Page 1

User’s Guide

Sign Cutting Plotter

Page 2

User’s Guide SC-PRO Cutting Plotter

2 AP-75280 – Rev. 1.1

Page 3

User’s Guide SC-PRO Cutting Plotter

3 AP-75280 – Rev. 1.1

COPYRIGHT NOTICE

COPYRIGHT 2008 Mutoh Europe N.V. All rights reserved.

Mutoh reserves the right to modify the information contained in this manual at any time without prior notice.

This document may not be reproduced by any means, in whole or in part, without written permission of the

copyright owner.

This document is furnished to support the Mutoh CutServer in combination with the MUTOH SC-Pro cutting

plotter. In consideration of the furnishing of the information contained in this document, the party to whom it

is given assumes its custody and control and agrees to the following:

The information herein contained is given in confidence, and any part thereof shall not be copied or

reproduced without written consent of Mutoh Europe N.V.

This document or the contents herein under no circumstances shall be used in the manufacture or

reproduction of the article shown and the delivery of this document shall not constitute any right or license to

do so.

05 September 2008

Published: Mutoh Europe N.V., Archimedesstraat 13, B-8400 Oostende, BELGIUM

Page 4

User’s Guide SC-PRO Cutting Plotter

4 AP-75280 – Rev. 1.1

Page 5

User’s Guide SC-PRO Cutting Plotter

5 AP-75280 – Rev. 1.1

Dear Customer,

Thank you for choosing a Mutoh SC-Pro series sign cutting plotter. The Mutoh SC-Pro drag knife cutting

plotter has been designed to be one of the most user-friendly and versatile cutting plotters in the market.

As a stand-alone cutting plotter, the SC-Pro can cut and plot designs onto PVC or paper as required.

In combination with an inkjet printer, the SC-Pro cutting plotter is ready for contour-cutting of pre-printed

signs made with any printer capable of printing onto cutting plotter compatible media. Contour-cutting is

made possible via the integrated EPOS (electronic positioning) technology and the in-the-box software.

But even more important, it is easy to use, as the following guide will show you.

Page 6

User’s Guide SC-PRO Cutting Plotter

6 AP-75280 – Rev. 1.1

Page 7

User’s Guide SC-PRO Cutting Plotter

7 AP-75280 – Rev. 1.1

TABLE OF CONTENTS

1 Regularisationandsafetyinformation.......................11

1.1Complywithfollowingregulations....................................................................11

1.2 Important notes .................................................................................................12

1.3 Safety Labels ......................................................................................................12

2 Product overview ...................................................... 15

2.1 Dimensions ........................................................................................................15

2.2 Installation environment requirements .............................................................15

2.3 Part names and functions ..................................................................................17

2.3.1 Front of the SC-PRO ....................................................................................17

2.3.2 Rear of the SC-PRO ......................................................................................18

2.3.3 Operation panel ..........................................................................................19

2.4 In-the-box contents ...........................................................................................20

3 Basics ........................................................................ 21

3.1 Installing and replacing tools .............................................................................21

3.1.1 Installing tools .............................................................................................21

3.1.2 Replace cutter blade ...................................................................................22

3.1.3 Replace auto sheet-off knife .......................................................................23

3.1.4 Replacing the cutting mat ...........................................................................24

3.2 Handling and storing media ...............................................................................25

3.2.1 Handling media ...........................................................................................25

3.2.2 Precaution on storing media .......................................................................25

3.3 Loading media ....................................................................................................26

3.3.1 Loading roll media .......................................................................................26

3.3.1.1 Loading cut vinyl ....................................................................................26

3.3.1.2 Loading pre-printed vinyl .......................................................................29

3.3.2 Loading sheet media ...................................................................................32

4 Walkthrough the operation panel ............................. 35

4.1 Direct key access ................................................................................................35

4.1.1 SHEET OFF key .............................................................................................36

4.1.2 ORIGIN key ..................................................................................................37

4.1.3 TEST key ......................................................................................................37

4.1.4 CONTOUR CUTTING key ..............................................................................38

4.1.5 SPEED key ....................................................................................................39

4.1.6 FORCE key ...................................................................................................40

4.1.7 OFFSET key ..................................................................................................41

Page 8

User’s Guide SC-PRO Cutting Plotter

8 AP-75280 – Rev. 1.1

4.1.8 TOOL key .....................................................................................................42

4.2 Menu overview ..................................................................................................43

4.2.1 Sheet off mode............................................................................................46

4.2.2 Sheet off margin ..........................................................................................46

4.2.3 Auto Shuffle ................................................................................................46

4.2.4 Pre-Feed length ...........................................................................................47

4.2.5 Max Sheet length ........................................................................................48

4.2.6 Page mode ..................................................................................................49

4.2.7 Origin ..........................................................................................................50

4.2.8 Laser speed .................................................................................................50

4.2.9 Tool-up speed .............................................................................................51

4.2.10 Job focus ................................................................................................51

4.2.11 Smoothing ..............................................................................................51

4.2.12 Factory default .......................................................................................52

4.2.13 Copies ....................................................................................................52

4.2.14 Bezier .....................................................................................................53

4.2.15 Language ................................................................................................53

4.2.16 Emulation ...............................................................................................53

4.2.17 Program step ..........................................................................................54

4.2.18 VS/ZF/AS ................................................................................................54

4.2.19 LCD contrast ...........................................................................................54

4.2.20 Keyboard beep .......................................................................................55

4.2.21 Versions .................................................................................................55

4.2.22 Basic / Full menu ....................................................................................55

4.2.23 Serial communication ............................................................................56

4.2.24 Network communication .......................................................................57

4.2.24.1 TCP/IP Address ...................................................................................57

4.2.24.2 SubnetMask ........................................................................................57

4.3 Special key combinations ...................................................................................58

4.3.1 EPOS laser ON .............................................................................................58

4.3.2 EPOS laser OFF ............................................................................................59

4.3.3 Bar code verification ...................................................................................59

4.3.4 Updating the keyboard ...............................................................................60

4.3.5 Reset the keyboard .....................................................................................60

4.3.6 Activate Sheet off knife ...............................................................................61

4.3.7 Factory default ............................................................................................61

4.4 Keys accessible during a cutting job ..................................................................62

4.4.1 While cutting ...............................................................................................62

4.4.2 While pausing a cutting job .........................................................................62

Page 9

User’s Guide SC-PRO Cutting Plotter

9 AP-75280 – Rev. 1.1

5 Fine-tuning your cutter .............................................. 63

5.1 Adjusting the knife depth ..................................................................................63

5.2 Setting the tool force .........................................................................................66

5.3 Offset principle ..................................................................................................66

5.4 EPOS test cuts ....................................................................................................67

5.4.1 EPOS alignment ...........................................................................................67

5.4.1.1 Tools necessary: .....................................................................................67

5.4.1.2 Alignment procedure .............................................................................67

5.4.1.3 Adjustments if necessary .......................................................................68

5.4.2 EPOS readout ..............................................................................................69

5.4.3 EPOS calibration ..........................................................................................70

5.5 XY-Distance Accuracy .........................................................................................73

6 Contour cutting ......................................................... 75

6.1 Different alignment methods ............................................................................75

6.2 Which Aligning Method should I use? ...............................................................76

6.3 Square details ....................................................................................................77

6.3.1 Hints – tips – recommendations .................................................................77

6.3.2 Automatic alignment without barcode .......................................................78

6.3.3 Automatic alignment with barcode – single frame .....................................79

6.3.4 Automatic alignment with barcode – multi frame ......................................80

6.4 Cut area measurement ......................................................................................81

7 Maintenance ............................................................. 83

7.1 Cleaning & Daily maintenance ...........................................................................83

7.1.1 Cleaning the grid rolls .................................................................................83

7.1.2 Cleaning the cutter blade ............................................................................84

7.1.3 Cleaning the cutting plotter ........................................................................84

8 Troubleshooting ........................................................ 85

8.1 Checking the communication settings ...............................................................86

8.1.1 For serial cable connections ........................................................................86

8.1.2 For network connections ............................................................................87

8.2 Error messages ..................................................................................................88

8.2.1 Recoverable errors messages .....................................................................88

8.2.2 Unrecoverable system errors ......................................................................91

9 Consumables ............................................................. 95

Page 10

User’s Guide SC-PRO Cutting Plotter

10 AP-75280 – Rev. 1.1

Page 11

User’s Guide SC-PRO Cutting Plotter

CHAPTER 1 : SAFETY INSTRUCTIONS

11 AP-75280 – Rev. 1.1

1 REGULARISATION AND SAFETY

INFORMATION

Safety terms in this manual are categorized into following three types, depending on the degree of the risk

(or the scale of accident)

Safety Terms Details

WARNING

Must be followed carefully to avoid death or serious bodily injury.

CAUTION

Must be observed to avoid bodily injury (moderately or lightly) or damage to your product

NOTES

Contains important information and useful tips on the operation of your product

1.1 COMPLY WITH FOLLOWING REGULATIONS

The CE marking is a mandatory European marking for certain product groups to

indicate conformity with the essential health and safety requirements set out in

European Directives.

By affixing the CE marking, the manufacturer, his authorized representative, or the

person placing the product on the market or putting it into service ensures that the item

meets all the essential requirements of all applicable EU directives and that the

applicable conformity assessment procedures have been applied.

This product is tested and approved by the Canadian Standards Association (CSA),

this to provide increased assurance of quality and safety.

The product is tested according to IEC60950.

This standard tries to cover all safety aspects.

Mechanical, electrical

Choice of components

Choice of materials: flammability!

Connectors, cables …

Fire enclosure

…

This means the product is safe for users, service personnel and production personnel.

CSA International certification is not a legal commitment but it assures the quality and

safety of the machine.

Your product is designed and manufactured with high-quality materials and

components, which can be recycled and reused.

When this crossed-out wheeled bin symbol is attached to a product, it means the

product is covered by the European Directive 2002/96/EC – WEEE regulation.

Please inform yourself about the local separate collection system for electrical and

electronic products.

Please act according to local rules and do not dispose of your old products with your

normal household waste. The correct disposal of your old product will help prevent

potential negative consequences for the environment and human health.

Page 12

User’s Guide SC-PRO Cutting Plotter

CHAPTER 1 : SAFETY INSTRUCTIONS

12 AP-75280 – Rev. 1.1

1.2 IMPORTANT NOTES

Technical problems and maintenance, which require the cutter to be opened, can only be done by

qualified personnel who were trained to repair this type of machine.

Unauthorized removing of covers and/or overruling safety locks can be dangerous and will result in

your guarantee becoming void.

After powering OFF the machine, wait at least 10 seconds before powering ON again. Not respecting

this time interval could damage the machine.

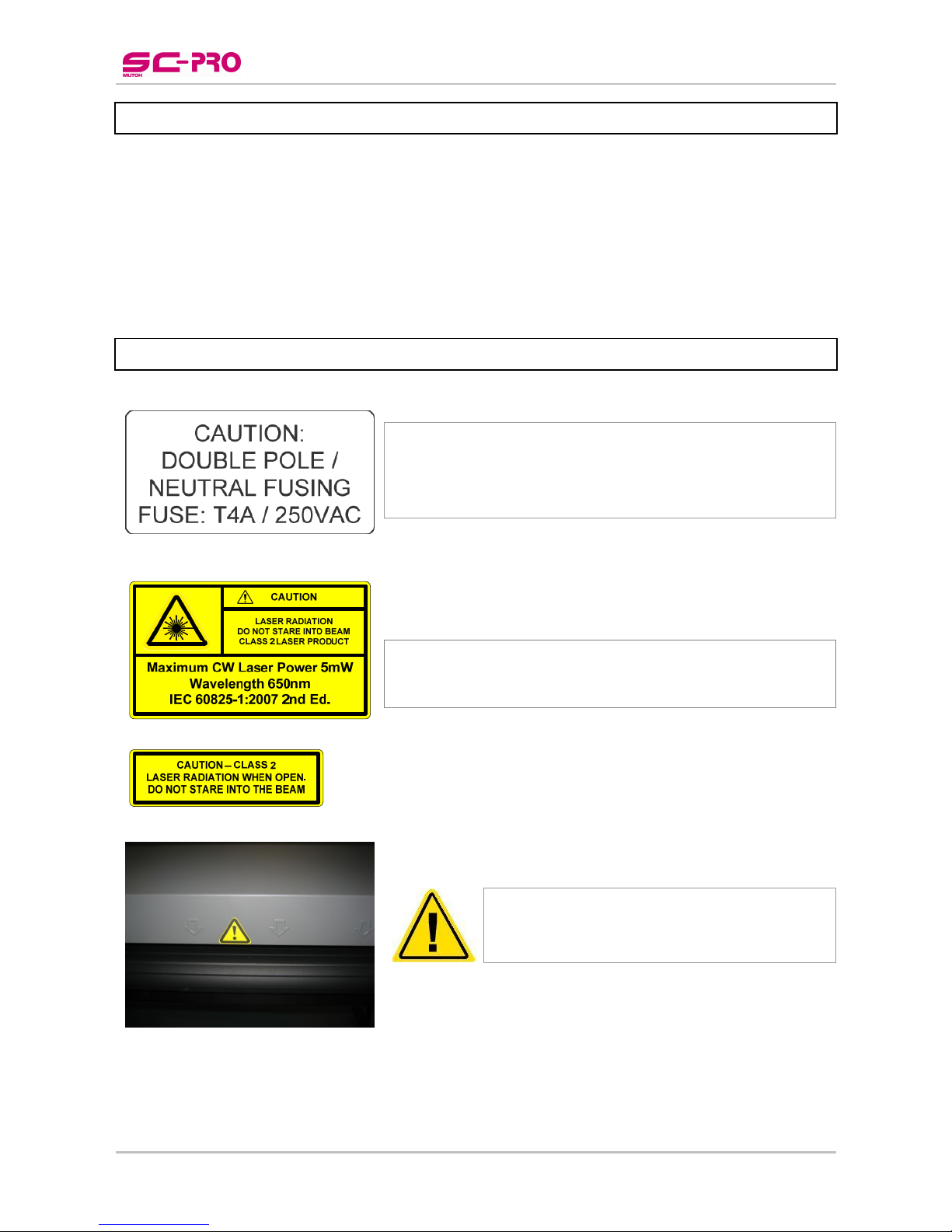

1.3 SAFETY LABELS

Be careful when servicing this machine. The cutter has two fuses.

One neutral and one in phase.

After operation of the fuse, parts of the equipment that remain

energized might represent a hazard during servicing.

Be sure not to stare in the laser mounted on the cutting head.

Be careful not to pinch your fingers between the

pressure rollers and grid rollers when loading media

for example.

Page 13

User’s Guide SC-PRO Cutting Plotter

CHAPTER 1 : SAFETY INSTRUCTIONS

13 AP-75280 – Rev. 1.1

Be careful not to get stuck between the following

moving parts:

► Cutting head

► Grid rollers

Be careful not to get stuck between the following

moving parts:

► Cutting head

► Grid rollers

Page 14

User’s Guide SC-PRO Cutting Plotter

CHAPTER 1 : SAFETY INSTRUCTIONS

14 AP-75280 – Rev. 1.1

Page 15

User’s Guide SC-PRO Cutting Plotter

CHAPTER 2 : PRODUCT OVERVIEW

15 AP-75280 – Rev. 1.1

2 PRODUCT OVERVIEW

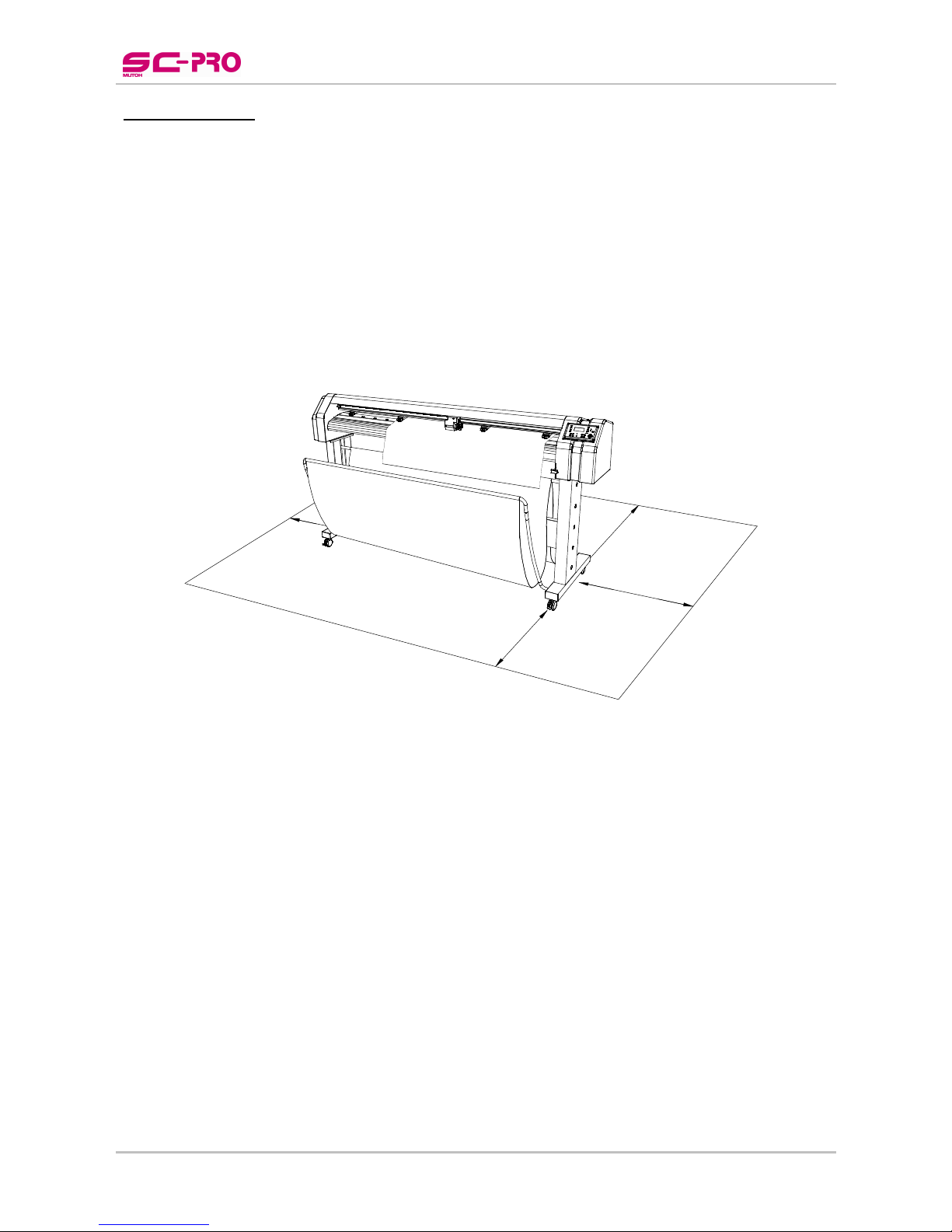

2.1 DIMENSIONS

Please find below the sizes of the SC Pro cutter with all dimensions in millimeters.

