the configuration menus.

It also has a multi-coloured LED display, which indicates the status

of the oven. For more information, see chapter 2.1.2.

A1

Memory Location Buttons

Each button is a quick memory location where a program or wash

cycle can be stored by long press. To start the stored program,

press slightly.

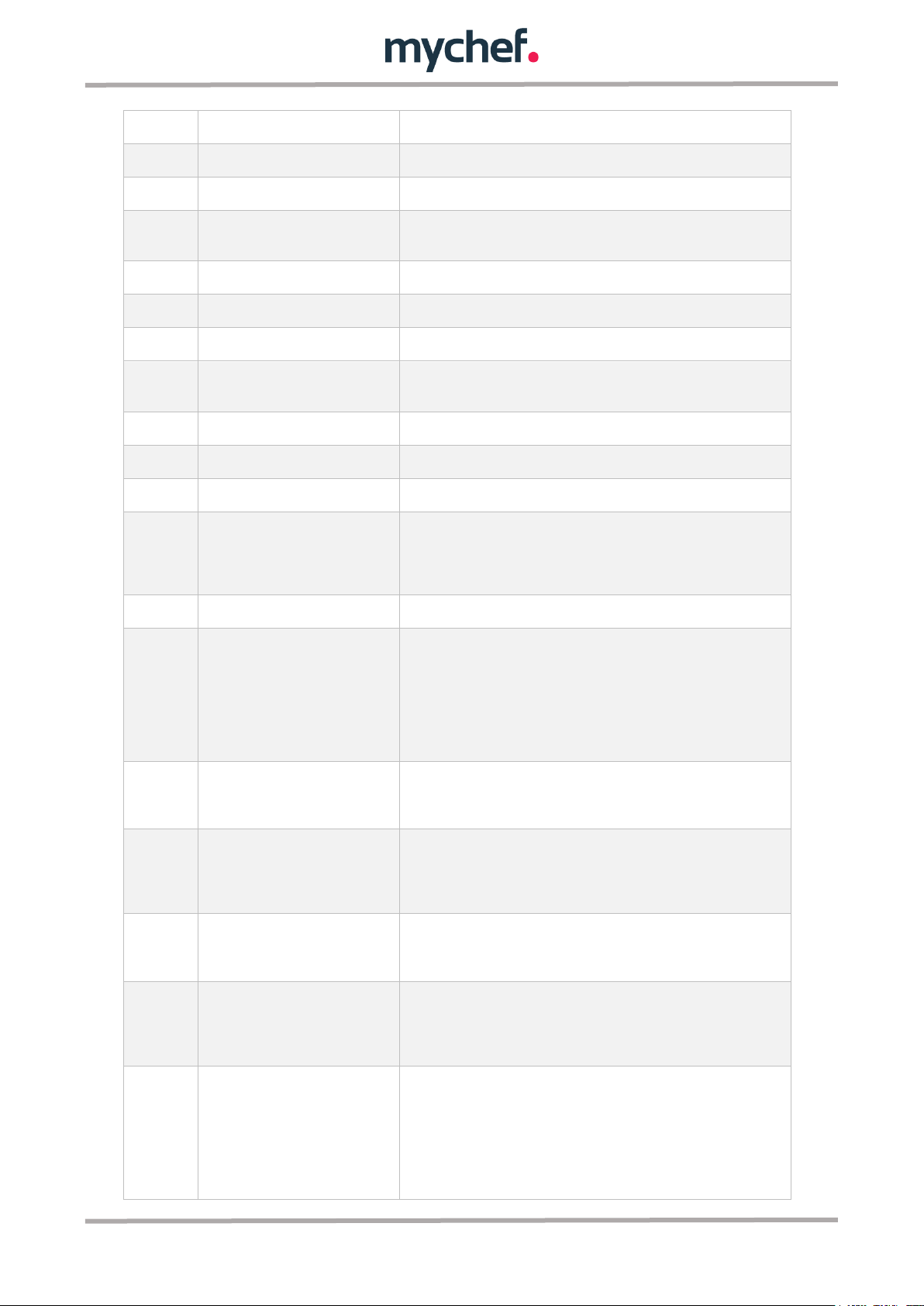

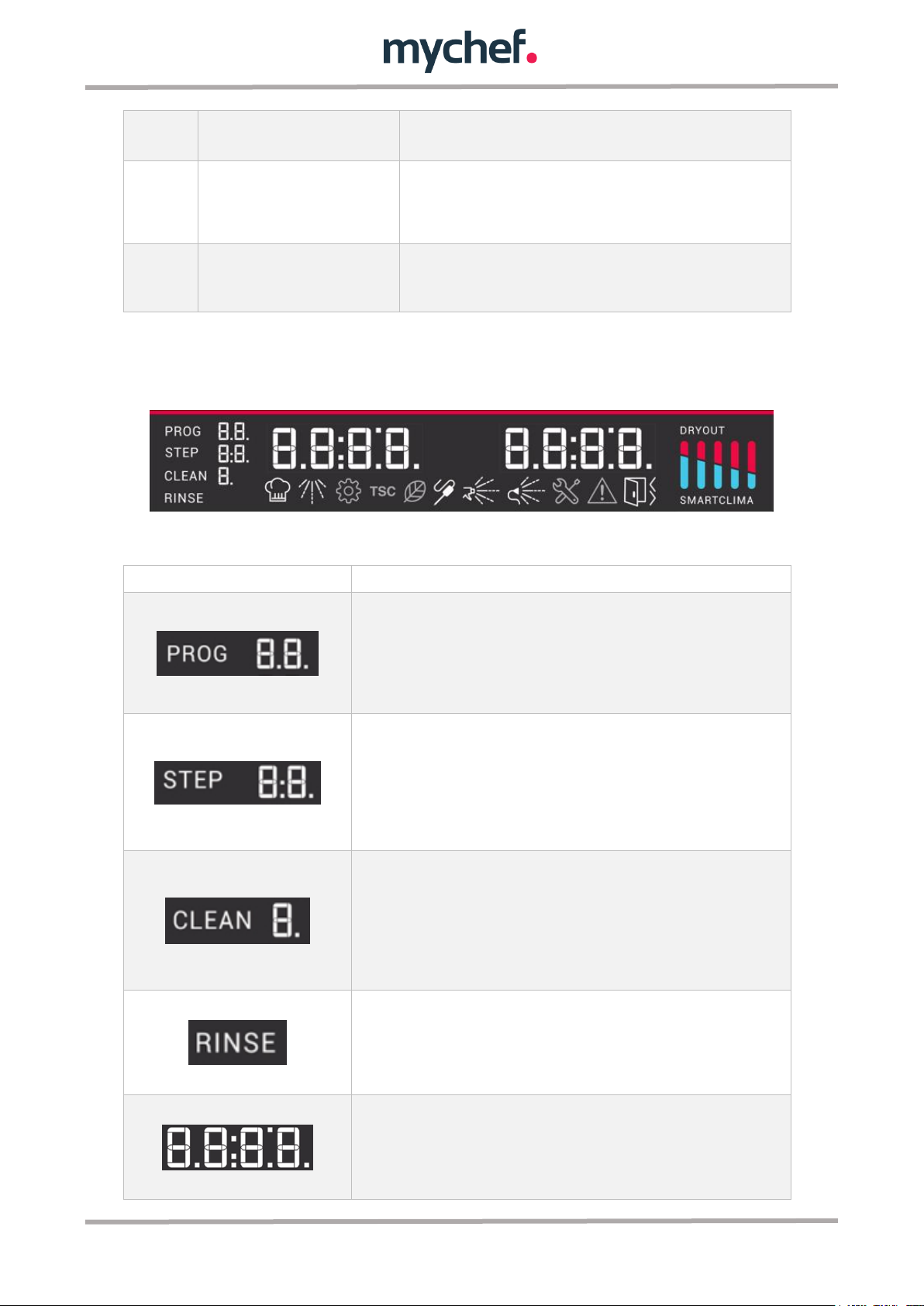

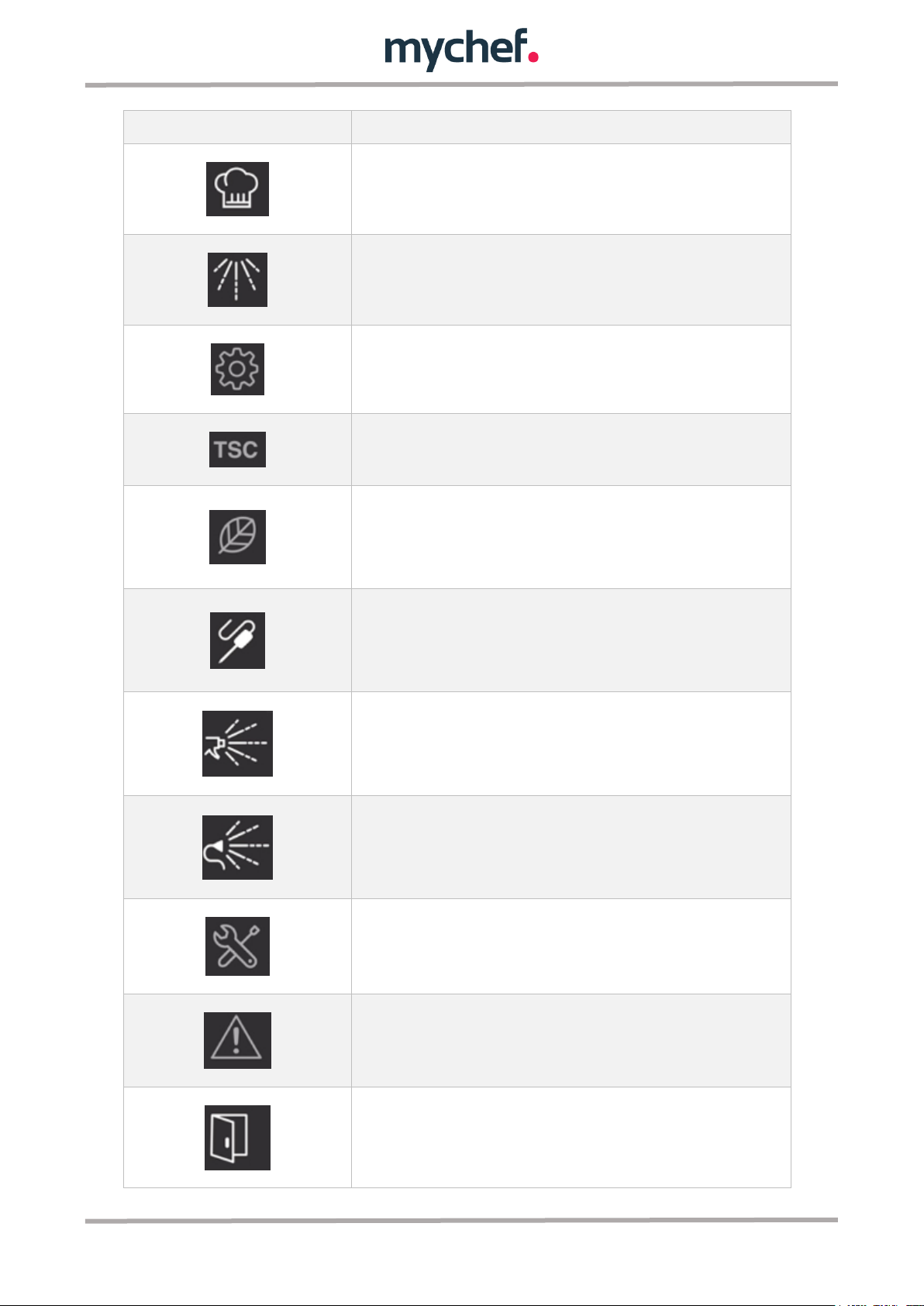

Icon

Function

This icon shows the selected cooking program, the digits on the left show

the program number; 1,2,... 99. The flashing PROG icon indicates that the

program is being edited and shows the two digits. By contrast, if the digits

are held steady and flashing, the program is being selected and it is possible

to navigate through the programs using the rotary knob.

This icon shows the firing phases of the programs. The first digit shows the

phase in which you are while the second digit shows the total number of

phases. Like the previous icon, if the STEP icon flashes, the firing phase

indicated in the first digit is being configured. However, if the digits are

flashing and the icon remains fixed, it is possible to navigate through the

different phases using the rotary knob.

This icon shows the 4 self-cleaning programs of the oven. The digit shows

the program number and blinking indicates that you can navigate through the

various cleaning programs with the rotary knob.

If the oven does not have self-cleaning, there is only one manual program

with cleaning assistance.

This icon shows that the rinse program of the oven chamber has been

selected.

If the oven is not self-cleaning, there is no such function.

There are two displays of this type. Both display temperature and time

values as well as other keywords that define the oven's behaviour. In normal

operating mode, the display on the left of the control indicates the

temperature set for cooking. The one on the right shows the remaining time

if a time firing has been chosen or the core probe temperature if a core

Table 1: Panel Control description.

The LCD display is a very important part of the oven interface. The meaning and

usefulness of each icon is explained below:

Figure 4: LCD screen.

9

temperature firing has been chosen.

This icon indicates that cooking has started.

This icon indicates that an automatic or assisted manual cleaning cycle is

being performed.

