Manual B – Operations - 1

Manual B

OPERATIONS MANUAL

B22

B25

Applicable to: B22 and B25 (all versions) Revision 1.3 – 02/24/2015

AeroPower

AeroPower

Manual B – Operations - 2

Before attempting any engine start carefully read Manual A containing

important safety information. Not following safety procedures could cause

severe injury or loss of life. Consult the aircraft instruction manual for more

information on safety.

All information, illustrations, instructions and technical data contained in this manual has been upgraded

before printing. MW Fly reserves the right to modify, correct or upgrade general data at any time without any

obligation or prior consent from third parties. Publication of any part of this document without written consent

of MW Fly is strictly prohibited.

This Manual forms part of the engine and must be kept safe. It must accompany the engine in case of sale to a

new owner. The original document is written in Italian and this language will be used to settle any dispute of a

legal or technical nature.

Applicable to: B22 and B25 (all versions) Revision 1.3 – 02/24/2015

Manual B – Operations - 3

B.1. SUMMARY 7

B.2. INTRODUCTION 7

B.2.1. Statement 7

B.2.2. Consultation Notes 7

B.2.3. Identification Data 9

B.2.4. MW Fly Authorized Service Centers 9

B.3. SAFETY 10

B.3.1. Statement 10

B.3.2. Safety Elements 10

B.3.2.1. Passive Safety 10

B.3.2.2. Active Safety Elements 12

B.3.3. Warning labels 14

B.3.3.1. Engine Oil Filler Cup 14

B.3.3.2. Reduction Gear Box Oil Filler Cup 14

B.3.3.3 Water Expansion Tank 15

B.3.3.4. Air Filter 15

B.3.3.5. ECU 15

B.3.3.6. Head Cover 15

B.3.3.7. Reduction Gear Box 15

B.3.3.8. Governor 16

B.3.3.9. Water Circuit Arrows 16

B.3.3.10. Fuel Circuit Arrows 16

B.3.4. Modifications and Accessories 17

B.3.4.1. Original Accessories 17

B.3.5. Use of the Technical Documentation 18

B.4. ENGINE DESCRIPTION 19

B.4.1. General Characteristics 19

B.4.2. Engine Models 19

B.4.3. Cylinder Numeration and Position 20

B.5. TECHNICAL CHARATERISTICS 21

B.5.1. End Use 21

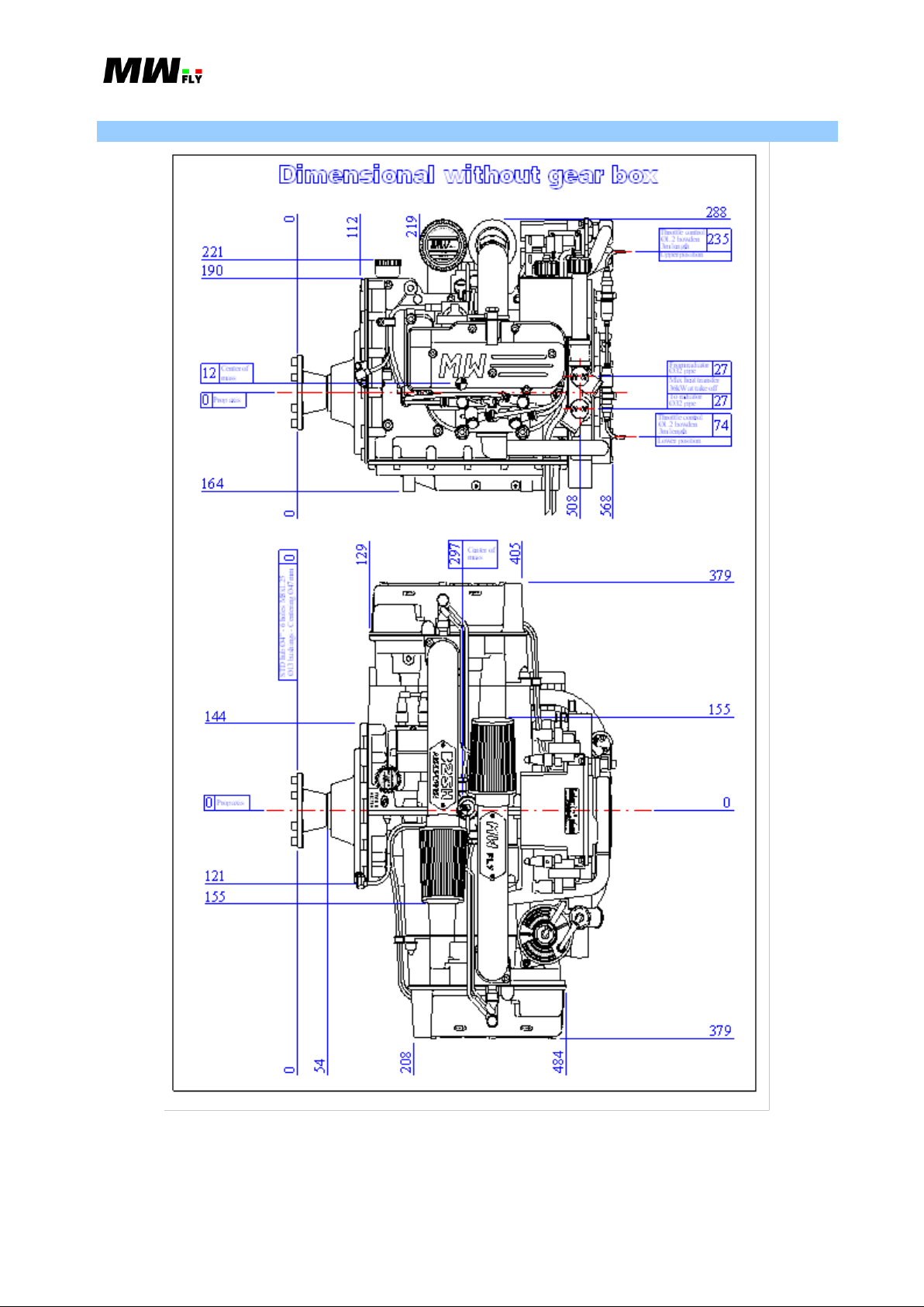

B.5.2. Dimension 22

B.5.3. Weight 24

B.5.3.1. Optional Accessory Weight 24

B.5.4. Performance 24

B.5.4.1. B22D 27

B.5.4.2. B22H 29

B.5.4.3. B22L 30

B.5.4.4. B22R 32

B.5.4.5 B25D 34

B.5.4.17.C 34

Applicable to: B22 and B25 (all versions) Revision 1.3 – 02/24/2015

Manual B – Operations - 4

5

10

15

20

25

30

35

40

2000 2250 2500 2750 3000 3250 3500 3750 4000 4250

[L/h]

[RPM]

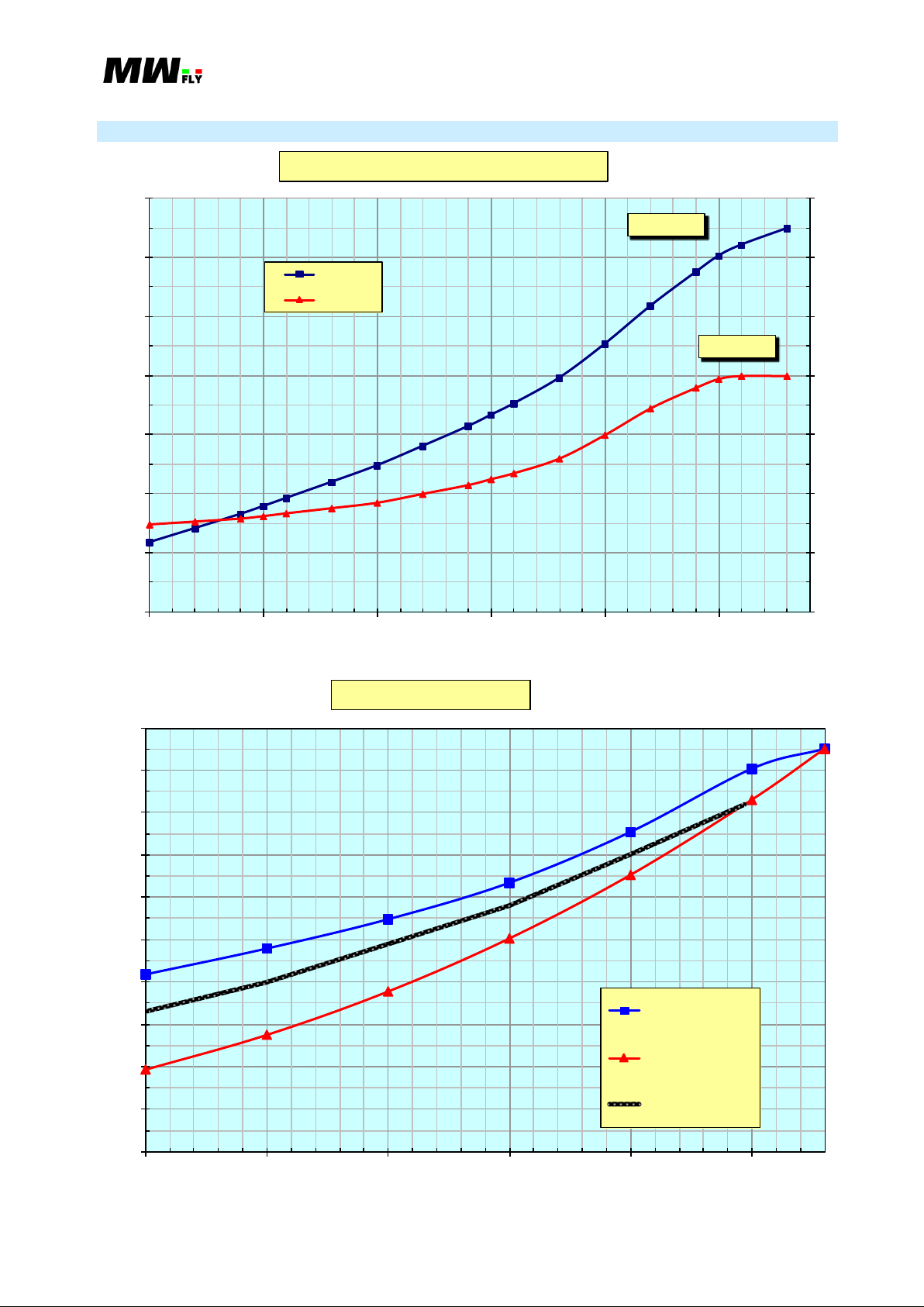

B25L Consumption @ constant MAP

29.9

28.5

27

25.5

24

22.5

B.5.4.6. B25H 36

B.5.4.7. B25L 37

B.5.4.8. B25R 39

B.5.4.9. Performance Variation 41

B.5.5. Ratio Power/Weight 42

B.5.6. Fuel Consumption 42

B.5.6.1. B22D 44

B.5.6.2. B22H 46

B.5.6.3. B22L 47

B.5.6.4. B22R 49

B.5.6.5. B25D 51

B.5.6.6. B25H 53

B.5.6.7. B25L

54

B.5.6.8. B25R 56

B.5.7. Propeller speed 58

B.5.8. Direction of the Rotation of the Propeller 58

B.6. DESCRIPTION OF THE SYSTEMS 60

B.6.1. Cooling system 60

B.6.2. Lubricant system 61

B.6.3. Fuel system 62

B.6.4. Electric system 63

B.6.4.1. ES-m Instrumentation 64

Applicable to: B22 and B25 (all versions) Revision 1.3 – 02/24/2015

Manual B – Operations - 5

B.7. OPERATING INSTRUCTION 65

B.7.1. Operating limits 65

B.7.1.1. RPM 65

B.7.1.2. Fuel Pressure 66

B.7.1.3. Engine oil pressure 66

B.7.1.4. Engine Oil Temperature 67

B.7.1.5. Reduction Gear Box Oil Temperature 67

B.7.1.6. Coolant Temperature 68

B.7.1.7. Air Intake Temperature 68

B.7.1.8. Load Factor 69

B.7.1.9. Inclination Angle 69

B.7.1.10 Electrical Voltage 70

B.7.2. Operative Fluid 70

B.7.2.1. Cooling Fluid 70

B.7.2.2. Engine Oil 70

B.7.2.3. Reduction Gear Box Oil 71

B.7.2.4. Fuel 71

B.7.3. General Criteria to Operate the Engine 72

B.7.3.1. Check Before Start 72

B.7.3.2. Start Operation 75

B.7.3.3. Engine Warm Up 76

B.7.3.4. Before Take Off 77

B.7.3.5. Take Off 78

B.7.3.6. Cruise 78

B.7.3.7. Landing 78

B.7.3.8. Engine Switch off 79

B.7.3.9. Use of the Engine in Winter Season 79

B.7.4. Behavior in Case of Emergency 81

B.7.4.1. Accidental Engine Stop – Start During Flight 81

B.7.4.2. Over Rev 81

B.7.4.3. Exceeding the Maximum Coolant Temperature 81

B.7.4.4. Exceeding the Maximum Oil Temperature 82

B.7.4.5. Oil Pressure Below the Limit in Flight 82

B.7.4.6. Oil Pressure Below the Limit on the Ground 82

B.7.4.7. Fuel Pressure Below the Limit in Flight 82

B.7.4.8. Fuel Pressure Below the Limit on the Ground 83

B.7.4.9. Battery Voltage Over the Limit 83

B.7.4.10. Battery Voltage Below the Limit 83

B.7.4.11. ECU Alarm 84

B.7.4.12. Generator Alarm 84

B.7.4.13. Abnormal Vibration 84

B.7.4.14. Irregular Operation 85

Applicable to: B22 and B25 (all versions) Revision 1.3 – 02/24/2015

Manual B – Operations - 6

B.8. ENGINE CONTROL 86

B.8.1. List of Tool Kit for the Pre-flight Checks or Emergency 86

B.8.2. Shelter from Service for Extended Period of Time 86

B.8.3. Return to Service After Long Inactivity 86

B.8.4. Engine Protection When Used in Cold Climates 87

B.9. MALFUNCTION RESOLUTION 88

B.9.1. Operation Malfunctions and Their Resolution 88

B.9.2. Anomalies to the Injection and Ignition Systems 89

B.9.3. Signal Engine Malfunction 90

B.10. AUTHORIZED DISTRIBUTOR 92

B.11. MANUAL UPDATE LIST 93

Applicable to: B22 and B25 (all versions) Revision 1.3 – 02/24/2015

Manual B – Operations - 7

This engine has not received any certification for aeronautical use.

