MXIC MX29F100TTC-55, MX29F100TTC-70, MX29F100TTC-90, MX29F100TMC-12, MX29F100TMC-55 Datasheet

...

FEATURES

MX29F100T/B

1M-BIT [128Kx8/64Kx16] CMOS FLASH MEMORY

•5V±10% for read, erase and write operation

• 131072x8/ 65536x16 switchable

• Fast access time:55/70/90/120ns

• Low power consumption

- 40mA maximum active current(5MHz)

- 1uA typical standby current

• Command register architecture

- Byte/ Word Programming (7us/ 12us typical)

- Erase (16K-Bytex1, 8K-Bytex2, 32K-Bytex1, and

64K-Byte x1)

• Auto Erase (chip) and Auto Program

- Automatically erase any combination of sectors or

with Erase Suspend capability.

- Automatically program and verify data at specified

address

• Status Reply

- Data polling & Toggle bit for detection of program

and erase cycle completion.

• Compatibility with JEDEC standard

- Pinout and software compatible with single-power

supply Flash

- Superior inadvertent write protection

• Sector protection

- Hardware method to disable any combination of

sectors from program or erase operations

- Sector protect/unprotect for 5V only system or 5V/

12V system

• 100,000 minimum erase/program cycles

• Latch-up protected to 100mA from -1 to VCC+1V

• Boot Code Sector Architecture

- T = Top Boot Sector

- B = Bottom Boot Sector

• Low VCC write inhibit is equal to or less than 3.2V

• Package type:

- 44-pin SOP

- 48-pin TSOP

• Ready/Busy pin(RY/BY)

- Provides a hardware method or detecting program

or erase cycle completion

• Erase suspend/ Erase Resume

- Suspend an erase operation to read data from, or

program data to a sector that is not being erased,

then resume the erase operation.

• Hardware RESET pin

- Hardware method of resetting the device to reading

the device to reading array data.

• 20 years data retention

GENERAL DESCRIPTION

The MX29F100T/B is a 1-mega bit Flash memory

organized as 131,072 bytes or 65,536 words.

MXIC's Flash memories offer the most cost-effective

and reliable read/write non-volatile random access

memory. The MX29F100T/B is packaged in 44-pin

SOP and 48-pin TSOP. It is designed to be reprogrammed and erased in-system or in-standard

EPROM programmers.

The standard MX29F100T/B offers access time as

fast as 55ns, allowing operation of high-speed microprocessors without wait states. To eliminate bus

contention, the MX29F100T/B has separate chip

enable (CE) and output enable (OE) controls.

MXIC's Flash memories augment EPROM functionality with in-circuit electrical erasure and

programming. The MX29F100T/B uses a command

register to manage this functionality. The command

register allows for 100% TTL level control inputs and

P/N:PM0548 REV. 1.2, NOV. 12, 2001

fixed power supply levels during erase and

programming, while maintaining maximum EPROM

compatibility.

MXIC Flash technology reliably stores memory contents even after 100,000 erase and program cycles.

The MXIC cell is designed to optimize the erase and

programming mechanisms. In addition, the combination of advanced tunnel oxide processing and low

internal electric fields for erase and programming

operations produces reliable cycling. The

MX29F100T/B uses a 5.0V±10% VCC supply to

perform the High Reliability Erase and auto

Program/Erase algorithms.

The highest degree of latch-up protection is

achieved with MXIC's proprietary non-epi process.

Latch-up protection is proved for stresses up to 100

milliamps on address and data pin from -1V to VCC

+ 1V.

