查询MX29LA128MB供应商

FEATURES

PRELIMINARY

MX29LA128M T/B

128M-BIT SINGLE VOLTAGE 3V ONLY

BOOT SECTOR FLASH MEMORY

GENERAL FEA TURES

• Single Po wer Supply Operatio n

- 2.7 to 3.6 volt for read, erase, and program operations

• Configuration

- 16,777,216 x 8 / 8,388,608 x 16 switchable

• Sector structure

- 8KB(4KW) x 8 and 64KB(32KW) x 255

• Latch-up protected to 250mA fro m -1V to VCC + 1V

• Low VCC write inhibit is equal to or less than 1.5V

• Compatible with JEDEC standard

- Pin-out and software compatible to single power supply Flash

PERFORMANCE

• High Perf ormance

- Fast access time: 90R/100ns

- Page read time: 25ns

- Sector erase time: 0.5s (typ.)

- 4 word/8 b yte page read buffer

- 16 word/ 32 b yte write buffer: reduces pro gramming

time fo r multiple-wo rd/byte updates

• Low Po wer Consumptio n

- Active read current: 18mA(typ.)

- Active write current: 20mA(typ.)

- Standby current: 20uA(typ.)

• Minimum 100,000 erase/prog ram cycle

• 20-years data retention

SOFTW ARE FEA TURES

• Support Commo n Flash Interf ace (CFI)

- Flash device parameters stored on the device and

provide the host system to access.

• Program Suspend/Pro gram Resume

- Suspend prog ram operatio n to read o ther secto rs

• Erase Suspend/ Erase Resume

- Suspends sector erase operation to read data/program o ther sectors

• Status Reply

- Data# polling & Toggle bits pro vide detectio n o f program and erase operation completion

HARDW ARE FEA TURES

• Ready/Busy (RY/BY#) Output

- Provides a hardware method of detecting program

and erase operation completion

• Hardware Reset (RESET#) Input

- Provides a hardware method to reset the internal

state machine to read mode

• WP#/ACC input

- Write pro tect (WP#) functio n allows pro tection o f all

sectors, regardless o f secto r pro tectio n settings

- ACC (high voltage) accelerates programming time

fo r higher throughput during system

SECURITY

• Sector Pro tection/Chip Unpro tect

- Pro vides sector gro up pro tect function to pre vent program o r erase o peration in the pro tected secto r gro up

- Provides chip unprotect function to allow code

changes

- Provides tempo rary secto r gro up unprotect functio n

fo r code changes in pre viously pro tected secto r groups

• Sector P ermanent Loc k

- A unique lock bit feature allows the content to be

permanently lock ed

(Please contact Macronix sales for specific information regarding this permanent lock feature)

• Secured Silicon Secto r

- Provides a 128-word OTP area for permanent, secure identification

- Can be programmed and lo ck ed at facto ry or by customer

P A CKAGE

• 56-pin TSOP

GENERAL DESCRIPTION

The MX29LA128M T/B is a 128-mega bit Flash memo ry

organiz ed as 16M bytes o f 8 bits or 8M wo rds of 16 bits.

MXIC's Flash memories o ffer the mo st co st-effective and

reliable read/write non-v o latile random access memo ry .

The MX29LA128M T/B is pac kaged in 56-pin TSOP. It is

designed to be reprog rammed and erased in system o r in

standard EPROM pro grammers.

P/N:PM1170 REV. 0.04, JUL. 11, 2005

The standard MX29LA128M T/B offers access time as

fast as 90ns, allowing operation of high-speed microprocessors without wait states. To eliminate bus contention, the MX29LA128M T/B has separate chip enable

(CE#) and output enab le (OE#) co ntrols.

MXIC's Flash memories augment EPROM functio nality

1

MX29LA128M T/B

with in-circuit electrical erasure and prog ramming. The

MX29LA128M T/B uses a co mmand register to manage

this functionality.

MXIC Flash technology reliably stores memory contents

even after 100,000 er ase and program cycles. The MXIC

cell is designed to optimize the erase and program

mechanisms. In addition, the combination of advanced

tunnel oxide processing and low internal electric fields

for erase and programming operations produces reliable

cycling. The MX29LA128M T/B uses a 2.7V to 3.6V

VCC supply to perform the High Reliability Erase and

auto Progr am/Erase algorithms.

The highest degree of latch-up protection is achieved

with MXIC's proprietary non-epi process. Latch-up protection is proved for stresses up to 100 milliamperes on

address and data pin from -1V to VCC + 1V.

AUTOMATIC PROGRAMMING

The MX29LA128M T/B is b yte/word/page pro grammab le

using the Auto matic Pro gramming algo rithm. The Automatic Programming algorithm makes the external system do not need to ha ve time o ut sequence no r to verify

the data prog rammed.

AUTOMATIC PROGRAMMING ALGORITHM

AUTOMATIC SECTOR ERASE

The MX29LA128M T/B is secto r(s) erasable using MXIC's

Auto Secto r Erase algo rithm. Secto r erase mo des allo w

sectors o f the arra y to be erased in o ne erase cycle. The

Auto matic Sector Er ase algorithm auto matically progr ams

the specified sector(s) prio r to electrical erase. The timing and verificatio n of electrical erase are co ntrolled internally within the device.

AUTOMATIC ERASE ALGORITHM

MXIC's Automatic Erase algorithm requires the user to

write commands to the command register using standard micropro cesso r write timings. The de vice will automatically pre-prog r am and verify the entire array. Then

the device automatically times the erase pulse width,

provides the erase verification, and counts the number

of sequences. A status bit toggling between consecutive read cycles provides feedback to the user as to the

status of the programming operation.

Register contents serve as inputs to an internal statemachine which controls the erase and programming circuitry . During write cycles, the co mmand register internally latches address and data needed for the programming and erase operations. During a system write cycle,

addresses are latched on the falling edge, and data are

latched on the rising edge o f WE# .

MXIC's Automatic Programming algorithm require the user

to only write program set-up commands (including 2 unlock write cycle and A0H) and a program command (program data and address). The de vice automatically times

the programming pulse width, provides the program verification, and counts the number of sequences. A status

bit similar to DATA# polling and a status bit to ggling between consecutive read cycles, provide feedback to the

user as to the status of the programming operation.

AUTOMATIC CHIP ERASE

The entire chip is bulk erased using 50 ms erase pulses

according to MXIC's A utomatic Chip Er ase algorithm. The

Automatic Erase algorithm automatically programs the

entire array prio r to electrical erase. The timing and verification o f electrical erase are co ntro lled internally within

the device.

P/N:PM1170

MXIC's Flash technology combines years of EPROM

experience to pro duce the highest le vels of quality, reliability, and cost effectiveness. The MX29LA128M T/B

electrically erases all bits simultaneously using FowlerNordheim tunneling. The bytes are pro grammed b y using the EPROM programming mechanism of hot electron injection.

During a program cycle, the state-machine will control

the program sequences and command register will not

respond to any command set. During a Sector Erase

cycle, the command register will only respond to Erase

Suspend command. After Erase Suspend is completed,

the device stays in read mode. After the state machine

has completed its task, it will allow the command register to respond to its full command set.

REV. 0.04, JUL. 11, 2005

2

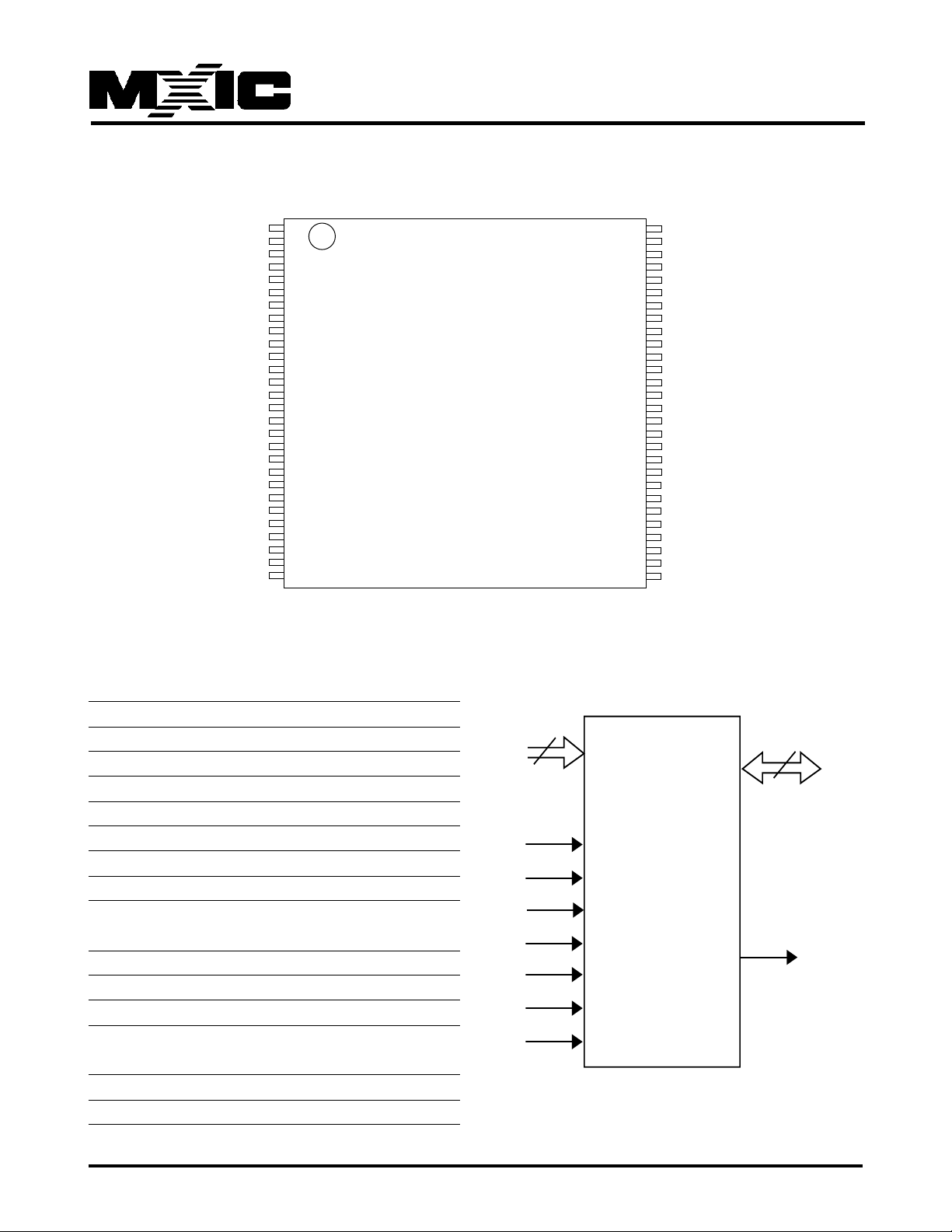

PIN CONFIGURATION

MX29LA128M T/B

56 TSOP

NC

A22

A15

A14

A13

A12

A11

A10

A19

A20

WE#

RESET#

A21

WP#/ACC

RY/BY#

A18

A17

NC

NC

1

2

3

4

5

6

7

8

9

A9

10

A8

11

12

13

14

15

16

17

18

19

20

A7

21

A6

22

A5

23

A4

24

A3

25

A2

26

A1

27

28

NC

56

NC

55

A16

54

BYTE#

53

VSS

52

Q15/A-1

51

Q7

50

Q14

49

Q6

48

Q13

47

Q5

46

Q12

45

Q4

44

V

43

42

41

40

39

38

37

36

35

34

33

32

31

30

29

CC

Q11

Q3

Q10

Q2

Q9

Q1

Q8

Q0

OE#

VSS

CE#

A0

NC

VIO

PIN DESCRIPTION

SYMBOL PIN NAME

A0~A22 Address Input

Q0~Q14 Data Inputs/Outputs

Q15/A-1 Q15(Word Mode)/LSB addr(Byte Mode)

CE# Chip Enable Input

WE# Write Enable Input

OE# Output Enable Input

RESET# Hardware Reset Pin, Active Low

WP#/ACC Hardware Write Protect/Prog ramming

Acceleration input

RY/BY# Read/Busy Output

BYTE# Selects 8 bit or 16 bit mode

VC C +3.0V single power supply

VI/O Output Buffer P ower (2.7V~3.6V this

input should be tied directly to VCC )

GN D Device Ground

N C Pin Not Connected Internally

LOGIC SYMBOL

23

A0-A22

CE#

OE#

WE#

RESET#

WP#/ACC

BYTE#

VI/O

Q0-Q15

16 or 8

(A-1)

