Page 1

PJ-162-FE

TOUCAN HYBRID

USER’S GUIDE

PRELIMINARY

Important :

Please check the ink status while printing in flatbed. When error

message “Ink not filled” is displayed, IR lamp will power on, this

can cause burning hazard.

With firmware versions, older than V 3.02 L, continually check ink

level. Because there will not be a message when bottles are almost

empty.

MUTOH EUROPE N.V.

Part N°: AP-750, Rev. 1.1. – 23/04/04

Page 2

User’s Guide – Toucan Hybrid

2

AP-750, Rev. 1.1 –- 23/04/04

Page 3

User’s Guide – Toucan Hybrid

3

AP-750, Rev. 1.1 –- 23/04/04

COPYRIGHT NOTICE

COPYRIGHT © 2004 Mutoh Europe N.V. All rights reserved.

This document may not be reproduced by any means, in whole or in part, without written

permission of the copyright owner.

This document is furnished to support the Mutoh Toucan Hybrid (PJ-162-FE) Inkjet printer.

In consideration of the furnishing of the information contained in this document, the party

to whom it is given assumes its custody and control and agrees to the following:

The information herein contained is given in confidence, and any part thereof shall not be

copied or reproduced without written consent of Mutoh Europe N.V.

This document or the contents herein under no circumstances shall be used in the

manufacture or reproduction of the article shown and the delivery of this document shall

not constitute any right or license to do so.

April 2004

Published: Mutoh Europe N.V., Archimedesstraat 13, B-8400 Oostende, BELGIUM

Page 4

User’s Guide – Toucan Hybrid

4

AP-750, Rev. 1.1 –- 23/04/04

Page 5

User’s Guide – Toucan Hybrid

5

AP-750, Rev. 1.1 –- 23/04/04

Important Notice

This product has been tested and found to comply with the limits of a Class A digital device, pursuant to Part

15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference when the product is operated in a commercial environment.

This product generates, uses, and can radiate radio frequency energy and if not installed and used in

accordance with this manual, may cause harmful interference to radio communications. Operation of this

product in a residential area is likely to cause harmful interference in which case the user will be required to

correct the interference at his own expense.

1. Radio interference

Product generates weak radio signals and may interfere with television reception and utilities. If a product

does interfere with radio or TV reception, try the following:

Change the direction of your radio and TV reception antenna or feeder.

Change the direction of the product.

Move either the product or the receiving antenna so there is more distance between them.

Be sure the product and the receiving antenna are on separate power lines.

2. Trademarks mentioned in this manual.

MUTOH, PJ-162-FE, Toucan Hybrid, MH-RTL are registered trademarks or product names of MUTOH

INDUSTRIES LTD.

Centronics and Bitronics are registered trademarks or product names of Centronics Data Computer

Corporation.

Windows95, Windows98, Windows NT4.0, Windows2000, and MS-DOS are registered trademarks o r

product names of Microsoft Corporation.

DOS/V is registered trademark and product name of International Business Machine Corpor ation (IBM).

Other company and product names may be registered trademarks or product names.

Caution :

No part of this product or publication may be reproduced, copied, or transmitted in any

form or by any means, except for personal use, without the permission of MUTOH

INDUSTRIES LTD.

The product and the contents of this publication may be changed without prior

notification.

MUTOH INDUSTRIES LTD. has made the best efforts to keep this publication free from

error, but if you find any uncertainties or misprints, please call us or the shop where you

bought this equipment.

MUTOH INDUSTRIES LTD. shall not be liable for any damages or troubles resulting

from the use of this equipment or this manual.

Page 6

User’s Guide – Toucan Hybrid

6

AP-750, Rev. 1.1 –- 23/04/04

Warranty Limitations

1. MUTOH INDUSTRIES LTD. warrants part repair or replacement as a sole measure only if a failure is

found in the system or in the materials and workmanship of the product the seller produced.

However, if the cause of failure is uncertain, action is decided after due mutual consultation.

2. The warranty shall not apply to any direct or indirect loss, or compensation for the loss when the product

that has been subject to misuse, neglect, or improper alternation.

About This Manual

1. Purpose and target readers

This manual explains preparations needed before using and procedures for o perations for MUTOH

INDUSTRIAL LTD. Grand Format Inkjet Printer (PJ-162-FE Toucan Hybrid)

This manual is prepared for the owners and operators of this printer.

Before using this printer, first understand the contents and directions in this manual.

2. Manual configuration

Section Contents

1 Safety Instructions Explains cautions and warnings labeled on the printer for the both

operators of the printer and maintenance personnel.

2 Product Overview Explains the features, part names, and functions of the printer.

3 Installation Explains how to install the printer

3 Preparing for a job Explains the procedures needed to prepare for a job

4 Handling the printer Explains how to handle the printer.

5 Maintenance Explains daily maintenance of the printer.

6 Troubleshooting Explains troubles that may occur when using the printer and how to solve

them.

7 Appendix Explains the specifications, optional parts and supplies, installation

procedures for optional parts, and user support for this printer.

Notes :

"Safety Instructions" through "Basic Installation" must be read before using the printer.

Read "Handling the printer" through “Appendix" as necessary.

Page 7

User’s Guide – Toucan Hybrid

7

AP-750, Rev. 1.1 –- 23/04/04

TABLE OF CONTENTS

1 SAFETY INSTRUCTIONS........................................................................................................................................13

1.1 INTRODUCTION ....................................................................................................................................................... 13

1.2 WARNINGS, CAUTIONS, AND NOTES.......................................................................................................................13

1.3 IMPORTANT SAFETY INSTRUCTIONS ........................................................................................................................14

1.4 WARNING LABELS...................................................................................................................................................18

1.4.1 Handling the warning labels...........................................................................................................................18

1.4.2 Locations and types of warning labels...........................................................................................................18

1.4.3 Other safety issues..........................................................................................................................................24

2. PRODUCT OVERVIEW...........................................................................................................................................27

2.1 INTRODUCTION ....................................................................................................................................................... 27

2.2 FEATURES...............................................................................................................................................................27

2.3 PART NAMES AND FUNCTIONS.................................................................................................................................28

2.3.1 Front...............................................................................................................................................................28

2.3.2 Rear section.................................................................................................................................................... 30

2.3.3 Flat stand........................................................................................................................................................31

2.3.4 Operation panel..............................................................................................................................................32

2.4 PRINTER STATUS.....................................................................................................................................................34

2.4.1 Normal ...........................................................................................................................................................34

2.4.2 Setup menu display........................................................................................................................................34

2.4.3 Changing the printer status.............................................................................................................................35

3 INSTALLATION.........................................................................................................................................................37

3.1 INTRODUCTION ....................................................................................................................................................... 37

3.2 UNPACKING ............................................................................................................................................................ 37

3.2.1 Unpacking procedure.....................................................................................................................................37

3.2.2 Verification of packaged items.......................................................................................................................39

3.3 ASSEMBLY..............................................................................................................................................................42

3.3.1 Removal of protective packaging material.....................................................................................................42

3.3.2 Installing panel sheet and panel cover............................................................................................................43

3.3.3 Installing the media sticking prevention screen ............................................................................................. 44

3.3.4 Installing the power cable clamp.................................................................................................................... 45

3.3.5 Assembling the flat stand...............................................................................................................................46

3.4 INSTALLATION ........................................................................................................................................................49

3.4.1 Choosing a place for the printer.....................................................................................................................49

3.4.2 Installing the printer.......................................................................................................................................51

3.4.3 Installing the flat stand...................................................................................................................................51

4 PREPARING FOR A JOB..........................................................................................................................................55

4.1 INTRODUCTION ....................................................................................................................................................... 55

4.2 CONNECTING THE POWER CABLE ............................................................................................................................ 55

4.3 CONNECTING THE FOOT SWITCH .............................................................................................................................58

4.4 SELECTION ROLL-TO-ROLL OR RIGID MATERIALS....................................................................................................60

4.5 TURNING THE POWER ON/OFF...............................................................................................................................61

4.5.1 Turning the power ON...................................................................................................................................61

4.5.2 Turning the power OFF..................................................................................................................................66

4.5.3 An emergency power OFF.............................................................................................................................71

4.6 REFILLING THE INK - JETWASH FLUID...................................................................................................................... 72

4.7 MEDIA HANDLING...................................................................................................................................................77

4.7.1 Setting of the rigid media...............................................................................................................................78

4.7.2 Removing the flat stand..................................................................................................................................82

4.7.3 Placement of the roll media............................................................................................................................84

4.7.4 Loading roll media.........................................................................................................................................88

4.7.5 Setting winding unit.......................................................................................................................................94

4.8 HEAD CLEANING BEFORE PRINTING.........................................................................................................................97

4.9 TESTPRINTING.......................................................................................................................................................101

4.9.1 Setup List ..................................................................................................................................................... 102

Page 8

User’s Guide – Toucan Hybrid

8

AP-750, Rev. 1.1 –- 23/04/04

4.9.2 Nozzle Check...............................................................................................................................................103

4.9.3 Alignment.....................................................................................................................................................103

4.9.4 Palette........................................................................................................................................................... 105

4.10 CONNECTING THE PRINTER TO YOUR PC.............................................................................................................106

4.10.1 System requirements..................................................................................................................................106

4.10.2 Selecting cables..........................................................................................................................................106

4.10.3 Connecting the interface cable...................................................................................................................107

5. HANDLING THE PRINTER..................................................................................................................................109

5.1 INTRODUCTION ..................................................................................................................................................... 109