1

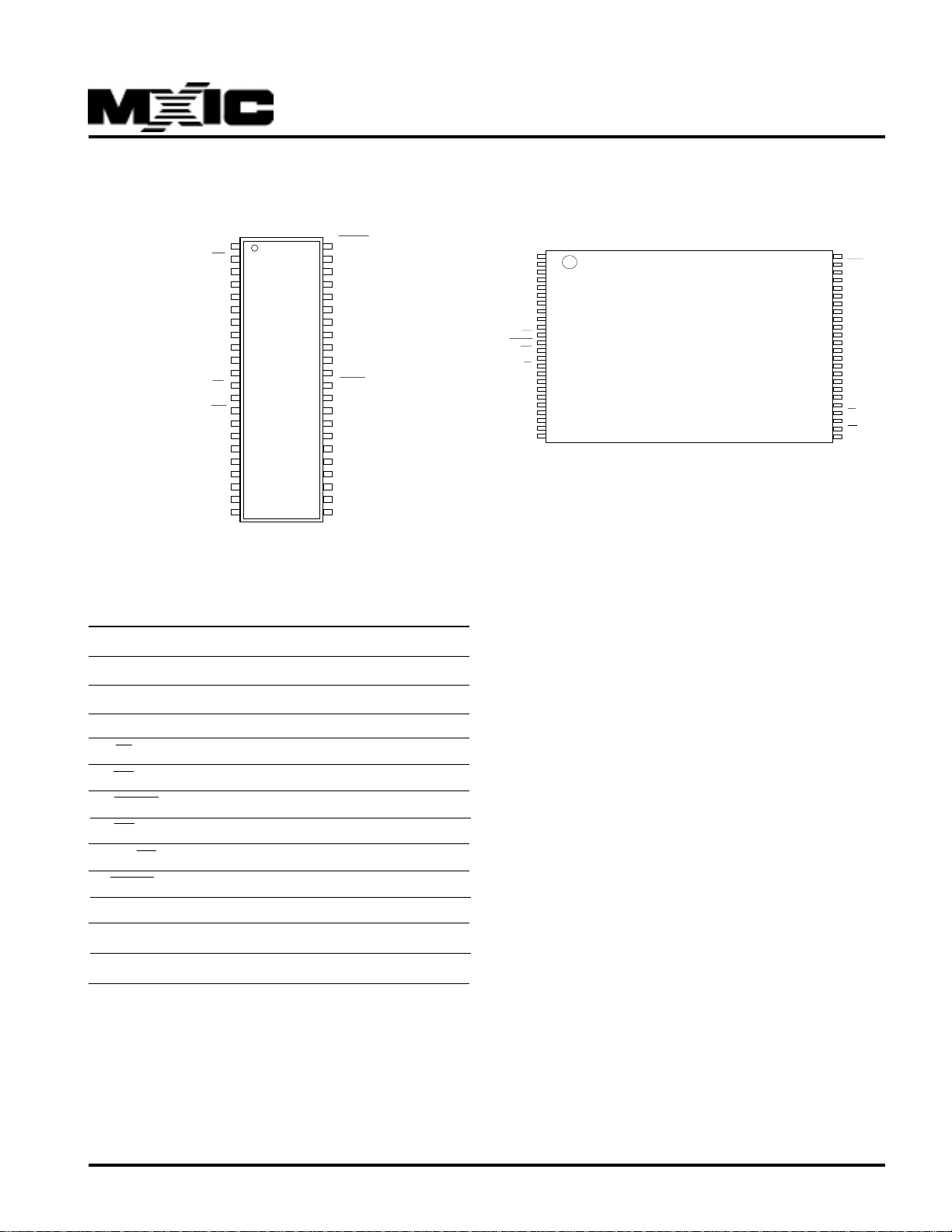

PIN CONFIGURATIONS

MX29F100T/B

44SOP(500mil)

NC

RY/BY

NC

A7

A6

A5

A4

A3

A2

A1

A0

CE

GND

OE

Q0

Q8

Q1

Q9

Q2

Q10

Q3

Q11

PIN DESCRIPTION:

SYMBOL PIN NAME

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

RESET

44

WE

43

A8

42

A9

41

A10

40

A11

39

A12

38

A13

37

A14

36

A15

35

NC

34

BYTE

33

GND

32

MX29F100T/B

Q15/A-1

31

Q7

30

Q14

29

Q6

28

Q13

27

Q5

26

Q12

25

Q4

24

VCC

23

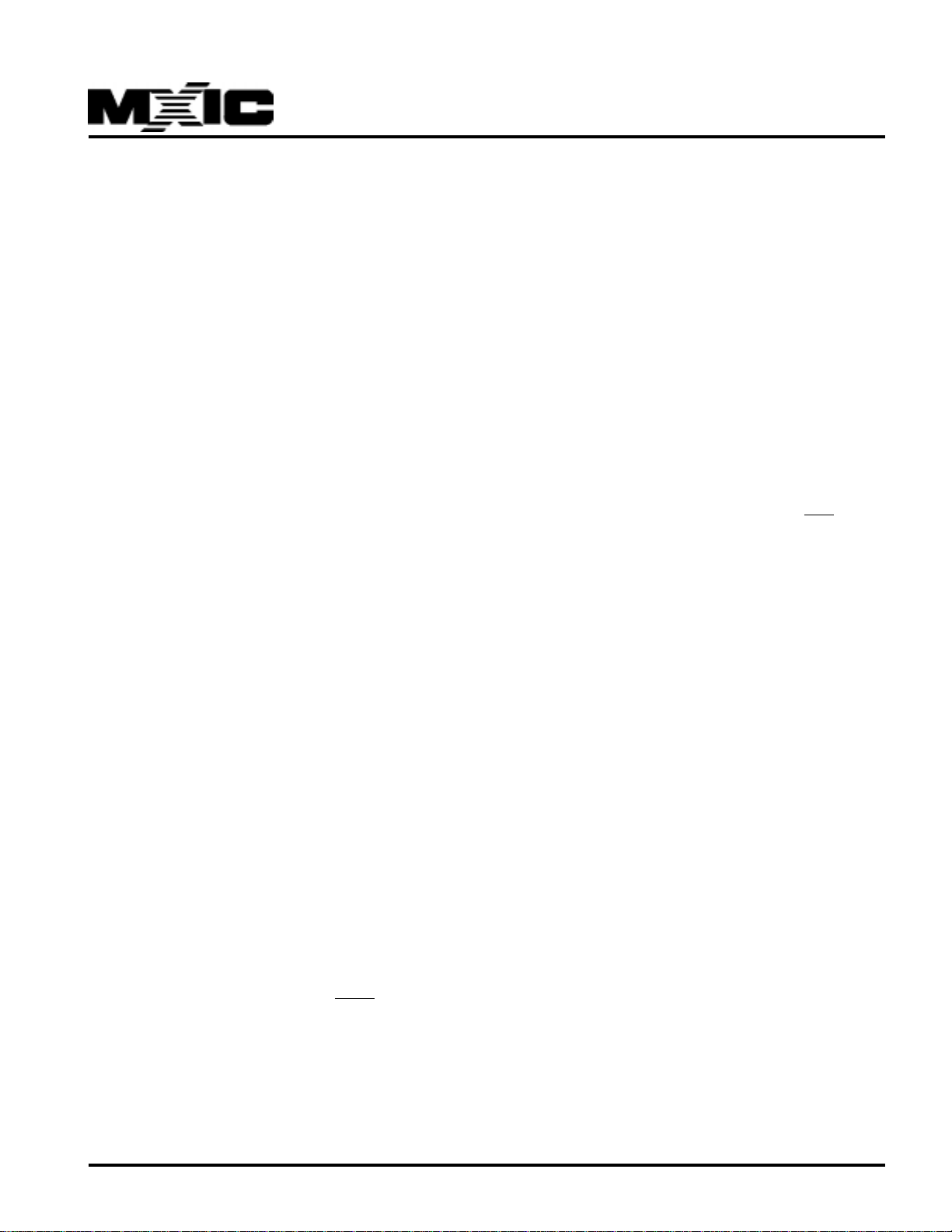

48 TSOP(TYPE I) (12mm x 20mm)

1

A15

2

A14

3

A13

4

A12

5

A11

6

A10

7

A9

8

A8

9

NC

10

NC

11

WE

RESET

RY/BY

12

13

NC

14

NC

15

16

NC

17

NC

18

A7

19

A6

20

A5

21

A4

22

A3

23

A2

24

A1

MX29F100T/B

(NORMAL TYPE)

48

NC

47

BYTE

46

GND

45

Q15/A-1

44

Q7

43

Q14

42

Q6

41

Q13

40

Q5

39

Q12

38

Q4

37

VCC

36

Q11

35

Q3

34

Q10

33

Q2

32

Q9

31

Q1

30

Q8

29

Q0

28

OE

27

GND

26

CE

25

A0

A0-A15 Address Input

Q0-Q14 Data Input/Output

Q15/A-1 Q15(Word mode)/LSB addr.(Byte mode)

CE Chip Enable Input

OE Output Enable Input

RESET Hardware Reset Pin, Active low

WE Write Enable Input

RY/BY Ready/Busy Output

BYTE Word/Byte Selection Input

VCC Power Supply Pin (+5V)

GND Ground Pin

NC Pin Not Connected Internally

P/N:PM0548

REV. 1.2, NOV. 12, 2001

2

MX29F100T/B

SECTOR STRUCTURE

MX29F100T Top Boot Sector Addresses Tables

A15 A14 A13 A12 (x8)Address Range (x16) Address Range

SA0 0 X X X 00000h-0FFFFh 64KB 00000h-07FFFh 32KW

SA1 1 0 X X 10000h-17FFFh 32KB 08000h-0BFFFh 16KW

SA2 1 1 0 0 18000h-19FFFh 8KB 0C000h-0CFFFh 4KW

SA3 1 1 0 1 1A000h-1BFFFh 8KB 0D000h-0DFFFh 4KW

SA4 1 1 1 X 1C000h-1FFFFh 16KB 0E000h-0FFFFh 8KW

MX29F100B Bottom Boot Sector Addresses Tables

A15 A14 A13 A12 (x8)Address Range (x16) Address Range

SA0 0 0 0 X 00000h-03FFFh 16KB 00000h-01FFFh 8KW

SA1 0 0 1 0 04000h-05FFFh 8KB 02000h-02FFFh 4KW

SA2 0 0 1 1 06000h-07FFFh 8KB 03000h-03FFFh 4KW

SA3 0 1 X X 08000h-0FFFFh 32KB 04000h-07FFFh 16KW

SA4 1 X X X 10000h-1FFFFh 64KB 08000h-0FFFFh 32KW

P/N:PM0548

REV. 1.2, NOV. 12, 2001

3

SECTOR DIAGRAM

CE

OE

WE

CONTROL

INPUT

LOGIC

PROGRAM/ERASE

HIGH VOLTAGE

MX29F100T/B

WRITE

STATE

MACHINE

(WSM)

A0-A15

A-1/Q15

ADDRESS

LATCH

AND

BUFFER

X-DECODER

MX29F100T/B

FLASH

ARRA Y

Y-DECODER

Y-PASS GATE

SENSE

AMPLIFIER

STATE

REGISTER

ARRAY

SOURCE

HV

COMMAND

DATA

DECODER

PGM

DATA

HV

COMMAND

DATA LATCH

PROGRAM

DATA LATCH

P/N:PM0548

Q0~Q14

I/O BUFFER

REV. 1.2, NOV. 12, 2001

4

MX29F100T/B

AUTOMATIC PROGRAMMING

The MX29F100T/B is byte/ word programmable using

the Automatic Programming algorithm. The Automatic

Programming algorithm does not require the system to

time out sequence or verify the data programmed. The

typical chip programming time of the MX29F100T/B at

room temperature is less than 3.5 seconds.

AUTOMATIC CHIP ERASE

The entire chip is bulk erased using 10 ms erase

pulses according to MXIC's Automatic Chip Erase

algorithm. Typical erasure at room temperature is

accomplished in less than 3 seconds. The Automatic

Erase algorithm automatically programs the entire

array prior to electrical erase. The timing and

verification of electrical erase are internally controlled

by the device.

