CONTROLLER

MWP W4B-120C

BATERÍES

DC 48 V, 24V, 12V

MWP W4B-120C

Installation and Operation Manual

CE Mark

Safety Approved

C-Trick Mark

Safety Approved

1- W4B-120C Description . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.1 Versions and Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2 Operating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.3 Adjustability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.4 General Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2- W4B-120C Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1 General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2 Installation Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.3 Control Terminal Connection . . . . . . . . . . . . . . . . . . . . . 8

2.4 Installation Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3- Front Cover of W4B-120C Operation . . . . . . . . . . . . . . . . 13

3.1 LED Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.2 Charge Control or Diversion Control Mode Indications 13

3.3 Equalization Mode Indication . . . . . . . . . . . . . . . . . . . . . 14

“Equalization LED” Blinking Orange: . . . . . . . . . . . . . . . . . . 14

3.4 Fault Mode Indication . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.5 LCD Meter Displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4- Battery Charging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.1 Battery Charging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.2 Standard Battery Charging Programs . . . . . . . . . . . . . . . 18

5 Diversion Charge Control . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.1 Diversion Charge Control . . . . . . . . . . . . . . . . . . . . 19

5.2 Diversion Current Ratings . . . . . . . . . . . . . . . . . . . . . . . 19

5.3 Standard Diversion Battery Charging Programs . . . . . . . 20

5.4 Selecting the Diversion Load . . . . . . . . . . . . . . . . . . . . . 21

5.5 Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6 Trouble Shooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

7 Battery Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

7.1 Sealed Batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

7.2 Flooded Batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

7.4 Nicad and NiFe Batteries . . . . . . . . . . . . . . . . . . . . . . . . 26

USER MANUAL

5

1- W4B-120C Description

The W4B-120C is a technically advanced wind charger. It includes DC diversion charge

control, so user has to install the diversion load with it.

The manual will help you to become familiar with the W4B-120C’s features and capabilities.

Some of these follow:

• LCD meter with easy to read messages.

• DIP switch to set up the wind charger for its intended use. All major functions can be

set with DIP switches.

• Rated for 12, 24, 48 voltage systems and 120 amps current.

• Eight standard charging with DIP switches.

• Continuous self-testing with fault notification

• LED indications and pushbutton functions.

1.1 Versions and Ratings

W4B-120C-120 (WS-120C):

• Rated for maximum 120 amps continuous current

• Rated for 12, 24, 48 Voltage DC systems

• Diversion Load (optional)

1.2 Operating

The W4B-120C will manage battery charging by 3-phase wind turbine from the battery to a

dedicated diversion load.