5.2 DRAWING FLOW....................................................................................................................................................109

5.3 USING MEDIA........................................................................................................................................................111

5.3.1 Media type....................................................................................................................................................111

5.3.2 Cautions on handling media......................................................................................................................... 112

5.3.3 Precaution on storing media.........................................................................................................................113

5.3.4 The printing area..........................................................................................................................................113

5.3.5 Criteria for the media feed ........................................................................................................................... 114

5.3.6 Media feed compensation.............................................................................................................................115

5.3.7 Installing media holder plate........................................................................................................................118

5.4 MENU SETUP ON THE OPERATION PANEL - ROLL-TO-ROLL ....................................................................................120

5.4.1 Setup menu...................................................................................................................................................121

5.4.2 Origin setup menu ........................................................................................................................................ 123

5.4.3 Test print menu ............................................................................................................................................ 124

5.4.4 Media setup menu........................................................................................................................................124

5.4.5 Media type menu..........................................................................................................................................125

5.4.6 User media menu..........................................................................................................................................125

5.4.7 Ink Dry menu............................................................................................................................................... 126

5.4.8 Head Height menu........................................................................................................................................127

5.4.9 Stiff menu.....................................................................................................................................................127

5.4.10 Thickness menu..........................................................................................................................................127

5.4.11 Platen heater menu.....................................................................................................................................128

5.4.12 Dryer menu.................................................................................................................................................128

5.4.13 Prevention stick menu................................................................................................................................129

5.4.14 Media feed compensation menu.................................................................................................................129

5.4.15 Printing by Media feed compensation menu.............................................................................................. 130

5.4.16 Change media feed compensation value menu...........................................................................................130

5.4.17 Print unit menu........................................................................................................................................... 131

5.4.18 Print depth menu........................................................................................................................................131

5.4.19 Data size menu...........................................................................................................................................132

5.4.20 PF size menu..............................................................................................................................................132

5.4.21 CR size menu.............................................................................................................................................133

5.4.22 Idle heat menu............................................................................................................................................133

5.4.23 Idle timeout menu ......................................................................................................................................134

5.4.24 Media cut menu..........................................................................................................................................134

5.4.25 Printing mode menu...................................................................................................................................135

5.4.26 Printing mode setup menu..........................................................................................................................135

5.4.27 Printing quality menu.................................................................................................................................135

5.4.28 Inter Lace Setup menu................................................................................................................................136

5.4.29 Printing direction menu.............................................................................................................................. 136

5.4.30 Repeat printing menu.................................................................................................................................136

5.4.31 Repeat times menu.....................................................................................................................................137

5.4.32 Interval time menu..................................................................................................................................... 137

5.4.33 Command setup menu................................................................................................................................ 138

5.4.34 Image resolution menu............................................................................................................................... 138

5.4.35 Online time out menu.................................................................................................................................139

5.4.36 Layout setup menu.....................................................................................................................................139

5.4.37 Joint printing menu .................................................................................................................................... 139

5.4.38 Joint margin menu......................................................................................................................................140

5.4.39 Function setup menu..................................................................................................................................140

5.4.40 CMY → K menu........................................................................................................................................ 141

5.4.41 Mirror menu...............................................................................................................................................141

Page 9

User’s Guide – Toucan Hybrid

9

AP-750, Rev. 1.1 –- 23/04/04

5.4.42 Centronics menu.........................................................................................................................................142

5.4.43 Network menu............................................................................................................................................ 142

5.4.44 Utility menu ...............................................................................................................................................142

5.4.45 Error Display menu....................................................................................................................................143

5.4.46 Media detection menu................................................................................................................................143

5.4.47 Take-up mechanism menu ......................................................................................................................... 143

5.4.48 Load unit menu .......................................................................................................................................... 144

5.4.49 Negative pressure pump menu...................................................................................................................144

5.4.50 Skew check menu.......................................................................................................................................145

5.4.51 Version Check Menu..................................................................................................................................145

5.4.52 Idle management setup menu..................................................................................................................... 145

5.4.53 Write mode menu....................................................................................................................................... 146

5.4.54 Reprint menu.............................................................................................................................................. 147

5.4.55 File delete menu.........................................................................................................................................148

5.4.56 Re-name menu ........................................................................................................................................... 148

5.4.57 Format menu..............................................................................................................................................149

5.4.58 Free area menu...........................................................................................................................................150

5.4.59 Initialize setup menu .................................................................................................................................. 151

5.4.60 All initialize menu...................................................................................................................................... 152

5.4.61 Media setup Initialize menu.......................................................................................................................152

5.4.62 Printing mode initialize menu.................................................................................................................... 152

5.4.63 Command setup initialize menu.................................................................................................................153

5.4.64 Layout setup initialize menu ...................................................................................................................... 153

5.4.65 Function setup initialize menu ..................................................................................................................153

5.4.66 Roll media setup initialize menu................................................................................................................154

5.4.67 Centronics initialize menu..........................................................................................................................154

5.4.68 Network initialize menu.............................................................................................................................154

5.4.69 Utility initialize menu.................................................................................................................................155

5.4.70 File management initialize menu .............................................................................................................. 155

5.4.71 Data dump menu........................................................................................................................................155

5.4.72 Head wash menu........................................................................................................................................156

5.4.73 Long term storage cleaning menu..............................................................................................................157

5.4.74 Maintenance setup menu............................................................................................................................ 158

5.4.75 Set Review Menu.......................................................................................................................................159

5.5 MENU SETUP ON THE OPERATION PANEL - RIGID MATERIAL.................................................................................. 160

5.5.1 Setup menu...................................................................................................................................................161

5.5.2 Origin setup menu ........................................................................................................................................ 162

5.5.3 Test print menu ............................................................................................................................................ 165

5.5.4 Media setup menu........................................................................................................................................165

5.5.5 Media type menu..........................................................................................................................................165

5.5.6 User media menu..........................................................................................................................................166

5.5.7 Ink Dry menu............................................................................................................................................... 167

5.5.8 Head Height menu........................................................................................................................................167

5.5.9 Dist Adj menu..............................................................................................................................................168

5.5.10 Printing by Media feed compensation menu.............................................................................................. 168

5.5.11 Change media feed compensation value menu...........................................................................................169

5.5.12 Print unit menu........................................................................................................................................... 169

5.5.13 Print depth menu........................................................................................................................................170

5.5.14 Data size menu...........................................................................................................................................170

5.5.15 Printing mode menu...................................................................................................................................171

5.5.16 Printing mode setup menu..........................................................................................................................171

5.5.17 Printing quality menu.................................................................................................................................172

5.5.18 Inter Lace Setup menu................................................................................................................................172

5.5.19 Printing direction menu.............................................................................................................................. 172

5.5.20 Repeat printing menu.................................................................................................................................173

5.5.21 Repeat times menu.....................................................................................................................................173

5.5.22 Interval time menu..................................................................................................................................... 173

5.5.23 Commend setup menu................................................................................................................................ 174

5.5.24 Image resolution menu............................................................................................................................... 174

5.5.25 Online time out menu.................................................................................................................................175

5.5.26 Layout setup menu.....................................................................................................................................175

Page 10

User’s Guide – Toucan Hybrid

10

AP-750, Rev. 1.1 –- 23/04/04

5.5.27 Joint printing menu .................................................................................................................................... 175

5.5.28 Joint margin menu......................................................................................................................................176

5.5.29 Function setup menu..................................................................................................................................176

5.5.30 CMY → K menu........................................................................................................................................ 177

5.5.31 Mirror menu...............................................................................................................................................177

5.5.32 Centronics menu.........................................................................................................................................178

5.5.33 Utility menu ...............................................................................................................................................178

5.5.34 Error Display menu....................................................................................................................................179

5.5.36 Media width menu......................................................................................................................................179

5.5.37 Negative pressure pump menu...................................................................................................................180

5.5.38 Infrared lamp menu....................................................................................................................................180

5.5.39 Vacuum menu............................................................................................................................................180

5.5.40 Version Check Menu..................................................................................................................................181

5.5.41 File management setup menu..................................................................................................................... 181

5.5.42 Write mode menu....................................................................................................................................... 182

5.5.43 Reprint menu.............................................................................................................................................. 182

5.5.44 File delete menu.........................................................................................................................................183

5.5.45 Re-name menu ........................................................................................................................................... 184

5.5.46 Format menu..............................................................................................................................................185

5.5.47 Free area menu...........................................................................................................................................186

5.5.48 Initialize setup menu .................................................................................................................................. 186

5.5.49 All initialize menu...................................................................................................................................... 187

5.5.50 Media setup Initialize menu.......................................................................................................................188

5.5.51 Printing mode initialize menu.................................................................................................................... 188

5.5.52 Command setup initialize menu.................................................................................................................188

5.5.53 Layout setup initialize menu ...................................................................................................................... 189

5.5.54 Function setup initialize menu ..................................................................................................................189

5.5.55 Roll media setup initialize menu................................................................................................................189

5.5.56 Centronics initialize menu..........................................................................................................................190

5.5.57 Utility initialize menu.................................................................................................................................190

5.5.58 File management initialize menu ............................................................................................................... 190

5.5.59 Data dump menu........................................................................................................................................191

5.5.60 Head wash menu........................................................................................................................................191

5.5.61 Long term storage cleaning menu..............................................................................................................192

5.5.62 Maintenance setup menu............................................................................................................................ 193

5.5.63 Set Review Menu.......................................................................................................................................194