AUTOMATIC SECTOR ERASE

The MX29F100T/B is sector(s) erasable using MXIC's

Auto Sector Erase algorithm. Sector erase modes allow

sectors of the array to be erased in one erase cycle. The

Automatic Sector Erase algorithm automatically programs the specified sector(s) prior to electrical erase.

The timing and verification of electrical erase are internally controlled by the device.

AUTOMATIC PROGRAMMING ALGORITHM

AUTOMATIC ERASE ALGORITHM

MXIC's Automatic Erase algorithm requires the user to

write commands to the command register using standard microprocessor write timings. The device will

automatically pre-program and verify the entire array.

Then the device automatically times the erase pulse

width, verifies the erase and counts the number of

sequences. A status bit toggling between consecutive

read cycles provides feedback to the user as to the

status of the programming operation.

Register contents serve as inputs to an internal statemachine which controls the erase and programming

circuitry. During write cycles, the command register

internally latches address and data needed for the

programming and erase operations. During a system

write cycle, addresses are latched on the falling edge,

and data are latched on the rising edge of WE.

MXIC's Flash technology combines years of EPROM

experience to produce the highest levels of quality, reliability, and cost effectiveness. The MX29F100T/B electrically erases all bits simultaneously using Fowler-Nordheim tunneling. The bytes are programmed by using the

EPROM programming mechanism of hot electron

injection.

During a program cycle, the state-machine will control the

program sequences and command register will not respond to any command set. During a Sector Erase cycle,

the command register will only respond to Erase Suspend command. After Erase Suspend is complete, the

device stays in read mode. After the state machine has

completed its task, it will allow the command register to

respond to its full command set.

MXIC's Automatic Programming algorithm requires

the user to only write program set-up commands

(include 2 unlock write cycle and A0H) and a program

command (program data and address). The device

automatically times the programming pulse width,

verifies the program and counts the number of

sequences. A status bit similar to DATA polling and a

status bit toggling between consecutive read cycles,

provides feedback to the user as to the status of the

programming operation.

P/N:PM0548

REV. 1.2, NOV. 12, 2001

5

MX29F100T/B

TABLE1. SOFTWARE COMMAND DEFINITIONS

First Bus Second Bus Third Bus Fourth Bus Fifth Bus Sixth Bus

Command Bus Cycle Cycle Cycle Cycle Cycle Cycle

Cycle Addr Data Addr Data Addr Data Addr Data Addr Data Addr Data

Reset 1 XXXH F0H

Read 1 RA RD

Read Silicon ID Word 4 555H AAH 2AAH 55H 555H 90H ADI DDI

Byte 4 AAAH AAH 555H 55H AAAH 90H ADI DDI

Sector Protect Word 4 555H AAH 2AAH 55H 555H 90H (SA)

Verify x02H XX01H

Byte 4 AAAH AAH 555H 55H AAAH 90H (SA) 00H

Porgram Word 4 555H AAH 2AAH 55H 555H A0H PA PD

Byte 4 AAAH AAH 555H 55 H AAAH A 0H PA PD

Chip Erase Word 6 555H AAH 2AAH 55H 555H 80H 555H AAH 2AAH 55H 555H 10H

Byte 6 AAAH AAH 555H 55H AAAH 80H AAAH AAH 555H 55H AAAH 10H

Sector Erase Word 6 555H AAH 2AAH 55 H 555H 8 0H 555H AAH 2AAH 55H SA 30H

Byte 6 AAAH AAH 555H 55 H AAAH 80H AAAH AAH 555H 55H SA 30H

Sector Erase Suspend 1 XXXH B 0H

Sector Erase Resume 1 XXXH 30 H

Unlock for sector 6 555H AAH 2AAH 5 5H 555H 80H 555H AAH 2AAH 5 5H 555H 20H

protect/unprotect

XX00H

x04H 01H

Note:

1. ADI = Address of Device identifier; A1=0, A0 = 0 for manufacture code,A1=0, A0 = 1 for device code.

(Refer to table 3)

DDI = Data of Device identifier : C2H for manufacture code, D9H/DFH(x8) and 22D9H/22DFH(x16) for device

code.

X = X can be VIL or VIH

RA=Address of memory location to be read.

RD=Data to be read at location RA.

2. PA = Address of memory location to be programmed.

PD = Data to be programmed at location PA.

SA = Address to the sector to be erased.

3. The system should generate the following address patterns: 555H or 2AAH to Address A10~A0 in word mode/

AAAH or 555H to Address A10~A-1 in byte mode.

Address bit A11~A15=X=Don't care for all address commands except for Program Address (PA) and Sector

Address (SA). Write Sequence may be initiated with A11~A15 in either state.

4. For Sector Protect Verify Operation : If read out data is 01H, it means the sector has been protected. If read out

data is 00H, it means the sector is still not being protected.

P/N:PM0548

REV. 1.2, NOV. 12, 2001

6

COMMAND DEFINITIONS

Device operations are selected by writing specific address and data sequences into the command register.

Writing incorrect address and data values or writing

them in the improper sequence will reset the device to

the read mode. Table 1 defines the valid register command sequences. Note that the Erase Suspend (B0H)

and Erase Resume (30H) commands are valid only

while the Sector Erase operation is in progress. Either

of the two reset command sequences will reset the

device(when applicable).

