DATA BULLETIN

Digitally Controlled

MX839

Analog I/O Processor

PRELIMINARY INFORMATION

Features Applications

x 4 input intelligent 10 bit A/D monitoring

subsystem

4 High and 4 Low Comparators

External IRQ Generator

Free Running Operation

x Three 8/10 bit DACs

x Two Variable Attenuators

x Selectable A/D Clock Frequencies

x Full Control via 4-wire Serial Interface

x Low Power 3.0 Operation

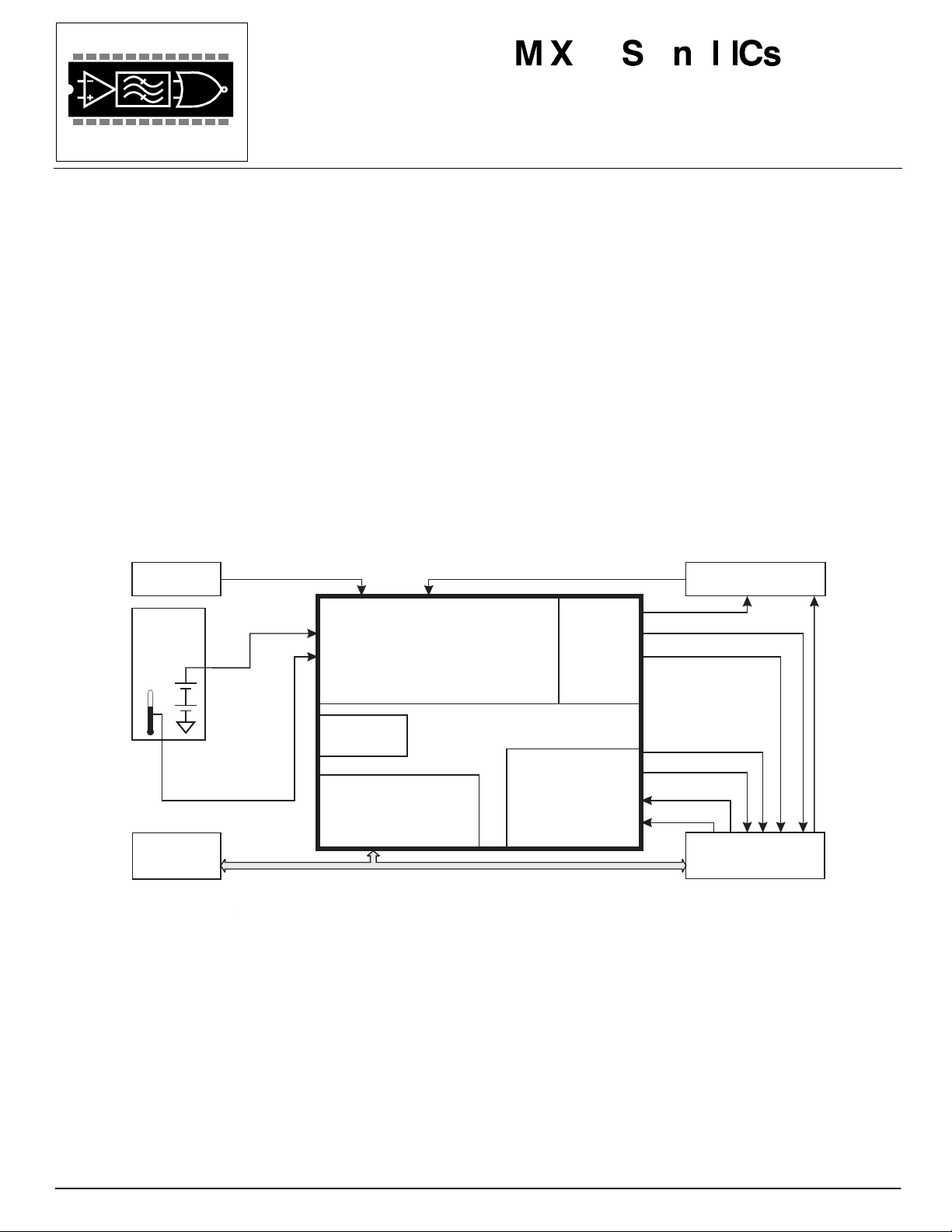

RECEIVER

RSSI VSWR

x PCS, Cellular, LMR, Wireless

Transceivers, and General Purpose

x Monitor and Control:

RSSI, Battery State, Temperature,

VSWR, and Error Voltages

x Digital Trim and Calibration:

VCOs, TCXO, Power Output, Bias,

Current, IF Gain, Deviation,

Modulation Depth, and Baseband

Gain

RF TRANSMITTER

RADIO

BATTERY

SYSTEM

The MX839 is a low power CMOS µC peripheral device which provides digitally controlled calibration, trimming, and

monitoring functions for PCS, cellular, LMR, wireless transceivers, and general purpose applications.