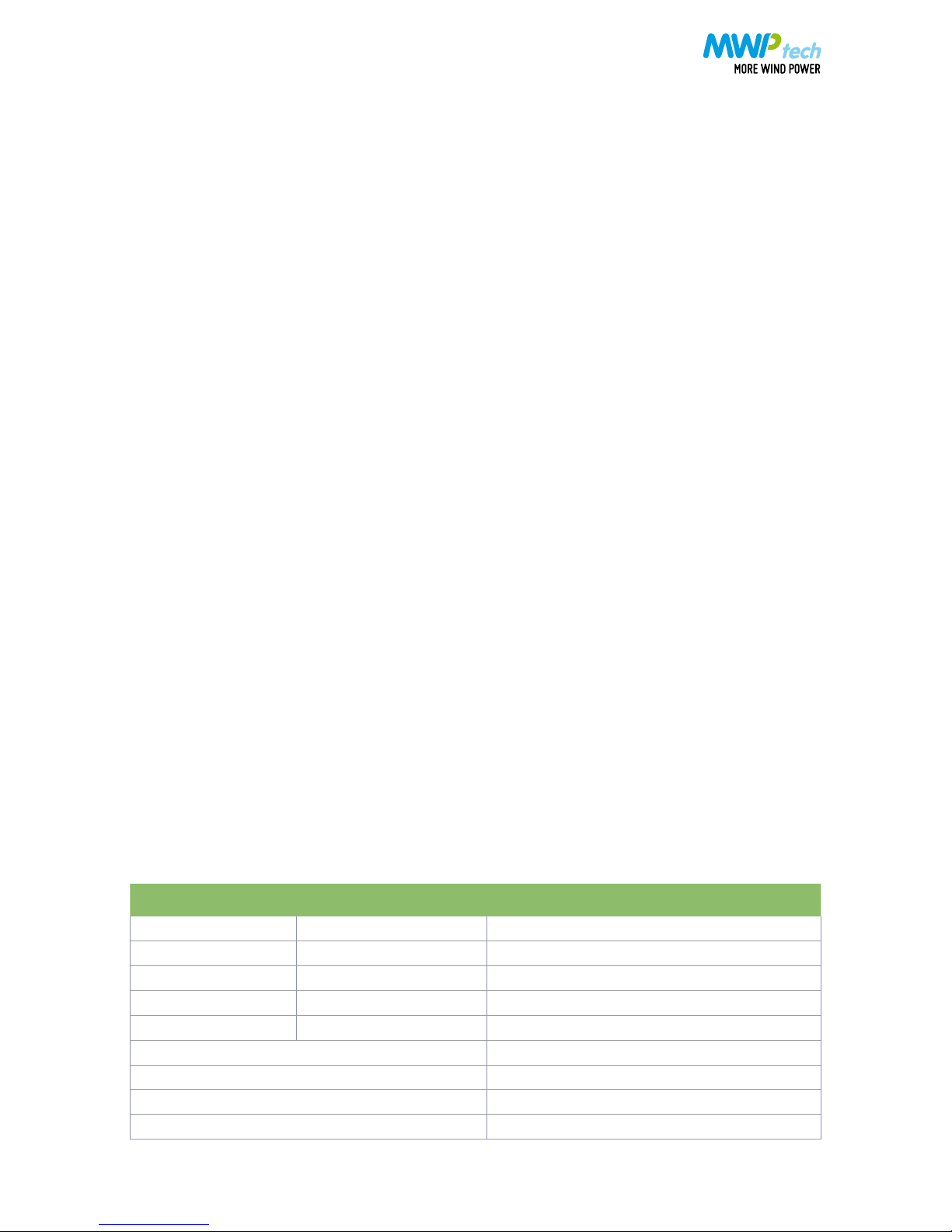

1.3 Adjustability

Eight DIP switches permit the following parameters to be adjusted at the installation site:

1.4 General Use

DIP switch Wind Charger

1 Always in the OFF position

2 3 Select Battery Voltage

OFF OFF 48V system

ON OFF 24V system

OFF ON 12V system

4~6 Standard battery charging programs

7 (OFF) Manual Equalization

(ON) Auto Equalization

8 Always in the OFF position

6

• The W4B-120C is configured for negative ground systems. There are no parts in the

wind charger’s negative leg. The enclosure can be grounded using the ground terminal in the wiring compartment.

• There are fuses or mechanical parts inside the W4B-120C to reset or change.

The W4B-120C is rated for indoor use. The wind charger is protected by conformal

coated circuit boards, stainless steel hardware, anodized aluminum, and a powder

coated enclosure, but it is not rated for corrosive environments or water entry.

• The construction of the W4B-120C is 100% solid state.

With bulk charging, absorption, float and equalization stages.

• The W4B-120C will accurately measure time over long intervals to manage events

such as automatic equalizations or battery service notification.

• LED’s, a pushbutton, and LCD meters provide both status information and various

manual operations.

USER MANUAL

7

2- W4B-120C Installation

The installation instructions describe wind battery charging.

2.1 General Information

The mounting location is important to the performance and operating life of the wind char-

ger. The environment must be dry and protected as noted below. The wind charger may

be installed in a ventilated enclosure with sealed batteries, but never in a sealed battery

enclosure or with vented batteries.

2.2 Installation Overview

The installation is straightforward, but it is important that each step is done correctly and

safely. A mistake can lead to dangerous voltage and current levels. Be sure to carefully fo-

llow each instruction in Section 2.3 and observe all cautions and warnings.

The following diagrams provide an overview of the connections and the proper order:

Collector

(Wind generator

Output Frequency)

1 2 1 2 3

WIND INPUT

Battery

Positive +

Battery

Negative -

Diversion load

Positive +

Diversion load

Negative -

PE

DIP

Switches

8

2.3 Control Terminal Connection

Install the counter with Collector 1 and Collector 2 by yourself and then you will know the wind speed of the Wind Turbine (rpm). The

output of the Collector 1 and 2 is the Wind Generator Output Frequency.

2.4 Installation Steps

The W4B-120C wind charger must be installed properly and in accordance with the local and

national electrical codes. It is also important that the installation be done safely, correctly and

completely to realize all the benefits that the W4B-120C can provide for your wind system.