It must be used exclusively on experimental aircraft where an engine failure

will not compromise flight safety. Its use in cetified aircraft is strictly

prohibited.

Operate the engine in compliance with the local rules and laws.

B.1. SUMMARY

B.2. INTRODUCTION

The A eroPower series of engines are designed and manufactured using the most modern

motor technology with the purpose of achieving good performance combined with a high level of

passive safety. If the engine is used correctly it will return years of pleasure and reliable service.

Please read this manual carefully before using the engine and apply all safety standards contained

in it, in addition to those that your experience and common sense suggest.

Remember that regular maintenance and careful inspection of the engine before flight are essential

safety factors.

MW Fly will be happy to provide additional information and all the technical support you will

need.

B.2.1. Statement

The purpose of this operations manual is to provide the users of the AeroPower engine

family with the basic operating instructions and safety information. Prior to commencing to

operate the engine it is crucial to read and understand the contents of this document. If any part of

this manual is unclear or there are any doubts on the interpretation, contact an MW Fly service

center.

For additional or more detailed information consult the Maintenance Manual and the Additional

Maintenance Manual.

It is fundamental to integrate the information of this manual with the safety precautions of the

aircraft manufacturer and with safety conditions from your personal experience.

B.2.2. Consultation Notes

This manual was originally printed in Italian. This will be the only language used for any

reference or dispute.

This manual is divided into sections, chapters and paragraphs. The paragraphs could be partitioned

into one or more topics. The title of each section, chapter and paragraph is indicated as follows:

SECTION

Chapter

Paragraph

Topic

Applicable to: B22 and B25 (all versions) Revision 1.3 – 02/24/2015

Manual B – Operations - 8

A 3D Cartesian coordinate

right hand is used in the

present manual. The axis

origin is on the propeller shaft.

In the intersection with the

propeller level on the propeller

flange, the x-axis positive

direction is towards the engine

(see picture B.2.2.1.P), the yaxis positive direction is

towards side #1, the z-axis

points up.

RAM

INTAKE

EFFECT

E

C

L

P

E

K

E

Y

D

N

A

D

R

FLY

A

N

T

S

G

S

Y

N

E

B

T

H

O

H

G

H

E

N

E

R

L

F

P

E

N

W

O

F

I

O

T

G

L

T

H

L

L

I

RESERVOIR

R

C

D

N

N

E

V

E

A

U

S

E

F

E

L

E

0

.

Y

7

A

P

A

C

I

O

C

I

L

O

L

E

T

E

H

C

E

C

K

L

V

M

O

L

A

N

T

O

T

/

2

N

E

P

U

K

N

O

3

Y

L

E

N

G

V

E

R

Y

2

C

E

H

A

E

C

Y

E

A

R

S

A

T

PRESSURIZED

Y

L

O

O

N

Y

C

L

PROTECT BEFORE WASHING

ONTROLUTHORITY

MAX OPERATING TEMPERATURE 85°C

CHECK WIRING LOOM BEFORE FLIGH T -

OPERATING ELECTRIC VOLTAGE 9-18V

NGINEIGITAL

FLY

ULL

BY

API GL-5 OR HIGHER

C

H

E

C

B

I

F

O

R

E

F

L

G

H

T

K

E

SAE 85W/140

T

I

C

A

P

A

C

3

.

0

Y

L

CTIVE AMPING ONTROL

GEAR

OIL

API SG OR HIGHER

C

H

E

C

B

I

F

O

R

E

F

L

G

H

T

K

E

SAE 15W/50

T

I

C

A

P

A

C

8

.

2

Y

L

ENGI NE

OIL

Z

X

Y

X

Y

Z

WARNING: Not following this instruction can cause severe personal injury or

loss of life.

B.2.2.1.P

The numeration is an alpha-numeric code that follows format below:

B.7.1.8.

The first letter indicates the type of manual:

A = installation manual

B = operations manual

C = maintenance manual

D = heavy maintenance manual

The first number (between the first and second dot): this number (one or two digits) indicates

the section.

The second number (between the second and third dot): this number (one or two digits)

indicates the chapter.

The third number (between the third and fourth dot): this number (one or two digit) indicates

the paragraph and is not always present.

The numeration of the pictures follows the same criteria for the first three parts of the code. The

third number is the number of the picture in the chapter. A letter P is added at the end of the code.

(e.g. B.5.8.2.P).

The numeration of the tables follows the same criteria for the first three parts of the code. The

third number is the number of the picture in the chapter. A letter C is added at the end of the code.

(e.g. B.5.8.2.C).

Specifications are given in the ST metric system (C.2.4.); in the table the measurement units are

indicated between square brackets [].

Symbols used in this manual have the following meaning:

Applicable to: B22 and B25 (all versions) Revision 1.3 – 02/24/2015

Manual B – Operations - 9

CAUTION: Not following this instruction could cause severe damage to the engine

or other components and possible engine failure.

NOTE: Refers to supplementary information to better understand or execute an

instruction.

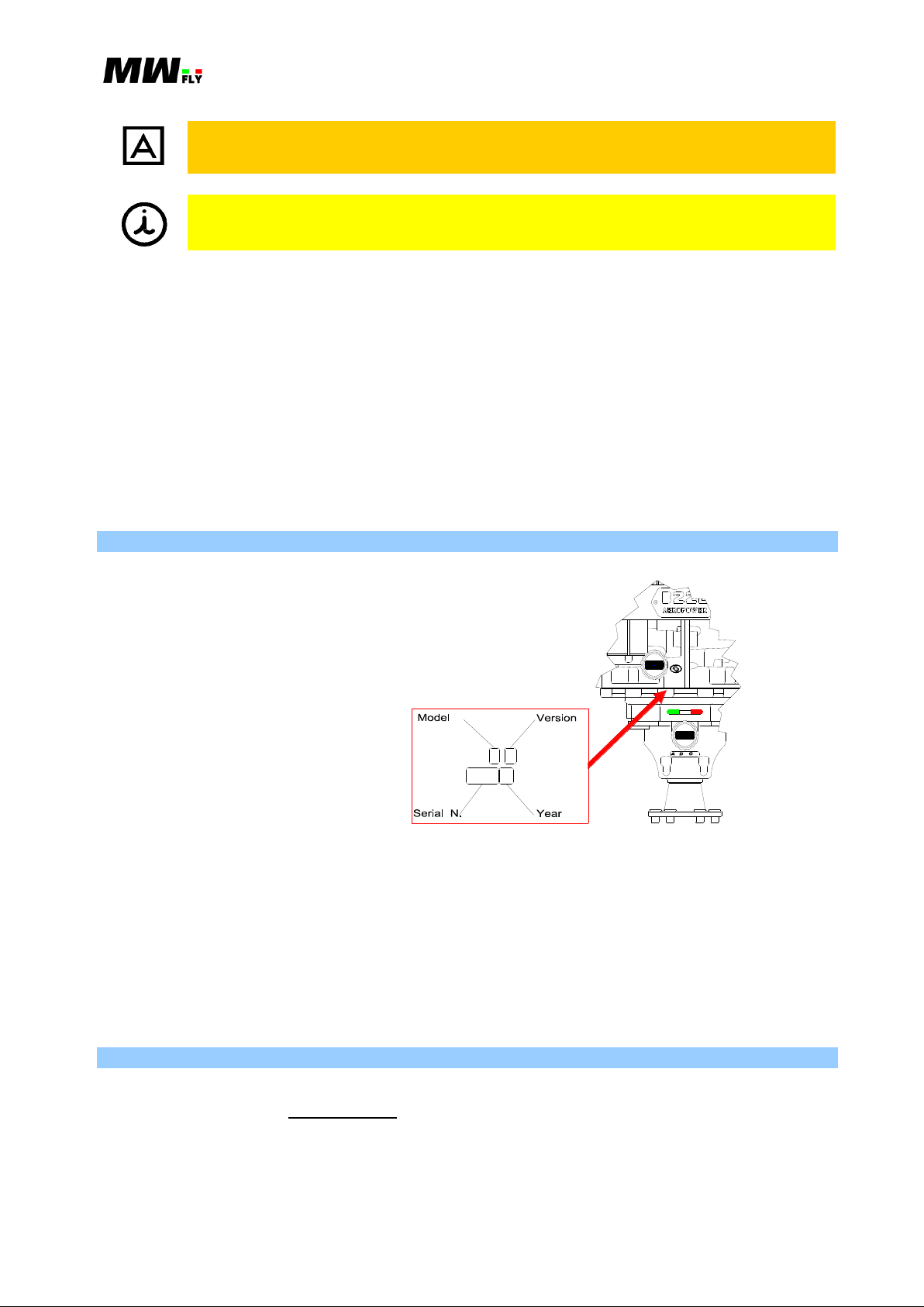

The Engine serial number is

located on the upper side of

crank case near oil dip stick.

It is composed of ten alpha

numeric codes where the third

and fourth symbol indicate

Model and Version, the

following four are the serial

number and the last two are

the year of manufacturing.

Identification code and

version is illustrated in chart

B.4.2.1.C.

API GL-5 OR HIGHER

C

H

E

C

B

I

F

O

R

E

F

L

G

H

T

K

E

SAE 85W/14 0

T

I

C

A

P

A

C

Y

3

.

0

GE A R

L

CTIVE AMPI NG ONTROL

OI L

API SG OR HI GHER

C

H

E

C

B

I

F

O

R

E

F

L

G

H

T

K

E

SAE 15W/50

T

I

C

A

P

A

C

8

.

2

Y

L

EN G IN E

OI L

B.2.3.1.P

1., 2., … This numbering is used to list tools and consumables needed to run an installation or

maintenance; it is also used to bring in parts lists or engine parts shown in the

illustrations.

a., b., … This numbering is used to indicate a list of actions or subjects with relation to inclusion:

all of the actions or options listed must be verified.

o This symbol is used to indicate a list of actions or subjects with relation to exclusion: only one

of the actions or options listed with this symbol must be verified.

This symbol is used to list the general characteristics of the engine, component specifications

or options for installation or maintenance.

B.2.3. Identification Data

The relationship between the engine serial number and the engine model is indicated in the table

B.4.2.1.C.

Deleting or modifying the serial number will revoke any warranty and obligation by MW Fly

toward current owner.

Provide the serial number on any request for an engine part or technical information.

B.2.4. MW Fly Authorized Service Centers

Contact the nearest service centre or web-site for any information regarding service, maintenance

or spare parts. (B.10. or www.mwfly.it).

Applicable to: B22 and B25 (all versions) Revision 1.3 – 02/24/2015

Manual B – Operations - 10

B.3. SAFETY

B.3.1. Statement

Just by reading this manual will not eliminate the hazards connected to the installation and use of

the engine. However the understanding and application of the information herein is essential for a

proper and safe use of the engine.

The information, components, system descriptions, pictures, tables and technical data contained in

the present manual are correct at the time of publication. MW Fly, however, maintains a policy of

continuous improvement of its products without imposing upon itself any obligation to install

them on its products previously manufactured.

The onus to install MW Fly B22 engine is at the sole discretion and responsibility of the Original

Manufacturer, Home Builder or Aircraft Owner. MW Fly cannot assume responsibility for a

successful installation in a specific airframe due to the variety of designs existing in the market.

For this reasons MW Fly declines responsibility regarding damage to engine parts, accessories or

aircraft structure during the installation and use of this engine. The owner accepts the

responsibility and the risk in using this engine.

MW Fly reserves the right at any time to discontinue or change specifications, designs, features,

models or equipment without incurring obligation. It is forbidden to copy any part of the present

manual without authorization from MW Fly.

