Provided By

http://www.MyBinding.com

http://www.MyBindingBlog.com

Duplo Docu Cutter

DC-545HC

Service Manual

SERVICE MANUAL

Ver.1

DOCU CUTTER

DC-545HC

Be sure to read this manual carefully, so that you

repair and service this machine safely and correctly.

Do not begin work until you have thoroughly

understood the contents of this manual.

Repairing or servicing the machine with insuffeicient

knowledge about it could lead to unforeseen

accidents or falls in the machine's performance or

quality.

DUPLO SEIKO CORP.

Introduction

The cause of most accidents is failure to adhere to basic safety rules and observe safety

instructions. It is important to prevent potential causes of accidents from occurring. In

order to do so, read this manual carefully, and be sure to understand all the safety instructions and correct inspection and servicing procedures that it provides before beginning

repair or servicing work.

Repairing or servicing the machine with insufficient knowledge about it could lead to

unforeseen accidents.

It is not possible to anticipate and describe in a manual such as this every possible

hazard that could arise in the course of repair and servicing. Therefore, besides observing

the safety instructions marked in this manual and on the machine's labels, service

personnel should be safety-conscious and take other safety precautions as necessary. When

performing repair or service work not covered by this manual, you should obtain safety

guidance from an appropriately knowledgeable person.

Copyright © 2003

DUPLO SEIKO CORPORATION

All Rights Reserved

1

Safety instructions

Safety instructions

1.Cautions regarding the installation location

Safety instructions

Installation environment

s Avoid installing the machine in places exposed to direct sunlight.

• Sunlight will cause the temperature in the machine’s interior to rise, possibly leading to malfunction of the control system.

• Sunlight could cause misoperation of the sensors.

• The heat of direct sunlight could cause deformation of the machine’s plastic parts.

* Also avoid installation near to a ground glass window; light and heat penetrate such windows

although they are opaque.

s Avoid installing the machine in places subject to high or low temperature or humidity.

• High or low temperature or humidity could cause the machine to operate abnormally.

Suitable temperature and humidity ranges are:

Ambient temperature: 5˚C–30˚C

Ambient humidity: 40%–70%

Optimum temperature and humidity: 20˚C, 65%

• If the machine is installed near to faucets, water heaters or humidifiers, or in cool (sunless) parts

of a building or in the vicinity of water sources, the paper could absorb moisture and curl,

leading to misfeeds or poor image quality.

s Avoid installing the machine in places with open flames, or where reflected heat or other hot air

currents (from stoves, etc), or cold air currents from coolers, etc will strike it directly.

s Avoid installing the machine in poorly ventilated places.

s Avoid installing the machine in dusty places.

s The machine should not be tilting when it is used.

• Install the machine so that it is level.

(The machine should be level to within 5mm in the front-rear direction, and 5mm in the lateral

direction.)

s Do not install the machine on shaky, sloping or otherwise unstable surfaces.

• The machine could fall over on such surfaces, or fall off them, causing injury.

2

Safety instructions

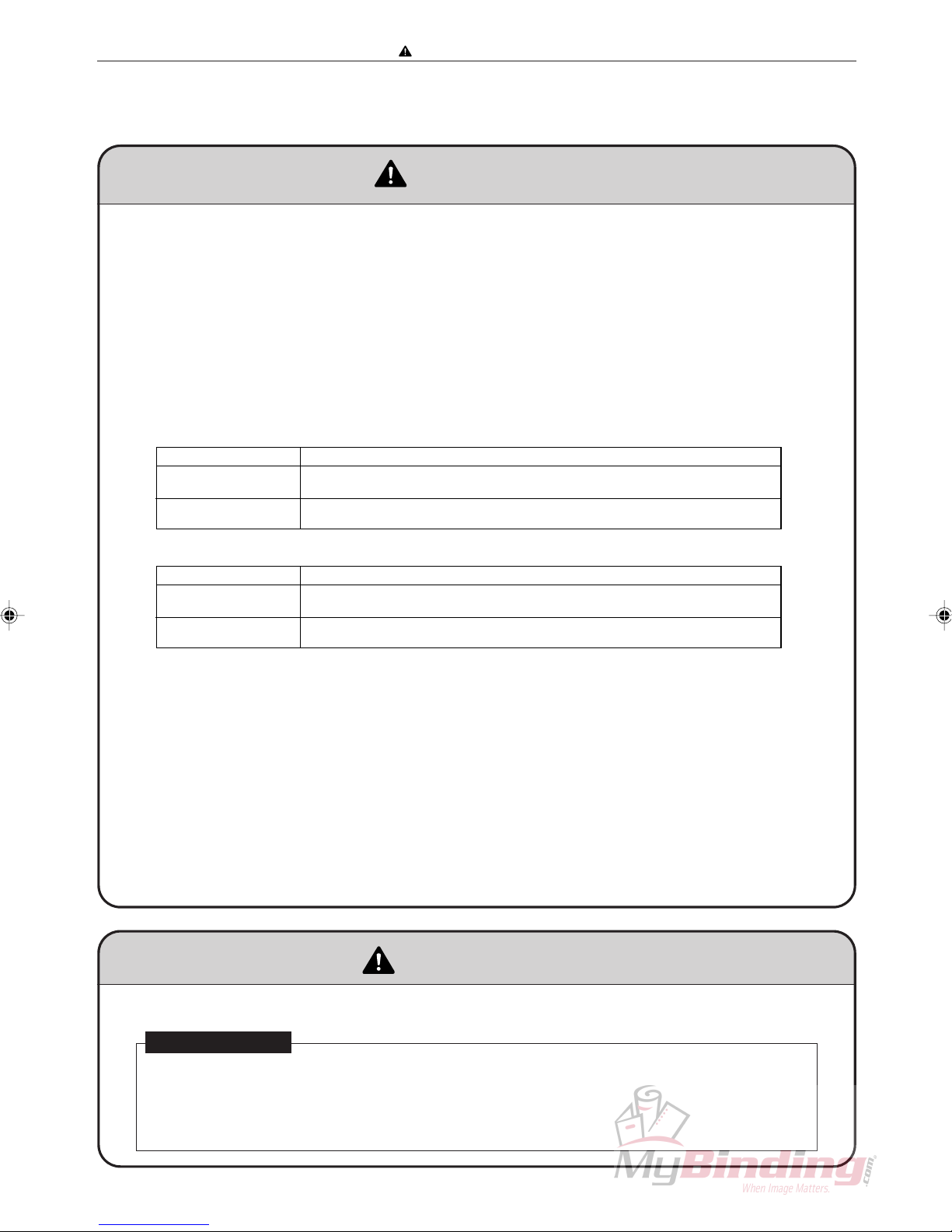

2. Cautions for installation work

Warning

• The machine’s power supply voltage and power consumption depend on the model. Details of this

are given in the tables below. The power supply voltage and power consumption for the machine

are given in the table below. The machine’s power supply voltage is indicated on the identification

plate located on the machine’s left side; the machine must be connected to a power supply of the

voltage indicated.

a Otherwise, fire or electric shock could result.

If the power supply voltage is unstable or if the power supply has insufficient capacity, the

machine may not operate normally.

Make sure that the power supply has sufficient capacity for the system as a whole, including

optional equipment.

* 120V AC model

Power supply voltage

With no load*

At full load

Power consumption

No more than 130V AC

At least 110V AC

During operation : 90W

In standby : 15W

Connect to outlet of 120V AC, 60Hz, at least 15A

Use power supply meeting these requirements

}

* 230V AC model

Power supply voltage

With no load*

At full load

Power consumption

* “With no load” - when the machine is on standby.

* “At full load” - when the machine is running at maximum power consumption.

No more than 250V AC

At least 210V AC

During operation : 90W

In standby : 15W

Connect to outlet of 230V AC, 50Hz, at least 8A

Use power supply meeting these requirements

}

• Use only the power cord that is provided among the accessories.

Insert the power cord plug firmly into the socket, so that proper electrical contact is effected.

• Install the machine close to its power supply. The outlet used should be exclusively for the

machine, and have no other equipment connected to it.

If an extension cord is necessary, it should have a ground terminal, and be of the following ratings:

* For a 120V AC model: 130V, at least 15A, length not exceeding 5m.

* For a 230V AC model: 250V, at least 8A, length not exceeding 5m.

• Never tread on the power cord or pinch it between other objects, or accidents could result.

CAUTION

• Install the machine in accordance with the installation procedure appended to this manual.

Using the stand

• Lock the casters after the machine is installed.

a Otherwise, the machine could move or fall over, causing injury.

• To move the machine, push it by its mounting base.

a Pushing the DC-545 could make it fall over.

3

Safety instructions

3. Cautions for maintenance, inspection and servicing

Warning

Precautions for safe servicing

• Always remove the power cord plug from the outlet before starting work.

aOtherwise, you could get a shock or your hands/fingers could be injured.

• However, the plug must be left connected to the outlet when performing function checks (of

individual motors, a given series of operations, or electrical circuits). When motors are operated

alone in function checks, interlocks are deactivated, so be aware of the conditions and positions of

related equipment, and take great care not to put your hands or fingers into moving parts.

• The cutter unit and slitter unit contain hazardous sharp blades. Exercise great care when inspecting

the cutter unit or replacing it or its parts.

aOtherwise, your hands/fingers could be injured.

• Do not touch the drum or rollers after turning on the jog switch.

• Do not put your hands or fingers inside the machine while the drum is rotating.

aOtherwise, your hands/fingers could get caught and crushed between the drum and rollers.

Working clothes

• Wear clothing than enables you to work safely.

CAUTION

Tools

• Use tools that are appropriate for the work.

4

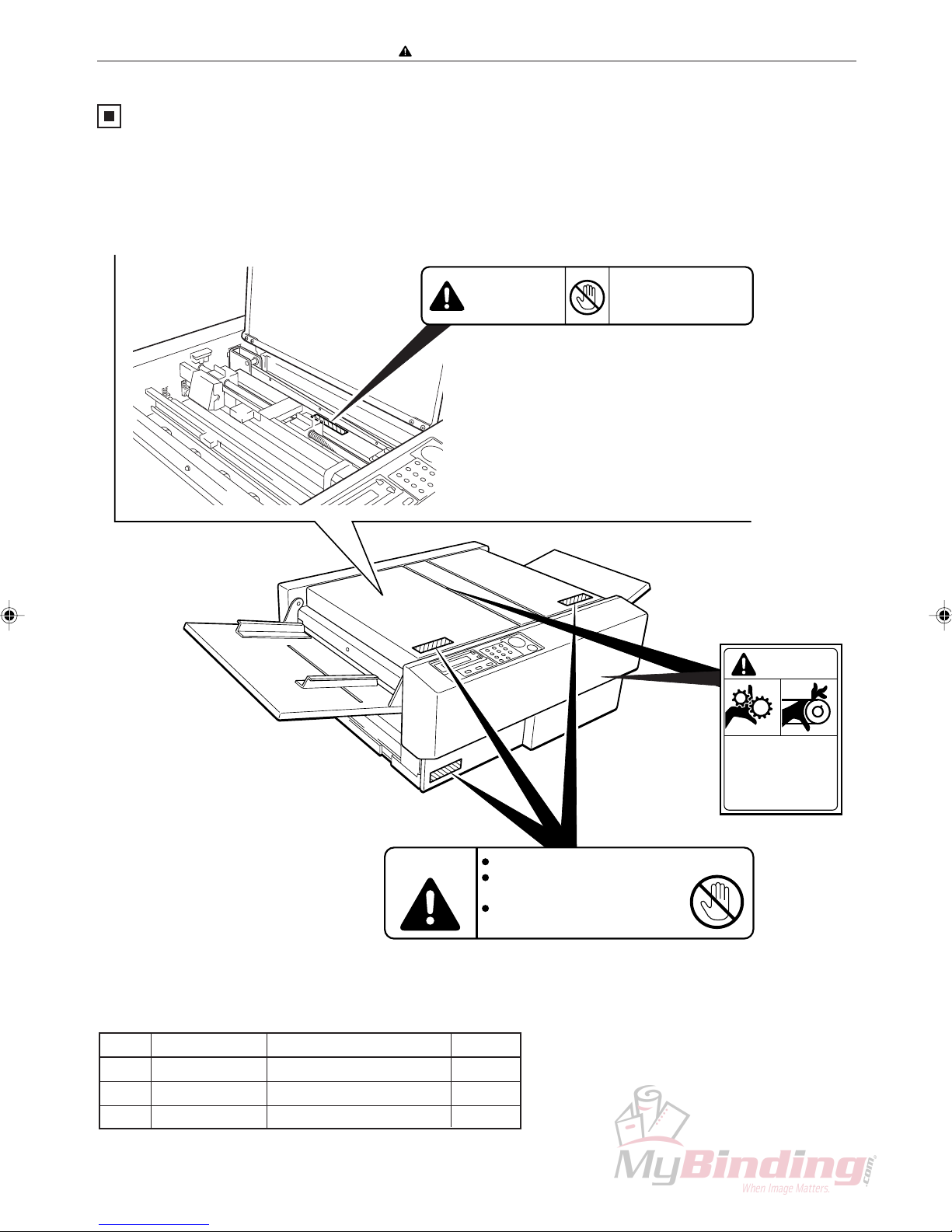

Safety instructions

Warning Sticker

Keep the WARNING stickers clean at all times. If labels become damaged or come off, have your service

representative replace them.

q

Do not touch blade!

WARNING

To remove jammed paper,

use the tweezers.

L8-T1100

w

WARNING

No. Parts No. Name Q’ty

q L8-T1100 Warning Sticker 1 1

w L8-T1080 Warning Sticker 2 3

e L8-T1090 Label Caution 2

e

Use caution when working

near movable parts.

Disconnect power before

servicing.

Cutters and movable parts are inside this cover.

Before opening the cover to work,

unplug the power cord.

Use caution when working near cutters

and movable parts.