MX29F100T/B

P/N:PM0548

REV. 1.2, NOV. 12, 2001

7

TABLE 2. MX29F100T/B BUS OPERATION

Pins CE OE WE A0 A1 A6 A9 D0 ~ Q15

Mode

MX29F100T/B

Read Silicon ID L L H L L X V

(2) C2H(Byte mode)

ID

Manfacturer Code(1) 00C2H(Word mode)

Read Silicon ID L L H H L X VID(2) D9H/DFH(Byte mode)

Device Code(1) 22D9H/22DFH

(Word mode)

Read L L H A0 A1 A6 A9 D

OUT

Standby H X X X X X X HIGH Z

Output Disable L H H X X X X HIGH Z

Write L H L A0 A1 A6 A9 DIN(3)

Sector Protect with 12V L VID(2) L X X L VID(2) X

system(6)

Chip Unprotect with 12V L VID(2) L X X H VID(2) X

system(6)

Verify Sector Protect L L H X H X VID(2) Code(5)

with 12V system

Sector Protect without 12V L H L X X L H X

system (6)

Chip Unprotect without 12V L H L X X H H X

system (6)

Verify Sector Protect/Unprotect L L H X H X H Code(5)

without 12V system (7)

Reset X X X X X X X HIGH Z

NOTES:

1. Manufacturer and device codes may also be accessed via a command register write sequence. Refer to Table 1.

2. VID is the Silicon-ID-Read high voltage, 11.5V to 12.5V.

3. Refer to Table 1 for valid Data-In during a write operation.

4. X can be VIL or VIH.

5. Code=00H/0000H means unprotected.

Code=01H/0001H means protected.

A15~A12=Sector address for sector protect.

6. Refer to sector protect/unprotect algorithm and waveform.

Must issue "unlock for sector protect/unprotect" command before "sector protect/unprotect without 12V system" command.

7. The "verify sector protect/unprotect without 12V sysytem" is only following "Sector protect/unprotect without 12V system"

command.

P/N:PM0548

8

REV. 1.2, NOV. 12, 2001

MX29F100T/B

READ/RESET COMMAND

The read or reset operation is initiated by writing the

read/reset command sequence into the command

register. Microprocessor read cycles retrieve array

data. The device remains enabled for reads until the

command register contents are altered.

If program-fail or erase-fail happen, the write of F0H

will reset the device to abort the operation. A valid

command must then be written to place the device in

the desired state.

SILICON-ID-READ COMMAND

Flash memories are intended for use in applications

where the local CPU alters memory contents. As such,

manufacturer and device codes must be accessible

while the device resides in the target system. PROM

programmers typically access signature codes by raising A9 to a high voltage. However, multiplexing high

voltage onto address lines is not generally desired

system design practice.

The MX29F100T/B contains a Silicon-ID-Read operation to supplement traditional PROM programming

methodology. The operation is initiated by writing the

read silicon ID command sequence into the command

register. Following the command write, a read cycle

with A1=VIL, A0=VIL retrieves the manufacturer code

of C2H/00C2H. A read cycle with A1=VIL, A0=VIH

returns the device code of D9H/22D9H for

MX29F100T, DFH/22DFH for MX29F100B.

SET-UP AUTOMATIC CHIP/SECTOR ERASE

COMMANDS

Chip erase is a six-bus cycle operation. There are two

"unlock" write cycles. These are followed by writing

the "set-up" command 80H. Two more "unlock" write

cycles are then followed by the chip erase command

10H.

The Automatic Chip Erase does not require the device

to be entirely pre-programmed prior to executing the

Automatic Chip Erase. Upon executing the Automatic

Chip Erase, the device will automatically program and

verify the entire memory for an all-zero data pattern.

When the device is automatically verified to contain an

all-zero pattern, a self-timed chip erase and verify

begin. The erase and verify operations are completed

when the data on Q7 is "1" at which time the device

returns to the Read mode. The system is not required

to provide any control or timing during these

operations.

When using the Automatic Chip Erase algorithm, note

that the erase automatically terminates when

adequate erase margin has been achieved for the

memory array(no erase verified command is required).

If the Erase operation was unsuccessful, the data on

Q5 is "1"(see Table 4), indicating the erase operation

exceed internal timing limit.

The automatic erase begins on the rising edge of the

last WE pulse in the command sequence and

terminates when the data on Q7 is "1" and the data on

Q6 stops toggling for two consecutive read cycles, at

which time the device returns to the Read mode.

P/N:PM0548

REV. 1.2, NOV. 12, 2001

9

MX29F100T/B

TABLE 3. EXPANDED SILICON ID CODE

Pins A0 A1 Q15~Q8 Q7 Q6 Q5 Q4 Q3 Q2 Q1 Q0 Code(Hex)

Manufacture code Word VIL VIL 00H 1 1 0 0 0 0 1 0 00C2H

Byte VIL VIL X 1 1 0 0 0 0 1 0 C2H

Device code Word VIH VIL 22H 1 1 0 1 1 0 0 1 22D9H

for MX29F100T Byte VIH VIL X 1 1 0 1 1 0 0 1 D 9H

Device code Word VIH VIL 22H 1 1 0 1 1 1 1 1 22DFH

for MX29F100B Byte VIH VIL X 1 1 0 1 1 1 1 1 DFH

Sector Protection X VIH X 0 0 0 0 0 0 0 1 01H(Protected)

Verification X VIH X 0 0 0 0 0 0 0 0 00H(Unprotected)

ERASE COMMANDS

The Automatic Sector Erase does not require the

device to be entirely pre-programmed prior to executing

the Automatic Set-up Sector Erase command and

Automatic Sector Erase command. Upon executing the

Automatic Sector Erase command, the device will

automatically program and verify the sector(s) memory

for an all-zero data pattern. The system does not

require to provide any control or timing during these

operations.