B.3.2. Safety Elements

It very important to understand all the safety aspects and to distinguish the two different safety

types; active and passive.

B.3.2.1. Passive Safety

Passive safety concerns the engine design and the engine installation criteria. The following is a

list of the main engine features designed to increase passive safety.

CRANK SHAFT ON BALL BEARINGS: This reduces the risk of engine stoppage in case of

lubricant system default or oil leakage. Moreover, unexpected wearing of the bearings is easy

to identify because it is characterized by a clear increase in noise on the lower side of the

crank case. Plain bearings do not provide any clear signal in case of unexpected wearing.

MONOLITIC CONNECTING ROD: This reduces the risk of the default of the crank that is

often connected to the wrong installation of the rod cup.

MACHINED PISTON: This increases the safety by avoiding the risk of deformation due to

intrusion in the fusion, press residual stress, and use of low thermal dilatation coefficient

alloy.

SINGLE OVER HEAD CAMSHAFT (SOHC): By using this it is not necessary to adopt

hydraulic tappets (that are necessary with a push rod system) and it avoids the risk of breaking

the valve in case of a drop in oil pressure. Moreover, the use of SOHC reduces the dynamic

load on the timing command thereby reducing the friction and the wear of the timing

mechanical parts.

REDUCTION GEAR BOX WITH SEPARATE LUBRICATION: The use a specific oil for

the reduction gear box increases the reliability and reduces the risk of a fatigue fracture and

pitting wear of the teeth.

MONOLITIC PROPELLER SHAFT: This reduces the risk of a fatigue fracture of the

propeller shaft and also increases its strength.

Applicable to: B22 and B25 (all versions) Revision 1.3 – 02/24/2015

Manual B – Operations - 11

ELECTRO-HYDRALIC DAMPING SYSTEM (ADC): This system avoids the use of a

mechanical damping system that is a component that is subject to wear and the risk of

breakage. Moreover the ADC system does not need any maintenance or periodical

adjustment.

FUEL INJECTION AND ELECTRONIC IGNITION: This system reduces the risk of icing

in the intake manifold because it doesn’t need a venturi to work. It also eliminates the risk

connected to fuel remaining in the float chamber of the carburetor, in particular the risk of a

stoppage of the engine during takeoff due to a forgotten closed fuel valve and the risk of fire

in case of flip over.

ECUS INSTALLED ON THE ENGINE: With the ECUs installed on the engine the wiring

harness and the ECUs are subjected to the same waggle produced by the engine. This reduces

the stress on the wire terminals.

PRE-INSTALLED HIGH QUALITY ELECTRICAL HARNESS: A pre-installed electrical

harness avoids any risk of homemade and untested electrical harnesses when you consider

that the electrical harness in the most critical part of a electronic system.

PRE-INSTALLED FUEL CIRCUIT: The pre-installed fuel circuit is made with metal pipe

with a small section which is much better than a rubber tube both in terms of mechanical and

thermal resistance.

ECU CONTROLLED FUEL PUMP: The main fuel pump is controlled by the ECUs so that

it is switched off as soon as the engine stops running. This will prevent a fuel leakage in case

of accident. Moreover the fuel pumps are “no transparent” to eliminate the possibility of fuel

leakage from the fuel tank when the engine is not running.

LIQUID COOL ENGINE: A liquid cool engine provides a better distribution of heat and the

engine runs at a constant temperature. This avoids the complicated setting of cooling that an

air cooled engine needs. With the liquid cool engine the real performance of the engine is

close to the theoretical performance because engine temperature does not depend at all on

external and flight conditions.

COOLING CIRCUIT IN STAINLESS STEEL: This solution has been designed to avoid any

risk of wear or loosening of the coolant circuit hoses.

PRE- INSTALLED THERMOSTAT: The thermostat protects the engine from thermal shock

and reduces warm up time.

PRE-INSTALLED EXPANSION TANK: This reduces the risk of a cooling circuit breakage.

SEMI-DRY SUMP: The advantage in terms of safety of this solution is that the oil in the

sump is guaranteed by gravitational force and a non-return valve. In a dry sump a default in

the lubricant circuit hose and pipe or gasket will cause a non return of oil in the sump.

NO OIL RADIATOR NEEDED: This avoids one of the main causes of engine stoppage that

is caused by the leakage of oil in the pipe from the engine to the oil radiator. Moreover the

absence of the oil radiator makes the installation of the engine simpler.

PRE-INSTALLED THROTTLE CABLE WITH INTEGRATED SPLITTER: Often the

installation of the throttle cable is not very well done. The installation on this engine has been

designed to eliminate all typical mistakes in the throttle command installation. Great attention

has been paid to the fixing point. The engine is delivered with the two synchronized throttles.

DOWNWORDS EXHAUST MANIFOLD: This has been designed to reduce the risk of burn

injuries and to avoid the overheating of other engine components.

COMPONENTS CERTIFICATION: All engine components have a certification document

of material and thermal treatment.

COMPONENT TESTING AND TRACEABILITY: All engine components fundamental for

engine life are tested and enumerated to ensure the traceability of the components.

GA STANDARD FOR ASSEMBLY: The assembly of the engine is executed following the

GA standards. All engines are tested at the end of the assembly line.

Applicable to: B22 and B25 (all versions) Revision 1.3 – 02/24/2015

Manual B – Operations - 12

Check often the engine attachment, the aircraft command, the fuel line,

electrical wiring harness and the filters.

Never fill the fuel supply with the risk of spilling on hot parts of the engine.

Always use approved fuel containers, using extreme caution in transportation.

Never pour fuel in an enclosed area or where fumes may reach the point of

ignition.

Never run the engine in an enclosed space. The exhaust gases contain carbon

monoxide, a particularly poisonous gas, which if inhaled in excessive amounts

causes rapid loss of consciousness and death.

Fly only when and where conditions, topography, and airspeeds are safest.

Never fly the aircraft equipped with this engine at locations, airspeeds, altitudes,

or other circumstances from which a successful no-power landing cannot be

made, after sudden engine stoppage. This engine is restricted to DAY VFR only

use.

Always do an accurate inspection of the engine before starting the engine.

This will help to prevent accident or damage. If there is any doubt as to the

state of the engine do not fly.

Do not operate engine on the ground if bystanders are close. When the engine

is running with the propeller make sure to have a clear vision of the dangerous

area.

The aircraft must not be left unattended while the engine is running.

EASY INSTALLATION: an easy installation of the engine increases the safety and reduces

pre-flight controls. In addition the engine has been designed to have an easy access to the

control of all pre –flight control areas.

WALL MOUNTING ATTACHMENT: this has been designed to avoid a threaded fixing

point in order to increase safety.

DEDICATED OIL: Separate engine and gear box oils have been designed for the

AeroPower engines to improve engine life and reduce engine wear. A spectrographic

analysis service is also included for each oil change in order to have advance warning of

unexpected engine wear.

BORESCOPE INSPECTION: The engine has been designed to allow a borescope inspection

of the engine. This allows a complete inspection of the engine without disassembling the

engine or even having to dismount the engine from the aircraft.

B.3.2.2. Active Safety Elements

Active safety concerns the mode of operation and maintenance of the engine. The following are

some important indications that good sense and caution suggest, even if they don’t include all the

situations or behaviors that could create a dangerous situation.

Applicable to: B22 and B25 (all versions) Revision 1.3 – 02/24/2015

Manual B – Operations - 13

This engine is not suitable for acrobatics (inverted flight, etc.).

Keep the engine in perfect condition by following the maintenance table in Manual

C and by performing all the checks at the prescribed time interval.

Note any anomalies in the engine in the engine diary and do not fly until the

problem has been resolved.

Respect all government or local rules pertaining to flight operation in your flying

area.

Never run the engine over the maximum RPM limit.

Never start the engine without the propeller as this can seriously damage the engine.

On the ground avoid keeping the engine operating above to 3200RPM for more than

1 minute, because the flow of the coolant may be inadequate and cause faults in the

engine components.

It is forbidden to use a propeller with a polar moment of inertia higher than the

maximum prescribed: that will release MW fly from any liability.

The engine has not received any certification for aeronautical use. It must be used

exclusively on experimental aircraft where an engine failure will not compromise

flight safety. Its use in certified aircraft is strictly prohibited. The user is informed

about the risk connected to the use of the engine and is aware of the above

stipulation.

To eliminate possible injury or damage, ensure any loose equipment or tools are

properly secured before starting the engine.

Never operate the engine and gearbox without sufficient quantities of lubricating oil.

Allow the engine to cool at idle for several minutes before turning off the engine.

The engine should only be used by someone who has followed a recognized

training course for the use of the engine and the aircraft and who continues to keep

themselves upgraded and are well informed regarding the risk connected to the use

of the engine.

Applicable to: B22 and B25 (all versions) Revision 1.3 – 02/24/2015

Manual B – Operations - 14

The present manual for engine operation is only part of the Technical Documentation

and will be supplemented by the respective Installation Manual, Maintenance

Manual and Spare Parts List. Pay attention to references to other documentation,

found in various parts of this Manual.

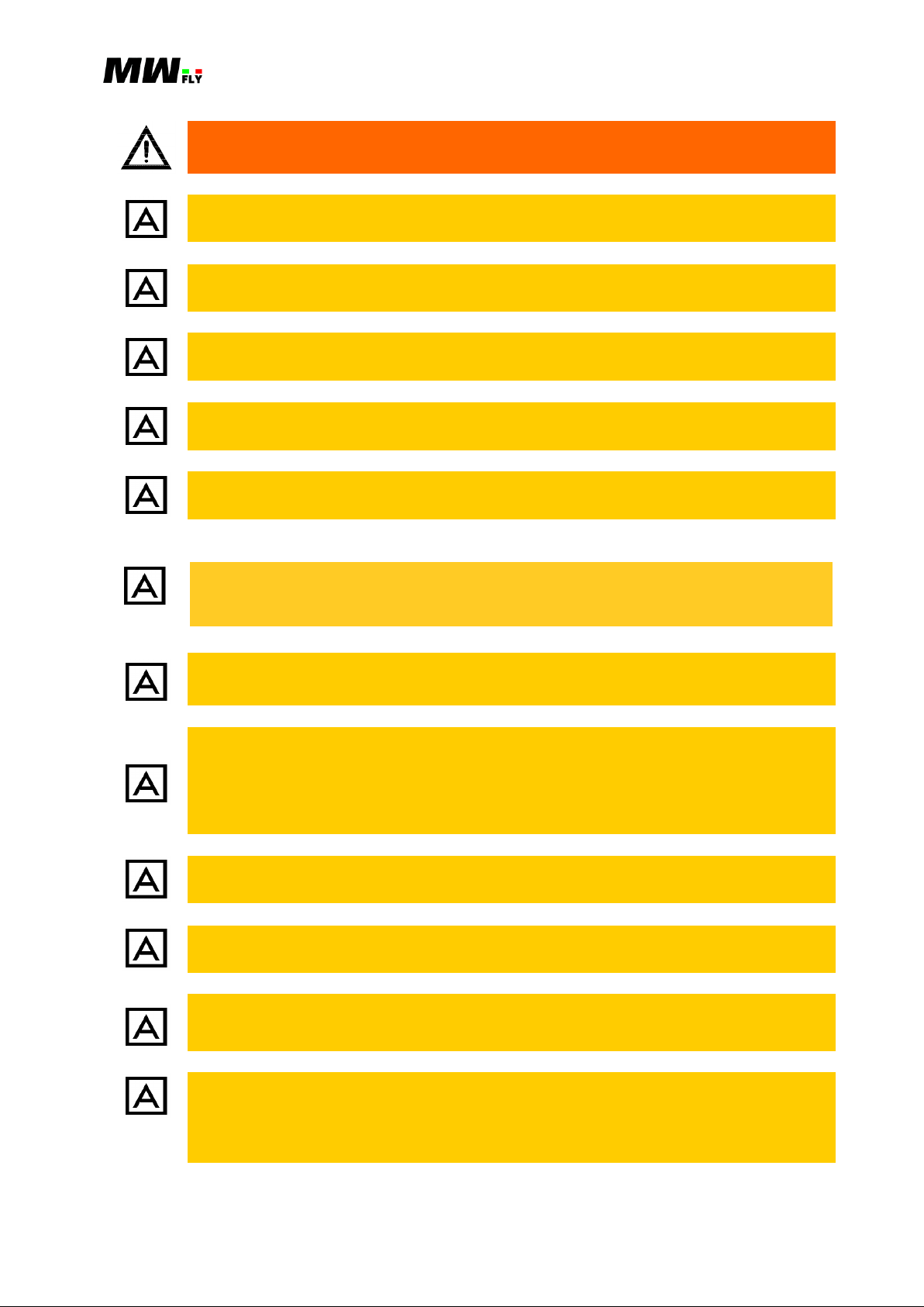

B.3.3.1.P

CAPACITY - 2.8 L

API SG OR HIGHER – this identifies the oil

specification as indicated by the American Petroleum

Institute (API)

ENGINE OIL – engine oil

SAE 15W/50 – oil thermal degree 15W/50 (to select the

correct oil thermal degree for the climate conditions of

the use of the engine refer to the Chapter A.10.3)