Before starting the installation, review these safety notes:

• Do not exceed a battery voltage of 48V (nominal). Do not use a battery less than 12V.

• Charge only 12, 24, or 48 volt lead-acid batteries when using the standard battery chargingprograms or NI-CAD batteries when DIP switch number 4~6 is ON position in the W4B-

120C.

• Verify the nominal charging voltage is the same as the nominal battery voltage.

• Do not install a W4B-120C in a sealed compartment with batteries.

Name Description

Collector 1 Positive connection of the Wind Generator Output Frequency

Collector 2 Negative connection of the Wind Generator Output Frequency

WIND INPUT 1 Connecting terminal for Wind Turbine

WIND INPUT 2 Connecting terminal for Wind Turbine

WIND INPUT 3 Connecting terminal for Wind Turbine

Battery + Battery cable Positive connection

Battery— Battery cable Negative connection

DIVERSION LOAD + Connecting terminal for Diversion load

DIVERSION LOAD— Connecting terminal for Diversion load

PE Connecting terminal for Ground

Dip Switch 1 Always in the OFF position

Dip Switch 2, 3 Selection of battery voltage for 12V or 24V or 48V system

Dip Switch 4, 5, 6 Battery charging algorithm

Dip Switch 7 Auto or Manual Equalization

Dip Switch 8 Always in the OFF position

USER MANUAL

9

• Never open the W4B-120C access cover unless both the wind turbine and battery

power has been disconnected.

• Never allow the Wind Turbine to be connected to the W4B-120C with the battery and

Diversion load disconnected. This can be a dangerous condition with high voltage

present at the terminals.

2.4.1 Mounting

Mounting Dimensions

• Locate the W4B-120C on a wall protected from direct sun, high temperatures, and

water. Do not install in a confined area where battery

gasses can accumulate.

• When mounting the W4B-120C, make sure the air flow

around the controller and heat sink is not obstructed.

There should be open space above and below the heat

sink, and at least 75 mm (3 inches) clearance around the

heat sink to allow free air flow for cooling.

• Before starting the installation, place the W4B-120C on

the wall where it will be mounted and determine where

the wires will enter the controller.

Unit: mm

Unit: mm

10

2.4.2 Diversion Charge Control DIP Switch Settings

The 8 DIP switches are located on the top of the PE terminal. Each switch is numbe-

red. The wind battery charging functions that can be adjusted with the DIP switches

follow:

DIP Switch Functions

As shown in the diagram, all the positions are in the “OFF” position except switch

number 3 and 7 which are in the “ON” position.

NOTE: The DIP switches should be changed only when there is no power to the wind char-

ger. Turn off disconnect switches and remove all power to the wind charger before chan-

ging a DIP switch. A fault will be indicated if a switch is changed while the wind charger is

powered.

CAUTION 1: The W4B-120C is shipped with all the switches in the “OFF” position. Each

switch position must be confirmed during installation. A wrong setting could cause damage

to the battery or other system components.

CAUTION 2: To change a switch from OFF to ON, slide the switch up toward the top of the

wind charger. Make sure each switch is fully in the ON or OFF position.

CAUTION 3: DIP Switch Number 1 and Number 8 are always in the OFF position.

DIP Switch Number 1 and Number 8: Always in the OFF position

DIP Switch Number 2, 3-System voltage

Switch 2 Switch 3 System Voltage

OFF OFF 48V system

ON OFF 24V system

OFF ON 12V system

USER MANUAL

11

Select one of the 7 standard battery charging algorithms, or select NiCad to determine the

charging of the battery.

The above setting voltage value is in the condition of 12V system. The voltage will be twi-

ce of above values in the 24V system and it will be four times of above values in the 48V

system.

Refer to section 7.0 of the manual for battery charging information.

The 7 standard charging algorithms above are described in section 4.2-standard battery

charging programs.

DIP Switch Number 7 (ON): Auto Equalization;

DIP Switch Number 7 (OFF): Manual Equalization

2.4.3 Finish Installation

Inspect for tools and loose wires that may have been left inside the enclosure.

Check the power conductors to make sure they are located in the lower part of the wiring

compartment and will not interfere with the cover and the LCD meter assembly.

NOTE: If the power conductors are bent upwards and touch the LCD meter assembly, pres-

sing the cover down on the wires can damage the meter.

• Carefully place the cover back on the wind charger and install the one cover screw.

• Closely observe the system behavior and battery charging for 2 to 4 weeks to confirm

the installation is correct and the system is operating as expected.

