Page 1

LOADER

MX C1

MX C2

MX 20Cu

MX 25Cu

MX 20C+

MX 25C+

MX 30C+

User manual

Please read carefully before using MX

loader

UK 362942 AE - 0711

Original instructions

Page 2

Page 3

Dear users,

Thanks you for confidence in our product. We are sure it will give you full satisfaction.

By taking a few minutes to read this manual, you will be able to obtain the best results from your MX loader, extend

its lifespan and work in complete safety.

The loader user manual is a very important document, please keep it with you in order to be able to use it if

required. Leave it available to any other user and give it to the next owner of this loader.

Pictures and technical information included in this document may not correspond precisely to your loader; but the

working conditions will be the same.

Page 4

Page 5

CONTENTS

Page

1. SAFETY REGULATIONS 6

2. SAFETY STICKERS 7

3. IDENTIFICATION PLATE 7

4. COUNTERWEIGHT 8

5. LOADER UNHITCHING 9

6. LOADER HITCHING 11

7. IMPLEMENT UNHITCHING - C+ LOADERS 13

8. IMPLEMENT HITCHING - C+ LOADERS 14

9. IMPLEMENT UNHITCHING / HITCHING - Cu, C1 and C2 LOADERS 16

10. IMPLEMENT LEVEL INDICATOR - C+ LOADERS 16

11. 3

rd

FUNCTION 17

12. MACH 2 17

13. SHOCK ELIMINATOR 18

14. LOADER MAINTENANCE 18

15. TRACTOR MAINTENANCE 19

16. SAFETY DEVICE ON LIFTING/CROWDING 20

17. CONTROL 20

18. GENERAL INFORMATION 21

19. TECHNICAL SPECIFICATIONS 22

DECLARATION OF CONFORMITY 23

Page 6

Page 7

5

Modification reserved • 19, rue de Rennes • BP 83221 • F - 35690 ACIGNÉ

The loader is a complex machine. The end user must read this

instruction book before first use.

Familiarise yourself with:

— Safety instructions.

— Hitching and unhitching of the loader.

— Hitching and unhitching of the implements.

— Full use of the controls.

Page 8

6

Modification reserved • 19, rue de Rennes • BP 83221 • F - 35690 ACIGNÉ

1. SAFETY INSTRUCTIONS

— Control the loader only from the driver’s seat. Do not let go of the controls until the movements are complete.

— Do not leave the seat before locking the controls to prevent any movement.

— Never leave the tractor while its loader is lifted. Following loader use, park the tractor with the loader lowered to the ground.

— It is compulsory to ensure that nobody is in the area while the loader is in use.

— The operation must use the implement designed and recommended by MX for the work to be carried out.

— The transport or elevation of persons using the loader is forbidden.

— Ensure tractor stability by using a counterweight. Please check the information regarding the counterweight in this user

manual.

— Restrict all movements while the load is lifted as the tractor may become unbalanced.

— The maximum front axle safe load provided by the tractor’s manufacturer must not be exceeded.

— The maximum front tyres safe load provided by the tyres’s manufacturer must not be exceeded.

— Check regularly tyres pressure.

— Regularly check the presence of safety pins and bolts. Do not replace with any other object such as nails, wire, etc.

— Hitch the loader only to a tractor fitted with a roll-over protective structure (ROPS) or a falling object protective structure

(FOPS). This should be in the protective position when using the loader.

— Watch out for overhead electrical and telephone cables when manoeuvring with the loader in the raised position.

— In compliance with the standard EN 12525, the controls for operating the loader and implements must be of the «sustained

action» type with the exception of the lift floating position which can be maintained in its position by a notching system.

— Any activity relating to defect investigation ( diagnosis ) and / or disassembly of parts may only be undertaken by an

accredited professional who shall assure his safety and the protection of the environment in which the actvity is conducted,

in particular in the event of an activity involving the loader staying in the lifted position.

CAUTION !

— The loader’s hydraulic circuit is designed to have a maximum service pressure of 200 bar.

— Never modify hose connections.