5.6 OPERATING FORM THE OPERATION PANEL ............................................................................................................ 195

5.6.1 To stop printing operation............................................................................................................................195

5.6.2 Operating the pressure rollers.......................................................................................................................196

5.6.3 Moving the Rigid Media..............................................................................................................................197

5.6.5 “Manual” becomes “Adjust”........................................................................................................................ 198

5.6.6 infrared lamp settings................................................................................................................................... 198

5.6.7 Vacuum settings...........................................................................................................................................198

5.6.8 Winding the roll media.................................................................................................................................199

5.6.9 Head cleaning............................................................................................................................................... 201

5.6.10 Checking printing mode............................................................................................................................. 202

5.7 OPERATIONS AFTER PRINTING...............................................................................................................................203

5.7.1 Removing the rigid media............................................................................................................................ 203

5.7.2 Roll media cutting procedure.......................................................................................................................205

5.7.3 Disposal of waste fluids...............................................................................................................................206

5.8 MEDIA TOUCHING THE CARRIAGE OR INFRARED LAMP .........................................................................................207

Page 11

User’s Guide – Toucan Hybrid

11

AP-750, Rev. 1.1 –- 23/04/04

6 MAINTENANCE.......................................................................................................................................................209

6.1 INTRODUCTION ..................................................................................................................................................... 209

6.2 REPLACING CONSUMABLES................................................................................................................................... 209

6.2.1 Refilling the ink and jetwash liquid .............................................................................................................209

6.2.2 Replacing roll media.................................................................................................................................... 211

6.2.3 Replacement of the ink filter........................................................................................................................213

6.2.4 Replacement of the print head and CR motor..............................................................................................214

6.2.5 Replacement of the infrared lamp................................................................................................................215

6.3 CLEANING THE PRINTER........................................................................................................................................216

6.3.1 Cleaning the outer case ................................................................................................................................ 216

6.3.2 Cleaning inside the printer...........................................................................................................................217

6.3.3 Cleaning of the print head surface................................................................................................................218

6.3.4 Washing print head ......................................................................................................................................220

6.4 LONG-TERM STORAGE CLEANING.......................................................................................................................... 224

6.5 TRANSFER AND TRANSPORTATION........................................................................................................................228

6.5.1 Transferring the printer................................................................................................................................228

6.5.2 Transporting the printer................................................................................................................................230

7 TROUBLESHOOTING............................................................................................................................................231

7.1 INTRODUCTION ..................................................................................................................................................... 231

7.2 FAILURES AND MALFUNCTIONS OF THE PRINTER...................................................................................................231

7.3 ERROR MESSAGES.................................................................................................................................................237

7.3.1 Status messages............................................................................................................................................ 237

7.3.2 Message type error display and solutions.....................................................................................................239

7.3.3 Data error display and solutions................................................................................................................... 241

7.3.4 Command error display and solutions..........................................................................................................241

7.3.5 Error requiring a restart................................................................................................................................ 242

7.4 WHEN MEDIA JAMS OCCUR ...................................................................................................................................243

7.4.1 Removing the rigid media............................................................................................................................ 243

7.4.2 How to remove the roll media.....................................................................................................................243

8 APPENDIX.................................................................................................................................................................245

8.1 INTRODUCTION ..................................................................................................................................................... 245

8.2 PRODUCT SPECIFICATIONS....................................................................................................................................245

8.2.1 TOUCAN HYBRID Unit specification........................................................................................................245

8.3 INTERFACE SPECIFICATIONS .................................................................................................................................247

8.3.1 Centronics Bidirectional Parallel Interface: IEEE1284)...............................................................................247

8.4 OPTIONS/SUPPLY LIST ...........................................................................................................................................248

8.4.1 Options.........................................................................................................................................................248

8.4.2 Supply..........................................................................................................................................................248

8.5 INSTALLING OPTIONS............................................................................................................................................ 249

8.5.1 Installation of the hard disk..........................................................................................................................249

Page 12

User’s Guide – Toucan Hybrid

12

AP-750, Rev. 1.1 –- 23/04/04

Page 13

User’s Guide – Toucan Hybrid

13

AP-750, Rev. 1.1 –- 23/04/04

1 SAFETY INSTRUCTIONS

1.1 INTRODUCTION

This chapter explains the meaning of safety terms for personnel who operates this equipment, important

safety instructions, and the positions of the warning labels.

Important :

Be sure to follow all instructions and warnings in this manual when using the

equipment.

1.2 WARNINGS, CAUTIONS, AND NOTES

Safety terms in this manual and the contents of warning labels attached to the printer are categorized into

the following three types depending on the degree of risk (or the scale of accident ).

Read the following explanations carefully, and follow the instructions in this manual.

Safety terms Details

Important

Must be followed carefully to avoid death or serious bodily injury.

Caution

Must be observed to avoid bodily injury (moderately or lightly) or damage to your

equipment.

Note

Contains important information and useful tips on the operation of your printer.

Page 14

User’s Guide – Toucan Hybrid

14

AP-750, Rev. 1.1 –- 23/04/04

1.3 IMPORTANT SAFETY INSTRUCTIONS

General safety instructions that must be observed to use the equipment safely are explained below.

Always wear protective goggles. Operators as well as technicians and visitors have to wear protective

goggles whenever the infrared lamp is active. It is obligated to wear them to avoid eye damage.

Do not touch the infrared lamp or infrared lamp house after or during operation. Doing so could result in

burns.

Please note that after operating the infrared lamp and infrared lamp house will remain hot for several

minutes. Let it cool off. Not doing so could result in burns.

In case the carriage or infrared lamp touches the media, power the unit OFF and ON. Do not touch the

carriage or infrared lamp.

Be careful not to pinch your fingers when lowering or lifting the media guide by using the lifting grip.

During printing on rigid materials, the fans will cool off the infrared lamp. Please note there is no

detection. Regularly check if the fans are working. You can do this by holding a sheet of paper between

the fan and lamp house.

When installing or removing the front stand 1, please make sure not to touch the carriage or the infrared

lamp. Doing so could cause permanent damage.

Do not place the printer in the following areas. Doing so may result in the printer tipping or falling over

and causing injury.

• Unstable surfaces

• Inclined surface

• Areas subject to vibration by other equipment

Do not stand on or place heavy objects on your printer. Doing so may result in the printer tipping or

falling over and may cause injury.

Do not cover the ventilation hole of your printer with cloth, such as a blanket or table cloth. Doing so

could obstruct ventilation and cause fire.

Do not place the printer in humid and dusty areas. Doing so may result in electrical shock or fire.

Do not use a damaged power cable. Doing so may result in electrical shock.

Do not attempt to plug in electrical plugs with wet hands. Doing so may result in electrical shock.

Do not connect earth cables in the following areas.

• Gas pipes → Doing so may cause fire or an explosion.

• Earth terminals for telephone line or lightning rod → Doing so may cause a large flow of

voltage if lightning occurs.

• Water pipes or faucets → If there is a plastic part in the pipe, the earth will not work properly.

The ink used in the product contains an organic solvent (CYCLOHEXANONE). It is flammable so open

flame is prohibited in the area. In a dry environment, static electricity can cause ignition, so before

handling the ink, jetwash liquid or waste liquids, touch a metallic object first to remove static electricity

from your body.

Do not insert or drop metal or inflammable objects into openings, such as ventilation outlets. Doing so

may result in electrical shock and fire.

Stop using your printer if a liquid is spilled into it. This may cause electrical shock or fire. Turn the

printer off as soon as possible, unplug the power cord, contact MUTOH local dealer.

Page 15

User’s Guide – Toucan Hybrid

15

AP-750, Rev. 1.1 –- 23/04/04

Be sure to use the attached cable. Otherwise, electrical shock or fire may occur.

Be sure to use the specified voltage (AC 100 V- 120 V or AC 220 V - 240 V). Otherwise, electrical shock

or fire may occur.

Use electricity directly from a power outlet (AC 100 V- 120 V or AC 220 V - 240 V). Do not put many

loads on one electrical output. Otherwise, heat may be generated and cause fire.

Be sure to use an outlet with an earth terminal and use the terminal correctly. Otherwise, electrical

shock or fire may occur.

The ink used in this product contains an organic solvent (CYCLOHEXANONE). Make sure to follow the

industrial waste disposal laws and ordinances of your local governments. It is necessary to install a local

ventilation unit, a push/pull type ventilation unit, or a total ventilation unit to perform adequate ventilation.

If ink or jetwash liquid is swallowed, do not make the person throw up, but immediately call a doctor and

a poison management centre. If there is contact with eyes or inhalation, it may cause irritation. Follow

the cautions and procedures labeled on the ink and jetwash bottles, and take action immediately.

Follow the instructions below when handling the power cable.

• Do not modify the cable

• Do not put heavy objects on the cable

• Do not bend, twist, or pull the cord

• Do not wire the cable near equipment that generates heat

Follow the instructions below when handling the power plug. Otherwise, fire may occur.

• Wipe away dust and any other residue before inserting the plug.

• Ensure that the plug is firmly inserted as far as it will go.

When handling the foot switch, be wary of the following:

• Do not place anything heavy on the foot switch

• Do not bend the cable of the foot switch with force, and do not pull.

• Do not place the foot switch near thermal devices.

When opening/closing the maintenance cover, be careful not to get fingers caught in the lid.

Be careful not to pinch your fingers between rigid media and the media tray

When moving the media, be careful not to pinch your fingers between the flat stand roller and the media

tray

The refilled ink or jetwash liquid must not exceed the upper limit (about 2 liters) of the main tank. If it

exceeds the upper limit, the ink will leak out and will cause printer problems.