CHECK BEFORE FLIGHT

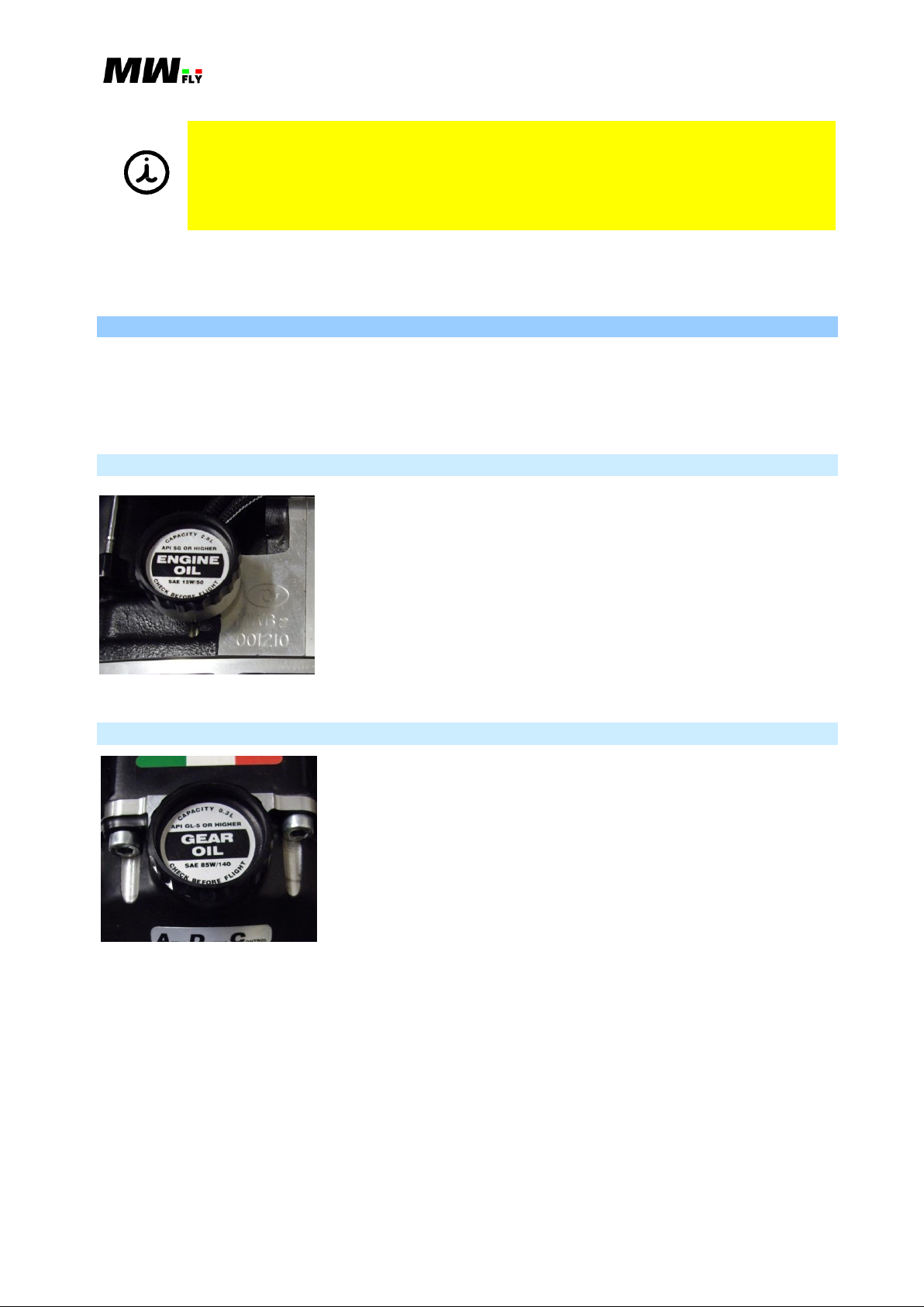

B.3.3.2.P

CAPACITY - 0.3 L

API GL-5 OR HIGHER – this identifies the oil

specification as indicated by the American Petroleum

Institute (API)

GEAR OIL

SAE 85W/140 – oil thermal degree 85W/140

CHECK BEFORE FLIGHT

Where differences exist between this Manual and regulations provided by any authority, the more

stringent regulation should be applied.

B.3.3. Warning labels

There are some warning labels on the engine that indicate the refilling requirements that need to

be done prior to flight as well as other information concerning engine characteristics and

operation. All labels are in English. The following is a list of the labels, their position and

meaning.

B.3.3.1. Engine Oil Filler Cup

B.3.3.2. Reduction Gear Box Oil Filler Cup

Applicable to: B22 and B25 (all versions) Revision 1.3 – 02/24/2015

Manual B – Operations - 15

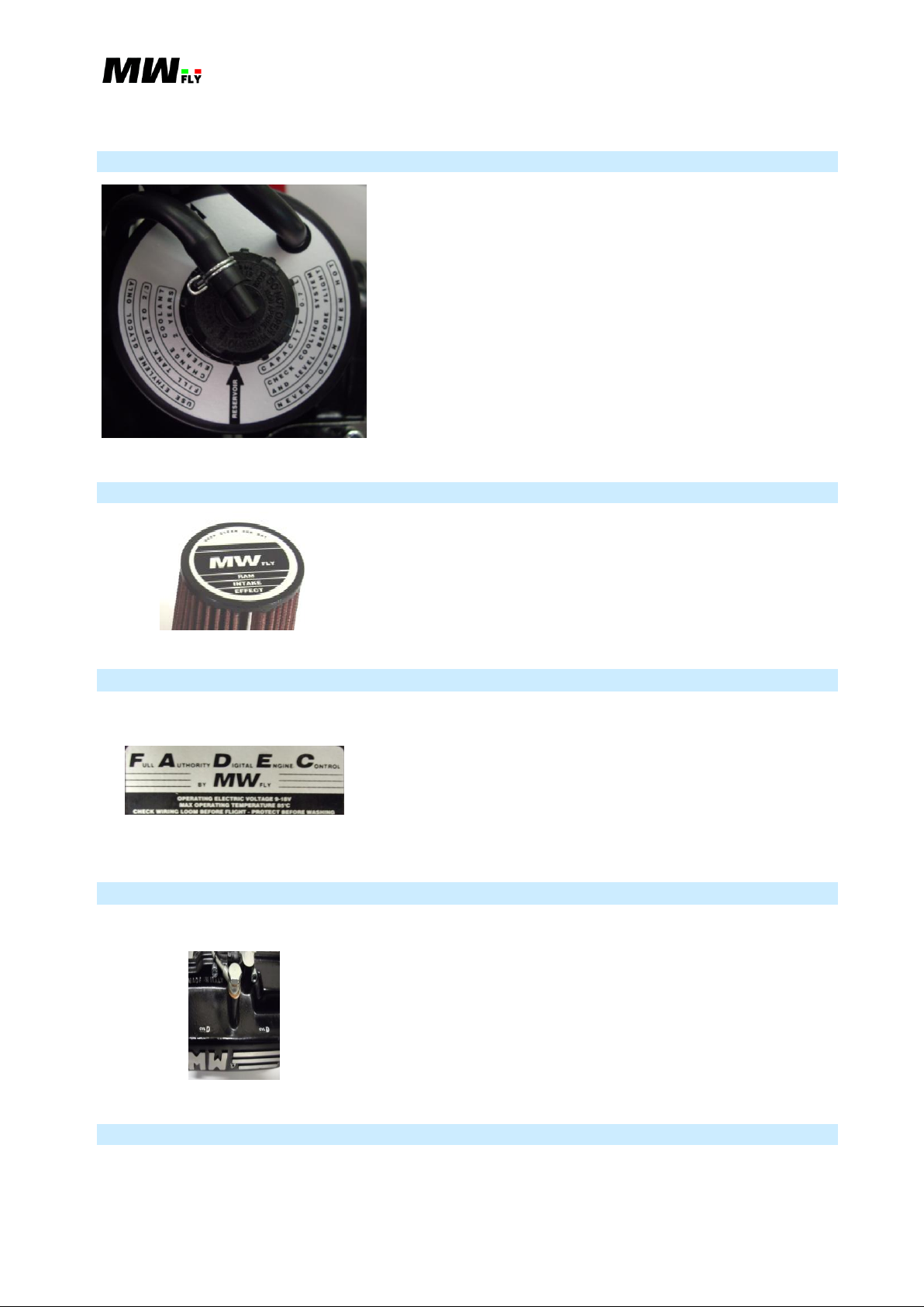

B.3.3.3.P

USE ETHYLENE GLYCOL ONLY –avoid the use of

propylene glycol or just water without ethylene glycol

FILL TANK UP TO 2/3

CHANGE COOLANT EVERY 2 YEARS

RESERVOIR – indicates the expansion tank cup (not

pressurized)

PRESSURIZED – indicates the coolant circuit filler cap

(pressurized)

CAPACITY 0.7 L – Expansion tank capacity

CHECK COOLING SYSTEM AND LEVEL BEFORE

FLIGHT

NEVER OPEN WHEN HOT – this refers to the coolant

circuit pressurized filler cap

B.3.3.4.P

KEEP CLEAN AND DRY

RAM INTAKE EFFECT – the intake manifold is

designed to take advantage of the “ram effect”

B.3.3.5.P

FULL AUTHORITY DIGITAL ENGINE CONTROL

(F.A.D.E.C.)

OPERATING ELECTRICAL VOLTAGE 9-18V

MAX OPERATING TEMPERATURE 85°C

CHECK WIRING LOOM BEFORE FLIGHT

PROTECT BEFORE WASHING

B.3.3.6.P

CYL1 – Cylinder number 1

CYL2 – Cylinder number 2

CYL3 – Cylinder number 3

CYL4 – Cylinder number 4

This label is not present on the engine model without reduction gear box.

B.3.3.3 Water Expansion Tank

B.3.3.4. Air Filter

B.3.3.5. ECU

This label is placed on the rear side of the ECU‘s bracket.

B.3.3.6. Head Cover

This label, on the engine head cover, indicates the cylinder number as indicated in Chapter B.4.3.

B.3.3.7. Reduction Gear Box

This label is placed on the upper side of the reduction gear box and indicates the Active Damping

Control designed for the AeroPower (B.5.5) family of engines.

Applicable to: B22 and B25 (all versions) Revision 1.3 – 02/24/2015

Manual B – Operations - 16

B.3.3.7.P

ACTIVE DAMPING CONTROL

B.3.3.8.P

PROP GOVERNOR INSIDE

FULLY INTEGRATED ELECTRO-HYDRAULIC

B.3.3.9.P

The arrows are place in correspondence to the in and out

water pump manifold and indicate the direction of the water

flow. The lower manifold is the output line from the engine

to the radiator and the upper manifold is the inlet line from

the radiator to the engine.

B.3.3.10.P

The arrows are placed on the fuel distributor and indicate

the distributor fuel in and out flow. The arrow on side#2

(left side) indicates the inlet line from the fuel pump to the

fuel distributor and the arrow on side#1 (right side)

indicates the outlet return line from the distributor to the

fuel tanks.

This label is not present on the engine version without a reduction gear box.

B.3.3.8. Governor

The engine with reduction gear box can also have an integrated constant speed electro-hydraulic

governor (A.15.1.2.) installed. In this case there is label on the governor oil pump cover on the

front side of the reduction gear box.

B.3.3.9. Water Circuit Arrows

B.3.3.10. Fuel Circuit Arrows

Applicable to: B22 and B25 (all versions) Revision 1.3 – 02/24/2015

Manual B – Operations - 17

Any modification or removal of any part of the engine can cause a dangerous

situation. Substitution of the original parts of the engine with non-original

parts can seriously compromise the technical characteristics of the engine and

its performance.

Any kind of modification, substitution or removal of engine parts not approved by

MW Fly will cause an immediate suspension of the warranty and will release MW

Fly from any liability.

Carefully check that the accessory doesn’t interfere with any part of the

engine that is in motion. Pay particular attention to verify that it doesn’t

interfere with the throttle command or with the propeller.

For no reason modify the engine wiring harness. Do not modify the engine

map of the ECUs.

Avoid installing any accessory that can block the normal coolant flow.

Always check that the total electrical absorption of all the electronic components

installed on the aircraft is not greater than the power supplied by the generator.

It is mandatory to connect each electronic component to the battery supply by using

a fuse (better if a breaker).

The use of non MW Fly original spare parts could compromise the correct

operation of the engine. In this case the guarantee is no longer valid and will

release MW fly from any liability.

B.3.4. Modifications and Accessories

All original MW Fly accessories have been designed and tested to operate with the engine. Since

MW Fly cannot test all of the accessories available on the market so that the operator is

responsible for the choice and installation of the non OEM accessories. Choose an accessory with

respect to the following:

For the installation and the maintenance of the engine, use only the consumables, accessories and

tools indicated at the beginning of each paragraph.