When the sector(s) is automatically verified to contain

an all-zero pattern, a self-timed sector erase and

verification begin. The erase and verification

operations are complete when the data on Q7 is "1"

and the data on Q6 stops toggling for two consecutive

read cycles, at which time the device returns to the

Read mode. The system does not require to provide

any control or timing during these operations.

When using the Automatic Sector Erase algorithm, note

that the erase automatically terminates when

adequate erase margin has been achieved for the

memory array (no erase verified command is

required). Sector erase is a six-bus cycle operation.

There are two "unlock" write cycles. These are

followed by writing the set-up command 80H. Two

more "unlock" write cycles are then followed by the

sector erase command 30H. The sector address is

latched on the falling edge of WE, while the

command(data) is latched on the rising edge of WE.

Sector addresses selected are loaded into internal

register on the sixth falling edge of WE. Each successive sector load cycle started by the falling edge of WE

must begin within 30us from the rising edge of the

preceding WE. Otherwise, the loading period ends and

internal auto sector erase cycle starts. (Monitor Q3 to

determine if the sector erase timer window is still open,

see section Q3, Sector Erase Timer.) Any command

other than Sector Erase (30H) or Erase Suspend (B0H)

during the time-out period resets the derice to read

mode.

ERASE SUSPEND

This command is only valid while the state machine is

executing Automatic Sector Erase operation, and therefore will only be responded to period during Automatic

Sector Erase operation. Writing the Erase Suspend

command during the Sector Erase time-out immediately

terminates the time-out immediately terminates the

time-out period and suspends the erase operation.

After this command has been executed, the command

register will initiate erase suspend mode. The state

machine will return to read mode automatically after

suspend is ready. At this time, state machine only

allows the command register to respond to the Read

Memory Array, Erase Resume and Program commands.

The system can determine the status of the program

operation using the Q7 or Q6 status bits, just as in the

standard program operation. After an erase-suspend

program operation is complete, the system can once

again read array data within non-suspended sectors.

P/N:PM0548

REV. 1.2, NOV. 12, 2001

10

Table 4. Write Operation Status

Status Q7 Q6 Q5 Q3 Q2 RY/BY

MX29F100T/B

Note1 Note2

Byte Program in Auto Program Algorithm Q7 Toggle 0 N/A No 0

Auto Erase Algorithm 0 Toggle 0 1 Toggle 0

Erase Suspend Read 1 No 0 N/A Toggle 1

(Erase Suspended Sector) Toggle

In Progress

Erase Suspended Mode Erase Suspend Read Data Data Data Data Data 1

(Non-Erase Suspended Sector)

Erase Suspend Program Q7 Toggle 0 N/A N/A 0

Byte Program in Auto Program Algorithm Q7 Toggle 1 N/A No 0

Exceeded

Time Limits Auto Erase Algorithm 0 Toggle 1 1 Toggle 0

Erase Suspend Program Q7 Toggle 1 N/A N/A 0

Toggle

Toggle

Note:

1. Q7 and Q2 require a valid address when reading status information. Refer to the appropriate subsection for further details.

2. Q5 switches to '1' when an Auto Program or Auto Erase operation has exceeded the maximum timing limits.

See "Q5:Exceeded Timing Limits " for more information.

P/N:PM0548

REV. 1.2, NOV. 12, 2001

11

MX29F100T/B

ERASE RESUME

This command will cause the command register to clear

the suspend state and return back to Sector Erase mode

but only if an Erase Suspend command was previously

issued. Erase Resume will not have any effect in all other

conditions.Another Erase Suspend command can be

written after the chip has resumed erasing.

SET-UP AUTOMATIC PROGRAM COMMANDS

To initiate Automatic Program mode, a three-cycle

command sequence is required. There are two "unlock" write cycles. These are followed by writing the

Automatic Program command A0H.

Once the Automatic Program command is initiated,

the next WE pulse causes a transition to an active

programming operation. Addresses are latched on the

falling edge, and data are internally latched on the

rising edge of the WE pulse. The rising edge of WE

also begins the programming operation. The system

is not required to provide further controls or timings.

The device will automatically provide an adequate

internally generated program pulse and verify margin.

If the program opetation was unsuccessful, the data

on Q5 is "1"(see Table 4), indicating the program

operation exceed internal timing limit. The automatic

programming operation is completed when the data

read on Q6 stops toggling for two consecutive read

cycles and the data on Q7 and Q6 are equivalent to

data written to these two bits, at which time the device

returns to the Read mode(no program verify command

is required).

WRITE OPERATION STATUS

DATA POLLING-Q7

The MX29F100T/B also features Data Polling as a method

to indicate to the host system that the Automatic Program

or Erase algorithms are either in progress or completed.

While the Automatic Programming algorithm is in

operation, an attempt to read the device will produce the

complement data of the data last written to Q7. Upon

completion of the Automatic Program Algorithm an attempt

to read the device will produce the true data last written

to Q7. The Data Polling feature is valid after the rising edge

of the fourth WE pulse of the four write pulse sequences

for automatic program.