When filling the main tank with ink, make sure not to make a mistake with the ink colour and the ink tube

colours. Filling the tank with wrong colour ink can make the print head useless.

During printing in roll mode, do not touch the media guide. The media guide is hot, and may cause burns

if touched.

During the winding operation, make sure to keep hands and fingers clear of moving parts.

Take extreme caution not to have your fingers pinched in the drive when moving the media.

When cutting the roll media, be careful of the following. Incorrect handling can result in injury to hands

and fingers from the blade.

• When holding the media, do not place fingers over the media cut groove.

• Move the blade slowly along the media cut groove.

Page 16

User’s Guide – Toucan Hybrid

16

AP-750, Rev. 1.1 –- 23/04/04

Do not use thinner, Benzene, alcohol or other active agents except for following parts. Doing so may

result in malfunction of the product.

• Inside the maintenance cover

• Print head surface

Be careful not to spill water inside the printer. Doing so may result in a short circuit.

Never open the covers fixed with screws. Doing so may result in electrical shock or a malfunction in the

printer.

When cleaning the print head, be careful of the following. Incorrect cleaning may result in clogging of the

nozzles.

• Do not touch the print head surface with bare hands.

• Clean the print head wiper every time when ink is adhered to it or soak it in jetwash.

Do not tilt the printer, place it against a wall, or turn it upside down. Doing so may cause ink to leak

inside the printer. Also, movement after transportation is not covered by the warranty.

Have four or more people unpack and transport the printer.

When lifting the printer out of the packing box, be sure to remove the vinyl cover first, then grab the

holding sides of the printer. Lifting the printer with the vinyl cover on may cause your hands to slip and

drop or damage the printer.

Ensure that the plug has been disconnected from the power socket when it is not used for a long time.

Earth wires must be connected to wires or terminals which fulfil the conditions below.

• Earth terminals of power socket

• Earth wires with copper morsel that is at least 650 mm under ground

When refilling ink or jetwash fluid, always wear the protective gloves supplied with the unit.

Be sure to close the lid of the main tank tightly. If the lid is not tightly closed or loose, it will cause a

defect when purging, loading or unloading the ink.

Always perform the following work with 2 people.

• Placement of the roll media / rigid media

• Setting of the roll media / rigid media

• Setting of the winding unit

• Moving of media tray

When performing a head cleaning:

• Put on the gloves supplied with the printer on both hands.

• Use the print head wiper or polynit wipes supplied with the printer to clean printhead.

Otherwise the nozzle may become clogged.

Immediately after printing in roll mode, the media guide and the platen is very hot. Perform work after

the media guide and the platen have cooled down.

When changing the ink filter, always perform the following:

• Turn the unit OFF.

• Unplug the electrical power cord

• Remove all cables connected with the unit

• If any of these are connected while replacing the filter, the unit may be damaged.

When changing the ink filter, always wear the gloves supplied with the unit on both hands.

When cleaning the waste fluid tray, always wear the protective gloves supplied with the unit.

When cleaning the print head surface, always wear the protective gloves supplied with the unit.

Page 17

User’s Guide – Toucan Hybrid

17

AP-750, Rev. 1.1 –- 23/04/04

When performing cleaning for long-term storage, always wear the protective gloves supplied with the

unit.

Be sure to turn the printer off and unplug the power cord before cleaning.

Keep the printer horizontal during transportation.

Be sure to do the following before attaching expansion memories.

• Turn the printer off

• Unplug the power cord from the socket

Unplug cables connected to the printer.

• Otherwise, damage to the printer or your computer may occur.

• Remove electrostatic charge form your clothes and body when touching the metal parts of

the printer.

• Electronic components such as the memory may malfunction if exposed to an electrostatic

charge.

Before installation of options, always perform the following.

• Remove the power source plug from the outlet.

• Remove all cables connected to the printer.

• Failure to do so could result in damage to the printer or your computer.

• Touch a metallic section of the product, to remove any static electricity in your body. The

electronic components can be damaged from static electricity.

When installing options, do not touch the elements on the circuit board. The elements on the boards

can be very hot, and can cause burns.

This equipment contains a Sealed Lead Acid Battery.

Dispose of in accordance with all applicable governmental regulations.

Page 18

User’s Guide – Toucan Hybrid

18

AP-750, Rev. 1.1 –- 23/04/04

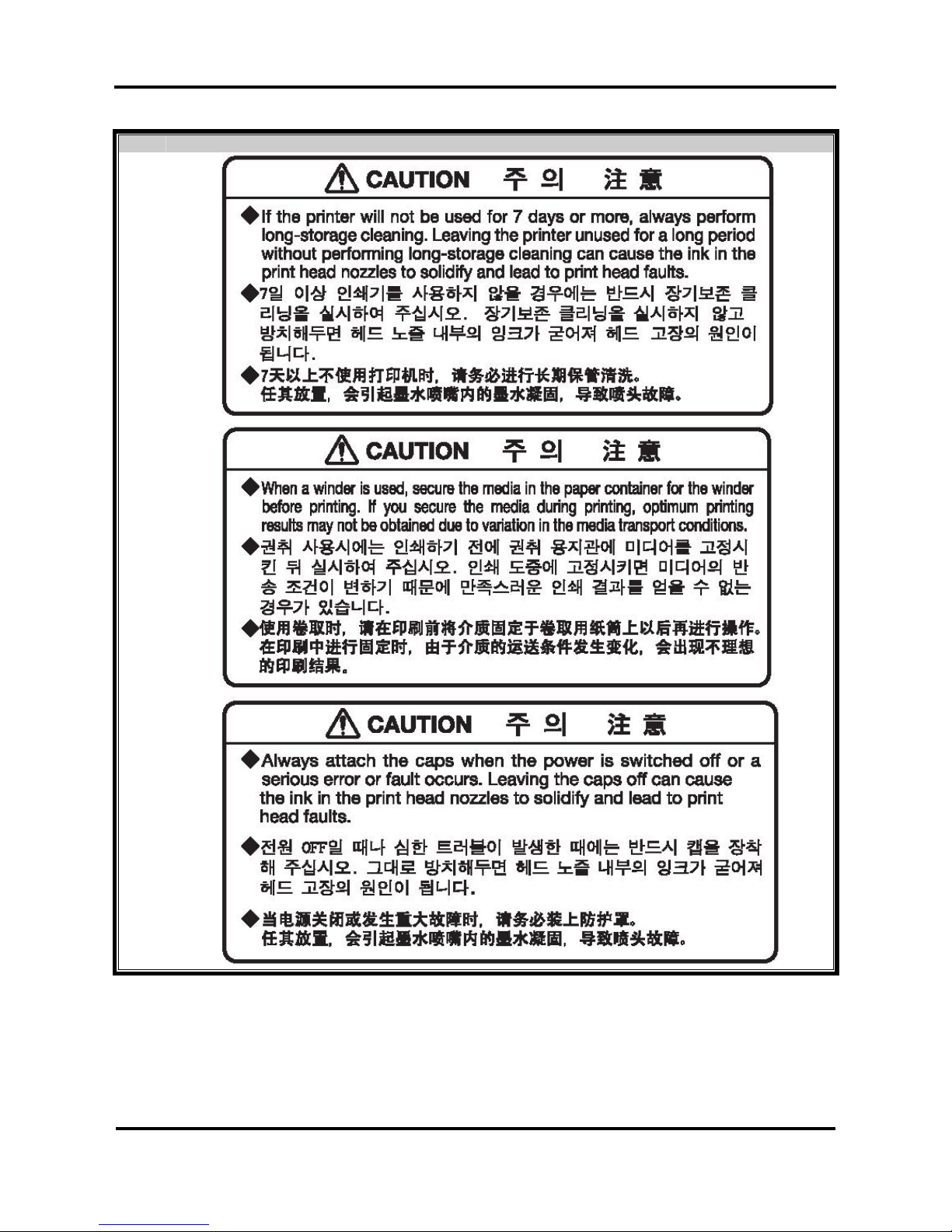

1.4 WARNING LABELS

The handling, attachment locations, and types of warning labels are explained below.

Warning labels are attached to areas where care should be taken. Read and understand the positions and

contents thoroughly before performing your work.

1.4.1 Handling the warning labels

Be sure to note the following when handling the labels.

Notes :

Make sure that all labels can be recognized. If text or illustrations cannot be seen

clearly, either clean or replace the label.

When cleaning labels, use a cloth with water or neutral detergent. Do not use a solvent

or gasoline.

If a warning label is damaged, lost, or cannot be recognized, replace the label. When

replacing warning labels, contact MUTOH local dealer.