2305 1062

1259

662

2.2 INSTALLATION ENVIRONMENT REQUIREMENTS

The location where you set up your equipment is very important. Please see to it that it meets following

conditions:

Power supply

100 - 240 VAC

50 - 60 Hz

Max. 1.5 A

Ambient Conditions:

Operating environment

Temperature 5 °C to 30 °C

Humidity 35 % - 75 % non-condensing

Recommended environment (dark area)

Temperature 16 °C to 25 °C

Humidity 50 % to 65 % non-condensing

Variation rate

Temperature 2 °C per hour

Humidity 5 % per hour

Storage environment

Temperature 0 °C to 50 °C

Page 16

User’s Guide SC-PRO Cutting Plotter

CHAPTER 2 : PRODUCT OVERVIEW

16 AP-75280 – Rev. 1.1

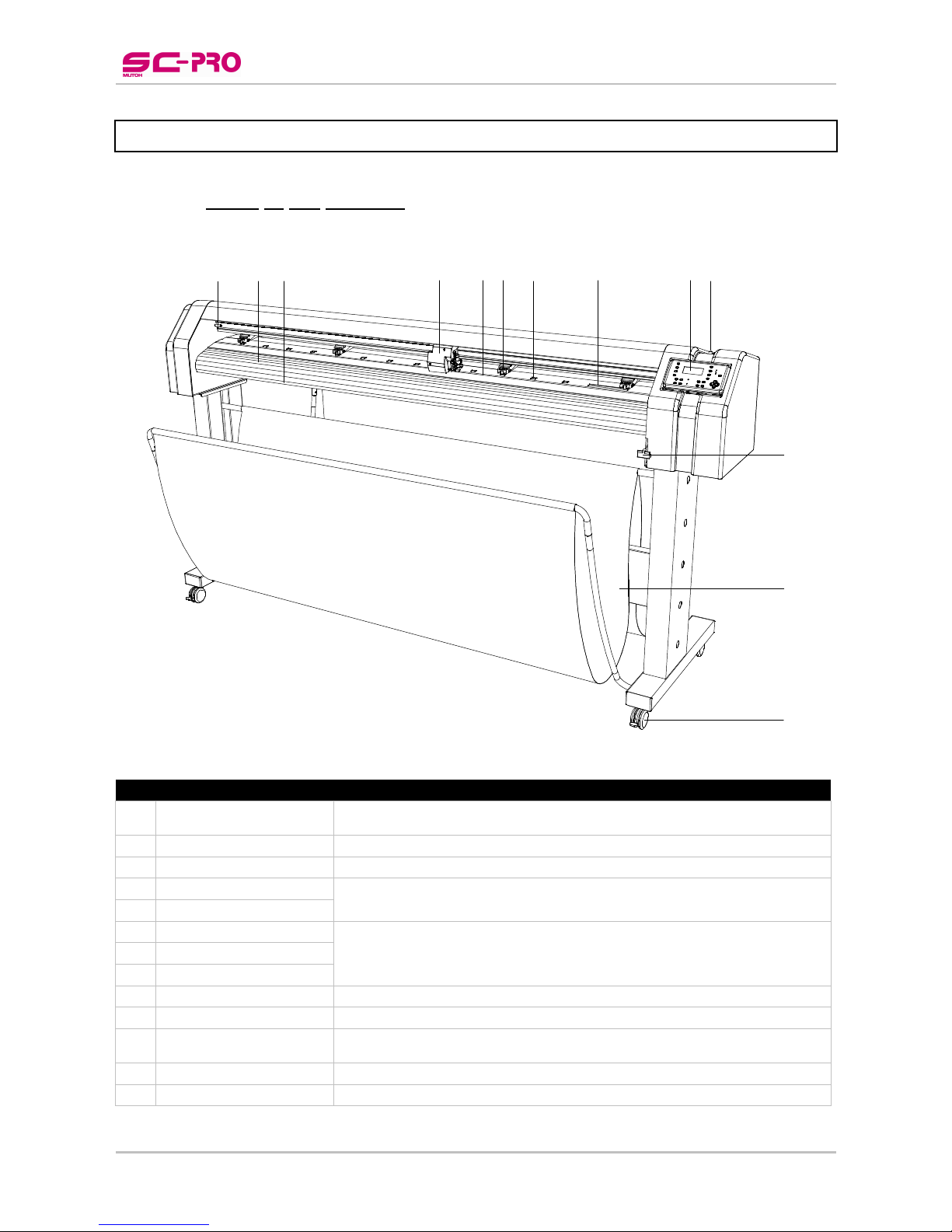

Room conditions

Please protect your cutter from moisture, dust, draughts and direct sunlight (to prevent possible

media detection and epos readout issues). It is best to keep your machine away from open

windows and air-conditioners.

See to it that there is an adequate space around the cutter so that ventilation is not obstructed.

Avoid unnecessary vibrations and set up your cutter on a level surface.

Be sure to have some free space on each side of the SC-Pro to ease the operating of it.

a

b

c

d

a = at least 1 meter

b = at least 1 meter

c = at least 1 meter

d = at least 0,1 meter

This means that you need the following room space in total: 3,20m x 2,66m (W x D)

Page 17

User’s Guide SC-PRO Cutting Plotter

CHAPTER 2 : PRODUCT OVERVIEW

17 AP-75280 – Rev. 1.1

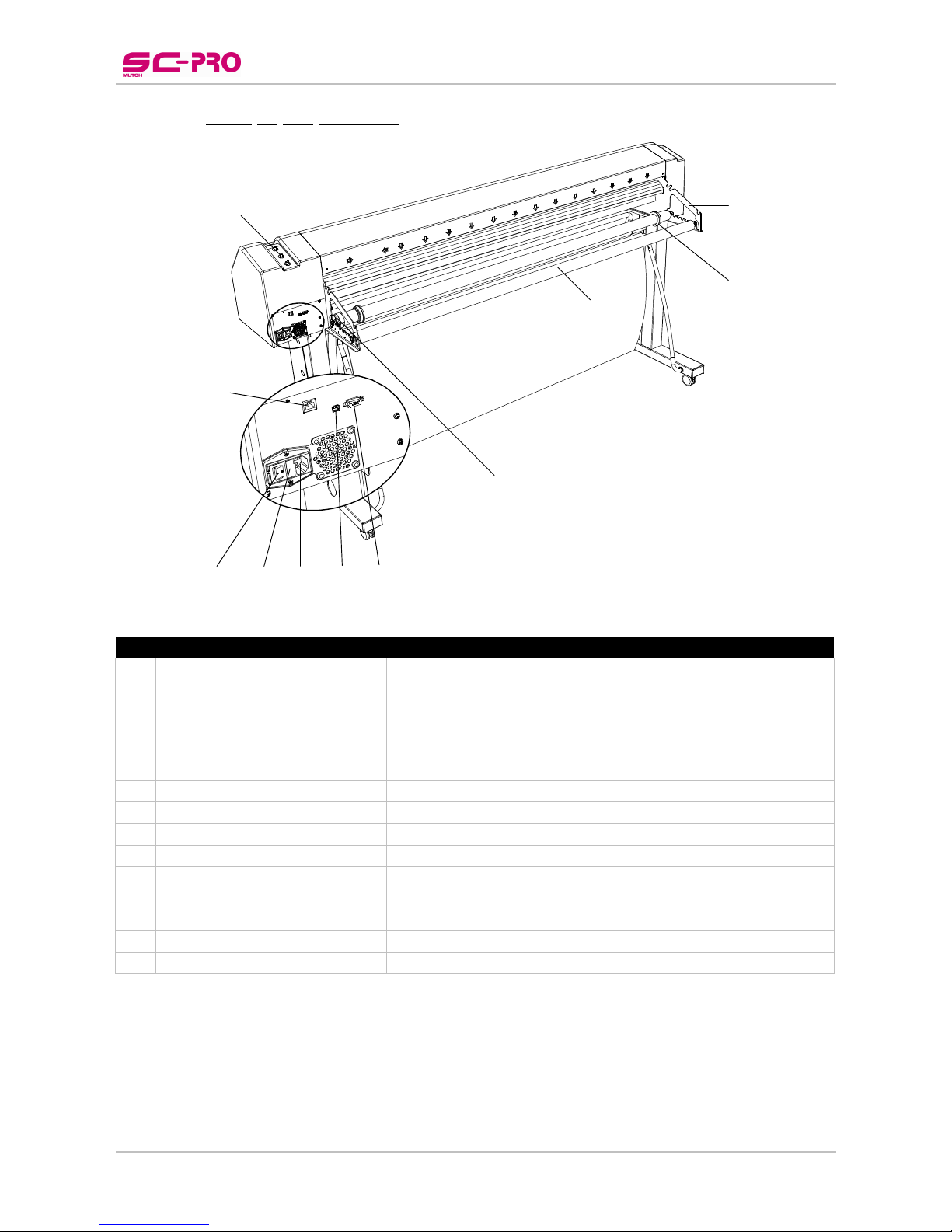

2.3 PART NAMES AND FUNCTIONS

2.3.1 Front of the SC-PRO

1

23

4

56

7

89

10

12

13

11

N° Part Function

1

Bumper

To avoid the head crashing against the side and to measure the width of

the machine during initialization.

2

Media guide To guide the media when moving front and backwards.

3

Cutting groove A groove to guide a knife to sheet of the media manually.

4

Cutting head Assembly of cutting knife, sheet-off knife and EPOS sensor.

5

Cutting mat Provides a reliable cutting surface and minimizes damage to the knife tip.

6

Pressure rollers To hold the media against the grid rollers.

7

Small grid rollers

Rollers with a lot of grip to move the media along front and backwards

There is 1 large one and 13 small ones.

8

Large grid roller

9

Control panel Removable panel with LCD display and control keys.

10

Tool storage holes Holes in the right cover to store 3 tools.

11

Pressure roller lever

To lower or raise the pressure rollers. Note that all sent data will be

removed out of the buffers when raising the lever.

12

Media collection bag Bag to collect the media when sheeted-off.

13

Caster wheels To move the cutter easily or to fix the stand using the brakes.

Page 18

User’s Guide SC-PRO Cutting Plotter

CHAPTER 2 : PRODUCT OVERVIEW

18 AP-75280 – Rev. 1.1

2.3.2 Rear of the SC-PRO

1

2

3

4

5

6789

11

12

10

N° Part Function

1

Grid roller marks

To mark the position of the grid rollers.

The pressure rollers should always be positioned on top of a grid

roller, if not, it will be impossible to start cutting.

2

Conveyor roll support brackets

To support the conveyor rolls. Multiple stands possible for the

conveyor rolls.

3

Conveyor roll guiding flanges To keep the loaded roll media in its position.

4

Conveyor roll To support and roll off the load media roll.

5

Conveyer roll brake To prevent that the loaded media keeps unwinding.

6

Serial interface connector To connect the serial interface cable.

7

USB interface connector To connect the USB cable.

8

Power cable connector To connect the power cable.

9

Fuse cover To easily access the two fuses.

10

Power switch To power ON/OFF the cutter.

11

Network interface connector To connect the network cable.

12

Tool storage place To store the pens and knifes.

Page 19

User’s Guide SC-PRO Cutting Plotter

CHAPTER 2 : PRODUCT OVERVIEW

19 AP-75280 – Rev. 1.1

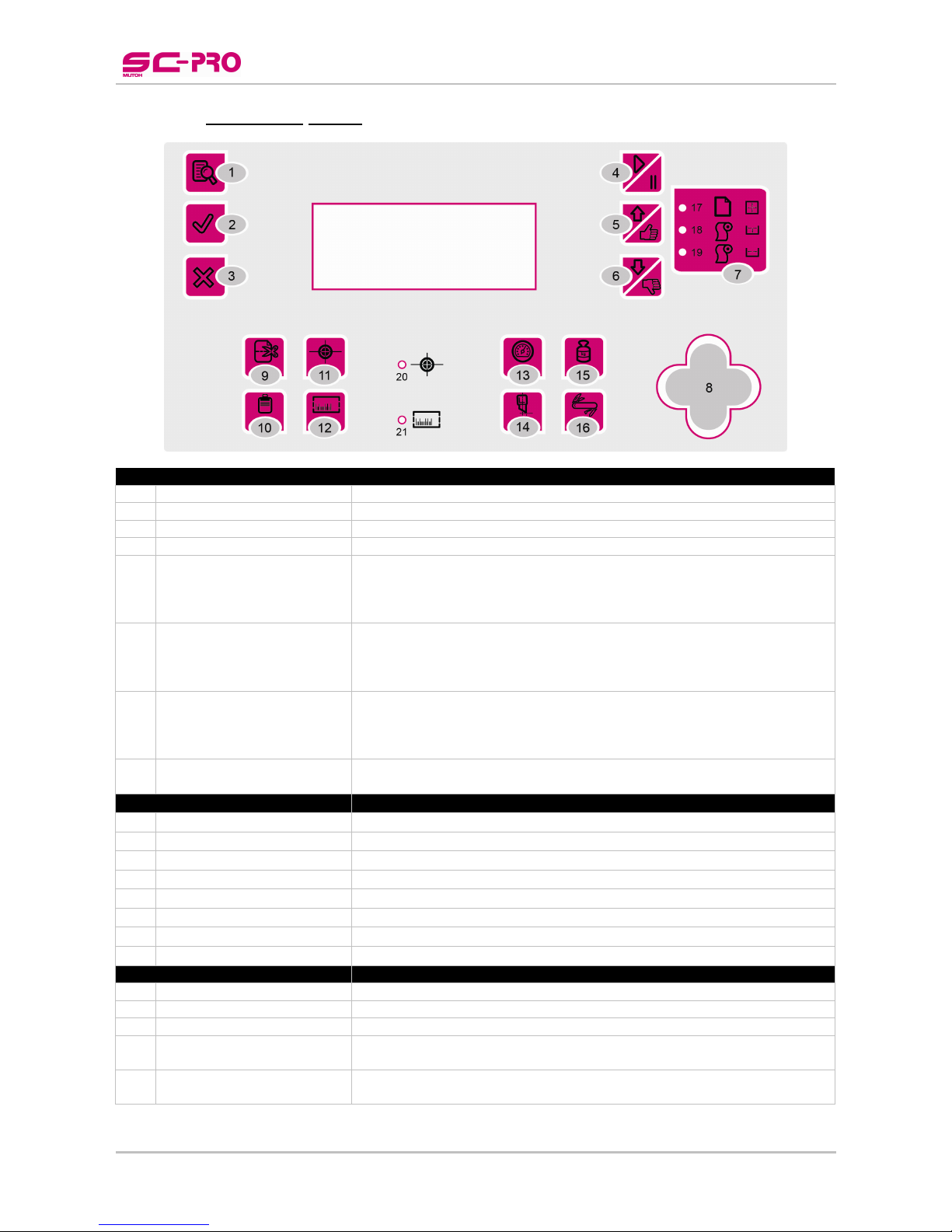

2.3.3 Operation panel

BASIC KEYS

1

MENU key To enter the main menu of the cutter

2

ENTER key To open a menu item or to confirm a setting

3

EXIT/CANCEL key To exit a menu item, to decline a setting or to cancel a cutting job.

4

RESUME / PAUSE key To interrupt or resume a cutting job

5

UP / YES key

This key has multiple functions

o Browse through the main menu

o Increase a value

o Confirm a setting

6

DOWN / NO key

This key has multiple functions

o Browse through the main menu

o Decrease a value

o Decline a setting

7

MEDIA TYPE key

To select the media type

o Sheet media initialization: front – rear – left – right

o Roll front media initialization: front – left – right

o Roll media initialization: left - right

8

ARROW key

To move the media forwards and backwards

To move the cutter head to the left or right

DIRECT KEYS

9

SHEET OFF key To enter the sheet off mode

10

TEST key To enter the test menu

11

ORIGIN key To enter the origin menu

12

CONTOUR CUTTING key To enter the contour cutting menu

13

SPEED key To enter the speed menu

14

OFFSET key To enter the offset menu

15

FORCE key To enter the force menu

16

TOOL key To enter the tool menu

LED’s

17

SHEET LED Lights up when selecting SHEET with the [MEDIA TYPE]-key.