This icon marks the setting mode. Allows you to display and edit the oven

configuration parameters.

This icon illuminates whenever the TSC, Thermal Stability Control, is

activated.

When this icon illuminates, the oven is in ECO mode. In this mode the oven

consumes a fraction of its usual power. The ECO mode is automatically

activated in situations where the oven requires little power, and

automatically deactivated in situations where full power is required.

This icon flashes when the oven does not detect any connected probe and

needs it to start or continue a firing cycle. If the probe is connected, the icon

will remain fixed when, without being in the firing process, the desired core

temperature is lower than the temperature read by the probe.

This icon lights up during the assisted manual cleaning process of the

camera. When this icon is lit and blinking, it indicates that liquid with

detergent must be introduced into the interior of the camera using a spray

gun.

This icon lights up during the manual cleaning process assisted by the

camera after the previous one. When this icon turns on and blinks, it

indicates that the shower faucet must be inserted into the interior of the

camera and rinsed.

This is the error icon. Lights up when an error occurs and is accompanied by

the error number on the right display.

This is the alarm icon. Lights up when an alarm occurs and is accompanied

by the alarm number on the right display.

This icon indicates if the door is open. The icon illuminates whenever the

oven door is not closed regardless of the operating moment.

10

This icon indicates that the oven needs to be charged to continue the firing

cycle. When it turns on and flashes, the door must be opened and charged to

continue.

If a self-cleaning process is being performed, the icon indicates that the

detergent tablet must be inserted into the camera.

This icon indicates that a cooking process may be finished. When it comes

on and blinks, open the door and unload the trays with the cooked products.

This icon is used to indicate humidity inside the camera.

The DRYOUT icon is associated with the red icons at the top of the graph.

These icons indicate the degree of moisture removal in the camera. There

are five levels and grow from left to right illuminating one more bar each

time a level is raised.

Similarly, the SMARTCLIMA icon and blue bars indicate the degree of steam

generation. In this case they increase from right to left to maintain the same

representation model.

In order to protect the oven from possible overheating, some protective

elements may work even if the oven is switched off. When the oven is at a

safe temperature, they will turn off automatically.

Mode

Temperature

This colour indicates that the oven is not cooking or

cleaning. The oven's not working.

Table 2: Description of LCD display icons.

2.1.1 Switching on the equipment

The equipment is turned on or off using a switch on the control panel to the left of the

panel.

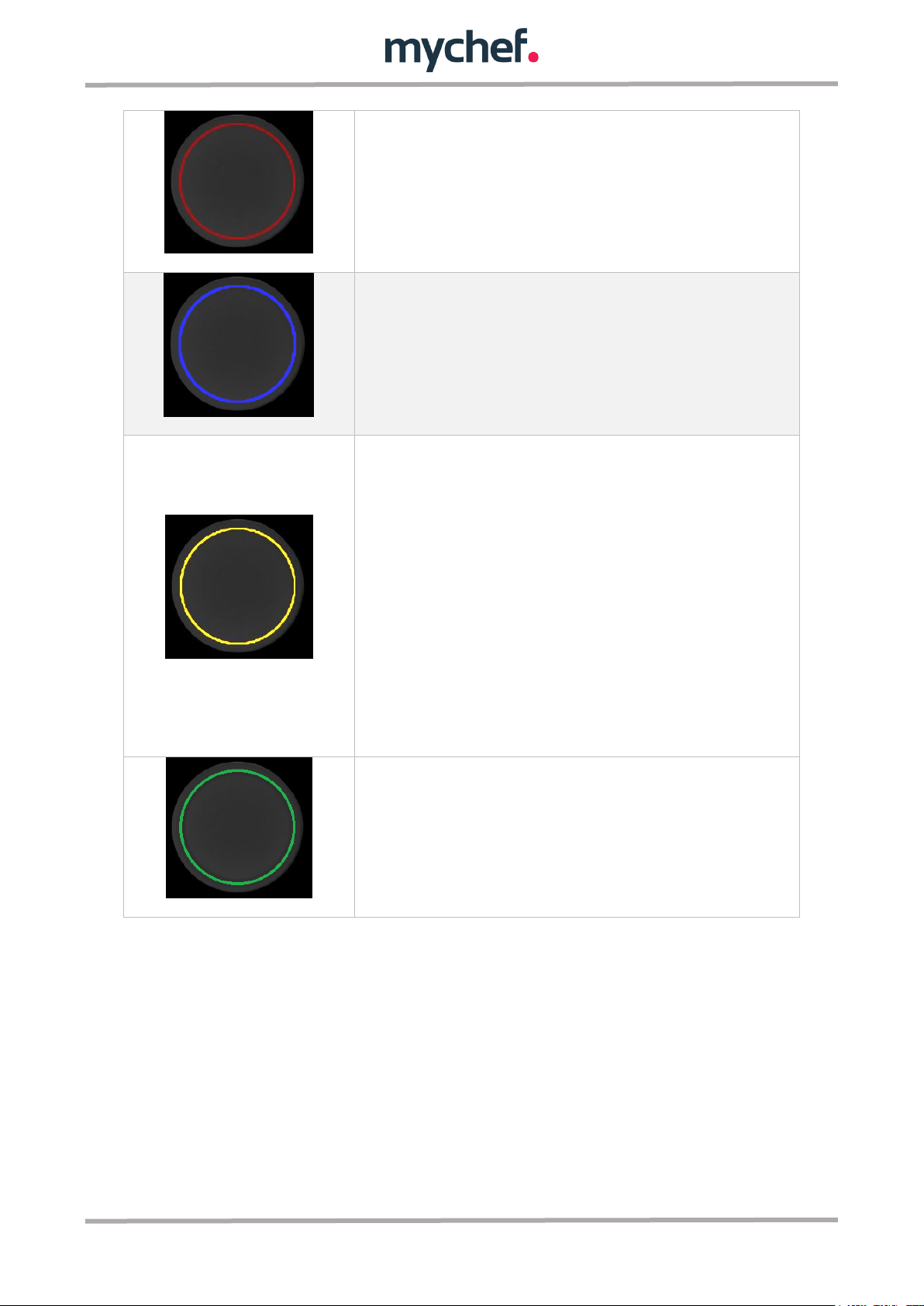

2.1.2 Rotary knob LED indicator

The rotary knob has an illuminated circle indicating the operating status of the oven.

This indicator changes colour depending on the state of the oven, allowing the user to

check easily and quickly and even while at a certain distance from the oven if a process

has been completed, etc.

The possible colours of the indicator and their meaning are given below:

11

This colour indicates that you are cooking.

This colour indicates that a cleaning or rinsing process

is in progress.

This colour has three different meanings.