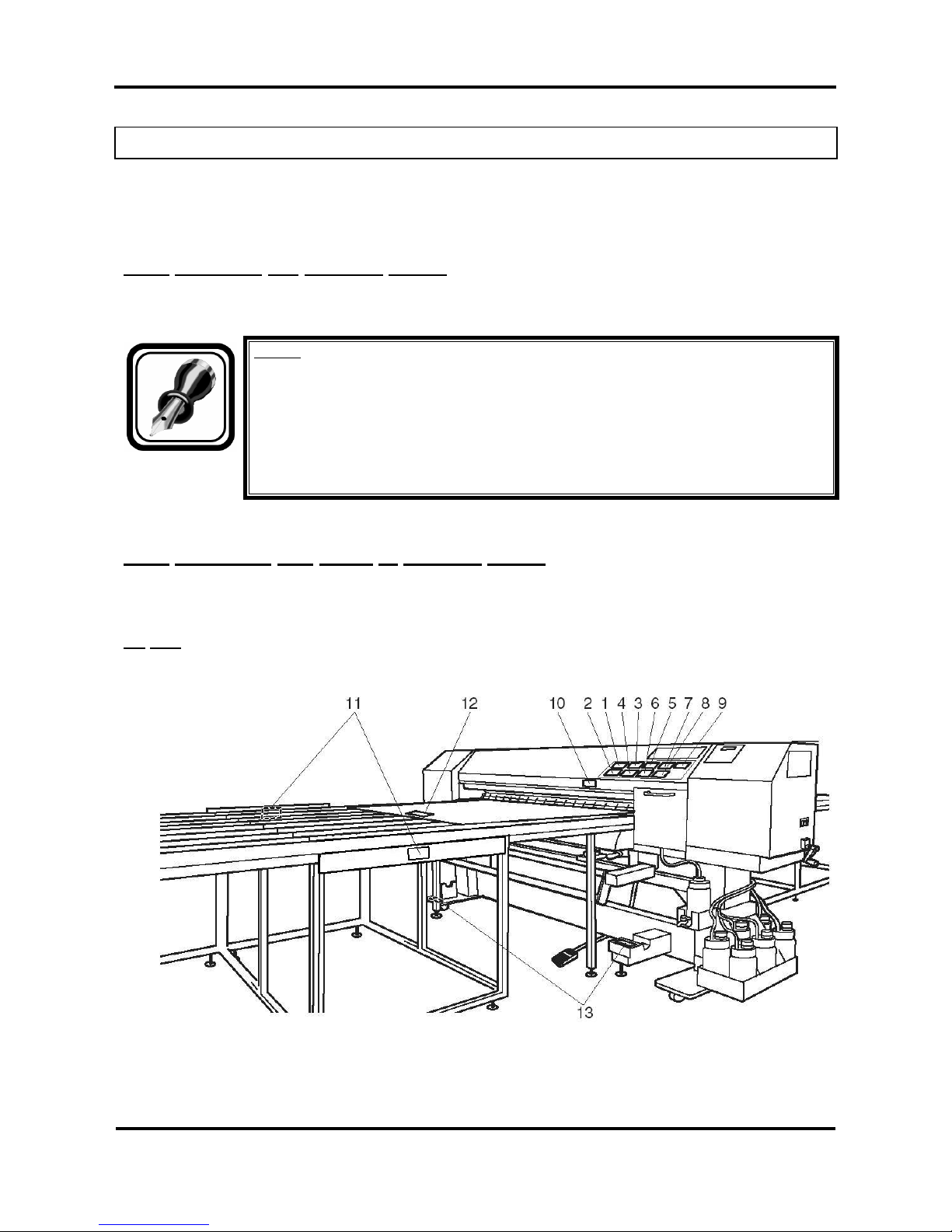

1.4.2 Locations and types of warning labels

The locations of warning labels are shown below.

