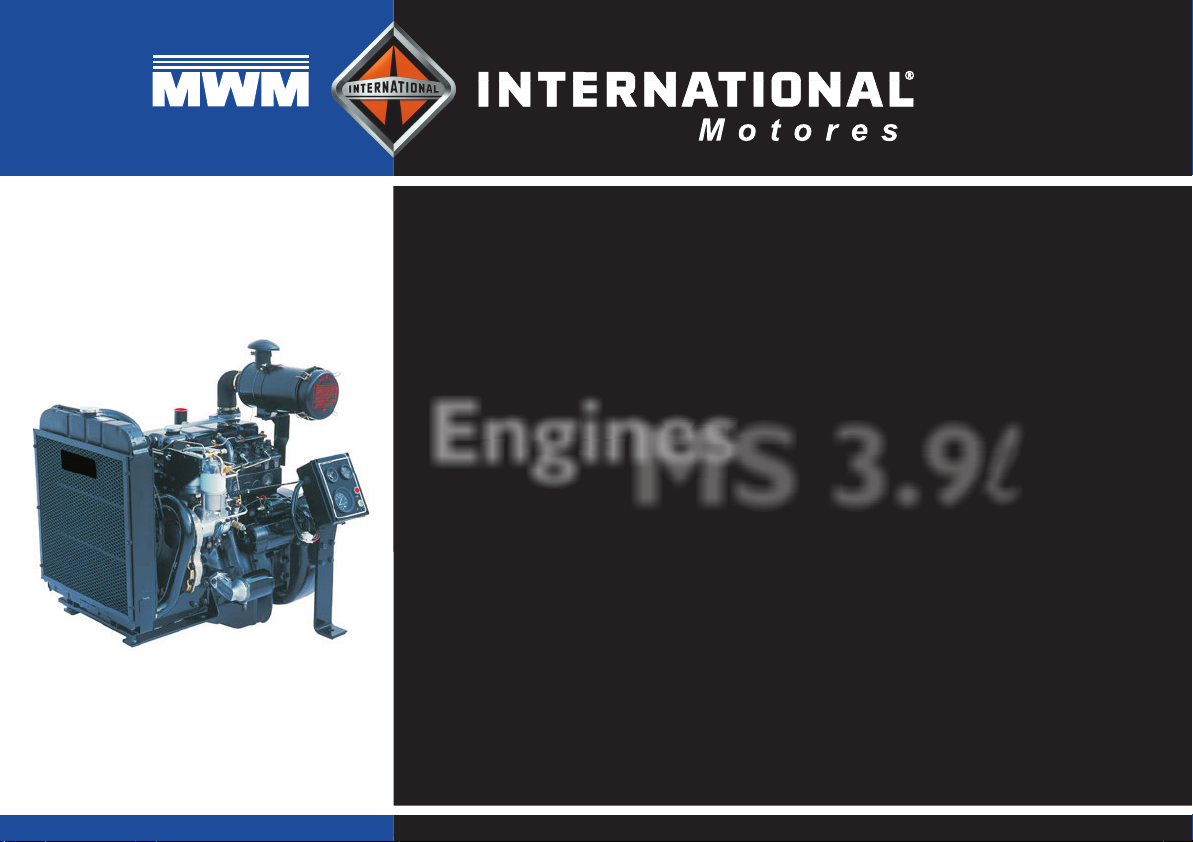

MWM MS 3.9L, MS 3.9T Maintance Manual

Engines

MS 3.9lMS 3.9l

Operation and Maintenance ManualOperation and Maintenance Manual

Engines

MS 3.9lMS 3.9l

Operation and Maintenance ManualOperation and Maintenance Manual

In Brazil Customer Assistance - MWM MOTORES Products Line (DDG) - 08000-110229

MWM- MOTORES

Phone: 55 (11) 3882-3318 / 3249 / 3541 - Fax: 55 (11) 3882-3573 / 3576

Phone: 55 (11) 3882-3323 / 3441 / 3442 - Fax: 55 (11) 3882-3594 / 5686-1554

Phone: 55 (11) 3882-3513 / 3759 / 3593 - Fax: 55 (11) 3882-3574

INTERNATIONAL

CEP 04795-915 - São Paulo - SP - Brasil

Internet:

Av. das Nações Unidas, 22.002

www.mwm-international.com.br

E-mail: servicos@mwm.com.br

Customer Assistance Department

Engines Sales

Spare Parts

NP 085.70.69 - 01/06

Printed in Brazil

A Few Words for the User

Congratulations!!!

