Page 1

Operating Instructions and Safety

Instructions

mvt Rotary Nozzle, 3000 bar

Page 2

Operating Instructions, Rotary

Nozzle

Before using the equipment for the first time, read these operating instructions

including the safety instructions. Act in accordance with all these instructions. Keep

them for use later on and hand them over to subsequent owners of the equipment.

In addition to the operating instructions, the general statutory safety and accident

prevention regulations must be observed.

TANGO hp - 1

Op Instrs

As at 09.01.2020

Contents

1 Safety 3-5

1.1 Important information

1.2 Significant risks

1.3 Danger from failure to follow the instructions

1.4 Clothing and protective equipment

1.5 Physical aptitude

1.6 Proper use

2 Operating for the first time 5-7

2.1 Inserting and removing nozzles

2.2 Fastening to the high-pressure lance

3 Technical data 8-11

3.1 Features of the TANGO hp-1

3.2 Nozzle arrangement

3.3 Nozzle selection table

3.4 Water quality

3.5 Flow rate table for the mvt 964 nozzle

4 Malfunction, rectification 12

4.1 General

4.2 Rectifying malfunctions

5 Maintenance / servicing 13

5.1 General

5.2 Wearing parts

6 Warranty 14

2/14 Copyright © 2020 mvt AG, Port, Switzerland

Page 3

Operating Instructions, Rotary

Nozzle

TANGO hp - 1

Op Instrs

As at 09.01.2020

1 Safety

1.1 Important information

If the equipment is used improperly, the high-pressure jet from the nozzle can be dangerous

and result in serious injury and damage. The water jet must never be aimed at people,

animals, active electrical equipment or at the high-pressure cleaner itself.

Before use, the high-pressure hoses, the high-pressure spray gun and the pump must all,

without fail, be inspected for possible damage. Hose lines must not be pinched, fed over sharp

edges, driven over by vehicles, tugged or bent. The rotary nozzle must not be operated if any

of the components mentioned above are damaged.

Any person engaged in operating, servicing, inspecting or assembling the equipment must be

appropriately qualified to carry out those tasks. The company operating the equipment must

produce precise instructions covering areas of responsibility, competence and how employees

are supervised.

Training and instruction must be given to any employees who do not have the necessary skills

and knowledge. If necessary, the manufacturer or supplier can provide this training on behalf

of the company operating the machine or pump. The company operating the equipment must

also ensure that their employees fully understand the contents of these operating instructions.

In addition to the safety instructions mentioned in these operating instructions, the

relevant statutory accident prevention and safety regulations must be observed and

adhered to!

1.2 Significant risks

Risk from the possible escape of liquid under high pressure

The water jet from high-pressure water jet equipment nozzles poses a risk due to its cutting

effect and its ability to penetrate objects, and because the high-pressure water jet nozzle and

hose may change direction or wander. Serious or even fatal injuries may be caused.

Hazardous substances may be released and it is also possible that parts of any object being

cleaned by the water jet may become loose.

Risk posed by handheld spray fixtures

Handheld spray fixtures pose a particular mechanical risk due to the recoil forces from the

water jet.

Risk posed by noise

Exposure to noise poses a risk. Exposure to noise can lead to loss of hearing, tinnitus or

physiological problems.

Noise can increase the risk of accidents because it may not be possible to hear alarms or

faults developing in the equipment.

Risk posed by vibrations

Pulsating vibrations from the pressure unit in handheld spray equipment poses a risk.

3/14 Copyright © 2020 mvt AG, Port, Switzerland

Page 4

Operating Instructions, Rotary

Nozzle

TANGO hp - 1

Op Instrs

As at 09.01.2020

1.3 Danger from failure to follow the instructions

There are potential risks to individuals and the environment if the rules for using the equipment

set out in these operating instructions and in the safety instructions in particular are not

followed.

Please take note of Section 1.2, 'Significant Risks'.