(1) Unit

Page 19

User’s Guide – Toucan Hybrid

19

AP-750, Rev. 1.1 –- 23/04/04

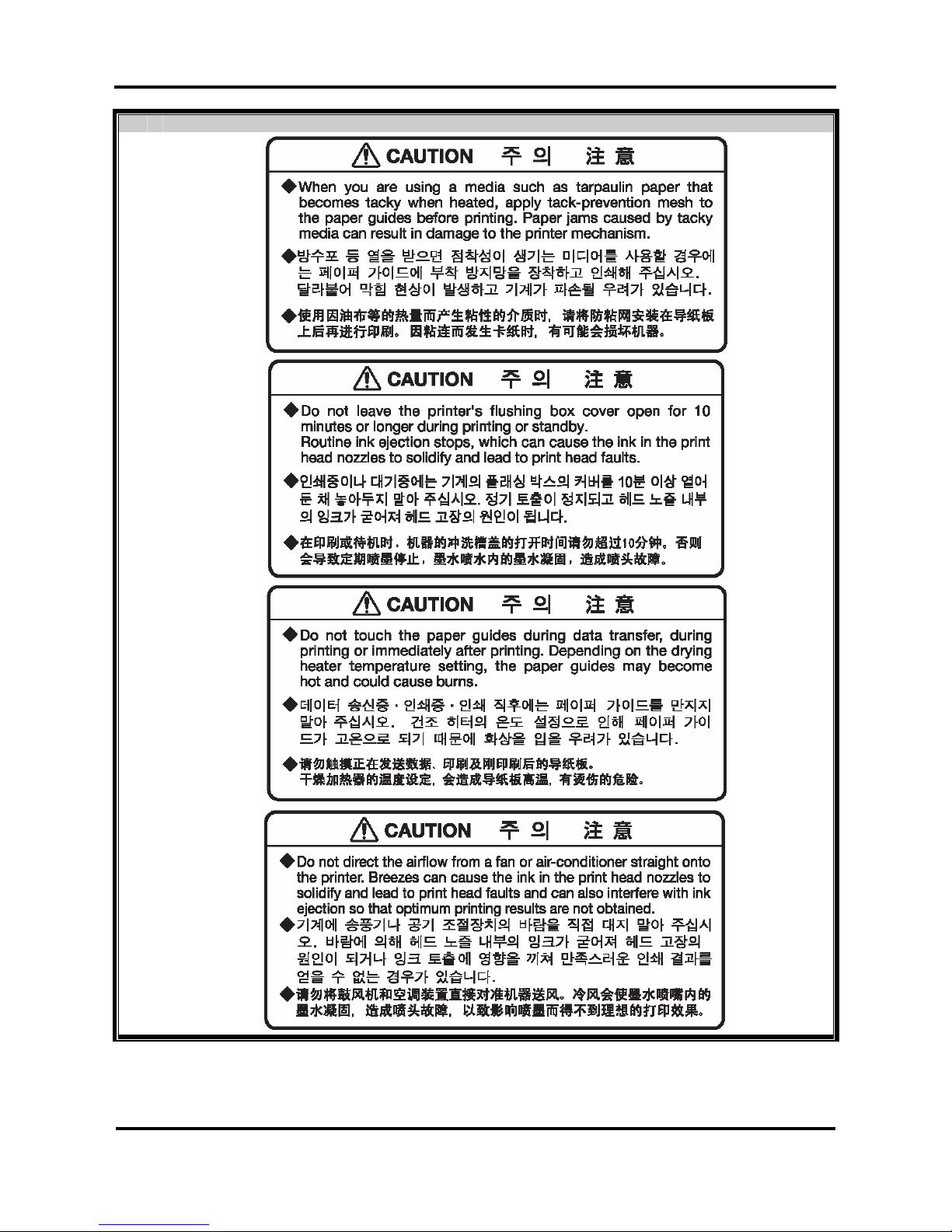

No. Type

1

2

3

Page 20

User’s Guide – Toucan Hybrid

20

AP-750, Rev. 1.1 –- 23/04/04

No. Type

4

5

6

7

Page 21

User’s Guide – Toucan Hybrid

21

AP-750, Rev. 1.1 –- 23/04/04

8

9

10

11

Page 22

User’s Guide – Toucan Hybrid

22

AP-750, Rev. 1.1 –- 23/04/04

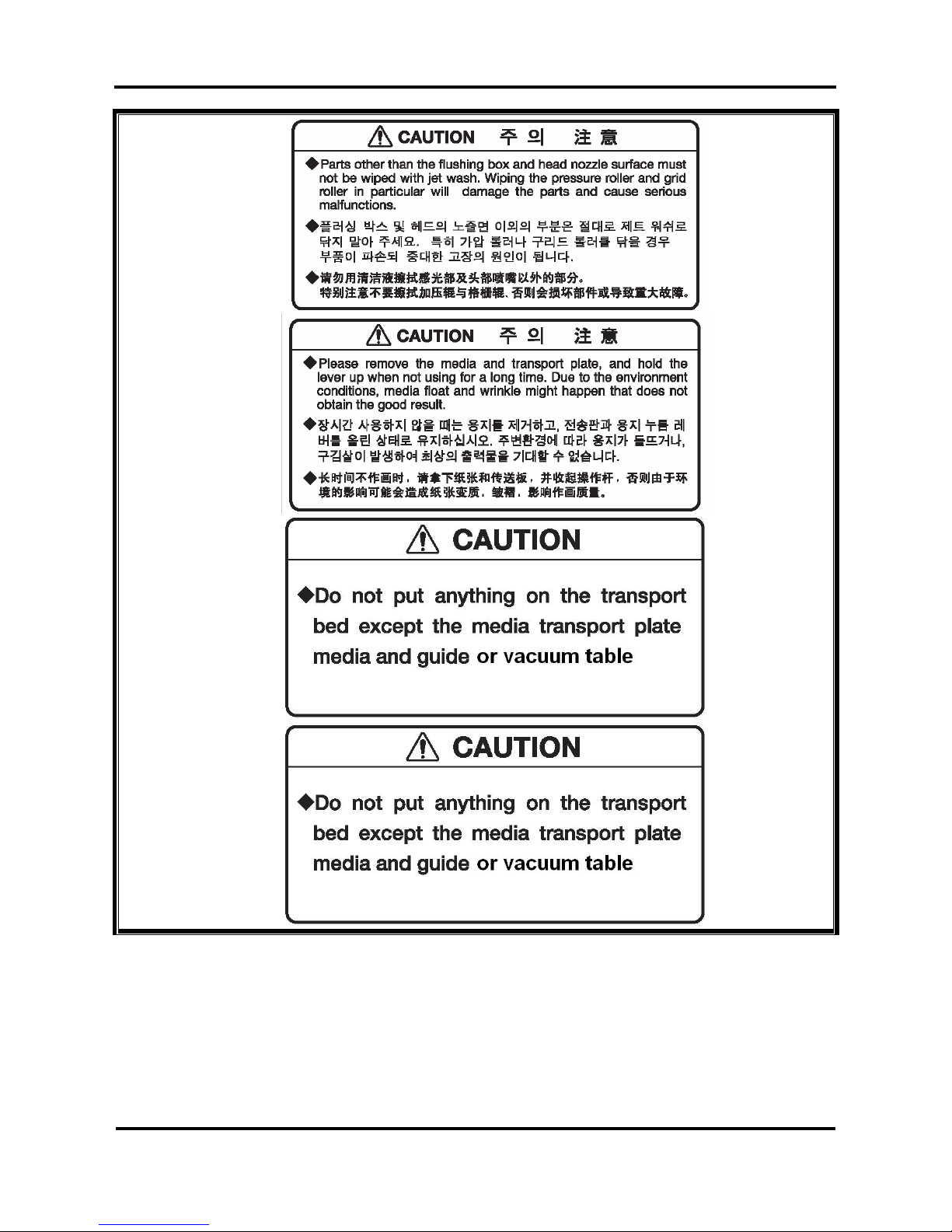

12

13

14

15

Page 23

User’s Guide – Toucan Hybrid

23

AP-750, Rev. 1.1 –- 23/04/04

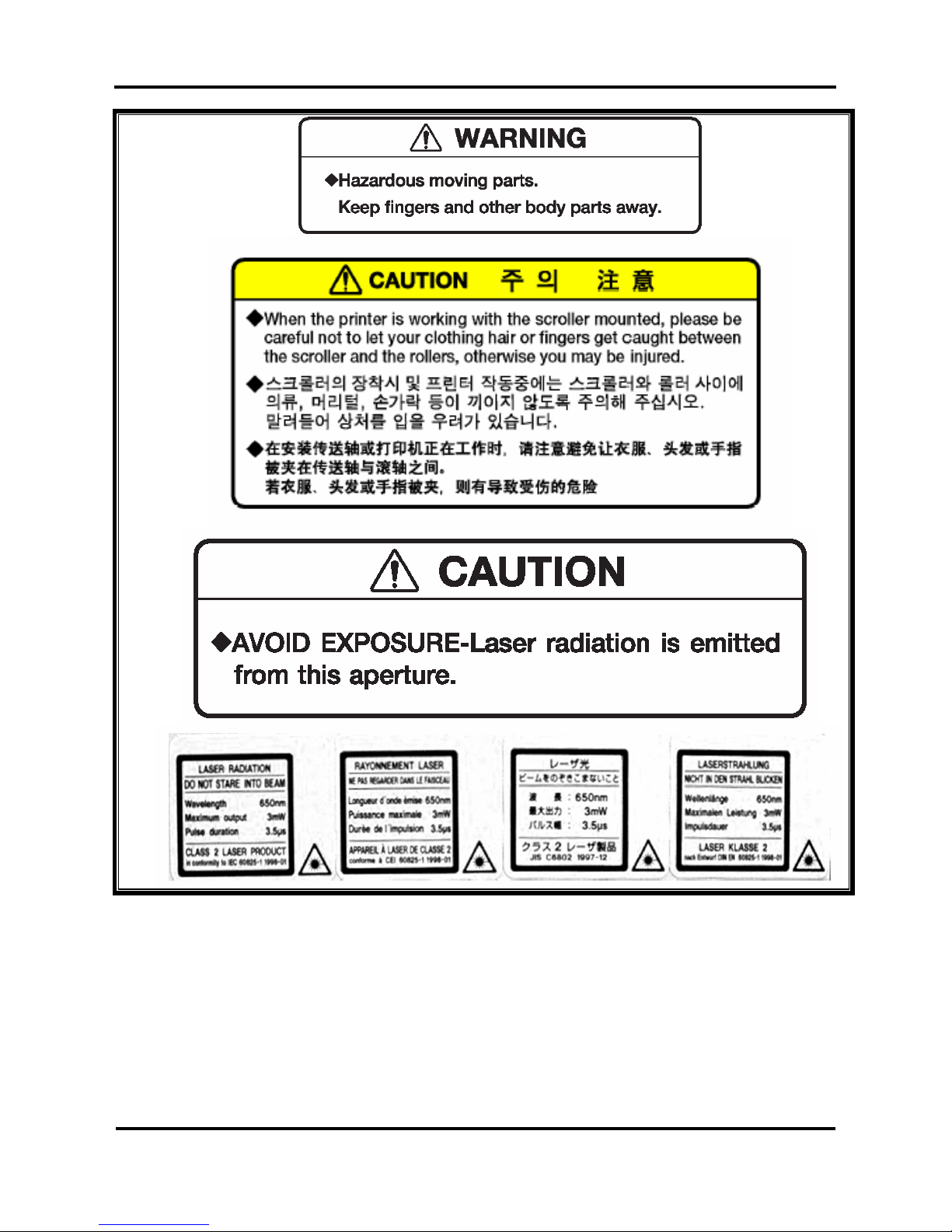

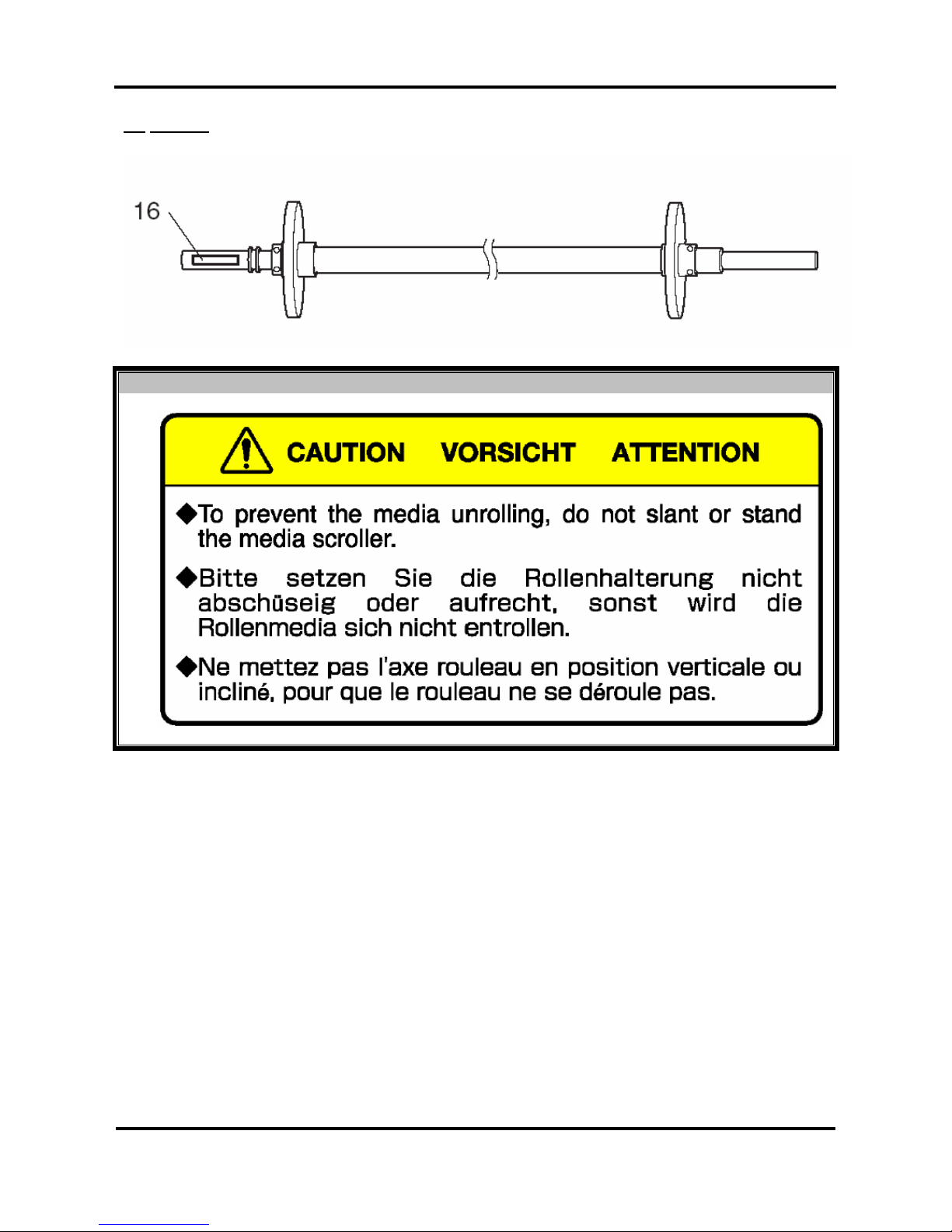

(2) Scroller

N°

Type

16

Page 24

User’s Guide – Toucan Hybrid

24

AP-750, Rev. 1.1 –- 23/04/04

1.4.3 Other safety issues

Infrared-radiation due to infrared-lamp

Obligation to wear protective goggles

Caution

Infrared light

1,2 – 1,4 µm

It is obligated to wear them to avoid eye damage. Operators as well as technicians and visitors have to wear

protective goggles whenever the infrared lamp is active.