DIP Switch Number 4, 5, 6-Battery charging algorithm

DIPSW-4 DIP

SW-5

DIP

SW-6

Bulk

voltage

Float

voltage

Equalize

Voltage

Equalize Time

(hours)

Equalize

Interval

(days)

OFF OFF OFF 14.0V 13.4V None - -

OFF OFF ON 14.1V 13.4V 14.2V 1 28

OFF ON OFF 14.3V 13.4V 14.4V 2 28

OFF ON ON 14.4V 13.4V 15.1V 3 28

ON OFF OFF 14.6V 13.4V 15.3V 3 28

ON OFF ON 14.8V 13.4V 15.3V 3 28

ON ON OFF 15.0V 13.4V 15.3V 3 14

ON ON ON 16.0V 14.5V - - -

USER MANUAL

13

3- Front Cover of W4B-120C Operation

There are 4 LEDs, 1 LCD Meter and 2 pushbuttons on W4B-120C front cover. The details

are described as follows:

3.1 LED Status Indicators

Four LED indicate operating status of the wind charger. When the wind charger works, the

charge mode (green) LED will blink. The Load Control Mode (red) LED is no function. When

battery equalization is in process, the Equalization (orange) LED is blinking. A red LED solid

or blinking indicates a fault condition.

3.2 Charge Control or Diversion Control Mode Indications

“Charge Mode LED” Solid Green:

The battery is being charged in the FLOAT stage. The status LED remains ON solid

unless the batteries drop below the float voltage setting for an accumulative period of

one hour. This allows the user to confirm that the system reached the float stage during

the charging process when checked at the end of the day. Reaching the float stage

frequently is a good indication of proper system operation and will maximize battery life

and performance.

14

“Charge Mode LED” Blinking Green:

The wind charger is CHARGE CONTROL or DIVERSION CONTROL Mode and the battery

is not fully charged. AS the battery voltage approaches the BULK setting, the status LED

will blink green several times (up to five) and then pause, indicating the battery voltage is

approaching the BULK setting and provides an indication of the battery condition. Refer to

the table 1 to determine the battery voltage.

NOTE: A single green flash indicates the battery is below the bulk voltage setting. It does

NOT indicate the batteries are charging.

3.3 Equalization Mode Indication

“Equalization LED” Blinking Orange:

The wind charger is in the Equalization Mode. It will automatically stop the equalization

process after accumulating setting Equalize Time of operation at Equalize Voltage above

the BULK setting.

The user can stop the equalization process at any time by pressing the reset pushbutton

until the status LED stops.

Battery Voltage (Using LED Status Indicator)

LED Status Green LED (Charge/Diver-

sion Mode)

Always ON Battery at FLOAT setting

5 Blinks Battery at BULK setting

Bulk Setting Minus (-)

4 Blinks 0.25 VDC 0.50 VDC 1.00 VDC

3 Blinks 0.50 VDC 1.00 VDC 2.00 VDC

2 Blinks 0.75 VDC 1.50 VDC 3.00 VDC

1 Blinks > 0.75 VDC > 1.50 VDC > 3.00 VDC

Below Bulk Below Bulk Below Bulk

DC Voltage 12 Volts 24 Volts 48 Volts

Table 1 Battery Voltage LED Indication

USER MANUAL

15

3.4 Fault Mode Indication

Solid Red:

The wind charger detects an over-current condition and the battery is disconnected. The

wind charger will try to automatically restart the battery after a 10 second delay. If the wind

charger will not restart, turn off all batteries and press the reset pushbutton. A delay up to

five seconds may occur before the wind charger attempts to restart after pressing the reset

pushbutton. The data exchange between CPU and the display panel can be detected a fault

by the wind charger by showing alarm CPF00.

3.5 LCD Meter Displays

These displays include a two-line, 32-characters LCD and Four status LED indicator.

The LCD provides the following information:

• Wind Turbine or DC Load press-through current: 0~120 amps DC

• Battery Voltage: 10.5 to 80 Volts DC

• Watts: 0 to 6000 Watts (Volts time Amps)

• Amp-hours: 0 to 655536Ah; can be reset to 0

• Totalizing amp-hours: 0 to 65536 Ah; reset to 0 when power is disconnected

• Battery charging status

• Display of BULK and FLOAT voltage setting value

• Display of Equalization Voltage, Equalization Time and Equalization Interval

• Display of heatsink temperature

• Fault Messages

16

3.5.1 LCD Displays Flow

3.5.2 Fault Messages

The LCD displays might have the following fault messages when W4B-120C stops ope-

rating.