If the oven is cooking or washing, it indicates that the

cooking is about to end: if there is 1 minute left to finish

a time cooking or cleaning process, or, if a probe

cooking is taking place, it will light up when 5ºC is

missing for the final temperature.

It also indicates whether the oven is performing a

temperature setting process, both preheating and

cooling.

Finally, it is also used to indicate that the oven is in

setup mode.

This colour indicates that a cooking or cleaning process

is complete.

Table 2: Colour description rotary knob.

2.1.3 Cooking programs

There are 99 programs that can be edited and retrieved at will. All of them can have up

to 5 cooking phases.

There is also a manual mode that allows you to modify the cooking parameters

(camera temperature, humidity, time, etc.) without saving them in any program. This

manual mode is displayed as "PROG -" in program selection.

In user programs, it is possible to change any cooking parameters (temperature,

humidity, time, cooking mode, etc.). To do this, press the button corresponding to the

parameter to be modified and adjust the parameter value by turning the rotary knob.

12

When you change any parameters of the user programs, the manual program

is automatically selected to avoid modifying the data of the original program.

For example, pressing the humidity button defined in Table 1 will flash the moisture

display and you can adjust the humidity level.

To leave a program in continuous mode, press the time button and turn the rotary knob

counter clockwise until "Cont" appears on the time display.

There are several safety measures that prevent abnormal operation of the equipment,

of which the user must be aware during use.

In case of any error, the unit will stop and display its code (see chapter 1.6).

The oven will not operate if the door is open.

2.1.4 Cooking mode

There are three cooking modes: convection, mixed and steam. To select a particular

mode, click on the corresponding button.

Figure 5: Cooking mode selectors.

The convection mode acts as a forced convection oven without adding or removing

moisture from the firing chamber.

The combi convection mode enables intelligent, oven-controlled regulation of moisture

removal or moisture input in the cooking chamber. To do this, press the humidity

button and turn the knob to the desired value. This value is shown through the graphic

that appears in the following image, allowing 11 values; 5 for humidity contribution to

the firing chamber (the blue inferior bars labelled SMARTCLIMA, intelligent control of

water injection), 5 for humidity extraction (the upper bars labelled SMARTCLIMA red

with DRYOUT, intelligent control of humidity extraction) and a neutral value (all graphic

off).

Figure 6: Humidity setting in mixed mode.

The steam mode saturates the cooking chamber with moisture.

13

Mode

Icon

Temperature

Humidity

Convection

30 a 300ºC

0%

Mixed

30 a 300ºC

-100 a 100%, in

leaps of 20%

Steam

30 a 130ºC

100%

In order to prolong the life of your oven, it may automatically reduce the

maximum cooking chamber temperature.

The table below summarizes the characteristics of each of them.

Table 4: Cooking modes in MyChef ovens.

In all cooking modes it is possible to humidify the chamber at will. To do this, press the

HUMIDITY button until the blue humidity graph bars on the left side of the LCD display

light up. In the case of steam cooking, the SMARTCLIMA icon disappears and

intelligent humidity control is deactivated by passing the steam injection control to the

user.

14

2.1.5 Cooking control

2.1.5.1 Cooking by temperature and time control

The temperature and time control mode is the simplest, we simply choose a

temperature and time by rotating the circular knob after pressing the TEMPERATURE

and TIME buttons respectively.

When the START/STOP button is pressed, the oven will start heating the chamber and

stop after the set time has elapsed. At this point, the timer will display the keyword

"End", the oven will beep for one second and the door opening icon will light up until the

user finishes cooking by slightly pressing the START/STOP button.

Example of cooking at 90º for 10 minutes:

Figure 7: Example. Cooking 90ºC in steam mode for 10

minutes.

Figure 7: Oven temperature.

2.1.5.2 Temperature cooking and time control with temperature adjustment

The temperature and time firing control mode with temperature setting is very similar

to the previous method. In this mode the oven automatically brings the temperature in

the chamber to the value selected by the user so that when the opening and loading of

15

the feed occurs, therefore the start of cooking, the temperature in the chamber is equal

to the selected one. The oven automatically calculates the ambient temperature in the

chamber and decides whether a heating or cooling process should be carried out

depending on the desired value.

To use this mode, as in the previous case, we choose the temperature and cooking

time by pressing the TEMPERATURE and TIME buttons respectively. This time, instead

of pressing the "START/STOP" button to start the process, press the SETUP key.

This key has two small visual indicators to the left and right, one blue and one red.

Depending on the light that comes on, a cooling (blue) or preheating (red) will be

carried out.

Before cooking begins, the process indicator for the required process according to the

temperature of the chamber will blink indicating that pressing the button initiates a

preheating or cooling process. When pressed, the indicator will stop flashing and will

remain permanently lit indicating that the process has started.

You can cancel the preheating and continue cooking by pressing the START/STOP

button.

Once the oven reaches preheating temperature, it will indicate to the user that the oven

can be charged by an audible and visual warning: the door opening icon will light up

and the charge arrow will flash.

To avoid excessive overheating, this state is maintained for a maximum of ten minutes.

When you open the door and load the oven, the preheating program will end and the

firing program will be executed.

Example of cooking at 90º for 10 minutes with preheating:

Figure 9: Example. Cooking 90ºC in steam mode for 10 minutes.

16

Figure 8: Oven temperature.

2.1.5.3 Temperature cooking and core probe control

The core probe controlled temperature control mode terminates cooking when the

temperature in the food core is equal to the selected temperature. The chamber

temperature is kept constant and equal to the value selected on the temperature

display.

To use this mode, select a chamber temperature and a desired temperature at the

heart of the food by pressing the TEMPERATURE and PROBE buttons respectively and

adjusting them with the rotary knob. When the START/STOP button is pressed, the

oven will start to warm up and stop when the core probe temperature is equal to the

setpoint temperature of the probe. At this point, the timer will mark "End" until the user

finishes cooking by briefly pressing the START/STOP button.

If the probe is not connected, the oven will indicate this by means of the corresponding

icon flashing, and acoustically. In this case, connect the probe and press START/STOP.

If the probe is connected, and the probe reading is higher than the desired temperature,

the probe icon will remain fixed and cooking cannot begin. Decrease the temperature

at the probe, or change the desired end temperature.

Figur3 9: Probe icon.

17

For this cooking mode, the multipoint probe or the sous-vide probe must be

connected.

If we try to start a heart-probe-controlled program, and it is not connected,

the oven will sound and visually warn and the program will not start.

When the oven is in the process of cooking controlled through a core probe,

the chamber temperature display shows the temperature to be reached in

the chamber, and the core probe display shows the actual temperature of the

food.