You have just acquired a product of the highest technology and quality on the market.

For your convenience and satisfaction, we have elaborated this Operation and Maintenance Manual aiming to help you

about the correct using and maintenance of the MS 3.9l engines, in order to achieve their best performance, cost

effectiveness and durability, this way rising your equipment's retailing value.

We hope that you use this Manual as your main working tool, and consider it your daily working guide.

We recommend that you read the "Warranty Certificate" that is supplied with this Manual.

It is of equal importance that revision, adjustment and maintenance services be done at our Dealers and/or Authorized

Services Network.

International

MWM-

previous notice and according with its criteria, at any moment that an innovation is introduced into its products.

Motores Ltda. reserves its right of changing the technical contents of this publication without

MWM-

INTERNATIONAL

Client Support Department

Av. das Nações Unidas, 22.002 - Santo Amaro

CEP 04795-915 - São Paulo - SP - Brasil

Tel: +55 (11) 3882-3200

Fax: +55 (11) 3882-3574

DDG: 08000-110229

Site: www.mwm-international.com.br

E-mail: servicos@mwm.com.br

Motores Ltda.

NP 085.70.69 - 01/06

1

Index

A Few Words for the User .......................................................................................................................................1

Index....................................................................................................................................................................... 2

Safety Precautions ................................................................................................................................................... 4

Technical Features ...................................................................................................................................................6

Location and identification of the engine number ..................................................................................................... 8

Engines View ........................................................................................................................................................... 9

Instruments panel..................................................................................................................................................10

Operation and Maintenance Recommendations ...................................................................................................... 13

Start and stop ....................................................................................................................................................... 13

Cold Start (for Engines with Start System Heating Kit) ........................................................................................... 14

Stop ...................................................................................................................................................................... 14

Running-in Period ................................................................................................................................................... 15

Revision Programs .................................................................................................................................................. 16

First Revision (Special) - 50 h..................................................................................................................................17

Periodic Maintenance ............................................................................................................................................. 19

Valves Adjustment ................................................................................................................................................. 21

Cooling System ......................................................................................................................................................23

Preventive Maintenance ......................................................................................................................................... 23

Level Check (Daily).................................................................................................................................................23

Cooling System Filling ............................................................................................................................................. 24

Coolant Circuit Drainage ......................................................................................................................................... 26

2

NP 085.70.69 - 01/06

Engine Coolant Refilling .......................................................................................................................................... 27

Coolant nozzle cap .................................................................................................................................................27

Fuel System ........................................................................................................................................................... 28

Preventive Maintenance ......................................................................................................................................... 28

Refueling ............................................................................................................................................................... 28

Fuel Filter and Pre-Filter..........................................................................................................................................29

Filter and Pre-Filter Drainage ................................................................................................................................... 30

Filters replacement.................................................................................................................................................31

Supply pump .........................................................................................................................................................32

Filter screen cleaning ............................................................................................................................................. 32

Air Bleeding ...........................................................................................................................................................33

Lubrication System.................................................................................................................................................36

Preventive maintenance ........................................................................................................................................36

Level ..................................................................................................................................................................... 36

Lubricating Oil and Filter Change.............................................................................................................................37

Belt .......................................................................................................................................................................39

Belt Tension Check ................................................................................................................................................39

Conservation of inactive engines ............................................................................................................................ 40

Engine preparation to return to operation..............................................................................................................42

Fuel storage...........................................................................................................................................................44

Influence of altitude in engine performance ...........................................................................................................45

NP 085.70.69 - 01/06

3

Safety Precautions

Caution: The text marked with the symbol above presents direct or indirect risks to personal safety.