RY/BY#

P/N:PM1170

REV. 0.04, JUL. 11, 2005

3

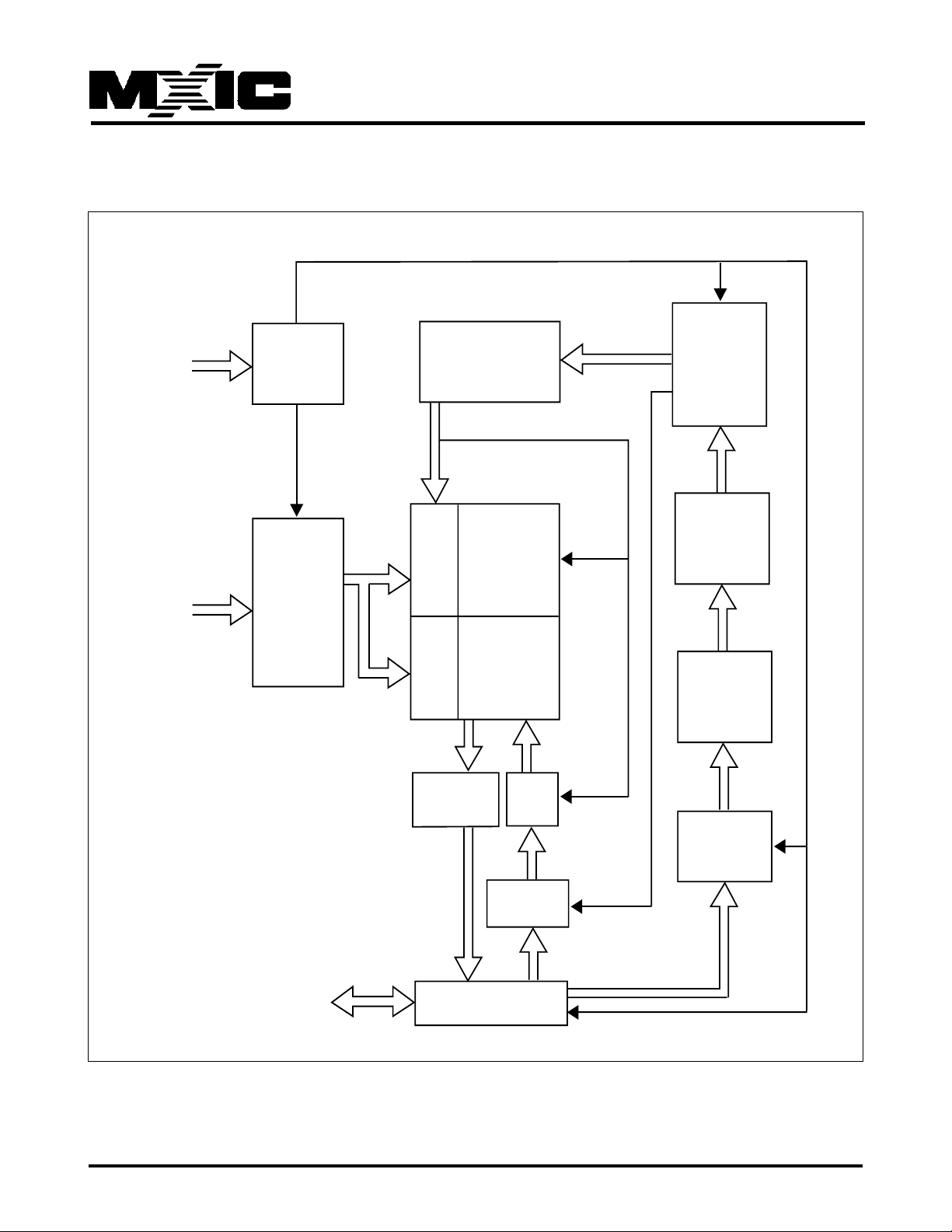

BLOCK DIAGRAM

MX29LA128M T/B

CE#

OE#

WE#

WP#

BYTE#

RESET#

A0-A22

CONTROL

INPUT

LOGIC

ADDRESS

LATCH

AND

BUFFER

PROGRAM/ERASE

HIGH VOLTA GE

X-DECODER

FLASH

ARRAY

Y-DECODER

Y-PASS GATE

WRITE

STATE

MACHINE

(WSM)

STATE

REGISTER

ARRAY

SOURCE

HV

COMMAND

DATA

DECODER

P/N:PM1170

Q0-Q15/A-1

SENSE

AMPLIFIER

I/O BUFFER

4

PGM

DATA

HV

COMMAND

DATA LATCH

PROGRAM

DATA LATCH

REV. 0.04, JUL. 11, 2005

MX29LA128M T/B

MX29LA128MT SECTOR ADDRESS TABLE

Sector Sector Sector Address Sector Size (x8) (x16)

Group A22-A12 (Kbytes/Kwords) Address Range Address Range

1 SA0 00000000xxx 64/32 000000-0FFFFF 000000-007FFF

1 SA1 00000001xxx 64/32 010000-1FFFFF 008000-00FFFF

1 SA2 00000010xxx 64/32 020000-2FFFFF 010000-017FFF

1 SA3 00000011xxx 64/32 030000-3FFFFF 018000-01FFFF

2 SA4 00000100xxx 64/32 040000-4FFFFF 020000-027FFF

2 SA5 00000101xxx 64/32 050000-5FFFFF 028000-02FFFF

2 SA6 00000110xxx 64/32 060000-6FFFFF 030000-037FFF

2 SA7 00000111xxx 64/32 070000-7FFFFF 038000-03FFFF

3 SA8 00001000xxx 64/32 080000-8FFFFF 040000-047FFF

3 SA9 00001001xxx 64/32 090000-9FFFFF 048000-04FFFF

3 SA10 00001010xxx 64/32 0A0000-AFFFFF 050000-057FFF

3 SA11 00001011xxx 64/32 0B0000-BFFFFF 058000-05FFFF

4 SA12 00001100xxx 64/32 0C0000-CFFFFF 060000-067FFF

4 SA13 00001101xxx 64/32 0D0000-DFFFFF 068000-06FFFF

4 SA14 00001110xxx 64/32 0E0000-EFFFFF 070000-077FFF

4 SA15 00001111xxx 64/32 0F0000-FFFFFF 078000-07FFFF

5 SA16 00010000xxx 64/32 100000-0FFFFF 080000-087FFF

5 SA17 00010001xxx 64/32 110000-1FFFFF 088000-08FFFF

5 SA18 00010010xxx 64/32 120000-2FFFFF 090000-097FFF

5 SA19 00010011xxx 64/32 130000-3FFFFF 098000-09FFFF

6 SA20 00010100xxx 64/32 140000-4FFFFF 0A0000-0A7FFF

6 SA21 00010101xxx 64/32 150000-5FFFFF 0A8000-0AFFFF

6 SA22 00010110xxx 64/32 160000-6FFFFF 0B0000-0B7FFF

6 SA23 00010111xxx 64/32 170000-7FFFFF 0B8000-0BFFFF

7 SA24 00011000xxx 64/32 180000-8FFFFF 0C0000-0C7FFF

7 SA25 00011001xxx 64/32 190000-9FFFFF 0C8000-0CFFFF

7 SA26 00011010xxx 64/32 1A0000-AFFFFF 0D0000-0D7FFF

7 SA27 00011011xxx 64/32 1B0000-BFFFFF 0D8000- 0DFFFF

8 SA28 00011100xxx 64/32 1C0000-CFFFFF 0E0000-0E7FFF

8 SA29 00011101xxx 64/32 1D0000-DFFFFF 0E8000-0EFFFF

8 SA30 00011110xxx 64/32 1E0000-EFFFFF 0F0000-0F7FFF

8 SA31 00011111xxx 64/32 1F0000-FFFFFF 0F8000-0FFFFF

9 SA32 00100000xxx 64/32 200000-0FFFFF 100000-107FFF

9 SA33 00100001xxx 64/32 210000-1FFFFF 108000-10FFFF

9 SA34 00100010xxx 64/32 220000-2FFFFF 110000-117FFF

9 SA35 00100011xxx 64/32 230000-3FFFFF 118000-11FFFF

10 SA36 00100100xxx 64/32 240000-4FFFFF 120000-127FFF

10 SA37 00100101xxx 64/32 250000-5FFFFF 128000-12FFFF

10 SA38 00100110xxx 64/32 260000-6FFFFF 130000-137FFF

P/N:PM1170

REV. 0.04, JUL. 11, 2005

5

MX29LA128M T/B

Sector Sector Sector Address Sector Size (x8) (x16)

Group A22-A12 (Kbytes/Kwords) Address Range Address Range

10 SA39 00100111xxx 64/32 270000-7FFFFF 138000-13FFFF

11 SA40 00101000xxx 64/32 280000-8FFFFF 140000-147FFF

11 SA41 00101001xxx 64/32 290000-9FFFFF 148000-14FFFF

11 SA42 00101010xxx 64/32 2A0000-AFFFFF 150000-157FFF

11 SA43 00101011xxx 64/32 2B0000-BFFFFF 158000-15FFFF

12 SA44 00101100xxx 64/32 2C0000-CFFFFF 160000-167FFF

12 SA45 00101101xxx 64/32 2D0000-DFFFFF 168000-16FFFF

12 SA46 00101110xxx 64/32 2E0000-EFFFFF 170000-177FFF

12 SA47 00101111xxx 64/32 2F0000-FFFFFF 178000-17FFFF

13 SA48 00110000xxx 64/32 300000-0FFFFF 180000-187FFF

13 SA49 00110001xxx 64/32 310000-1FFFFF 188000-18FFFF

13 SA50 00110010xxx 64/32 320000-2FFFFF 190000-197FFF

13 SA51 00110011xxx 64/32 330000-3FFFFF 198000-19FFFF

14 SA52 00110100xxx 64/32 340000-4FFFFF 1A0000-1A7FFF

14 SA53 00110101xxx 64/32 350000-5FFFFF 1A8000-1AFFFF

14 SA54 00110110xxx 64/32 360000-6FFFFF 1B0000-1B7FFF

14 SA55 00110111xxx 64/32 370000-7FFFFF 1B8000-1BFFFF

15 SA56 00111000xxx 64/32 380000-8FFFFF 1C0000-1C7FFF

15 SA57 00111001xxx 64/32 390000-9FFFFF 1C8000-1CFFFF

15 SA58 00111010xxx 64/32 3A0000-AFFFFF 1D0000-1D7FFF

15 SA59 00111011xxx 64/32 3B0000-BFFFFF 1D8000-1DFFFF

16 SA60 00111100xxx 64/32 3C0000-CFFFFF 1E0000-1E7FFF

16 SA61 00111101xxx 64/32 3D0000-DFFFFF 1E8000-1EFFFF

16 SA62 00111110xxx 64/32 3E0000-EFFFFF 1F0000-1F7FFF

16 SA63 00111111xxx 64/32 3F0000-FFFFFF 1F8000-1FFFFF

17 SA64 01000000xxx 64/32 400000-0FFFFF 200000-207FFF

17 SA65 01000001xxx 64/32 410000-1FFFFF 208000-20FFFF

17 SA66 01000010xxx 64/32 420000-2FFFFF 210000-217FFF

17 SA67 01000011xxx 64/32 430000-3FFFFF 218000-21FFFF

18 SA68 01000100xxx 64/32 440000-4FFFFF 220000-227FFF

18 SA69 01000101xxx 64/32 450000-5FFFFF 228000-22FFFF

18 SA70 01000110xxx 64/32 460000-6FFFFF 230000-237FFF

18 SA71 01000111xxx 64/32 470000-7FFFFF 238000-23FFFF

19 SA72 01001000xxx 64/32 480000-8FFFFF 240000-247FFF

19 SA73 01001001xxx 64/32 490000-9FFFFF 248000-24FFFF

19 SA74 01001010xxx 64/32 4A0000-AFFFFF 250000-257FFF

19 SA75 01001011xxx 64/32 4B0000-BFFFFF 258000-25FFFF

20 SA76 01001100xxx 64/32 4C0000-CFFFFF 260000-267FFF

20 SA77 01001101xxx 64/32 4D0000-DFFFFF 268000-26FFFF

20 SA78 01001110xxx 64/32 4E0000-EFFFFF 270000-277FFF

20 SA79 01001111xxx 64/32 4F0000-FFFFFF 278000-27FFFF

P/N:PM1170

REV. 0.04, JUL. 11, 2005

6

MX29LA128M T/B

Sector Sector Sector Address Sector Size (x8) (x16)