— The breaking of the seals will result in the cancellation of the MX responsibility for all the equipment supplied.

— The assembly of an MX loader which excludes the recommendations in the MX price list in force at the purchase date,

cancels the MX guarantee on all the equipment supplied.

— Any modification to a section of any MX equipment (implements, loader, bracket, etc.) or the use of an implement or element

installed on the MX loader of foreign origin, cancels the MX guarantee for all equipment supplied.

— Use only MX original spare parts. Do not modify your MX loader or its accessories yourself or have another person modify

them (mechanical, electrical, hydraulic, pneumatic characteristics), without prior written agreement from MX. Failure to

respect these regulations may make the loader dangerous. MX will disclaim all responsibility in the event of damage or

injury.

— The guarantee is immediately invalid when the instructions for use, and the MX loader maintenance schedule outlined in

"User Manual" are not observed.

Page 9

19, rue de Rennes F - 35690 ACIGNÉ

Type / Model / Typ

N˚ de série

Serial number

Seriennummer

Poids à vide

Unloaded weight / Leergewicht

kg

328462

Désignation/

Designation

Année / Year

7

Modification reserved • 19, rue de Rennes • BP 83221 • F - 35690 ACIGNÉ

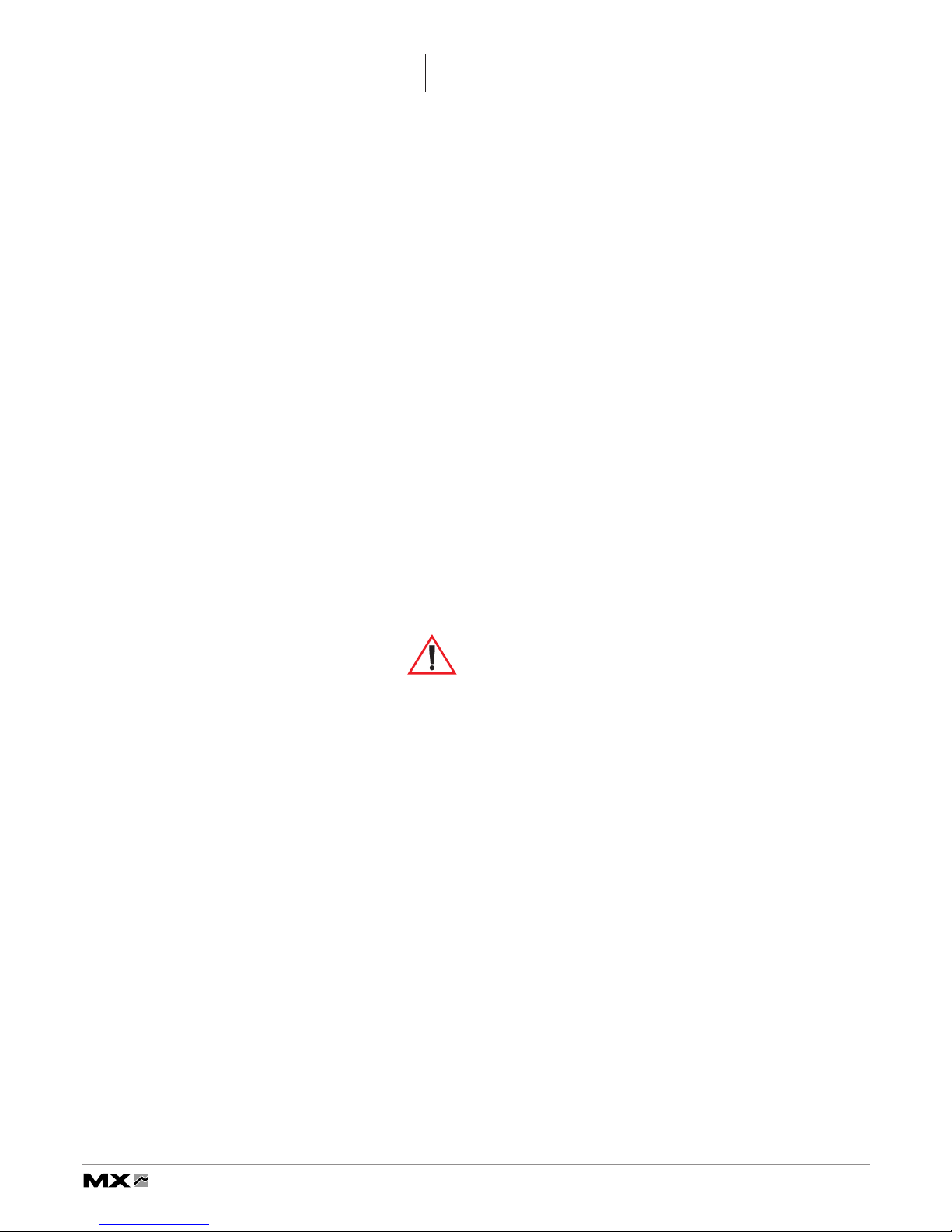

2. SAFETY STICKERS

Security stickers are located on the loader. Keep them readable and clean, and change them if damaged.

3. IDENTIFICATION PLATE

The identification plate is located inside the LH arm, next to

the implement level indicator.

The serial number and loader type which are indicated on

this plate might be requested when requiring spare parts or

technical assistance.

C1 and C2 loaders

C+ and Cu loaders

Page 10

5 N b + I2 (P + N - 5 G)

5 (I1 + I2) - I2

M >

8

Modification reserved • 19, rue de Rennes • BP 83221 • F - 35690 ACIGNÉ

4. COUNTERWEIGHT

The stability of the tractor and loader can only be ensured with a counterweight on the rear of the tractor. This counterweight

must ensure that a minimun of 20 % of the total weight (Tractor, loader, implement, maximum load and counterweight)