B.3.4.1. Original Accessories

The following is a list of the original accessories available for the A eroP ower engine:

Adapter for bed mounting (cod. S039)

Fuel pump (cod. Q030)

Shock absorber 45Sh (cod. M028), 60Sh (cod. M034), 70Sh (cod. M038), 80Sh (cod. M039)

Standard exhaust system (cod. C075)

Standard radiator kit (cod. C101)

Fuel Delivery Module FD-m (cod. Q050)

Electric Hub Module EH-m (cod. E591)

Applicable to: B22 and B25 (all versions) Revision 1.3 – 02/24/2015

Manual B – Operations - 18

The user is responsible for the risk of not using original accessories and spare

parts. These components can seriously compromise flight safety or change

engine characteristics and performance.

Use only MW Fly original spare parts. These are available to any authorized MW

Fly service center. In case of non-fulfillment the guarantee will not any longer

valid.

Tool ES-m (cod. K472)

Accessories for PVV hydraulic constant speed (cod. C104)

Accessories for governor for constant speed control (cod. C103)

2-Blade Propeller hub for PVV system (cod. C030)

B.3.5. Use of the Technical Documentation

The technical documentation is an essential educational instrument. For complete education it is

necessary to take part in the training courses for the correct installation and use of the engine.

The information given in the engine technical documentation is based on data and experience that

is considered applicable for professionals under normal conditions.

A – Installation Manual: includes all necessary information for the correct installation of the

engine.

B – Operations Manual: includes all the necessary information to correctly operate the engine.

C – Maintenance Manual: includes all the necessary information to correctly execute the

planned maintenance program of the engine.

D – Heavy Maintenance Manual: includes all the information to correctly execute any

unplanned maintenance as the result of an engine failure.

E – Illustrated Parts Catalogue: includes the list of all of the spare parts and accessories.

F – Overhaul Manual: includes all necessary information to carry out a complete overhaul of

the engine because the engine life has reached the TBO, or as a result of a serious failure.

L – Service Letter: includes all the information to upgrade the product or to improve the use

of the engine.

Q – Quick Start Guide: The content is extracted from Manual A

S – Service Bulletin: includes the modifications, control and caution that are required to be

done not later than the date indicated.

X – Alert Service Bulletin: includes all the mandatory modifications, controls and cautions

that must be done before flying.

The rapid technical progress and variations of installation might render present laws and

regulations inapplicable or inadequate.

The illustrations in this Manual are mere sketches and show a typical arrangement. They may not

represent the actual part in all its details but depict parts of the same or similar function. Therefore

deduction of dimensions or other details from illustrations is not permitted.

All necessary documentation is available from the MW Fly Authorized Distributors or their

Service Centers.

Applicable to: B22 and B25 (all versions) Revision 1.3 – 02/24/2015

Manual B – Operations - 19

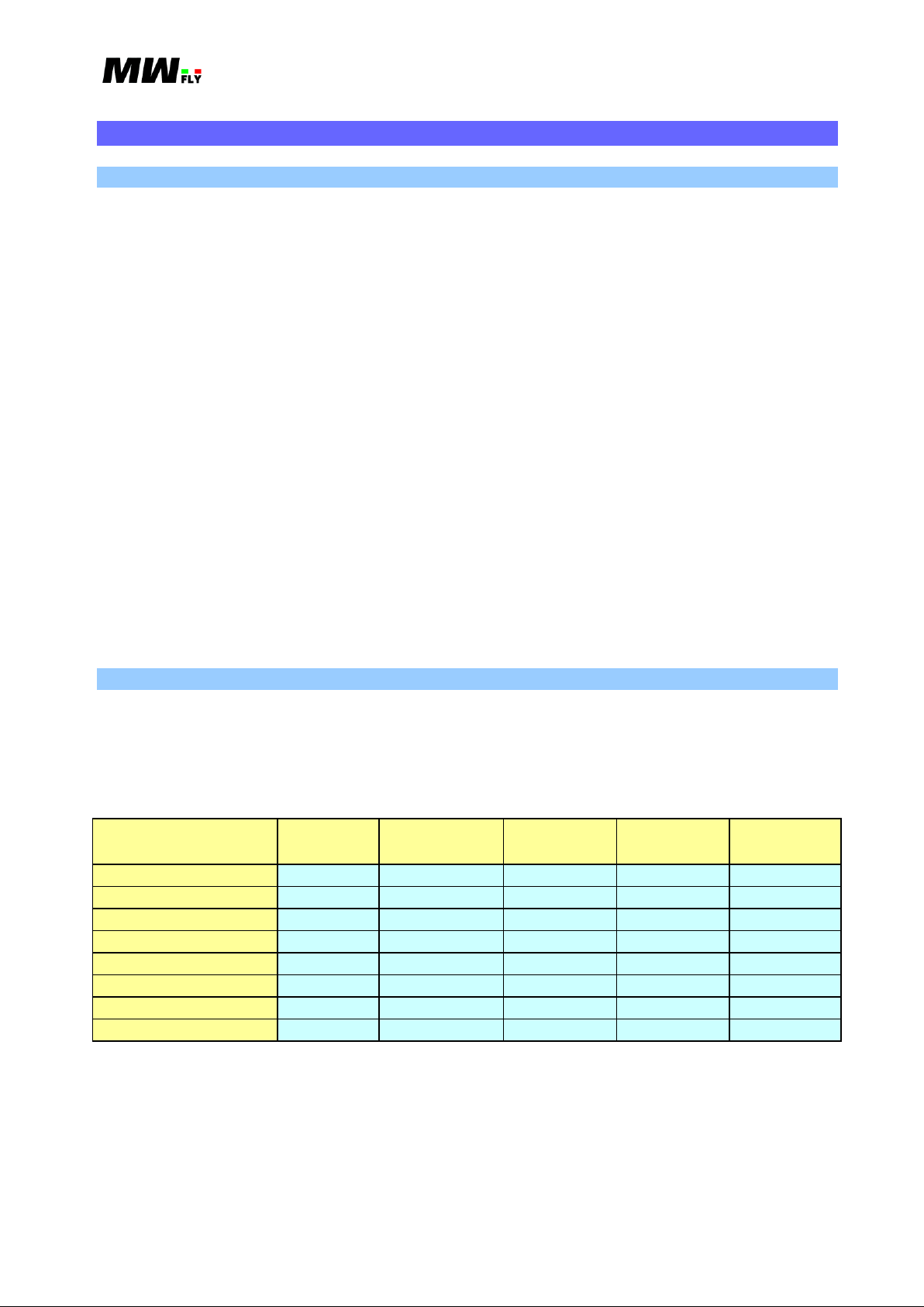

Name

Model

Version

Power

[CV]

Engine RPM

[rpm]

Prop RPM

[rpm]

B22D

MWB

A

95

3300

3300

B22H

MWB

B

131.5*

4300

---

B22L

MWB

C

114.7

3950

2280

B22R

MWB

D

130.3

4550

2320

B25D

MWC

E

110

3300

3300

B25L

MWC

F

133.1

3950

2280

B25R

MWC

G

154.2

4550

2320

B25H

MWC

H

156*

4300

---

B.4. ENGINE DESCRIPTION

B.4.1. General Characteristics

4 stroke Otto cycle

4 cylinder boxer

Single Over Head Camshaft (SOHC), timing with gears and chain, cam follower and tapper

with valve shim, two valves per cylinder.

Cooling system with a coolant and pump with two different circuits, one for each side of the

engine, expansion tank and thermostat integrated on the engine. All cooling circuit pipes are

stainless steel.

Forced lubrication with internal gear (geretor) pump, semi-dry sump without external pipe.

Mapped ignition f(RPM,MAP), with inductive coil, with dwell time mapped f(VBATT) and

ignition correction f(engine temperature)

Mapped fuel injection f (RPM,MAP), with correction f(engine temperature, air temperature)

Data transmission from the ECUs to EMS system on CAN bus

Fuel system with an electric fuel pump controlled by the ECUs, and an auxiliary electric fuel

pump, the fuel circuit is done with steel pipe, and the fuel pressure regulator is integrated in

the fuel circuit

The reduction gear box uses specific oil that is separate from the engine oil, it has a helical

gear and monolithic propeller shaft, and it is designed for an oil pump for the hydraulic

constant speed governor.

ADC (Automatic Damping Control) to control the torsional vibration up to 2500 rpm

Electric starter motor and start relay pre-installed on the engine

Oil cooled alternator and voltage regulator pre-installed on the engine.

B.4.2. Engine Models

The following table summarizes the main features of the A eroPower family of engines.

Next to the name is shown the model and the respective version, which appears in the

identification code shown on the top of each engine. (see picture B.2.3.1.P).

B.4.2.1.C

* Data refers to the version without reduction gear box

The B22H and B25H models are available with or without a reduction gear box. In the second

case the performance is reduced by 5%.

All of the engine models can be supplied with a pre-installed EMS kit which includes sensors and

cables for any EFIS and EMS instrumentation with a CAN line available to receive the data from

the ECUs. For more detail see paragraph A.16.1.

Applicable to: B22 and B25 (all versions) Revision 1.3 – 02/24/2015

Manual B – Operations - 20

ULL

UTHORITY I GITAL NGINE ONTROL

FLYBY

MAX OPERATING TEMPERATURE 85°C

CHECK WIRING LOOM BEFORE FLIGHT -

OPERATING ELECTRIC VOLTAGE 9-18V

PROTECT BEFORE WASHING

RESERVOIR

PRESSURIZED

N

E

V

E

R

O

P

E

N

W

H

E

N

O

T

H

C

A

P

A

C

I

T

0

.

Y

7

L

U

S

E

E

T

H

Y

L

E

N

E

E

C

H

A

N

G

E

C

O

O

L

A

N

T

V

E

R

Y

2

Y

E

A

R

S

E

C

E

A

H

C

O

C

K

I

L

O

N

S

T

E

L

D

N

O

F

E

B

E

R

T

H

G

I

L

F

G

S

Y

M

L

E

V

G

L

Y

C

L

O

O

N

Y

L

F

A

T

L

L

I

O

T

P

U

K

N

/

3

2

API SG OR HI GHER

C

H

E

C

B

I

F

O

R

E

F

L

G

H

T

K

E

GE A R

SAE 15W/50

T

I

C

A

P

A

C

8

.

2

Y

L

OI L

API SG OR HI GHER

C

H

E

C

B

I

F

O

R

E

F

L

G

H

T

K

E

EN G IN E

SAE 15W/50

T

I

C

A

P

A

C

8

.

2

Y

L

OI L

#1

#2

#3

#4

side #1

Side # 2

The EMS is not integrated in the engine identification code, because that option is available for all

of the engines as an aftermarket kit.

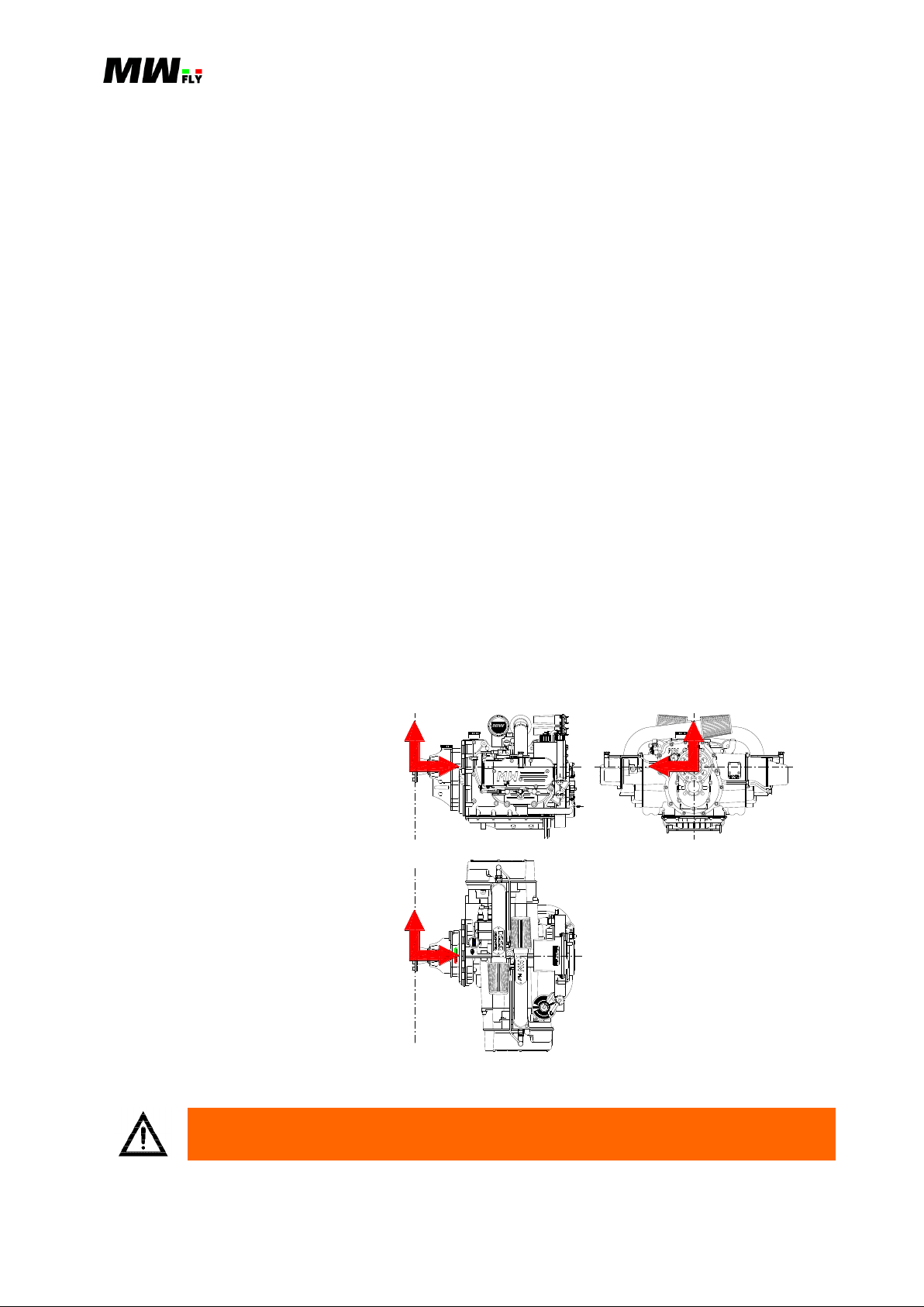

B.4.3. Cylinder Numeration and Position

The cylinders are numbered in the same order that they fire. From a top view of the engine (as

show in picture B.4.3.1.P), cylinder #1 is on the top left, cylinder #2 is on the bottom left, cylinder

#3 is on top right and cylinder #4 is on the bottom right. The same criterion is used to number the

sides of the engine; cylinder #1 and #2 are on side #1 and cylinder #3 and #4 are on side #2.