Group A22-A12 (Kbytes/Kwords) Address Range Address Range

21 SA80 01010000xxx 64/32 500000-0FFFFF 280000-287FFF

21 SA81 01010001xxx 64/32 510000-1FFFFF 288000-28FFFF

21 SA82 01010010xxx 64/32 520000-2FFFFF 290000-297FFF

21 SA83 01010011xxx 64/32 530000-3FFFFF 298000-29FFFF

22 SA84 01010100xxx 64/32 540000-4FFFFF 2A0000-2A7FFF

22 SA85 01010101xxx 64/32 550000-5FFFFF 2A8000-2AFFFF

22 SA86 01010110xxx 64/32 560000-6FFFFF 2B0000-2B7FFF

22 SA87 01010111xxx 64/32 570000-7FFFFF 2B8000-2BFFFF

23 SA88 01011000xxx 64/32 580000-8FFFFF 2C0000-2C7FFF

23 SA89 01011001xxx 64/32 590000-9FFFFF 2C8000-2CFFFF

23 SA90 01011010xxx 64/32 5A0000-AFFFFF 2D0000-2D7FFF

23 SA91 01011011xxx 64/32 5B0000-BFFFFF 2D8000-2DFFFF

24 SA92 01011100xxx 64/32 5C0000-CFFFFF 2E0000-2E7FFF

24 SA93 01011101xxx 64/32 5D0000-DFFFFF 2E8000-2EFFFF

24 SA94 01011110xxx 64/32 5E0000-EFFFFF 2F0000-2F7FFF

24 SA95 01011111xxx 64/32 5F0000-FFFFFF 2F8000-2FFFFF

25 SA96 01100000xxx 64/32 600000-0FFFFF 300000-307FFF

25 SA97 01100001xxx 64/32 610000-1FFFFF 308000-30FFFF

25 SA98 01100010xxx 64/32 620000-2FFFFF 310000-317FFF

25 SA99 01100011xxx 64/32 630000-3FFFFF 318000-31FFFF

26 SA100 01100100xxx 64/32 640000-4FFFFF 320000-327FFF

26 SA101 01100101xxx 64/32 650000-5FFFFF 328000-32FFFF

26 SA102 01100110xxx 64/32 660000-6FFFFF 330000-337FFF

26 SA103 01100111xxx 64/32 670000-7FFFFF 338000-33FFFF

27 SA104 01101000xxx 64/32 680000-8FFFFF 340000-347FFF

27 SA105 01101001xxx 64/32 690000-9FFFFF 348000-34FFFF

27 SA106 01101010xxx 64/32 6A0000-AFFFFF 350000-357FFF

27 SA107 01101011xxx 64/32 6B0000-BFFFFF 358000-35FFFF

28 SA108 01101100xxx 64/32 6C0000-CFFFFF 360000-367FFF

28 SA109 01101101xxx 64/32 6D0000-DFFFFF 368000-36FFFF

28 SA110 01101110xxx 64/32 6E0000-EFFFFF 370000-377FFF

28 SA111 01101111xxx 64/32 6F0000-FFFFFF 378000-37FFFF

29 SA112 01110000xxx 64/32 700000-0FFFFF 380000-387FFF

29 SA113 01110001xxx 64/32 710000-1FFFFF 388000-38FFFF

29 SA114 01110010xxx 64/32 720000-2FFFFF 390000-397FFF

29 SA115 01110011xxx 64/32 730000-3FFFFF 398000-39FFFF

30 SA116 01110100xxx 64/32 740000-4FFFFF 3A0000-3A7FFF

30 SA117 01110101xxx 64/32 750000-5FFFFF 3A8000-3AFFFF

30 SA118 01110110xxx 64/32 760000-6FFFFF 3B0000-3B7FFF

30 SA119 01110111xxx 64/32 770000-7FFFFF 3B8000-3BFFFF

31 SA120 01111000xxx 64/32 780000-8FFFFF 3C0000-3C7FFF

P/N:PM1170

REV. 0.04, JUL. 11, 2005

7

MX29LA128M T/B

Sector Sector Sector Address Sector Size (x8) (x16)

Group A22-A12 (Kbytes/Kwords) Address Range Address Range

31 SA121 01111001xxx 64/32 790000-9FFFFF 3C8000-3CFFFF

31 SA122 01111010xxx 64/32 7A0000-AFFFFF 3D0000-3D7FFF

31 SA123 01111011xxx 64/32 7B0000-BFFFFF 3D8000 -3DFFFF

32 SA124 01111100xxx 64/32 7C0000-CFFFFF 3E0000-3E7FFF

32 SA125 01111101xxx 64/32 7D0000-DFFFFF 3E8000-3EFFFF

32 SA126 01111110xxx 64/32 7E0000-EFFFFF 3F0000-3F7FFF

32 SA127 01111111xxx 64/32 7F0000-FFFFFF 3F8000-3FFFFF

33 SA128 10000000xxx 64/32 800000-0FFFFF 400000-407FFF

33 SA129 10000001xxx 64/32 810000-1FFFFF 408000-40FFFF

33 SA130 10000010xxx 64/32 820000-2FFFFF 410000-417FFF

33 SA131 10000011xxx 64/32 830000-3FFFFF 418000-41FFFF

34 SA132 10000100xxx 64/32 840000-4FFFFF 420000-427FFF

34 SA133 10000101xxx 64/32 850000-5FFFFF 428000-42FFFF

34 SA134 10000110xxx 64/32 860000-6FFFFF 430000-437FFF

34 SA135 10000111xxx 64/32 870000-7FFFFF 438000-43FFFF

35 SA136 10001000xxx 64/32 880000-8FFFFF 440000-447FFF

35 SA137 10001001xxx 64/32 890000-9FFFFF 448000-44FFFF

35 SA138 10001010xxx 64/32 8A0000-AFFFFF 450000-457FFF

35 SA139 10001011xxx 64/32 8B0000-BFFFFF 458000-45FFFF

36 SA140 10001100xxx 64/32 8C0000-CFFFFF 460000-467FFF

36 SA141 10001101xxx 64/32 8D0000-DFFFFF 468000-46FFFF

36 SA142 10001110xxx 64/32 8E0000-EFFFFF 470000-477FFF

36 SA143 10001111xxx 64/32 8F0000-FFFFFF 478000-47FFFF

37 SA144 10010000xxx 64/32 900000-0FFFFF 480000-487FFF

37 SA145 10010001xxx 64/32 910000-1FFFFF 488000-48FFFF

37 SA146 10010010xxx 64/32 920000-2FFFFF 490000-497FFF

37 SA147 10010011xxx 64/32 930000-3FFFFF 498000-49FFFF

38 SA148 10010100xxx 64/32 940000-4FFFFF 4A0000-4A7FFF

38 SA149 10010101xxx 64/32 950000-5FFFFF 4A8000-4AFFFF

38 SA150 10010110xxx 64/32 960000-6FFFFF 4B0000-4B7FFF

38 SA151 10010111xxx 64/32 970000-7FFFFF 4B8000-4BFFFF

39 SA152 10011000xxx 64/32 980000-8FFFFF 4C0000-4C7FFF

39 SA153 10011001xxx 64/32 990000-9FFFFF 4C8000-4CFFFF

39 SA154 10011010xxx 64/32 9A0000-AFFFFF 4D0000-4D7FFF

39 SA155 10011011xxx 64/32 9B0000-BFFFFF 4D8000 -4DFFFF

40 SA156 10011100xxx 64/32 9C0000-CFFFFF 4E0000-4E7FFF

40 SA157 10011101xxx 64/32 9D0000-DFFFFF 4E8000-4EFFFF

40 SA158 10011110xxx 64/32 9E0000-EFFFFF 4F0000-4F7FFF

40 SA159 10011111xxx 64/32 9F0000-FFFFFF 4F8000-4FFFFF

41 SA160 10100000xxx 64/32 A00000-0FFFFF 500000-507FFF

41 SA161 10100001xxx 64/32 A10000-1FFFFF 508000-50FFFF

P/N:PM1170

REV. 0.04, JUL. 11, 2005

8

MX29LA128M T/B

Sector Sector Sector Address Sector Size (x8) (x16)

Group A22-A12 (Kbytes/Kwords) Address Range Address Range

41 SA162 10100010xxx 64/32 A20000-2FFFFF 510000-517FFF

41 SA163 10100011xxx 64/32 A30000-3FFFFF 518000-51FFFF

42 SA164 10100100xxx 64/32 A40000-4FFFFF 520000-527FFF

42 SA165 10100101xxx 64/32 A50000-5FFFFF 528000-52FFFF

42 SA166 10100110xxx 64/32 A60000-6FFFFF 530000-537FFF

42 SA167 10100111xxx 64/32 A70000-7FFFFF 538000-53FFFF

43 SA168 10101000xxx 64/32 A80000-8FFFFF 540000-547FFF

43 SA169 10101001xxx 64/32 A90000-9FFFFF 548000-54FFFF

43 SA170 10101010xxx 64/32 AA0000-AFFFFF 550000-557FFF

43 SA171 10101011xxx 64/32 AB0000-BFFFFF 558000-55FFFF

44 SA172 10101100xxx 64/32 AC0000-CFFFFF 560000-567FFF

44 SA173 10101101xxx 64/32 AD0000-DFFFFF 568000-56FFFF

44 SA174 10101110xxx 64/32 AE0000-EFFFFF 570000-577FFF

44 SA175 10101111xxx 64/32 AF0000-FFFFFF 578000-57FFFF

45 SA176 10110000xxx 64/32 B00000-0FFFFF 580000-587FFF

45 SA177 10110001xxx 64/32 B10000-1FFFFF 588000-58FFFF

45 SA178 10110010xxx 64/32 B20000-2FFFFF 590000-597FFF

45 SA179 10110011xxx 64/32 B30000-3FFFFF 598000-59FFFF

46 SA180 10110100xxx 64/32 B40000-4FFFFF 5A0000-5A7FFF

46 SA181 10110101xxx 64/32 B50000-5FFFFF 5A8000-5AFFFF

46 SA182 10110110xxx 64/32 B60000-6FFFFF 5B0000-5B7FFF

46 SA183 10110111xxx 64/32 B70000-7FFFFF 5B8000-5BFFFF

47 SA184 10111000xxx 64/32 B80000-8FFFFF 5C0000-5C7FFF

47 SA185 10111001xxx 64/32 B90000-9FFFFF 5C8000-5 CFFFF

47 SA186 10111010xxx 64/32 BA0000-AFFFFF 5D0000-5D7FFF

47 SA187 10111011xxx 64/32 BB0000-BFFFFF 5D800 0 - 5 DFFFF

48 SA188 10111100xxx 64/32 BC0000-CFFFFF 5E0000-5E7FFF

48 SA189 10111101xxx 64/32 BD0000-DFFFFF 5E8000-5EFFFF

48 SA190 10111110xxx 64/32 BE0000-EFFFFF 5F0000-5F7FFF

48 SA191 10111111xxx 64/32 BF0000-FFFFFF 5F8000-5FFFFF

49 SA192 11000000xxx 64/32 C00000-0FFFFF 600000-607FFF

49 SA193 11000001xxx 64/32 C10000-1FFFFF 608000-60FFFF

49 SA194 11000010xxx 64/32 C20000-2FFFFF 610000-617FFF

49 SA195 11000011xxx 64/32 C30000-3FFFFF 618000-61FFFF

50 SA196 11000100xxx 64/32 C40000-4FFFFF 620000-627FFF

50 SA197 11000101xxx 64/32 C50000-5FFFFF 628000-62FFFF

50 SA198 11000110xxx 64/32 C60000-6FFFFF 630000-637FFF

50 SA199 11000111xxx 64/32 C70000-7FFFFF 638000-63FFFF

51 SA200 11001000xxx 64/32 C80000-8FFFFF 640000-647FFF

51 SA201 11001001xxx 64/32 C90000-9FFFFF 648000-64FFFF

51 SA202 11001010xxx 64/32 CA0000-AFFFFF 650000-657FFF

P/N:PM1170

REV. 0.04, JUL. 11, 2005

9

MX29LA128M T/B

Sector Sector Sector Address Sector Size (x8) (x16)

Group A22-A12 (Kbytes/Kwords) Address Range Address Range

51 SA203 11001011xxx 64/32 CB0000-BFFFFF 658000-65FFFF

52 SA204 11001100xxx 64/32 CC0000-CFFFFF 660000-667FFF

52 SA205 11001101xxx 64/32 CD0000-DFFFFF 668000-66FFFF

52 SA206 11001110xxx 64/32 CE0000-EFFFFF 670000-677FFF

52 SA207 11001111xxx 64/32 CF0000-FFFFFF 678000-67FFFF

53 SA208 11010000xxx 64/32 D00000-0FFFFF 680000-687FFF

53 SA209 11010001xxx 64/32 D10000-1FFFFF 688000-68FFFF

53 SA210 11010010xxx 64/32 D20000-2FFFFF 690000-697FFF

53 SA211 11010011xxx 64/32 D30000-3FFFFF 698000-69FFFF

54 SA212 11010100xxx 64/32 D40000-4FFFFF 6A0000-6A7FFF

54 SA213 11010101xxx 64/32 D50000-5FFFFF 6A8000-6AFFFF

54 SA214 11010110xxx 64/32 D60000-6FFFFF 6B0000-6B7FFF

54 SA215 11010111xxx 64/32 D70000-7FFFFF 6B8000-6BFFFF

55 SA216 11011000xxx 64/32 D80000-8FFFFF 6C0000-6C7FFF

55 SA217 11011001xxx 64/32 D90000-9FFFFF 6C8000-6CFFFF

55 SA218 11011010xxx 64/32 DA0000-AFFFFF 6D0000-6D7FFF

55 SA219 11011011xxx 64/32 DB0000-BFFFFF 6D8000- 6DFFFF

56 SA220 11011100xxx 64/32 DC0000-CFFFFF 6E0000-6E7FFF

56 SA221 11011101xxx 64/32 DD0000-DFFFFF 6E8000-6EFFFF

56 SA222 11011110xxx 64/32 DE0000-EFFFFF 6F0000-6F7FFF

56 SA223 11011111xxx 64/32 DF0000-FFFFFF 6F8000-6FFFFF

57 SA224 11100000xxx 64/32 E00000-0FFFFF 700000-707FFF

57 SA225 11100001xxx 64/32 E10000-1FFFFF 708000-70FFFF

57 SA226 11100010xxx 64/32 E20000-2FFFFF 710000-717FFF

57 SA227 11100011xxx 64/32 E30000-3FFFFF 718000-71FFFF

58 SA228 11100100xxx 64/32 E40000-4FFFFF 720000-727FFF

58 SA229 11100101xxx 64/32 E50000-5FFFFF 728000-72FFFF

58 SA230 11100110xxx 64/32 E60000-6FFFFF 730000-737FFF

58 SA231 11100111xxx 64/32 E70000-7FFFFF 738000-73FFFF

59 SA232 11101000xxx 64/32 E80000-8FFFFF 740000-747FFF

59 SA233 11101001xxx 64/32 E90000-9FFFFF 748000-74FFFF

59 SA234 11101010xxx 64/32 EA0000-AFFFFF 750000-757FFF

59 SA235 11101011xxx 64/32 EB0000-BFFFFF 758000-75FFFF

60 SA236 11101100xxx 64/32 EC0000-CFFFFF 760000-767FFF

60 SA237 11101101xxx 64/32 ED0000-DFFFFF 768000-76FFFF

60 SA238 11101110xxx 64/32 EE0000-EFFFFF 770000-777FFF

60 SA239 11101111xxx 64/32 EF0000-FFFFFF 778000-77FFFF

61 SA240 11110000xxx 64/32 F00000-0FFFFFF 780000-787FFF

P/N:PM1170

REV. 0.04, JUL. 11, 2005

10

MX29LA128M T/B

Sector Sector Sector Address Sector Size (x8) (x16)