L8-T1080

WARNING

L8 T1090

5

Safety instructions

6

Introduction

Description of Operation

Mechanical

Standard Adjustments

Chapter 1

Chapter 2

Chapter 3

Chapter 4

Maintenance Checks

Troubleshooting

HELP Mode

Miscallaneous

Chapter 5

Chapter 6

Chapter 7

Chapter 8

7

Table of Contents

Introduction ....................................................... 1

Safety instructions............................................ 2

1. Cautions regarding the installation

location .......................................................... 2

2. Cautions for installation work ...................... 3

3. Cautions for maintenance, inspection and

servicing ........................................................ 4

Warning Sticker................................................. 5

Chapter 1 Introduction

z Specifications ............................................. 10

x Dimensions ................................................. 11

c Part Names and Functions ........................ 12

v Work Flow .................................................... 15

b Options ........................................................ 16

Chapter 2 Description of Operation

z Paper Feed Unit .......................................... 18

x CCD Mechanism ......................................... 30

c Margin Slitter............................................... 32

v Guillotine Cutter Unit ................................. 34

b Creaser Unit ................................................ 35

n Center Slitter ............................................... 37

m Paper Eject Tray .......................................... 39

, Main Drive ................................................... 40

. Skew Adjustment Mechanism ................... 43

⁄0 BAR CODE .................................................. 44

⁄1 REGISTER MARK ....................................... 45

Chapter 4 Standard Adjustments

z LCD Panel.................................................... 94

x Slitter Position ............................................ 95

c Cutter Registration ..................................... 98

v Creaser Calibration .................................. 100

b CCD Horizontal Line Alignment .............. 102

n Adjusting Crease Depth........................... 104

m Feed Solenoid Adjustment ...................... 105

, Gate Solenoid Adjustment (Without the

DC-545HC)................................................. 106

. Cutter Assembly Perpendicularity

Adjustment................................................ 107

⁄0 Creaser Perpendicularity Adjustment .... 108

⁄1 CCD Vertical Line Alignment ................... 109

⁄2 Elevator Switch Height Adjustment........ 111

⁄3 Cover Switch (AF-100 : 1 position,

DC-545 : 2 positions)................................ 112

⁄4 Shutter Solenoid....................................... 113

⁄5 Creaser Sensor Plate Adjustment........... 118

Chapter 5 Maintenance Checks

z Cleaning and Oiling.................................. 120

x Periodic Maintenance Check List............ 120

Chapter 6 Troubleshooting

z T roubleshooting Guide............................. 124

x Error Display ............................................. 132

Chapter 3 Mechanical

z Exterior ........................................................ 49

x Feed Section ............................................... 52

c CCD Section................................................ 59

v Margin Slitter Section................................. 60

b Cutter Section ............................................. 67

n Creaser Section .......................................... 69

m Center Slitter Section ................................. 71

, Driving Section ........................................... 79

. Electric Section........................................... 85

Chapter 7 Help Mode

z HELP Mode List ........................................ 140

x Functions and operation procedures for

each HELP mode ...................................... 141

c HELP Description ..................................... 142

v Select Language for Displays ................. 150

Chapter 8 Miscallaneous

z Job List...................................................... 152

x

Position and Function of Electronic Parts ..

c Overall Wiring Diagram ............................ 161

8

156

Chapter 1 Introduction

z Specifications ............................................ 10

x Dimensions ................................................ 11

c Part Names and Functions ....................... 12

1. Appearance........................................... 12

2. Operation Panel.................................... 14

v Work Flow................................................... 15

1. Operations ............................................ 15

b Options ....................................................... 16

1

9

Chap.1

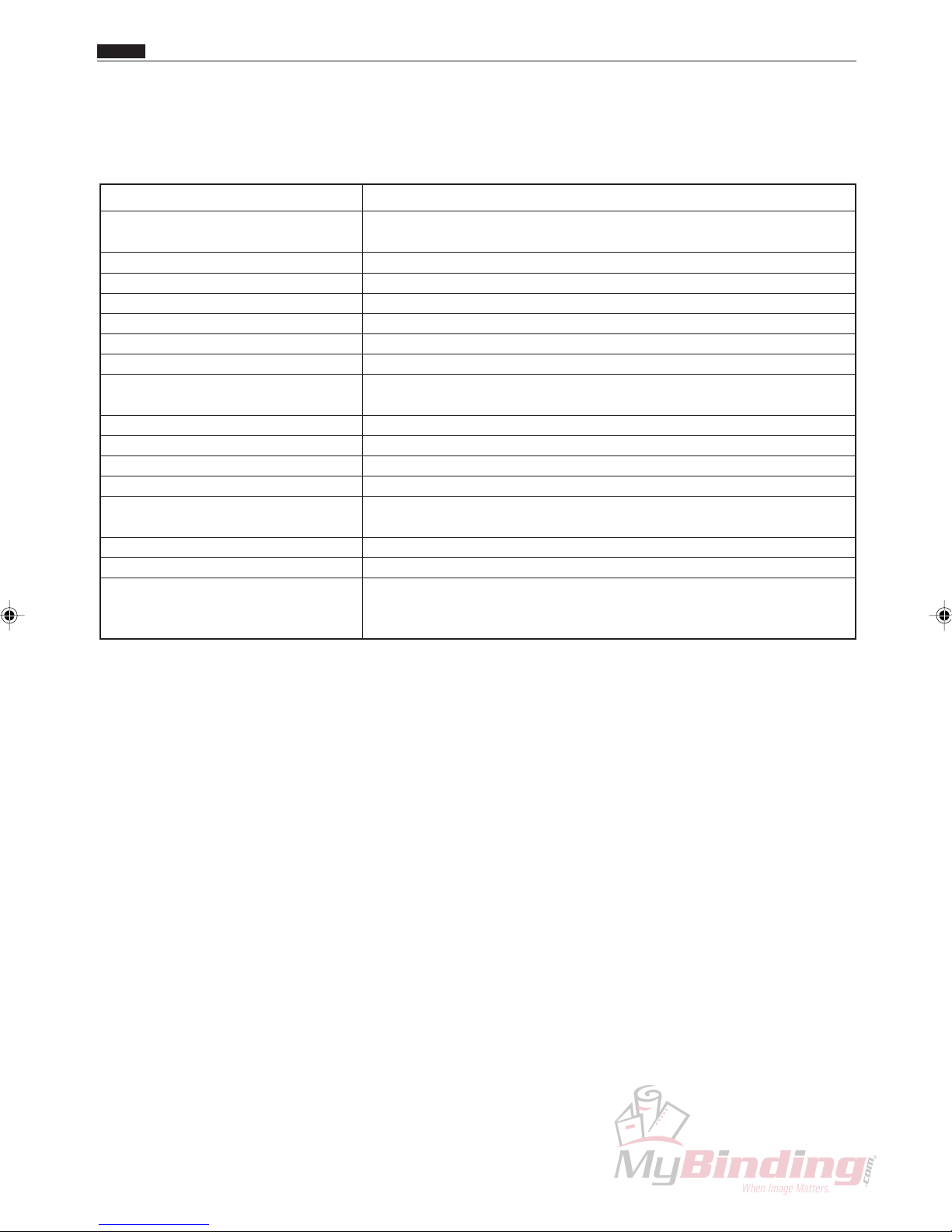

z Specifications

z Specifications

Product name/Model No. DC-545 with HC AUTO FEEDER

Input paper size Min.: 8.5” x 11”/A4

Max.: 12.6” x 18”/A3

Input paper weight Min.: 110 gsm, Max.: 230 gsm <No curl in the paper>

Finishing size Min.: 2” (Width) x 3.5” (Length) <Business card size>

Lead edge trim Min.: 0.125” (3.2 mm)

Trail edge trim Min.: 0.125” (3.2 mm)

Side edge trim Min.: 0.125” (3.2 mm), Max.: 4.5” (114 mm)

Speed Max.: 9 ppm (A4 lengthwise, 4-side trim, 1 crease)

Trim/Crease tolerance ± 0.03” (± 0.762 mm)

<With paper cutting length not exceeding 18”>

Media type Range: Regular copy paper to coated heavy weight paper

Feeding method Automatic Feeding (Air suction method)

Feed tray capacity 100 mm

Stacker Drop type

Power supply AC 120 V ±10%, 50/60 Hz, 1.0 A

AC 230 V ±10%, 50/60 Hz, 0.6 A

Machine dimensions (mm) 1376 (W) x 576 (D) x 948 (H)

Machine weight (kg) 109.6 (Main body 56.4, Feeder 20.4, Stand 32.8)

1. Four creases perpendicular to the feed direction.

Other Features 2. Up to ten cuts perpendicular to the feed direction.

3. Automatic setting of slit, cut and crease position.

10

x Dimensions

Chap.1

x Dimensions

11

Chap.1

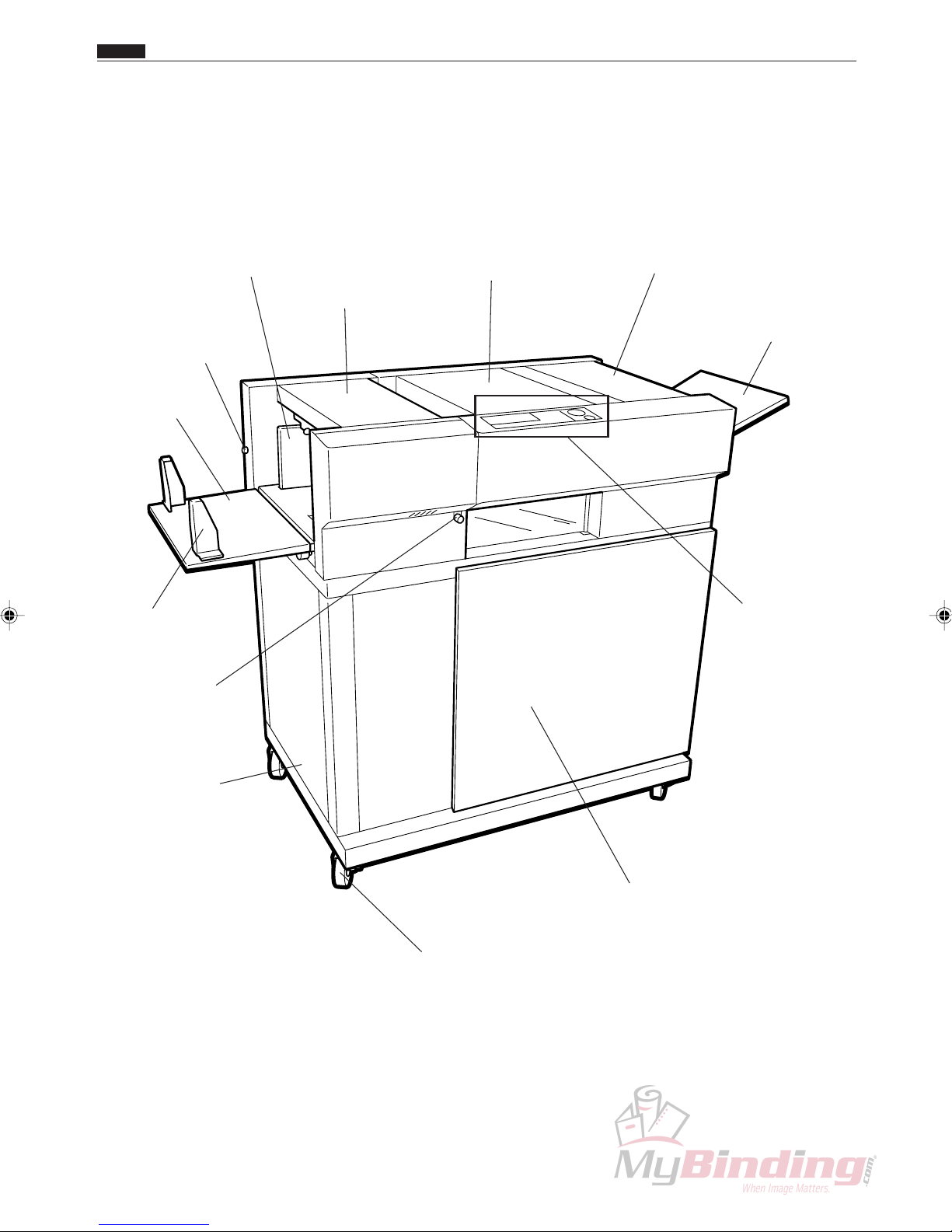

c Part Names and Functions

c Part Names and Functions

1. Appearance

Guide Plate

Blower Air ADJ Knob

Feed Tray

Guide Plate

Separator ADJ Knob

Feeder Cover

Cover (front)

Cover (rear)

