MVVS 26 IFS - V1.10, 26 IFS SP - V1.10, MVVS 26 IFS SP, 3094IU, 3094SP Operating Instructions Manual

Page 1

Operating instructions

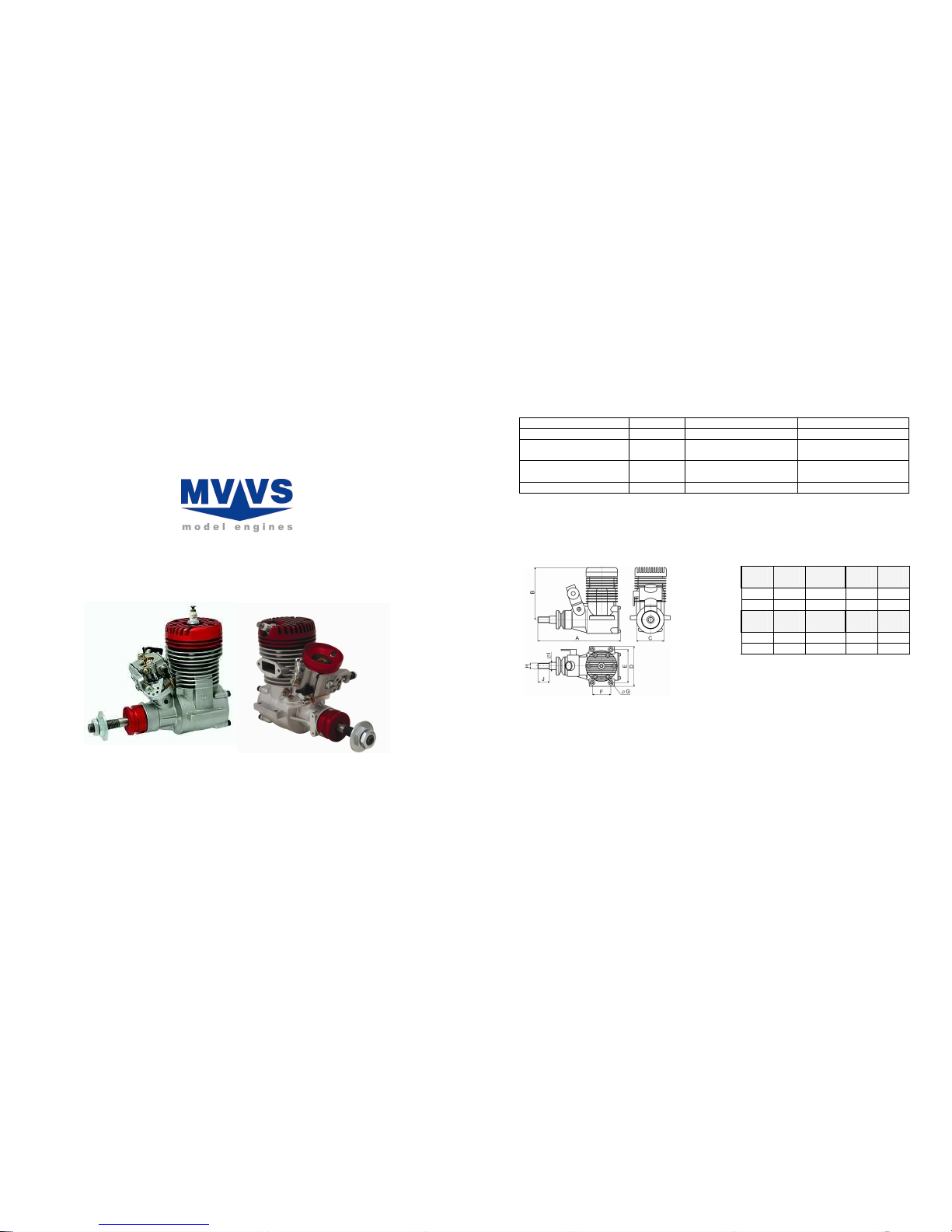

MVVS 26 IFS č.: 3094IU

MVVS 26 IFS SP č.: 3094SP

Version 1.10

Before using the engine, carefully read these instructions

Congratulations on choosing the gas engine MVVS 26 ccm.

MVVS 26 has been designed and manufactured for propeller-powered radio-controlled model planes. It is

able to meet all of your expectations of an acrobatic racing engine.