Example of cooking at 90º until the temperature in the heart of the food is

55º:

Figure 12: Example. Cooking 90ºC in steam mode and core temperature 55ºC.

Figure 13: Oven temperature (blue) and core probe (yellow).

If we are performing a core probe controlled cooking cycle, the time/sound display will

indicate the actual probe temperature. By pressing the PROBE button, the display for

the probe will indicate the desired core probe temperature and can be modified by

rotating the encoder if desired.

2.1.6 Programs edition

Programs 1 to 99 can be modified by pressing the PROG button for a few seconds after

the program to be edited has been selected by rotating the knob. When an acoustic

signal sounds and the "PROG" icon to the right of the LCD flashes, the firing parameters

can be edited.

18

The first number in the phase indicator indicates the current phase and the

second number indicates the total of existing phases.

To add or remove phases in programs 1 to 99 before, enter program editing

mode.

If we are editing a program that has not been saved, the temperature and other values

will appear empty in the display screens and the LEDs will guide us to define all

cooking parameters. The indicator will blink along with the segments of the display

that represent the value associated with each parameter.

If we are editing an already stored program, the values will be set and the indicators will

show the parameters of the program. When selecting a parameter by pressing the

corresponding button, the segments associated with it will blink and the value can be

changed using the knob.

In any case we can edit the cooking mode, chamber temperature, humidity in combined

mode, cooking time or probe temperature depending on the selected end condition and

fan speed.

To save the program after this process is complete, press the PROG button until the

acoustic signal sounds again and the program number stops flashing.

2.1.7 Step Edition

The editing of the phases can be done directly in the manual program (---) or phases

can be added to the user programs. If you want to modify the phases in any user

program (programs 1 to 99), you must first enter the program editing mode of that

program. The editing process follows the same pattern as before using the flashing

segments and indicators to edit the parameters of each phase.

Navigation between steps

To navigate between the various phases, press the STEP key slightly. The digits to the

right of the STEP icon showing the current phase and the total number of existing

phases will flash and can be skipped from phase to phase using the rotary knob.

2.1.7.1 Add a Step

To add a step, enter the program editing mode. If the program has only one phase, the

program icon will blink and pressing the STEP button will add a new phase. If the

program already contained more than one phase, press the STEP button to navigate

through them until you reach the last one. At this point, pressing it again will add one

more phase. After adding all desired phases, press the PROG button for a few seconds

until the acoustic signal indicates that all changes have been saved.

Once a phase has been added, the firing parameters of the phase can be modified as

specified in the previous subchapters.

19

2.1.7.2 Delete

To delete a phase, enter program editing mode. Briefly pressing the STEP button will

take you from one phase to the next until you want to delete it. This will be deleted by

pressing the "Convection”, “Combined" or "Steam" button (depending on the mode

selected in the previous phase) whose light indicator will flash. Pressing it will erase

the current step and all subsequent steps allowing you to complete the program again

from the step you wanted to delete.

An example to clarify this elimination process would be to delete the second phase of a

three-phase program. To start, press and hold the PROG button with the selected

program until you enter edit mode. The STEP button should then be pressed to

navigate from the first phase to the second. At this point, press the convection button

that would blink in the upper left corner of the panel (since the second phase is

supposed to be a convection phase in the example) removing all values from step 2

and step 3 altogether.

2.1.8 Starting the cooking cycle

Once the cooking parameters have been selected, either manually or in a specific

program, we can start the process.

To do this, press the START/STOP key, and its indicator on the LCD will light up.

Figure 10: cooking indicator

2.1.9 End of step

At the end of a cooking cycle, the equipment visually and acoustically signals this

state. Specifically:

- The visual indicator on the rotary knob lights up in green

- 3 beeps of 2 seconds are emitted, with an interval of 10 seconds.

- The keyword "End" appears on the time/sound display of the LCD display until

the user finishes cooking.

To finish cooking, press START/STOP.

2.1.10 Fast cooling

Rapid cooling is a particular use of the temperature setting mode (preheating or

cooling) explained above. If a quick cooling process is desired, the preheating or

cooling firing start mode must be used. To do this, select a low temperature value in

manual mode, e. g. 30°C or "Off", and press the SET button.

In this mode the convection fan is switched on and the resistors are switched off. In

this particular case, even if the oven door is opened, the process will not stop and the

20

Note that in this mode, the convection fan works when the door is open.

Take appropriate precautions.

In order to be able to regulate the temperature in the chamber correctly, in

certain situations (low temperature, etc.) the oven can automatically select

the reduced convection speed.

Set the oven date and time when recording HACCP data.

fan will continue to rotate. This way, and with the door open, the temperature of the

chamber can be lowered in a few seconds.

Once in this mode, the display for the camera probe shows the temperature of the

camera probe continuously. To exit the quench mode, briefly press START/STOP.

2.1.11 Speed selection

In any cooking mode, the user can select the speed of the convection fan that best

suits his needs. To do this, press the fan speed button.

If the speed indicator is off, the oven will operate at maximum convection speed. If, on

the other hand, it is switched on, the oven will rotate the convection fan at a reduced

speed.

Figure 15: Maximum and reduced speed.

The fan has 3 operating speeds. Low speed with pulsed operation, low without pulsed

and high operation. The first one is only used for temperatures below 40ºC, the second

one only for temperatures above 40ºC and the last one for temperatures above 60ºC.

2.1.12 HACCP data recording

The equipment allows the recording of temperatures and events occurring during

normal use. To record data, insert a memory into the USB connector in the lower right

corner of the oven.

Figure 16: USB connector housing.

This data can be retrieved using the HACCPManager software (optional). They can also

be viewed from a computer.

21

For the use of the washing processes in as much as for the handling of the

products used in the process, appropriate protections must be used.

Figure 11: HACCPManager.

2.2 Cleaning the cooking chamber

Depending on the oven model, there are two types of processes for cleaning the firing

chamber: manual assisted and automatic.

The assisted manual programs are predefined in ovens that do not have a self-cleaning

system. Those that do have this system have predefined the different automatic

programs.

You can change the cleaning type by accessing the configuration parameters.

2.2.1 Manually assisted cleaning

This chapter applies only to ovens without self-cleaning system (optional).

Before manual cleaning, make sure you have all the necessary equipment. This

material can be purchased from your local mychef dealer.

- Cleaning shower

- Spray gun for spraying cleaning products

- Distform DA21, detergent liquid and brightener in one, or equivalent:

Combination of substances, including:

o potassium hydroxide 10 - <25%

o Complex mixture of glycols, sequestrants, surfactants and alkalis.

o Physical appearance: Oily liquid

22

When the appliance is in operation, open the door slowly and carefully to

avoid possible burns from the steam or hot air that may come out of the

cooking chamber.

o Density 1.1 gr/cc. approx.

o pH: >13

Then remove any solid food scraps/rests that may be inside the chamber manually. Do

not use the manual shower faucet accessory to remove food scraps from the cooking

chamber, remove them beforehand and prevent them from coming out of the drain. Do

not place trays or grills during the washing process. It should always be carried out

without load, to ensure proper cleaning of the equipment.