18

ROLL FRONT LED Lights up when selecting ROLL FRONT with the [MEDIA TYPE]-key.

19

ROLL LED Lights up when selecting ROLL with the [MEDIA TYPE]-key.

20

ORIGIN LED

Lights up when an origin is set by the user.

Blinks when you are busy setting the origin.

21

CONTOUR CUTTING LED

Light up while contour cutting.

Blinks when the cutter is measuring the reference box.

Page 20

User’s Guide SC-PRO Cutting Plotter

CHAPTER 2 : PRODUCT OVERVIEW

20 AP-75280 – Rev. 1.1

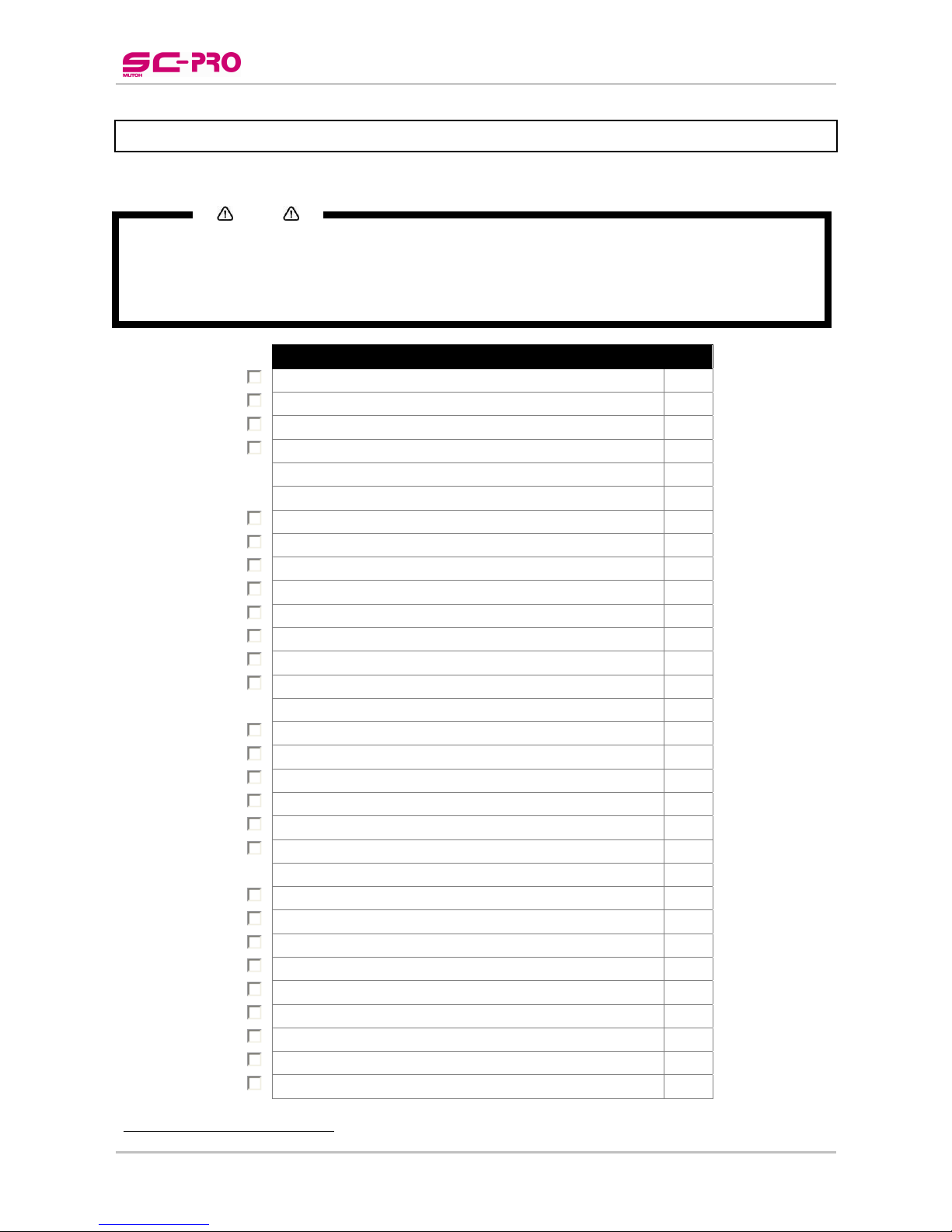

2.4 IN-THE-BOX CONTENTS

After unpacking each box, inspect if there are no damaged parts and that all necessary parts are present.

NOTES

THE CONTENTS OF THE PACKAGES MAY BE DIFFERENT DEPENDING ON THE MARKET WHERE THEY ARE USED.

CONTACT YOUR LOCAL MUTOH DEALER OR DISTRIBUTOR FOR DETAILS.

I

F ANY PART IS MISSING OR BROKEN, CONTACT EITHER OF THE FOLLOWING:

o T

HE SHOP WHERE YOU BOUGHT YOUR MUTOH CUTTER

o YOUR LOCAL MUTOH DISTRIBUTOR.

(*)

When ordered as a bundle together with a Mutoh Printer, the in-the-box software may be replaced with one software which handles cutting, printing and contour cutting.

Description Qty

Cutter unit

1

Stand assembly

1

Media bag assembly

1

Conveyor system

1

Commercial kit

1

Tools

1

Knife holder and blade 1

Cutter blade 45° 1

Blade for auto sheet-off 1

Pressurized BallPoint Pen 1

Spare cutting mat 1

Mutoh knife 1

Core support 3” 2

Set of wing screws 1

Cables

1

Power cable EU 1

Power cable UK 1

Power cable US 1

USB cable 1

Adapter cable (9 – 25 pin) 1

Interface (RS-232) cable 1

Documentation

1

User’s Guide 1

Application Guide 1

Installation Guide 1

Installation Sheet 1

Installation CD 1

CD with manuals of all Mutoh machines 1

In-The-Box WEEE regularisation 1

Starter software kit (*)

1

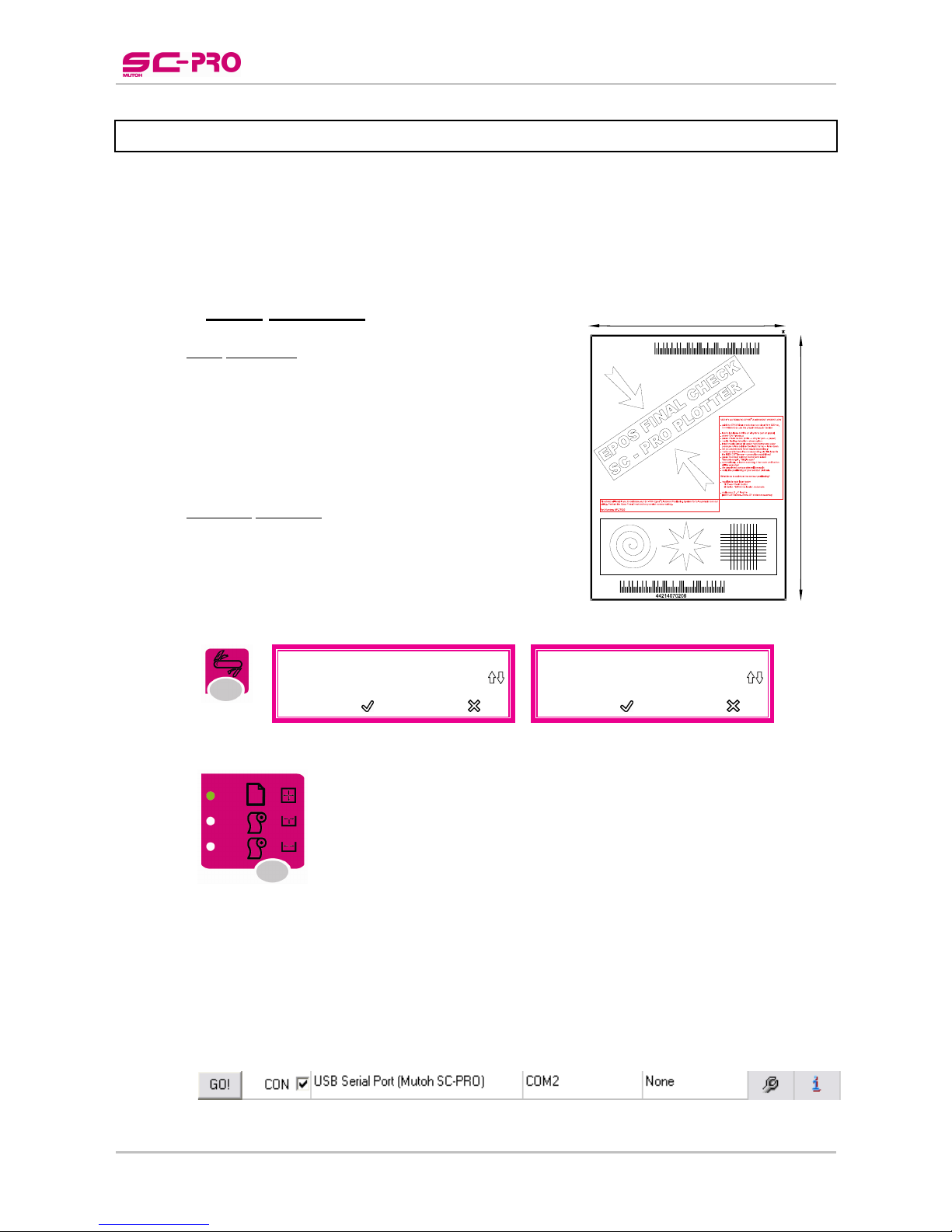

Quality test sheet of this machine

1

Page 21

User’s Guide SC-PRO Cutting Plotter

CHAPTER 3 : BASICS

21 AP-75280 – Rev. 1.1

3 BASICS

3.1 INSTALLING AND REPLACING TOOLS

3.1.1 Installing tools

At the right-hand side of the cutter head, you will find a pivoting mounting bracket. Opening this bracket will

enable you to install a full range of cutting and drawing tools.

To do so, please follow the instructions mentioned below.

Step 1 : Open the screw (1) to unlock the tool head-mounting bracket.

Step 2 : Hold back the clip (2) of the tool head and slide the tool into position, making sure the tool collar

fits into the groove just beneath the locking screw (3).

Step 3 : Fasten the screw to secure the tool into position.

Page 22

User’s Guide SC-PRO Cutting Plotter

CHAPTER 3 : BASICS

22 AP-75280 – Rev. 1.1

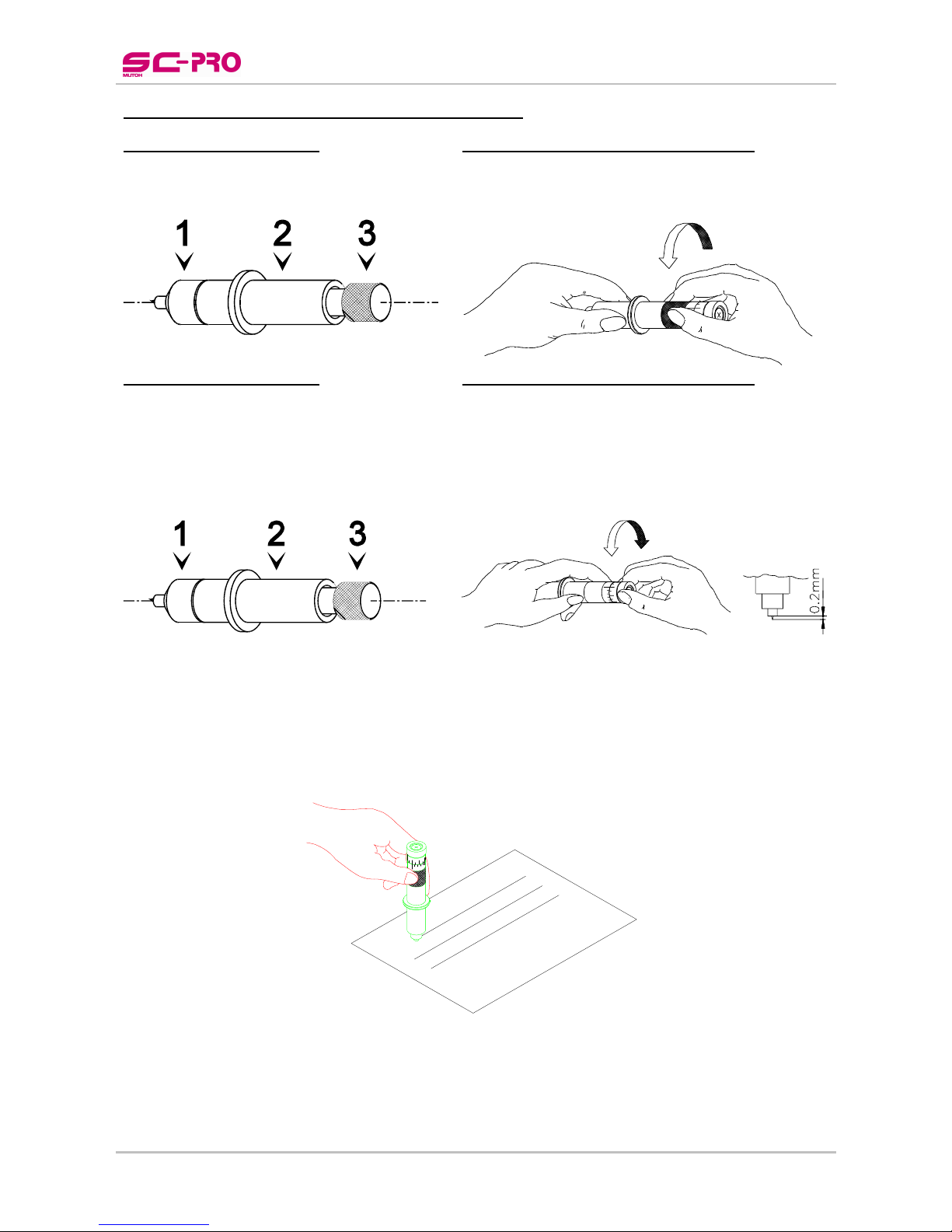

3.1.2 Replace cutter blade

To replace a blade, please proceed as follows:

STANDARD KNIFE HOLDER

Step 1 : Hold the body (2) into one hand and

unscrew the base part (1)

Step 2 : Remove the spring (3) and the cutting

blade (4).

Step 3 : Slide the spring over the new cutting

blade

Step 4 : Place the new blade with its spring into

the base part and screw the whole

assembly onto the body.

KNIFE HOLDER WITH NONIUS

Step 1 : Take the body into one hand and remove

the base part

Step 2 : Pull the old blade out of the holder and

insert a new one

Step 3 : Place the base part on top of the holder

assembly and twist it tightly.

Page 23

User’s Guide SC-PRO Cutting Plotter

CHAPTER 3 : BASICS

23 AP-75280 – Rev. 1.1

3.1.3 Replace auto sheet-off knife

When you frequently use the auto-sheet-off utility, it is a good practice to regularly clean the knife and to

replace it when it starts to wear.

To replace the auto sheet-off knife, please follow the instructions mentioned below.

Step 1 : Power OFF the unit and remove the power cable.

Step 2 : Remove the 2 screws fixing the head cover.

Step 3 : Higher the cutter cap (1) and swing it away (2). Do not loosen the spring.

Step 4 : Remove the sheet-off knife (3).

Step 5 : Clean the sheet-off knife, removing any material residues that might be clogged to the blade. In

case the blade is worn, reinstall a new knife.

Step 6 : Place the (new) knife into the auto sheet-off assembly (4). Make sure the knife is correctly

oriented.

Step 7 : Reinstall the cutter cap onto the auto sheet-off knife.

Step 8 : Reinstall the head cover.