is applied on the back axle of the tractor in order to work in a safe condition.

Below is the calculation method which indicates the required counterweight (M)

G : Weight on the rear axle, wihtout counterweight, with an empty implement (kg).

G1 : Weight on the front axle, without counterweight, with an empty implement (kg).

b : Distance from the front axle to the implement centre of gravity (mm).

I1 : Distance from rear linkage pins to the rear axle (mm).

I2 : Wheelbase.

N : Loader payload at 2 m (Kg).

P : G + G1 (kg)

M : Weight of the counterweight (kg).

Page 11

9

Modification reserved • 19, rue de Rennes • BP 83221 • F - 35690 ACIGNÉ

5. LOADER UNHITCHING

Caution

This operation must be carried out by the driver who must leave the seat and

ensure all manoeuvres are forbidden while he is working on the loader.

The loader must always be coupled to an implement to unhitch it.

5.1 Choose a flat and stable area.

5.2 Put the implement dumped on the ground slightly (20°

approx.).

5.3 Fit the parking stand(s).

5.4 Remove the frame locking pins and insert them into the

dedicated holes.

C1 and C2 loaders

C+ and Cu loaders

Page 12

10

Modification reserved • 19, rue de Rennes • BP 83221 • F - 35690 ACIGNÉ

5.5 Lower the loader using the DA, to retract the lift rams.

Crowd slightly to position the parking stands.

5.6 Crowd the implement slightly, driving forward to release

the loader towers away from the bracket.

Pull the parking brake. Turn off the engine..

5.7 Completely decompress all the hydraulic circuits.

5.8 Close the tap and disconnect the hydraulic couplings.

Page 13

11

Modification reserved • 19, rue de Rennes • BP 83221 • F - 35690 ACIGNÉ

5.9 Position the protective covers (clean) to the male and

female couplings.

Store the hoses on the loader.

5.10 Reverse the tractor a little, to clear the loader from the

bracket.

6. LOADER HITCHING

6.1 Drive slowly forward so that the bracket is some 5cm away

from the loader towers.

Pull the parking brake. Turn off the engine.

Page 14

12

Modification reserved • 19, rue de Rennes • BP 83221 • F - 35690 ACIGNÉ

6.2 Completely decompress all the hydraulic circuits.

6.3 Connect the hydraulic couplers, matching the colour

codes.