While the Automatic Erase algorithm is in operation, Q7

will read "0" until the erase operation is competed. Upon

completion of the erase operation, the data on Q7 will read

"1". The Data Polling feature is valid after the rising edge

of the sixth WE pulse of six write pulse sequences for

automatic chip/sector erase.

The Data Polling feature is active during Automatic

Program/Erase algorithm or sector erase time-out.(see

section Q3 Sector Erase Timer)

RY/BY:Ready/Busy

The RY/BY is a dedicated, open-drain output pin that

indicates whether an Automatic Erase/Program algorithm

is in progress or complete. The RY/BY status is valid after

the rising edge of the final WE pulse in the command

sequence. Since RY/BY is an open-drain output, several

RY/BY pins can be tied together in parallel with a pull-up

resistor to Vcc.

If the outputs is low (Busy), the device is actively erasing

or programming. (This includes programming in the

Erase Suspend mode.) If the output is high (Ready), the

device is ready to read array data (including during the

Erase Suspend mode), or is in the standby mode.

TOGGLE BIT-Q6

The MX29F100T/B features a "Toggle Bit" as a method to

indicate to the host system that the Auto Program/Erase

algorithms are either in progress or completed.

While the Automatic Program or Erase algorithm is in

progress, successive attempts to read data from the

device will result in Q6 toggling between one and zero.

Once the Automatic Program or Erase algorithm is

completed, Q6 will stop toggling and valid data will be

read. The toggle bit is valid after the rising edge of the

sixth WE pulse of the six write pulse sequences for chip/

sector erase.

The Toggle Bit feature is active during Automatic Program/

Erase algorithms or sector erase time-out.(see section

Q3 Sector Erase Timer)

P/N:PM0548

REV. 1.2, NOV. 12, 2001

12

MX29F100T/B

Q5

Exceeded Timing Limits

Q5 will indicate if the program or erase time has exceeded

the specified limits(internal pulse count). Under these

conditions Q5 will produce a "1". This time-out condition

indicates that the program or erase cycle was not

successfully completed. Data Polling and Toggle Bit are

the only operating functions of the device under this

condition.

If this time-out condition occurs during sector erase

operation, it specifies that a particular sector is bad and

it may not be reused. However, other sectors are still

functional and may be used for the program or erase

operation. The device must be reset to use other sectors.

Write the Reset command sequence to the device, and

then execute program or erase command sequence.

This allows the system to continue to use the other active

sectors in the device.

If this time-out condition occurs during the chip erase

operation, it specifies that the entire chip is bad or

combination of sectors are bad.

If this time-out condition occurs during the byte

programming operation, it specifies that the entire sector

containing that byte is bad and this sector maynot be

reused, (other sectors are still functional and can be

reused).

The time-out condition may also appear if a user tries to

program a non blank location without erasing. In this case

the device locks out and never completes the Automatic

Algorithm operation. Hence, the system never reads a

valid data on Q7 bit and Q6 never stops toggling. Once

the Device has exceeded timing limits, the Q5 bit will

indicate a "1". Please note that this is not a device failure

condition since the device was incorrectly used.

Q3

Sector Erase Timer

After the completion of the initial sector erase command

sequenc the sector erase time-out will begin. Q3 will

remain low until the time-out is complete. Data Polling

and Toggle Bit are valid after the initial sector erase

command sequence.

used to determine if the sector erase timer window is still

open. If Q3 is high ("1") the internally controlled erase

cycle has begun; attempts to write subsequent commands

to the device will be ignored until the erase operation is

completed as indicated by Data Polling or Toggle Bit. If

Q3 is low ("0"), the device will accept additional sector

erase commands. To insure the command has been

accepted, the system software should check the status of

Q3 prior to and following each subsequent sector erase

command. If Q3 were high on the second status check,

the command may not have been accepted.

Reading Toggle Bits Q6

Whenever the system initally begins reading toggle bit

status, it must read Q7-Q0 at least twice in a row to

determine whether a toggle bit is toggling. Typically, the

system would note and store the value of the toggle bit

after the first read. After the second read, the system

would compare the new value of the toggle bit with the

first. If the toggle bit is not toggling, the device has

completed the program or erase operation. The system

can read array data on Q7-Q0 on the following read cycle.

However, if after the initial two read cycles, the system

determines that the toggle bit is still toggling, the system

also should note whether the value of Q5 is high (see the

section on Q5). If it is, the system should then determine

again whether the toggle bit is toggling, since the toggle

bit may have stopped toggling just as Q5 went high. If the

toggle bit is no longer toggling, the device has successfully

completed the program ot erase operation. If it is still

toggling, the device did not complete the operation

successfully, and the system must write the reset command

to return to reading array data.

The remaining scenario is that system initially determines

that the toggle bit is toggling and Q5 has not gone high.

The system may continue to monitor the toggle bit and Q5

through successive read cycles, determining the status

as described in the previous paragraph. Alternatively, it

may choose to perform other system tasks. In this case,

the system must start at the beginning of the algorithm

when it returns to determine the status of the operation.

If Data Polling or the Toggle Bit indicates the device has

been written with a valid erase command, Q3 may be

P/N:PM0548

REV. 1.2, NOV. 12, 2001

13

MX29F100T/B

DATA PROTECTION

The MX29F100T/B is designed to offer protection against

accidental erasure or programming caused by spurious

system level signals that may exist during power transition.