Technical specifications

Bore 33 mm Maximum power output ** 3.8 PS/9000 RpM

Stroke 30.1 mm Maximum torque ** 3.1Nm/8000 RpM

Weight of complete

engine without ignition*

936 g Fuel Unleaded 95-octane fuel

Weight of ignition unit 165 g Lubrication Oil with petrol in mixture

1:40

RpM range 1400–9500

* The value in the table above stands for the weight of a completely assembled engine, including the

spark plug, carburetor, drive washer and prop screws.

** Power output varies with the exhaust used. The value given in the table stands for the maximum

available power output.

Engine’s dimensions

A

mm B mm C mm D mm E mm

146 99 50 70 60

F

mm G mm H mm I mm J mm

31 4,3 M10x1 10 33

Safety precautions

1) Never use the engine for any manned vehicles.

2) When operating model planes, always follow the rules and laws in effect in your country.

3) The manufacturer declines all responsibility for all damages arising from the operation of models

and other appliances droved by MVVS engine.

4) Always use original spare parts.

5) Never tamper with the engine construction.

6) Before each flight check that all the propeller screws are tightened up and in good condition. If you

use a spinner, check that it is tightened up, too. When mounting the spinner always follow the

assembly instructions.

7) Before each flight check that all the propeller screws are tightened up and in good condition. If you

use a spinner, check that it is tightened up, too. When mounting the spinner always follow the

assembly instructions.

8) Before starting the engine always make sure that the model is safely fixed in place and cannot start

moving.

9) Fuel is combustible and therefore must be kept in an enclosed container at a safe distance from the

engine when it is running.

10) When preparing fuel carefully follow the manufacturer’s or dealer’s instructions.

Page 2

11) Small objects must be kept at a safe distance from the engine when it is running. Never throw any

objects towards the spinning propeller.

12) Be careful in choosing the location where you wish to start the engine. Avoid dusty or sandy areas.

13) Start the engine in well-ventilated areas only. Never start the engine indoors.

14) When starting the engine make sure that bystanders, especially children, are at a safe distance of at

least 10 meters.

15) The engine power output makes it possible to fly big models. Mal-operation of such models may

cause serious damage. Start using the MVVS 26 in model planes only after you have mastered

operating smaller models.

16) Periodically check that the engine is firmly fixed to the engine mounts. Never start a loose engine!

17) Always use a balanced propeller! Always replace the propeller when damaged!

18) Make sure that no part of your body intersects the plane of the spinning propeller.

19) Always wear close-fitting, well-fastened clothes when starting or operating the running engine.

Never wear loosely hanging clothes (ties, scarf, etc.).

20) Never try to stop the engine by any part of your body.

21) Always stop the engine either by turning off the ignition switch or by completely closing the

carburetor throttle valve.

Selecting a suitable propeller

It is usually the case that propellers of the same dimensions coming from different manufacturers are not

the same. Oftentimes not even propellers of the same dimensions produced by a same manufacturer are

not the same. The engine power is best utilized when the propeller dynamics curve and engine power

curve (revolutions / power output) intersect in the area of the engine top power output. Unfortunately, no

propeller manufacturer provides this information. Engine power output is also a variable quality. It

depends above all on the silencer used and can considerably vary. The situation is further complicated by

environmental parameters (temperature and atmospheric pressure in particular): low temperature and high

pressure increase propellers’ input requirements by 20% in comparison with input at hot weather.

MVVS 26 has been designed to generate maximum power at 8500 RpM, according to the type of exhaust

used. If you wish to utilize the maximum power output, choose a propeller which allows the engine to

reach these revolutions, or slightly lower revolutions (given the unloading of the propeller depending on

the speed of flight) on the ground.

We do not recommend using propellers with which the engine reaches more than 9000 RpM. on the

ground.

Suggested propeller dimensions: 16x8, 16x10, 16x11, 16x12, 17x8, 17x10, 17x 12, 18x8

Fuel

Always use unleaded 95-octane petrol mixed in the proportion 40 volume units of petrol to 1 unit of

Mobil Racing 2T oil. If necessary, quality brand-name synthetic oil intended for racing two-stroke

engines can be used too. Mix it in the proportion 30:1.

Never use inexpensive oil developed for garden appliances or synthetic oils intended for the operation of

methanol model engines. The manufacturer declines all responsibility for all engine damages arising from

the use of low-quality fuel.

Store fuel in containers designed for this purpose. Do not use mixed fuel older than 90 days.

Assembly

Since air is used to cool the engine, sufficient air circulation under the cowl must be ensured. Never

forget about a hot air outlet – which must be bigger than the intake. Gas engines heat up to a much greater

degree than methanol ones!