Group A22-A12 (Kbytes/Kwords) Address Range Address Range

61 SA241 11110001xxx 64/32 F10000-1FFFFF 788000-78FFFF

61 SA242 11110010xxx 64/32 F20000-2FFFFF 790000-797FFF

61 SA243 11110011xxx 64/32 F30000-3FFFFF 798000-79FFFF

62 SA244 11110100xxx 64/32 F40000-4FFFFF 7A0000-7A7FFF

62 SA245 11110101xxx 64/32 F50000-5FFFFF 7A8000-7AFFFF

62 SA246 11110110xxx 64/32 F60000-6FFFFF 7B0000-7B7FFF

62 SA247 11110111xxx 64/32 F70000-7FFFFF 7B8000-7BFFFF

63 SA248 11111000xxx 64/32 F80000-8FFFFF 7C0000-7C7FFF

63 SA249 11111001xxx 64/32 F90000-9FFFFF 7C 800 0- 7CFFFF

63 SA250 11111010xxx 64/32 FA0000-AFFFFF 7D0000-7D7FFF

63 SA251 11111011xxx 64/32 FB0000-BFFFFF 7D8000- 7DFFFF

64 SA252 11111100xxx 64/32 FC0000-CFFFFF 7E0000-7E7FFF

64 SA253 11111101xxx 64/32 FD0000-DFFFFF 7E8000-7EFFFF

64 SA254 11111110xxx 64/32 FE0000-EFFFFF 7F0000-7F7FFF

65 SA255 11111111000 8/4 FF0000-FF1FFF 7F8000-7F8FFF

66 SA256 11111111001 8/4 FF2000-FF3FFF 7F9000-7F9FFF

67 SA257 11111111010 8/4 FF4000-FF5FFF 7F A000-7FAFFF

68 SA258 11111111011 8/4 FF6000-FF7FFF 7FB000-7FBFFF

69 SA259 11111111100 8/4 FF8000-FF9FFF 7FC000-7FCFFF

70 SA260 11111111101 8/4 FFA000-FFBFFF 7FD000-7FDFFF

71 SA261 11111111110 8/4 FFC000-FFDFFF 7FE000-7FEFFF

72 SA262 11111111111 8/4 FFE000-FFFFFF 7FF000-7FFFFF

P/N:PM1170

REV. 0.04, JUL. 11, 2005

11

MX29LA128M T/B

MX29LA128MB SECTOR ADDRESS TABLE

Sector Sector Sector Address Sector Size (x8) (x16)

Group A22-A12 (Kbytes/Kwords) Address Range Address Range

1 SA0 00000000000 8/4 000000-001FFF 000000-000FFF

2 SA1 00000000001 8/4 002000-003FFF 001000-001FFF

3 SA2 00000000010 8/4 004000-005FFF 002000-002FFF

4 SA3 00000000011 8/4 006000-007FFF 003000-003FFF

5 SA4 00000000100 8/4 008000-009FFF 004000-004FFF

6 SA5 00000000101 8/4 00A000-00BFFF 005000-005FFF

7 SA6 00000000110 8/4 00C000-00DFFF 006000-006FFF

8 SA7 00000000111 8/4 00E000-00FFFF 007000-007FFF

9 SA8 00000001xxx 64/32 010000-1FFFFF 008000-00FFFF

9 SA9 00000010xxx 64/32 020000-2FFFFF 010000-017FFF

9 SA10 00000011xxx 64/32 030000-3FFFFF 018000-01FFFF

10 SA11 00000100xxx 64/32 040000-4FFFFF 020000-027FFF

10 SA12 00000101xxx 64/32 050000-5FFFFF 028000-02FFFF

10 SA13 00000110xxx 64/32 060000-6FFFFF 030000-037FFF

10 SA14 00000111xxx 64/32 070000-7FFFFF 038000-03FFFF

11 SA15 00001000xxx 64/32 080000-8FFFFF 040000-047FFF

11 SA16 00001001xxx 64/32 090000-9FFFFF 048000-04FFFF

11 SA17 00001010xxx 64/32 0A0000-AFFFFF 050000-057FFF

11 SA18 00001011xxx 64/32 0B0000-BFFFFF 058000-05FFFF

12 SA19 00001100xxx 64/32 0C0000-CFFFFF 060000-067FFF

12 SA20 00001101xxx 64/32 0D0000-DFFFFF 068000-06FFFF

12 SA21 00001110xxx 64/32 0E0000-EFFFFF 070000-077FFF

12 SA22 00001111xxx 64/32 0F0000-FFFFFF 078000-07FFFF

13 SA23 00010000xxx 64/32 100000-0FFFFF 080000-087FFF

13 SA24 00010001xxx 64/32 110000-1FFFFF 088000-08FFFF

13 SA25 00010010xxx 64/32 120000-2FFFFF 090000-097FFF

13 SA26 00010011xxx 64/32 130000-3FFFFF 098000-09FFFF

14 SA27 00010100xxx 64/32 140000-4FFFFF 0A0000-0A7FFF

14 SA28 00010101xxx 64/32 150000-5FFFFF 0A8000-0AFFFF

14 SA29 00010110xxx 64/32 160000-6FFFFF 0B0000-0B7FFF

14 SA30 00010111xxx 64/32 170000-7FFFFF 0B8000-0BFFFF

15 SA31 00011000xxx 64/32 180000-8FFFFF 0C0000-0C7FFF

15 SA32 00011001xxx 64/32 190000-9FFFFF 0C8000-0CFFFF

15 SA33 00011010xxx 64/32 1A0000-AFFFFF 0D0000-0D7FFF

15 SA34 00011011xxx 64/32 1B0000-BFFFFF 0D8000-0DFFFF

16 SA35 00011100xxx 64/32 1C0000-CFFFFF 0E0000-0E7FFF

16 SA36 00011101xxx 64/32 1D0000-DFFFFF 0E8000-0EFFFF

16 SA37 00011110xxx 64/32 1E0000-EFFFFF 0F0000-0F7FFF

16 SA38 00011111xxx 64/32 1F0000-FFFFFF 0F8000-0FFFFF

P/N:PM1170

REV. 0.04, JUL. 11, 2005

12

MX29LA128M T/B

Sector Sector Sector Address Sector Size (x8) (x16)

Group A22-A12 (Kbytes/Kwords) Address Range Address Range

17 SA39 00100000xxx 64/32 200000-0FFFFF 100000-107FFF

17 SA40 00100001xxx 64/32 210000-1FFFFF 108000-10FFFF

17 SA41 00100010xxx 64/32 220000-2FFFFF 110000-117FFF

17 SA42 00100011xxx 64/32 230000-3FFFFF 118000-11FFFF

18 SA43 00100100xxx 64/32 240000-4FFFFF 120000-127FFF

18 SA44 00100101xxx 64/32 250000-5FFFFF 128000-12FFFF

18 SA45 00100110xxx 64/32 260000-6FFFFF 130000-137FFF

18 SA46 00100111xxx 64/32 270000-7FFFFF 138000-13FFFF

19 SA47 00101000xxx 64/32 280000-8FFFFF 140000-147FFF

19 SA48 00101001xxx 64/32 290000-9FFFFF 148000-14FFFF

19 SA49 00101010xxx 64/32 2A0000-AFFFFF 150000-157FFF

19 SA50 00101011xxx 64/32 2B0000-BFFFFF 158000-15FFFF

20 SA51 00101100xxx 64/32 2C0000-CFFFFF 160000-167FFF

20 SA52 00101101xxx 64/32 2D0000-DFFFFF 168000-16FFFF

20 SA53 00101110xxx 64/32 2E0000-EFFFFF 170000-177FFF

20 SA54 00101111xxx 64/32 2F0000-FFFFFF 178000-17FFFF

21 SA55 00110000xxx 64/32 300000-0FFFFF 180000-187FFF

21 SA56 00110001xxx 64/32 310000-1FFFFF 188000-18FFFF

21 SA57 00110010xxx 64/32 320000-2FFFFF 190000-197FFF

21 SA58 00110011xxx 64/32 330000-3FFFFF 198000-19FFFF

22 SA59 00110100xxx 64/32 340000-4FFFFF 1A0000-1A7FFF

22 SA60 00110101xxx 64/32 350000-5FFFFF 1A8000-1AFFFF

22 SA61 00110110xxx 64/32 360000-6FFFFF 1B0000-1B7FFF

22 SA62 00110111xxx 64/32 370000-7FFFFF 1B8000-1BFFFF

23 SA63 00111000xxx 64/32 380000-8FFFFF 1C0000-1C7FFF

23 SA64 00111001xxx 64/32 390000-9FFFFF 1C8000-1CFFFF

23 SA65 00111010xxx 64/32 3A0000-AFFFFF 1D0000-1D7FFF

23 SA66 00111011xxx 64/32 3B0000-BFFFFF 1D8000-1DFFFF

24 SA67 00111100xxx 64/32 3C0000-CFFFFF 1E0000-1E7FFF

24 SA68 00111101xxx 64/32 3D0000-DFFFFF 1E8000-1EFFFF

24 SA69 00111110xxx 64/32 3E0000-EFFFFF 1F0000-1F7FFF

24 SA70 00111111xxx 64/32 3F0000-FFFFFF 1F8000-1FFFFF

25 SA71 01000000xxx 64/32 400000-0FFFFF 200000-207FFF

25 SA72 01000001xxx 64/32 410000-1FFFFF 208000-20FFFF

25 SA73 01000010xxx 64/32 420000-2FFFFF 210000-217FFF

25 SA74 01000011xxx 64/32 430000-3FFFFF 218000-21FFFF

26 SA75 01000100xxx 64/32 440000-4FFFFF 220000-227FFF

26 SA76 01000101xxx 64/32 450000-5FFFFF 228000-22FFFF

26 SA77 01000110xxx 64/32 460000-6FFFFF 230000-237FFF

26 SA78 01000111xxx 64/32 470000-7FFFFF 238000-23FFFF

27 SA79 01001000xxx 64/32 480000-8FFFFF 240000-247FFF

P/N:PM1170

REV. 0.04, JUL. 11, 2005

13

MX29LA128M T/B

Sector Sector Sector Address Sector Size (x8) (x16)

Group A22-A12 (Kbytes/Kwords) Address Range Address Range

27 SA80 01001001xxx 64/32 490000-9FFFFF 248000-24FFFF

27 SA81 01001010xxx 64/32 4A0000-AFFFFF 250000-257FFF

27 SA82 01001011xxx 64/32 4B0000-BFFFFF 258000-25FFFF

28 SA83 01001100xxx 64/32 4C0000-CFFFFF 260000-267FFF

28 SA84 01001101xxx 64/32 4D0000-DFFFFF 268000-26FFFF

28 SA85 01001110xxx 64/32 4E0000-EFFFFF 270000-277FFF

28 SA86 01001111xxx 64/32 4F0000-FFFFFF 278000-27FFFF

29 SA87 01010000xxx 64/32 500000-0FFFFF 280000-287FFF

29 SA88 01010001xxx 64/32 510000-1FFFFF 288000-28FFFF

29 SA89 01010010xxx 64/32 520000-2FFFFF 290000-297FFF

29 SA90 01010011xxx 64/32 530000-3FFFFF 298000-29FFFF

30 SA91 01010100xxx 64/32 540000-4FFFFF 2A0000-2A7FFF

30 SA92 01010101xxx 64/32 550000-5FFFFF 2A8000-2AFFFF

30 SA93 01010110xxx 64/32 560000-6FFFFF 2B0000-2B7FFF

30 SA94 01010111xxx 64/32 570000-7FFFFF 2B8000-2BFFFF

31 SA95 01011000xxx 64/32 580000-8FFFFF 2C0000-2C7FFF

31 SA96 01011001xxx 64/32 590000-9FFFFF 2C8000-2CFFFF

31 SA97 01011010xxx 64/32 5A0000-AFFFFF 2D0000-2D7FFF

31 SA98 01011011xxx 64/32 5B0000-BFFFFF 2D8000-2DFFFF

32 SA99 01011100xxx 64/32 5C0000-CFFFFF 2E0000-2E7FFF

32 SA100 01011101xxx 64/32 5D0000-DFFFFF 2E8000-2EFFFF

32 SA101 01011110xxx 64/32 5E0000-EFFFFF 2F0000-2F7FFF

32 SA102 01011111xxx 64/32 5F0000-FFFFFF 2F8000-2FFFFF

33 SA103 01100000xxx 64/32 600000-0FFFFF 300000-307FFF

33 SA104 01100001xxx 64/32 610000-1FFFFF 308000-30FFFF

33 SA105 01100010xxx 64/32 620000-2FFFFF 310000-317FFF

33 SA106 01100011xxx 64/32 630000-3FFFFF 318000-31FFFF

34 SA107 01100100xxx 64/32 640000-4FFFFF 320000-327FFF

34 SA108 01100101xxx 64/32 650000-5FFFFF 328000-32FFFF

34 SA109 01100110xxx 64/32 660000-6FFFFF 330000-337FFF

34 SA110 01100111xxx 64/32 670000-7FFFFF 338000-33FFFF

35 SA111 01101000xxx 64/32 680000-8FFFFF 340000-347FFF

35 SA112 01101001xxx 64/32 690000-9FFFFF 348000-34FFFF

35 SA113 01101010xxx 64/32 6A0000-AFFFFF 350000-357FFF

35 SA114 01101011xxx 64/32 6B0000-BFFFFF 358000-35FFFF

36 SA115 01101100xxx 64/32 6C0000-CFFFFF 360000-367FFF

36 SA116 01101101xxx 64/32 6D0000-DFFFFF 368000-36FFFF

36 SA117 01101110xxx 64/32 6E0000-EFFFFF 370000-377FFF

36 SA118 01101111xxx 64/32 6F0000-FFFFFF 378000-37FFFF

37 SA119 01110000xxx 64/32 700000-0FFFFF 380000-387FFF

37 SA120 01110001xxx 64/32 710000-1FFFFF 388000-38FFFF

P/N:PM1170

REV. 0.04, JUL. 11, 2005

14

MX29LA128M T/B

Sector Sector Sector Address Sector Size (x8) (x16)