Exit Tray

Operation Panel

Stand

Door

Caster

12

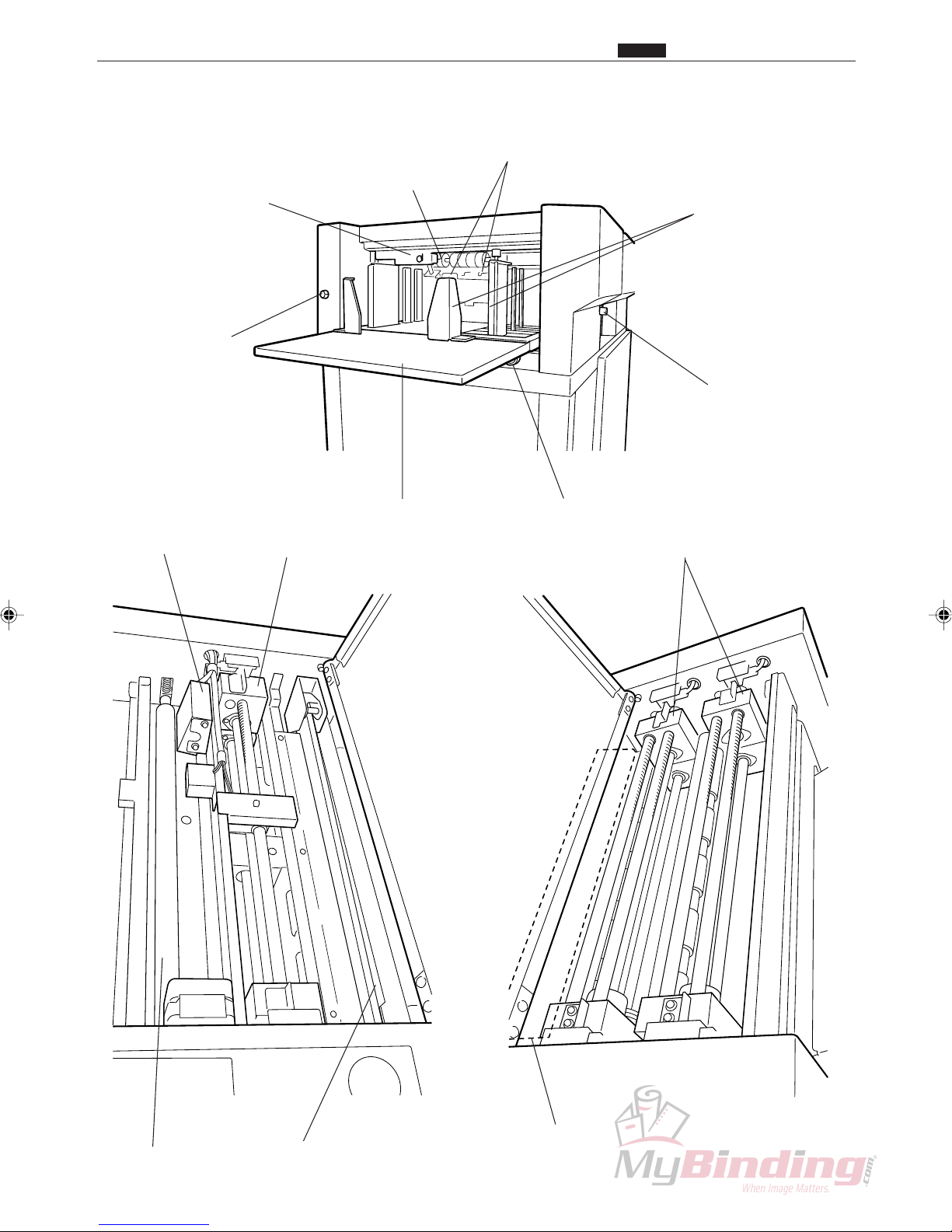

Feeding Section

Separator

Chap.1

c Part Names and Functions

Level ADJ Lever

Blower Air ADJ Knob

CCD

Margin Slitter

Flat Belt

Feed Tray

Guide Plate

Separator ADJ Knob

Skew ADJ Knob

Center Slitter

2nd Roller

Cutter

Creaser

13

Chap.1

c Part Names and Functions

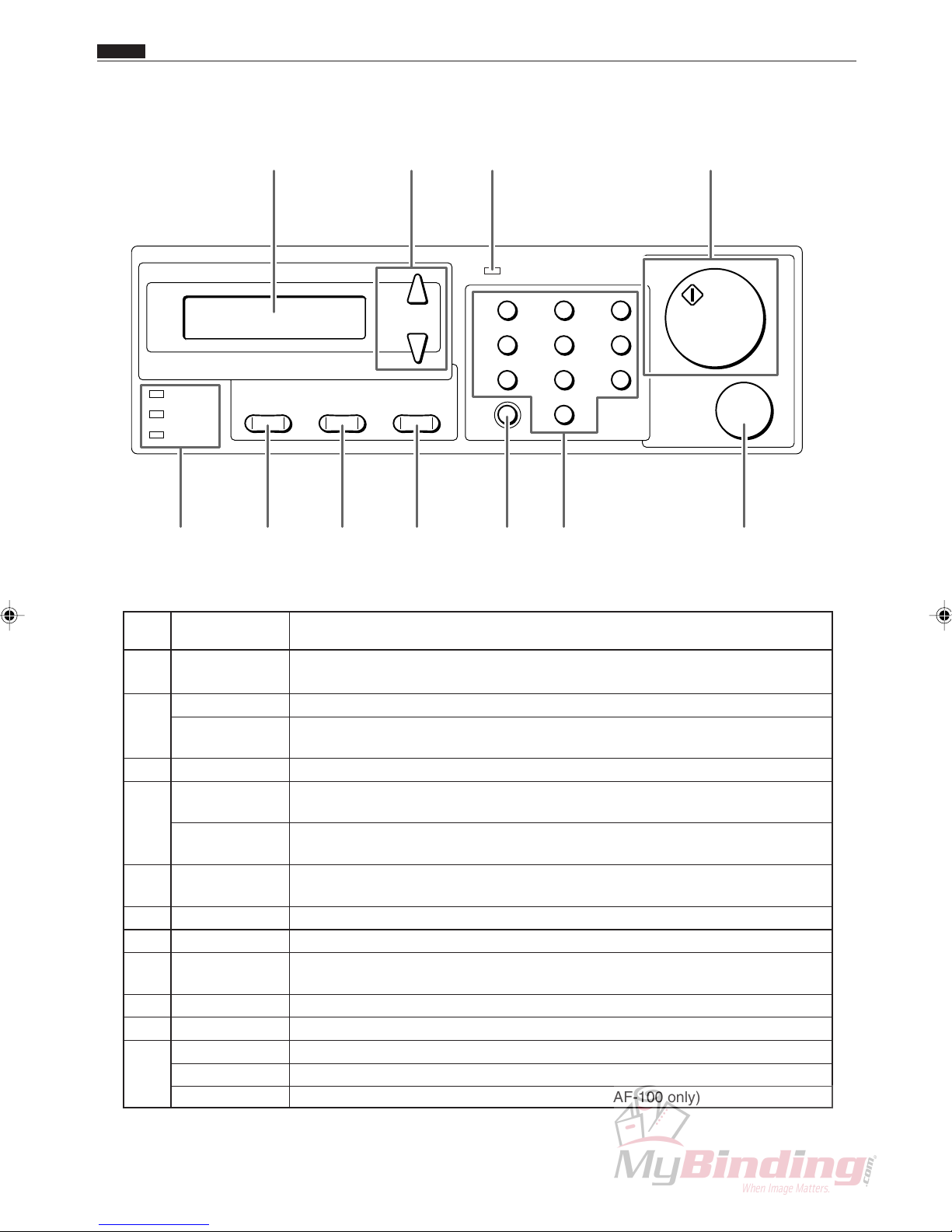

2. Operation Panel

w e rq

START

STOP

COVER

JAM

PAPER

POWER

+

–

F

MODE SET

C

1

4

7

2

5

8

3

6

9

0

!0!1 o i u ty

No. Name Function

q LCD panel Displays the status of the machine.

Displays messages when an error or paper jam occurs.

w <+> key Press to eject the document from the machine at the time of paper jam.

<-> key Press to eject the document from the machine at the time of paper jam. During

programming mode enables backward movement through the program steps.

e POWER lamp Lights up when the power is switched on.

r <START> key Not used when the DC-545 is operated without the autofeeder - AF-100. Press

to start processing when the AF-100 is attached.

START lamp Normally lights up in green. Lights up in red when the front cover or the rear

cover is open.

t <STOP> key Press to stop automatic feeding after the current sheet is processed.

Press to clear jam indication after the paper is cleared.

y Key pad Press to enter print numbers and enter values during manual programming.

u <CLEAR> key Press to clear the count. Press to cancel manual programming.

i <SET> key Press to confirm selection/entry. Used to test process a single sheet. (for

systems with the AF-100 only)

o <MODE> key Press to change the mode.

!0 <F> key The AF-100 Feed Tray lowers while the <F> + <-> keys are being pressed.

!1 COVER lamp Blinks when the front cover or the rear cover is open.

JAM lamp Blinks when a paper jam has occurred.

PAPER lamp Blinks when paper runs out. (systems with the AF-100 only)

14

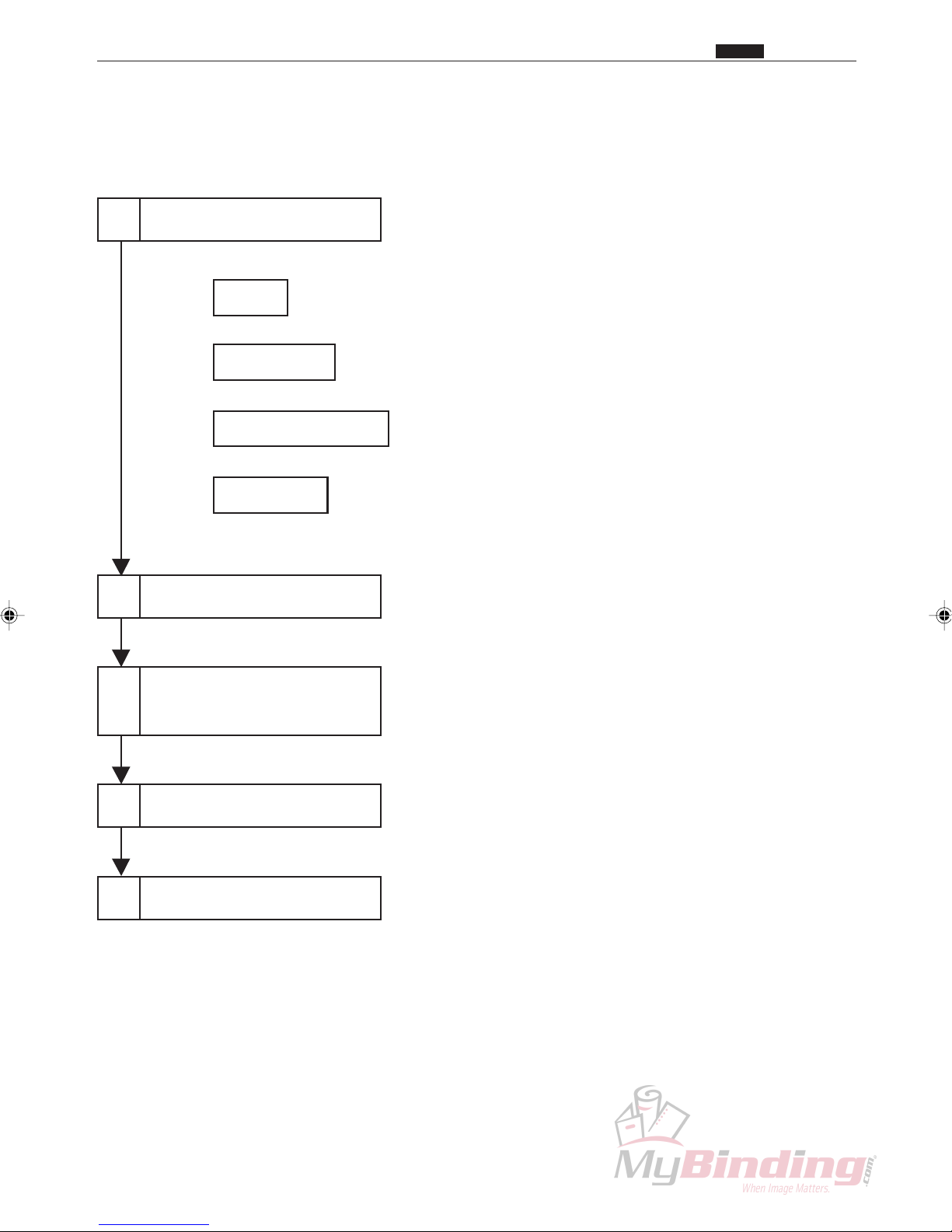

v Work Flow

1. Operations

1

V arious Settings

Chap.1

v Work Flow

INPUT

BAR CODE

REGISTER MARK

AUTO CUT

Setting the paper

2

Select the Program

3

Except when bar code is on.

.....................................How to create job programs

........................ When to use bar codes

............When to use register marks

...........................When to use AUTO CUT

<Start> Key

4

5

Finish

15

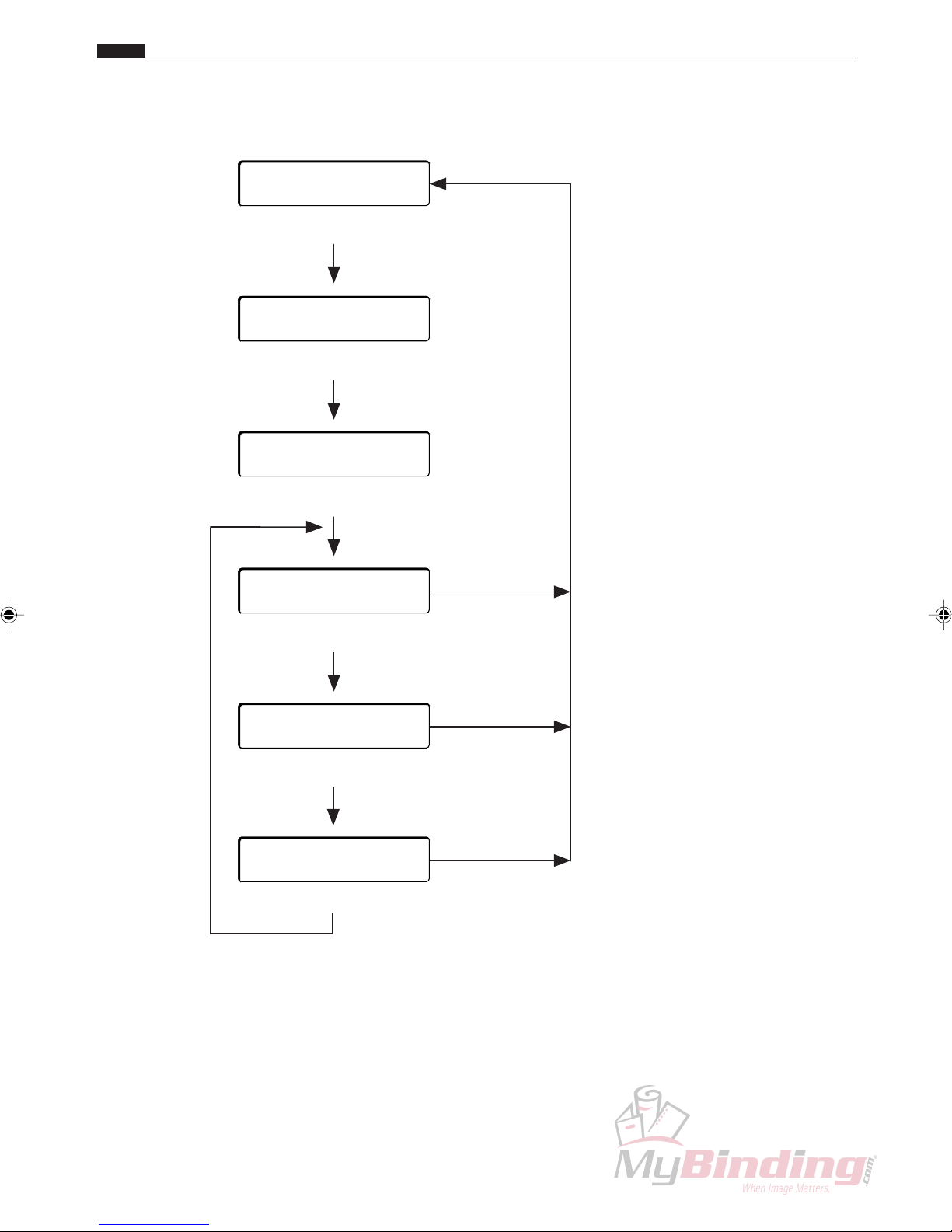

Chap.1

v Work Flow b Options

MODE switching is shown next.

[RUN] P–04

<MODE> KEY

[SELECT] P–04

<MODE> KEY

[INPUT]

––

INPUT

>SET

<MODE> KEY

BARCODE

*ON OFF

<SET> KEY

REGISTER MARK

*ON OFF

<SET> KEY

AUTO CUT

*ON OFF

<SET> KEY

<MODE> KEY

<MODE> KEY

<MODE> KEY

b Options

Setting the Optional Slitter 2

16

17

Chapter 2 Description of Operation

z Paper Feed Unit ......................................... 18

1. Description............................................ 18

2. Operation .............................................. 18

3. Operation of each unit ......................... 19

(1) Fan (Blower) ............................................ 19

(2) Fan (Suction)............................................ 20

(3) Paper Level Sensor .................................. 21

(4) Suction Unit and Feed Motor................... 22

(5) Separator Gap .......................................... 23

(6) Elevator Motor .........................................24

(7) Elevator Upper Switch............................. 25

(8) Elevator Lower Switch ............................ 26

(9) Paper Detection Sensor ............................27

(10) Feed Solenoid ........................................ 28

(11) Feed Stepping Motor.............................. 29

x CCD Mechanism ........................................ 30

1. Description............................................ 30

2. Operation .............................................. 30

c Margin Slitter.............................................. 32

1. Description............................................ 32

2. Operation .............................................. 33

v Guillotine Cutter Unit................................. 34

1. Description............................................ 34

2. Operation .............................................. 34

b Creaser Unit ............................................... 35

1. Description............................................ 35

2. Operation .............................................. 35

n Center Slitter .............................................. 37

1. Description............................................ 37

2. Operation .............................................. 37

m Paper Eject Tray......................................... 39

1. Description............................................ 39

, Main Drive................................................... 40

1. Description............................................ 40

2. Operation .............................................. 41

. Skew Adjustment Mechanism .................. 43

1. Description............................................ 43

⁄0 BAR CODE.................................................. 44

1. Description............................................ 44

⁄1 REGISTER MARK....................................... 45

2

18

z Paper Feed Unit

1. Description

The paper loaded on the feed tray is raised by the

elevator motor. When the paper is in the required

position, a jet of air from a fan in front of the paper

causes several sheets of paper to rise up. The suction

unit pulls up the top sheet only, and then the feed motor

drives the suction belt to transfer the paper.

When the paper from the AF-100 reaches the PPS1 in

the DC-545, the paper is transferred to the paper path by

the press roller and the feed stepping motor.

A separator mechanism is used to prevent two or more

sheets from being transferred at one time.

Suction Assembly

Feed Tray

Feed Motor

Fan (Suction)

Elevator Motor

Fan (Blower)

Elevator

Upper SW

Elevator

Lower SW

Level Sensor

2. Operation

1) Processing starts (processing does not start if there is no paper).