To know the position of all components of the engine see paragraph A.4.3.

Applicable to: B22 and B25 (all versions) Revision 1.3 – 02/24/2015

B.4.3.1.P

Manual B – Operations - 21

If not specified, the data refers to all engine models.

For safe use of the engine, always respect the operation limits and the

prescribed maintenance time table.

It is not possible to extend the guarantee condition for different uses of the engine.

MW Fly declines any responsibility for damage or bodily injury due to the

improper end use of the engine.

An improper end use of the engine will cause an immediate suspension of the

guarantee and will release MW fly from any liability.

The engine life cannot exceed the TBO limit (see table C.5.2.1.C): when the engine

reach the TBO limit it’s mandatory a complete overhaul check of the engine that

should be done only by an MW Fly authorized service center.

For engine safety it’s important to install and operate in correct way. It important to

use the instrumentation to control that all the engine parameters indicated in the

paragraph A.9.2, are in the operating limit in any working condition.

B.5. TECHNICAL CHARATERISTICS

B.5.1. End Use

B

22

and B25 AeroPo wer engines have been designed to equip ULM, Experimental

and LSA aircraft, two or three axis, with power requirements that conform to the power delivered

by the engine.

AeroPower engines are designed exclusively for recreational purposes in installations where

a sudden stoppage of the engine does not compromise flight safety.

Applicable to: B22 and B25 (all versions) Revision 1.3 – 02/24/2015

Manual B – Operations - 22

B.5.2. Dimension

Applicable to: B22 and B25 (all versions) Revision 1.3 – 02/24/2015

B.5.2.1.P

Manual B – Operations - 23

Ø13 bushings - Centering Ø47mm

STD hub Ø4" - 6 holes M8x1.25

0

209

144

121

84

0

Prop axis

OI LO IL

L

F

SAE 85W/ 140

ONTROL

T

H

G

I

AMPINGCTIVE

C

E

K

R

O

F

B

E

C

E

H

.

3

GE A RGE A R

API GL-5 OR HIGHER

L

A

P

A

C

I

T

0

Y

C

98

L

Y

C

Y

O

O

L

N

PRESSURIZ ED

560

284

3CYL CY L 4

C

E

K

C

D

O

L

C

L

E

E

V

R

V

E

E

P

O

7

L

T

O

L

I

I

Y

0

N

G

W

N

E

H

O

R

E

F

B

E

S

N

.

F

Y

M

E

L

S

T

O

H

T

I

G

H

T

G

E

K

Y

A

E

RESERVOIR

N

P

H

A

C

C

A

E

N

S

U

N

H

T

T

E

E

L

Y

A

E

N

R

E

H

C

F

I

L

A

V

N

G

E

L

S

/

L

O

A

L

O

R

A

E

Y

C

U

P

T

O

2

N

2

T

3

379

C

A

P

A

L

2

.

8

E

OI LO IL

SAE 15W/50

API SG OR HIGHER

EN G IN EE NG IN E

T

F

G

L

F

E

R

I

O

H

C

K

B

C

E

H

C

I

Y

T

CHECK WIRIN G LOOM BEFORE FLIGHT -PROTECT BEFORE WASHINGPROTECT BEFORE WASHING

MAX OPERATING TEMPERATURE 85°C

OPERATING ELECTR IC VOLTAGE 9-18V

FLY

ONTROLNGINE

BY

IGITALUTHORITYU LL

0

209

Dimensional w ith gear box

68

0

247

0 0

205

Center of

mass

Prop axis

88

107

0

188

mass

Center of

1CYL

371

481

CY L 2

644

584

379

Throttle control

Lower position

3m length

Ø1.2 bowden

Max heat transfer

34.5kW at take off

157

110

To radiator

Ø32 pipe

56

Prop axis

Ø32 pipe

From radiator

0

D

C

P

N

295

EFFECT

INTAKE

RAM

E

K

E

Y

FL Y

R

D

A

L

E

N

A

3m length

Upper position

Throttle control

Ø1.2 bowden

151

204

Applicable to: B22 and B25 (all versions) Revision 1.3 – 02/24/2015

B.5.2.2.P

Manual B – Operations - 24

Max dimension [mm]

direction -

direction +

Total

Max along X axis

10

644 (568*)

654 (578*)

Max along Y axis

379

379

758

Max along Z axis

247 (164)

204 (288)

451

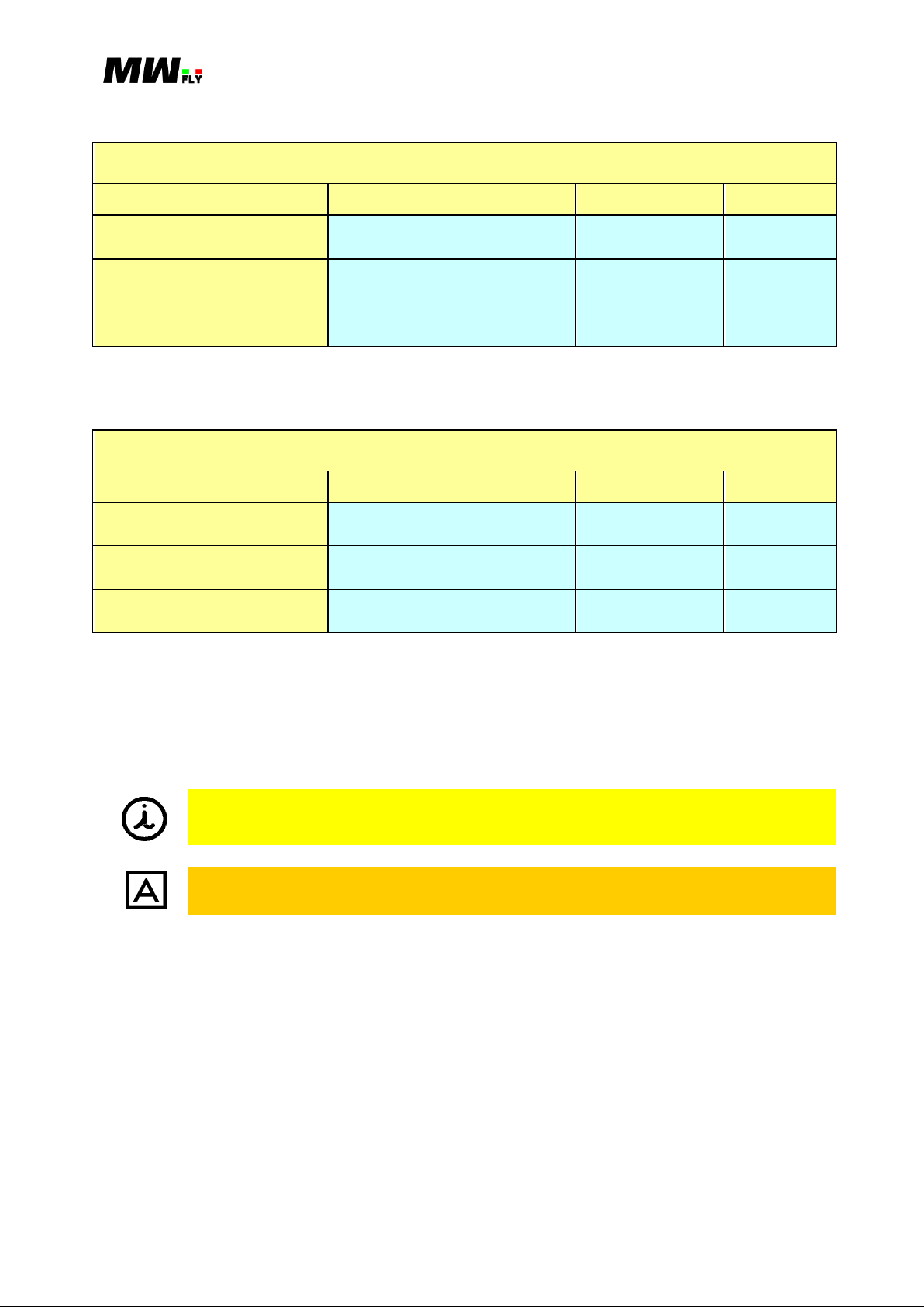

Weight [Kg]

Dry

With lubricants

B22D/B25D

79.5

82.3

B22H*/B25H*

78.7

81.5

B22L/B25L

83.6

86.6

B22R/B25R

83.6

86.6

Adapter for bed mount (4 pieces)

0.37 Kg

Exhaust system

~ 5.1 Kg

Coolant radiator kit

~ 1.7 Kg

Auxiliary fuel pump

0.66 Kg

Governor**

~0.5 Kg

Propeller with hub **

---

Instrument ES-m (without wiring

loom)**

---

EH-m (Electric Hub Module)

~ 0.98 Kg

FD- m (Fuel Delivery Module)

~ 2.75 Kg

The value and the graph of the present chapter indicate the engine performance

with 15°C of air temperature and at sea level (1013 mbar) and with 0% of humidity

(condition ISA-International Standard Atmosphere).

Maximum Dimensions of the Engine

B.5.2.1.C

* model without reduction gear box

The tolerance on these dimensions is ±1 mm.

B.5.3. Weight

Table B.5.3.1.C shows the dry weight of the engine and the weight with lubricants. The weight

includes all the accessories needed to fly (internal generator, voltage regulator, starter relay,

thermostat, water expansion tank, throttle control, fuel injection wiring loom, two ECU’s, rubber

mounting, air filter). Only the radiator coolant and exhaust system are not included in the weight

shown in the table.

B.5.3.1.C

* Model without reduction gear box; with the reduction gear box the weight is 83.6 and 86.6.

B.5.3.1. Optional Accessory Weight

** Data not available

B.5.4. Performance

Applicable to: B22 and B25 (all versions) Revision 1.3 – 02/24/2015

Manual B – Operations - 25

B22 Version

Power [HP (kW)]

B22D

B22H*

B22L

B22R

Take off (max for 5 minutes)

@rpm

95 (69.8)

@3400

131.5 (96.7)

@4300

114.7 (84.3)

@3950

130.3 (95.8)

@4550

max continuous

@rpm

82 (60.3)

@3320÷3400

112.5 (82.7)

@4300

98 (72)

@4010÷4200

110 (80.9)

@4420÷4700

Smaller specific consumption

@MAP[inHg]

64 (47.1)

@24

92.5 (68)

@25.6

84.5 (62.1)

@25.6

96.5 (70.9)

@25.7

B25 Version

Power [HP (kW)]

B25D

B25H*

B25L

B25R

Take off (max for 5 minutes)

@rpm

110 (80.8)

@3400

156 (114.6)

@4300

133.1 (97.9)

@3950

154.2 (113.4)

@4550

max continuous

@rpm

95 (69.8)

@3330÷3400

133.5 (98.1)

@4300

115 (84.5)

@4070÷4200

132 (97)

@4500÷4700

Smaller specific consumption

@MAP[inHg]

74.2 (54.5)

@24

111.5 (82)

@25.7

98.5 (72.4)

@25.7

116 (85.3)

@25..8

During flight the preferred power is set with high RPM and low MAP.

The use of the engine at maximum continuous power for a long period can

seriously damage the engine and can cause a sudden stoppage of the engine.