Refer to their description and causes listed as below in order to remove the faults.

USER MANUAL

17

4- Battery Charging

4.1 Battery Charging

Selecting the best method for charging your battery together with a good maintenance pro-

gram will ensure a healthy battery and long service life. Although the W4B-120C’s battery

charging is fully automatic, the following information is important to know for getting the

best performance from your W4B-120C wind charger and battery.

4.1.1 Four Stages of Charging

Figure 4.1.1 Charging Stages

1. Bulk Charging: In this stage, the battery will accept all the current provided by the wind

system.

2. PWM Absorption: When the battery reaches the regulation voltage, the PWM begins to

hold the voltage constant. This is to avoid over-heating and over-gassing the battery. The

current will taper down to safe levels as the battery becomes more fully charged.

3. Equalization: Many batteries benefit from a periodic boost charge to stir the electrolyte,

level the cell voltages, and complete the chemical reactions.

4. Float: When the battery is fully recharged, the charging voltage is reduced to prevent

further heating or gassing of the battery.

18

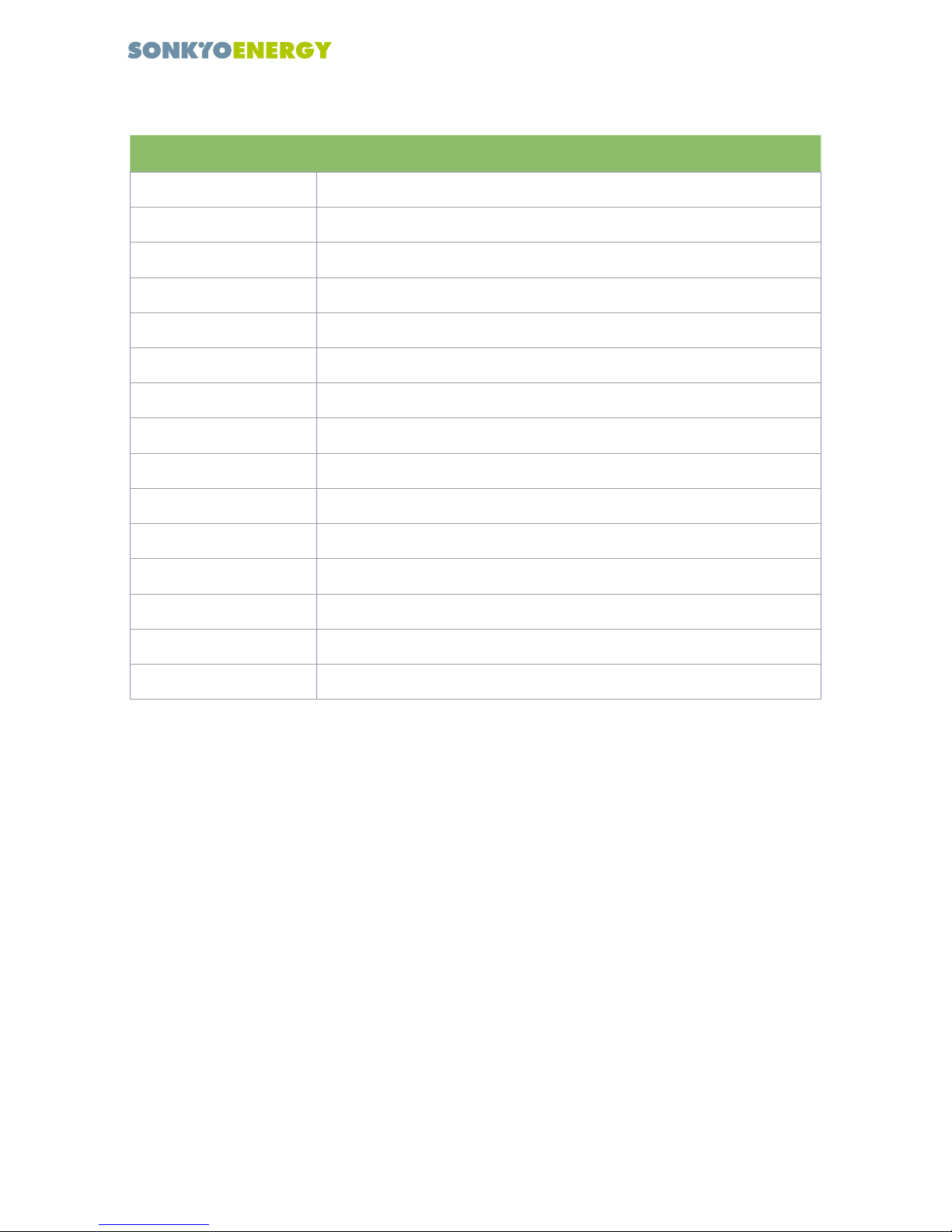

4.2 Standard Battery Charging Programs

The W4B-120C provides 8 standard battery charging algorithms (programs) that

are selected with the DIP switches. These standard algorithms are suitable for

lead-acid batteries ranging from sealed (gel, AGM, maintenance free) to flooded

to L-16 cells and Ni-cad etc.

The table below summarizes the major parameters of the standard charging algorithms.

Note that all the voltages are for 12V systems (24V = 2X, 48V = 4X)

A. Battery Type – These are generic lead-acid and Ni-cad battery types. See Section 8.0 for

more information about battery types and appropriate battery charging.

B. BULK Voltage –This is the PWM Absorption stage with constant voltage charging.

The “PWM voltage” is the maximum battery voltage that will be held constant. As the

battery becomes more charged, the charging current tapers down until the battery is

fully charged.

C. Float Voltage –When the battery is fully charged, the charging voltage will be reduced to

13.4 volts for all battery types.

D. Equalization Voltage –During an equalization cycle, the charging voltage will be held

constant at this voltage.

All values are 25ºC (77ºF).

A B C D E

DIP Equalize

Switches Battery Type Bulk Float Equalize Time

(4-5-6) Voltage Voltage Voltage (hours)

off-off-off 1 – Sealed 14.0 13.4 None -

off-off-on 2 – Sealed 14.1 13.4 14.2 1

off-on-off 3 - Sealed 14.3 13.4 14.4 2

off-on-on 4 - Flooded 14.4 13.4 15.1 3