6.4 Open the tap.

6.5 Tip the implement so as to lift the front of the loader: by

rotating it, the frames must fit into the bracket yokes.

Page 15

0.3 m

0.3 m

13

Modification reserved • 19, rue de Rennes • BP 83221 • F - 35690 ACIGNÉ

6.6 Raise the implement horizontally to 0.30 m from the

ground.

6.7 Lock the loader frame on the bracket with the pins and split

pins.

Fold the parking stands away.

7. IMPLEMENT UNHITCHING - C+ LOADERS

Caution

This operation must be carried out by the driver who must leave the seat and

ensure all manoeuvres are forbidden while he is working on the loader.

7.1 Select a stable parking area.

Lower the implement horizontally to 0.30 m from the

ground.

Pull the parking brake. Turn off the engine.

Page 16

"Clac"

14

Modification reserved • 19, rue de Rennes • BP 83221 • F - 35690 ACIGNÉ

7.2 From the L.H. side of the loader, pull on the lever to the end.

Never operate from the front of the implement.

7.3 Then, move the lever backwards to lock it (compressed

springs).

7.4 Start the tracteur and lower the loader dumping the

implement.

As soon as it is down to the ground, slightly reverse the

tractor in line while lowering the loader.

8. IMPLEMENT HITCHING - C+ LOADERS

Caution

This operation must be carried out by the driver who must leave the seat and

ensure all manoeuvres are forbidden while he is working on the loader.

Page 17

15

Modification reserved • 19, rue de Rennes • BP 83221 • F - 35690 ACIGNÉ

8.1 Ensure that the locking lever is in the "HITCHING" position:

pins retracted and the springs compressed.

8.2 Approach the loader in line with the implement, the tool

carrier being slightly dumped.

8.3 Enter the hitch into the implement hooks.

8.4 Crowd the implement back while driving forwards until the

unlocking lever is triggered.

Page 18

2

1

1

2

16

Modification reserved • 19, rue de Rennes • BP 83221 • F - 35690 ACIGNÉ

Checking before work.

Press on the ground to check if implement is correctly locked on the loader. Use D.A. mode.

Maneuver each hydraulic service to its maximum, in each direction to check the correct operation of the hydraulic

system and that there are no leaks.

9. IMPLEMENT UNHITCHING / HITCHING - Cu, C1 and C2 LOADERS

9.1 Implement unhitching

Select a stable parking area.

Position the implement on the ground.

Remove the split pins then the crowd ram-implement link

pins

1

.

Remove the split pins then the boom-implement link pins

2

.

9.2 Implement hitching

Fit the boom-implement link pins, then the split pins

1

.

Fit the crowd ram link pins, then the split pins

2

. Adjust the

ram rod extension if necessary.

10. IMPLEMENT LEVEL INDICATOR - C+ loader

The implement level indicator is useful for implement repositioning. Efficient even while lowering the loader, it is adjustable

according to the implement type.

Implement in position

Indicator

Page 19

17

Modification reserved • 19, rue de Rennes • BP 83221 • F - 35690 ACIGNÉ

11. 3rd FUNCTION

he front couplers mounted on the loader cross beam are used to

feed an implementc/w grab or any other attachement which

requires a DA extra function (option).

The connection will be easier after the engine is turned off and the

3rd function residual pressure is released.

Crowd and press the green switch at the same time to operate the

3rd service.

12. MACH 2

The Mach 2 (option) enables to instantly plug any implement

hydraulic function without any effort.

The Mach 2 kit includes 600 mm hoses to feed the MX implements.

Back-up control to be pressed if the solenoid

valve locks.

Page 20

18

Modification reserved • 19, rue de Rennes • BP 83221 • F - 35690 ACIGNÉ

13. SHOCK ELIMINATOR

No shocks anymore when driving or when suddenly stop the

loader during lowering (option).

Suspension off

Suspension on

14. LOADER MAINTENANCE

14.1 Clean the implement and the loader front after each use.

CAUTION : some detergents may attack the paint and steel of the loader.