Featuring a four input intelligent 10 bit A/D monitoring subsystem, an interrupt generator, three 8/10 bit DACs, and two

variable attenuator functions, the MX839 automatically monitors, produces, and trims up to nine analog signals via a

simple four wire serial control bus. The free running A/D intelligent monitoring subsystem includes independent high and

low limit comparators for each of four analog input signals which can be configured to generate external µC interrupts.

The MX839’s high level of integration reduces end product parts count, component size, and software complexity. MX839

digital trimming functions also reduce manufacturing costs by eliminating manual trimming operations.

Featuring an operating range of 3.0V to 5.5V the MX839 is available in 24-pin SSOP (MX839DS), 24-pin SOIC

(MX839DW), and 24-pin PDIP (MX839P) packages.

BATTERY STATE

TEMPERATURE

µC

C-BUS SERIAL BUS 0 : 3

4 x 10 bit Free Run A/D

4 x Hi Comparator

4 x Low Comparator

IRQ on Compare

Clock Osc

& Dividers

MX839

C-BU S In te rface

& Control Logic

3 x

8/10 bit

DAC

2 x

Variable

Attenuator

TX POWER

REF.OFFSET TRIM

VCO TRIM

MOD 1 OUT

MOD 2 OUT

MOD 1 IN

MOD 2 IN

TRANSMITTER

MODULATOR

© 1998 MXxCOM Inc. www.mxcom.com Tele: 800 638-5577 336 744-5050 Fax: 336 744-5054 Doc. # 20480164.002

4800 Bethania Station Road, Winston-Salem, NC 27105-1201 USA All trademarks and service marks are held by their respective companies.

Digitally Controlled Analog I/O Processor 2 MX839 PRELIMINARY INFORMATION

CONTENTS

Section Page

1 Block Diagram ................................................................................................................................ 3

2 Signal List ....................................................................................................................................... 4

3 External Components..................................................................................................................... 5

4 General Description ....................................................................................................................... 6

4.1 Variable Attenuators............................................................................................................................... 6

4.2 Digital to Analog Converters...................................................................................................................6

4.3 Analog to Digital Converter and A/D Clock Generator ........................................................................... 6

4.4 Magnitude Comparators and Interrupt Request..................................................................................... 7

4.5 Software Description .............................................................................................................................. 7

4.6 Read Only Registers (8-Bit and 16-Bit).................................................................................................. 9

4.7 Write Only Register Description ............................................................................................................. 9

4.8 Read Only Register Description............................................................................................................ 13

5 Application..................................................................................................................................... 13

5.1 C-Bus Clock .......................................................................................................................................... 13

6 Performance Specification ........................................................................................................... 14

6.1 Electrical Performance .......................................................................................................................... 14

6.2 Packaging.............................................................................................................................................. 19

MXxCOM, Inc. reserves the right to change specifications at any time and without notice.

© 1998 MXxCOM Inc. www.mxcom.com Tele: 800 638-5577 336 744-5050 Fax: 336 744-5054 Doc. # 20480164.002

4800 Bethania Station Road, Winston-Salem, NC 27105-1201 USA All trademarks and service marks are held by their respective companies.