Read this Manual carefully and always maintain it close at hand to eliminate any doubts.

Don't try to operate the equipment without prior knowledge of all its controls and full

understanding of its functioning. Use always the following safety precautions before proceeding

with any work, because they are listed for your protection:

Do not change the original features of the engine;

• Do not smoke when refueling the fuel tank;

• Clean immediately any and all spilled fuel. Place all used material in a clean and safe area;

• Do not refuel an operating engine, unless it is absolutely necessary;

• Never clean, lubricate or adjust an engine while it is running;

• Do not make any adjustment, if you do not know how to do it correctly;

• Do not operate the engine within closed areas, because the exhaust gases are extremely poisonous;

• Do not allow people or animals near the engine, vehicle or equipment while it is running;

• Do not allow people with baggy clothing or with long, loosen hair to approach the movable parts;

• Maintain a safe distance from any rotary parts. Remember that fans, for example, cannot be seen distinctly while the engine is running;

• Do not remove the radiator cap if the engine is hot, because a spray of engine coolant, under pressure, is extremely dangerous and could

cause a serious burnings;

• Do not use salty water or any other liquid that could cause corrosion in the cooling system;

• Avoid sparks and flames near the batteries, especially when they are being charged, because they can cause explosions. The battery

electrolyte can boil and any contact with your skin and/or eyes is dangerous;

• Disconnect the battery terminals before doing any repair to the electrical system;

• Seek medical assistance immediately if the high-pressure diesel fuel penetrates into the skin.