During power up the device automatically resets the state

machine in the Read mode. In addition, with its control

register architecture, alteration of the memory contents

only occurs after successful completion of specific

command sequences. The device also incorporates

several features to prevent inadvertent write cycles

resulting from VCC power-up and power-down transition

or system noise.

TEMPORARY SECTOR UNPROTECT

This feature allows temporary unprotection of previously

protected sector to change data in-system. The Temporary

Sector Unprotect mode is activated by setting the RESET

pin to VID(11.5V-12.5V). During this mode, formerly

protected sectors can be programmed or erased as unprotected sector. Once VID is remove from the RESET

pin, all the previously protected sectors are protected

again.

WRITE PULSE "GLITCH" PROTECTION

SECTOR PROTECTION WITH 12V SYSTEM

The MX29F100T/B features hardware sector protection.

This feature will disable both program and erase operations

for these sectors protected. To activate this mode, the

programming equipment must force VID on address pin

A9 and control pin OE, (suggest VID = 12V) A6 = VIL and

CE = VIL.(see Table 2) Programming of the protection

circuitry begins on the falling edge of the WE pulse and is

terminated on the rising edge. Please refer to sector

protect algorithm and waveform.

To verify programming of the protection circuitry, the

programming equipment must force VID on address pin

A9 ( with CE and OE at VIL and WE at VIH. When A1=1,

it will produce a logical "1" code at device output Q0 for a

protected sector. Otherwise the device will produce 00H

for the unprotected sector. In this mode, the

address,except for A1, are in "don't care" state. Address

locations with A1 = VIL are reserved to read manufacturer

and device codes.(Read Silicon ID)

It is also possible to determine if the sector is protected in

the system by writing a Read Silicon ID command.

Performing a read operation with A1=VIH, it will produce

a logical "1" at Q0 for the protected sector.

Noise pulses of less than 5ns(typical) on CE or WE will not

initiate a write cycle.

LOGICAL INHIBIT

Writing is inhibite by holding any one of OE = VIL, CE =

VIH or WE = VIH. To initiate a write cycle CE and WE must

be a logical zero while OE is a logical one.

POWER SUPPLY DECOUPLING

In order to reduced power switching effect, each device

should have a 0.1uF ceramic capacitor connected between

its VCC and GND.

CHIP UNPROTECT WITH 12V SYSTEM

The MX29F100T/B also features the chip unprotect mode,

so that all sectors are unprotected after chip unprotect is

completed to incorporate any changes in the code. It is

recommended to protect all sectors before activating chip

unprotect mode.

To activate this mode, the programming equipment must

force VID on control pin OE and address pin A9. The CE

pins must be set at VIL. Pins A6 must be set to VIH.(see

Table 2) Refer to chip unprotect algorithm and waveform

for the chip unprotect algorithm. The unprotection

mechanism begins on the falling edge of the WE pulse

and is terminated on the rising.

It is also possible to determine if the chip is unprotected

in the system by writing the Read Silicon ID command.

Performing a read operation with A1=VIH, it will produce

00H at data outputs(Q0-Q7) for an unprotected sector. It

is noted that all sectors are unprotected after the chip

unprotect algorithm is completed.

P/N:PM0548

REV. 1.2, NOV. 12, 2001

14

MX29F100T/B

SECTOR PROTECTION WITHOUT 12V SYSTEM

The MX29F100T/B also feature a hardware sector

protection method in a system without 12V power suppply.

The programming equipment do not need to supply 12

volts to protect sectors. The details are shown in sector

protect algorithm and waveform.

ABSOLUTE MAXIMUM RATINGS

RATING VALUE

Ambient Operating Temperature -40oC to 125oC

Ambient Temperature with Power -55oC to 125oC

Applied

Storage Temperature -65oC to 125oC

Applied Input Voltage -0.5V to 7.0V

Applied Output Voltage -0.5V to 7.0V

VCC to Ground Potential -0.5V to 7.0V

A9 & OE & RESET -0.5V to 13.5V

CHIP UNPROTECT WITHOUT 12V SYSTEM

The MX29F100T/B also feature a hardware chip

unprotection method in a system without 12V power

supply. The programming equipment do not need to

supply 12 volts to unprotect all sectors. The details are

shown in chip unprotect algorithm and waveform.

POWER-UP SEQUENCE

The MX29F100T/B powers up in the Read only mode. In

addition, the memory contents may only be altered after

successful completion of the predefined command

sequences.

NOTICE:

Stresses greater than those listed under ABSOLUTE

MAXIMUM RATINGS may cause permanent damage to

the device. This is a stress rating only and functional

operational sections of this specification is not implied.

Exposure to absolute maximum rating conditions for

extended period may affect reliability.

NOTICE:

Specifications contained within the following tables are

subject to change.

CAPACITANCE TA = 25oC, f = 1.0 MHz

SYMBOL PARAMETER MIN. TYP MAX. UNIT CONDITIONS

CIN1 Input Capacitance 8 pF VIN = 0V

CIN2 Control Pin Capacitance 1 2 pF VIN = 0V

COUT Output Capacitance 12 pF VOUT = 0V

P/N:PM0548

15

REV. 1.2, NOV. 12, 2001

Loading...

Loading...