Once this is done, the assisted manual cleaning process can be started. To start the

process press the CLEAN button and then press the START/STOP button to start the

process.

Meanwhile, refill the spray gun with Distform DA21, degreasing liquid and polish in one.

After 20 minutes of starting the semi-automatic cleaning process, the following icon

will illuminate. This indicates that the door must be opened, the chamber sprayed with

the spray gun and the door closed again.

Figure 12: Spraying detergent icon.

At the end of the second phase, after 20 minutes, clean the camera with a cloth to

avoid damaging it. Afterwards, rinse the chamber with the shower faucet until no

detergent remains. The icon below will illuminate to indicate that rinsing is required.

Figure 13: Rinse icon.

The last phase, also 20 minutes, corresponds to a drying of the chamber. If any

moisture remains, wipe the inner chamber dry with a cloth.

2.2.2 Self-Cleaning System

2.2.2.1 Self-cleaning and rinsing programs

Using the MyCare cleaning system makes it possible to automatically clean the

cooking chamber and has 4 wash programmes plus a rinse programme.

23

Automatic cleaning programs are only enabled if the oven is equipped

with this option.

Use MyCare Cleanduo in ovens equipped with automatic washing system,

and DA21 in ovens with manual washing system assisted. The use of other

products voids the warranty.

For the use of the cleaning processes as well as for the handling of the

products used in the process, appropriate protections must be used. Never

touch the detergent with your hands.

Program

Description

Duration

CLEAN 1

ECO self-cleaning program

63 min

CLEAN 2

Self-cleaning program for low dirt level

103 min

CLEAN 3

Self-cleaning program for medium dirt level

143 min

CLEAN 4

Self-cleaning program for high dirt level

183 min

RINSE

Rinse program.

10 min

Before starting any cleaning process, make sure that the water flow to the

unit is open.

Cleaning programs are specifically designed to use MyCare cleanduo detergent. The

special formulation of this product stands out for having twice the concentration of

active product than that of most similar products available on the market. It also

includes a polishing additive for a perfect all-in-one finish. This makes it possible to use

only one MyCare Cleanduo tablet per wash, with the consequent savings and ease of

use.

The time required to carry out each program and the use and usefulness of each

program are listed in the table below.

Table 3: Self-cleaning and rinsing programmes

Before the self-cleaning cycle, remove any solid food scraps/rests that may be inside

the chamber manually. Do not use the manual shower faucet accessory to remove

food scraps from the cooking chamber, remove them beforehand and prevent them

from coming out of the drain. Do not place trays or grills during the washing process. It

should always be carried out without load, to ensure proper cleaning of the equipment.

24

Never place the detergent with the convection fan moving.

The automatic cleaning cycle can then be started. To do this, select one of the cleaning

programs or rinse process on the control panel depending on the dirt in the chamber.

To do this, press the CLEAN button and navigate through all four programs with the

rotary knob. If you want to perform a short rinsing process instead of cleaning, press

the RINSE button.

Before inserting the MyCare CleanDuo tablet, check that the cooking chamber

temperature is not too high. If the blue temperature adjustment indicator blinks, it

indicates that the temperature in the chamber must be lowered before the detergent is

introduced into the chamber. In this case, press the SET button to lower the cooking

chamber temperature.

Figure 20: Setting the required temperature

The oven will begin a cooling process that can be done with the door open to make it

faster.

When the oven indicates this with the corresponding icon, the temperature from which

it is safe to introduce the detergent into the firing chamber has been reached.

Figure 21: Cooling completed. Introduce MyCare detergent.

At this point it is important to stop the fan using the START/STOP button, open the

door and insert the detergent into the dedicated housing. Once entered, close the door

again to start the cleaning program.

If cooling is not required, you can place the MyCare detergent directly in its assigned

space and start the cleaning or rinsing cycle by pressing the START/STOP key.

25

Before starting any cleaning or rinsing process, check that a temperature

adjustment of the cooking chamber is not necessary.

Before starting any cleaning process other than rinsing, make sure that the

detergent tablet has been placed in the oven.

To insert the detergent tablet into the chamber, it is essential to stop the fan.

It is important not to introduce the detergent while it is running in order to

prevent the detergent from being drawn into the air stream and endangering

the health of the user.

The duration of the self-cleaning programs specified in Table 5 does not

take into account any cooling of the chamber.

Never open the door of the cooking chamber during an automatic cleaning

process.

Figure 22: Housing for MyCare detergent.

Once you have started the automatic process do not open the door under any

circumstances, as chemicals used for cleaning and steam may escape. This situation

would pose a significant risk of corrosion and burns.

The process can be stopped in case of emergency with the START/STOP button. In

doing so, the process will stop and the CLEAN and RINSE icons will flash on the screen

to indicate that a button must be pressed to continue.

If we press the CLEAN button the process will resume normally. Pressing the RINSE

button will perform a rinse to remove all chemical residue from the chamber and finish

cleaning. If you press the second key to cancel the cleaning program, it is not

necessary to remove any residue from the tablet that has not dissolved using chemical

26

If the cleaning process has been stopped without the cleaning process being

completed automatically, it is mandatory to remove all undissolved pieces of

detergent tablet from the chamber before proceeding with the final rinse.

Always run a self-cleaning or rinsing program when error 26 occurs.

protective gloves. Open the door, remove all the pieces, close it and then press RINSE

for perfect rinsing.

If at the end of any of the automatic cleaning processes you detect that there are any

detergent residue left in the chamber (even behind the fan cover plate), perform a

rinsing program or perform a thorough manual rinsing of the cooking chamber.

If there is a power failure during the cleaning process, an error message will be

displayed on the control panel (error 26) when the oven is turned on again. In this case,

to prevent detergent and brightener residue from remaining in the chamber, run a rinse

program.

27

2.3 Configuration menu

To access the setup menu, first change the temperature value in the camera to "Off".

Then simultaneously press the CONVECTION and START/STOP button.

Figure 14: Access to the configuration menu.

The following icon will light up when you confirm the entry in the setup menu.

Figure 24: Configuration menu icon

This menu is structured in 6 blocks of registers or parameters that contain all the oven

information from the date and time settings to the firmware or serial number.