Group A22-A12 (Kbytes/Kwords) Address Range Address Range

37 SA121 01110010xxx 64/32 720000-2FFFFF 390000-397FFF

37 SA122 01110011xxx 64/32 730000-3FFFFF 398000-39FFFF

38 SA123 01110100xxx 64/32 740000-4FFFFF 3A0000-3A7FFF

38 SA124 01110101xxx 64/32 750000-5FFFFF 3A8000-3AFFFF

38 SA125 01110110xxx 64/32 760000-6FFFFF 3B0000-3B7FFF

38 SA126 01110111xxx 64/32 770000-7FFFFF 3B8000-3BFFFF

39 SA127 01111000xxx 64/32 780000-8FFFFF 3C0000-3C7FFF

39 SA128 01111001xxx 64/32 790000-9FFFFF 3C8000-3CFFFF

39 SA129 01111010xxx 64/32 7A0000-AFFFFF 3D0000-3D7FFF

39 SA130 01111011xxx 64/32 7B0000-BFFFFF 3D8000 -3DFFFF

40 SA131 01111100xxx 64/32 7C0000-CFFFFF 3E0000-3E7FFF

40 SA132 01111101xxx 64/32 7D0000-DFFFFF 3E8000-3EFFFF

40 SA133 01111110xxx 64/32 7E0000-EFFFFF 3F0000-3F7FFF

40 SA134 01111111xxx 64/32 7F0000-FFFFFF 3F8000-3FFFFF

41 SA135 10000000xxx 64/32 800000-0FFFFF 400000-407FFF

41 SA136 10000001xxx 64/32 810000-1FFFFF 408000-40FFFF

41 SA137 10000010xxx 64/32 820000-2FFFFF 410000-417FFF

41 SA138 10000011xxx 64/32 830000-3FFFFF 418000-41FFFF

42 SA139 10000100xxx 64/32 840000-4FFFFF 420000-427FFF

42 SA140 10000101xxx 64/32 850000-5FFFFF 428000-42FFFF

42 SA141 10000110xxx 64/32 860000-6FFFFF 430000-437FFF

42 SA142 10000111xxx 64/32 870000-7FFFFF 438000-43FFFF

43 SA143 10001000xxx 64/32 880000-8FFFFF 440000-447FFF

43 SA144 10001001xxx 64/32 890000-9FFFFF 448000-44FFFF

43 SA145 10001010xxx 64/32 8A0000-AFFFFF 450000-457FFF

43 SA146 10001011xxx 64/32 8B0000-BFFFFF 458000-45FFFF

44 SA147 10001100xxx 64/32 8C0000-CFFFFF 460000-467FFF

44 SA148 10001101xxx 64/32 8D0000-DFFFFF 468000-46FFFF

44 SA149 10001110xxx 64/32 8E0000-EFFFFF 470000-477FFF

44 SA150 10001111xxx 64/32 8F0000-FFFFFF 478000-47FFFF

45 SA151 10010000xxx 64/32 900000-0FFFFF 480000-487FFF

45 SA152 10010001xxx 64/32 910000-1FFFFF 488000-48FFFF

45 SA153 10010010xxx 64/32 920000-2FFFFF 490000-497FFF

45 SA154 10010011xxx 64/32 930000-3FFFFF 498000-49FFFF

46 SA155 10010100xxx 64/32 940000-4FFFFF 4A0000-4A7FFF

46 SA156 10010101xxx 64/32 950000-5FFFFF 4A8000-4AFFFF

46 SA157 10010110xxx 64/32 960000-6FFFFF 4B0000-4B7FFF

46 SA158 10010111xxx 64/32 970000-7FFFFF 4B8000-4BFFFF

47 SA159 10011000xxx 64/32 980000-8FFFFF 4C0000-4C7FFF

47 SA160 10011001xxx 64/32 990000-9FFFFF 4C8000-4CFFFF

47 SA161 10011010xxx 64/32 9A0000-AFFFFF 4D0000-4D7FFF

47 SA162 10011011xxx 64/32 9B0000-BFFFFF 4D8000 -4DFFFF

P/N:PM1170

REV. 0.04, JUL. 11, 2005

15

MX29LA128M T/B

Sector Sector Sector Address Sector Size (x8) (x16)

Group A22-A12 (Kbytes/Kwords) Address Range Address Range

48 SA163 10011100xxx 64/32 9C0000-CFFFFF 4E0000-4E7FFF

48 SA164 10011101xxx 64/32 9D0000-DFFFFF 4E8000-4EFFFF

48 SA165 10011110xxx 64/32 9E0000-EFFFFF 4F0000-4F7FFF

48 SA166 10011111xxx 64/32 9F0000-FFFFFF 4F8000-4FFFFF

49 SA167 10100000xxx 64/32 A00000-0FFFFF 500000-507FFF

49 SA168 10100001xxx 64/32 A10000-1FFFFF 508000-50FFFF

49 SA169 10100010xxx 64/32 A20000-2FFFFF 510000-517FFF

49 SA170 10100011xxx 64/32 A30000-3FFFFF 518000-51FFFF

50 SA171 10100100xxx 64/32 A40000-4FFFFF 520000-527FFF

50 SA172 10100101xxx 64/32 A50000-5FFFFF 528000-52FFFF

50 SA173 10100110xxx 64/32 A60000-6FFFFF 530000-537FFF

50 SA174 10100111xxx 64/32 A70000-7FFFFF 538000-53FFFF

51 SA175 10101000xxx 64/32 A80000-8FFFFF 540000-547FFF

51 SA176 10101001xxx 64/32 A90000-9FFFFF 548000-54FFFF

51 SA177 10101010xxx 64/32 AA0000-AFFFFF 550000-557FFF

51 SA178 10101011xxx 64/32 AB0000-BFFFFF 558000-55FFFF

52 SA179 10101100xxx 64/32 AC0000-CFFFFF 560000-567FFF

52 SA180 10101101xxx 64/32 AD0000-DFFFFF 568000-56FFFF

52 SA181 10101110xxx 64/32 AE0000-EFFFFF 570000-577FFF

52 SA182 10101111xxx 64/32 AF0000-FFFFFF 578000-57FFFF

53 SA183 10110000xxx 64/32 B00000-0FFFFF 580000-587FFF

53 SA184 10110001xxx 64/32 B10000-1FFFFF 588000-58FFFF

53 SA185 10110010xxx 64/32 B20000-2FFFFF 590000-597FFF

53 SA186 10110011xxx 64/32 B30000-3FFFFF 598000-59FFFF

54 SA187 10110100xxx 64/32 B40000-4FFFFF 5A0000-5A7FFF

54 SA188 10110101xxx 64/32 B50000-5FFFFF 5A8000-5AFFFF

54 SA189 10110110xxx 64/32 B60000-6FFFFF 5B0000-5B7FFF

54 SA190 10110111xxx 64/32 B70000-7FFFFF 5B8000-5BFFFF

55 SA191 10111000xxx 64/32 B80000-8FFFFF 5C0000-5C7FFF

55 SA192 10111001xxx 64/32 B90000-9FFFFF 5C8000-5 CFFFF

55 SA193 10111010xxx 64/32 BA0000-AFFFFF 5D0000-5D7FFF

55 SA194 10111011xxx 64/32 BB0000-BFFFFF 5D800 0 - 5 DFFFF

56 SA195 10111100xxx 64/32 BC0000-CFFFFF 5E0000-5E7FFF

56 SA196 10111101xxx 64/32 BD0000-DFFFFF 5E8000-5EFFFF

56 SA197 10111110xxx 64/32 BE0000-EFFFFF 5F0000-5F7FFF

56 SA198 10111111xxx 64/32 BF0000-FFFFFF 5F8000-5FFFFF

57 SA199 11000000xxx 64/32 C00000-0FFFFF 600000-607FFF

57 SA200 11000001xxx 64/32 C10000-1FFFFF 608000-60FFFF

57 SA201 11000010xxx 64/32 C20000-2FFFFF 610000-617FFF

57 SA202 11000011xxx 64/32 C30000-3FFFFF 618000-61FFFF

P/N:PM1170

REV. 0.04, JUL. 11, 2005

16

MX29LA128M T/B

Sector Sector Sector Address Sector Size (x8) (x16)

Group A22-A12 (Kbytes/Kwords) Address Range Address Range

58 SA203 11000100xxx 64/32 C40000-4FFFFF 620000-627FFF

58 SA204 11000101xxx 64/32 C50000-5FFFFF 628000-62FFFF

58 SA205 11000110xxx 64/32 C60000-6FFFFF 630000-637FFF

58 SA206 11000111xxx 64/32 C70000-7FFFFF 638000-63FFFF

59 SA207 11001000xxx 64/32 C80000-8FFFFF 640000-647FFF

59 SA208 11001001xxx 64/32 C90000-9FFFFF 648000-64FFFF

59 SA209 11001010xxx 64/32 CA0000-AFFFFF 650000-657FFF

59 SA210 11001011xxx 64/32 CB0000-BFFFFF 658000-65FFFF

60 SA211 11001100xxx 64/32 CC0000-CFFFFF 660000-667FFF

60 SA212 11001101xxx 64/32 CD0000-DFFFFF 668000-66FFFF

60 SA213 11001110xxx 64/32 CE0000-EFFFFF 670000-677FFF

60 SA214 11001111xxx 64/32 CF0000-FFFFFF 678000-67FFFF

61 SA215 11010000xxx 64/32 D00000-0FFFFF 680000-687FFF

61 SA216 11010001xxx 64/32 D10000-1FFFFF 688000-68FFFF

61 SA217 11010010xxx 64/32 D20000-2FFFFF 690000-697FFF

61 SA218 11010011xxx 64/32 D30000-3FFFFF 698000-69FFFF

62 SA219 11010100xxx 64/32 D40000-4FFFFF 6A0000-6A7FFF

62 SA220 11010101xxx 64/32 D50000-5FFFFF 6A8000-6AFFFF

62 SA221 11010110xxx 64/32 D60000-6FFFFF 6B0000-6B7FFF

62 SA222 11010111xxx 64/32 D70000-7FFFFF 6B8000-6BFFFF

63 SA223 11011000xxx 64/32 D80000-8FFFFF 6C0000-6C7FFF

63 SA224 11011001xxx 64/32 D90000-9FFFFF 6C8000-6CFFFF

63 SA225 11011010xxx 64/32 DA0000-AFFFFF 6D0000-6D7FFF

63 SA226 11011011xxx 64/32 DB0000-BFFFFF 6D8000- 6DFFFF

64 SA227 11011100xxx 64/32 DC0000-CFFFFF 6E0000-6E7FFF

64 SA228 11011101xxx 64/32 DD0000-DFFFFF 6E8000-6EFFFF

64 SA229 11011110xxx 64/32 DE0000-EFFFFF 6F0000-6F7FFF

64 SA230 11011111xxx 64/32 DF0000-FFFFFF 6F8000-6FFFFF

65 SA231 11100000xxx 64/32 E00000-0FFFFF 700000-707FFF

65 SA232 11100001xxx 64/32 E10000-1FFFFF 708000-70FFFF

65 SA233 11100010xxx 64/32 E20000-2FFFFF 710000-717FFF

65 SA234 11100011xxx 64/32 E30000-3FFFFF 718000-71FFFF

66 SA235 11100100xxx 64/32 E40000-4FFFFF 720000-727FFF

66 SA236 11100101xxx 64/32 E50000-5FFFFF 728000-72FFFF

66 SA237 11100110xxx 64/32 E60000-6FFFFF 730000-737FFF

66 SA238 11100111xxx 64/32 E70000-7FFFFF 738000-73FFFF

67 SA239 11101000xxx 64/32 E80000-8FFFFF 740000-747FFF

67 SA240 11101001xxx 64/32 E90000-9FFFFF 748000-74FFFF

67 SA241 11101010xxx 64/32 EA0000-AFFFFF 750000-757FFF

67 SA242 11101011xxx 64/32 EB0000-BFFFFF 758000-75FFFF

P/N:PM1170

REV. 0.04, JUL. 11, 2005

17

MX29LA128M T/B

Sector Sector Sector Address Sector Size (x8) (x16)