4

NP 085.70.69 - 01/06

NOTES

NP 085.70.69 - 01/06

5

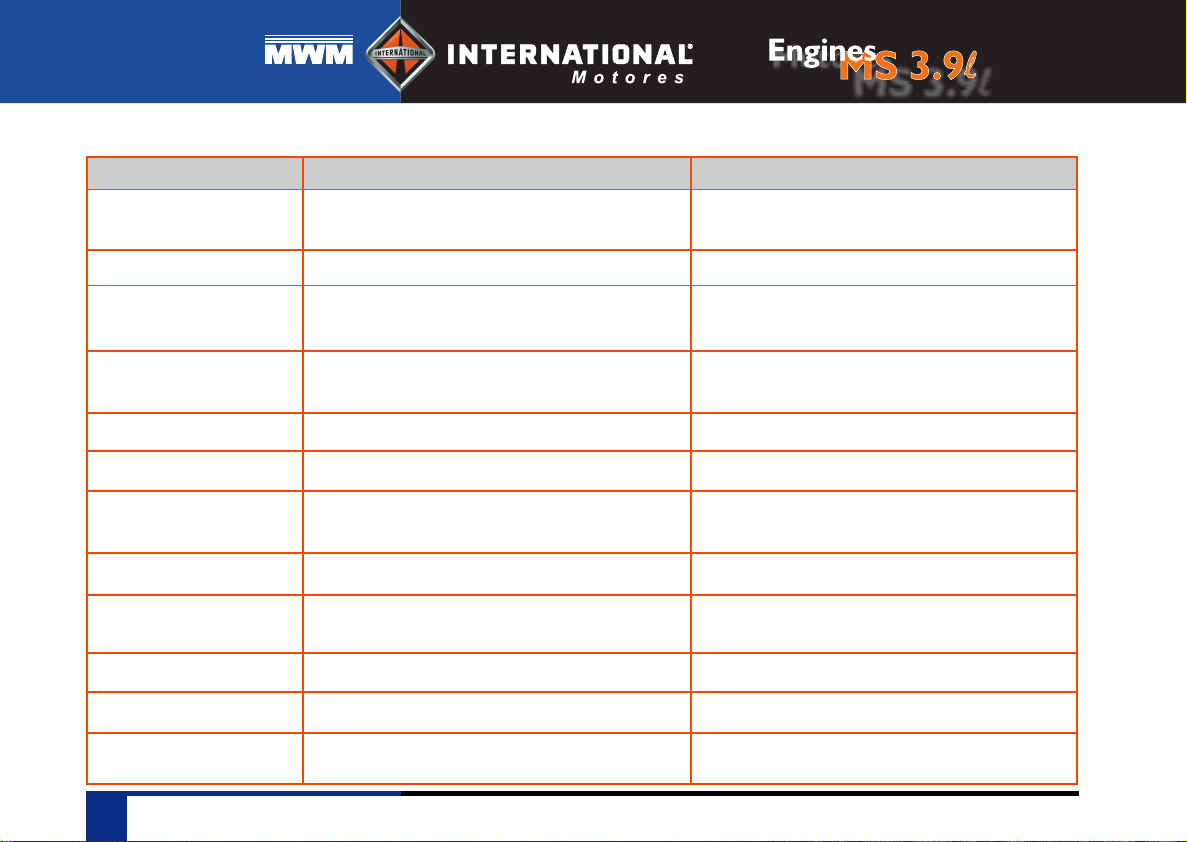

Technical Features

Type MS 3.9

LP number C72, C73, C47 C57, C48

Aspiration

Number of cylinders

and arrangement

Cylinders nominal

bore

Piston stroke

Cycle

Compression ratio

Total displacement

Combustion system

Direction of rotation

Firing order

Operating temperature

4 in line

98,43 mm 98,43 mm

127 mm (5 pol.) 127 mm (5 pol.)

Diesel 4 stroke Diesel 4 stroke

3,9 liters 3,9 liters

Direct injection Direct injection

Clockwise Clockwise

1 - 3 - 4 - 2 1 - 3 - 4 - 2

82 - 95 °C 82 - 95 °C

LL

L

LL

Natural Turbocharger

16:1 16:1

MS 3.9T

4 in line

6

NP 085.70.69 - 01/06

Type MS 3.9

LL

L

LL

MS 3.9T

Lubricant oil

pressure

Idle Speed

Cooling system

Output

Torque

2,1bar (min) 4,2 bar (max) 2,1bar (min) 5,9 bar (max)

700 - 750 rpm

Liquid - Water pump Liquid - Water pump

67 cv @ 1800 rpm

DIN 6271 / ISO 3046

(LP C47)

65 cv @ 2200 rpm

NBR 5484

(LP C72 / C73)

26,5 m.kgf @ 1800 rpm

DIN 6271 / ISO 3046

(LP C47)

24 m.kgf @ 1400 rpm

NBR 5484

(LP C72 / C73)

90 cv @ 1800 rpm DIN 6271 / ISO 3046

36,2 m.kgf @ 1800rpm DIN 6271 / ISO 3046

700 - 750 rpm

(LP C48 / C57)

(LP C48 / C57)