1.4 Clothing and protective equipment

So as to operate the rotary nozzle safely, it is recommended that appropriate protective

equipment is worn, e.g. shoes with soles which provide a good grip, protective helmets,

hearing protection, goggles, visors, waterproof protection suits including protective gloves and

boots, high-pressure protective gaiters and aprons; high-pressure hose burst protection should

also be used.

1.5 Physical aptitude

Anyone working with the rotary nozzle must be well-rested, fit and in good health. Anyone

who, for health reasons, may not carry out strenuous tasks, should consult their doctor about

whether it is possible for them to work using the rotary nozzle.

No work should be carried out using the rotary nozzle after taking medication which has the

effect of slowing reactions or after consuming alcohol or taking drugs.

1.6 Proper use

The rotary nozzle is designed for use on manually-controlled high-pressure spray guns.

Particular attention should be paid to the instructions about operating the equipment for the

first time (Point 2) as regards the design of the nozzles (Point 3.2) and the permissible recoil

forces (see Point 3.3 below).

In addition, the relevant accident prevention regulations and any work instructions, operating

and safety instructions issued by the company owning the equipment should also be followed.

Possible applications for the equipment are listed below:

Refurbishing concrete and removing material

Cleaning surfaces

Deburring and cleaning castings

Removing layers of coating such as paint, etc.

Cleaning oil and gas platforms

Cleaning containers, metal gratings, construction machinery, etc.

4/14 Copyright © 2020 mvt AG, Port, Switzerland

Page 5

Operating Instructions, Rotary

Nozzle

Cleaning and removing paint from a variety of metal surfaces, e.g. in the marine sector

... and many more applications

For hygiene reasons, the rotary nozzle is not suitable for cleaning surfaces and materials

which come into contact with foodstuffs.

TANGO hp - 1

Op Instrs

As at 09.01.2020

2 Operating for the first time

2.1 Inserting and removing nozzles

1. Before fitting the nozzles, the high-pressure water jet equipment must be switched off.

2. If the nozzles have protective caps, these must first be removed before the nozzles are

fitted.

3. Apply metal lubricating paste to the screw connection threads on the nozzles.

4. Hold the nozzle head with an open-ended wrench (32mm wrench size) and screw the

nozzles in with an Allen key (5mm wrench size).