Group A22-A12 (Kbytes/Kwords) Address Range Address Range

68 SA243 11101100xxx 64/32 EC0000-CFFFFF 760000-767FFF

68 SA244 11101101xxx 64/32 ED0000-DFFFFF 768000-76FFFF

68 SA245 11101110xxx 64/32 EE0000-EFFFFF 770000-777FFF

68 SA246 11101111xxx 64/32 EF0000-FFFFFF 778000-77FFFF

69 SA247 11110000xxx 64/32 F00000-0FFFFFF 780000-787FFF

69 SA248 11110001xxx 64/32 F10000-1FFFFF 788000-78FFFF

69 SA249 11110010xxx 64/32 F20000-2FFFFF 790000-797FFF

69 SA250 11110011xxx 64/32 F30000-3FFFFF 798000-79FFFF

70 SA251 11110100xxx 64/32 F40000-4FFFFF 7A0000-7A7FFF

70 SA252 11110101xxx 64/32 F50000-5FFFFF 7A8000-7AFFFF

70 SA253 11110110xxx 64/32 F60000-6FFFFF 7B0000-7B7FFF

70 SA254 11110111xxx 64/32 F70000-7FFFFF 7B8000-7BFFFF

71 SA255 11111000xxx 64/32 F80000-8FFFFF 7C0000-7C7FFF

71 SA256 11111001xxx 64/32 F90000-9FFFFF 7C 800 0- 7CFFFF

71 SA257 11111010xxx 64/32 FA0000-AFFFFF 7D0000-7D7FFF

71 SA258 11111011xxx 64/32 FB0000-BFFFFF 7D8000- 7DFFFF

72 SA259 11111100xxx 64/32 FC0000-CFFFFF 7E0000-7E7FFF

72 SA260 11111101xxx 64/32 FD0000-DFFFFF 7E8000-7EFFFF

72 SA261 11111110xxx 64/32 FE0000-EFFFFF 7F0000-7F7FFF

72 SA262 11111111xxx 64/32 FF0000-FF1FFF 7F8000-7F8FFF

P/N:PM1170

REV. 0.04, JUL. 11, 2005

18

MX29LA128M T/B

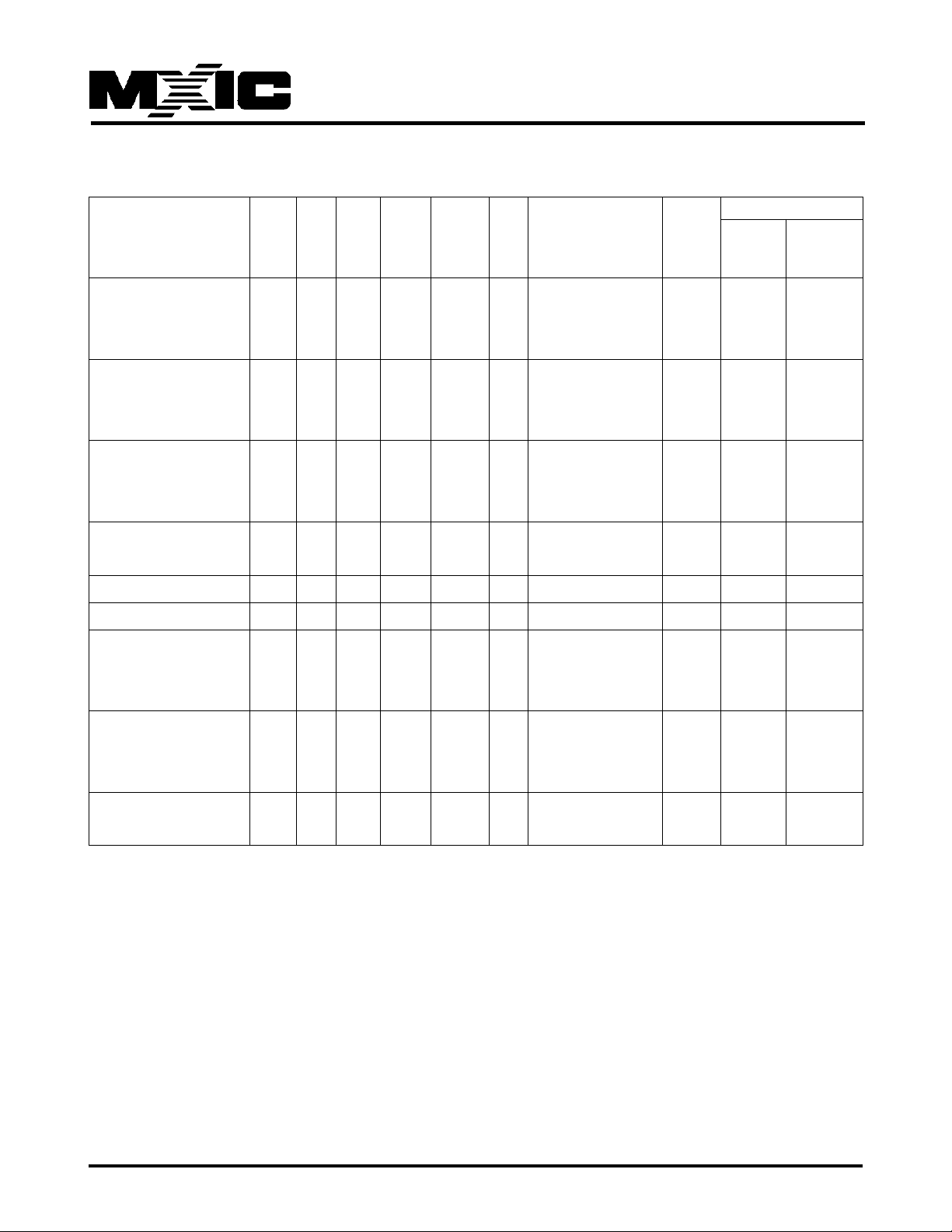

Table 1. BUS OPERATION (1)

Q8~Q15

Operation CE# OE# W E # RE- WP# ACC Address Q0~Q7 Word Byte

SET# Mode Mode

Read L L H H X X A

IN

D

OUT

D

OUT

Q8-Q14=

High Z

Q15=A-1

Write (Program/Erase) L H L H (Note 3) X A

IN

(No te 4) (Note 4 Q8-Q14=

High Z

Q15=A-1

Accelerated Program L H L H (Note 3) V

HH

A

IN

(No t e 4 ) (No t e 4 ) Q8-Q14=

High Z

Q15=A-1

Standby VC C ± X X VCC± X H X High-Z High-Z High-Z

0.3V 0.3V

Output Disable L H H H X X X High-Z High-Z High-Z

Reset X X X L X X X High-Z High-Z High-Z

Sector Group Protect L H L V

ID

H X Sector Addresses, (Note 4) X X

(Note 2) A6=L,A3=L, A2=L,

A1=H,A0=L

Chip unprotect L H L V

ID

H X Sector Addresses, (Note 4) X X

(Note 2) A6=H, A3=L, A2=L,

A1=H, A0=L

Temporary Sector X X X V

ID

HX AIN(Note 4) (Note 4) High-Z

Group Unprotect

Legend:

L=Logic LOW=VIL, H=Logic High=VIH, VID=12.0±0.5V, VHH=12.0±0.5V, X=Don't Care, AIN=Address IN, DIN=Data IN,

D

=Data OUT

OUT

No tes:

1. Address are A21:A0 in word mo de; A21:A-1 in byte mo de . Secto r addresses are A21:A15 in bo th mo des.

2 . The sector gro up pro tect and chip unpro tect functio ns may also be implemented via pro gramming equipment. See

the "Sector Gro up Pro tectio n and Chip Unpro tect" section.

3. If WP#=VIL, all the secto rs remain protected. If WP#=VIH, all sectors pro tectio n depends o n whether they were last

protected o r unpro tect using the method described in "Secto r/ Secto r Bloc k Protectio n and Unpro tect".

4. DIN or D

P/N:PM1170

as required by co mmand sequence, Data# po lling or secto r pro tect algo rithm (see Figure 15).

OUT

REV. 0.04, JUL. 11, 2005

19

MX29LA128M T/B

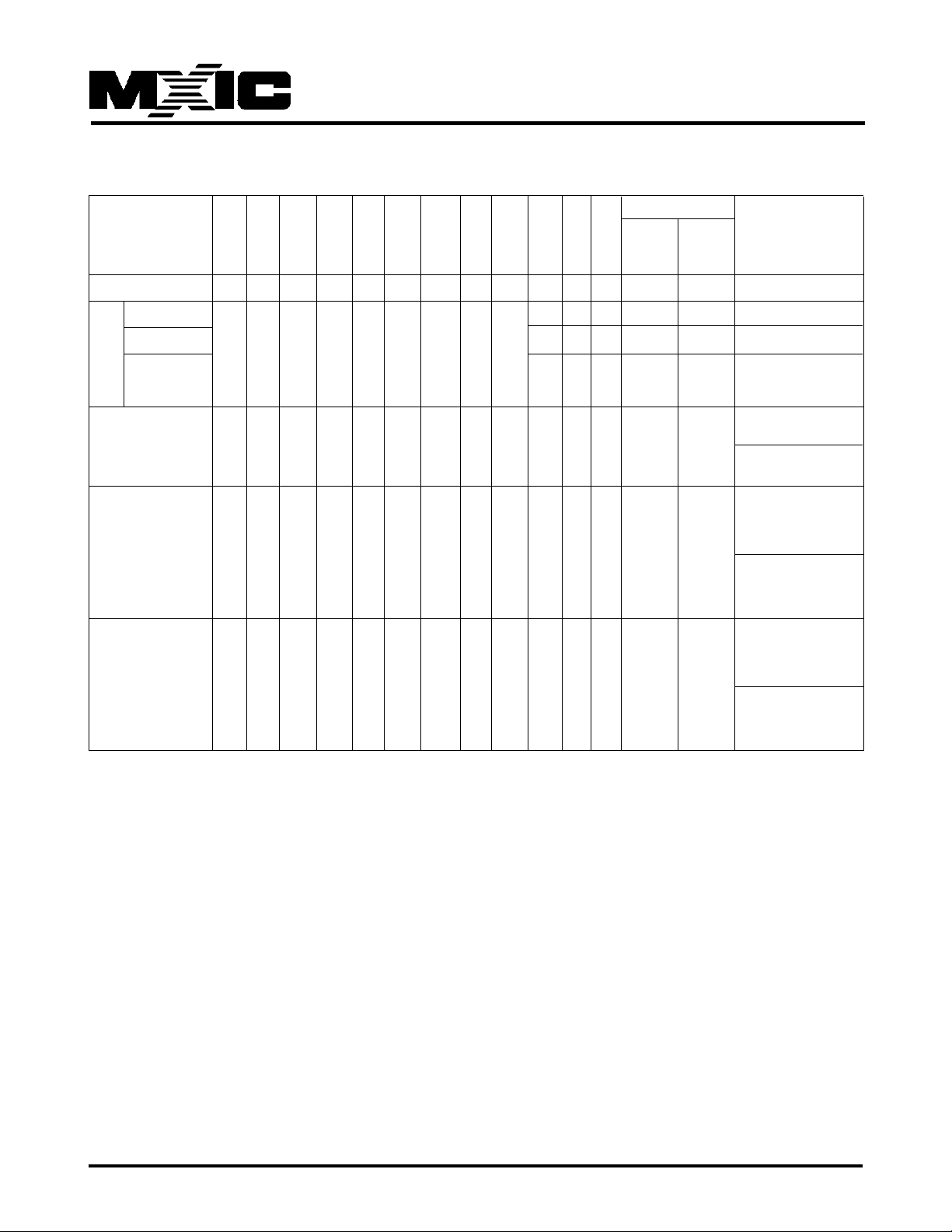

Table 2. AUTOSELECT CODES (High Voltage Method)

A22 A14 A8 A5 A3 Q8 to Q15

Description CE# OE# WE# to to A9 to A6 to to A1 A0 Word Byte Q7 t o Q 0

A15 A10 A7 A4 A2 Mode Mode

Manufacturer ID L L H X X VID X L X L L L 00 X C2h

Cycle 1 L L H 2 2 X 7Eh

Cycle 2 L L H X X VID X L X H H L 22 X 1 1h

Cycle 3 H H H 22 X 00h (bottom boot)

29LA128MT/B

Sector Group 01h (protected),

Protection L L H SA X VID X L X L H L X X

Verification 00h (unprotected)

Secured Silicon 98h

Sector Indicator (factory locked),

Bit (Q7), WP# L L H X X VID X L X L H H X X

protects top two 18h

01h (top boot)

address sector (not factory locked)

Secured Silicon 88h

Sector Indicator (factory locked),

Bit (Q7), WP# pro- L L H X X VID X L X L H H X X

tects botto m tw o 08h

address sector (not factory locked)

Legend: L = Logic Low = VIL, H = Logic High = VIH, SA = Sector Address, X = Don't care.