NP 085.70.69 - 01/06

7

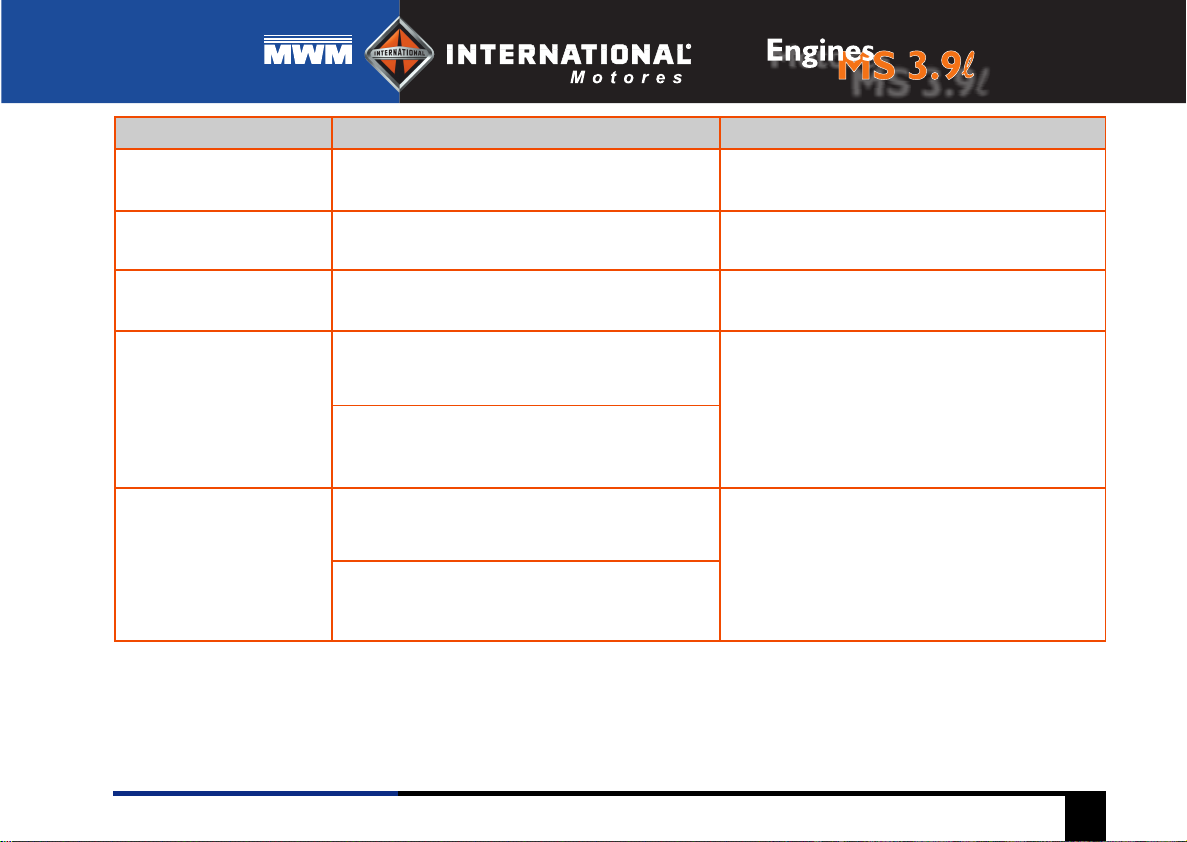

Location and identification of the engine number

Identification

I39T C65 XXXXXX B

Manufacturing

Year

Serial Number

Parts List

Number (LP)

Engine Model /

Type

8

NP 085.70.69 - 01/06

Engines View

* Illustrative picture subject to changing

NP 085.70.69 - 01/06

Engine MS 3.9T

9

Instruments panel

O Painel possui uma série de instrumentos que permite

observar, na partida e durante a operação, o bom

funcionamento do motor.

Portanto, é de fundamental importância que o operador fique

atento aos mesmos.

Tachometer (engine speed meter)

This instrument indicates engine's rotations per minute and

it should be monitored constantly to achieve the best output

and torque performance from the engine.

Engine coolant temperature indicator lamp

If engine coolant temperature exceeds the normal operating

temperature, this lamp will turn on simultaneously with fuel

cutoff and consequent engine stopping.

Note: Keep the coolant level correct and

check water pump belt's tension.

Oil pressure indicator lamp

This lamp will turn on when the ignition key is turned to

"ON" position, and it will turn off just after the engine is

running. In case of engine oil low pressure, this lamp will

turn on and there will be a fuel cutoff.

Hour meter

It registers the total of running hours of the engine. The

rightmost numeral indicates tenths of an hour, corresponding

to six (6) minutes for each registered unit.

Battery charging indicator lamp

When turning the ignition key to "ON" position, this lamp

turns on, and it turns off when the engine is running, which

indicates that the alternator is charging the battery. The

correct level of electrolyte and tensioning of the alternator's

belt is of extreme importance for charging the battery.

Note: Keep the correct level of battery

electrolyte.

Air filter restriction indicator lamp

Whenever an air filter restriction occurs, which impairs

engine's performance, this lamp will turn on.

Clean or replace the element within the recommended

periods

Note: Keep the air filter element always clean.

Note: Check lubricating oil on a daily basis.