14.2 Grease after each wash

(grease eliminates water)

and particularly after

washing with a high

pressure cleaner.

Caution

Change the tractor hydraulic oil and filters regularly in accordance with the tractor

manufacturer recommendations. Used oil does not lubricate, it also contributes to the

damage of all hydraulic components (pump, valves, rams…).

C1 and C2 loaders C+ and Cu loaders

Page 21

19

Modification reserved • 19, rue de Rennes • BP 83221 • F - 35690 ACIGNÉ

Check the following each month, and more frequently when used intensively:

– Condition of the loader articulations. If necessary, replace the wear bushes and/or the pins.

The wear bushes must be replaced if they are less than 1 mm thick.

– The tractor’s hydraulic oil level and the sealing of the hydraulic system. If you notice any internal or external leaks on

the hydraulic parts (rams, hoses, connectors, Mach, couplings, etc.), contact your dealer.

– Condition of the hoses: replace them if you notice any small cracks or oil seepage.

– Correct operation of the monolever (cables, play, locking, etc.).

– Condition of the electric wiring. Please contact your dealer if there is any damage to connectors or cables.

– Mechanical condition (any cracking, deformation, fretting on stops, play, parking stands, etc.). Please contact your

dealer if there is any abnormal wear.

Check the tightness of the bracket after 10, 50 hours then every 100 hours or when carring out tractor maintenance. In case of

untightness, please contact your dealer.

IMPORTANT:

All the screws needing to be retightened must be inspected, changed if necessary, cleaned and smeared with loctite.

Tighten the screws to the tightening torque specified in the table below.

Use of a pneumatic spanner to tighten the screws on the tractor is forbidden.

Tightening torque (Nm)

15. TRACTOR MAINTENANCE

Pour les opérations d’entretien et de réglage du tracteur, il est vivement conseillé de dételer le chargeur.

Le dételage du chargeur est une opération simple et rapide qui offre les meilleures garanties de sécurité et d’efficacité pour

l’entretien du tracteur et du chargeur.

Close the tap fitted on the lifting coupler.

Thread

Class of bolt

8.8 10.9 12.9

M 8 21 29 35

M 10 42 58 70

M 12 72 101 121

M 14 114 160 193

M 16 174 245 295

M 18 240 340 405

M 20 340 475 570

M 22 455 640 765

M 30 x 150 500

M 40 x 150 500

For any maintenance operations made whilst

the loader is the raised position, the loader

must be locked into position

Page 22

20

Modification reserved • 19, rue de Rennes • BP 83221 • F - 35690 ACIGNÉ

16. SAFETY DEVICE ON LIFTING/CROWDING

If the loaders lifting operation requires people to be in the close proximity, the hydraulic circuit of the loader must have safety

device fitted to it.

This in accordance with the standard EN 12525/A1, from July 2006.

17. CONTROL

Important: Never leave the tractor with loader in raised position.

All spool valves produce an internal leak required for correct operation.

17.1 On tractor valves

Please report to the tractor’s instruction book.

17.2 On MX valves:

17.2.1 Security:

Involuntary loader manoeuvre can be avoided. The

MX joystick can be locked. See diagram.

17.2.2 Lifting-crowding movements

17.2.3 Other

3

rd

FUNCTION :

Green button + Crowding.

Multifunction monolever

C+ and Cu loaders

Monolever

C1 and C2 loaders

Page 23

21

Modification reserved • 19, rue de Rennes • BP 83221 • F - 35690 ACIGNÉ

18. GENERAL INFORMATION

Each implement is designed for a specific use and has its own resistance limits.

Land clearing and stump extraction are forbiden. Such work should be carried out by a specialist vehicle and is not possible

for an agricultural loader.

Use the tractor’s power to enter in the material to be moved rather than approaching it with speed, which will generate high

stress on tractor and loader.

When the load to be manoeuvred is too heavy, do not apply force to the hydraulic components. This also applies when rams

are fully closed or extended. Please release the control lever.