The fan (blower) and the fan (suction) start running.

2) The feed tray starts rising.

3) The feed tray stops when the paper level sensor turns on (light is not transmitted).

4) The shutter solenoid operates and the shutter opens and the paper is sucked onto the suction unit.

5) The feed motor starts and the suction belt begins turning to transfer the paper.

6) The feed motor stops when the paper reaches PPS1 (light is not transmitted).

If paper does not reach PPS1 within about 2.5 seconds, the elevator falls repeating operations 3) to 5) until

the paper level sensor turns off (light is transmitted). If the operation is repeated three times before the paper

reaches PPS1, a J2: FEED JAM error occurs and the machine stops.

\See page 132

Chap.2

z Paper Feed Unit

19

3. Operation of each unit

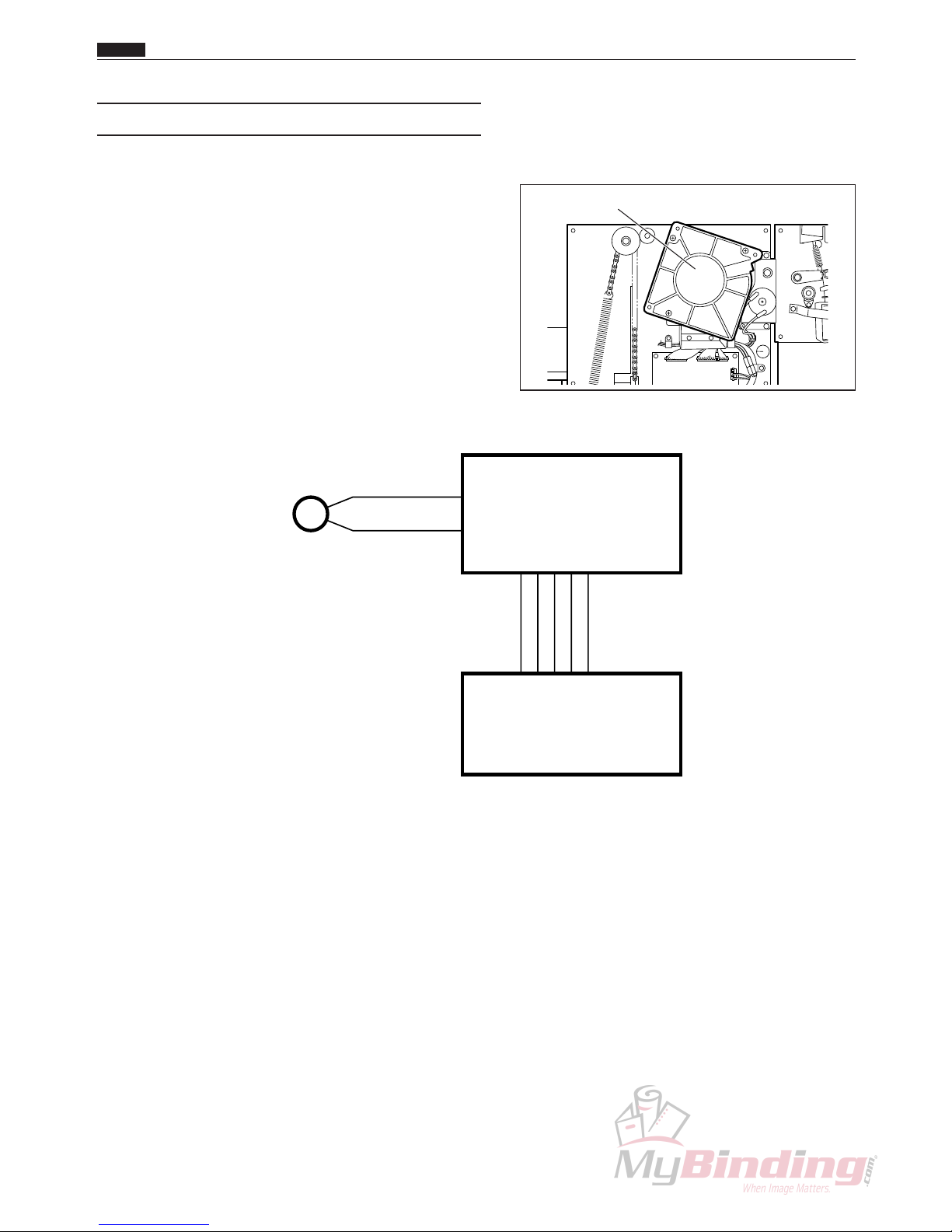

(1) Fan (blower)

Description

Paper on the feed tray is transferred to the blower and several sheets are floated up.

The airflow of the blower is adjusted by changing the position of the shutter and fan unit.

The level the paper is floated up is adjusted by changing the airflow of the blower and the paper level sensor.

The fan (blower) is usually running during processing.

Operation

The blower airflow can be increased by turning the knob so the numbers increase.

The gap between the shutter and the fan increases, which increases the air intake and therefore increases the

amount of air blown out.

The blower airflow can be decreased by turning the knob so the numbers decrease.

The gap between the shutter and the fan decreases, which decreases the air intake and therefore decreases the

amount of air blown out.

Circuit diagram

Shutter

Fan (Blower)

Knob

Chap.2

z Paper Feed Unit

RED

BLACK

CN2-3

24V

FAN(Exhaust)

GND

GND

24V

CN1-1CN1-1

-3

-12

CN11-10

-19

-3

-12

-17

-18

-4

FAN(Blower)

N4-X105*

Feed P.W.B. unit

N4-V303*

Main P.W.B. unit

N4-V300*

M

20

(2) Fan (Suction)

Description

Air near the suction belt is sucked in, and then blown

out on the right side of the AF-100.

The fan (suction) is usually running during processing.

Circuit diagram

Fan(Suction)

Chap.2

z Paper Feed Unit

RED

BLACK

CN3-1

24V

FAN(Intake)

GND

GND

24V

CN1-1CN1-1

-2

-12

CN11-10

-19

-2

-12

-17

-18

-3

FAN(Suction)

N4-X105*

Feed P.W.B. unit

N4-V303*

Main P.W.B. unit

N4-V300*

M

21

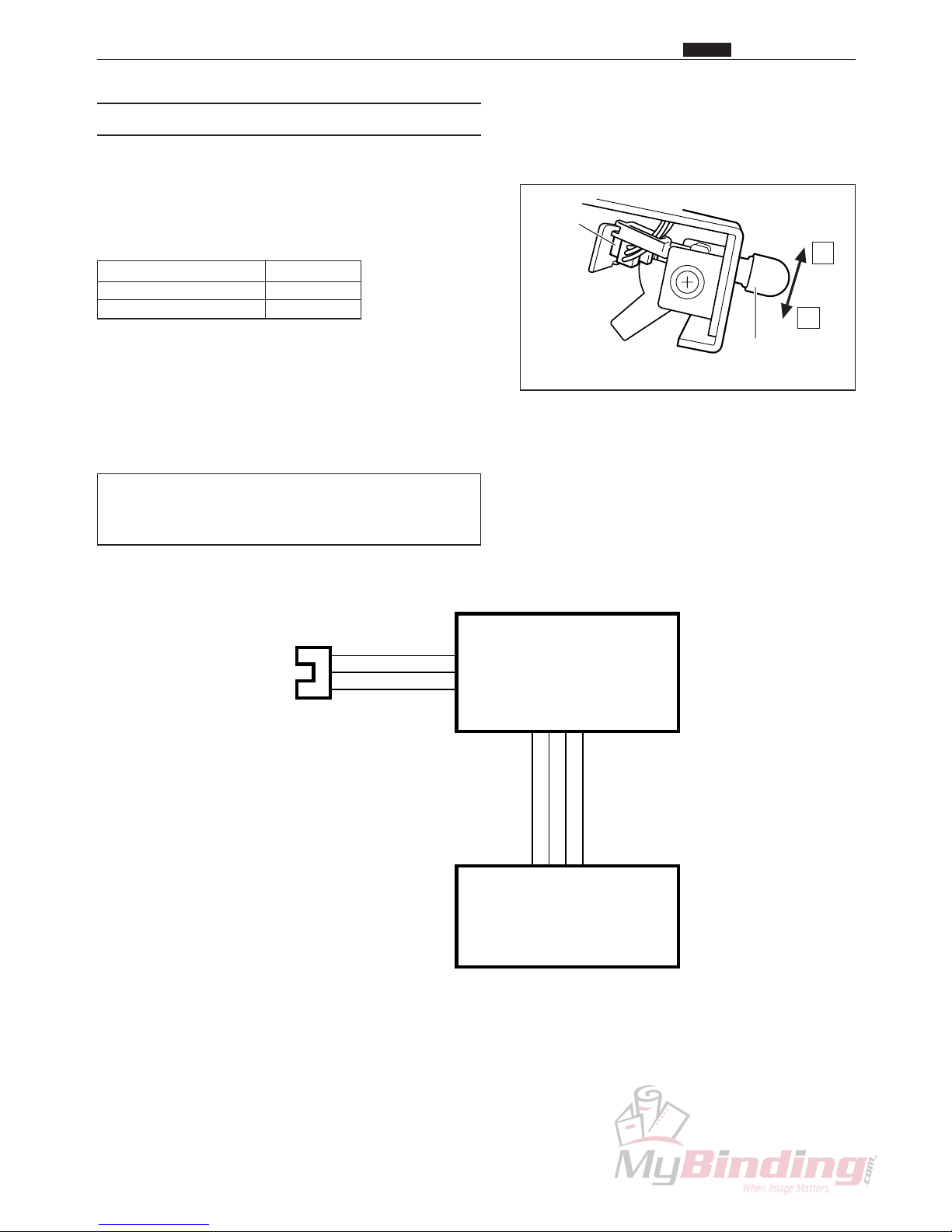

(3) Paper Level Sensor

Description

The paper level sensor controls the elevator motor to

determine the position of the feed tray by detecting the

position of the topmost sheet of paper on the feed tray.

Status Output

Light not transmitted 5V

Light transmitted 0V

To reduce the force of the suction, move the adjustment

lever towards q to increase the gap between the suction

belt and the paper.

To increase the force of the suction, move the

adjustment lever towards w to decrease the gap

between the suction belt and the paper.

Turn the lever towards q if the paper is double feed.

Turn the lever towards w if the paper is not being

sucked on to the suction unit.

Circuit diagram

Chap.2

z Paper Feed Unit

Level

Sensor

q

w

Level Sensor

Adjustment Lever

RED

BLUE

YELLOW

1

3

2

CN4-11

-12

5V

GND

Level Sensor

GND

CN1-11CN1-11

-12

-14

CN11-10

-12

-14

-17

-13

Level Sensor

CA021

Feed P.W.B. unit

N4-V303*

Main P.W.B. unit

N4-V300*

22

Chap.2

z Paper Feed Unit

(4) Suction Unit and Feed Motor

Description

Because the fan (suction) is running during processing,

when the shutter solenoid is on, the topmost sheet of

paper on the feed tray is sucked on to the suction unit.

The feed motor starts running about 0.3 seconds after

the shutter solenoid turns on, and the suction belt turns

and transfers the paper to the DC-545.

Circuit diagram

Shutter (inner)

Shutter Solenoid

RIGHT

BLUE

RIGHT

BLUE

RED

RED

CN2-7

24V

solenoid

Feed

GND

GND

CN1-1CN1-1

-6

-7

CN11-10

-19

-6

-7

-12

-17

24V

-18

-8

Shutter Solenoid

FEED MOTOR

N4-X101*

Feed P.W.B. unit

N4-V303*

Main P.W.B. unit

N4-V300*

SOL

BROWN

BLACK

CN2-9

-10

N4-X104*

M

23

Chap.2

z Paper Feed Unit

(5) Separator Gap

Description

The separator gap is a mechanism between the separator

and the suction belt that allows paper that is sucked on

to the suction unit to be transferred one sheet at a time

to the paper path.

This gap is regulated by turning the knob to raise and

lower the separator.

Turn the knob so that the numbers increase to make the

gap narrower. The separator rises and the gap narrows.

Turn the knob so that the numbers decrease to make the

gap wider. The separator falls and the gap widens.

Raise the separator if the paper being transferred is

double feed.

Lower the separator if paper is mis-feeding.

Separator

Separator Adjustment Knob

24

Chap.2

z Paper Feed Unit

(6) Elevator Motor

Description

The elevator motor raises and lowers the feed tray.

When there is no paper on the feed tray, the feed tray

lowers until it triggers the elevator lower SW.

However, if paper is loaded on the feed tray while it is

lowering (paper sensor is not transmitting light), the

elevator motor stops and the feed tray stops lowering.

The feed tray rises until the paper level sensor is on

(light is not transmitted) while paper is being fed.

During a paper feed retry operation, the feed tray

continues to lower until the paper level sensor goes off

(light is transmitted) for a period. Then the feed tray

rises until the paper level sensor goes on (light is not

transmitted).

If paper does not reach the elevator upper switch,

elevator lower switch, or paper level sensor after a set

time (*) after the elevator operation, an E8: ELEVATOR

ERROR occurs.

* 10 seconds when rising at start, 3.5 seconds during

paper feed operations, 9 seconds when lowering at

stop

\See page 138

Circuit diagram

Elevator Motor

BROWN

BLACK

CN2-5

24V

ELEVATOR1

ELEVATOR2

GND

GND

24V

CN1-1CN1-1

-4

-5

CN11-10

-19

-4

-5

-17

-18

-6

Elevator Motor

N4-X106*

Feed P.W.B. unit

N4-V303*

Main P.W.B. unit

N4-V300*

M

25

Chap.2

z Paper Feed Unit

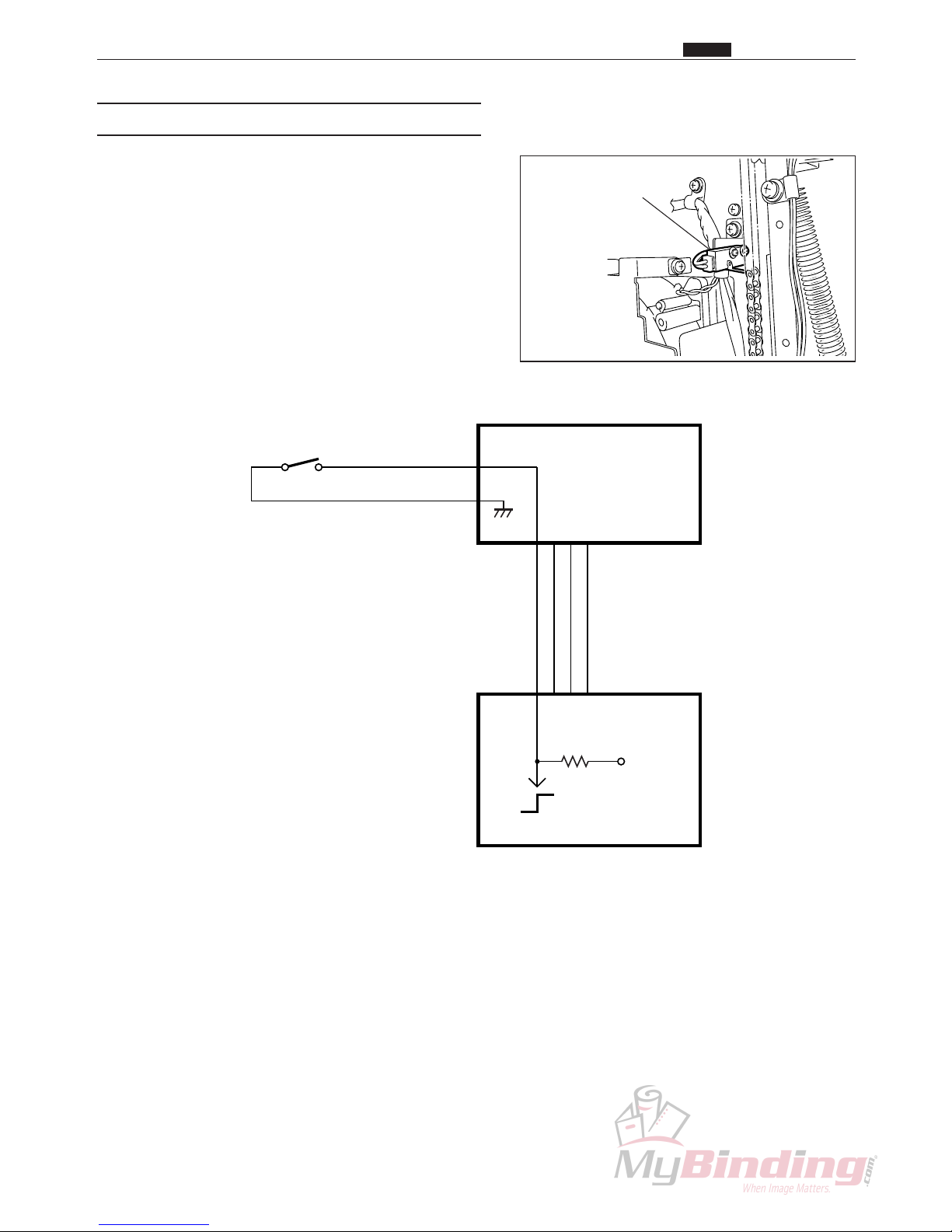

(7) Elevator Upper Switch

Description

The feed tray stops when the angle that is attached to

the chain that raises and lowers the feed tray turns the

micro switch on.