5. Tighten the nozzles to a maximum of 25 Nm.

5/14 Copyright © 2020 mvt AG, Port, Switzerland

Page 6

Operating Instructions, Rotary

Nozzle

TANGO hp - 1

Op Instrs

As at 09.01.2020

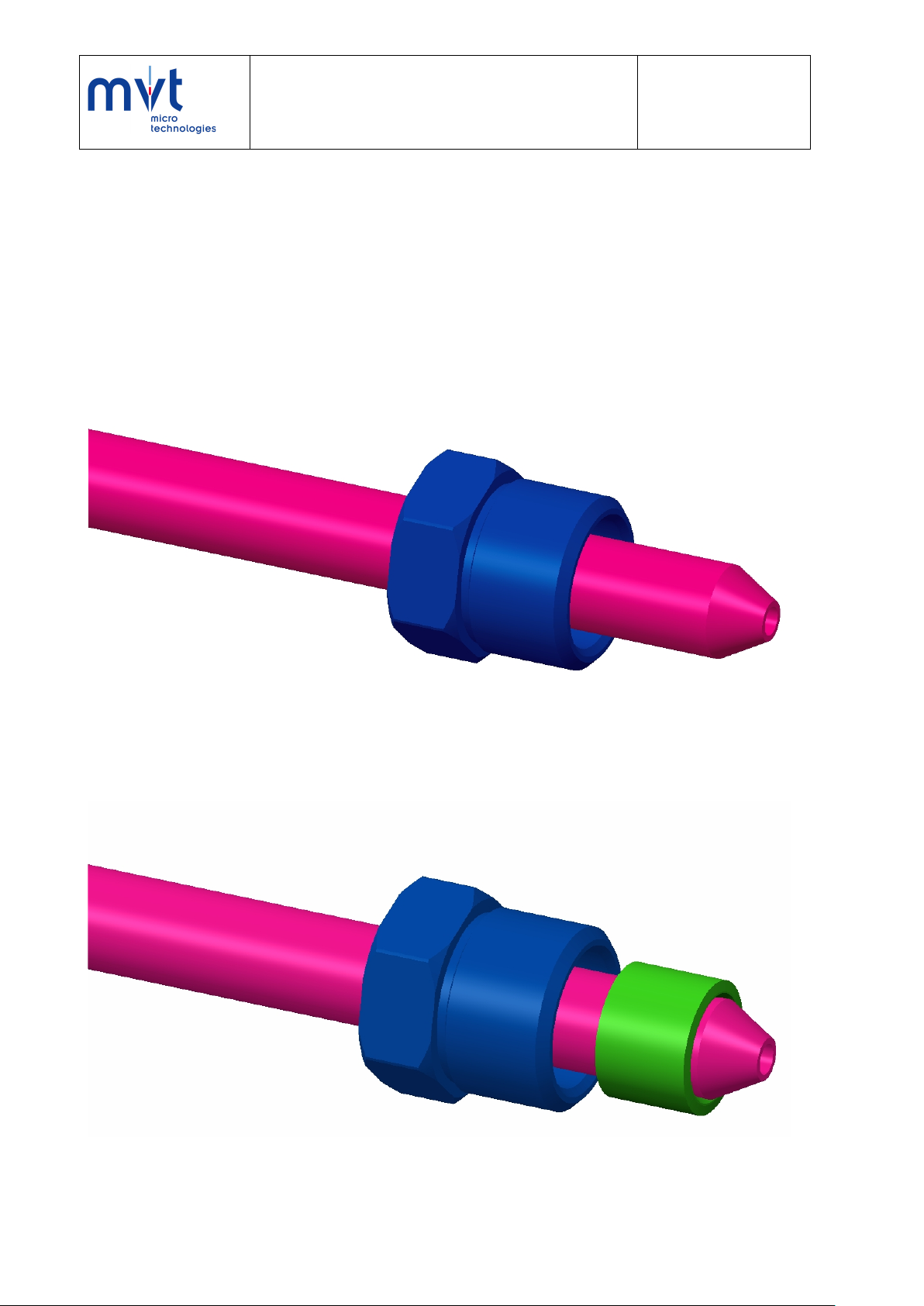

2.2 Fastening to the high-pressure lance

It is recommended that a torque wrench be used when fitting a nozzle onto a lance. The

required tightening torque is 70 Nm.

Rotary nozzles must always be unscrewed from the lance before servicing them.

Check the high-pressure threaded screw connections for cleanliness and apply metal

lubricating paste to them before fitting.

1. Slide the M26 pressure screw onto the lance.

2. Screw the thrust ring onto the lance (left-hand thread). Screw the thrust ring onto the

lance to the full extent of its threaded area.