Digitally Controlled Analog I/O Processor 3 MX839 PRELIMINARY INFORMATION

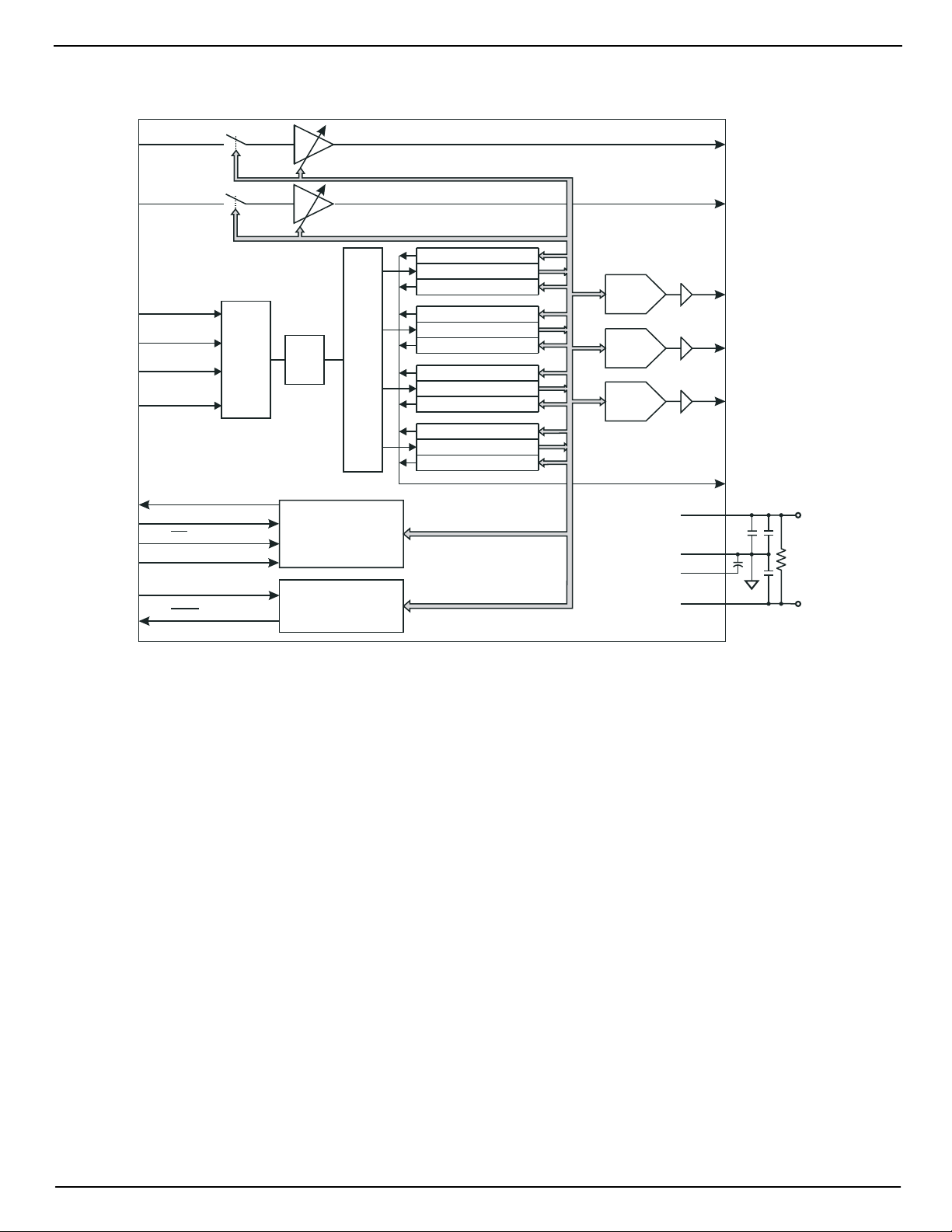

1 Block Diagram

MOD1 IN

MOD2 IN

MUTE1

MUTE2

A/DIN1

A/DIN2

4:1

A/DIN3

MUX

A/DIN4

REPLY DATA

COMMAND DATA

CS

SERIAL CLOCK

XTAL/CLOCK

XTAL

0 to 12dB x 0.4dB Steps

0 to 16dB x 0.2dB Steps

A/D

10

bit

1:4

MUX

4-wire

SERIAL INTERFACE

AND LOGIC

CONTROL

CLOCK

OSCILLATOR

AND DIVIDERS

HIGH COMPARATOR

A/D REG1

LOW COMPARATOR

HIGH COMPARATOR

A/D REG2

LOW COMPARATOR

HIGH COMPARATOR

A/D REG3

LOW COMPARATOR

HIGH COMPARATOR

A/D REG4

LOW COMPARATOR

MOD1OUT

MOD2OUT

DACOUT1

DAC1

8/10 bit

DACOUT2

DAC2

8/10 bit

DACOUT3

DAC3

8/10 bit

ADC COMP IRQ

AV

DD

V

SS

V

BIAS

DV

DD

AV

DV

DD

DD

Figure 1: Block Diagram

© 1998 MXxCOM Inc. www.mxcom.com Tele: 800 638-5577 336 744-5050 Fax: 336 744-5054 Doc. # 20480164.002

4800 Bethania Station Road, Winston-Salem, NC 27105-1201 USA All trademarks and service marks are held by their respective companies.