on-off-off 5 - Flooded 14.6 13.4 15.3 3

on-off-on 6 - Flooded 14.8 13.4 15.3 3

on-on-off 7 - L-16 15.0 13.4 15.3 3

on-on-on 8-NiCad 16.0 14.5 None -

Table 4.2 Standard Battery Charging Programs

USER MANUAL

19

E. Equalization Time –The charging at the selected equalization voltage will continue for this

number of hours. This may take more than one day to complete.

F. E qu a li z ati o n I nte r v al –Equalizations are typically done once a month. Most of the

cycles are 28 days so the equalization will begin on the same day of the month. It can

be set by Dip Switch 4~6 for different interval days.

Each new cycle will be reset as the equalization starts so that a setting day period will

be maintained.

These 8 standard battery charging algorithms will perform well for the majority of battery

systems.

5 Diversion Charge Control

As the battery becomes fully charged, the W4B-120C will divert excess current from

the battery to a dedicated diversion load.

This diversion load must be large enough to absorb all the excess energy, but not too

large to cause a controller overload condition.

5.1 Diversion Charge Control

The W4B-120C will use PWM charging regulation to divert excess current to an external

load. As the battery becomes fully charged, the FET switches are closed for longer periods

of time to direct more current to the diversion load.

As the battery charges, the diversion duty cycle will increase. When fully charged, all the

source energy will flow into the diversion load if there are no other loads. The generating

source is typically a wind or hydro generator.

The most important factor for successful diversion charge control is the correct sizing of

the diversion load.

If you are not confident and certain about the installation, a professional installation by your

dealer is recommended.

5.2 Diversion Current Ratings

The maximum diversion load current capability for the W4B-120C WS-120C is 120 amps.

The diversion loads must be sized so that the peak load current cannot exceed the maxi-

mum rating.

20

5.3 Standard Diversion Battery Charging Programs

The SunStar provides 8 standard diversion charging algorithms (programs) that are selected

with the DIP Switches.

The table below summarizes the major parameters of the standard diversion battery charging

algorithms. Note that all the voltages are for 12V systems (24V = 2X, 48V = 4X).

A. PWM BULK Voltage - This is the PWM Absorption stage with constant voltage char-

ging. The PWM absorption voltage is the maximum battery voltage that will be held

constant.

B. Float Voltage - When the battery is fully charged, the charging voltage will be reduced to

13.4 volts for all diversion settings.