3. Insert the lance cone into the Tango nozzle's counter-cone.

6/14 Copyright © 2020 mvt AG, Port, Switzerland

Page 7

Operating Instructions, Rotary

Nozzle

TANGO hp - 1

Op Instrs

As at 09.01.2020

4. Screw in the M26 pressure screw and tighten it (tightening torque 70 Nm).

7/14 Copyright © 2020 mvt AG, Port, Switzerland

Page 8

3 Technical data

Operating Instructions, Rotary

Nozzle

TANGO hp - 1

Op Instrs

As at 09.01.2020

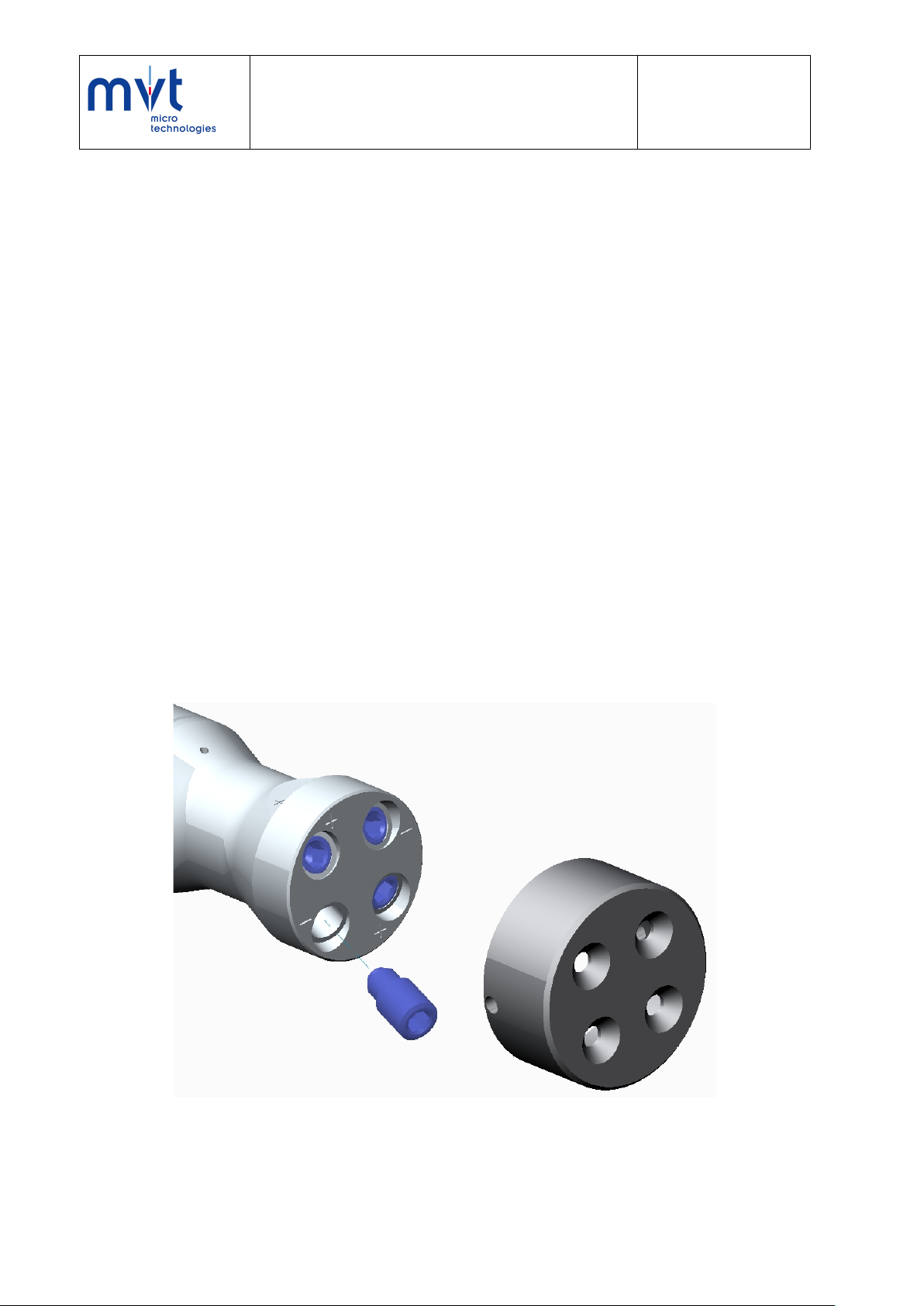

3.1 Features of the TANGO hp-1

Unique seal (patent applied for); this does away with the usual need to change sealing

systems.

Rotating shaft supported radially and axially by bearings on both sides makes for

maximum robustness – perfect for operating in a harsh environment.