Page 24

User’s Guide SC-PRO Cutting Plotter

CHAPTER 3 : BASICS

24 AP-75280 – Rev. 1.1

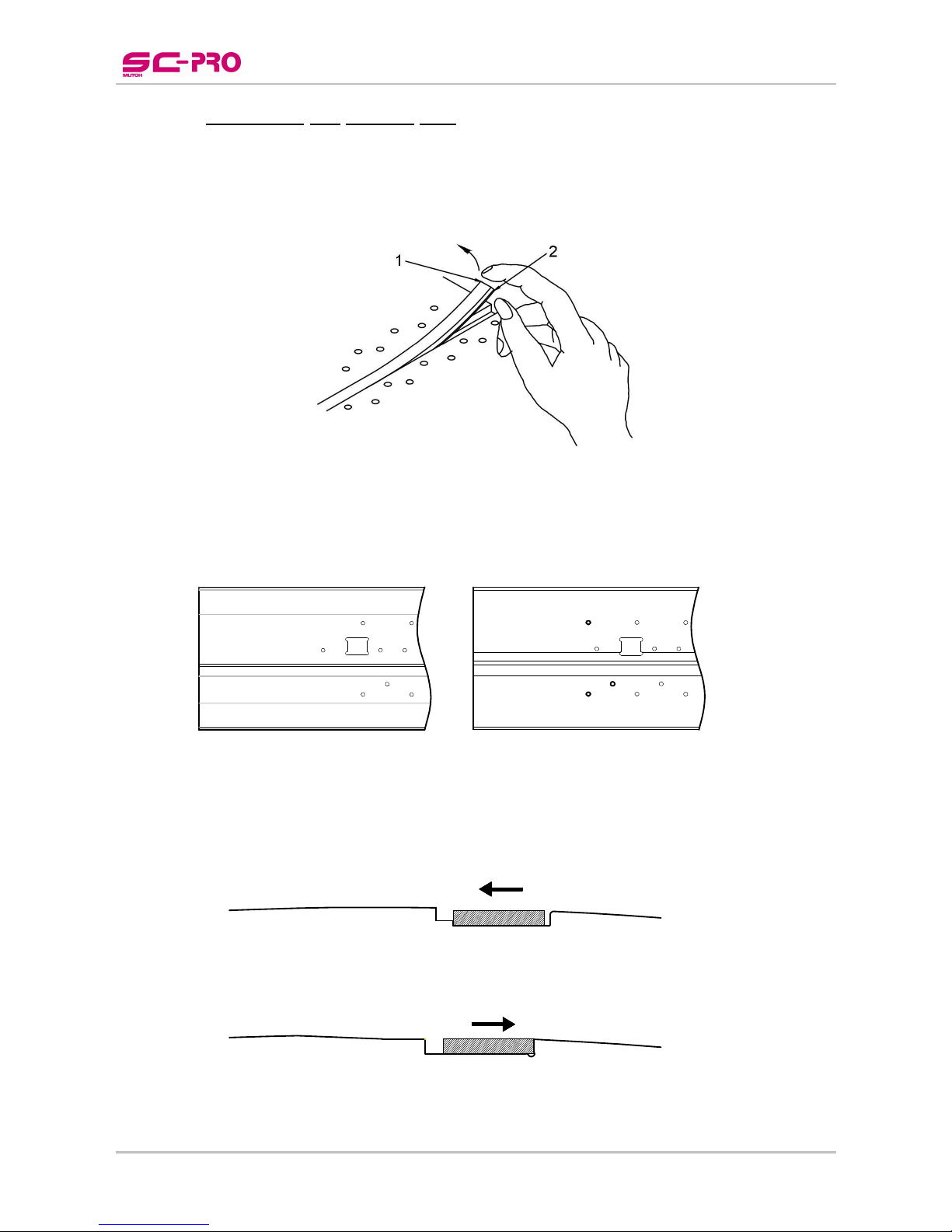

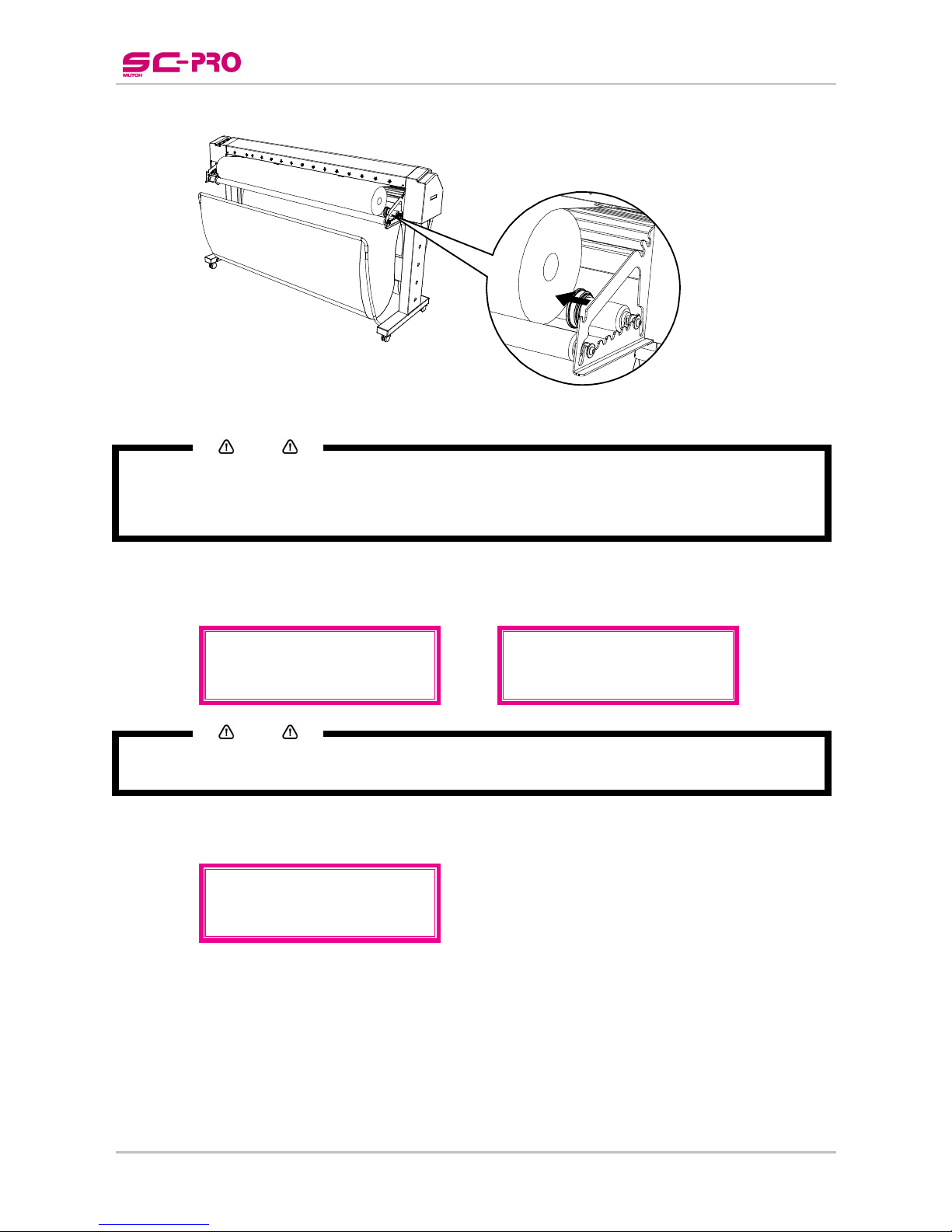

3.1.4 Replacing the cutting mat

To replace the cutting mat, proceed as follows:

Step 1 : First of all, remove the worn cutting mat (1) by pulling it out, together with the underlying strip of

vinyl (2).

Step 2 : Depending on the type of grid roll cover, the cutting mat should be installed differently. You can

recognize the type of cover by the amount of holes at the left side (refer to picture below).

T

YPE 1

T

YPE 2

Step 3 : Install the new cutting mat.

a. For TYPE 1

Stick the cutting mat as close as possible to the rear of the machine.

REAR FRON

T

b. For TYPE 2

Stick the vinyl as close as possible to the front of the machine.

REAR FRON

T

Step 4 : Please contact an Authorized Mutoh technician to perform a Y-Z profile measurement and

sheeting-off knife adjustment.

Page 25

User’s Guide SC-PRO Cutting Plotter

CHAPTER 3 : BASICS

25 AP-75280 – Rev. 1.1

3.2 HANDLING AND STORING MEDIA

Before you will be able to cut a job, it is necessary to know which media to use.

3.2.1 Handling media

When you handle media, please pay attention to the following:

Use recommended media in an appropriate environment. Following are the appropriate temperature

and humidity ranges for printing.

Temperature Humidity

Recommended working environment 20-30°C 40% to 65%

Rate of change Within 2°C per hour Within 5% per hour

Do not use creased, damaged, torn, curled, or wrapped media.

Temperature changes will influence the size of media that is used. Before using sheet media, place the

sheet in the working environment to have it match to the temperature of the working area.

Printing before the media has been able to accommodate to the printing environment may cause media

jams due to slippage or creases. This also adversely affects the quality of printing.

Media has a printable side and a non-printable side. If you print on a not printable side, blurring or slight

touching may occur.

Do not touch the printable side of media. Moisture or oil from hands affects the printing quality.

Do not leave the printer for a long time with media loaded. The media may curl, resulting in

misalignment, media jams, or decreased printing quality. In particular, avoid this in winter, dry seasons,

or during final printing.

Do not throw away the box or wrapping bag for storing media.

3.2.2 Precaution on storing media

When storing media, pay attention to the following:

Do not store media in high temperatures, high humidity, or direct sunlight.

Store sheet media in the original bag after unpacking.

Unused roll media must be removed from the scroller, rewound tightly, and stored in the original

wrapping bag and the box.

Do not wet media.

Page 26

User’s Guide SC-PRO Cutting Plotter

CHAPTER 3 : BASICS

26 AP-75280 – Rev. 1.1

3.3 LOADING MEDIA

3.3.1 Loading roll media

Please follow the procedure below to load roll media properly.

Be aware that there is a loading cycle difference between loading cut vinyl and pre-printed vinyl meant for

contour cutting.

3.3.1.1 Loading

cut vinyl

Configuration to start from:

► Raised pressure rollers.

► Rear media collection bag open and EMPTY.

► Front media collection bag open when the cutting job is smaller than 4m.

Front media collection bag closed when the cutting job is larger than 4 m.

► Install the brake and two flanges on the conveyor roll closest to the cutter.

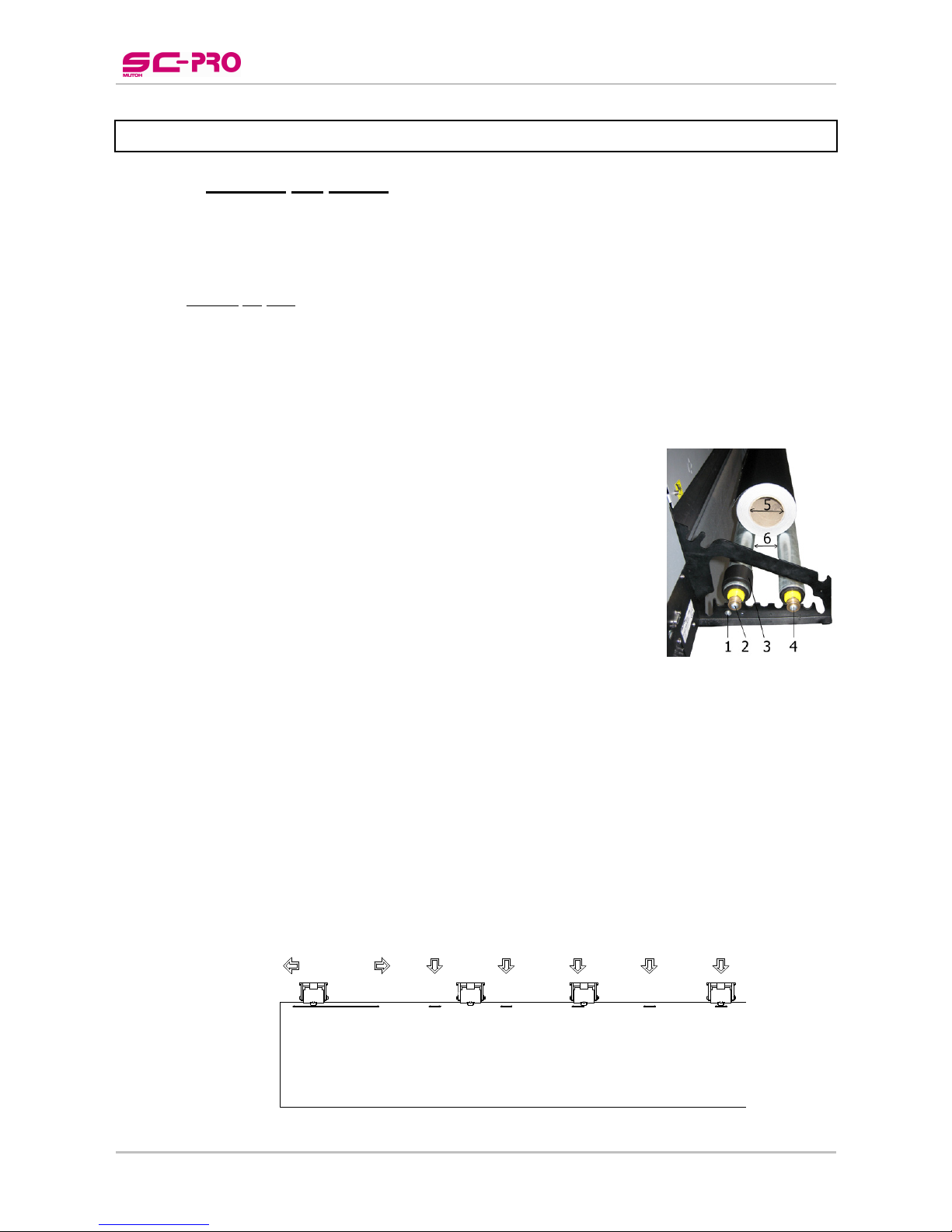

Step 1 : Place the vinyl on the conveyor rolls (2 & 4).

Pay attention to the following:

► Position the conveyor rolls so that the space (6) between them is

maximum the core diameter (5). Otherwise the core will fall

through when the roll is (almost) empty.

► Be sure that the slip ring obstructer (1) is positioned at the left

side of the rear conveyor roll (2). It is recommended to install the

rear conveyor roll in the following position ► ► ►

Step 2 : Position the media roll on the two conveyor rolls.

Pay attention to the following:

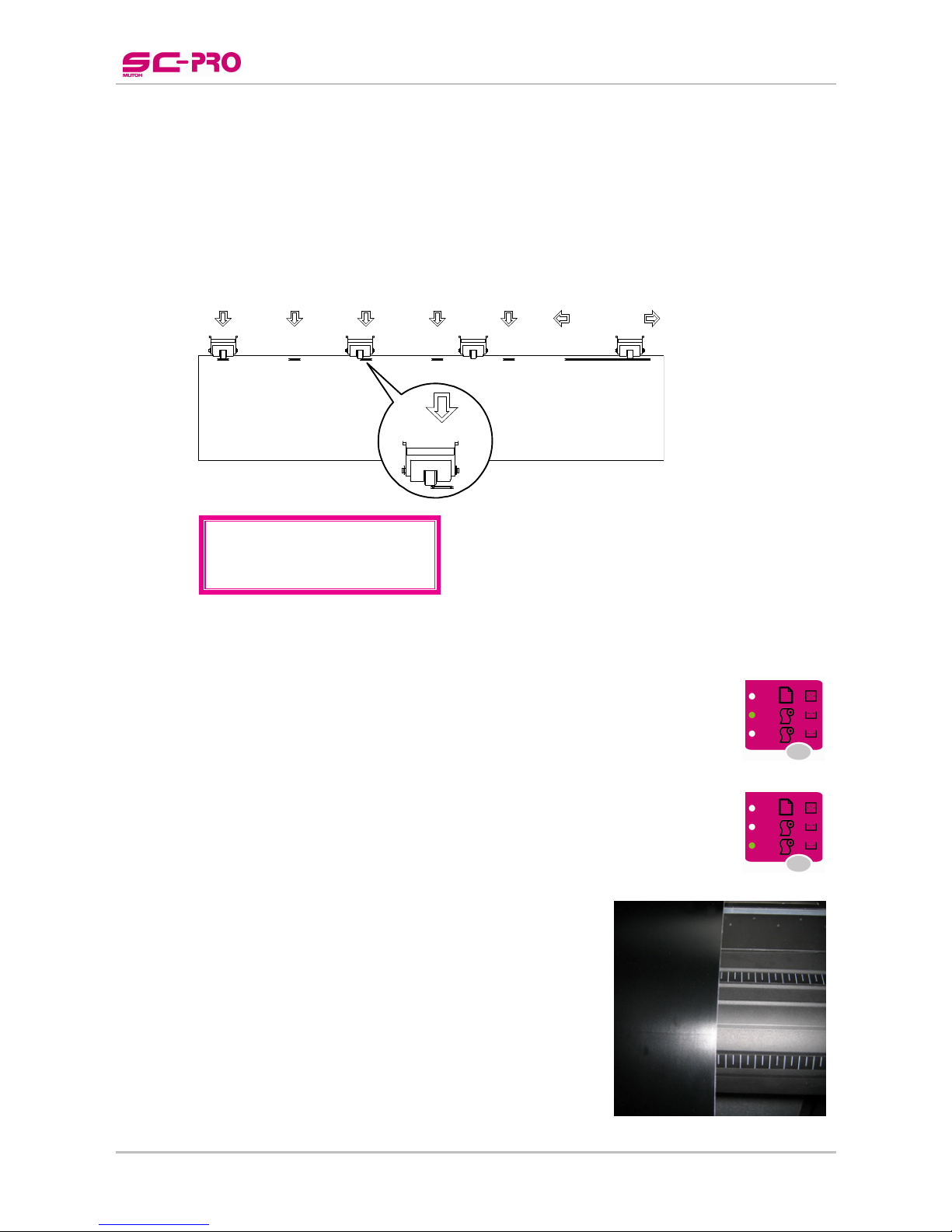

► The outer left and the outer right pressure rollers always have to be used. The middle rollers

2 and 3 (half of the pressure as roller 1 and 4) can be used, but they may also be disabled (in

between two arrows (as number 2 on the picture below). This to eliminate roller marks on

vulnerable vinyl for example. The left pressure roller can only move between the two flat

arrows.

► On the rear cover, arrows are marked. These arrows represent the possible position of the

pressure rollers. The left pressure roller can have a various position; the other three have a

fixed position.

► The cutter will cut between the centres of the outer pressure rollers, regardless of the width

of the cut vinyl. Therefore, it is recommended to position the outer pressure rollers about 1cm

inside the media. It is not recommended that the rollers run on the very edge of the material.

REAR of the machine

1234

Page 27

User’s Guide SC-PRO Cutting Plotter

CHAPTER 3 : BASICS

27 AP-75280 – Rev. 1.1

Step 3 : Guide the media under the pressure rollers to the front of the cutter.