10

NP 085.70.69 - 01/06

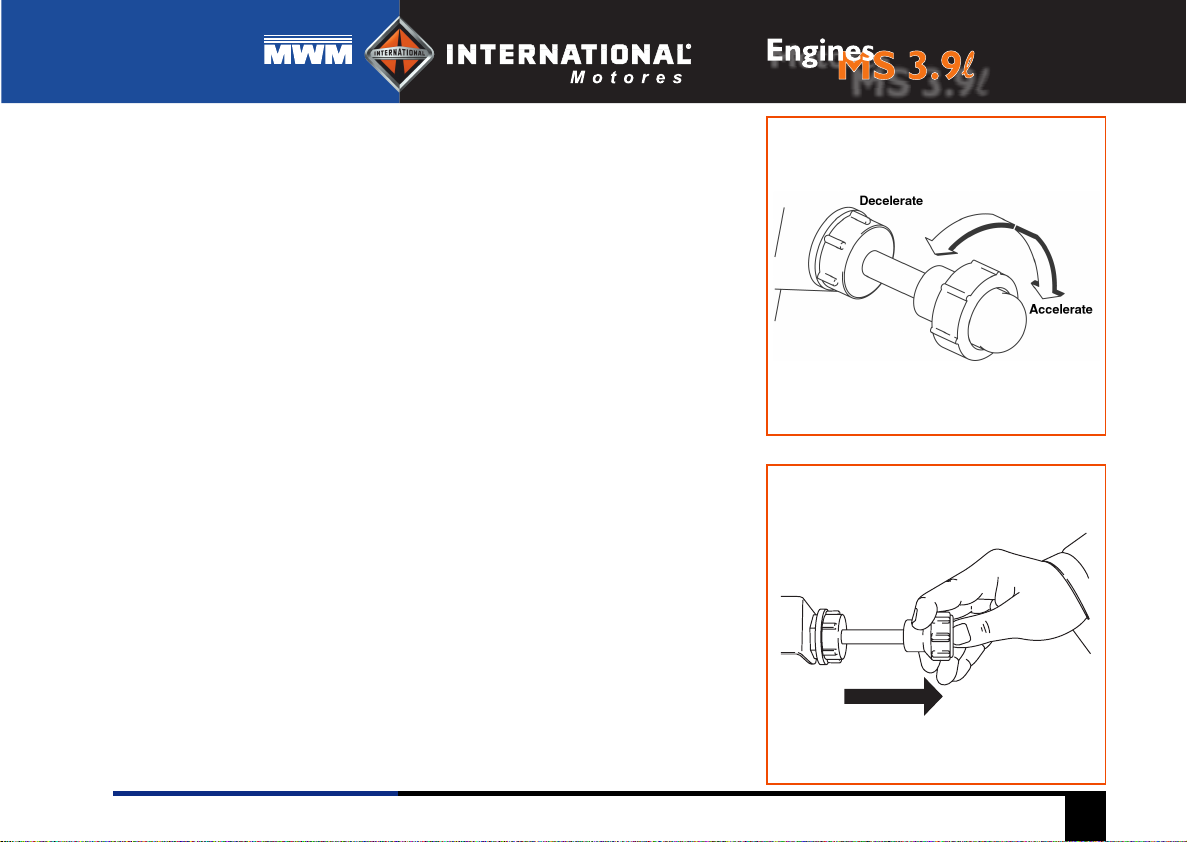

Acceleration control

1. Turn the acceleration control clockwise to achieve a gradual acceleration

of the engine, and turn it counterclockwise to decelerate it.