C. Equalization Voltage - During an equalization cycle, the charging voltage will be held

constant at this voltage. Equalizations are manual, and can be selected for automatic.

D. Equalization Time- Charging at the selected equalization voltage will continue for this

setting number of hours.

E. Equalization Interval - Equalizations are typically done once a month cycles can be set

in the Equalization Interval in units of days so the equalization will begin according to the

setting value. Each new cycle will be reset as the equalization starts.

All values are 25ºC (77ºF).

A B C D E

DIP Equalize

Switches Battery Type Bulk Float Equalize Time

(4-5-6) Voltage Voltage Voltage (hours)

off-off-off 1 – Sealed 14.0 13.4 None -

off-off-on 2 – Sealed 14.1 13.4 14.2 1

off-on-off 3 - Sealed 14.3 13.4 14.4 2

off-on-on 4 - Flooded 14.4 13.4 15.1 3

on-off-off 5 - Flooded 14.6 13.4 15.3 3

on-off-on 6 - Flooded 14.8 13.4 15.3 3

on-on-off 7 - L-16 15.0 13.4 15.3 3

on-on-on 8-NiCad 16.0 14.5 None -

Table 5.3 Standard Diversion Charging Programs

USER MANUAL

21

5.4 Selecting the Diversion Load

It is critical that the diversion load be sized correctly. If the load is too small, it cannot divert enough

power from the source (wind, hydro, etc). The battery will continue charging and could be overcharged.

If the diversion load is too large, it will draw more current than the rating of the W4B-120C.

CAUTION: The diversion load must be able to absorb the full power output of the source, but

the load must never exceed the current rating of the W4B-120C wind charger. Otherwise,

the battery can be overcharged and damaged.

5.5 Capacity

1. When WS-120C connects with 48VDC batteries, it can support 6KW Wind Turbine.

2. When WS-120C connects with 24VDC batteries, it can support 3KW Wind Turbine.

3. When WS-120C connects with 12VDC batteries, it can support 1.5KW Wind Turbine.

USER MANUAL

23

6 Trouble Shooting

General Troubleshooting

W4B-120C is not powering up

• Confirm that all circuit breakers and switches in the system are closed

• Check all fuses

• Check for loose wiring connections and wiring continuity

• Verify that the battery voltage is not below 9Vdc

• Verify that the battery power connection is not reversed polarity

Troubleshooting Charging

• Over-charging or under-charging the battery

• DIP switch settings may be wrong

• Over-temperature condition is reducing the charging current (heat sink cooling may

be blocked)

• Voltage drop between W4B-120C and battery is too high

• Load is too large and is discharging the battery

Not charging the battery

• DIP switch settings may be wrong (check each switch position carefully)

• Circuit breaker or disconnect is open

• Reversed polarity connections at the PMG terminals (PMG: Permanent Magnet Gene-

rator)

• Short circuit in the wind system has eliminated part of the wind power output

• Wind energy is not providing enough current

• Battery is failing and cannot hold a charge

Troubleshooting Diversion Control

• Diversion load is too small so PWM reaches 99%

• Diversion load is burned out so PWM reaches 99%

• Diversion load is too large so W4B-120C faults on overcurrent

• An overtemperature condition may have caused the load to be disconnected

• Voltage drops between the W4B-120C and battery are too high

24

7 Battery Information

The standard battery charging programs in the W4B-120C charger, as described in Section

4.2, are typical charging algorithms for four battery types:

• sealed (VRLA)

• flooded (vented)

• L-16 group

• Nicad and NiFe

CAUTION: Never attempt to charge a primary (non-rechargeable) battery.

All charging voltages noted below will be for 12V batteries at 25°C.

7.1 Sealed Batteries

The general class of sealed batteries suitable for renewable systems are called VRLA (Valve

Regulated Lead-Acid) batteries. The two main characteristics of VRLA batteries are electro-

lyte immobilization and oxygen recombination. As the battery recharges, gassing is limited

and is recombined to minimize the loss of water.

The two types of VRLA batteries most often used in renewable systems are AGM and Gel.

AGM:

Absorbed Glass Mat batteries are still considered to be a “wet cell” because the electrolyte

is retained in fiberglass mats between the plates. Some newer AGM battery designs recom-

mend constant voltage charging to 2.45 volts/cell (14.7V). For cycling applications, charging

to 14.4V or 14.5V is often recommended.