The feed tray is determined to be at its upper limit when

the micro switch is on, and the feed tray will not rise

any higher.

Circuit diagram

Elevator Upper SW

PURPLE

PURPLE

CN4-3

-4

Elevator Upper SW

5V

GND

GND

CN1-9CN1-9

-11

-12

CN11-10

-11

-12

-17

ELEVATOR UPPER SW

LA028

Feed P.W.B. unit

N4-V303*

Main P.W.B. unit

N4-V300*

0

5V5VON:0V

OFF:5V

26

Chap.2

z Paper Feed Unit

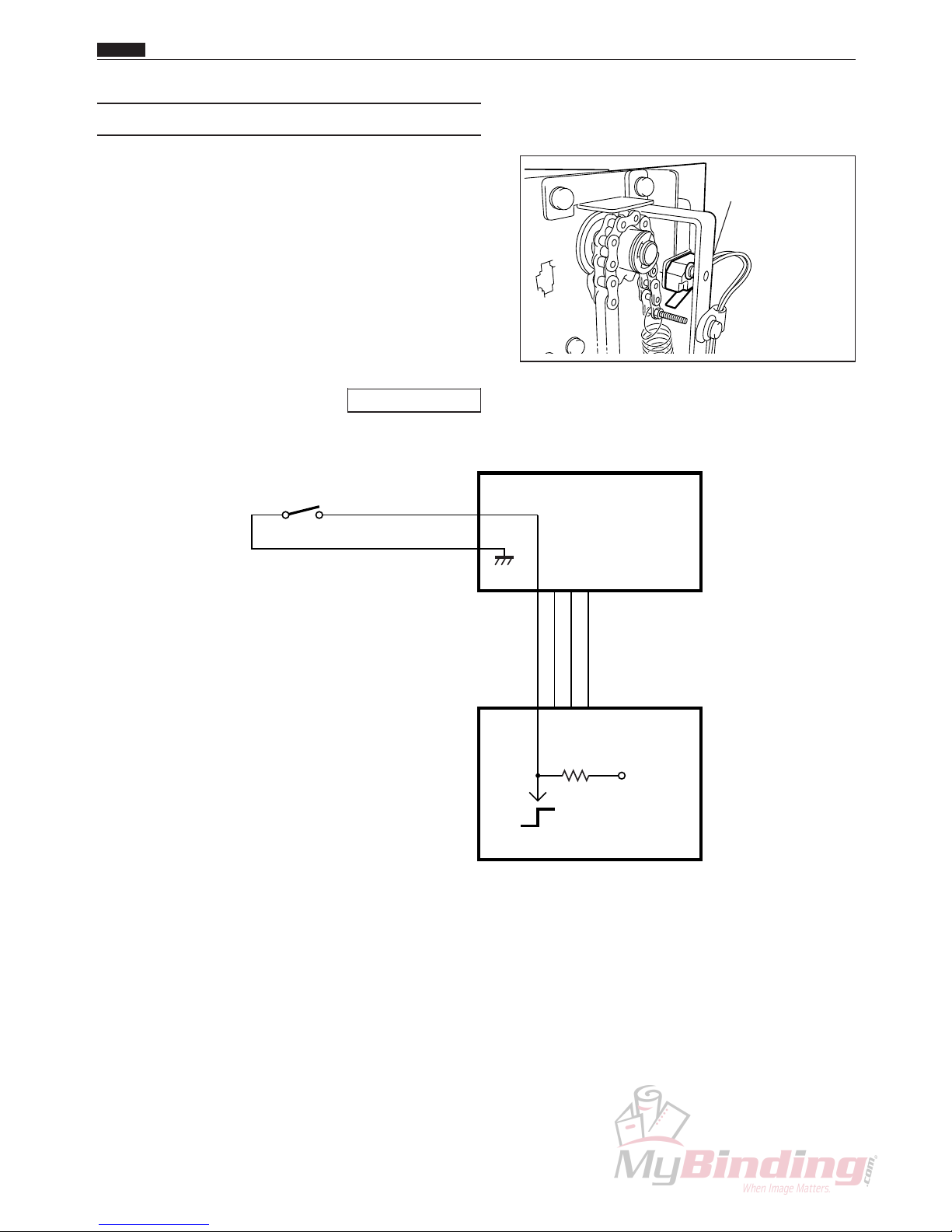

(8) Elevator Lower Switch

Description

The feed tray stops when the screw that is attached to

the chain that raises and lowers the feed tray turns the

micro switch on.

The feed tray is determined to be at its lower limit when

the micro switch is on, and the feed tray will not go any

lower.

If the elevator lower switch is on because there is too

much paper loaded on the feed tray, and the paper level

sensor is on (light is not transmitted), then a J5: OVER

CAPACITY error occurs.

\See page 133

Circuit diagram

Elevator Lower SW

ORANGE

ORANGE

CN4-1

-2

Elevator Lower SW

5V

GND

GND

CN1-10CN1-10

-11

-12

CN11-10

-11

-12

-17

ELEVATOR LOWER SW

LA028

Feed P.W.B. unit

N4-V303*

Main P.W.B. unit

N4-V300*

0

5V5VON:0V

OFF:5V

27

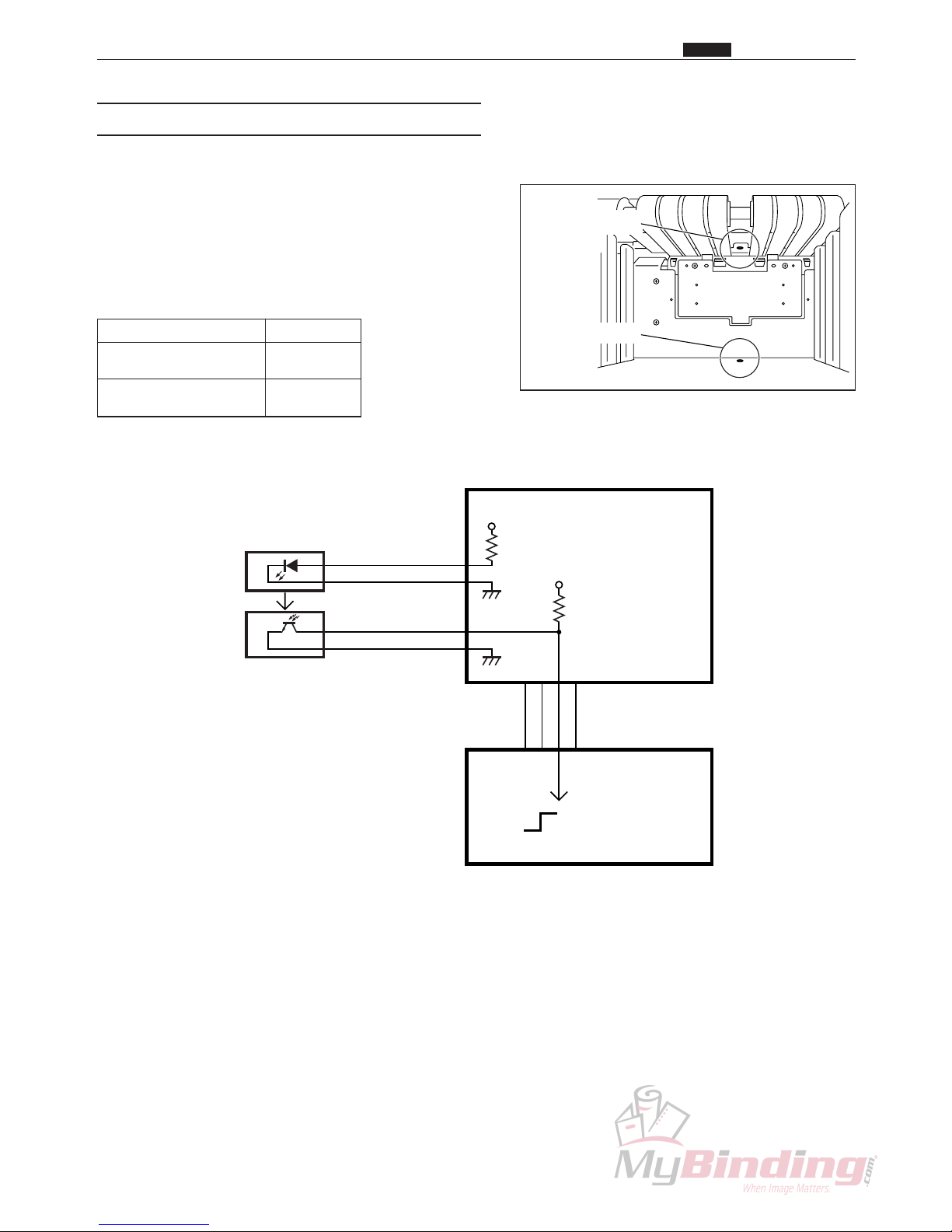

Feed PPS Photo

Diode

Feed PPS Photo

Transistor

Feed PPS Photo

Transistor

Chap.2

z Paper Feed Unit

(9) Paper Detection Sensor

Description

The paper detection sensor detects whether or not there

is paper on the feed tray.

If there is no paper, the elevator goes to its lower level

and stops.

When there is not paper (light is transmitted) the LED

(PAPER) on the operation panel blinks.

Status Output

Paper is present

5V

(light is not transmitted)

Paper is not present

0V

(light is transmitted)

Circuit diagram

BROWN

BLUE

CN4-7

-8

5V

GND

Feed PPS

GND

CN1-11CN1-11

-12

-13

CN11-10

-12

-13

-17

Feed PPS Photo Diode

Feed PPS Photo Transistor

N4-W109*

Feed P.W.B. unit

N4-V303*

Main P.W.B. unit

N4-V300*

0

5V

5V

5V

Paper is present :5V

Paper is not present :0V

WHITE

BLUE

CN4-9

-10

N4-W206*

28

(10) Feed Solenoid

Description

Paper that reaches PPS1 is transferred to the paper path

when feeding paper.

As the feed solenoid turns on, the roller driven by the

feed stepping motor presses the paper onto the press

roller and sends it to the main paper path.

Circuit diagram

Feed Solenoid

Chap.2

z Paper Feed Unit

RED

RED

CN6-1

-2

Feed Solenoid

N4-X101*

Main P.W.B. unit

N4-V300*

SOL

29

(11) Feed Stepping Motor

Description

Paper that reaches PPS1 is transferred to the main paper

path.

Circuit diagram

Feed Stepping Motor

CN3-3

-8

FEED STEPPING MOTOR

M7-X111*

Main P.W.B. unit

N4-V300*

M

Chap.2

z Paper Feed Unit

30

x CCD Mechanism

1. Description

The CCD mechanism reads the bar code and register

mark on the paper that is being processed and transfers

the data to the main P.W.B. unit.

The job is automatically selected according to the bar

code (code 39) and the register mark compensates for

incorrect printing positioning.

2. Operation

1) When the paper feeding operation is finished, the

CCD starts reading the bar code.

If the data transfer between the CCD and the main

P.W.B. is not done correctly, then E2: RS232C

ERROR is displayed and the machine stops.

If bar code is off go to Step 4.

\See page 135

2) Data is transferred to the main P.W.B. after the bar

code has been read.

If, when reading starts, the paper is transferred

50 mm but the bar code could not be read, then E3:

BARCODE ERROR is displayed and the machine

stops.

\See page 135

3) The job is set based on the data in the bar code.

4) The machine is in standby until each slitter has been

moved.

If register mark is turned off go to Step 9.

5) The front edge of the paper backs up to PPS2

temporarily.

6) The CCD starts to read the register mark.

7) The amount of compensation is calculated after the

register mark has been read.

If the register mark can not be read even though the

paper has been transferred 40 mm after reading has

started, then E4: REG. MARK ERROR is displayed

and the machine stops.

\See page 135

8) The position of each slitter, cutter and scorer is

adjusted.

9) The CCD processing is finished.

CCD Unit

Chap.2

x CCD Mechanism

31

Chap.2

x CCD Mechanism

CN5-1

CN5-10

Main P.W.B. unit N4-V300*

CCD unit N4-X103*

~

Circuit diagram

32

c Margin Slitter

1. Description

The margin slitter position motor starts, turning the lead

screw, and the margin slitter is moved to the designated

position.

These slitters are used for removing the left and right

margins to the waste tray.

Right Margin Slitter

Left Margin Slitter

Sensor

Right Margin Slitter

Sensor

Left Margin Slitter

Left Margin Slitter Position Motor

Left Margin Slitter

Position Motor

Slitter Driving Motor

Chap.2

c Margin Slitter

33

2. Operation

1) After paper feeding has finished (after the feed

stepping motor stops) the margin slitter returns to the

home position under the following conditions.

q The first process after the power was turned on.

w After all the covers have been opened.

e After the machine stops due to an error.

r There is no paper in the feed tray, after paper is

loaded in the feed tray again.

t After the job has been changed.

2) When the margin slitter moves from the home

position to the position indicated for the job, if the

margin slitter moves 8 mm and light is still not being

transmitted at the slitter sensor, then E5: SLITTER

ERROR is displayed and the machine stops.

\See page 136

Possible range for each slitter

Name Possible range

Left Margin Slitter 0 to 120 mm

Right Margin Slitter 200 to 320 mm

NOTE :

• 3.2 mm is the smallest possible margin

width.