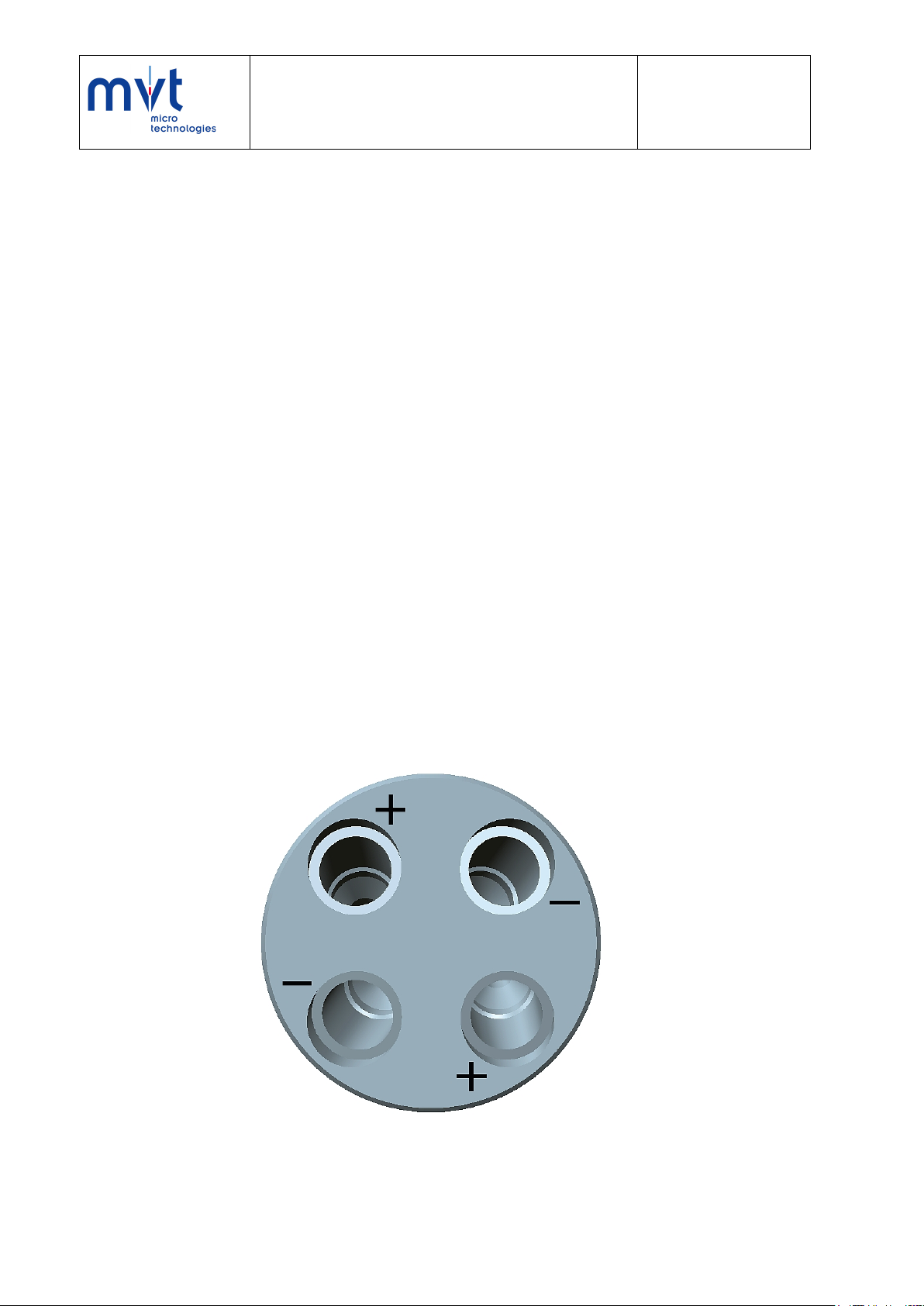

So that material removal is achieved as effectively as possible, two nozzles are aligned

clockwise (Drive +) and two counter-clockwise (Brake -).