2. For a quick acceleration, depress the button and pull the control knob.

NP 085.70.69 - 01/06

11

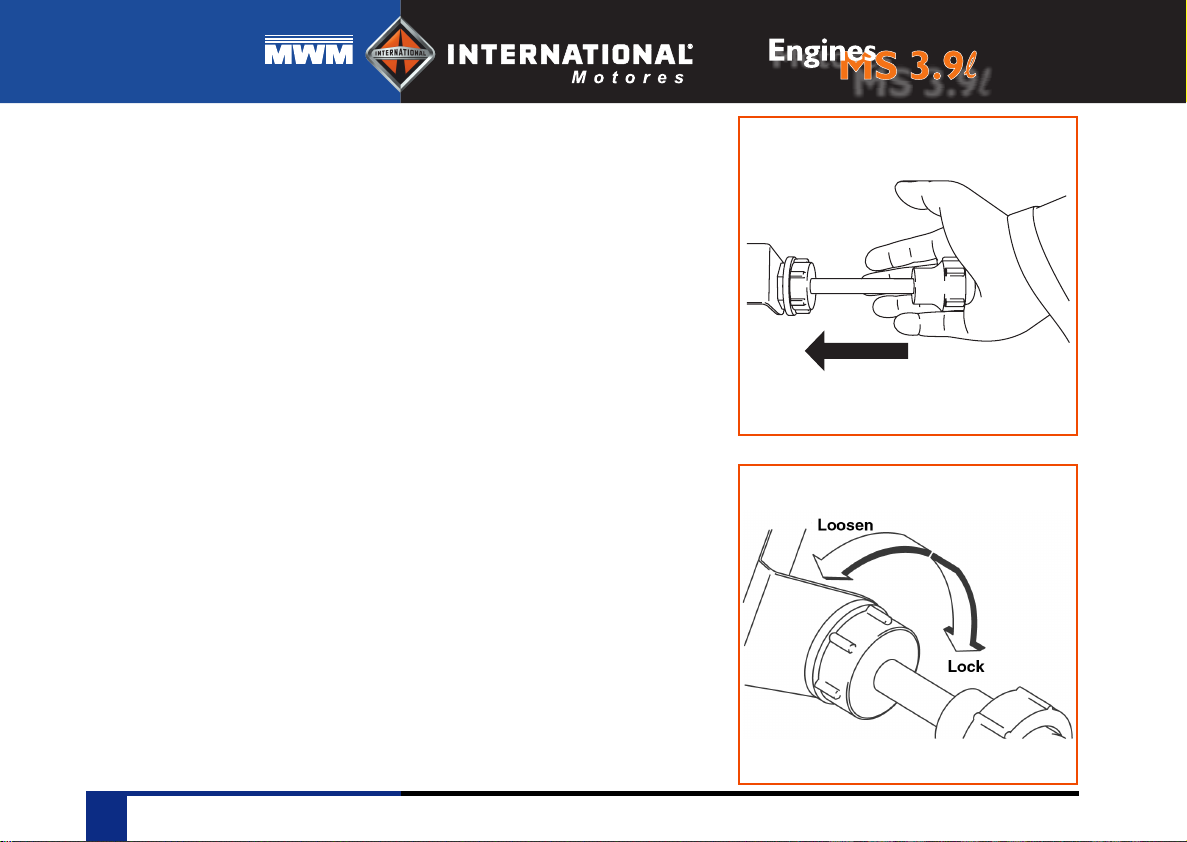

3. To quickly get the engine idling or a fast deceleration, depress the button

and push the control knob.

4. After achieving the optimal engine speed, turn the control lock clockwise

to hinder it of changing the acceleration by itself while engine is running.

Turn it counterclockwise to change the engine speed regime.

Note: Apply the control lock only after you get the optimal

engine speed regime.

Keep the engine idling whenever the engine is turned

off.

12

NP 085.70.69 - 01/06

Operation and Maintenance Recommendations

Start and stop

Normal Start

Caution: Put the transmission shift in neutral (Agricultural).

1. Perform the "Daily Maintenance" routine.

Note: If the engine was inactive for a long period, bleed the

fuel system.