P/N:PM1170

REV. 0.04, JUL. 11, 2005

20

MX29LA128M T/B

REQUIREMENTS FOR READING ARRAY

DATA

To read array data from the outputs, the system must

drive the CE# and OE# pins to VIL. CE# is the power

control and selects the device. OE# is the output control

and gates array data to the o utput pins . WE# should remain at VIH.

The internal state machine is set for reading array data

upon device power-up, or after a hardware reset. This

ensures that no spurious alteration of the memory content occurs during the power transition. No command is

necessary in this mode to obtain array data. Standard

micropro cesso r read cycles that assert valid address on

the device address inputs produce valid data on the device data outputs . The de vice remains enabled fo r read

access until the command register contents are altered.

PAGE MODE READ

The MX29LA128M T/B o ffers "f ast page mode read" function. This mode provides faster read access speed for

random locations within a page. The page size of the

device is 4 words/8 bytes. The appropriate page is selected by the higher address bits A0~A1(Wo rd Mo de)/A1~A1(Byte Mode) This is an asynchro nous o peratio n; the

microprocessor supplies the specific word location.

The system perfo rmance could be enhanced by initiating

1 normal read and 3 fast page read (for word mode A0A1) or 7 fast page read (for byte mode A-1~A1). When

CE# is deasserted and reasserted fo r a subsequent access, the access time is tACC or tCE. Fast page mode

accesses are obtained by keeping the "read-page addresses" constant and changing the "intra-read page"

addresses.

WRITING COMMANDS/COMMAND SEQUENCES

T o pro gram data to the device o r erase secto rs of memo ry ,

the system must drive WE# and CE# to VIL, and OE# to

VIH.

An erase operation can erase one sector, multiple sectors, or the entire device. Table indicates the address

space that each sector occupies. A "sector address"

consists o f the address bits required to uniquely select a

sector . The Writing specific address and data commands

or sequences into the co mmand register initiates de vice

operations. Table 1 defines the valid register command

sequences. Writing inco rrect address and data values o r

writing them in the improper sequence resets the device

to reading array data. Section has details on erasing a

sector or the entire chip, or suspending/resuming the erase

operation.

After the system writes the Automatic Select command

sequence, the device enters the Automatic Select mode.

The system can then read Automatic Select codes from

the internal register (which is separate from the memory

array) on Q7-Q0. Standard read cycle timings apply in

this mode. Refer to the Automatic Select Mode and Automatic Select Command Sequence section for more

information.

ICC2 in the DC Characteristics table represents the active current specification for the write mode. The "AC

Characteristics" section contains timing specification

table and timing diagrams for write operations.

WRITE BUFFER

Write Buffer Programming allows the system to write a

maximum of 16 words/32 bytes in one programming operatio n. This results in faster eff ective pro gramming time

than the standard programming algorithms. See "Write

Buffer" for more information.

ACCELERATED PROGRAM OPERATION

The device offers accelerated program operations through

the ACC function. This is one of two functions provided

by the ACC pin. This function is primarily intended to

allow faster manuf acturing throughput at the f actory .

If the system asserts VHH on this pin, the device automatically enters the aforementioned Unlock Bypass

mode, temporarily unprotects any protected sectors, and

uses the higher voltage on the pin to reduce the time

required fo r pro gram oper ations . Remo ving VHH from the

ACC

pin must not be at VHH for operations o ther than accelerated programming, or device damage may result.

P/N:PM1170

REV. 0.04, JUL. 11, 2005

21

MX29LA128M T/B

STANDBY MODE

When using both pins o f CE# and RESET#, the de vice

enter CMOS Standby with bo th pins held at VCC ± 0.3V .

If CE# and RESET# are held at VIH, but not within the

range o f VCC ± 0.3V , the device will still be in the standby

mode, b ut the standby current will be larger. During Auto

Algorithm o peration, VCC active current (ICC2) is required

even CE# = "H" until the operation is completed. The

device can be read with standard access time (tCE) from

either of these standby modes, before it is ready to read

data.

AUTOMATIC SLEEP MODE

The automatic sleep mode minimizes Flash device energy consumptio n. The de vice auto matically enables this

mode when address remain stab le for tA CC+30ns . The

automatic sleep mo de is independent of the CE#, WE#,

and OE# control signals. Standard address access timings pro vide new data when addresses are changed. While

in sleep mode, output data is latched and always available to the system. ICC4 in the DC Characteristics table

represents the automatic sleep mode current specification.

OUTPUT DISABLE

With the OE# input at a logic high level (VIH), output

from the de vices are disabled. This will cause the output

pins to be in a high impedance state.

RESET# OPERATION

but not within VSS±0.3V, the standby current will be

greater.

The RESET# pin may be tied to system reset circuitry.

A system reset would that also reset the Flash memo ry ,

enabling the system to read the boot-up firmware from

the Flash memory.

If RESET# is asserted during a program or erase

operatio n, the R Y/BY# pin remains a "0" (busy) until the

internal reset operation is complete, which requires a time

of tREADY (during Embedded Algo rithms). The system

can thus monito r RY/BY# to determine whether the reset

operation is complete. If RESET# is asserted when a

program or erase operation is completed within a time of

tREAD Y (not during Embedded Algo rithms). The system

can read data tRH after the RESET# pin returns to VIH.

Refer to the AC Characteristics tables for RESET#

parameters and to Figure 3 for the timing diagram.

SECTOR GROUP PROTECT OPERATION

The MX29LA128M T/B f eatures hardw are secto r g roup

protection. This feature will disable both program and

erase operations for these sector group protected. In

this device, a sector group consists of four adjacent sectors which are protected or unprotected at the same time.

T o activ ate this mode, the pro gramming equipment must

fo rce VID o n address pin A9 and contro l pin OE#, (suggest VID = 12V) A6 = VIL and CE# = VIL. (see Tab le 2)

Programming of the protection circuitry begins on the

falling edge of the WE# pulse and is terminated on the

rising edge. Please refer to sector group protect algorithm and waveform.

The RESET# pin provides a hardware method of resetting

the device to reading arra y data. When the RESET# pin

is driven low for at least a period of tRP, the device

immediately terminates any operation in progress,

tristates all output pins, and ignores all read/write

commands for the duration of the RESET# pulse. The

device also resets the internal state machine to reading

array data. The o peratio n that was interrupted should be

reinitiated once the device is ready to accept another

command sequence, to ensure data integrity

Current is reduced for the duration of the RESET# pulse.

When RESET# is held at VSS±0.3V, the device draws

CMOS standby current (ICC4). If RESET# is held at VIL

P/N:PM1170

MX29LA128M T/B also pro vides ano ther metho d. Which

requires VID on the RESET# only. This method can be

implemented either in-system or via programming equipment. This method uses standard microprocessor bus

cycle timing.

T o v erify programming o f the pro tection circuitry , the programming equipment must fo rce VID o n address pin A9

( with CE# and OE# at VIL and WE# at VIH). When

A1=1, it will produce a logical "1" code at device output

Q0 fo r a pro tected sector . Otherwise the device will produce 00H for the unprotected sector. In this mode, the

addresses, except for A1, are don't care. Address locations with A1 = VIL are reserved to read manufacturer

and device codes. (Read Silicon ID)

REV. 0.04, JUL. 11, 2005

22

MX29LA128M T/B

It is also possib le to determine if the gro up is protected

in the system by writing a Read Silicon ID command.

Perf o rming a read operatio n with A1=VIH, it will produce

a logical "1" at Q0 for the protected sector.

CHIP UNPROTECT OPERATION

The MX29LA128M T/B also f eatures the chip unpro tect

mode, so that all sectors are unprotected after chip

unprotect is completed to incorporate any changes in

the code. It is recommended to protect all sectors before

activating chip unprotect mode.

T o activ ate this mode , the programming equipment m ust

force VID on control pin OE# and address pin A9. The

CE# pins must be set at VIL. Pins A6 must be set to

VIH. (see Table 2) Refer to chip unprotect algo rithm and

wavef o rm for the chip unpro tect algo rithm. The unprotect

mechanism begins on the f alling edge o f the WE# pulse

and is terminated on the rising edge.

MX29LA128M T/B also pro vides ano ther metho d. Which

requires VID on the RESET# only. This method can be

implemented either in-system or via programming equipment. This method uses standard microprocessor bus

cycle timing.

It is also possible to determine if the chip is unprotect in

the system by writing the Read Silicon ID command.

Perf orming a read o peratio n with A1=VIH, it will pro duce

00H at data outputs (Q0-Q7) f o r an unpro tect sector . It is

noted that all sectors are unprotected after the chip

unprotect algorithm is completed.

WRITE PROTECT (WP#)

last protected o r unpro tect using the method described in

"Sector/Secto r Gro up Pro tection and Chip Unpro tect".

Note that the WP# pin must no t be left flo ating o r unco nnected; inconsistent behavior of the device may result.

TEMPORARY SECTOR GROUP UNPROTECT

OPERATION

This feature allows temporary unprotect of previously

protected secto r to change data in-system. The Temporary Sector Unprotect mode is activated by setting the

RESET# pin to VID(11.5V -12.5V). During this mo de, fo rmerly protected sectors can be programmed or erased

as unprotect sector. Once VID is remove from the RESET# pin, all the previously protected sectors are protected again.

SILICON ID READ OPERATION

Flash memories are intended for use in applications where

the local CPU alters memory contents. As such, manufacturer and device codes must be accessible while the

device resides in the target system. PROM programmers typically access signature codes by raising A9 to

a high vo ltage. Howe ver , m ultiplexing high v o ltage onto

address lines is not generally desired system design practice.

MX29LA128M T/B pro vides hardware metho d to access

the silicon ID read o peratio n. Which metho d requires VID

on A9 pin, VIL on CE#, OE#, A6, and A1 pins. Which

apply VIL o n A0 pin, the de vice will output MXIC's manufacture co de of which apply VIH o n A0 pin, the device will

output MX29LA128M T/B de vice cod e.

The write protect function provides a hardware method

to protect all sectors witho ut using VID.

If the system asserts VIL on the WP# pin, the device

disables pro gram and erase functio ns in all sectors independently of whether those sectors were protected or

unprotect using the method described in Sector/Sector

Group Pro tectio n and Chip Unpro tect".

If the system asserts VIH on the WP# pin, the device

reverts to whether the sectors were last set to be protected or unprotect. That is, sector protection or

unprotectio n fo r the secto rs depends on whether they w ere

P/N:PM1170

VERIFY SECTOR GROUP PROTECT STATUS

OPERATION

MX29LA128M T/B pro vides hardware metho d f or secto r

group protect status verify. Which method requires VID

on A9 pin, VIH on WE# and A1 pins, VIL on CE#, OE#,

A6, and A0 pins, and secto r address on A16 to A21 pins.

Which the identified sector is protected, the device will

output 01H. Which the identified sector is no t pro tect, the

device will o utput 00H.

REV. 0.04, JUL. 11, 2005

23

MX29LA128M T/B

DATA PROTECTION

The MX29LA128M T/B is designed to offer protection

against accidental erasure or programming caused by

spurious system level signals that may exist during power

transition. During power up the device automatically resets the state machine in the Read mode. In addition,

with its control register architecture, alteration of the

memory contents only occurs after successful completion of specific command sequences. The device also

incorpo rates sev eral features to prev ent inadvertent write

cycles resulting from VCC power-up and pow er-down transition or system noise.

SECURED SILICON SECTOR

The MX29LA128M T/B features a OTP memory region

where the system may access through a command sequence to create a permanent par t identification as so

called Electronic Serial Number (ESN) in the device.

Once this region is programmed, any further modificatio n on the regio n is impo ssible. The secured silicon sector is a 128 words in length, and uses a Secured Silicon

Sector Indicator Bit (Q7) to indicate whether or not the

Secured Silicon Sector is locked when shipped from the

factory. This bit is permanently set at the factory and

cannot be changed, which prevent duplication of a factory locked part. This ensures the security of the ESN

once the product is shipped to the field.

The MX29LA128M T/B offers the device with Secured

Silicon Sector either factory locked or customer lockable. The f actory-lo cked versio n is alwa ys protected when

shipped from the factory , and has the Secured Silicon

Sector Indicator Bit permanently set to a "1". The customer-lockable version is shipped with the Secured Silicon Sector unprotected, allowing customers to utilize that

sector in any form they prefer. The customer-lockable

version has the secured sector Indicator Bit permanently

set to a "0". Theref ore, the Secured Silico n Sector Indicator Bit pre v ents custo mer, lo ckab le device from being

used to replace devices that are factory locked.

The system access the Secured Silicon Sector through

a command sequence (refer to "Enter Secured Silicon/

Exit Secured Silicon Secto r co mmand Sequence). After

the system has written the Enter Secured Silicon Secto r

command sequence, it may read the Secured Silicon

Sector by using the address normally occupied by the

first sector SA0. Once entry the Secured Silicon Secto r

the operatio n o f boo t secto rs is disabled but the o peratio n

of main sectors is as normally. This mode of operation

continues until the system issues the Exit Secured Silicon Secto r co mmand sequence, o r until power is remo ved

from the device. On power-up, or following a hardware

reset, the device rev erts to sending co mmand to secto r

SA0.