Circuit diagram

Chap.2

c Margin Slitter

CN6-3

-3

-2

CN8-1

3

2

1

BLUE

YELLOW

RED

-6

CN7-1

-4

Main P.W.B. unit

N4-V300*

-23

-22

CN4-21

3

2

1

BLUE

PEACH

RED

M

M

-14

CN3-9

M

~~

Left Margin Slitter Sensor

CA003

Right Margin Slitter Sensor

CA003

Slitter Driving Motor

L8-X1010

Left Margin Slitter Position Motor

M7-X111*

Right Margin Slitter Position Motor

M7-X111*

34

Cutter

Cutter Motor

Cutter Position

Switch

v Guillotine Cutter Unit

1. Description

The paper is cut vertically in relation to the direction the

paper is moving.

Turning on the power starts the cutter motor in standby

in the home position.

One cut can be done in approximately 0.3 seconds.

2. Operation

1) Main transfer stops temporarily when the paper

reaches the cutting position.

2) The cutter motor starts and cutting begins.

3) The cutter motor stops when the cutter position

sensor goes from off to on, and the main transfer

starts again. If the cutter position sensor does not

change (if its on then it stays on) 0.6 seconds after

the cutter motor starts running, then J7: CUTTER

LOCK is displayed and the machine stops.

\See page 134

Circuit diagram

Chap.2

v Guillotine Cutter Unit

CN6-5

-6-7-8

RED

BLACK

RED

BLACK

YELLOW

YELLOW

YELLOW

YELLOW

YELLOW

YELLOW

YELLOW

YELLOW

Main P.W.B. unit

N4-V300*

COVER SW

N4-W120*

COVER SW

N4-W119*

CUTTER UNIT

L8-X109*

CUTTER M.

POSITION SW

35

b Creaser Unit

Chap.2

b Creaser Unit

1. Description

The paper is creased vertically in relation to the direction the paper is moving.

One crease can be done in approximately 1.5 seconds.

Turning on the power starts the creaser motor in standby in the home position.

2. Operation

1) Main transfer stops temporarily when the paper reaches the crease position.

2) The creaser motor starts and cutting begins.

3) The creaser motor stops when the creaser position sensor goes from off to on, and the main transfer starts

again. If the creaser position sensor does not change (if light is transmitted then it continues to transmit) 2.0

seconds after the creaser motor starts running, then J8: CREASE LOCK is displayed and the machine stops.

\See page 134

Creaser Position Sensor

Creaser Unit

Creaser Unit

Creaser Motor

36

Circuit diagram

Chap.2

b Creaser Unit

RED

BLUE

YELLOW

1

3

2

CN8-1

-2

-3

Main P.W.B. unit

N4-V300*

RED

BLACK

CN3-15

-16

CREASER MOTOR

N4-X102*

CREASER SENSOR

CA021

M

37

Chap.2

n Center Slitter

1. Description

The slitter position motor starts, turning the lead screw, and the center slitter is moved to the designated

position and the paper is cut horizontally in reference to the direction the paper is moving.

A maximum of 4 center slitters can be installed.

2. Operation

1) After paper feeding has finished (after the feed stepping motor stops) the center slitter returns to the home

position under the following conditions.

q The first process after the power was turned on.

w After all the covers have been opened.

e After the machine stops due to an error.

r There is no paper in the feed tray, after paper is loaded in the feed tray again.

t After the job has been changed.

2) When the margin slitter moves from the home position to the position indicated for the job, if the margin

slitter moves 8 mm and light is still not being transmitted at the slitter sensor, then E5: SLITTER ERROR is

displayed and the machine stops.

\See page 136

n Center Slitter

OP1 Slitter

Right Center Slitter

Right Center Slitter Sensor

OP2 Slitter Sensor

OP2 Slitter

Left Center Slitter

Left Center Slitter Sensor

OP1 Slitter Sensor

OP1 Slitter

Position Motor

OP2 Slitter

Position Motor

Right Center Slitter

Position Motor

Left Center Slitter

Position Motor

Slitter Driving Motor

38

Chap.2

n Center Slitter

Possible range for each slitter

Name Possible range Comments

Left center slitter 0 to 160 mm Example:

Right center slitter Left center slitter position +50 mm to 320 mm When the left center slitter is set

at 120.2 mm, settings from

170.2 are possible.

OP1 slitter 0 to 320 mm (when OP2 is not installed.)

0 to 160 mm (OP2 is installed)

OP2 slitter OP1 position +50 mm to 320 mm Example:

(This is an optional slitter) When the OP1 is set at 110.0

mm, settings from 160.0 mm are

possible.

Circuit diagram

CN6-9

-9

-8

CN8-7

3

2

1

BLUE

PEACH

RED

-18

CN7-13

-10

Main P.W.B. unit

N4-V300*

-26

-25

CN4-24

3

2

1

BLUE

ORANGE

RED

M

M

-12

CN7-7

M

~~

Left Center Slitter Sensor

CA003

Right Center Slitter Sensor

CA003

Slitter Driving Motor

L8-X1010

Left Center Slitter Position Motor

M7-X111*

Right Center Slitter Position Motor

M7-X111*

-6

CN14-1

-9

-8

CN9-7

3

2

1

BLUE

PURPLE

RED

M

-6

CN9-1

M

~~

OP1 Slitter Sensor

CA003

-9

-8

CN14-7

3

2

1

BLUE

PURPLE

RED

OP2 Slitter Sensor

CA003

OP1 Slitter Position Motor

M7-X111*

OP2 Slitter Position Motor

M7-X111*

39

Chap.2

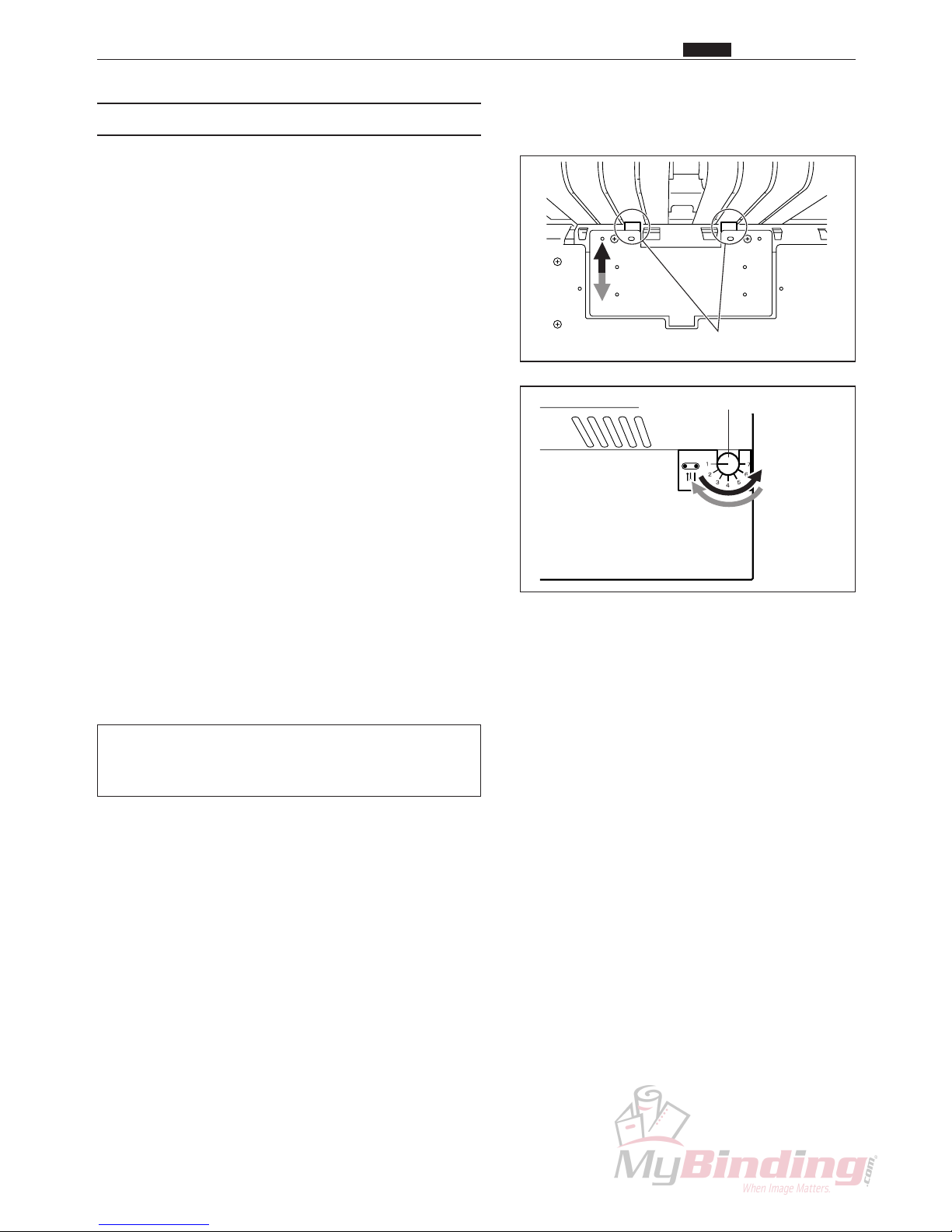

m Paper Eject Tray

m Paper Eject Tray

1. Description

Paper that is ejected from the DC-545 is collected here.

It is possible to adjust the paper being ejected into two

levels. Refer to the image below for the installation

position.

Position

A

Ejected

amount.......too small

B

Ejected

amount.......too large

A

B

40

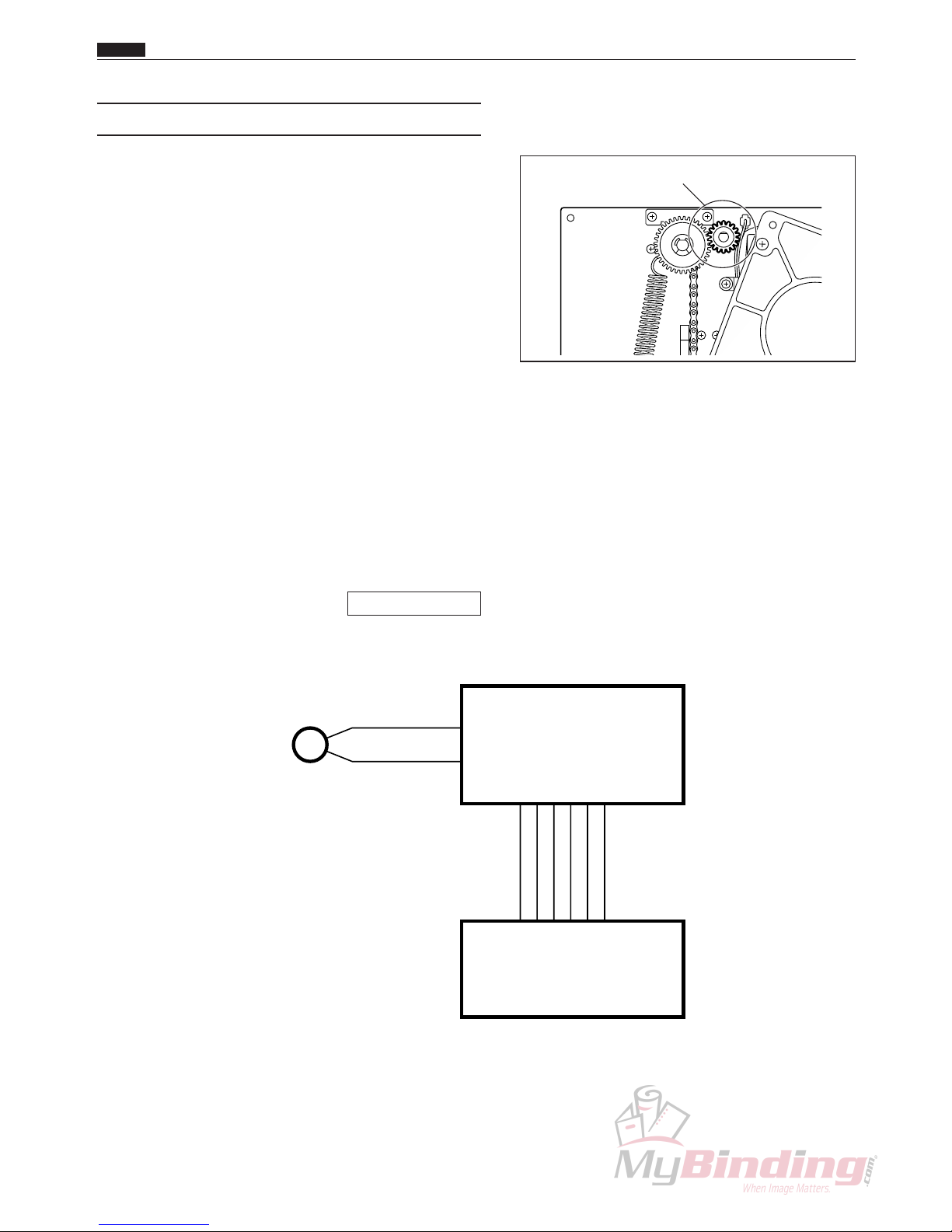

, Main Drive

1. Description

The paper is transferred by the main motor.

All the rollers except the rollers driven by the feed

stepping motor use two timing belts driven by the main

motor.

Chap.2

, Main Drive

Main Motor Main Motor Driver

PPS4 Photo Diode

PPS4 Photo Transistor

PPS3 Photo Diode

PPS2 Photo

Transistor

PPS1 Photo

Transistor

PPS3 Photo

Transistor

PPS2 Photo

Diode

PPS1 Photo Diode

41

2. Operation

1) After paper stops being fed (after the Feed Stepping Motor stops) the Main Motor starts running and the

paper is transferred to the paper path section.

2) The paper stops temporarily at the CCD and then continues being transferred. If read BAR CODE

(REGISTER MARK) has been set, then the paper continues being transferred after the BAR CODE

(REGISTER MARK) has been read.

3) Main motor stops temporarily when cutting and scoring. When cutting and scoring have finished, transfer

starts again, and stops a short period after the paper is ejected.

The below two conditions cause J3: CENTER JAM to be displayed, and the machine to stop.

\See page 133

Chap.2

, Main Drive

q When paper does not reach PPS3 (PPS3 is not

transmitting light) although the paper has

transferred 100 mm from after the front edge of

the paper has reached PPS2 (PPS2 is not

transmitting light).

w When paper is not extracted from PPS3 (PPS3 is

not transmitting light) although the total length of

the paper +30 mm has been transferred from after

the front edge of the paper has reached PPS3

(PPS3 is not transmitting light).

No

No

No

Yes

Yes

Yes

J3:CENTER JAM

Start Processing

Has the paper reached

PPS2?

Has the paper reached

PPS3?

Count start

Go to the next path

Has the paper been

transferred 100 mm?

Start processing

Count start

Go to the next path

No

No

No

Yes

Yes

J3:CENTER JAM

Yes

Has the paper reached

PPS3?

Has the paper

separated from PPS3?

Has the paper being

processed been tranferred

a distance more than the

total length of the paper

plus 30 mm?

42

q When paper does not reach PPS4 (PPS4 is not

transmitting light) although the paper has

transferred 500 mm from after the front edge of

the paper has reached PPS3 (PPS3 is not

transmitting light).