Due to the reflection of the infrared-radiation on the media or the media media tray or vacuum table, it is

necessary to wear protective goggles, specific for this spectrum range.

The lamp has its peak wavelength at 1.2 µm – 1.4 µm.

Two safety goggles are delivered with your Toucan Hybrid. They offer 100% block protection from 0.8 µm

up to 1.6 µm

Touching the infrared lamp and/or infrared lamp house

Caution:

Hot surface

People can get hurt due to the hot surface of the infrared lamp itself and the infrared lamp house. This label

warns for hot accessible parts on the equipment.

The lamp house heats up to 150 °C (302 F), touching it could cause severe burns.

The lamp house or / and the print head should NEVER be TOUCHED when the infrared lamp is on or has

been on in the last 15 minutes.

Caution :

By using an infrared temperature gun, measuring the temperature is done safely.

You can buy this infrared temperature gun in any local technical shop.

Holding still of the infrared lamp

If the carriage stands still, the media under it can get overheated due to remaining heat of the infrared lamp.

This leads to a possible searing, melting and/or cockling of the media.

Due to the remaining heat, media can melt and / or cockle.

Please perform a power off and a power on so the carriage moves back to the capping station automatically.

The lamp house heats up to 150 °C (302F), touching it will cause severe burns.

The lamp house or / and the print head should NEVER be TOUCHED when the infrared lamp is on or has

been on in the last 15 minutes.

Page 25

User’s Guide – Toucan Hybrid

25

AP-750, Rev. 1.1 –- 23/04/04

Do not leave unattended when operating

A label on the machine should also warn operators and technicians that the machine should not operate

when not attended.

DO NOT LEAVE UNATTENDED

In case media touches the infrared lamp and / or the lamp house

Due to the high temperature of the lamp house and the lamp, the media may melt or sear when it is in

contact with the lamp or lamp house for some time. When the head stops due to a media crash the Toucan

Hybrid should be shut down.

DO NOT TOUCH THE CARRIAGE, NOR THE LAMP HOUSE. The lamp house heats up to 150 °C (302F),

touching it could cause severe burns.

When a media crash occurs, the lamp will hold still above the media which can melt or sear. Please perform

a power off and a power on so the carriage moves back to the capping station automatically.

Use the Toucan Hybrid in a well ventilated area

Be aware that poisonous fumes may be released in little concentrations when media gets seared. Due to the

infrared lamp, solvents evaporate much faster, so it is highly recommended to use an air purification system.

Mechanical hazard due to moving print head carriage

You can get hurt due to the movement of the carriage. Do not touch the lamp house or the carriage while it is

moving.

Do not stare in the laser beam.

A label on the machine should also warn operators and technicians not to stare in the laser beam without

wearing protective goggles.

WARNING

HAZARDOUS MOVING PARTS

KEEP FINGERS AND OTHER BODY PARTS AWAY

Page 26

User’s Guide – Toucan Hybrid

26

AP-750, Rev. 1.1 –- 23/04/04

Page 27

User’s Guide – Toucan Hybrid

27

AP-750, Rev. 1.1 –- 23/04/04

2. PRODUCT OVERVIEW

2.1 INTRODUCTION

This chapter explains the features, part names, and functions of the printer.

2.2 FEATURES

The features of the printer are explained below.

(1) High speed output

The Toucan Hybrid large-format printer delivers high speed and top image quality for your large produ ction

jobs. The TOUCAN HYBRID can print up to a maximum width of 1575mm (62”) in roll mode. The TOUCAN

HYBRID offers you the ability to print roll-to-roll as well as printing onto rigid material.

(2) E weather resistance

With the specially developed solvent-type ink, the output product can last up to 3 years for roll media and 3

years for rigid materials even without lamination. Not only is delivery time reduced, but total cost is reduced

as well.

(3) Wide variety of compatible media

This machine is applicable to various uncoated media rolls, sheets and rigid material up to the thickness of

70 mm as the height of head is adjustable.

(4) Vibrant Colour Reproduction

To reproduce clear and vibrant colours, the Toucan Hybrid uses 6 colours. Both models use 2000cc ink

tanks, allowing continuous operation, and raising productivity.

(5) Effective usage of media

A JOG feature is provided to allow setting of the printing position as required. Because printing can be

performed on media that has already been printed on, excess space can be used effectively.

→ Specifications are liable to changes without prior notice. All trademarks mentioned are property of their

respective owners.