Secured Silicon ESN factory Customer

Sector address locked lockable

range

000000h-000007h ESN Determined by

000008h-00007Fh Unavailable Customer

FACTORY LOCKED:Secured Silicon Sector

Programmed and Protected At the Factory

In device with an ESN, the Secured Silicon Sector is

protected when the device is shipped from the factory.

The Secured Silicon Sector cannot be modified in any

way. A f actory lo cked de vice has an 8-wo rd rando m ESN

at address 000000h-000007h.

CUSTOMER LOCKABLE:Secured Silicon

Sector NOT Programmed or Protected At the

Factory

As an alternative to the factory-locked version, the device

may be ordered such that the customer may program

and protect the 128-word Secured Silicon Sector.

Programming and protecting the Secured Silicon Sector

must be used with caution since, once protected, there

is no procedure available for unprotected the Secured

Silicon Sector area and none of the bits in the Secured

Silicon Sector memory space can be modified in any

way.

The Secured Silicon Sector area can be protected using

one of the following procedures:

Write the three-cycle Enter Secured Silicon Sector Region

command sequence, and then follow the in-system

sector protect algorithm as shown in Figure 15, except

that RESET# may be at either VIH or VID . This allo ws insystem protection of the Secured Silicon Sector without

raising any device pin to a high voltage. Note that method

is only applicab le to the Secured Silico n Secto r.

P/N:PM1170

REV. 0.04, JUL. 11, 2005

24

MX29LA128M T/B

Write the three-cycle Enter Secured Silicon Secto r Regio n

co mmand sequence, and then alternate method of secto r

protectio n described in the :Secto r Group Pro tectio n and

Unprotect" section.

Once the Secured Silicon Sector is programmed, locked

and verified, the system must write the Exit Secured

Silicon Sector Region command sequence to return to

reading and writing the remainder of the arra y .

LOW VCC WRITE INHIBIT

When VCC is less than VLKO the device does not accept any write cycles. This protects data during VCC

power-up and power-do wn. The command register and

all internal program/erase circuits are disabled, and the

device resets. Subsequent writes are igno red until VCC

is greater than VLKO . The system must pro vide the proper

signals to the control pins to prevent unintentional write

when VCC is greater than VLK O.

WRITE PULSE "GLITCH" PROTECTION

POWER SUPPLY DE COUPLING

In order to reduce power switching effect, each device

should have a 0.1uF ceramic capacitor connected between its VCC and GND .

Noise pulses of less than 5ns (typical) on CE# or WE#

will not initiate a write cycle.

LOGICAL INHIBIT

Writing is inhibited by holding any one of OE# = VIL,

CE# = VIH o r WE# = VIH. T o initiate a write cycle CE#

and WE# must be a logical zero while OE# is a logical

one.

POWER-UP SEQUENCE

The MX29LA128M T/B pow ers up in the Read only mo de.

In addition, the memory contents may only be altered

after successful completion of the predefined command

sequences.

POWER-UP WRITE INHIBIT

If WE#=CE#=VIL and OE#=VIH during power up, the

device does not accept commands on the rising edge of

WE#. The internal state machine is automatically reset

to the read mode on power-up.

P/N:PM1170

REV. 0.04, JUL. 11, 2005

25

MX29LA128M T/B

SOFTWARE COMMAND DEFINITIONS

Erase Resume (30H) commands are valid only while the

Sector Erase operation is in progress. Either of the two

Device operations are selected by writing specific address and data sequences into the command register.

reset command sequences will reset the device (when

applicable).

Writing incorrect address and data values or writing them

in the improper sequence will reset the device to the

read mod e. Table 3 defines the valid register command

sequences. Note that the Erase Suspend (B0H) and

All addresses are latched on the f alling edge of WE# or

CE#, whichever happens later. All data are latched on

rising edge of WE# o r CE#, whichev er happens first.

TABLE 3. MX29LA128M T/B COMMAND DEFINITIONS

First Bus Second Bus Third Bus Fourth Bus Fifth Bus Sixth Bus

Command Bus Cycle Cycle Cycle Cycle Cycle Cycle

Cycles Addr Data Addr Data Addr Data Addr Data Addr Data Addr Data

Read (Note 5) 1 RA R D

Reset (Note 6) 1 XXX F0

Automatic Select (Note 7)

Manufacturer ID Word 4 555 AA 2AA 55 555 90 X00 C2H

Byte 4 AAA AA 555 55 AAA 90 X00 C2H

Device ID Word 4 555 AA 2AA 55 555 90 X01 ID1 X0E ID2 X0F ID3

(Note 8) Byte 4 AAA AA 555 55 AAA 90 X02 ID1 X1C ID2 X1E ID3

Secured Sector Fact- Word 4 555 AA 2AA 55 555 90 X03 see

ory Protect (Note 9) Byte 4 AAA AA 555 55 AAA 90 X06 note 9

Sector Group Protect Word 4 555 AA 2AA 55 555 90 (SA)X02 XX00/

Verify (Note 10) Byte 4 AAA AA 555 55 AAA 90 (SA)X04 XX01

Enter Secured Silicon Word 3 55 5 AA 2AA 55 5 55 8 8

Sector Byte 3 AAA AA 555 55 AAA 88

Exit Secured Silicon Word 4 5 55 AA 2AA 5 5 55 5 90 XXX 0 0

Sector Byte 4 AAA AA 55 5 55 AAA 90 XXX 00

Program Word 4 555 AA 2AA 55 555 A0 PA PD

Byte 4 AAA AA 555 55 AAA A0 PA PD

Write to Buffer (Note 11) Word 6 555 AA 2AA 55 SA 25 SA WC PA PD WBL PD

Byte 6 AAA AA 555 55 SA 25 SA BC PA PD WBL PD

Program Buffer to Flash Word 1 SA 2 9

Byte 1 SA 29

Write to Buffer Abort Word 3 555 AA 2AA 55 555 F0

Reset (Note 12) Byte 3 AAA AA 55 5 55 AAA F0

Chip Erase Word 6 555 AA 2AA 55 55 5 80 55 5 AA 2 AA 5 5 555 1 0

Byte 6 AAA AA 555 55 AAA 80 AAA AA 555 55 AAA 10

Sector Erase Word 6 55 5 AA 2 AA 55 55 5 8 0 55 5 AA 2AA 55 SA 30

Byte 6 AAA AA 555 55 AAA 80 AAA AA 555 55 SA 30

Program/Erase Suspend (Note 13) 1 XXX B0

Program/Erase Resume (Note 14) 1 XXX 30

CFI Query (Note 15) Word 1 55 9 8

Byte 1 A A 98

P/N:PM1170

REV. 0.04, JUL. 11, 2005

26

MX29LA128M T/B

Legend:

X=Don't care

RA=Address of the memory location to be read.

RD=Data read from location RA during read operation.

PA=Address o f the memo ry lo catio n to be pro grammed.

Addresses are latched on the f alling edge o f the WE# or

CE# pulse, whichever happen later .

DDI=Data of device identifier

C2H for manufacture code

Notes:

1. See Table 1 f o r descriptions o f b us oper ations .

2. All values are in hexadecimal.

3. Except when reading array or auto matic select data, all bus cycles are write o peratio n.

4. Address bits are do n't care f or unloc k and co mmand cycles , e xcept when PA or SA is required.

5. No unlo ck o r co mmand cycles required when de vice is in read mo de.

6. The Reset co mmand is required to return to the read mo de when the device is in the auto matic select mo de o r if

Q5 goes high.

7. The fourth cycle of the auto matic select command sequence is a read cycle.

8. The device ID m ust be read in three cycles. The data is 01h fo r top bo o t and 00h f or bottom bo o t.

9. If WP# protects the top two address sectors, the data is 98h for factory locked and 18h for not factory locked. If

WP# protects the botto m two address sectors, the data is 88h for facto ry lo c k ed and 08h f or not f actor lo c ked.

10. The data is 00h for an unprotected secto r/secto r blo c k and 01h fo r a pro tected secto r/sector blo c k.

11. The total number o f cycles in the co mmand sequence is determined by the n umber o f words written to the write

buffer . The maximum number o f cycles in the co mmand sequence is 21(W ord Mo de) / 37(Byte Mo de).

12 . Command sequence resets device f or ne xt command after abo rted write-to-buffer o peration.

13. The system may read and prog ram functions in no n-erasing secto rs, o r enter the auto matic select mo de, when in

the erase Suspend mo de. The Erase Suspend co mmand is v alid only during a secto r erase o peratio n.

14. The Erase Resume command is valid only during the Erase Suspend mod e.

15. Command is valid when de vice is ready to read arr ay data or when device is in automatic select mo de.

PD=Data to be programmed at location PA. Data is

latched on the rising edge o f WE# o r CE# pulse .

SA=Address of the sector to be erase or verified (in

autoselect mode).

Address bits A21-A12 uniquely select any secto r .

WBL=Write Buffer Location. Address must be within the

same write buffer page as PA.

WC=Word Count. Number of write buffer locations to load

minus 1.

BC=Byte Count. Number of write buffer locations to load

minus 1.

P/N:PM1170

REV. 0.04, JUL. 11, 2005

27

MX29LA128M T/B

READING ARRAY DATA

The device is automatically set to reading array data

after device power-up. No commands are required to retrieve data. The device is also ready to read array data

after completing an Automatic Program or Automatic

Erase algorithm.

After the device accepts an Erase Suspend command,

the device enters the Erase Suspend mode. The system can read array data using the standard read timings, except that if it reads at an address within erasesuspended sectors, the device outputs status data. After completing a programming operation in the Erase

Suspend mode, the system may once again read array

data with the same exception. See Erase Suspend/Erase

Resume Commands for more information on this mode.

The system must issue the reset command to re-enable the device for reading array data if Q5 goes high, or

while in the automatic select mode. See the "Reset Command" section, next.

RESET COMMAND

array data (also applies during Erase Suspend).

SILICON ID READ COMMAND SEQUENCE

The SILICON ID READ command sequence allows the

host system to access the manufacturer and devices

codes, and determine whether or not a sector is protected. T ab le 2 shows the address and data requirements.

This method is an alternative to that shown in Table 1,

which is intended for PROM programmers and requires

VID on address bit A9.

The SILICON ID READ command sequence is initiated

by writing two unlock cycles, followed by the SILICON

ID READ command. The device then enters the SILICON ID READ mode, and the system may read at any

address any number of times, without initiating another

command sequence. A read cycle at address XX00h

retrieves the manufacturer code. A read cycle at address

XX01h returns the device code. A read cycle containing

a sector address (SA) and the address 02h returns 01h if

that sector is protected, or 00h if it is unprotected. Refer

to T a ble fo r valid sector addresses.

Writing the reset command to the device resets the device to reading array data. Address bits are don't care for

this command.

The reset command may be written between the sequence cycles in an erase command sequence before

erasing begins. This resets the device to reading array

data. Once er asure begins, howe ver , the device igno res

reset commands until the operation is complete.

The reset command may be written between the sequence cycles in a program command sequence before

programming begins. This resets the device to reading

array data (also applies to programming in Erase Suspend mode). Once programming begins, however, the

device ignores reset commands until the operation is

complete.

The reset command may be written between the sequence cycles in an SILICON ID READ command sequence. Once in the SILICON ID READ mode, the reset

command must be written to return to reading array data

(also applies to SILICON ID READ during Erase Suspend).

The system must write the reset command to exit the

automatic select mode and return to reading array data.

BYTE/WORD PROGRAM COMMAND SEQUENCE

The command sequence requires four bus cycles, and

is initiated by writing two unlock write cycles, followed

by the pro gram set-up co mmand. The pro gram address

and data are written next, which in turn initiate the Embedded Program algorithm. The system is not required

to provide further controls or timings. The device automatically generates the program pulses and verifies the

progr ammed cell margin. Tab le 3 shows the address and

data requirements for the byte program command sequence.

When the Embedded Program algorithm is complete, the

device then returns to reading array data and addresses

are no longer latched. The system can determine the

status of the pro g ram o peratio n b y using Q7, Q6, or R Y/

BY#. See "Write Operation Status" for information on

these status bits.

If Q5 goes high during a program or erase operation,

writing the reset command returns the device to reading

P/N:PM1170

Any commands written to the device during the Embedded Program Algorithm are ignored. Note that a hard-

REV. 0.04, JUL. 11, 2005

28

MX29LA128M T/B

ware reset immediately terminates the programming o peration. The Byte/Word Program command sequence

should be reinitiated once the device has reset to reading array data, to ensure data integrity.

Programming is allowed in any sequence and across

sector boundaries. A bit cannot be programmed from a

"0" back to a "1". Attempting to do so may halt the operation and set Q5 to "1", or cause the Data# Polling

algorithm to indicate the operation was successful. However, a succeeding read will show that the data is still

"0". Only erase operations can convert a "0" to a "1".

Write Buffer Programming

Write Buffer Programming allows the system write to a

maximum of 16 words/32 bytes in one programming operation. This results in faster eff ective pro gramming time

than the standard programming algorithms. The Write

Buffer Programming command sequence is initiated by

first writing two unloc k cycles. This is f ollowed b y a third

write cycle containing the Write Buffer Load command