Step 4 : Position the pressure rollers as you have decided in step 2. Pressure rollers 2-3-4 have a tactile

and audible click system which makes it easier to position them correctly. The right pressure

roller (1) can never be malpositioned.

If one of the others is malpositioned, a message will be displayed after media initialization.

Please refer to the picture.

FRONT of the machine

1234

P

ressure roll

3

malpositioned!

Step 5 : Set the media load type prior to loading media. Select if you want the cutting plotter to look for the

front edge of the vinyl.

► ROLL front The cutter will measure the left, right and front of the media.

The origin will be defined from the front of the roll.

There will be a shuffle of the set Pre-Feed length.

► ROLL The cutter will measure the left and right side of the media.

The origin will be defined from the position of the roll when

lowering the lever.

There will be a shuffle of the set Pre-Feed length.

Step 6 : Load the media properly:

It is best that you hold the front edge of the media in the

middle with one hand and with the other hand the roll itself.

As you are holding the roll firmly into position, pull the front

edge of the media forward so that there is an even tension

across the whole width of the roll (= equal tension method)

Do NOT use the rulers to align a roll of media! They are for

use with sheets only. Rolls can only be correctly installed

using the equal tension method.

The rulers will help you monitoring if the media is not

meandering too much.

Page 28

User’s Guide SC-PRO Cutting Plotter

CHAPTER 3 : BASICS

28 AP-75280 – Rev. 1.1

Step 7 : Push the guiding flanges against the left and right side of roll to be sure it does not drift.

Step 8 : Be sure that the media is cut off straight at the front to avoid media initialization mismatches.

Notes

Before lowering the pressure rollers, be sure that there is a knife or pen installed in the head. This because

during the media initialization, the penhead will also be initialized. If you insert a pen/knife afterwards, the

machine will not know how to wind the coil of the penhead. This could result in cutting lines across the

complete print.

Step 9 : Pull the lever down. This action will initialize the media loading sequence, during which the cutter

will shuffle a pre-set distance of vinyl (Pre-Feed Length). The following messages can be

displayed:

Roll Front Roll

Pl

ease wait

Pl

ease wait

Notes

The head will move fast over the media. Be careful not to pinch your fingers during this action.

Please refer to “chapter 4 - Pre-feed Length” to understand the important function of this feature.

Step 10 : After a successful measurement, the main screen will appear. The width of the media will be

displayed:

*READY*

X Roll Y 500

D

rag Knife Too

l

60 cm/s

100

g

Step 11 : The SC-Pro is ready to receive data from the host computer.

Page 29

User’s Guide SC-PRO Cutting Plotter

CHAPTER 3 : BASICS

29 AP-75280 – Rev. 1.1

3.3.1.2 Loading pre-printed vinyl

Configuration to start from:

► Raised pressure rollers.

► Rear media collection bag open and EMPTY.

► Front media collection bag open when the cutting job is smaller than 4m.

Front media collection bag closed when the cutting job is larger than 4 m.

► Install the brake and two 3” cones on the conveyor roll closest to the cutter.

Step 1 : Install the vinyl between the two 3” cones but do not fix the cones already.

Step 2 : Position the pre-printed vinyl on the conveyor roll.

Pay attention to the following:

► The outer left and the outer right pressure rollers always have to be used. The middle rollers

2 and 3 (half of the pressure as roller 1 and 4) can be used, but they may also be disabled (in

between two arrows (as number 2 on the picture below). This to eliminate roller marks on

vulnerable vinyl for example. The left pressure roller can only move between the two flat

arrows.

► On the rear cover, arrows are marked. These arrows represent the possible position of the

pressure rollers. The left pressure roller can have a various position; the other three have a

fixed position.

► The cutter will cut between the centres of the outer pressure rollers, regardless of the width

of the cut vinyl. Therefore, it is recommended to position the outer pressure rollers about 1cm

inside the media. It is not recommended that the rollers run on the very edge of the material.

REAR of the machine

Step 3 : Lock the 3” cones with one screw each.

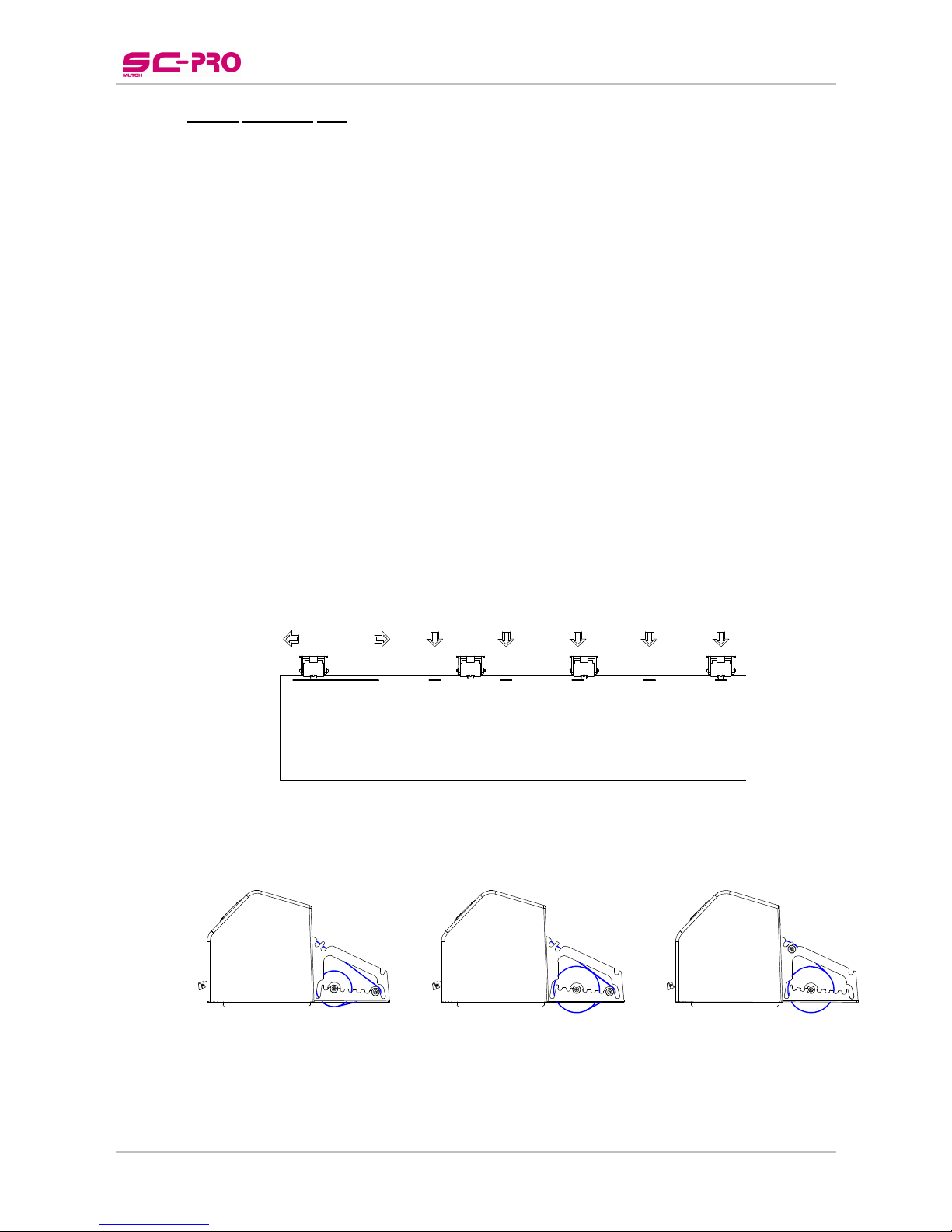

Step 4 : Guide the media under the pressure rollers to the front of the cutter on one of the two following

possibilities:

123

It is recommended to load the media as shown on picture 1. If the vinyl touches the core as on

picture 2, load the media as on picture 3.

1234

Page 30

User’s Guide SC-PRO Cutting Plotter

CHAPTER 3 : BASICS

30 AP-75280 – Rev. 1.1

Step 5 : Position the pressure rollers as you have decided in step 2. Pressure rollers 2-3-4 have a tactile

and audible click system which makes it easier to position them correctly. The right pressure

roller (1) can never be malpositioned.

If one of the others is malpositioned, a message will be displayed after media initialization.

Please refer to the picture.

FRONT of the machine

1234

P

ressure roll

3

malpositioned!

Step 6 : Set the media load type prior to loading media. Select if you want the cutting plotter to look for the

front edge of the vinyl.

► ROLL front The cutter will measure the left, right and front of the media.

The origin will be defined from the front of the roll.

There will be a shuffle of the set Pre-Feed length.

► ROLL The cutter will measure the left and right side of the media.

The origin will be defined from the position of the roll when

lowering the lever.

There will be a shuffle of the set Pre-Feed length.

Step 7 : Load the media properly:

It is best that you hold the front edge of the media

in the middle with one hand and with the other

hand the roll itself.

As you are holding the roll firmly into position, pull

the front edge of the media forward so that there is

an even tension across the whole width of the roll

(= equal tension method)

Do NOT use the rulers to align a roll of media!

They are for use with sheets only. Rolls can only

be correctly installed using the equal tension

method.

The rulers will help you monitoring if the media is

not meandering too much.

Page 31

User’s Guide SC-PRO Cutting Plotter

CHAPTER 3 : BASICS

31 AP-75280 – Rev. 1.1

Step 8 : Be sure that the media is cut off straight at the front to avoid media initialization mismatches.

Notes

Before lowering the pressure rollers, be sure that there is a knife or pen installed in the head. This because

during the media initialization, the penhead will also be initialized. If you insert a pen/knife afterwards, the

machine will not know how to wind the coil of the penhead. This could result in cutting lines across the

complete print.

Step 9 : Pull the lever down. This action will initialize the media loading sequence, during which the cutter

will shuffle a pre-set distance of vinyl (Pre-Feed Length). The following messages can be

displayed:

Roll front Roll

Pl

ease wait

Pl

ease wait

Notes

The head will move fast over the media. Be careful not to pinch your fingers during this action.

Please refer to “chapter 4 - Pre-feed Length” to understand the important function of this feature.

Step 10 : After a successful measurement, the main screen will appear. The width of the media will be

displayed:

*READY*

X Roll Y 500

D

rag Knife Too

l

60 cm/s

100

g

Step 11 : The SC-Pro is ready to receive data from the host computer or Mutoh CutServer.

Page 32

User’s Guide SC-PRO Cutting Plotter

CHAPTER 3 : BASICS

32 AP-75280 – Rev. 1.1

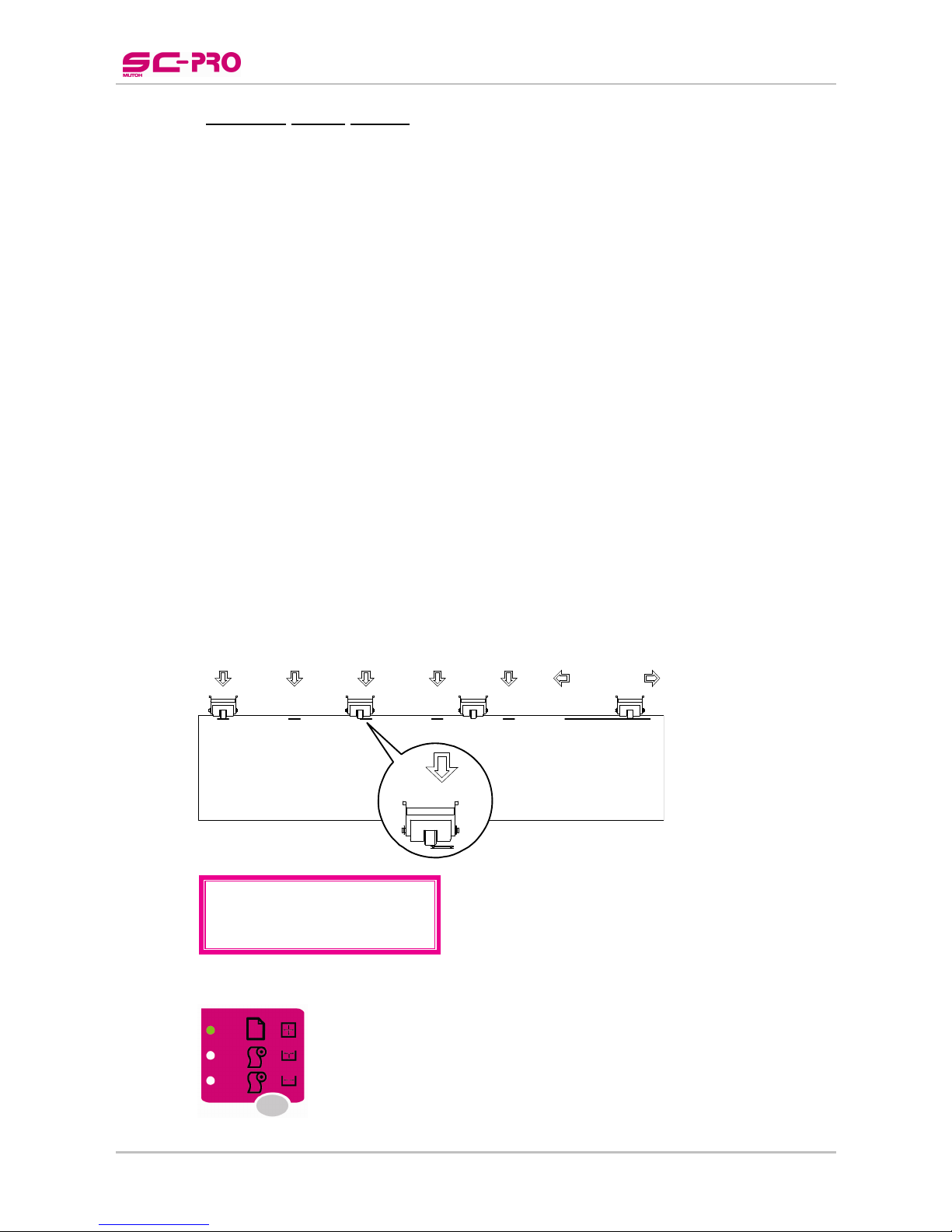

3.3.2 Loading sheet media

Configuration to start from:

► Raised pressure rollers.

► Remove conveyor rolls.

► Rear media collection bag open and EMPTY.

► Front media collection bag open when the cutting job is smaller than 4m.

Front media collection bag closed when the cutting job is larger than 4m.

Step 1 : Guide the media under the pressure rollers at the front of the cutter.

Step 2 : Position the sheet paying attention to the following:

► The outer left and the outer right pressure rollers always have to be used. The middle rollers

2 and 3 (half of the pressure as roller 1 and 4) can be used, but they may also be disabled (in

between two arrows (as number 2 on the picture below). This to eliminate roller marks on

vulnerable vinyl for example. The left pressure roller can only move between the two flat

arrows.

► The cutter will cut between the centres of the outer pressure rollers, regardless of the width

of the cut vinyl. Therefore, it is recommended to position the outer pressure rollers about 1cm

inside the media. It is not recommended that the rollers run on the very edge of the material.

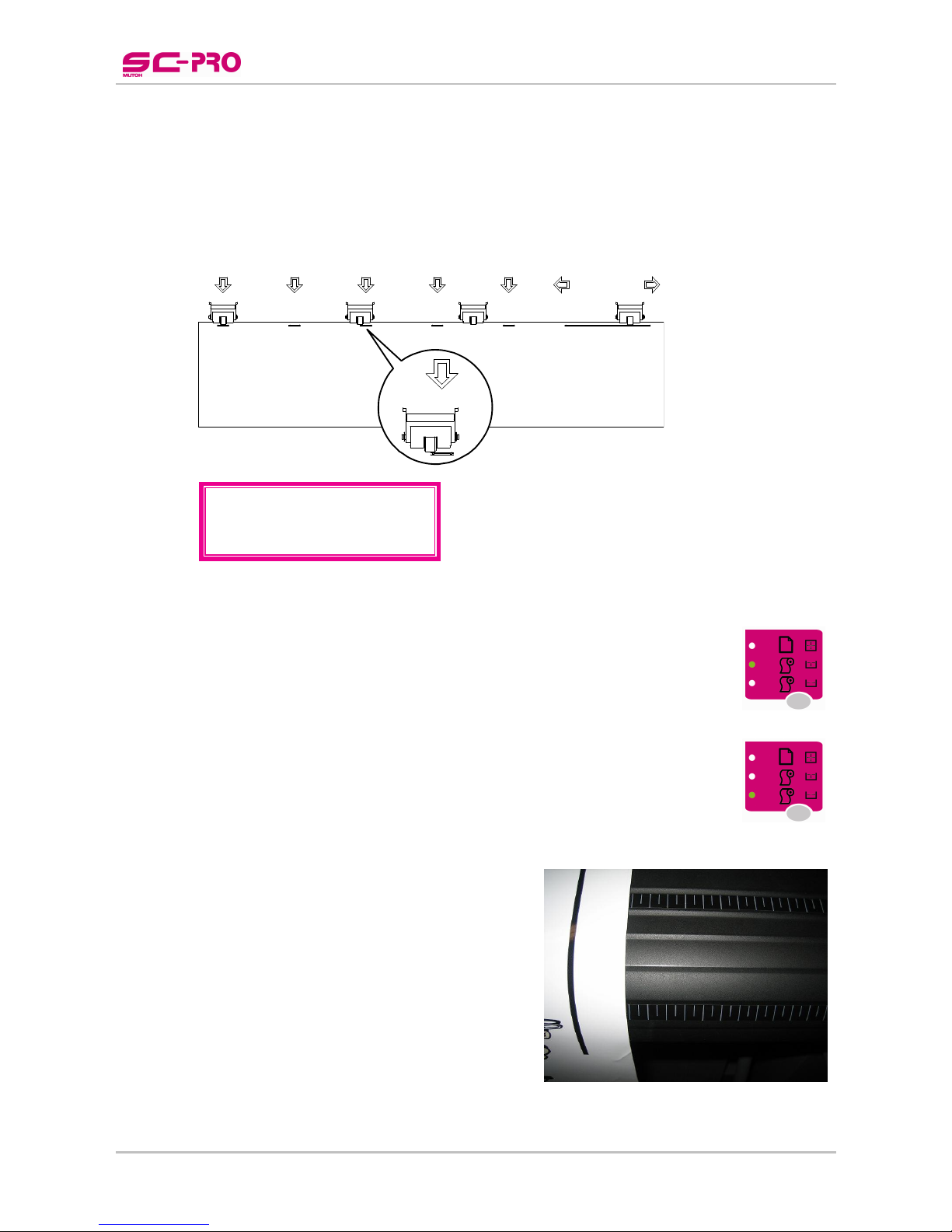

Step 3 : Position the pressure rollers as you have decided in step 2. Pressure rollers 2-3-4 have a tactile

and audible click system which makes it easier to position them correctly. The right pressure

roller (1) can never be malpositioned.