Page 28

User’s Guide – Toucan Hybrid

28

AP-750, Rev. 1.1 –- 23/04/04

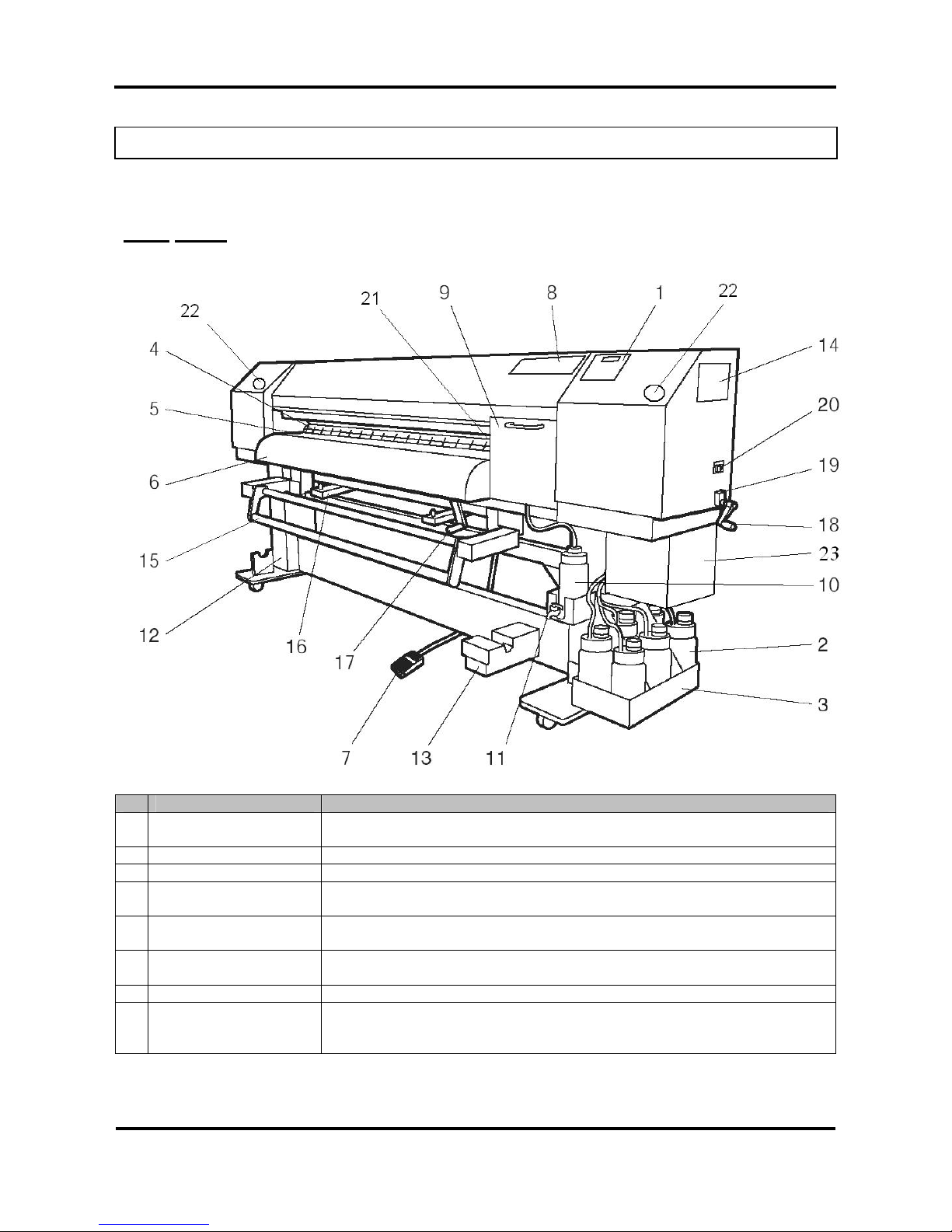

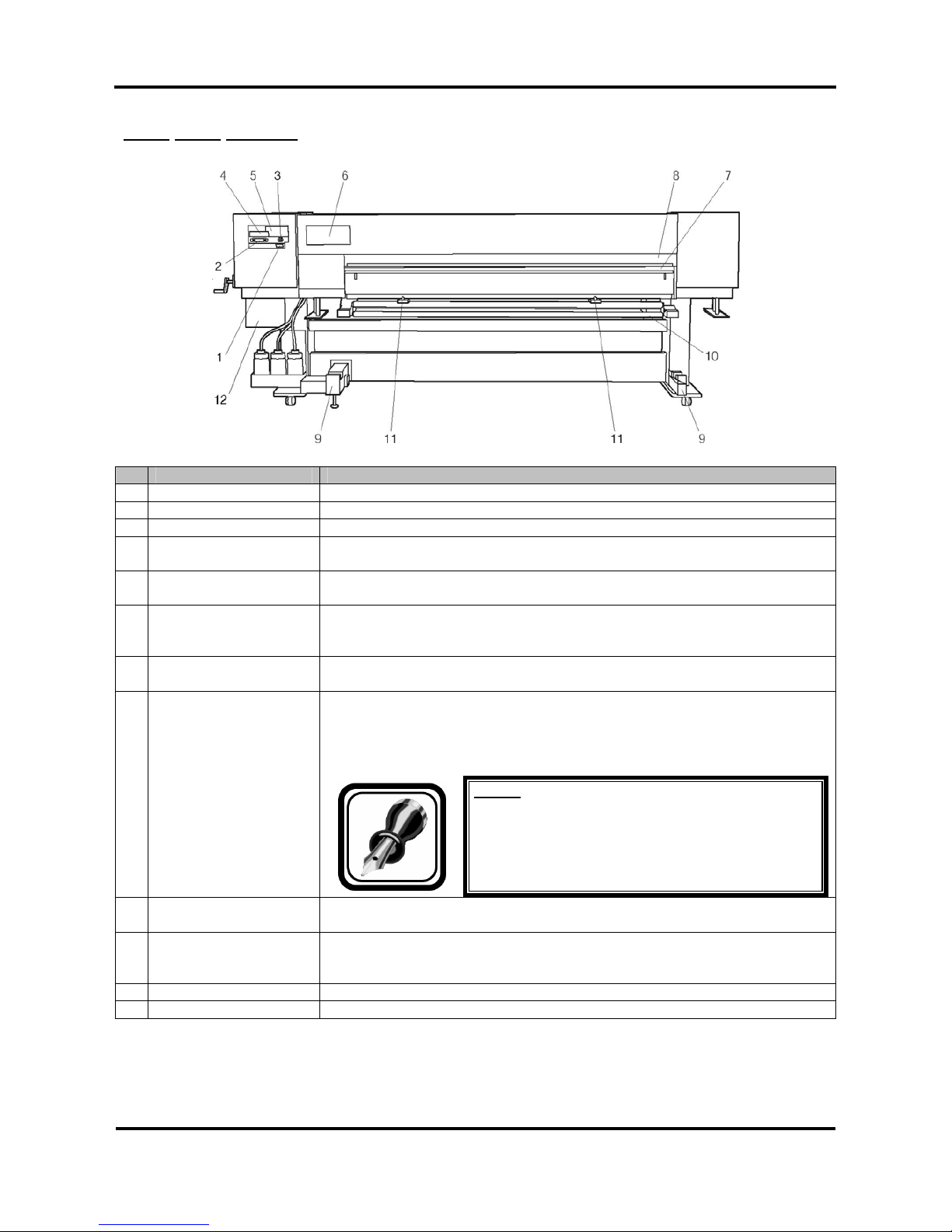

2.3 PART NAMES AND FUNCTIONS

Part names and functions are explained below.

2.3.1 Front

N° Name Function

1 Operation panel This panel is used to set operational conditions, the status of the printer, and

other functions.

2 Main tank Container for holding the ink and the jetwash fluid.

3 Tank tray Used to attach the main tanks to the product.

4 Pressurizing roller This roller is used to press the media from above and keep it flat when

printing.

5 Platen There is an ink drying device (up to 45°C) built in. On the surface, there is a

cutter groove for paper cutting.

6 Media guide This is used to feed the media smoothly when setting the media and when

printing. Used for drying (up to 70°C)

7 Foot switch This switch is used to raise and lower the pressure roller.

8 Valve cover This is a cover to protect the use r from the internal components of the

product. It is opened when cleaning the print head or the sub-tank, and is

normally closed.

Page 29

User’s Guide – Toucan Hybrid

29

AP-750, Rev. 1.1 –- 23/04/04

9 Maintenance cover This is a cover to protect the user from the internal components of the

product. This is opened during the following conditions:

When turning the unit ON or OFF

When cleaning the print head surface.

When cleaning the print head inside the cover, there is a waste fluid tray

to collect waste fluid from the print head.

10 Waste fluid tank A tank for storing waste fluids discharged from the product.

11 Waste fluid valve Opened when discharging waste fluid from the waste fluid tank. This is

normally closed.

12 Stand This stand is used to install the printer on a flat surface.

13 Winding unit Winds and co llects the printed media.

14 Memory cover This is a cover to protect the user from the internal components of the

product. The cover is opened when changing the expansion memory. This

is normally closed.

15 Cushioning roller Use to guide the printed media to the take-up mechanism.

16 Front stand fixing block This is used to fix the front stand 1 on the printer body.

17 Lifting grip This is used to lift or lower the media guide.

18 Head gap adjusting

handle

This is used to lift or lower the print head.

19 Head gap counter This indicates the head gap between the print head and grid roller.

20 Head gap sensor lamp This is used when adjusting the head gap. If the print head touches the

media due to narrower head gap, this lamp (green) lights up.

21 infrared lamp The infrared lamp is connected with the carriage. During printing on rigid

materials it assists to fix ink onto the material. (up to 150°C)

22 Emergency stop Only to be used in case of great malfunction and danger.

23 PCB Contains the IR board

Page 30

User’s Guide – Toucan Hybrid

30

AP-750, Rev. 1.1 –- 23/04/04

2.3.2 Rear section

N° Name Function

1 AC inlet The power cable plug is inserted here.

2 Interface connector A connector to connect the Centronics interface.

3 Foot switch connector A connector to attach the foot switch cable.

4 Interface slot The network interface board attaches here. When not using the network

interface, keep the cover closed.

5 Hard disk slot The expansion hard disk attaches here. When not using an expansion hard

disk, keep the cover closed.

6 Ink filter cover This cover protects the user from the internal components of the product.

There is an ink filter inside the cover.

The cover is opened when changing the ink filter. This is normally closed.

7 Media feed slot This is the media feed slot for placing the media during the media setting

procedure.

8 Infeed slot cover This cover protects the user from the mechanism inside the printer. Head

gap sensor is located inside the cover.

This cover automatically opens/closes according to the lifting/lowering of the

print head.

Notes :

Do not look inside at the media feed slot cover. You

may get injured as the head gap sensor uses laser

beam.

9 Feed Unit This is the device which sets the media, and feeds it to the printing start

position

10 Tension roller Set the printing intervals when perform printing by media feed compensation.

When the tension roller is lifted up, the feeding device feeds the media

automatically.

11 Rear stand fixing This is used to fix the rear stand 1 or the conveyer table on the printer body.

12 PCB Contains IR board

Page 31

User’s Guide – Toucan Hybrid

31

AP-750, Rev. 1.1 –- 23/04/04

2.3.3 Flat stand

No. Name Function

1 Front stand 1

2 Front stand 2

3 Front stand 3

4 Rear stand 1

5 Rear stand 2

6 Rear stand 3

These are used for printing on the rigid media.

Both the front stand 1 and the rear stand 1 can be removed when using

the roll media.

7 Media tray

This is the tray for placing the rigid media. This is used to feed the rigid

media frontward or backward.

Page 32

User’s Guide – Toucan Hybrid

32

AP-750, Rev. 1.1 –- 23/04/04

2.3.4 Operation panel

The operation panel is used to set operational conditions, display the status of the printer, and set other

functions.

The names and functions of the operation keys and status lamps are explained below.

Notes :

See the sections below for using the operation panel.

When setup menus using the operation panel: → “Menu setup on the operation panel”

When setting functions using the operation panel: → “Operating from the operation”

panel.

(1) Operation keys

Notes :

Some keys have multiple functions depending on the printer status (normal or setup

menu display). Refer to “Printer status” for more details.

Page 33

User’s Guide – Toucan Hybrid

33

AP-750, Rev. 1.1 –- 23/04/04

N° Name

Normal

Setup menu display

1. [POWER] key Turn the p rod uct ON and OFF. Turn the product ON and OFF.

2. [F1] key Executes the function assigned to F1. Executes the function assigned to F1.

3. [F2] key Executes the function assigned to F2. Executes the function assigned to F2.

4. [F3] key Executes the function assigned to F3. Executes the function assigned to F3.

5. [F4] key Executes the function assigned to F4. Executes the function assigned to F4.

6.

[MENU ⇑ ] key

Changes the LCD monitor display to

setup menu status.

Changes the menu in reverse order.

7.

[MENU ⇓ ] key

Changes the LCD monitor display to

setup menu status.

Changes the menu in forward order.

8. [ENTER] key Changes the LCD monitor display to

print mode display.

Determines the new parameter value

changes the LCD monitor display to

the next and menu. Sets the parameter

value and changes the LCD monitor

display to the next menu.

9. [CANCEL] key - Cancels the new parameter value and

changes the LCD monitor display to

the next menu.

Clears the parameter value and

changes the LCD monitor display to

the next menu.

(2) LCD monitor and status lamps

N° Name Colour Status Function

10. LCD monitor - - This monitor displays the operation status

and error messages of the product.

On The product is ON. 11. POWER lamp Green

Off The product is OFF.

Flashing An error has occurred. The contents will be

displayed on the LCD monitor.

12. ERROR lamp Red

Off Either there is no error in the product or the

power is OFF.

On The product is receiving the print data.

Flashing The product is analyzing received data.

13. DATA lamp Orange

Off The product is waiting to receive print data.

On The pressure roller is in the release

position.

The media is not set.

14. MEDIA SET

lamp

Orange

Off The pressure roller is in the secured

position.

The media is set.

15. ROLL lamp - - Disuse

16. SHEET lamp - - Disuse

Page 34

User’s Guide – Toucan Hybrid

34

AP-750, Rev. 1.1 –- 23/04/04

2.4 PRINTER STATUS

The status of the printer is explained below.

2.4.1 Normal

Indicates that the printer can draw print data when media is loaded.