The below two conditions cause J4: SLITTER OR STACK to be displayed, and the machine to stop.

\See page 133

w When paper is not extracted from PPS4 (PPS4 is

not transmitting light) although the total length of

the paper +50 mm has been transferred from after

the front edge of the paper has reached PPS4

(PPS4 is not transmitting light).

No

No

No

Yes

Yes

Yes

J4:SLITTER OR STACK

Start processing

Count start

Go to the next path

Has the paper reached

PPS3?

Has the paper reached

PPS4?

Has the paper been

transferred 500 mm?

No

No

No

Yes

Yes

Yes

J4:SLITTER OR STACK

Start processing

Count start

Go to the next path

Has the paper reached

PPS4?

Has the paper

separated from PPS4?

Has the paper being

processed been tranferred

a distance more than the

total length of the paper

plus 50 mm?

Circuit diagram

Main P.W.B. unit

N4-V300*

M

-11

CN1-1

~

-5

CN2-1

~

-12

CN1-1

~

BROWN

BLUE

5V 5V

WHITE

BLUE

CN4-13

-14

-15

-16

PPS4 Photo Transistor

N4-W108*

PPS4 LED

N4-W123*

BROWN

BLUE

5V 5V

WHITE

BLUE

CN4-9

-10

-11

-12

PPS3 Photo Transistor

N4-W111*

PPS3 LED

N4-W110*

BROWN

BLUE

5V 5V

WHITE

BLUE

CN4-5

-6

-7

-8

PPS2 Photo Transistor

N4-W110*

PPS2 LED

N4-W109*

BROWN

BLUE

5V 5V

WHITE

BLUE

CN4-1

-2

-3

-4

PPS1 Photo Transistor

N4-W108*

PPS1 LED

N4-W109*

MAIN MOTOR

M2-X1010

STEPPING DRIVER

L8-X1080

Chap.2

, Main Drive

43

. Skew Adjustment Mechanism

1. Description

If the paper is skewed while processing , use the adjustment knob to adjust the guide and straighten paper.

Adjustment procedure

qw

Turning the knob Turning the knob clockwise

counterclockwise

Angle

Chap.2

. Skew Adjustment Mechanism

44

⁄0 BAR CODE

1. Description

This machine uses code 39 bar code.

Example: The bar code for P-11 is shown below.

The DC-545 can use this bar code if it is converted to CODE-39.

If the bar code comes in the following range, the CCD automatically replaces the data and sends the data (pre-

set no.) to the DC-545.

START/STOP bit

*

112

*

Preset no. Check digit

Code-39

BAR CODE

8 mm

60 mm

Within 35 mm

Paper feeding Direction

8 mm

Chap.2

⁄0 BAR CODE

45

⁄1 REGISTER MARK

Mark 1

1) The paper is transferred in increments of 0.1 mm

from PPS2, and the mark is read by the CCD.

2) When the edge of the reg. mark is detected, the

reference clock count in the CCD is stored in the

buffer in the microcomputer.

3) After another 0.1 mm is transferred, it is compared

with the clock count before the position of the edge is

detected, and if it is within a fixed range, the count is

then +1, and the reference clock in the CCD is stored

in the microcomputer buffer (up to 10 items). The

count is cleared if it is outside the range.

4) When the counter reaches 45 (the edge is the same

for 4.5 mm) the value for the mark is the average of

the values of the 10 values for the reference clock in

the buffer in the CCD.

MARK1

MARK2

10 mm

The clock count within 10 mm in

this space is 70.

CCD Reading Range

Paper Feeding

Direction

Basic clock

in the CCD

Read data

in the CCD

Mark 2

1) The edge of the REGISTER MARK is detected.

2) The paper is transferred in increments of 0.1 mm, and

the mark is read by the CCD. If the REGISTER

MARK has the position of the detected edge (it is

OK even if it is not the edge), if the counter is not +1,

the counter goes to 0 and returns to Step 1.

3) The position of mark 2 is determined as 1.0 mm

before the position when a continuous count of 10

(1.0 mm) is read for the REGISTER MARK.

0.1 mm

1.0 mm

REG.MARK Edge

Chap.2

⁄1 REGISTER MARK

46

* The width of Reg. Mark line is 0.4 mm or more.

* a<=b

Positioning REGISTER MARK and BAR CODE

5 mm

BAR CODE

REG. MARK

*

a

*b

REG. MARK Position range

60 mm or less

35 mm or less

10 mm or more

5 mm

30 mm

8 mm

8 mm

40 mm

* 0.4 mm or

more

5 mm

or more

5 mm or more

8 mm or

more

Chap.2

⁄1 REGISTER MARK

Chapter 3 Mechanical

z Exterior ....................................................... 49

(1) Removing the AF 100 Cover R Unit ............. 49

(2) Removing the AF 100 Cover L Unit ............. 49

(3) Removing the DC 545 Cover R Unit ............ 49

(4) Removing the DC 545 Cover L Unit ............. 50

(5) Removing the Lid .......................................... 50

(6) Removing the Front Cover Switch ................ 50

(7) Removing the Rear Cover Switch ................. 51

x Feed Section .............................................. 52

(1) Removing the AF 100 .................................... 52

(2) Removing the Suction Assembly ................... 53

(3) Removing the Flat Belts ................................ 53

(4) Removing the Fan Motor (Blower) ............... 53

(5) Removing the Feed PCB Unit ....................... 54

(6) Removing the Separator ................................. 54

(7) Removing the Elevator Upper Switch ........... 54

(8) Removing the Elevator Lower Switch ........... 55

(9) Removing the Paper Level Sensor ................. 55

(10) Removing the Feed Motor ........................... 56

(11) Removing the Shutter Solenoid ................... 56

(12) Removing the Shutter .................................. 57

(13) Removing the AF 100 Cover Switch ........... 58

(14) Removing the Elevator Motor ..................... 58

(15) Removing the Fan Motor (Suction) ............. 58

c CCD Section ............................................... 59

(1) Removing the CCD Sensor ............................ 59

v Margin Slitter Section................................ 60

(1) Removing the Margin Slitter

Driving Motor ................................................ 60

(2) Removing the Right Margin Slitter Position

Motor ............................................................. 60

(3) Removing the Left Margin Slitter Position

Motor ............................................................. 61

(4) Removing the Right Margin

Slitter Sensor .................................................. 62

(5) Removing the Left Margin

Slitter Sensor .................................................. 62

(6) Removing the Right Margin Slitter................ 63

(7) Removing the Left Margin Slitter .................. 64

(8) Removing the Margin Slitter’s

Upper Blade ................................................... 65

(9) Removing the Margin Slitter’s

Lower Blade ................................................... 66

b Cutter Section ............................................ 67

(1) Removing the Cutter Assembly ..................... 67

(2) Removing the Cutter Motor ........................... 67

(3) Removing the Cutter Position Switch ............ 68

n Creaser Section ......................................... 69

(1) Removing the Creaser Motor ......................... 69

(2) Removing the Creaser Sensor ........................ 69

(3) Removing the Creaser Assembly ................... 70

m Center Slitter Section ................................ 71

(1) Removing the Center Slitter

Drive Motor ................................................... 71

(2) Removing the Center Right Slitter

Positioning Motor .......................................... 71

(3) Removing the Center Left Slitter

Positioning Motor .......................................... 71

(4) Removing the Optional Slitter 1

Positioning Motor .......................................... 72

(5) Removing the Optional Slitter 2

Positioning Motor .......................................... 72

(6) Removing the Center Right

Slitter Sensor .................................................. 73

(7) Removing the Center Left Slitter Sensor ....... 73

(8) Removing the Optional Slitter 1 Sensor ........ 74

(9) Removing the Optional Slitter 2 Sensor ........ 74

(10) Removing the Center Right Slitter and the

Center Left Slitter ........................................ 75

(11) Removing the Optional Slitter 1 and the

Optional Slitter 2 .......................................... 76

(12) Removing the Center Slitter’s

Upper Blade ................................................. 77

(13)

Removing the Center Slitter’s Lower Blade ...

78

3

47

, Driving Section .......................................... 79

(1) Removing the Main Motor ............................ 79

(2) Removing the Feed Stepper ........................... 79

(3) Removing the 1st Roller (Lower) .................. 80

(4) Removing the 2nd and 3rd Rollers

(Lower) .......................................................... 80

(5) Removing the 4th Roller (Lower) .................. 81

(6) Removing the 5th Roller (Lower) .................. 82

(7) Removing the 6th and 7th Rollers

(Lower) .......................................................... 83

(8) Removing the 8th Roller (Lower) .................. 84

. Electric Section.......................................... 85

(1) Removing the PPS1 Phototransistor .............. 85

(2) Removing the Panel PWB Unit ..................... 85

(3) Removing the Motor Driver .......................... 86

(4) Removing the PPS2 Phototransistor and

PPS3 Photodiode ........................................... 86

(5) Removing the PPS1 and PPS2

Photodiode ..................................................... 87

(6) Removing the PPS3 Phototransistor .............. 88

(7) Removing the Feed Solenoid ......................... 89

(8) Removing the Gate Solenoid

(Without using the DC 545HC) .................... 89

(9) Removing the Main P.W.B. Unit ................... 90

(10) Removing the Power Supply, Power Board,

and Memory Board ...................................... 90

48

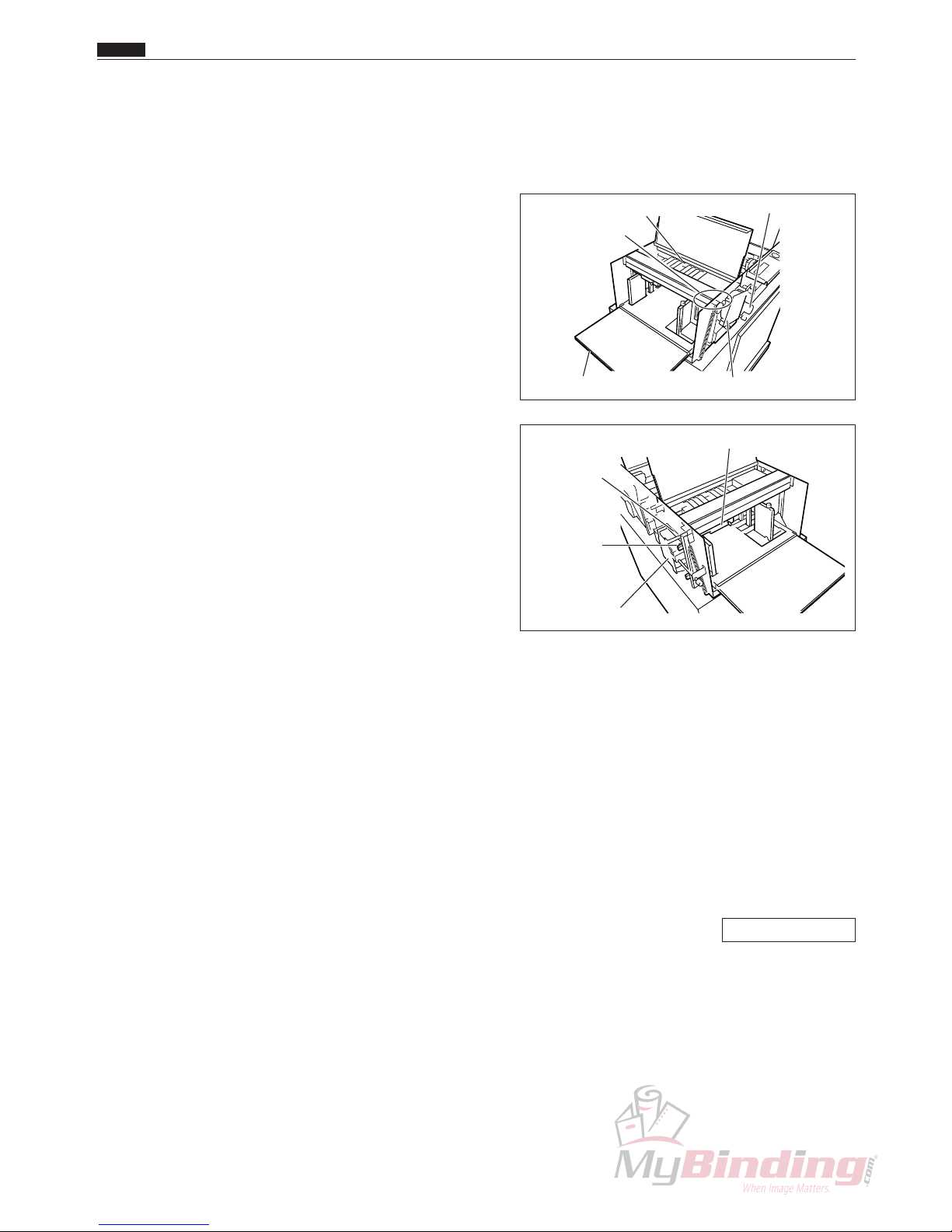

z Exterior

(1) Removing the AF-100 Cover R Unit

Chap.3

z Exterior

q Remove the AF-100 from the stand.

\See page 52

w Take out the 4 screws, and remove the cover R unit.

(2) Removing the AF-100 Cover L Unit

q Remove the AF-100 from the stand.

\See page 52

w Take out the 4 screws, and remove the cover L unit.

(3) Removing the DC-545 Cover R Unit

Cover R UnitCover L Unit

ScrewsScrews

q Remove the AF-100 from the stand.

\See page 52

w Take out the 4 screws, and remove the auxiliary

plate.

e Take out the 4 screws, and remove the cover R unit.

NOTE :

• Be sure to attach the auxiliary plate after

attaching the cover.

Auxiliary Plate

Screws

49

Chap.3

z Exterior

(4) Removing the DC-545 Cover L Unit

q Remove the AF-100 from the stand.

\See page 52

w Take out the 4 screws, and remove the cover L unit.

(5) Removing the Lid

q Take out the 6 screws, and remove the lid.

Screws Screws

Cover

L Unit

Screws

Cover

R Unit

Screws

(6) Removing the Front Cover Switch

q Remove the cover R unit from the DC-545.

\See page 49

w Remove the cutter motor.

\See page 67

e Remove the connector for the switch. (2 positions)

r Take out the 2 screws, and remove the front cover

switch.

Reinstallation

Front Cover

Switch Screws

Lid

Screws

Rear Cover

Switch Screws

IMPORTANT:

• Adjust the position in which to install the

cover switch.

\See page 112

50

(7) Removing the Rear Cover Switch

q Remove the cover R unit from the DC-545.

\See page 49

w Remove the cutter motor.

\See page 67

e Remove the connector. (1 position)

r Take out the 2 screws, and remove the rear cover

switch.

Reinstallation

IMPORTANT:

• Adjust the position in which to install the

cover switch.

\See page 112

Front Cover

Switch Screws

Chap.3

z Exterior

Rear Cover

Switch Screws

51

Chap.3

x Feed Section

x Feed Section

(1) Removing the AF-100

q Take out the two screws.

NOTE :

• The machine made to U.S. specifications has

no screws.

w Remove the DC-545 and AF-100 connector.

IMPORTANT:

• Be sure to remove the power cord from the

electric outlet before starting work. Not

doing so may damage the main P.W.B. unit.

Screws

WARNNG

e Remove the AF-100.

52

(2) Removing the Suction Assembly

q Take out the 2 screws, and remove the joint.

w Remove the thumb screw and connector. (1 each)

Chap.3

Joint & Screws

x Feed Section

e Remove the suction assembly.