2. Actuate the throttle to approximately ¼ of its total stroke.

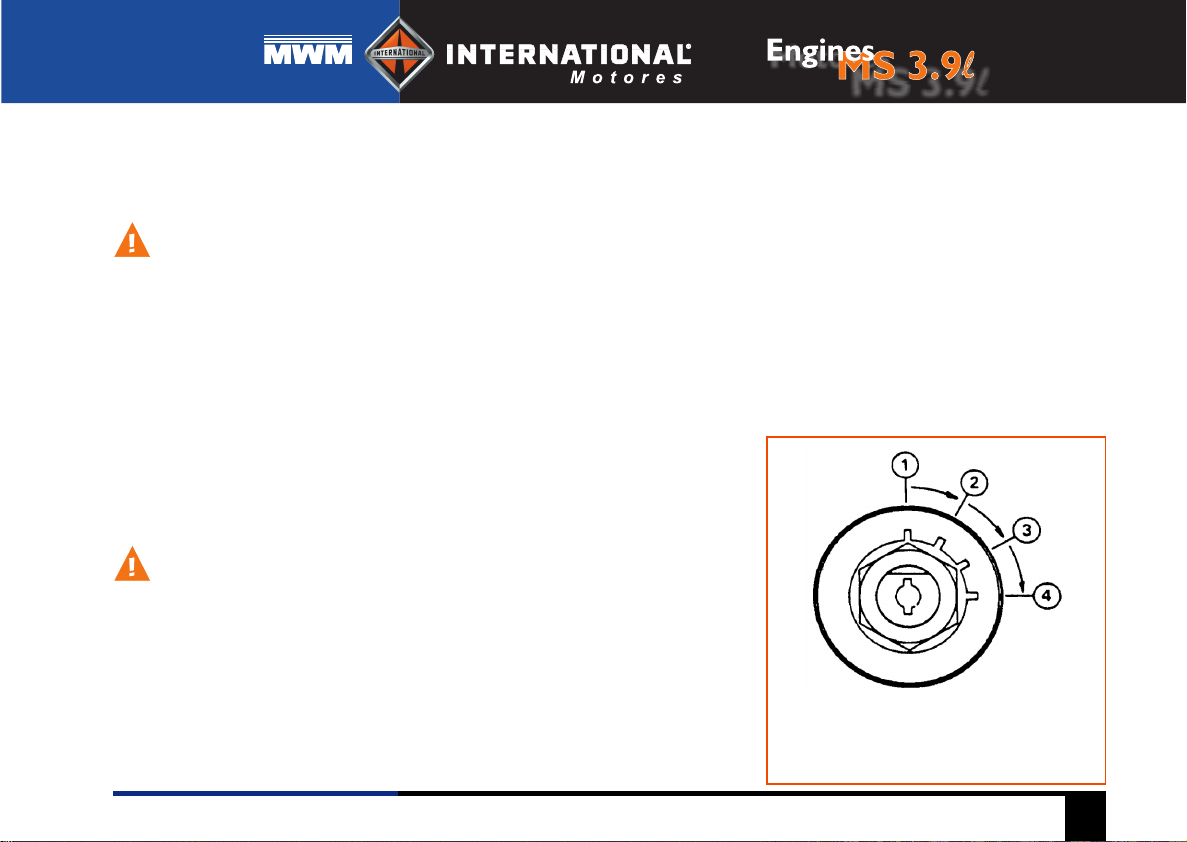

3. Turn the start key to position 4 during 7 (seven) seconds at most.

Caution: Do not keep the key turned on too long, because it

will damage the starter motor.

In turbocharged engines, after the start, wait for 30

(thirty) seconds in idling to avoid damage to the

turbocharger.

NP 085.70.69 - 01/06

1. Off

Key positions

2. Contact

Illustration valid for agricultural application

3. Preheating

4. Start

13

Cold Start (for Engines with Start System Heating Kit)

Caution: Put the transmission shift in neutral (Agricultural).

1. Perform the “Daily Maintenance” routine.

2. If the engine has a manual stopping control, make sure it is deactivated (start position).

3. Turn the start key to position 3 and keep it in this condition for 15 seconds.

4. Operate the throttle to position of maximum speed.

5. Turn the key to position 4 and start the engine.

6. If the engine doesn't run, turn the start key back to position 3 and keep it in this condition for 10 seconds. Then, try

to start the engine again.

Caution: Do not operate the key for a long time, this will damage the starter motor.

Stop

1. Keep the engine idling and the transmission shift in neutral.

2. Turn the start key to position 1.

Note: If the engine has manual stopping control, operate it and make sure it is deactivated.

14

NP 085.70.69 - 01/06

Loading...

Loading...