Digitally Controlled Analog I/O Processor 4 MX839 PRELIMINARY INFORMATION

2 Signal List

Pin No. Name Type Description

1

XTAL

2 XTAL/CLOCK input The input to the on-chip oscillator inverter, for external Xtal circuit or clock.

3 SERIAL CLOCK input The 'C-BUS' serial clock input. This clock, produced by the µC, is used for

4 COMMAND DATA input The 'C-BUS' serial data input from the µC. Data is loaded into this device in

5 REPLY DATA output The 'C-BUS' serial data output to the µC. The transmission of REPLY DATA

6

7

CS

IRQ

8 A/DIN1 input Analog to digital converter input 1 (A/D1)

9 A/DIN2 input Analog to digital converter input 2 (A/D2)

10 A/DIN3 input Analog to digital converter input 3 (A/D3)

11 A/DIN4 input Analog to digital converter input 4 (A/D4)

12 V

13 V

SS

BIAS

14 N/C No internal connection. Do not make any connection to this pin.

15 DACOUT1 output Digital to analog converter No. 1 output (DAC1)

16 DACOUT2 output Digital to analog converter No. 2 output (DAC2)

17 DACOUT3 output Digital to analog converter No. 3 output (DAC3)

18 N/C No internal connection. Do not make any connection to this pin.

19 AV

DD

20 MOD1 IN input Input to MOD1 variable attenuator.

21 MOD2 IN input Input to MOD2 variable attenuator.

22 MOD1 output Output of MOD1 variable attenuator.

23 MOD2 output Output of MOD2 variable attenuator.

24 DV

DD

output The output of the on-chip oscillator inverter.

transfer timing of commands and data to and from the device. See Figure 5.

8-bit bytes, MSB (B7) first, and LSB (B0) last, synchronized to the SERIAL

CLOCK. See Figure 5.

bytes is synchronized to the SERIAL CLOCK under the control of the

CS

input.

This tri-state output is held at high impedance when not sending data to the

µC. See Figure 5.

input The 'C-BUS' data loading control function. This input is provided by the µC.

Data transfer sequences are initiated, completed or aborted by the

CS signal.

See Figure 5.

output This output indicates an interrupt condition to the µC by going to a logic '0'.

This is a 'wire-ORable' output, enabling the connection of up to 8 peripherals

to 1 interrupt port on the µC. This pin has a low impedance pulldown to logic

'0' when active and a high-impedance when inactive. An external pullup

resistor is required.

The conditions that cause interrupts are indicated in the IRQ FLAG register

and are effective if not disabled.

power Negative supply (ground) for both analog and digital supplies.

output An analog bias line for the internal circuitry, held at AVDD/2. This pin must be

bypassed by a capacitor mounted close to the device pins.

power Positive analog supply. Analog levels and voltages are dependent upon this

supply. This pin should be bypassed to V

by a capacitor.

SS

power Positive digital supply. Digital levels and voltages are dependent upon this

supply. This pin should be bypassed to V

by a capacitor.

SS

© 1998 MXxCOM Inc. www.mxcom.com Tele: 800 638-5577 336 744-5050 Fax: 336 744-5054 Doc. # 20480164.002

4800 Bethania Station Road, Winston-Salem, NC 27105-1201 USA All trademarks and service marks are held by their respective companies.