Do not forget that the engine needs oxygen from the air to be able to operate. Therefore ensure access of

air to the engine intake as well. Caution: intake of warm air from beneath the cowl may cut the engine

power output.

Caution! When mounting the engine in the model use seals to protect all openings and prevent the

pollution of the engine’s inside with sawdust, residual abrasives etc.

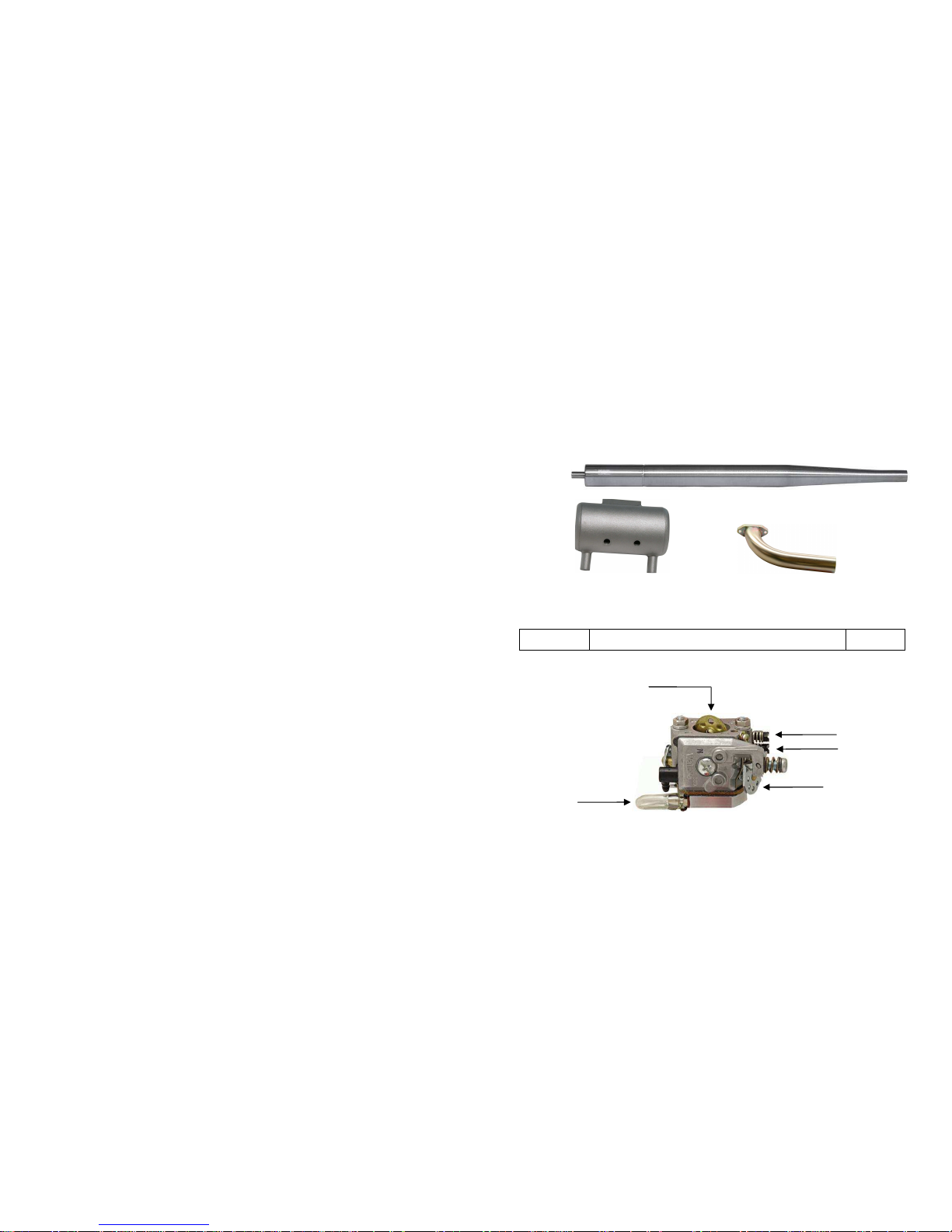

Exhaust

Use only factory-made exhausts pipes designed for this type of engine, preferably brand-name MVVS

engines with which you also get the power output guaranteed.

The manufacturer declines all responsibility for all engine damages arising from the use of improper

exhaust systems.

When mounting the exhaust follow the manufacturer’s instructions. Make sure to secure sufficient

cooling of the exhaust.