If one of the others is malpositioned, a message will be displayed after media initialization.

Please refer to the picture.

FRONT of the machine

1234

P

ressure roll

3

malpositioned!

Step 4 : Set the media type to sheet:

Page 33

User’s Guide SC-PRO Cutting Plotter

CHAPTER 3 : BASICS

33 AP-75280 – Rev. 1.1

Step 5 : Make sure that about half of the sheet hangs in front of the machine and half hangs at the back.

This will make it easier to align the media correctly.

Step 6 : Load the media straight. To help you, two rulers are attached to the front platen.

Step 7 : Be sure that the media is cut off straight at the front to avoid media initialization mismatches.

Step 8 : Be sure that the set maximum sheet length is smaller than the actual length of the loaded sheet.

If not, the cutter will automatically swap from sheet to roll front mode.

M

ax Sheet Leng

th

2000

[mm]

Save: Exit:

Notes

Before lowering the pressure rollers, be sure that there is a knife or pen installed in the head. This because

during the media initialization, the penhead will also be initialized. If you insert a pen/knife afterwards, the

machine will not know how to wind the coil of the penhead. This could result in cutting lines across the

complete print.

Step 9 : Lower the lever.

Notes

the head will move fastly over the media. Be careful not to pinch your fingers during this action.

Step 10 : The cutter will measure the paper. The following message will be displayed:

Sheet

Pl

ease wait

Notes

Please refer to “chapter 4 - Pre-feed Length” to understand the important function of this feature.

Step 11 : When no problems occur, the main screen will appear. The measured width of the media will be

displayed:

*READY*

X 950 Y 500

X = Media length in mm

Drag Knife Tool

Y = Media width in mm

60 cm/s

100

g

Step 12 : You are ready to cut.

Page 34

User’s Guide SC-PRO Cutting Plotter

CHAPTER 3 : BASICS

34 AP-75280 – Rev. 1.1

Page 35

User’s Guide SC-PRO Cutting Plotter

CHAPTER 4 : WALKTHROUGH THE OPERATION PANEL

35 AP-75280 – Rev. 1.1

4 WALKTHROUGH THE OPERATION

PANEL

The operation panel has been build up out of different keys as described in Chapter 2: “Product Overview Operation Panel”.

o Direct access keys

With these keys, it is possible to enter the frequently used menu items directly without the necessity

to go via the main menu.

o Basic keys

With these keys, you can enter the main menu, move media and cutter head…

o Special key combinations

With these combinations of keys, some features can be activated or de-activated.

Please find in the next coming chapters all information about these keys, menus, features…

This chapter is based on firmware version SP1.2.0 and keyboard version KB1.0.0

4.1 DIRECT KEY ACCESS

The following functions are directly accessible on the keyboard via the direct keys.

Note that these keys are only accessible when the display is in its start screen.

SHEET-OFF KEY To perform a sheet-off of the loaded media.

ORIGIN SET KEY To set the origin.

TEST KEY To calibrate, align and test the EPOS system.

COUNTOUR

CUTTING KEY

To set and start contour cutting.

SPEED KEY To set the cutting speed (in cm/s).

FORCE KEY To set the cutting force (in grams).

OFFSET KEY To set the offset of the knife.

TOOL KEY To select a tool.

Page 36

User’s Guide SC-PRO Cutting Plotter

CHAPTER 4 : WALKTHROUGH THE OPERATION PANEL

36 AP-75280 – Rev. 1.1

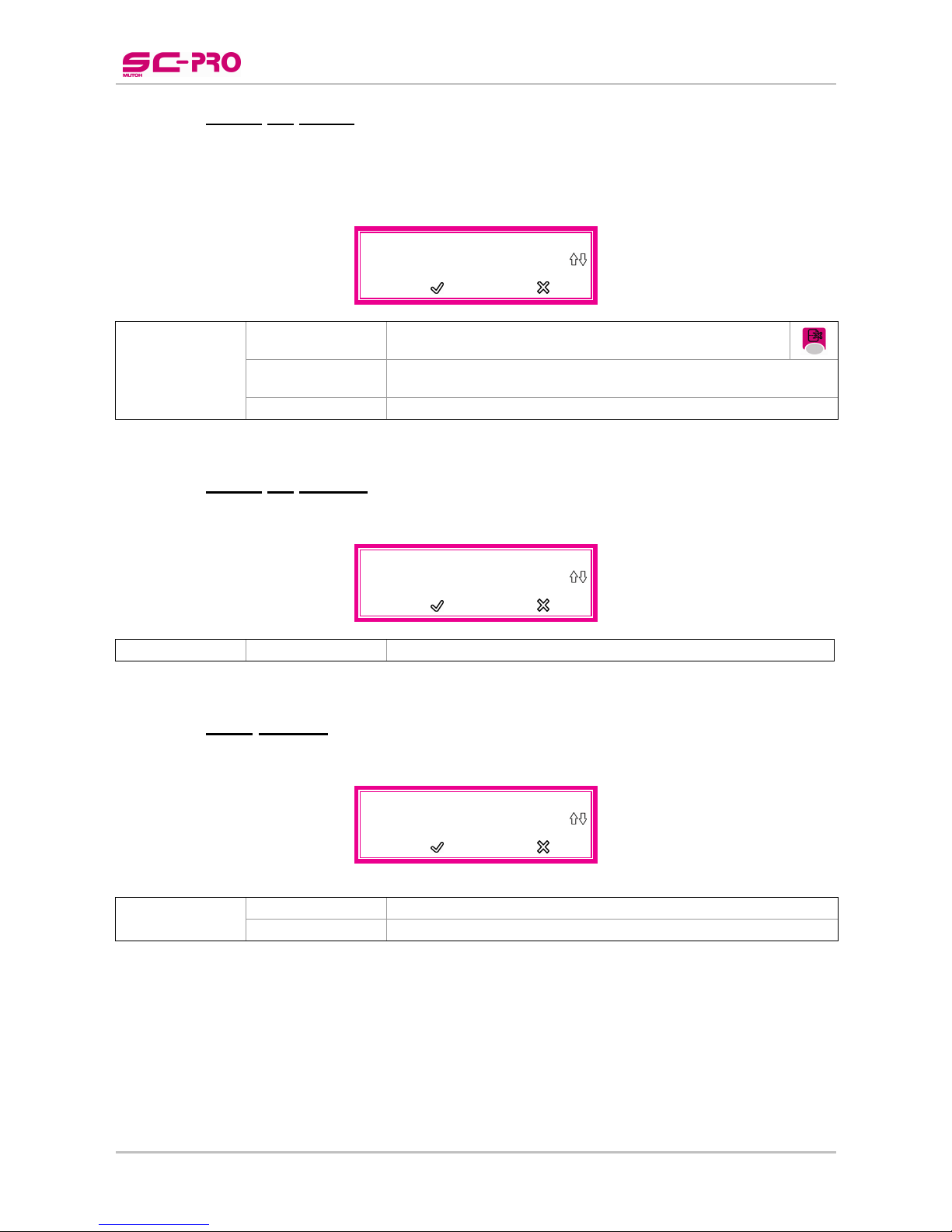

4.1.1 SHEET OFF key

When a job has been finished and the media has to be sheeted off, this function can be used.

Notes

Please refer also to the “sheet off mode” and “sheet off margin” menu.

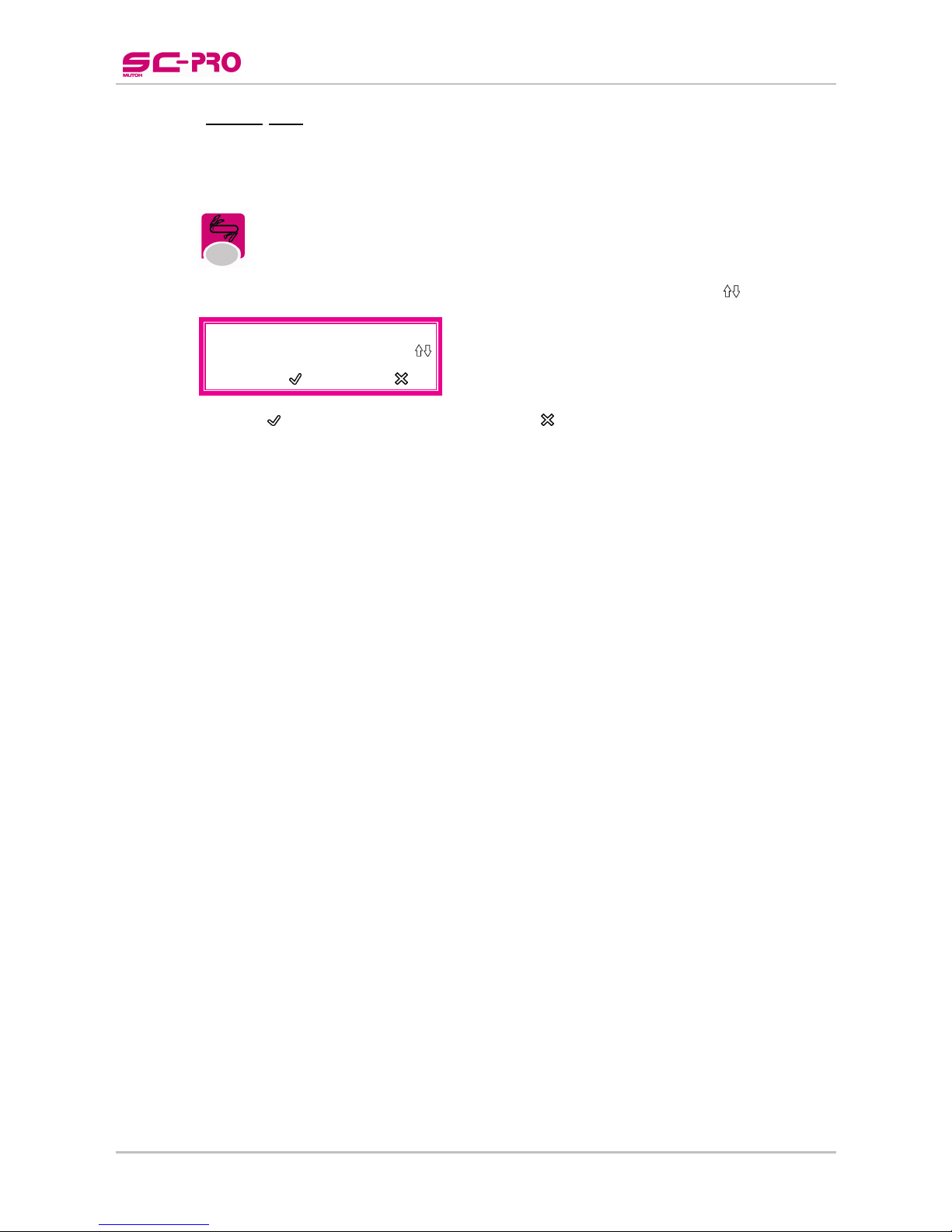

Step 1 : Feed the media using the

keys to the desired position.

Step 2 : Press the [SHEET OFF] key.

Step 3 : Press the [ ] key to start to sheet-off sequence or the [ ] key to cancel.

AUTOMATIC

SHEET-OFF?

Yes :

or

No :

or

Step 4 : When selecting YES, the cutter will perform one of the following actions, depending on the sheet-

off settings.

a. When Sheet off mode is set to automatic, the media will be sheeted off near to the pressure

rollers.

b. When Sheet off mode is set to manual, the media will be fed toward the cutting groove.

The following message will be displayed:

Pl

ease

manually cut off

and

press

a k

ey when ready

c. When Sheet off mode is set to disable, the media can not be sheeted off.

The following message will be displayed:

SHEET-OFF

IS DISABLED !

P

ress any key

Step 5 : The main screen will automatically be displayed when the sheeting off sequence has been

finished correctly.

Step 6 : If the media has not been sheet-off (completely), the following message will be displayed:

Sheet

off

problem

detected

press any key

t

o continue

Page 37

User’s Guide SC-PRO Cutting Plotter

CHAPTER 4 : WALKTHROUGH THE OPERATION PANEL

37 AP-75280 – Rev. 1.1

4.1.2 ORIGIN key

Please follow the instructions below to change / control the origin.

Notes

Please make sure media is loaded. If not, the SC-Pro positioning calculation is based on previously

installed media.

Step 1 : Press the [ORIGIN] key.

Step 2 : The EPOS laser will be activated automatically. The display will show following message:

Origi

n

Set new:

Move to:

Move with ◄►▲▼

Step 3 : Press the [

] key to move to the actual origin and/or use the keys to move the laser to the

desired origin position and press the [

] key to set the new origin.

Step 4 : The main screen will automatically be displayed again.

4.1.3 TEST key

To be able to contour cut, an Epos® feature has been incorporated. This feature will search for the black

reference box and measure the position of the design(s). When you see some deviation during contour

cutting, it is recommended to perform the test cuts described below.

Step 1 : Press the [TEST] key.

Step 2 : Select one of the tests with the - keys.

Test

Test

EPOS readout EPOS calibrate

60

cm/s

100

g

METHOD: <TEST>

T

o start:

T

o start:

Notes

Please refer to “chapter 5: Fine-tuning your cutter” for all details about these tests.

Page 38

User’s Guide SC-PRO Cutting Plotter

CHAPTER 4 : WALKTHROUGH THE OPERATION PANEL

38 AP-75280 – Rev. 1.1

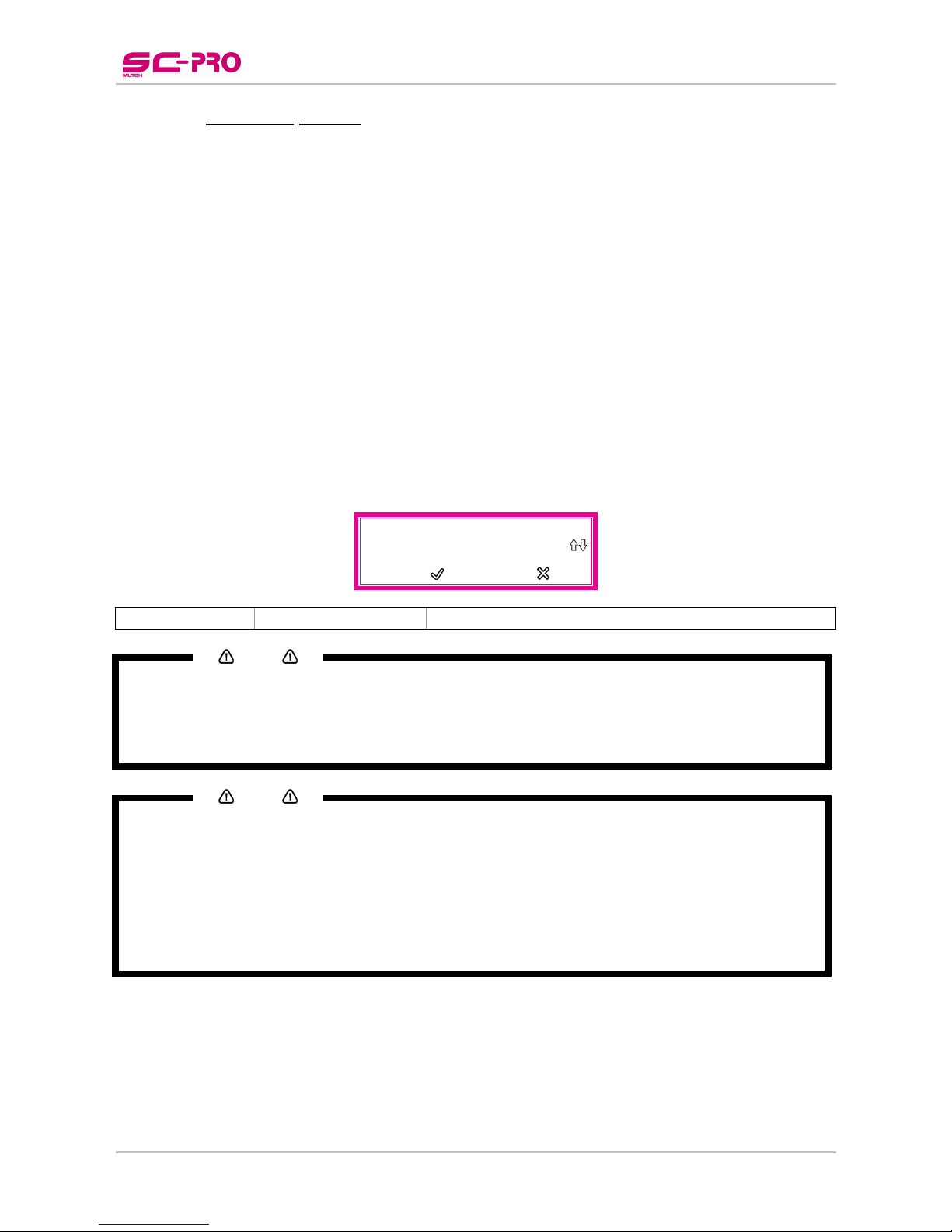

4.1.4 CONTOUR CUTTING key

Please follow the instructions below to select an alignment method, to set parameters and to start contour

cutting.