The maximum volume flow at 3000 is 75 litres/minute. Beware of the recoil force!

Important: identical-size nozzles must

always be inserted diagonally opposite

each other in order to prevent any

imbalance occurring during rotation (risk

of injury).

Technical data

Operating pressure: 1,500 – 3,000 bar

Volume flow: max. 75 L/Min. in accordance

with nozzle selection table 3.2

Rotational speed: approx. 500 – 4000 rpm.

Dimensions: Ø40 x 180 mm

Weight: approx. 1.2 Kg

Nozzle type: mvt 964 / 965 (Saphir) with or

without jet smoothing insert

Brake: eddy current brake

Operating temperature: max. 100°C in

continuous operation

Max. rotational speed: 8500 rpm.

Connection thread: M14x1.5 LH or 9/16"-18

UNF

Structure of the rotary nozzle

1. Housing

2. M26 pressure screw

3. Pressure ring M14x1.5 LH or 9/16“-18 UNF

4. Nozzle head

5. Nozzles

8/14 Copyright © 2020 mvt AG, Port, Switzerland

Page 9

Operating Instructions, Rotary

Nozzle

TANGO hp - 1

Op Instrs

As at 09.01.2020

3.2 Nozzle arrangement

So that material removal is achieved as effectively as possible, two nozzles on the 4-jet nozzle

head are set as Drive + and two nozzles as Brake –.

It is important that identical-size nozzles are always inserted diagonally opposite each other in

order to prevent any imbalance occurring during rotation (risk of injury). In other words, the two

Drive Nozzles + must always be the same size and the two Brake Nozzles – must always be

the same size.

The Drive Nozzles + must always be bigger than the Brake Nozzles –.

The available pump capacity should be split in the ratio of approx. 70% as Drive + and 30% as

Brake –.

The nozzle head must always rotate clockwise (looking from the lance towards the nozzle

head). If the head does not rotate, the material being cleaned could possibly be damaged

since the pressure against a single point will be too high. In order to start the nozzle head

rotating, it is important that the nozzles are paired as described above. If the head still does

not rotate, there might be a mechanical blockage or the bearing could be defective. Look at

the instructions in Section 4 'Malfunction / Rectification' below.

Example of nozzles fitted for a pump operating at 2500 bar and 21.58 l/min:

Ratio 70/30 =16.1 l/min for the Drive + and 5.48 l/min for the Brake –

Drive Nozzles +=8.05 l/min per nozzle = nozzle Ø 0.60

Brake Nozzles –=2.74 l/min per nozzle = nozzle Ø 0.25

9/14 Copyright © 2020 mvt AG, Port, Switzerland

Page 10

Operating Instructions, Rotary

Pressure/bar

Drive +

Brake

- Flow rate/L

Recoil force/N

Nozzle

TANGO hp - 1

Op Instrs

As at 09.01.2020

3.3 Nozzle selection table when using 4 nozzles (Keep to the ratio!)

3000 2x x 0.55mm 2x x 0.20mm 17.6 225

2500 2x x 0.60mm 2x x 0.30mm 21.1 246

2000 2x x 0.65mm 2x x 0.35mm 22.8 238

1500 2x x 0.75mm 2x x 0.35mm 24.8 225

When using handheld high-pressure spray guns and lances, the recoil force which has to be

absorbed in the longitudinal axis of the spray equipment must not exceed 250N!

If the recoil force exceeds 150N, body support must be worn by equipment operators!