Page 24

22

Modification reserved • 19, rue de Rennes • BP 83221 • F - 35690 ACIGNÉ

19. TECHNICAL SPECIFICATIONS

MX C1, C2 MX 20Cu MX 20C+ MX 25Cu MX 25C+ MX 30C+

Length : ( A )

1.20 m 1.45 m 1.45 m 1.60 m 1.60 m 1.75 m

Width : ( B )

0.90 m 0.90 m 0.90 m 0.90 m 0.90 m 1.05 m

Height : ( C )

1.05 m 1.05 m 1.05 m 1.20 m 1.20 m 1.25 m

Weight (Without option)

135 Kg

(with implement)

130 Kg 140 Kg 140 Kg 165 Kg 205 Kg

Maximum height at implement pivot *

1.92 m 2.15 m 2.15 m 2.45 m 2.45 m 2.60 m

Maximum height under horizontal bucket (1) #

1.80 m 1.95 m 1.95 m 2.25 m 2.25 m 2.35 m

Maximum height under dumped bucket (2) #

1.50 m 1.60 m 1.60 m 1.90 m 1.90 m 2.00 m

Digging depth #

0.10 m 0.15 m 0.15 m 0.15 m 0.15 m 0.15 m

Dumping angle at maximum height (3) #

40° 35° 68° 35° 68° 68°

Dumping angle on the ground (4) #

125° 90° 90° 115° 115° 122°

Crowd angle (5) #

30° 25° 45° 25° 45° 45°

Forward reach available for discharge (6) #

900 mm

850-950 mm 850-950 mm 950-1050 mm 950-1050 mm 1050-1150

mm

Lift force at implement pivot * (Kg)

450 Kg 660 Kg 660 Kg 730 Kg 730 Kg 1400 Kg

Lift capacity at implement pivot over the entire lifting range * (Kg)

420 Kg 570 Kg 570 Kg 630 Kg 630 Kg 990 Kg

Payload on pallet 0.50 m in front of the forks

At ground level (Kg)

390 Kg 470 Kg 490 Kg 510 Kg 540 Kg 1250 Kg

At 1 m height (Kg)

370 Kg 435 Kg 450 Kg 480 Kg 500 Kg 1100 Kg

At 2 m height (Kg)

– 395 Kg 410 Kg 425 Kg 450 Kg 930 Kg

At maximum height (Kg)

350 Kg 375 Kg 390 Kg 410 Kg 425 Kg 710 Kg

Lifting time (s)

3 sec 4.5 sec 4.5 sec 4.5 sec 4.5 sec 3.8 sec

Dumping time (s)

3 sec 2.2 sec 2.2 sec 2.5 sec 2.5 sec 3.3 sec

Data varies according to the type of tractor used.

Specifications measured at 140 bar and a flow rate of 15 litres/min for MX C1 and C2.

Specifications measured at 140 bar and a flow rate of 20 litres/min for MX 20Cu/20C+ and MX 25Cu/25C+.

Specifications measured at 180 bar and a flow rate of 30 litres/min for MX 30C+.

# Indicated data are with a loose material bucket.

* Values at ground level and at implement pivot are not considered to be working data.

(A)

(B)

(C)

Page 25

DECLARATION OF CONFORMITY

We manufacturer:

MX

19,Rue de Rennes

F - 35690 Acigné

Declare that the product:

MX C1, MX C2, MX 20Cu, MX 20C+, MX 25Cu, MX 25C+, MX 30C+ loaders

Comply with standard EN 12525, and its amendments A1 and A2, which presupposes

compliance with the requirements of directive 2006/42 EC of the European Parliament

and of the Council of 17 May 2006 on machinery.

Acigné, the 30th of June 2011.

Loïc Mailleux

Technical Manager

Page 26

Page 27

Page 28

19, rue de Rennes

BP 83221

F - 35690 ACIGNE

Tél. : +33 (0)2 99 62 52 60

Fax : +33 (0)2 99 62 50 22

e-mail : contact@m-x.eu

Loading...

Loading...