To browse through the registers and be able to consult values and edit them, we must

first select the block of registers to which we want to access. Each block is associated

with a memory button: button M1 to block P1, M2 to P2, M3 to P3... Pressing the button

briefly will select the block. Once set, you can navigate between the different registers

using the rotary knob. On the right display of the LCD we will see the value associated

with each register.

Figure 25: Example. Displaying record 00 in block P1

If you want to change any of the editable values, press the PROG button with the record

to be modified selected. The display on the right side of the screen that shows the

register value will blink and by rotating the encoder it will be possible to modify its

value. Pressing the rotary knob will save the value and return to the register selection

28

Block

Register

Name

Parameter

Editable

P1

00

SerialNumber

Serial Number (Thousands)

No

01

SerialNumber

Serial Number (Units)

No

02

FirmwareVersion

Firmware version

Yes

03

FirmwareDefault

Restore default values

04

Lock

Blocking programs

Yes

05

Light

Light timer, in seconds.

Si

06

Reservado

Not used

Si

07

TotalTime

Displays total oven usage hours

Yes

08

EquivalentTime

Displays equivalent hours of oven

use, depending on temperature

Yes

09

USB upload

Records programs from the USB

memory stick to the oven memory.

Yes

10

USB download

Saves programs from the oven

memory to the USB memory stick

Yes

mode by pressing the button associated with the block and scrolling through the

registers with the encoder.

All records are presented below:

2.3.1 Block P1, oven configuration

The parameters of this block contain machine and software identification information

and allow general operating parameters to be configured.

Table 6: Block P1, oven configuration.

2.3.1.1 Firmware Version

Record number 2 "FirmwareVersion" of block P1 indicates the firmware version of the

equipment.

The firmware can also be updated here. To do this, with a FLASH memory connected to

the USB port, press the START/STOP button for a few seconds. The new firmware

must be located in the drive's DISTFORM®MYCHEF®FW folder and be called IMAGE.

HEX.

Figure 26: Location of the new firmware to be loaded.

29

If the FLASH memory is connected, the display shows 0001. If it is not, 0000

will appear.

If the FLASH memory is connected, the display shows 0001. If it is not, 0000

will appear.

Block

Register

Name

Parameter

Editable

P2

00

Year

Date and time setting: Year

Yes

01

Month

Date and time setting: Month

Yes

02

Day

Date and time setting: Day

Yes

2.3.1.2 Firmware Default

Restores factory default values. To do this, enter the configuration mode as explained

at the beginning of the section. Access the first parameter block, find register 3 and

press the START/STOP button. The restoration will start automatically.

All values shall be restored except for the oven type, the number of TSC channels, the

self-cleaning type, the fan type and the statistical values of the oven.

2.3.1.3 Lock

It is possible to lock the programs by accessing register 4 "Lock" of block P1 and

editing the stored value, where 1 is lock and 0 is not lock. This lock prevents the user

from editing the oven programs.

2.3.1.4 Light

The "Light" record number 5 of block P1 shows how long the light will remain on since

any control panel command was last pressed.

This parameter must be set to change the time. If the value is greater than zero, it

indicates the seconds that the light will remain on, up to a maximum of 600. If it is -1,

the light will remain on permanently each time the oven is turned on.

2.3.1.5 USB upload

Loads the programs from a FLASH memory connected to the USB port and records

them in the memory of programs 1 to 99 of the oven. To do this, with a FLASH memory

connected to the USB port, press the START/STOP button for a few seconds.

2.3.1.6 USB download

Record the programs 1 to 99 of the oven in a FLASH memory connected to the USB

port. To do this, with a FLASH memory connected to the USB port, press the

START/STOP button for a few seconds.

2.3.2 Block P2, Date and time

This block allows you to set the time and date.

30

03

Hours

Date and time setting: Hour

Yes

04

Minutes

Date and time setting: Minute

Yes

05

Seconds

Date and time setting: Seconds

Yes

Block

Register

Name

Parameter

Editable

P3

00

Password

Password of the technical service

Yes

01

Type

Oven type

No(SAT)

02

Tsc

Number of TSC channels (0 - 4)

No(SAT)

03

Autoclean

Type of self-cleaning

No(SAT)

04

FanConfig

Fan and inverter type

No(SAT)

05

RelayTest

Relay test relays 1 to 15

No(SAT)

06

GPIOTest

GPIOs Test

No(SAT)

07

TSCTest

TSC test

No(SAT)

08

InverterTest

Inverter test

No(SAT)

09

AutoReverseTemp

Auto-reverse activation

temperature

No(SAT)

10

HysteresisHeating

Temperature hysteresis

No(SAT)

11

LogPeriod

Period between HACCP, in

seconds

No(SAT)

12

AutomaticRecovery

Automatic recovery

No(SAT)

13

SteamVenting

Active ventilation

No(SAT)

14

EncoderSensibility

Encoder sensitivity

No(SAT)

15

SmartClimaSetting

Humidity control settings

No(SAT)

16

RelayRemap

Free relay remapping

No(SAT)

17

ProbeRemap

Probe for temperature control in

chamber

No(SAT)

18

ErrorInhibit

Disable error control

No(SAT)

This function will only continue with cooking in the event of a power failure

and subsequent recovery of the power supply.

Table 7: Block P2, Date and time.

Each register allows you to query and edit values to enter the date and time in the oven.

2.3.3 Block P3, Configuration SAT

This block allows to consult the internal configuration parameters of the oven and

facilitates the diagnosis of faults and malfunctions as well as its solution to the

technical assistance service.

Table 4: Block P3, Configuration SAT.

Parameters report a very wide range of features ranging from the type of oven to fan

configuration, etc. and also allow the service technician to perform tests and tests to

ensure perfect operation.

2.3.3.1 NightWatch

NightWatch allows the oven to automatically continue cooking after a power failure.

This feature is especially useful for unattended cooking.

31

This function can be disabled by your dealer. Make sure that you fully

understand the risks involved.

To minimize risks, analyze the food after such a low temperature warning

when it is automatically recovered from cooking, or discard it (Error 28).

Use the HACCP data record to always check firings. See chapter 2.1.12.

This function is deactivated at the factory and must be activated by your

dealer.

Please note that steam extraction only works in the final moments of

cooking. Therefore, this action does not occur when the oven door is opened

during cooking.

This function will only be activated in time-controlled cooking.

When a cut occurs and the power supply is subsequently restored, the oven recovers

the current firing (if any) and continues it with the same parameters prior to cutting.

If it is not cancelled, the MyChef oven automatically checks the temperature of the

cooking chamber. If the temperature is below 56°C there may be a risk of bacterial

contamination. In this case, the oven will continue cooking but will display error 28

when pressing the START/STOP button to end the firing cycle. In this case, the final

user shall decide the fate of the food, taking into account the risks of possible bacterial

contamination.