F

OR MORE INFORMATION ON HOW TO CONTOUR CUT, PLEASE REFER TO:

► THE APPLICATION GUIDE DESCRIBING ALL DETAILS ABOUT CONTOUR CUTTING.

► CHAPTER 6 OF THIS MANUAL

Step 1 : Press the [CONTOUR CUTTING] key.

Step 2 : Select the alignment method with the

- keys and confirm with the - key.

Cont

ourcu

tti

ng

Manua

l

Barcode Single

Barcode Multi

Start

:

Next

:

Step 3 : Press the [CONTOUR CUTTING]-key to make a selection and continue to the next setting.

Step 4 : The next screen depends on the previous selection.

a. When you have selected “Manual”, the following can be set.

Cont

ourcu

tti

ng

X Length (mm)

Y

Width (mm)

Roll direction

Start

: Next:

► Press the [CONTOUR CUTTING]-key to set the X-length. Use the keys to change

the value. Press the [

]-key to go to the previous screen.

Adjust the Y-width and roll direction in the same way.

Cont

ourcu

tti

ng

X Length (mm

)

500

Start: Exit:

Cont

ourcu

tti

ng

Y

Width

(mm

)

500

Start: Exit:

Cont

ourcu

tti

ng

Roll direction

(Non)Reverse

Start: Exit:

Page 39

User’s Guide SC-PRO Cutting Plotter

CHAPTER 4 : WALKTHROUGH THE OPERATION PANEL

39 AP-75280 – Rev. 1.1

b. When you have selected “Barcode Single” or “Barcode Multi”, you have to decide if the job

has to be performed only once (“Single Scan”) or multiple times (“Repeat Mode”).

Cont

ourcu

tti

ng

Single scan

Repeat Mode

Start: Exit:

Step 5 : When all settings have been made, press the [

]-key to start contour cutting.

Notes

Please refer to the application guide to know how to transfer cut data to your cutter.

4.1.5 SPEED key

Please follow the instructions below to change / control the cutting speed.

Step 1 : Press the [SPEED] key.

Step 2 : The current speed (in cm/s) will be displayed. Change the value with the - keys.

S

peed

60

[cm/s

]

Start: Exit:

Step 3 : Press the [

] key to change the current value or the [ ] key to abort.

Notes

The speed can be viewed / changed in following modes:

o READY mode

o BUSY mode

o PAUSE mode

Notes

The cutting speed, tool up or laser speed are independent and different settings.

Page 40

User’s Guide SC-PRO Cutting Plotter

CHAPTER 4 : WALKTHROUGH THE OPERATION PANEL

40 AP-75280 – Rev. 1.1

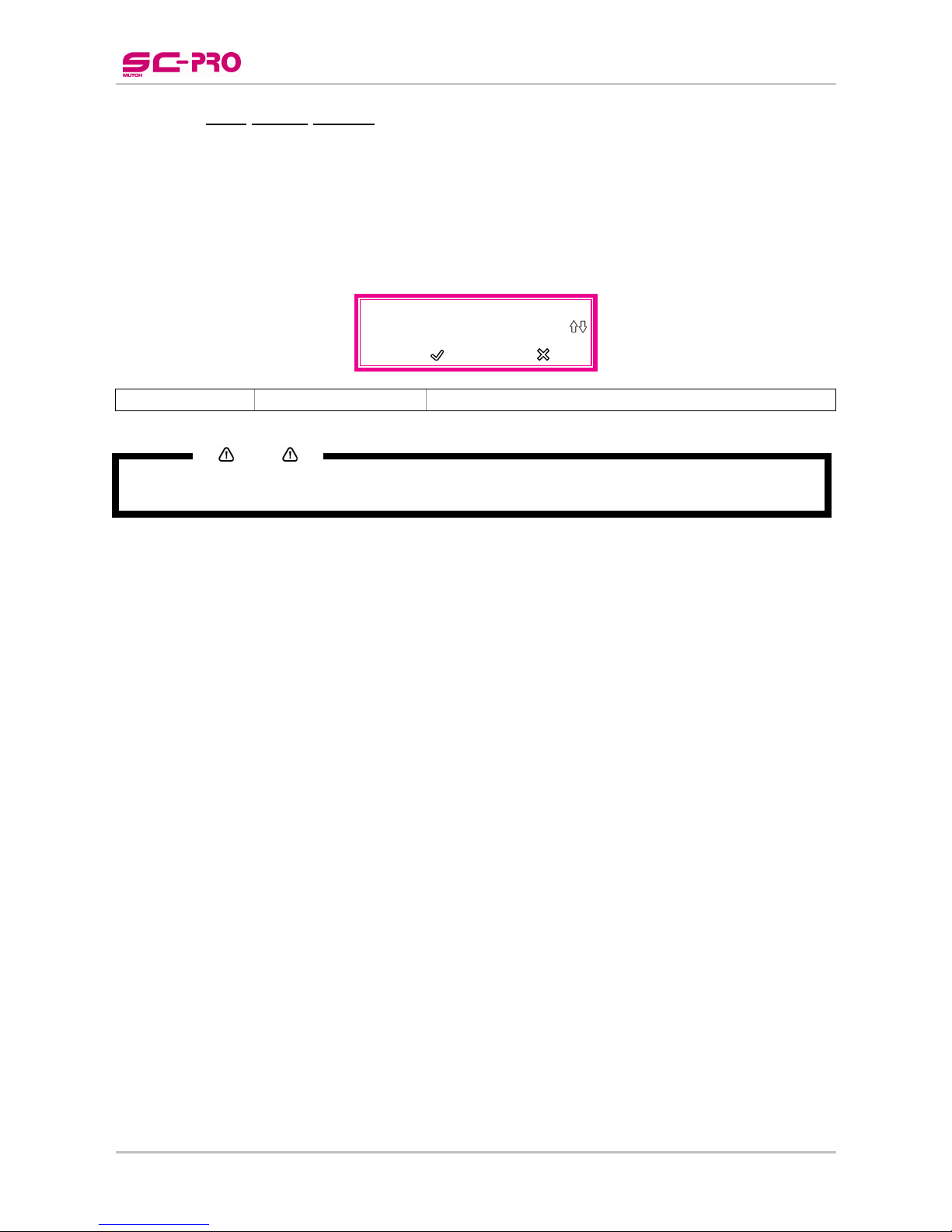

4.1.6 FORCE key

Please follow the instructions below to change / control the tool force.

Tool force is the amount of downward pressure that the cutter applies on the knife / pen.

We merely want to point out that you have to try to cut your design with the lowest possible pressure that

gives no trouble to weed. Some cast media require only 20 grams to be cut completely through. In that case

there is no need to apply 100 grams of pressure. Too much pressure can cause a decrease of quality.

Be sure that the knife depth has been set correctly. Otherwise, this setting is useless.

Step 1 : Press the [FORCE] key.

Step 2 : The current force (in gram) will be displayed. Change the value with the

- keys.

F

orce

100

[g]

Start

: Test:

Step 3 : Press the [FORCE] key once again to make a test cut to verify the new force.

Step 4 : Weed out the pattern

Step 5 : Check if the top layer is cut completely and that you can see a slight scratch on the backing.

Step 6 : Press the [

] key to accept the new value.

Page 41

User’s Guide SC-PRO Cutting Plotter

CHAPTER 4 : WALKTHROUGH THE OPERATION PANEL

41 AP-75280 – Rev. 1.1

4.1.7 OFFSET key

Please follow the instructions below to change / control the offset.

Step 1 : Press the [OFFSET] key.

Step 2 : The current offset (in mm) will be displayed. Change the value with the

- keys.

Offset

0.50

[mm]

Start: Exit:

Step 3 : Press the [ ] key to change/test the current value or the [ ] key to abort.

Step 4 : The following message will be displayed when you have changed the value:

Test offset

Test : or

No test : or

Step 5 : The following pattern will be cut:

Each square will be cut with a different offset.

0,45 0,46 0,47 0,48 0,49 0,50 0,51 0,52 0,53 0,54

Step 6 : Use the

keys to forward the media.

Step 7 : Weed out the boxes as

and check the patterns and determine which of them gives best quality.

Especially look for good quality of the corners and easy weeding.

Step 8 : Select one of the offsets with the left-right arrow keys. The EPOS laser will point to the selected

offset / test pattern.

Step 9 : Press the [

] key to accept the new offset.

Page 42

User’s Guide SC-PRO Cutting Plotter

CHAPTER 4 : WALKTHROUGH THE OPERATION PANEL

42 AP-75280 – Rev. 1.1

4.1.8 TOOL key

Please follow the instructions below to change the tool.

Step 1 : Press the [TOOL] key.

Step 2 : The current selected tool will be displayed. Switch between knife or pen with the

- keys.

Tool

Pen

Start: Exit:

Step 3 : Press the [

] key to change the current value or the [ ] key to abort.

Page 43

User’s Guide SC-PRO Cutting Plotter

CHAPTER 4 : WALKTHROUGH THE OPERATION PANEL

43 AP-75280 – Rev. 1.1

4.2 MENU OVERVIEW

Before to be able to browse through the menu,

be sure that the cutter is in normal conditions.

▼

*READY*

X Roll Y 1181

D

rag Knife Tool

60

cm/s

100

g

▼

Press the [MENU]-key to open the menu.

▼

▼

Use the

- keys to browse through

all the different menus.

▼

Sheetoff Mode

Sheetoff M

argin

Pre-

Feed L

ength

M

ax Sheetlength

▼

Press the [

] key to open the requested menu

▼

▼

Sheetoff Mod

e

AUTOMATIC

Save: Exit:

▼

▼

▼

▼

Press the [

] key to go back to the menu overview

▼

▼

Sheetoff Mode

Sheetoff M

argin

Pre-

Feed L

ength

M

ax Sheetlength

▼

Press the [

] key to go back to the main menu

▼

▼

*READY*

X Roll Y 1181

D

rag Knife Tool

60

cm/s

100

g

Page 44

User’s Guide SC-PRO Cutting Plotter

CHAPTER 4 : WALKTHROUGH THE OPERATION PANEL

44 AP-75280 – Rev. 1.1

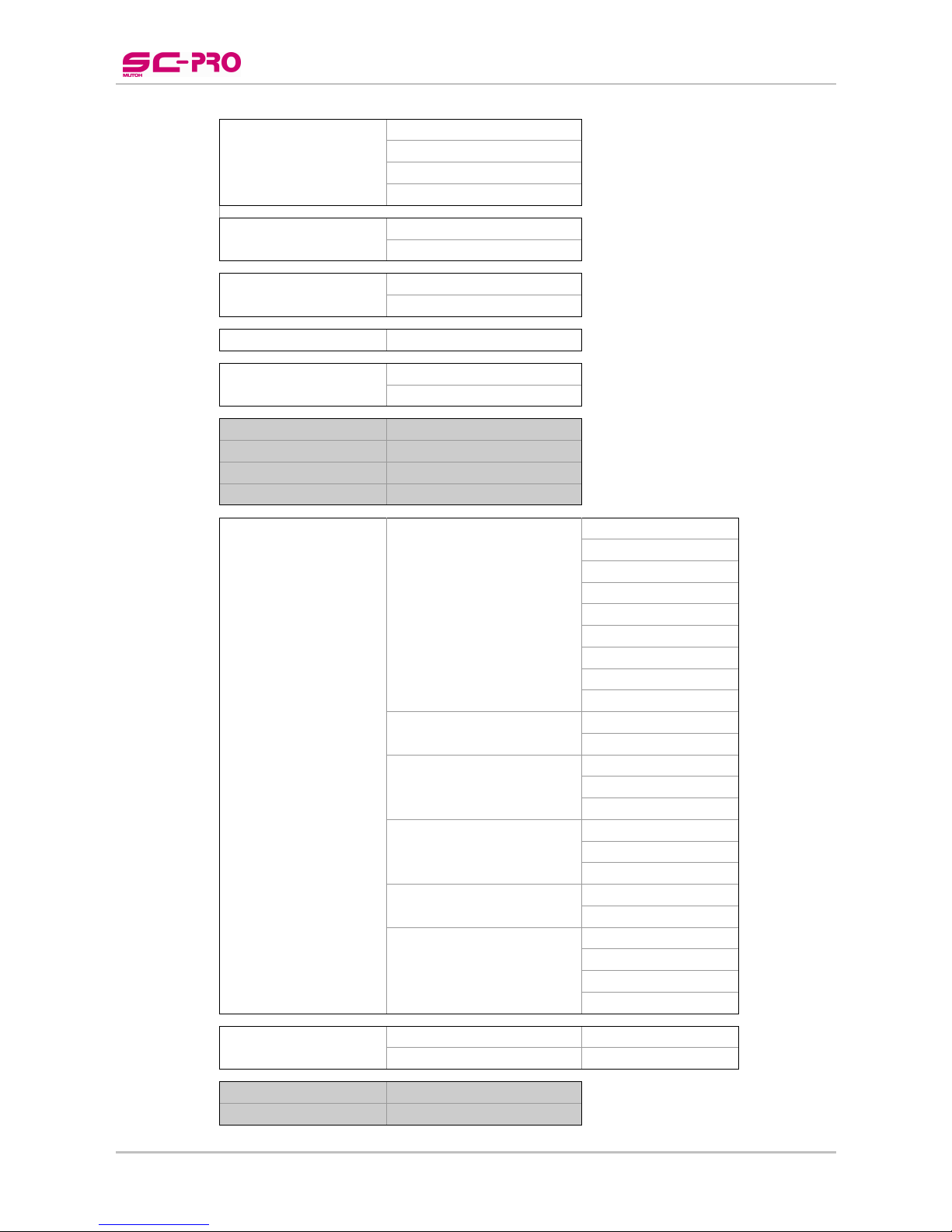

PLEASE FIND BELOW A COMPLETE OVERVIEW OF THE EXISTING MENUS. THE DEFAULT VALUES ARE MARKED IN BOLD.

Note that it is possible to view the full or basic menu. The items shown in the basic menu are marked in grey.

Sheetoff Mode AUTOMATIC

DISABLE

MANUAL

Sheetoff Margin

1 – 5 – 250 [mm]

Auto Shuffle Enabled

Disabled

PRE-FEED LENGTH

0 – 1000 - 10000 [mm]

Max Sheetlength

0 – 2000 - 10000 [mm]

Page Mode

0

1

2

Origin L RIGHT

CENTER

U RIGHT

U LEFT

L LEFT

Laser Speed

2 – 15 – 100 [cm/s]

TOOL-UP SPEED

2 -100 [cm/s]

JOB FOCUS

Speed

Accuracy

Smoothing Enabled

Disabled

Factory default No

Yes

Copies

0 – 1 – 100

Bezier

1.0 – 10.0

LANGUAGE

ENGLISH

JAPANESE

ESPANOL

DEUTSCH

FRANCAIS

NEDERLANDS

ITALIANO

Page 45

User’s Guide SC-PRO Cutting Plotter

CHAPTER 4 : WALKTHROUGH THE OPERATION PANEL

45 AP-75280 – Rev. 1.1

Emulation HPGL2

MHGL

MHGL2

HPGL

Program Step 0,010mm

0,025mm

VS / ZF / AS ACCEPT

IGNORE

LCD contrast

0 – 16 – 32

Keyboard beep No

Yes

VERSIONS

Application ► SP x.x.x

X port ► XP x.x.x

FPGA ► FPGA x.x.x

Keyboard ► KB x.x.x

Serial comm.

Baudrate 1200

2400

4800

9600

19200

28800

38400

57600

115200

Databits 7

8

Parity

NONE

EVEN

ODD

StopBits 0

1

2

FlowControl

Software

Hardware

RS232/USB/ETH

Auto

USB

RS232

ETHERNET

Network comm.

TCP/IP Address 192.168.001.199

Subnet mask 255.255.255.0

BASIC/FULL MENU

FULL

BASIC

Page 46

User’s Guide SC-PRO Cutting Plotter

CHAPTER 4 : WALKTHROUGH THE OPERATION PANEL

46 AP-75280 – Rev. 1.1

4.2.1 Sheet off mode

The auto-sheet-off mechanism of your cutter can be very easily used to cut the front edge of a new roll of

vinyl straight as well as to cut off a sheet of vinyl from a roll, to be used as a separate sheet.

With the sheet-off mode, you can select “AUTOMATIC”, “MANUAL” or “DISABLE”.

Sheetoff Mod

e

AUTOMATIC

Save: Exit:

Sheetoff Mode AUTOMATIC

A sheet-off will be done automatically when pressing the

sheet-off key.

MANUAL

A sheet-off can be done with a snap-off blade knife; the media will

feed towards the cut groove after a job is done.

DISABLE No sheet-off possible.