3270 compact, medium level of power output

3266 tuned pipe, with adaptor 3265 provides the highest power output, with the flat torque curve,

useful for the model planes

3266

3270 3265

Carburetor adjustment

Basic setting:

adjusting needle ( L ) for low RpM range 1 turn and 50 minutes

adjusting needle ( H ) for high RpM range 1 turn and 35 minutes

for WT 793

(Minutes refer to hands of a clock)

Walbro WT 793

The new engine comes adjusted to the basic setting.

After the engine has been run in, adjust it following the instructions below:

- start the engine and warm it up

- let the engine run at idle speed for approx. 5 seconds

Step I

Accelerate to 2/3 of the throttle range within approx. 1 sec (faster acceleration). Repeat three

times – if the engine accelerates quickly and without a hiccup go to Step III. If acceleration is not smooth

go on to Step II.

Choke

H needle adjusting screw

L needle adjusting screw

Lever - throttle

Pressure pulse inlet

Page 3

Step II

Faulty acceleration with hiccups and a tendency to cut out is usually attributable to a poor fuel

mixture in the medium-revolutions range. Stop the engine and recheck the fuel feed (the hose-pipe must

not be pinched or broken; if fitted, check also the fuel filter permeability). Restart the engine and test

acceleration again. If problems persist adjust the carburetor. Open the adjusting needle L by 5 min and

retest acceleration. If acceleration is smooth, open the needle by another 3-5 min - this should be done

because the needle was previously set at a boundary value; if atmospheric conditions changed during

flight, the problems might recur.

If the engine continues to not accelerate properly open the low speed needle by 10 minutes. If

the engine’s operation does not improve, shut it off and check the basic setting. Set the adjusting needle L

at 1 turn and 50 min and the adjusting needle H at 1 turn and 10 min., restart the engine and test the

acceleration. If the engine runs correctly go to Step III. If it continues to not accelerate properly, open the

low speed needle by another 10 minutes. If acceleration is faulty, the defect is likely to lie somewhere

other than an adjustment.

Step III

If the engine accelerates correctly, according to the above test, set it at idle speed and

accelerate to full speed. Repeat twice more. If the engine functions correctly, go to Step IV. If it cuts out,

open the L needle by 5-10 minutes more.

If the engine does not respond to acceleration fast enough, keep closing the L needle until the

engine starts to cut out in response to throttle opening. At that point reopen the L nozzle by 5-10 minutes.

Step IV

If the engine reacts correctly set it at full speed. If revolutions do not drop, the engine has been

adjusted successfully. If revolutions seem to drop, open the adjusting needle H by about 5-10 minutes.

Caution!!! The engine must be stopped while you adjust the carburetor in order to prevent injury by

the propeller.

Starting and running in a new engine

Before you first start the engine, make sure that the plug is screwed in and tightened up and that the plug

socket is fitted in place and fastened down properly.

Fix the ignition sensor in proper position above the magnet with screws enclosed.

Unless the spark plug is inserted in plug socket, never turn the engine with ignition turned on. This

could lead to ignition damage!

1) Make sure that the ignition is switched off, the choke valve is closed and the throttle valve is about half

opened. Then give the engine 3-4 turns, provided that carburetor is not overflowing. If it is overflowing,

only give the engine 1-2 turns.

2) Switch the ignition on, close the choke valve, set the throttle at slightly higher idle speed and give the

engine a few quickly turns. If even after the fourth turn, with the choke valve closed, you do not hear a

suggestion of the engine starting, give the engine 2 turns following the instructions in paragraph 1 above.

Then proceed according to instructions given in paragraph 2.

3) If the engine does not start even after another set of turns open the choke valve and the throttle to

maximum and give the engine approx. 4 turns. Switch the ignition off and on again and restart the engine

with throttle turned slightly down and the choke valve set open.

4) If the engine still would not start, unscrew the plug and check its contacts. Clean any possible petrol

moisture (i.e. an indication of engine overflow) and screw it in again. Further starting should only be done

with the throttle turned down. If the plug is dry then probably not enough fuel has been drawn into the

carburetor. If that is the case, check the fuel feed and then return to the instructions given in paragraph 1.

Having started the engine, leave it running for about 5 minutes at a higher idle speed. Then run it in for

about 10 min, while changing revolutions from idle to 1/2-3/4 of the range and shortly holding each

position - gradually prolong the holding periods. After 10 minutes of operation, open the throttle at

maximum for a period of about one minute. At this point stop the engine and let it cool down. Then

restart it and check the adjustment. If everything is all right, you can first take off. During first few flights

do not overload the engine and do not let it run at high revolutions for long periods of time (very

important at hot weather). Use up all fuel that was produced as a mixture with the oil (we recommend the

MOBIL Racing 2T). From now on, fuel and oil should be mixed in the proportion 40:1.