(3) Removing the Flat Belts

q Remove the suction assembly.

\See page 53

w Slide the flat belts off to remove them.

Thumb Screw

Connector

Flat Belts

(4) Removing the Fan Motor (Blower)

q Remove the AF-100 cover L unit.

w Remove the connector for the fan motor. (1 position).

e Remove the spring.

r Take out the 2 screws, and remove the shutter.

t Remove the 4 screws, and remove the fan motor

(blower).

\See page 49

53

Connector

Fan Motor

Shutter

Screws

Screws

Screws

Spring

Chap.3

x Feed Section

(5) Removing the Feed PCB Unit

q Remove the AF-100 cover R unit.

\See page 49

w Remove the connector for the feed PCB unit.

(4 positions)

e Take out the 4 screws, and remove the feed PCB

unit.

(6) Removing the Separator

Screws

q Remove the suction assembly.

\See page 53

w Take out the 2 screws, and remove the separator.

(7) Removing the Elevator Upper Switch

q Remove the AF-100 cover L unit.

\See page 49

w Remove the connector for the upper switch.

(1 position)

e Take out the 2 screws, and remove the angle.

r Take out the 2 screws, and remove the elevator

upper switch.

Upper Angle

& Screws

Connector

Separator

Screws

Lower Angle

& Screws

Connector

Elevator Lower

Switch

Reinstallation

IMPORTANT:

• Adjust the position in which to install the

upper switch.

\See page 111

54

(8) Removing the Elevator Lower Switch

Chap.3

x Feed Section

q Remove the AF-100 cover L unit.

\See page 49

w Remove the connector for the lower switch.

(1 position).

e Take out the 2 screws, and remove the angle.

r Take out the 2 screws, and remove the elevator

lower switch.

Reinstallation

IMPORTANT:

• Adjust the position in which to install the

lower switch.

\See page 111

(9) Removing the Paper Level Sensor

q Open the cover of the AF-100.

Upper Angle

& Screws

Connector

Lower Angle

& Screws

Connector

Elevator Lower

Switch

w Remove the connector from the inside of the frame.

(1 position)

e Take out the 3 screws, and remove the plate unit.

r Remove the connector for the sensor, and then

remove the paper level sensor.

Connector

Screws

Connector

Sensor

55

Chap.3

x Feed Section

(10) Removing the Feed Motor

q Remove the AF-100 cover R unit.

\See page 49

w Remove the connector for the motor. (1 position)

e Take out the 4 screws, and remove the bracket.

r Loosen the set screws, and remove the pulley unit.

t Take out the 3 screws, and remove the feed motor.

Connector

Screws

Blacket & Screws

Blacket & Screws

Pulley Unit & Set Screw

(11) Removing the Shutter Solenoid

q Remove the suction assembly.

\See page 53

w Take out the 2 screws, and remove the lid.

Lid

Screws

56

Chap.3

x Feed Section

e Remove the connector for the solenoid. (1 position)

r Remove the wire unit from the spring.

t Loosen the set screws on the shaft, and remove the

wire unit.

y Take out the 2 screws, and remove the shutter

solenoid.

Reinstallation

IMPORTANT:

• Adjust the shutter position when install

the shutter solenoid.

\See page 113

(12) Removing the Shutter

q Remove the Shutter Solenoid.

\See page 56

Shaft &

Set Screw

Screws

Shutter

Solenoid

ConnectorSpringWire Unit

Lid & Screws Plate & Screws

w Take out the 4 screws, and remove the plate.

e Take out the 8 screws, and remove the lid.

r Take out the 2 screws, and remove the shutter.

Reinstallation

IMPORTANT:

• Adjust the shutter position when install

the shutter solenoid.

\See page 113

Shutter

Lid & Screws

Screws

57

Chap.3

x Feed Section

(13) Removing the AF-100 Cover Switch

q Remove the AF-100 cover L unit.

\See page 49

w Remove the connector for the switch. (1 position)

e Take out the 2 screws, and remove the AF-100 cover

switch.

Reinstallation

IMPORTANT:

• Adjust the position in which to install the

AF-100 cover switch.

\See page 112

(14) Removing the Elevator Motor

q Remove the AF-100 cover R unit.

\See page 49

w Loosen the set screws, and remove the motor gear.

e Take out the 3 screws, and remove the motor.

Screws

Connector

Screws Connector

r Remove the connector from inside the frame.

(1 position)

(15) Removing the Fan Motor (Suction)

q Remove the AF-100 cover R unit.

\See page 49

w Remove the connector for the fan motor. (1 position)

e Take out the 3 screws, and remove the fan motor.

Screws

Set Screw

Fan Motor

Connector

58

c CCD Section

(1) Removing the CCD Sensor

q Remove the cover L unit from the DC-545.

\See page 50

w Take out the 6 screws, and remove the lid.

\See page 50

e Remove the connector for the main PWB CN5.

(1 position)

r Cut the tie wraps. (4 positions)

NOTE :

• Do not cut any other bundles of wires.

Tie Wrap

Chap.3

c CCD Section

t Remove the code band. (6 positions)

y Cut the tie wraps. (7 positions)

NOTE :

• Do not cut any other bundles of wires.

u Take out the 2 screws, and remove the CCD sensor.

Reinstallation

IMPORTANT:

• Make adjustments after installing the

CCD sensor.

\See page 102, 109

Tie Wrap

Screws

Tie Wrap

Tie Wrap

CCD

Paper

59

Chap.3

v Margin Slitter Section

v Margin Slitter Section

(1)

Removing the Mar gin Slitter Driving Motor

q Remove the cover R unit from the DC-545.

\See page 49

w Take out the 2 screws, and remove the bundled cable

plate.

Timing Belt

e Take out the 4 screws, and remove the margin slitter

driving motor.

r Remove the timing belt.

t Extract the motor, and remove the connector.

(1 position)

y Take out the set screw, and remove the pulley unit.

u Take out the 3 screws, and remove the margin slitter

driving motor.

(2) Removing the Right Margin Slitter

Position Motor

q Remove the cover R unit from the DC-545.

\See page 49

Bundled Cable Plate

Margin Slitter Driving Motor Assembly

Pulley Unit & Set Screw

Screws

Control Plate Assembly

Screws

Screws

w Take out the 4 screws, and remove the panel bracket.

e Take out the 4 screws, and remove the right margin

slitter position motor.

r Remove the connector for the motor. (1 position)

Connector

Screws

60

(3) Removing the Left Margin Slitter

Position Motor

q Remove the cover L unit from the DC-545.

\See page 50

w Take out the 6 screws, and remove the lid.

\See page 50

Chap.3

v Margin Slitter Section

e Open the door in the stand, and remove the waste

tray.

r Take out the 2 screws, and remove the cover.

t Undo the thumb screws, and remove the guide unit.

y Remove the connector for the motor. (1 position)

u Take out the 4 screws, and remove the left margin

slitter position motor.

Thumb

Screws

Guide Unit

Screws

Guide

Screws Cover

61

Chap.3

v Margin Slitter Section

(4) Removing the Right Margin Slitter

Sensor

q Open the cover (front) of the DC-545.

w Remove the connector for the sensor. (1 position)

Sensor

e Remove the right margin slitter sensor from the

angle.

Reinstallation

IMPORTANT:

• Make adjustments after installing the

sensor.

\See page 95

Optional 1 Slitter Sensor Optional 2 Slitter Sensor

Center Left Slitter Sensor Center Right Slitter Sensor

This image shows the right margin slitter sensor.

Angle

Connector

Left Margin Slitter Sensor Right Margin Slitter Sensor

Feed Direction

DC-545 Position Sensor Layout

(5) Removing the Left Margin Slitter

Sensor

q Open the cover (front) of the DC-545.

w Remove the connector for the sensor. (1 position)

e Remove the left margin slitter sensor from the angle.

Reinstallation

IMPORTANT:

• Make adjustments after installing the

sensor.

\See page 95

62

(6) Removing the Right Margin Slitter

Chap.3

v Margin Slitter Section

q Remove the cover R unit from the DC-545.

\See page 49

w Take out the screw, and remove the clamper.

(2 positions)

e Loosen the 4 screws and slide the motor plate

towards the exit tray.

r Face the key groove on the shaft downwards, and

pull it out on the operation side. (2 positions)

NOTE :

• Do not drop the bearings from opposite the

operation side into the machinery. (2 positions)

• Do not drop the left or right margin slitter key

into the machinery. (4 positions)

t Remove the timing belt.

y Take out the 2 screws, and remove the lead screw.

Motor

Plate

Timing Belt

Clamper & Screws

Screws

Lead

Screw

Shafts

NOTE :

• Do not drop the bush that is on the lead

screw into the machinery.

Reinstallation

IMPORTANT:

• Make adjustments after installing the

slitter.

\See page 95

• Adjust the play in the Lead Screw to be

less than 0.1 mm.

63

Chap.3

v Margin Slitter Section

(7) Removing the Left Margin Slitter

q Remove the cover R unit from the DC-545.

\See page 49

w Remove the cover L unit from the DC-545.

\See page 50

e Take out the 1 screw, and remove the clamper on the

operation side. (2 positions)

r Loosen the 4 screws and slide the motor plate

towards the feeder.

t Face the key groove on the shaft downwards, and

pull it out on the operation side. (2 positions)

NOTE :

• Do not drop the bearings from opposite the

operation side into the machinery. (2 positions)

• Do not drop the left or right margin slitter key

into the machinery. (4 positions)

Motor

Plate

Timing Belt

Clamper & Screws

Screws

Lead

Screw

Shafts

Screws

Lead Screw

Timing Belt

y Remove the timing belt.

u Take out the 2 screws, and remove the lead screw.

NOTE :

• Do not drop the bush that is on the lead

screw into the machinery.

Reinstallation

IMPORTANT:

• Make adjustments after installing the

slitter.

\See page 95

• Adjust the play in the Lead Screw to be

less than 0.1 mm.

64

(8) Removing the Margin Slitter’s Upper

Blade

q Remove the right margin slitter, left margin slitter.

\See page 63, 64

Chap.3

v Margin Slitter Section

w Take out the 4 screws, and remove the upper

assembly.

e Take out the 2 screws from the upper assembly, and

remove the lid. (2 positions)

r Remove the bearings. (2 positions)

t Remove the upper blade assembly.

NOTE :

• Be careful not to cut yourself on the edge of

the blade.

Screws

Upper Assembly Lid Upper Blade

Assembly

Screws

Bearings

y Remove the C-clip, and then remove the disk,

spring, and the upper blade.

C-Clip

Spring

Upper Blade

Boss

65

Chap.3

v Margin Slitter Section

(9) Removing the Margin Slitter’s Lower

Blade

q Remove the right margin slitter and the left margin

slitter.

\See page 63, 64

w Take out the 2 screws, and remove the lower

assembly.

e Take out the screws from the lower assembly, and

remove the guide plate.

r Take out the 2 screws, and remove the lid.

(2 positions)

t Remove the bearing. (2 positions)

y Remove the lower blade unit.

NOTE :

• Be careful not to cut yourself on the edge of

the blade.

Screws

Lower Assembly Lower Blade Unit

Guide Plate

Screws

Lid & Screws

66

b Cutter Section

(1) Removing the Cutter Assembly

q Remove the cover R unit from the DC-545.

\See page 49

Chap.3

b Cutter Section

w Remove the cover L unit from the DC-545.

\See page 50

e Remove the connector for the motor. (1 position)

r Take out the 2 screws, and remove the cutter

assembly.

Reinstallation

IMPORTANT:

• Make adjustments after installing the

cutter assembly.

\See page 98, 107

(2) Removing the Cutter Motor

Screw

Connector

Screw

q Remove the cutter assembly.

\See page 67

w Take out the 2 screws, and remove the cutter motor

assembly.

e Loosen the set screws, and remove the eccentric

shaft.

r Take out the 3 screws, and remove the cutter motor.

Screw Cutter Motor Assembly

Tie Wrap

Screw

Set Screw

Eccentric Shaft

67

Chap.3

b Cutter Section

(3) Removing the Cutter Position Switch

q Remove the cover R unit from the DC-545.

\See page 49

w Cut the tie wrap on the cutter motor wires.

e Remove the connector for the switch and the motor.

(2 positions)

NOTE :

• Switch wires are yellow and yellow. Motor

wires are red and black.

r Take out the 2 screws, and remove the cutter

position switch.

Screws

Hole for

access

to screws

Tie Wrap

Motor Connector

Switch Connector

68

n Creaser Section

(1) Removing the Creaser Motor

q Remove the cover L unit from the DC-545.

\See page 50

w Take out the 6 screws, and remove the lid.

\See page 50

e Remove the main P.W.B.

Chap.3

n Creaser Section

\See page 90

r Take out the 3 screws, and remove the plate.

t Remove the motor connector and Power Supply

PCB connector.

y Loosen the set screws, and remove the pulley unit.

u Take out the 4 screws, and remove the creaser motor

assembly.

Screws

Connector

(2) Removing the Creaser Sensor

q Remove the cover R unit from the DC-545.

w Remove the connector for the sensor. (1 position)

e Remove the creaser sensor from the sensor angle.

Pulley Unit & Set Screw

Connector

\See page 49

Sensor

69

Chap.3

n Creaser Section

(3) Removing the Creaser Assembly

q Remove the cover R unit from the DC-545.

\See page 49

w Remove the cover L unit from the DC-545.

\See page 50

e Take out the screw, and remove the cover (front).

r Take out the screw, and remove the cover (rear).

t Take out the 4 screws, and remove the upper cover.

y Take out the 4 screws, and remove the creaser belt.

u Take out the screw, and remove the pillar from the

main rear drive.

i Remove the timing belt.

o Take out the screws, and remove the sensor plate.

Cover (Rear)

& Screw

Pillar & Screw Screws

Screw

Upper Cover & Screws

Cover (Front)

& Screw

Creaser

Assembly

Timing Belt

!0 Take out the 4 screws from the auxiliary plate

(upper).

!1 Pull the creaser assembly out opposite the operation

side.

Reinstallation

IMPORTANT:

• Make adjustments after installing the

creaser assembly.

\See page 108

Sensor

Plate

Screws

Auxiliary Plate (Upper)

70

m Center Slitter Section

(1) Removing the Center Slitter Drive

Motor

Chap.3

m Center Slitter Section

q Remove the cover R unit from the DC-545.

\See page 49

w Take out the 4 screws, and remove the center slitter

drive motor assembly.

e Remove the connector for the motor. (1 position)

r Loosen the set screws, and remove the pulley unit.

t Take out the 3 screws, and remove the center slitter

drive motor.

(2) Removing the Center Right Slitter

Positioning Motor

q Remove the cover R unit from the DC-545.

\See page 49

w Take out the 2 screws, and remove the center right

slitter positioning motor assembly.

e Remove the connector from the motor. (1 position)

Pulley Unit

Center Slitter

Drive Motor

Assembly

Screws

Center Left Slitter Positioning Motor

Center Right

Slitter Positioning

Motor

r Take out the 4 screws, and remove the center right

slitter positioning motor.

(3) Removing the Center Left Slitter Posi-

tioning Motor

q Remove the cover R unit from the DC-545.

w Take out the 2 screws, and remove the center left

slitter positioning motor assembly.

e Remove the connector from the motor. (1 position)

r Take out the 4 screws, and remove the center left