Digitally Controlled Analog I/O Processor 5 MX839 PRELIMINARY INFORMATION

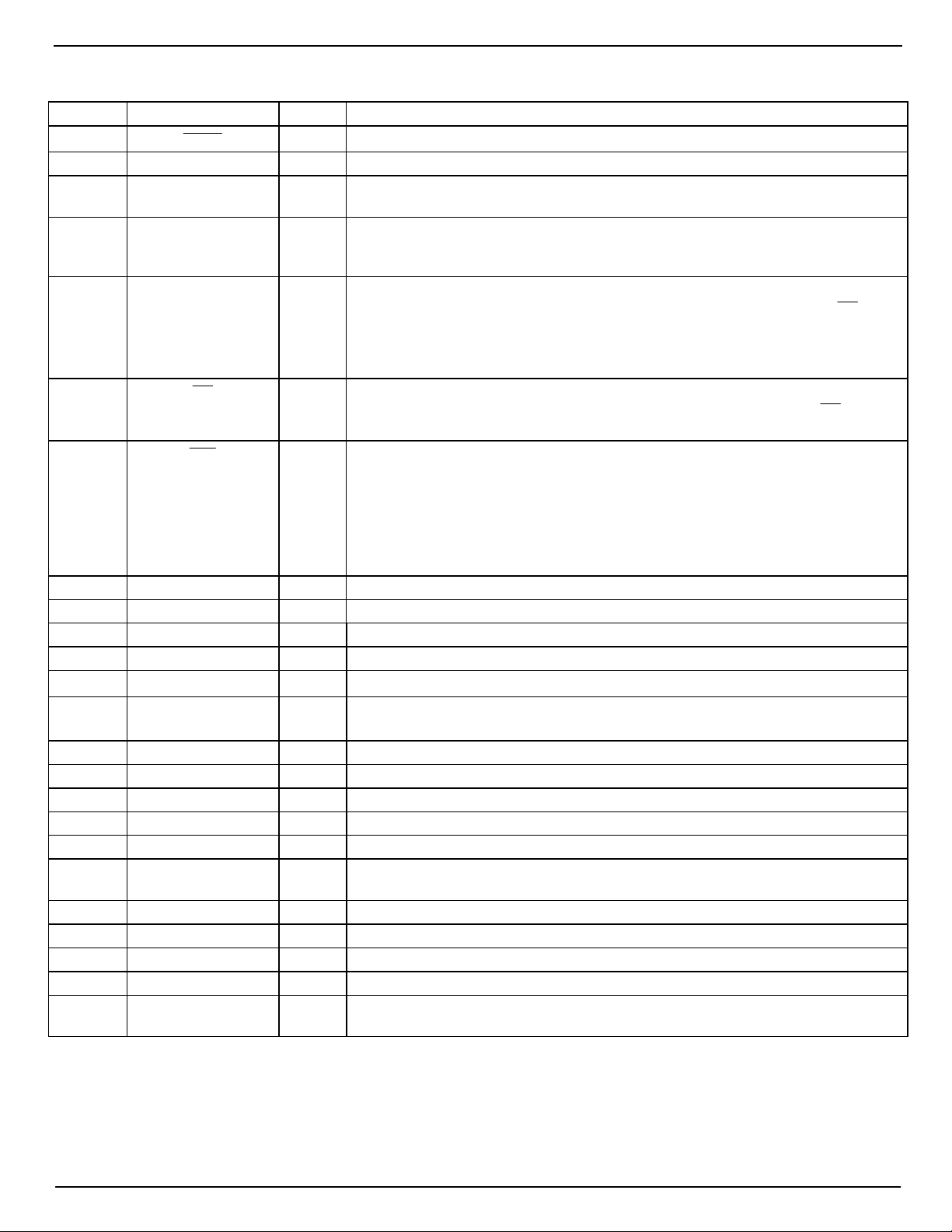

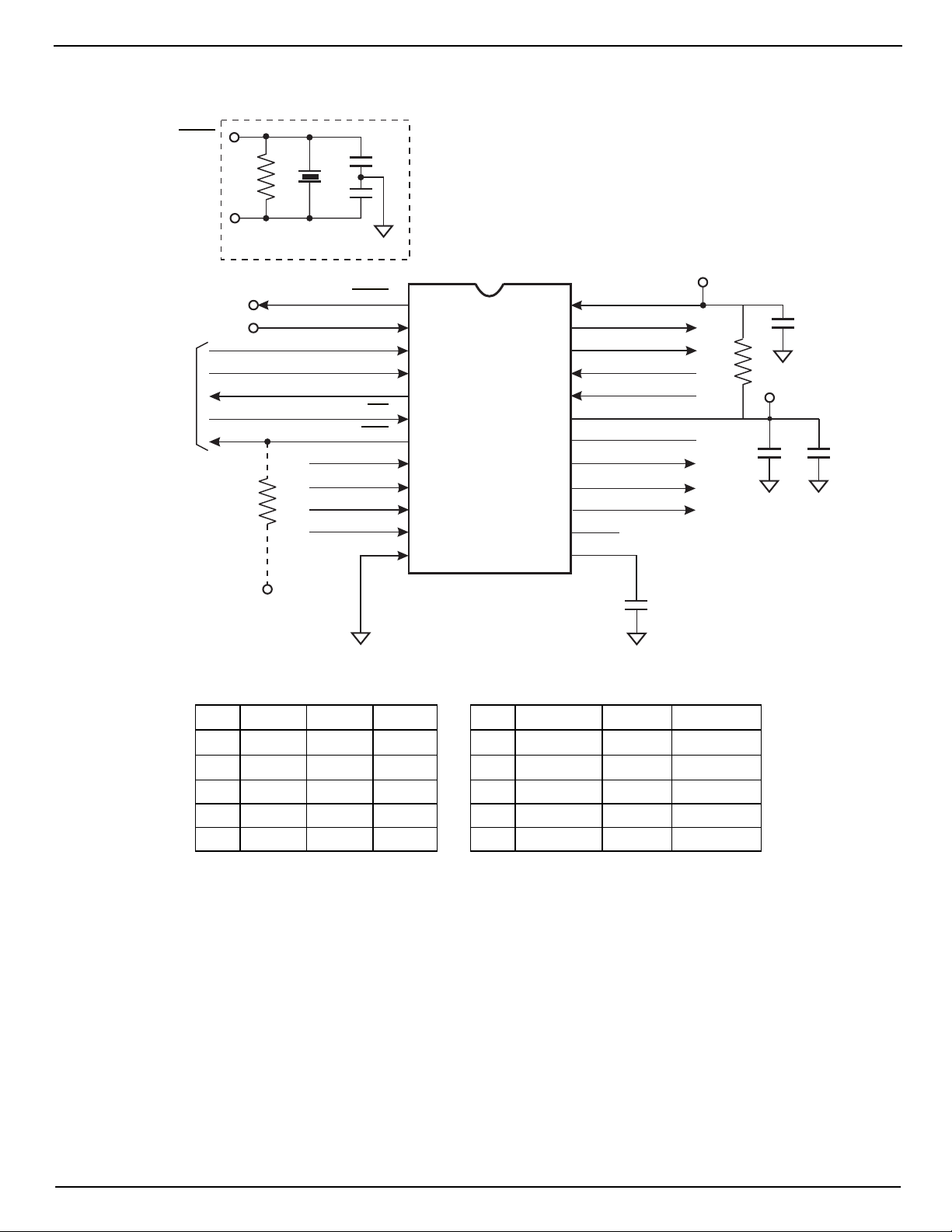

3 External Components

XTAL

X1

R1

XTAL/CLOCK

SERIAL CLOCK

COMMAND DATA

C-BUS

INTERFACE

R2

C2

C1

XTAL

XTAL/CLOCK

REPLY DATA

CS

IRQ

ADCIN1

ADCIN2

ADCIN3

ADCIN4

V

1

2

3

4

5

6

MX839

7

8

9

10

11

SS

12 13

24

23

22

21

20

19

18

17

16

15

14

DV

DD

MOD2 OUT

MOD1 OUT

MOD2 IN

MOD1 IN

AV

DD

N/C

DA COUT3

DA COUT2

DA COUT1

N/C

V

BIAS

DV

R3

DD

C5

AV

DD

C4

C6

DV

DD

C3

Figure 2: Recommended External Components

R1 1M

: ±5% C4 Note 1 0.1µF ±20%

R2 22k: ±10% C5 0.1µF ±20%

R3 Note 1 10: ±10% C6 Note 1 10.0µF ±20%

C1 22pF ±20%

C2 22pF ±20%

C3 0.1µF ±20% X1 Note 2, 3 ±100ppm

Table 1: Recommended External Components

Notes:

1. These values should be determined in regard to the amount of supply filtering required for D/A outputs.

2. If an external clock is to be used, then it should be connected to Pin 2 and the components C1, C2, R1, and X1

omitted. The ADC clock frequency is derived from the crystal or external clock by means of internal programmable

dividers. See Section 6 for details of crystal or external clock frequency range.

3. For best results, a crystal oscillator design should drive the clock inverter input with signal levels of at least 40% of

, peak to peak. Tuning fork crystals generally cannot meet this requirement. To obtain crystal oscillator design

V

DD

assistance, consult your crystal manufacturer.