DO NOT PROCESS THE RUNNING-IN AT IDLE SPEED!

You should get following results if the engine is settled up and in run correctly

Engine Propeller RpM Silencer

APC 16/12 7300-7400 3266

APC 16/10 8100-8300 3266

Mejzlik 18/8 8100-8200 3266

26 IFS

7200-7300 3270

These values are only approximate and may vary with the factors described in the previous section, as

well as with the type of the exhaust system used.

Possible faults of the engine and how to dispose those

If the engine does not start:

- check and possibly replace the spark plug (check the spark: put the plug into the cable end and by

turning the engine you’ll see the necessary spark. Note: The plug must touch a metal part of the

engine.)

- check fuel lines

- check for proper mechanical function by turning the engine over

- check that carburetor’s nozzles are adjusted correctly

- remove the carburetor cover from the feed side; check the filter and blow off carburetor with

compressed air; (Caution: When using compressed air, use eye protection.) When re-assembling be

careful of maintain the proper order of the components

- check the vacuum feed line

Mechanical faults (if the engine can not be turned over easily) must always be handled by a

professional service department

Service suggestions

After each 20 hours of running or 1 year change the spark plug.

After 100 hours of operation time commit the engine to the professional service department for check-up.

Re-assembling

These operations are very complicated and it is not recommended to do it on your own. Please commit to

professional service.

Possible guide instructions we publish are as follows:

Demount rear cover, head and carburetor. It is not possible to re-assemble the engine unless the cylinder

part of the engine is heated up to 80° - 100°C. Then it is possible to remove steel piston insert without

rotating (!). Next step is piston and connecting rod removal. Crankshaft has to be in the top dead centre

(TDC). Pull off the connecting rod from pin on the crankshaft in direction to rear cover out of the

crankcase. After getting off the drive washer and Woodruff (safety) key, it is possible to pull out the

crankshaft again in direction to rear cover out of the crankcase. You will get the bearing out after heating

up (again between 80°- 100°C). Assembling passes off in opposite meaning.

Page 4

Spare parts list

No: Description: No: Description:

N0101 Crankcase

N0951 Connecting rod

0202 Front bearing

N1001 Crankshaft

0203 Rear bearing

I1101 Drive washer

0301 Rear cover

1102 Drive washer key

0302 Rear cover screws - set

1103 Propeller nut

0304 Pressure nipple

1104 Propeller washer

0306 Rear cover „O“ - ring

1106 Drive washer shim

0403 Sealing ring

3224 Walbro Carburetor

0404 Carburetor screw

1321 Carburetor flange

I0501 Cylinder head

1310 Thermo-isolation washer

N0501 Cylinder head 26 SP

1305 Carburetor flange gasket (2pcs)

0502 Cylinder head screws - set

1307 Carburetor screws (2pcs)

0503 Cylinder head gasket

1308 Nuts (2pcs)

0601 Cylinder sleeve

1309 Nut’s washers (2pcs)

N0650 Cylinder-piston ass.

1405 Ignition sensor fixing screws

0701 Piston

0702 Piston ring

3314L Electronic ignition unit ICU-L

0801 Piston pin

3309 Spark plug

0802 Piston pin circlips

3227D/26 Diffusor 26 SP

Warranty

The MVVS gas engines come with a three-year guarantee against defects in workmanship and materials.

Only original buyers of the engines are eligible warranty claimants. The warranty cannot be transferred

with a change in ownership.

This guarantee does not cover:

- any normal wear that might occur

- damage arising from accidents

- damage arising from the use of an unbalanced or damaged propeller

- damage arising from the use of a too small or a too big propeller

- damage arising from the use of low-quality fuel

- damage arising from the use of other than original spare parts and accessories

- damage arising from sucking a foreign object into the engine

- damage arising from any improper use

Certificate of Warranty

Date: Serial Number:

Dealer: Buyer’s name and address:

Produced by: MVVS, spol. s r.o., tř. Kpt. Jaroše 35, 60200 Brno, Czech Republic

Ph.: +420 545 211 683, fax: +420 545 211 418

E - Mail: mvvs@mvvs.cz

Http: www.mvvs.cz

Loading...

Loading...