3.4 Water quality

Filter unit 1.0 µm

Solids content max. 50 mg/l (20)

Hardness (CaCO3) max. 25 mg/l (50-175)

Iron content (Fe) max. 0.1 mg/l

Manganese content (Mn) max. 0.1 mg/l

Chloride content (Cl) max. 100 mg/l

Turbidity max. 5 NTU

Free chlorine max. 1.0 mg/l

pH between 6.5 and 8.5

10/14 Copyright © 2020 mvt AG, Port, Switzerland

Page 11

Operating Instructions, Rotary

Nozzle

3.5 Flow rate table for the mvt 964 nozzle

TANGO hp - 1

Op Instrs

As at 09.01.2020

11/14 Copyright © 2020 mvt AG, Port, Switzerland

Page 12

Operating Instructions, Rotary

Malfunction

Reason

Rectificat

ion

Nozzle

TANGO hp - 1

Op Instrs

As at 09.01.2020

4 Malfunction / rectification

4.1 General

In order not to run any risks when rectifying malfunctions, it is important to take account of

everything contained in the operating instructions – especially the "Safety Instructions"

(Section 2), the relevant accident prevention regulations, generally applicable legislation and

directives, and internal company rules.

All the rotary nozzle's component parts may only be replaced by original component

parts supplied by mvt AG.

4.2 Rectifying malfunctions

Threaded connections on the

nozzles / lance not fully

tightened

Operating pressure is not

reached

Water loss at the rotary

nozzle

Mechanical noises Bearings worn Contact service partner

Rotary nozzle does not

rotate

The nozzles chosen do not

comply with the flow rate

table

Threaded connections on the

nozzles / lance not fully

tightened

Defective shaft seal Contact service partner

Mechanical blockage,

defective bearing

Drive nozzle too small; brake

nozzle too big

Check that the threaded

connections are clean and

firmly seated.

Replace nozzle in

accordance with the flow rate

table

Check that the threaded

connections are clean and

firmly seated.

Contact service partner

Adjust nozzle ratio; increase

drive nozzle size; reduce

brake nozzle size.

5

Material removal

performance worsens

Check the nozzle's jetting

pattern

12/14 Copyright © 2020 mvt AG, Port, Switzerland

Replace nozzles

Page 13

Operating Instructions, Rotary

Nozzle

TANGO hp - 1

Op Instrs

As at 09.01.2020

Maintenance / servicing

5.1 General

The mvt Tango rotary nozzle is maintenance-free.

If a malfunction or a defect should occur while using the equipment, contact the local mvt

agent in your country or contact mvt AG directly.

mvt service number: Tel.+41 32 332 97 60 / info@mvt.ch

5.2 Wearing parts

Wearing parts are mvt Type 964 / 965 nozzles plus the protection cap.

The degree of any wear depends on the level of soiling in the water used, on the application

and on the operating pressure.

When replacing nozzles, it is recommended that all 4 nozzles be replaced at the same time.

13/14 Copyright © 2020 mvt AG, Port, Switzerland

Page 14

Operating Instructions, Rotary

Nozzle

TANGO hp - 1

Op Instrs

As at 09.01.2020

6 Warranty

Essentially, mvt AG's General Sales and Delivery Conditions shall apply. These conditions can

be found on our website www.mvt.ch.

Warranty and liability claims are excluded if they are attributable to one or more of the

following causes:

Improper use of the nozzle

Incorrect assembly, start-up, operation and maintenance of the rotary nozzle

Operating without using safety equipment or with defective safety equipment

Wrongly fitted or non-functioning safety equipment and

protective equipment

Operating without wearing protective clothing

Operating with damaged high-pressure hose lines, connectors and adapters

Inadequate monitoring of those component parts which are subject to wear

Operating after making one's own structural modifications to the rotary nozzle

Operating with non-original mvt spare parts

Repairs and servicing carried out improperly

Disastrous damage due to foreign objects, and force majeure

mvt AG

Spärsstrasse 5

CH–2562 Port

Tel. +41 32 332 97 60

info@mvt.ch

www.mvt.ch

14/14 Copyright © 2020 mvt AG, Port, Switzerland

Loading...

Loading...