B.5.4.1.C

* Data refers to the engine model without reduction gear box

B.5.4.2.C

* Data refers to the engine model without reduction gear box

The use of the engine at maximum power is only allowed for 5 minutes continuous. The

maximum continuous power is a function of the MAP and RPM: the limit at high RPM is due to

the thermodynamics; the limit at low RPM is to avoid overload on the reduction gear box.

In the following paragraph there is the performance graph for each engine model:

Graph POWER/RPM and TORQUE/RPM: this is the maximum power and the maximum

torque with the engine at full throttle in function of RPM.

Graph NECESSARY POWER/AVAILABLE POWER: this is the range of use of the engine,

(the area between the two graphs), the graph of the available power, is the power output of the

engine, the necessary power is the power that is required to keep the speed of the propeller

constant (a propeller that makes the engine run at maximum RPM limit and not over). The

graph also indicates, in bold, the maximum continuous power.

Graph POWER/RPM with constant MAP: each graph refers to a different value of MAP as

indicated in inches of mercury (inHg) and indicates the power in function of the RPM. The

bold indicates the maximum continue power in function of the RPM.

Applicable to: B22 and B25 (all versions) Revision 1.3 – 02/24/2015

Manual B – Operations - 26

5% difference from the graph is permitted.

Graph POWER/MAP with constant RPM: each graph indicates the power output in reference

to the different values of RPM in function of MAP. The bold indicates the maximum

continuous power in function of the MAP.

Applicable to: B22 and B25 (all versions) Revision 1.3 – 02/24/2015

Manual B – Operations - 27

B.5.4.1. B22D

20@3400

95@3400

12

14

16

18

20

22

24

26

30

40

50

60

70

80

90

100

2000 2250 2500 2750 3000 3250

[HP]

[Kgm]

[RPM]

B22D Performance @ full throttle

Power

Torque

0

10

20

30

40

50

60

70

80

90

100

2000 2250 2500 2750 3000 3250

[HP]

[RPM]

Range of use B22D

Available power

Necessary power

Max cont. power

B.5.4.3.C

Applicable to: B22 and B25 (all versions) Revision 1.3 – 02/24/2015

B.5.4.4.C

Manual B – Operations - 28

20

30

40

50

60

70

80

90

100

2000 2250 2500 2750 3000 3250 3500

[[HP]

[RPM]

B22D Power @ constant MAP

29.9

28.5

27

25.5

24

22.5

max

cont.

20

30

40

50

60

70

80

90

100

22 23 24 25 26 27 28 29 30

[HP]

[inHg]

B22D Power @ constant RPM

3400

3250

3000

2750

2500

2250

2000

max cont.

B.5.4.5.C

Applicable to: B22 and B25 (all versions) Revision 1.3 – 02/24/2015

B.5.4.6.C

Manual B – Operations - 29

B.5.4.2. B22H

131,5@4300

22@4200

14

16

18

20

22

24

26

28

30

32

50

60

70

80

90

100

110

120

130

140

2250 2500 2750 3000 3250 3500 3750 4000 4250

[HP]

[Kgm]

[RPM]

B22H performace @ full throttle

Power

Torque

Max cont.

112,5@27,8inHg

60

70

80

90

100

110

120

130

140

22 23 24 25 26 27 28 29

[HP]

[inHg]

B22H Power @ 4300 giri

B.5.4.7.C

Applicable to: B22 and B25 (all versions) Revision 1.3 – 02/24/2015

B.5.4.8.C

Manual B – Operations - 30

B.5.4.3. B22L

20,8@3950

114,7@3950

14

16

18

20

22

24

26

28

50

60

70

80

90

100

110

120

2250 2500 2750 3000 3250 3500 3750 4000

[HP]

[Kgm]

[RPM]

B22L Performance @ full throttle

Power

Torque

0

20

40

60

80

100

120

2500 2750 3000 3250 3500 3750 4000

[HP]

[RPM]

B22L Range of use

Available power

Necessary power

Max cont. power

B.5.4.9.C

Applicable to: B22 and B25 (all versions) Revision 1.3 – 02/24/2015

B.5.4.10.C

Manual B – Operations - 31

30

40

50

60

70

80

90

100

110

120

2750 3000 3250 3500 3750 4000 4250

[HP]

[RPM]

B22L Power @ constant MAP

29,9

28,5

27

25,5

24

22,5

max cont.

30

40

50

60

70

80

90

100

110

120

22 23 24 25 26 27 28 29 30

[HP]

[inHg]

B22L Power @ constant RPM

4200

4000

3750

3500

3250

3000

2750

max cont.

B.5.4.11.C

Applicable to: B22 and B25 (all versions) Revision 1.3 – 02/24/2015

B.5.4.12.C

Manual B – Operations - 32

B.5.4.4. B22R

21@4200

130,3@4550

14

16

18

20

22

24

26

28

30

32

50

60

70

80

90

100

110

120

130

140

2250 2500 2750 3000 3250 3500 3750 4000 4250 4500

[HP]

[Kgm]

[RPM]

B22R Performace @ full throttle

Power

Torque

0

20

40

60

80

100

120

140

2500 2750 3000 3250 3500 3750 4000 4250 4500

[HP]

[RPM]

B22R Range of use

Available Power

Necessary Power

Max. cont. Power

B.5.4.13.C

Applicable to: B22 and B25 (all versions) Revision 1.3 – 02/24/2015

B.5.4.14.C

Manual B – Operations - 33

30

40

50

60

70

80

90

100

110

120

130

140

2750 3000 3250 3500 3750 4000 4250 4500 4750

[HP]

[RPM]

B22R Power @ constant MAP

29.9

28.5

27

25.5

24

22.5

max cont.

30

40

50

60

70

80

90

100

110

120

130

140

22 23 24 25 26 27 28 29 30

[HP]

[inHg]

B22R Power @ constant RPM

4700

4500

4250

4000

3750

3500

3250

3000

max cont.

B.5.4.15.C

B.5.4.16.C

Applicable to: B22 and B25 (all versions) Revision 1.3 – 02/24/2015

Manual B – Operations - 34

B.5.4.5 B25D

23,2@3400

110@3400

12

14

16

18

20

22

24

26

28

30

30

40

50

60

70

80

90

100

110

120

2000 2250 2500 2750 3000 3250

[HP]

[Kgm]

[RPM]

B25D Performance @ full throttle

Power

Torque

0

20

40

60

80

100

120

2000 2250 2500 2750 3000 3250

[HP]

[RPM]

B25D Range of use

Available power

Necessary power

Max. cont. power

B.5.4.17.C

Applicable to: B22 and B25 (all versions) Revision 1.3 – 02/24/2015

B.5.4.18.C

Manual B – Operations - 35

20

30

40

50

60

70

80

90

100

110

120

2000 2250 2500 2750 3000 3250 3500

[HP]

[RPM]

B25D Power @ constant MAP

29.9

28.5

27

25.5

24

22.5

max cont.

20

30

40

50

60

70

80

90

100

110

120

22 23 24 25 26 27 28 29 30

[CV]

[inHg]

B25D Power @ constant RPM

3400

3250

3000

2750

2500

2250

2000

max cont.

B.5.4.19.C

Applicable to: B22 and B25 (all versions) Revision 1.3 – 02/24/2015

B.5.4.20.C

Manual B – Operations - 36

B.5.4.6. B25H

156@4300

26,1@4200

16

18

20

22

24

26

28

30

32

34

36

60

70

80

90

100

110

120

130

140

150

160

2250 2500 2750 3000 3250 3500 3750 4000 4250

HP]

[Kgm]

[RPM]

B25H Performance @ full throttle

Power

Torque

Max cont.

133,5@27,8inHg

60

70

80

90

100

110

120

130

140

150

160

22 23 24 25 26 27 28 29

[HP]

[inHg]

B25H at 4300 RPM

B.5.4.21.C

Applicable to: B22 and B25 (all versions) Revision 1.3 – 02/24/2015

B.5.4.22.C

Manual B – Operations - 37

B.5.4.7. B25L

24,1@3950

133,1@3950

16

18

20

22

24

26

28

30

32

60

70

80

90

100

110

120

130

140

2250 2500 2750 3000 3250 3500 3750 4000

[HP]

[Kgm]

[RPM]

B25L Performance @ full throttle

Power

Torque

0

20

40

60

80

100

120

140

2500 2750 3000 3250 3500 3750 4000

[HP]

[RPM]

B25L Range of use

Available power

Necessary power

Max. cont. power

B.5.4.23.C

Applicable to: B22 and B25 (all versions) Revision 1.3 – 02/24/2015

B.5.4.24.C

Manual B – Operations - 38

30

40

50

60

70

80

90

100

110

120

130

140

2750 3000 3250 3500 3750 4000 4250

[HP]

[RPM]

B25LPower @ constant MAP

29.9

28.5

27

25.5

24

22.5

max cont.

30

40

50

60

70

80

90

100

110

120

130

140

22 23 24 25 26 27 28 29 30

[HP]

[inHg]

B25L Power @ constant RPM

4200

4000

3750

3500

3250

3000

2750

max cont.

B.5.4.25.C

Applicable to: B22 and B25 (all versions) Revision 1.3 – 02/24/2015

B.5.4.26.C

Manual B – Operations - 39

B.5.4.8. B25R

24,9@4200

154,2@4550

16

18

20

22

24

26

28

30

32

34

36

60

70

80

90

100

110

120

130

140

150

160

2250 2500 2750 3000 3250 3500 3750 4000 4250 4500

[HP]

[Kgm]

[RPM]

B25R Performance @ full throttle

Power

Torque

0

20

40

60

80

100

120

140

160

2500 2750 3000 3250 3500 3750 4000 4250 4500

[HP]

[RPM]

B25R Range of use

Available power

Necessary power

Max. cont. power

B.5.4.27.C

Applicable to: B22 and B25 (all versions) Revision 1.3 – 02/24/2015

B.5.4.28.C

Manual B – Operations - 40

30

40

50

60

70

80

90

100

110

120

130

140

150

160

2750 3000 3250 3500 3750 4000 4250 4500 4750

[HP]

[RPM]

B25R Power @ constant MAP

29.9

28.5

27

25.5

24

22.5

max cont.

30

40

50

60

70

80

90

100

110

120

130

140

150

160

22 23 24 25 26 27 28 29 30

[HP]

[inHg]

B25R Power @ constant RPM

4700

4500

4250

4000

3750

3500

3250

3000

max cont.

B.5.4.29.C

Applicable to: B22 and B25 (all versions) Revision 1.3 – 02/24/2015

B.5.4.30.C

Manual B – Operations - 41

50%

60%

70%

80%

90%

100%

0 500 1000 1500 2000 2500 3000 3500 4000

[m]

% performance variation based on height

80%

85%

90%

95%

100%

105%

110%

115%

120%

-20 -10 0 10 20 30 40

[°C]

% performance variation based on air temperature

B.5.4.9. Performance Variation

Outside of the ISA conditions, the performance of the engine can vary based on height, air

temperature and humidity.

The variation of engine performance based on height is approximately 1% every 100 meters of

height. The graph B.5.4.18.C shows the variation of engine performance based height.

B.5.4.31.C

The variation of the engine performance not in the standard ISA conditions can be calculated with

the following formula:

Q=Q(ISA)*288/T(K)

Where Q is the power calculated, Q(ISA) is the power in standard ISA condition and T(K) is the

temperature in Kelvin degree : T(K)= T(°C)+273.

The graph B.5.4.19.C shows the power variation based on air temperature.

Applicable to: B22 and B25 (all versions) Revision 1.3 – 02/24/2015

B.5.4.32.C

Manual B – Operations - 42

The fuel injection system automatically changes the quantity of fuel based on the

air temperature and height, so that the engine will run with the correct air//fuel ratio

in any atmospheric condition.

Ratio power

weight [HP/Kg]

Dry weight

Engine with

lubricant

B22D

1.19

1.15

B22H*

1.67

1.61

B22L

1.37

1.32

B22R

1.56

1.50

B25D

1.38

1.34

B25H*

1.98

1.91

B25L

1.59

1.54

B25R

1.84

1.78

All consumption data indicated in the manual refers to the engine running with the

“Power” mode (engine fuel map “Power”). With the engine running in “Economy”

mode the fuel consumption is 10% less than the value indicated.

B22 Version

Consumption[l/h]

@rpm/MAP [inHg]

B22D

B22H*

B22L

B22R

Take off

23.7@3400/29.9

29.8@4300/29.9

29.6@4200/29.9

32.5@4700/29.9

Max continuous

19.6@3320/27.7

25@4300/27.8

23.8@4010/27.7

25.5@4420/27.7

At 75% max cont.

15.5@3020/26

19.2@4300/24.6

17.2@3640/25.7

19.6@4020/25.5

At 65% max cont.

14.2@2880/25.5

---

16@3470/24.8

17.2@3830/24.5

At 55% max cont.

12.8@2720/25

---

13.9@3280/23.7

14.8@3620/23.7

There is no significant variation in engine performance based on the humidity.

B.5.5. Ratio Power/Weight

Table B.5.5.1.C shows the value of the power/weight ratio for all engine models both with and

without lubricant.

B.5.5.1.C

* Data refers to the model without reduction gear box.