© 1998 MXxCOM Inc. www.mxcom.com Tele: 800 638-5577 336 744-5050 Fax: 336 744-5054 Doc. # 20480164.002

4800 Bethania Station Road, Winston-Salem, NC 27105-1201 USA All trademarks and service marks are held by their respective companies.

Digitally Controlled Analog I/O Processor 6 MX839 PRELIMINARY INFORMATION

4 General Description

The device comprises four groups of related functions: variable attenuators, digital to analog converters, a multiplexed

analog to digital converter with multiplexer, clock generator and four 8-bit magnitude comparators with variable reference

levels. These functions are all controlled by the 'C-BUS' serial interface and are described below:

4.1 Variable Attenuators

The two variable attenuators have a range of 0 to -12dB and 0 to -6dB respectively and may be controlled independently.

4.2 Digital to Analog Converters

Three DACs are provided with default resolutions of 8 bits, which are defined at the initial chip reset. In this mode the

'C-BUS' data is transferred in a single byte. An option is provided to define any one or more of the DAC resolutions to be

10 bits, then the DAC requires the transfer of two 'C-BUS' data bytes.

The upper and lower DAC reference voltages are defined internally as AV

expressed as:

V

= AVDD x (DATA / 2n) [Volts]

OUT

Where, n is the DAC resolution (8 or 10 bits) and DATA is the decimal value of the input code. For example: n = 8 and

binary code = 11111111 therefore DATA = 255

V

= AVDD x (255 / 256) [Volts]

OUT

Any one of the three DAC input latches might be loaded by sending an address/command byte followed by one or two

data bytes to the 'C-BUS' interface. The data is then latched and the static voltage is updated at the appropriate output.

When a DAC is disabled, its output is defined as open-circuit.

and VSS respectively. The output voltage is

DD

4.3 Analog to Digital Converter and A/D Clock Generator

A single successive approximation A/D is provided with four multiplexed inputs. After a general reset command $01, the

A/D converter subsystem is disabled. To start conversions the Clock Control ($D0) and A/D control ($D7) registers must

be written (refer to Tables 2,6, and 8). Please note that A/D channel 1 must be active for any other channel to work. Also

note that A/D control register bit 5 (

conversions so the data being read does not change during the read which could otherwise result in erroneous data being

read. To re-enable conversions the A/D control register bit 5 (

The internal A/D clock frequency (f

control of this clock signal via the Clock Control Register ($D0), DIVIDER set per Table 6, and the choice of an external

system clock signal or a dedicated crystal. f

Since the typical application is for monitoring slowly changing control voltages, a Sample and Hold circuit is not included

at the input of the A/D. Thus, for the analog to digital conversion to be accurate, the input signal should not change

significantly during the conversion time. For ‘n-bit’ accuracy (with a maximum error of 1LSB) the maximum signal ‘linear

rate of change,’ ‘S,’ is defined by:

where: n is the number of bits of accuracy with a maximum error of 1 LSB

f

where:

A/D_CLK

XTAL

=f

DIVIDER

, DIVIDER is selected per Table 6.

For Example: The most significant bits (n) of accuracy.

For (n = 6) bit accuracy with AV

S = 9.77 [mV/PS]

For (n = 8) bit accuracy with AV

S = 1.95 [mV/PS]

For (n = 10) bit accuracy with AV

S = 0.27 [mV/PS]

The input signal should therefore be band limited to ensure the maximum signal ‘linear rate of change’ is not exceeded for

the desired accuracy.

READ) should be set low prior to issuing a ‘READ A/D DATA x’ command to disable

READ) bit must be set back high.

A/D_CLK

) is generated with a programmable clock generator. Users have flexible

A/D_CLK

should be chosen not to exceed 1MHz.

fAV

=S

n

=5V and f

DD

=5V and f

DD

=3.3V and f

DD

A/D_CLKDD

A/D_CLK

A/D_CLK

)2+n(10002

= 1MHz

= 1MHz

A/D_CLK

[mV/

= 1MHz

PS]

© 1998 MXxCOM Inc. www.mxcom.com Tele: 800 638-5577 336 744-5050 Fax: 336 744-5054 Doc. # 20480164.002

4800 Bethania Station Road, Winston-Salem, NC 27105-1201 USA All trademarks and service marks are held by their respective companies.

Loading...

Loading...