2.3.3.2 Automatic steam extraction from the chamber

In order to avoid burns or steam discomfort when opening the door, MyChef ovens can

remove steam from the chamber at the end of the cooking process. Even when in

convection mode, this extraction can be useful to eliminate steam that may be

released from food in the cooking chamber.

When the oven enters the steam extraction process, a large amount of steam can

escape through the chimney, depending on the saturation level. The use of a

condensing hood is recommended for MyChef ovens.

32

Block

Register

Name

Parameter

Editable

P4

00

Probe 1

Multipoint probe. Point 1

Yes

01

Probe 2

Multipoint probe. Point 2

Yes

02

Probe 3

Multipoint probe. Point 3

Yes

03

Probe 4

Multipoint probe. Point 4

Yes

04

Probe 5

Not used

Yes

05

Probe 6

Not used

Yes

06

Probe 7

SmartClimate Probe

Yes

07

Probe 8

Probe Camera

Yes

08

Probe 9

PCB temperature

Yes

09

Probe10

Inverter temperature

Yes

If the temperature of a sensor is higher than 350ºC or lower than -50ºC it

means that the sensor is not connected.

Block

Register

Name

Parameter

Editable

P5

00

T_000_050

Operating hours between 0ºC and

50ºC

No

01

T_050_100

Operating hours between 50ºC and

100ºC

No

02

T_100_150

Operating hours between 100ºC and

150ºC

No

03

T_150_200

Operating hours between 150ºC and

200ºC

No

04

T_200_250

Operating hours between 200ºC and

250ºC

No

05

T_250_300

Operating hours between 250ºC and

300ºC

No

06

Rinse

Number of rinses

No

07

Clean1

Number of cleanings level 1

No

08

Clean2

Number of cleanings level 2

No

09

Clean3

Number of cleanings level 3

No

10

Clean4

Number of cleanings level 4

No

11

Door

Number of door openings divided by

10

No

2.3.4 Block P4, Probe

This block allows you to consult the temperature readings of the oven at different

points.

Table 9: Block P4, Probes.

Each register is associated to a temperature reading point of the oven, allowing to

control different critical points of the oven.

2.3.5 Block P5, Statistics

This block collects statistical values of the oven's operation, allowing to obtain trends

and graphs that allow Distform to improve its products and adapt them to the user's

needs.

Table 5: Block P5, Statistics.

33

Block

Register

Name

Parameter

Editable

P6

00

Error 0

Last error occurred

No

01

Error 1

Penultimate error occurred

No

02

Error 2

First to last mistake made

No

03

Error 3

Previous to Error 2

No

04

Error 4

Previous to Error 3

No

05

Error 5

Previous to Error 4

No

06

Error 6

Previous to Error 5

No

07

Error 7

Previous to Error 6

No

Figure 15: Alarm icon.

Figure 16: Error icon.

Error

Internal definition

Details

0

NO ERROR

Without error

1

ERROR GENERAL PURPOSE INPUT

General error entry. Not used.

2

ERROR OVERTEMPERATURE

General temperature input. Not used.

3

ERROR OVERTEMPERATURE PCB

Over temperature PCB. Check that the cooling fans of the

electronics are working properly, that there is sufficient space

between the rear and the wall, and that the ambient temperature

is not excessive.

4

ERROR COMMUNICATION

Plate communication is not responding. Check the cable

connecting the power board and control board.

5

ERROR EEPROM

The communication processor and EEPROM do not work. Check

the control card.

6

ERROR MOTOR

Motor/inverter error. Check motor wiring.

These statistical records primarily store values of operating time, cycle repetition, and

the rate of use and wear of certain elements to monitor the useful life and maximize

the efficiency of all oven components.

2.3.6 Block P6, Errors

This block is a record of the last 7 errors that have occurred during the operation of the

oven.

Table 11: Block P6, Errors.

2.4 Errors y alarms

Errors and alarms can occur during the preparation and execution of any of the

programs available in the oven. If this is the case, the LCD will show the alarm or error

icon and the right display will show the error or alarm code.

The table below shows the different errors and alarms, as well as possible solutions to

them.

34

7

ALARM WATER

No water detected. Make sure that the water supply is connected

correctly.

8

ERROR WASHING

No detergent/brightener detected. Not used.

9

ERROR PROBE1 TEMP SENSOR NOT

CONNECTED

External probe not connected. Check the external probe and

connector.

10

ERROR PROBE1 TEMP SENSOR SHORTED

External short-circuited probe. Check the external probe and

connector.

11

ERROR PROBE2 TEMP SENSOR NOT

CONNECTED

External probe not connected. Check the external probe and

connector.

12

ERROR PROBE2 TEMP SENSOR SHORTED

External short-circuited probe. Check the external probe and

connector.

13

ERROR PROBE3 TEMP SENSOR NOT

CONNECTED

External probe not connected. Check the external probe and

connector.

14

ERROR PROBE3 TEMP SENSOR SHORTED

External short-circuited probe. Check the external probe and

connector.

15

ERROR PROBE4 TEMP SENSOR NOT

CONNECTED

Reserved. Not used.

16

ERROR PROBE4 TEMP SENSOR SHORTED

Reserved. Not used.

17

ERROR PROBE5 TEMP SENSOR NOT

CONNECTED

Reserved. Not used.

18

ERROR PROBE5 TEMP SENSOR SHORTED

Reserved. Not used.

19

ERROR PROBE6 TEMP SENSOR NOT

CONNECTED

Reserved. Not used.

20

ERROR PROBE6 TEMP SENSOR SHORTED

Reserved. Not used.

21

ERROR PROBE7 TEMP SENSOR NOT

CONNECTED

Reserved. Not used.

22

ERROR PROBE7 TEMP SENSOR SHORTED

Reserved. Not used.

23

ERROR PROBE8 TEMP SENSOR NOT

CONNECTED

Camera probe not connected. Check probe and wiring.

24

ERROR PROBE8 TEMP SENSOR SHORTED

Short circuit camera probe. Check probe and wiring.

25

ERROR PROGRAM NOT TERMINATED

Reserved. Not used.

26

ERROR CLEANING PROGRAM NOT

TERMINATED

The oven has been switched off by running a self-cleaning

program. Make a rinse.

27

ERROR CLEANING TEMPERATURE TOO

HOT

The temperature of the oven during a self-cleaning program has

risen above a maximum temperature.

28

ALARM RECOVERY TEMP TOO LOW

The oven has recovered from a power outage, and the

temperature in the chamber was below 56ºC (NightWatch). Risk

of bacterial contamination. Discard or test the product.

Table 12: Errors, alarms and possible solutions.

35

Always run a self-cleaning or rinsing program when Error 26 occurs.

36

Loading...

Loading...