B.5.6. Fuel Consumption

The fuel consumption is a function of the power output and the fluid-dynamic conditions.

The following table indicates the consumption in 5 different flight conditions.

B.5.6.1.C

* Data refers to the engine model without reduction gear box

Applicable to: B22 and B25 (all versions) Revision 1.3 – 02/24/2015

Manual B – Operations - 43

B25 Version

Consumption[l/h]

@rpm/MAP [inHg]

B25D

B25H*

B25L

B25R

Take off

27.6@3400/29.9

35.4@4300/29.9

34.5@4200/29.9

38.5@4700/29.9

Max continuous

23@3330/27.7

29.6@4300/27.8

28@4070/27.7

30.3@4500/27.7

At 75% max cont.

17.8@3030/25.7

22.8@4300/24.6

20.9@3700/25.6

23.5@4090/25.5

At 65% max cont.

16.2@2880/25.3

---

18.7@3530/24.6

20.6@3900/24.5

At 55% max cont.

14.7@2730/24.8

---

15.9@3330/23.4

17.4@3690/23.4

Deviations from the curves shown are possible to the extent of 5%, as a result of

dimensional tolerances and assembly.

B.5.6.2.C

* Data refers to the engine model without reduction gear box

The fuel consumption indicated in the table refers to an engine working with a fixed pitch

propeller, so that the engine power output is unequivocally related to the propeller speed. In the

case of a variable pitch propeller, it is possible to calculate the fuel consumption using the

following graph. As a general consideration, with the same power output, the consumption is

lower at higher RPM and lower throttle position.

The following paragraph indicates the fuel consumption of each engine model:

Graph CONSUMPTION PER H/RPM with constant MAP: each curve refers to a value of

MAP (indicated in inches of mercury inHg), and it is the fuel consumption in liters per hour,

in function of the RPM.

Graph CONSUMPTION PER H/MAP constant speed: each curve refers to a regime of

rotation of the motor and returns the hourly consumption expressed in liters, obtained as a

function of pressure in the inlet manifold pressure (MAP).

Graph CONSUMPTION PER H/RPM at constant power: each curve is related to a certain

value of power and represents the consumption per hour, expressed in liters, depending on the

engine regime. This graph is particularly useful, if you use a variable pitch propeller in flight,

to evaluate which is the best consumption with the same horsepower output.

Graph specific consumption / MAP constant speed: each curve refers to a regime of rotation

of the engine and is the hourly consumption, expressed in liters, per horse power output,

expressed in grams of fuel.

Applicable to: B22 and B25 (all versions) Revision 1.3 – 02/24/2015

Manual B – Operations - 44

B.5.6.1. B22D

5

7

9

11

13

15

17

19

21

23

25

2000 2250 2500 2750 3000 3250 3500

[L/h]

[RPM]

B22D Consumption @ constant MAP

29,9

28,5

27

25,5

24

22,5

5

7

9

11

13

15

17

19

21

23

25

22 23 24 25 26 27 28 29 30

[L/h]

[inHg]

B22D consumption @ constant RPM

3400

3250

3000

2750

2500

2250

2000

B.5.6.3.C

B.5.6.4.C

Applicable to: B22 and B25 (all versions) Revision 1.3 – 02/24/2015

Manual B – Operations - 45

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

2000 2250 2500 2750 3000 3250

[L/h]

[RPM]

B22D consumption @ constant power

90

85

80

75

70

65

60

55

50

45

40

35

30

170

180

190

200

210

220

230

240

250

260

22 23 24 25 26 27 28 29 30

[gHP/h]

[inHg]

B22D specific consumption @ constant RPM

3400

3250

3000

2750

2500

2250

2000

B.5.6.5.C

Applicable to: B22 and B25 (all versions) Revision 1.3 – 02/24/2015

B.5.6.6.C

Manual B – Operations - 46

B.5.6.2. B22H

5

10

15

20

25

30

35

22 23 24 25 26 27 28 29

[L/h]

[inHg]

B22H consumption @ 4300 RPM

160

170

180

190

200

22 23 24 25 26 27 28 29

[gHP/h]

[inHg]

B22H specific consumption @ 4300 RPM

B.5.6.7.C

Applicable to: B22 and B25 (all versions) Revision 1.3 – 02/24/2015

B.5.6.8.C

Manual B – Operations - 47

B.5.6.3. B22L

5

10

15

20

25

30

35

2000 2250 2500 2750 3000 3250 3500 3750 4000 4250

[L/h]

[RPM]

B22L consumption @ constant MAP

29,9

28,5

27

25,5

24

22,5

5

10

15

20

25

30

35

22 23 24 25 26 27 28 29 30

[L/h]

[inHg]

B22L consumption @ constant RPM

4200

4000

3750

3500

3250

3000

2750

B.5.6.9.C

Applicable to: B22 and B25 (all versions) Revision 1.3 – 02/24/2015

B.5.6.10.C

Manual B – Operations - 48

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

2750 3000 3250 3500 3750 4000 4250

[L/h]

[RPM]

B22L consumption @ constant power

110

105

100

95

90

85

80

75

70

65

60

55

50

170

180

190

200

210

220

230

22 23 24 25 26 27 28 29 30

[gHP/h]

[inHg]

B22L specific consumption @ constant RPM

4200

4000

3750

3500

3250

3000

2750

B.5.6.11.C

Applicable to: B22 and B25 (all versions) Revision 1.3 – 02/24/2015

B.5.6.12.C

Manual B – Operations - 49

B.5.6.4. B22R

5

10

15

20

25

30

35

2500 2750 3000 3250 3500 3750 4000 4250 4500 4750

[L/h]

[RPM]

B22R Consumption @ constant MAP

29,9

28,5

27

25,5

24

22,5

5

10

15

20

25

30

35

22 23 24 25 26 27 28 29 30

[L/h]

[inHg]

B22R consumption @ constant RPM

4700

4500

4250

4000

3750

3500

3250

3000

B.5.6.13.C

Applicable to: B22 and B25 (all versions) Revision 1.3 – 02/24/2015

B.5.6.14.C

Manual B – Operations - 50

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

2750 3000 3250 3500 3750 4000 4250 4500 4750

[L/h]

[RPM]

B22R Consumption @ constant power

125

120

115

110

105

100

95

90

85

80

75

70

65

60

55

50

170

180

190

200

210

220

230

22 23 24 25 26 27 28 29 30

[gHP/h]

[inHg]

B22R specific consumption @ constant RPM

4500

4700

4000

4250

3750

3500

3250

3000

2750

B.5.6.15.C

Applicable to: B22 and B25 (all versions) Revision 1.3 – 02/24/2015

B.5.6.16.C

Manual B – Operations - 51

B.5.6.5. B25D

5

10

15

20

25

30

2000 2250 2500 2750 3000 3250 3500

[L/h]

[RPM]

B25D Consumption @ constant MAP

29.9

28.5

27

25.5

24

22.5

5

10

15

20

25

30

22 23 24 25 26 27 28 29 30

[L/h]

[inHg]

B25D Consumption @ constant RMP

3400

3250

3000

2750

2500

2250

2000

B.5.6.17.C

Applicable to: B22 and B25 (all versions) Revision 1.3 – 02/24/2015

B.5.6.18.C

Manual B – Operations - 52

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

2000 2250 2500 2750 3000 3250

[L/h]

[RPM]

B25D Consumption @ constant power

105

100

95

90

85

80

75

70

65

60

55

50

45

170

180

190

200

210

220

230

240

250

260

22 23 24 25 26 27 28 29 30

[gCv/h]

[inHg]

B25D Specific consuption @ constant RPM

3400

3250

3000

2750

2500

2250

2000

B.5.6.19.C

Applicable to: B22 and B25 (all versions) Revision 1.3 – 02/24/2015

B.5.6.20.C

Manual B – Operations - 53

B.5.6.6. B25H

5

10

15

20

25

30

35

40

22 23 24 25 26 27 28 29

[L/h]

[inHg]

B25H Consumption @ 4300 RPM

160

170

180

190

200

22 23 24 25 26 27 28 29

[gCv/h]

[inHg]

B25H Specific consumption @ 4300 RPM

B.5.6.21.C

B.5.6.22.C

Applicable to: B22 and B25 (all versions) Revision 1.3 – 02/24/2015

Manual B – Operations - 54

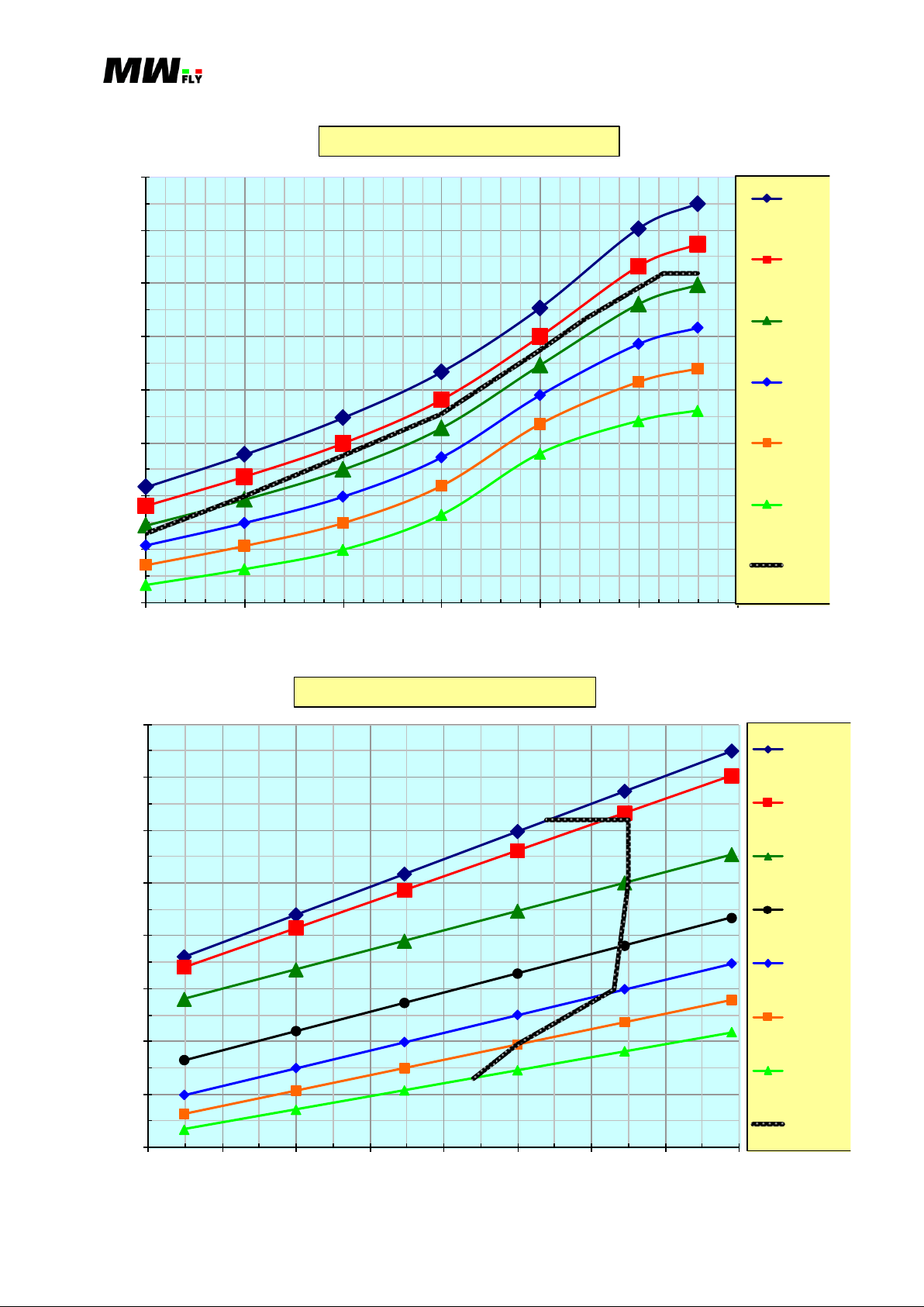

B.5.6.7. B25L

5

10

15

20

25

30

35

40

2000 2250 2500 2750 3000 3250 3500 3750 4000 4250

[L/h]

[RPM]

B25L Consumption @ constant MAP

29.9

28.5

27

25.5

24

22.5

5

10

15

20

25

30

35

40

22 23 24 25 26 27 28 29 30

[L/h]

[inHg]

B25L Consumption @ constant RPM

4200

4000

3750

3500

3250

3000

2750

B.5.6.23.C

Applicable to: B22 and B25 (all versions) Revision 1.3 – 02/24/2015

B.5.6.24.C

Manual B – Operations - 55

12

14

16

18

20

22

24

26

28

30

32

34

2750 3000 3250 3500 3750 4000 4250

[L/h]

[RPM]

B25L Consumption @ constant Power

130

125

120

115

110

105

100

95

90

85

80

75

70

65

60

55

170

180

190

200

210

220

230

22 23 24 25 26 27 28 29 30

[gCv/h]

[inHg]

B25L Specific consumption @ constant RPM

4200

4000

3750

3500

3250

3000

2750