AGM batteries are better suited to low discharge applications than daily cycling. These

batteries should not be equalized since gassing can be vented which causes the battery to

dry out. There is also a potential for thermal runaway if the battery gets too hot, and this will

destroy the battery. AGM batteries are affected by heat, and can lose 50% of their service

life for every 8°C (15°F) over 25°C (77°F).

It is very important not to exceed the gas recombination capabilities of the

AGM. The optimum charging temperature range is from 5 to 35°C (40 to 95°F).

Gel:

Gel batteries have characteristics similar to AGM, except a silica additive immobilizes the

electrolyte to prevent leakage from the case. And like AGM, it is important to never exceed

the manufacturer’s maximum charging voltages. Typically, a gel battery is recharged in cy-

cling applications from 14.1V to 14.4V. The gel design is very sensitive to overcharging.

USER MANUAL

25

For both AGM and Gel batteries, the goal is for 100% recombination of gasses so that no

water is lost from the battery. True equalizations are never done, but a small boost charge

may be needed to balance the individual cell voltages.

Other Sealed Batteries:

Automotive and “maintenance-free” batteries are also sealed. However, these are not dis-

cussed here because they have very poor lifetimes in renewable cycling applications.

NOTE: Consult the battery manufacturer for the recommended charging settings for the

battery being used.

7.2 Flooded Batteries

Flooded (vented) batteries are preferred for larger cycling renewable systems.

The advantages of flooded batteries include:

• ability to add water to the cells

• deep cycle capability

• vigorous recharging and equalization

• long operating life

In cycling applications, flooded batteries benefit from vigorous charging and equalization

cycles with significant gassing. Without this gassing, the heavier electrolyte will sink to the

bottom of the cell and lead to stratification. This is especially true with tall cells. Hydrocaps

can be used to limit the gassing water loss.

Note that a 4% mixture of hydrogen in air is explosive if ignited. Make certain the battery

area is well ventilated.

Typical equalization voltages for flooded batteries are from 15.3 volts to 16 volts. However, a re-

newable system is limited to what the renewable system can provide. If the equalization voltage

is too high, the array I-V curve may go over the “knee” and sharply reduce the charging current.

Lead-Calcium:

Calcium batteries charge at lower voltages (14.2 to 14.4 typically) and have strong advan-

tages in constant voltage or float applications. Water loss can be only 1/10th of antimony

cells. However, calcium plates are not as suitable for cycling applications.

Lead-Selenium:

These batteries are similar to calcium with low internal losses and very low water consump-

tion throughout their life. Selenium plates also have poor cycling life.

26

Lead-Antimony:

Antimony cells are rugged and provide long service life with deep discharge capability.

However, these batteries self-discharge much faster and the selfdischarging increases up to

five times the initial rate as the battery ages. Charging the antimony battery is typically from

14.4V to 15.0V, with a 120% equalization overcharge. While the water loss is low when the

battery is new, it will increase by five times over the life of the battery.

There are also combinations of plate chemistries that offer beneficial tradeoffs. For exam-

ple, low antimony and selenium plates can offer fairly good cycling performance, long life,

and reduced watering needs.

NOTE: Consult the battery manufacturer for the recommended charging settings for the

battery being used.

7.3 L-16 Cells

One particular type of flooded battery, the L-16 group, is often used in larger renewable

systems. The L-16 offers good deep-cycle performance, long life, and low cost.

The L-16 battery has some special charging requirements in a renewable system. A study

found that nearly half of the L-16 battery capacity can be lost if the regulation voltage is too

low and the time between finish-charges is too long. One standard charging program in the

SunStar is specifically for L-16 batteries, and it provides for higher charging voltages and

more frequent equalizations. Additional equalizations can also be done manually with the

pushbutton.

NOTE: The best charging algorithm for flooded, deep-cycle batteries depends on the normal

depth-of-discharge, how often the battery is cycled, and the plate chemistry. Consult the

battery manufacturer for the recommended charging settings for the

battery being used.

7.4 Nicad and NiFe Batteries

The W4B-120C is compatible with Nicad (nikel-cadmium), NiFe (nikel-iron) and alkaline type

batteries which must be charged to a higher voltage level to achieve a full charge. When

Nicad mode is selected, the equalization process is disabled.

Polígono de Raos. P12.B3. 39600.

Santander (Cantabria) Spain

Tel.: +34.942319192 Fax.: +34.942319193

E.MAIL: info@sonkyoenergy.com

www.sonkyoenergy.com

windspot_es

windspotsonkyoenergy

windspot

28

Loading...

Loading...