4.2.2 Sheet off margin

It is sometimes useful that the media is fed an amount of millimetres after a job, before sheeting off.

Sheetoff M

argin

5

[mm

]

Save: Exit:

Sheetoff Margin

1 – 5 – 250 [mm] The media will be fed 5 mm extra before sheeting off.

4.2.3 Auto Shuffle

Set if it is necessary to perform an automatic media shuffle after a sheet-off procedure.

Sheetoff Mod

e

AUTOMATIC

Save: Exit:

Auto Shuffle ENABLED

An automatic shuffle will be executed after a sheet-off

Disabled No automatic shuffle will be executed after a sheet-off

Page 47

User’s Guide SC-PRO Cutting Plotter

CHAPTER 4 : WALKTHROUGH THE OPERATION PANEL

47 AP-75280 – Rev. 1.1

4.2.4 Pre-Feed length

This parameter is directly related to the loading of ROLL FRONT / ROLL media. The Pre-Feed length or

SHUFFLE length has to be set before a roll is loaded.

There are three reasons for using a Pre-Feed Length:

1.

The length of media set for the Pre-Feed length parameter will be pulled off the roll, before the cutting

job starts. This will prevent media from being pulled off the roll at high speed and acceleration. High

speed can only be properly used on condition that the media can move freely, without having to be

pulled off the roll during a job.

2.

Before actually cutting starts the complete length of the media is shuffled back and forth through the

cutter, ensuring that the pressure rollers have a discrete path while the user has the time to verify if

the vinyl transport goes well.

3.

Your SC-Pro cutter has been equipped with MUTOH’s unique AUTO-SHEET-OFF feature, to

automatically cut off media at the end of a cutting sequence. Following an automatic PAGE command

or a manual PAGE command initiated via the control panel, the cutter will shuffle through the pre-set

Pre-Feed length of media, to ensure that there is enough media left for a possible replot. If there is

not enough media left, the cutter will stop before the end of the assigned media length and switches to

SHEET mode. The cutter will not initiate the media again in between two contour cutting jobs.

Pre-

Feed L

eng

th

1000

[mm

]

Save: Exit:

Pre-Feed Length

0 – 1000 - 10000 [mm] The media will be fed 1 meter before the cutting job will start.

Notes

Please note that the use of the PRE-FEED LENGTH should not be regarded as a loss of time. If the

shuffle movement is executed without difficulty, the user can be convinced that the sign to be cut will be

executed with very little risk of media tracking problems. As such, it will result in a time-saving

operation, preventing that the user will have to re-cut a very complex design because of bad media

alignment.

Notes

Please note that the cutting range is not limited by the Pre-Feed Length which you have set. In case a

design, which exceeds the shuffle length, is sent to the cutting plotter, the cutter will react as follows:

o The first vector, which exceeds the limit, will be cut using reduced speed for the distance exceeding

the limit.

o The cutter will continue at the requested speed until the new limit is exceeded.

o However, this should not be a reason for you not to change the pre-feed length at all, as by omitting

to change it; you will be inhibited to check the full vinyl transport before the job is launched

o When there is an end of roll detection during the pre-feed, the cutter will automatically switch to

SHEET mode.

Page 48

User’s Guide SC-PRO Cutting Plotter

CHAPTER 4 : WALKTHROUGH THE OPERATION PANEL

48 AP-75280 – Rev. 1.1

4.2.5 Max Sheet length

After installation of a sheet and sheet being selected in the menu, the cutting plotter will measure the width

and length of the sheet.

To avoid unrolling a full roll of media when a roll is loaded while the media type is set to sheet, you can

define a maximum allowed sheet length.

In case sheet is selected in the menu, the SC-Pro will not measure more than the length in the Max. Sheet

Length menu, preventing the roll media to be rolled off completely.

M

ax Sheet Leng

th

2

000

[mm

]

Save: Exit:

Max Sheet length

0 – 2000 - 10000 [mm] The maximum sheet length / maximum feeding will be 2 m.

Notes

When there is NO end of roll detection during the sheet measurement, the cutter will automatically

switch to ROLL mode.

Page 49

User’s Guide SC-PRO Cutting Plotter

CHAPTER 4 : WALKTHROUGH THE OPERATION PANEL

49 AP-75280 – Rev. 1.1

4.2.6 Page mode

P

age Mode

1

Save: Exit:

The page mode determines the cutter’s reaction to a PAGE command sent by the cutting software. The

PAGE command is a command, which is used to relocate the origin after a job is finished and which can take

control remotely of the cutter’s automatic sheet-off feature. Sheeting-off automatically, without user

intervention, is a feature which is unique to Mutoh cutting-plotters and which enhances the cutter’s versatility

and overall performance enormously.

A page-command looks like this: “PG;” or “PGN;” with “n” a number in millimetres.

If the PAGE command “PG;” is sent, the cutter will automatically sheet of regardless of the Page mode,

minimizing the loss of vinyl.

If the PAGE command “PGN;” is sent, the number mentioned after the PG command will be interpreted

differently, depending on the page mode you have chosen:

Page Mode 0 :

The number after the page command is ignored. The media will be cut 5 mm (0.2”) after the latest downvector. The new cutting limit will be located 0.5 (0.2”) from the lower media border.

Page Mode 1 :

The new origin is located “n” millimetres beyond the last down-vector that was sent.

Page Mode 2 :

The new origin is located “n” millimetres beyond the previous origin position.

“PGN” is sent (n is a number in mm).

A : Original origin

B : End point last vector

C : New origin with Page Mode 1

D : New origin with Page Mode 2

Page 50

User’s Guide SC-PRO Cutting Plotter

CHAPTER 4 : WALKTHROUGH THE OPERATION PANEL

50 AP-75280 – Rev. 1.1

4.2.7 Origin

Change / control the default origin after a media load sequence.

Notes

Please make sure media is loaded. If this is not the case, the SC-Pro positioning calculation is based on

previously installed media.

Origi

n

L

RIGHT

Save: Exit:

Pre-Feed Length

MediaWidth

REAR

FRONT

U LEFT U RIGHT

L LEFT L RIGHT

CENTER

Origin L RIGHT

The origin will be set in the lower right corner.

CENTER The origin will be set in the centre.

U RIGHT The origin will be set in the upper right corner.

U LEFT The origin will be set in the upper left corner.

L LEFT The origin will be set in the lower left corner.

4.2.8 Laser speed

It is possible to perform a test contour cutting with the SC-Pro cutting plotter. Contour lines will be indicated

by the EPOS laser beam. In case the speed of the test contour cutting is not acceptable, you can decrease

or increase the speed.

L

aser Spee

d

15

[cm/s

]

Save: Exit:

Laser Speed

2 – 15 – 100 [cm/s] Laser speed can be set between 2 and 100 cm / s

Notes

The laser speed has nothing to do with the speed of measuring a frame.

Page 51

User’s Guide SC-PRO Cutting Plotter

CHAPTER 4 : WALKTHROUGH THE OPERATION PANEL

51 AP-75280 – Rev. 1.1

4.2.9 Tool-up speed

Tool-up movements are mostly long movements (which reach their maximum speed) between the short tooldown movements. These movements could cause abrupt media transport (which could cause tracking

problems). Therefore, it is recommended to select a tool-up speed lower than the speed selection in the

menu.

Tool

-

up S

pee

d

100

[cm/s

]

Save: Exit:

Tool-up Speed

2 -100 [cm/s] Tool-up speed can be set between 2 and 100 cm / s

4.2.10 Job focus

A lot of advanced cutting settings will be made in the background without any need of intervention by the

end-user. Select by means of the table below the correct job settings (focus)

Job F

ocus

Accuracy

Save: Exit:

Job Focus Accuracy

Give in some speed, gain quality.

Speed Give in some quality, gain speed.

4.2.11 Smoothing

Smoothing can be ENABLED or DISABLED. Depending on your choice, cutting of obtuse angles will be

dealt differently by the cutter.

If the complementary angle between two consecutive vectors A & B is larger than the smoothing angle, the

cutter will slow down and cut a sharp corner (1). If the angle is smaller, the cutter will maintain its speed and

cut a rounded corner (2). The optimum smoothing angle is calculated internally.

When smoothing is DISABLED all corners will be cut sharply.

S

moo

thi

ng

ENABLED

Save: Exit:

Smoothing ENABLED

Smoothing has been enabled (recommended)

DISABLED Smoothing has been disabled

= 30°

Page 52

User’s Guide SC-PRO Cutting Plotter

CHAPTER 4 : WALKTHROUGH THE OPERATION PANEL

52 AP-75280 – Rev. 1.1

4.2.12 Factory default

Restore the factory defaults as follows

Fact

ory defau

lt

YES

Save: Exit:

Fact

ory defau

lt

Pl

ease wa

it

w

hil

e machine

i

s restarting

!

Wait until the main screen appears to perform further actions

*READY*

X Roll Y 1181

D

rag Knife Too

l

60

cm/s

100

g

4.2.13 Copies

In case multiple outputs of a specific design are needed, you can use the copies function. This function will

replot the last set of data, which was sent to the cutting plotter. That is, all data that was sent since the last

INITIALISATION command (“IN”).

Copi

es

1

Save: Exit:

Copies

0 – 1 -100 Set number of copies between 0 and 100

Notes

When you want to make copies, make sure that the ‘Sheet Off’ mode is enabled. Otherwise you’ll

perform a multi-cut. The cutter will cut continuously on the same place.

In case of identical frames without barcode, copying contour cutting tasks can be done via the COPY

menu option as well as from roll and sheet.

When you perform a lever up action during a job, all data will be cleared out of the buffers, which

means, no copies can be made anymore of the job.

Page 53

User’s Guide SC-PRO Cutting Plotter

CHAPTER 4 : WALKTHROUGH THE OPERATION PANEL

53 AP-75280 – Rev. 1.1

4.2.14 Bezier

This is the calculation accuracy factor for the incorporated Bézier curve generation. The value can be set

between 1 and 10.

Bezi

er

1.

0

Save: Exit:

Bezier

1.0 – 10.0 Bezier can be set between 1.0 and 10.0

4.2.15 Language

Select in the language of the user interface.

L

anguage

ENGLISH

Save: Exit:

Language ENGLISH

JAPANESE

ESPANOL

DEUTSCH

FRANCAIS

NEDERLANDS

ITALIANO

4.2.16 Emulation

Your cutter is able to understand different graphic languages. It is highly recommended to leave this setting

unchanged.

Emulati

on

HPGL2

Save: Exit:

Emulation HPGL2

Default graphic language

MHGL For internal use only

MHGL2 For internal use only

HPGL For internal use only

Page 54

User’s Guide SC-PRO Cutting Plotter

CHAPTER 4 : WALKTHROUGH THE OPERATION PANEL

54 AP-75280 – Rev. 1.1

4.2.17 Program step

Please note that some software packages use the “step per mm” terminology, in which case a program step

of 0.025 mm corresponds with 40 steps per mm and a program step of 0.010 mm with 100 steps per mm.

Contour cutting supports only 0.010 mm program step.

Notes

If the plot unit is not set correctly, all your cutting jobs will be cut 2.5 times too large or too small.

P

rogram step

0.

010

[mm

]

Save: Exit:

Program Step 0,010mm

Set the step to 0.010 mm

0,025mm Set the step to 0.025 mm

4.2.18 VS/ZF/AS

Several cutting software packages enable the user to send speed, force and acceleration commands to the

cutter. The cutter can be set up to ACCEPT or IGNORE these commands.

VS/ZF

/AS

ACCEPT

Save: Exit:

VS / ZF / AS ACCEPT

IGNORE

Notes

When VS and ZF commands are sent and accepted, they will override the speed, force and acceleration

settings the user may have set from the cutter operation panel.

When the VS and ZF commands are ignored, the cutter will always use the settings, which are set-up from

the cutter operation panel.

4.2.19 LCD contrast

Change the LCD contrast as you wish.

LCD

contras

t

16

Save: Exit:

LCD contrast

0 – 16 – 32

Set LCD contrast between 0 and 32

0 = bright

32 = dark

Page 55

User’s Guide SC-PRO Cutting Plotter

CHAPTER 4 : WALKTHROUGH THE OPERATION PANEL

55 AP-75280 – Rev. 1.1

4.2.20 Keyboard beep

Decide whether the keyboard should beep every time you strike a key or not.

Keyb

oard beep

NO

Save: Exit:

Keyboard beep No

No keyboard beeps will sound

Yes A keyboard beep will sound after pushing a key.

4.2.21 Versions

Check which versions are installed on the SC-Pro cutter.

V

ersions

SP x.x.x

Save: Exit:

Versions

SP x.x.x Application firmware version

XP x.x.x Ethernet module firmware version

FPGA x.x.x On board chip firmware version

KB x.x.x Keyboard firmware version

4.2.22 Basic / Full menu

You do not need all menu items every day or time you want to cut. Therefore, it is possible to hide some

functions when you select “Basic”-menu. When you select “Full”- menu, all menus will be visible.

Basic/Full

menu

FULL

Save: Exit:

Basic/Full menu

Basic Only the most frequently used menus will be viewed

► Pre-Feed Length

► Tool Up Speed

► Job Focus

► Language

► Versions

► Basic/Full menu

Full

All menus will be visible

Page 56

User’s Guide SC-PRO Cutting Plotter

CHAPTER 4 : WALKTHROUGH THE OPERATION PANEL

56 AP-75280 – Rev. 1.1

4.2.23 Serial communication

In order for your plotter to be able to communicate well with your host computer, the communication settings

on both machines have to match exactly. Please refer to the manual of your software to determine which

communication setting will be used by your software. Your cutter can be set up to use any settings

necessary.

To change the communication selection, please follow the instructions mentioned below:

Step 1 : Select with the

- keys the setting you want to change.

Baudrate

DataBit

s

Parit

y

StopBit

s

FlowControl

RS232/USB/ETH

Step 2 : Press the [

] – key to confirm your selection.

Step 3 : Change the value with the

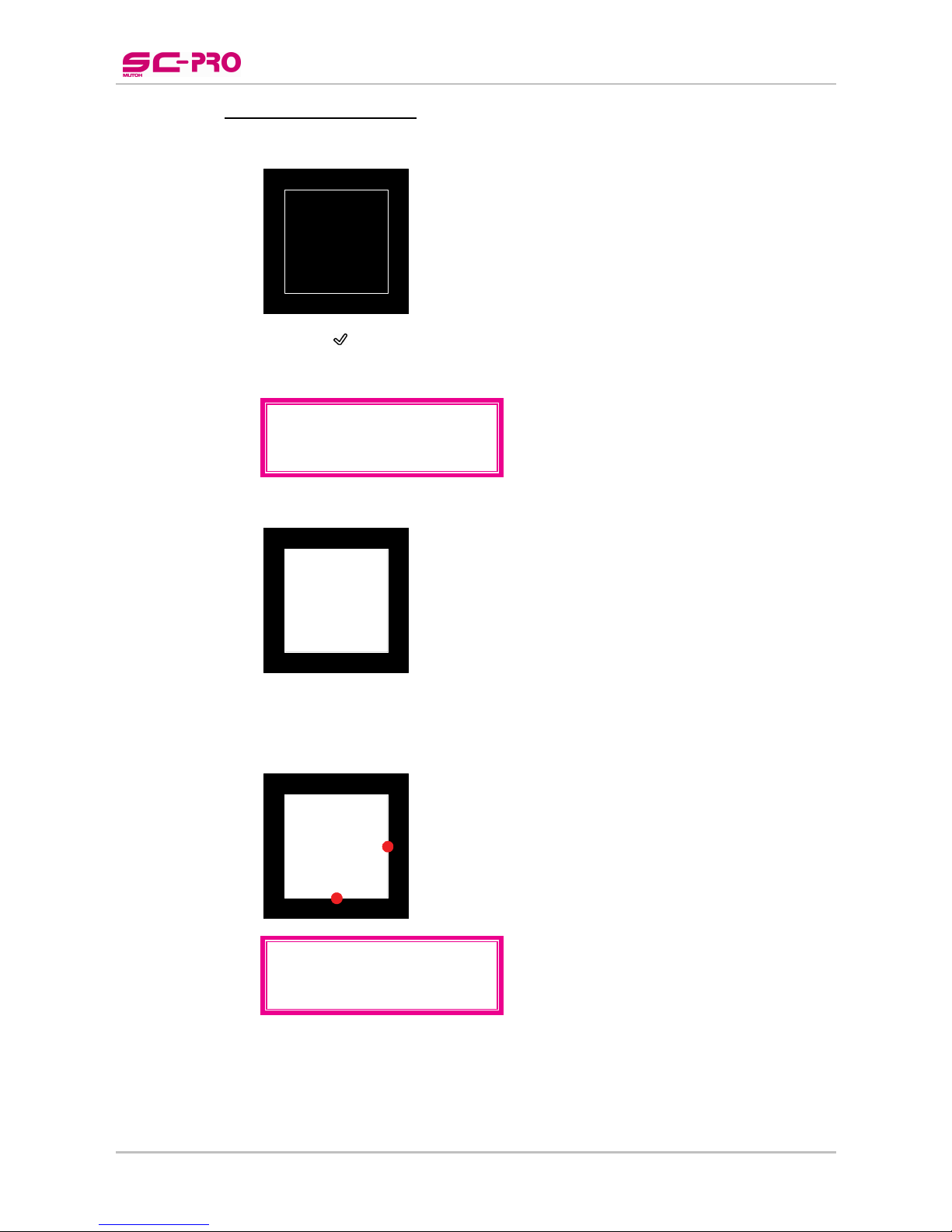

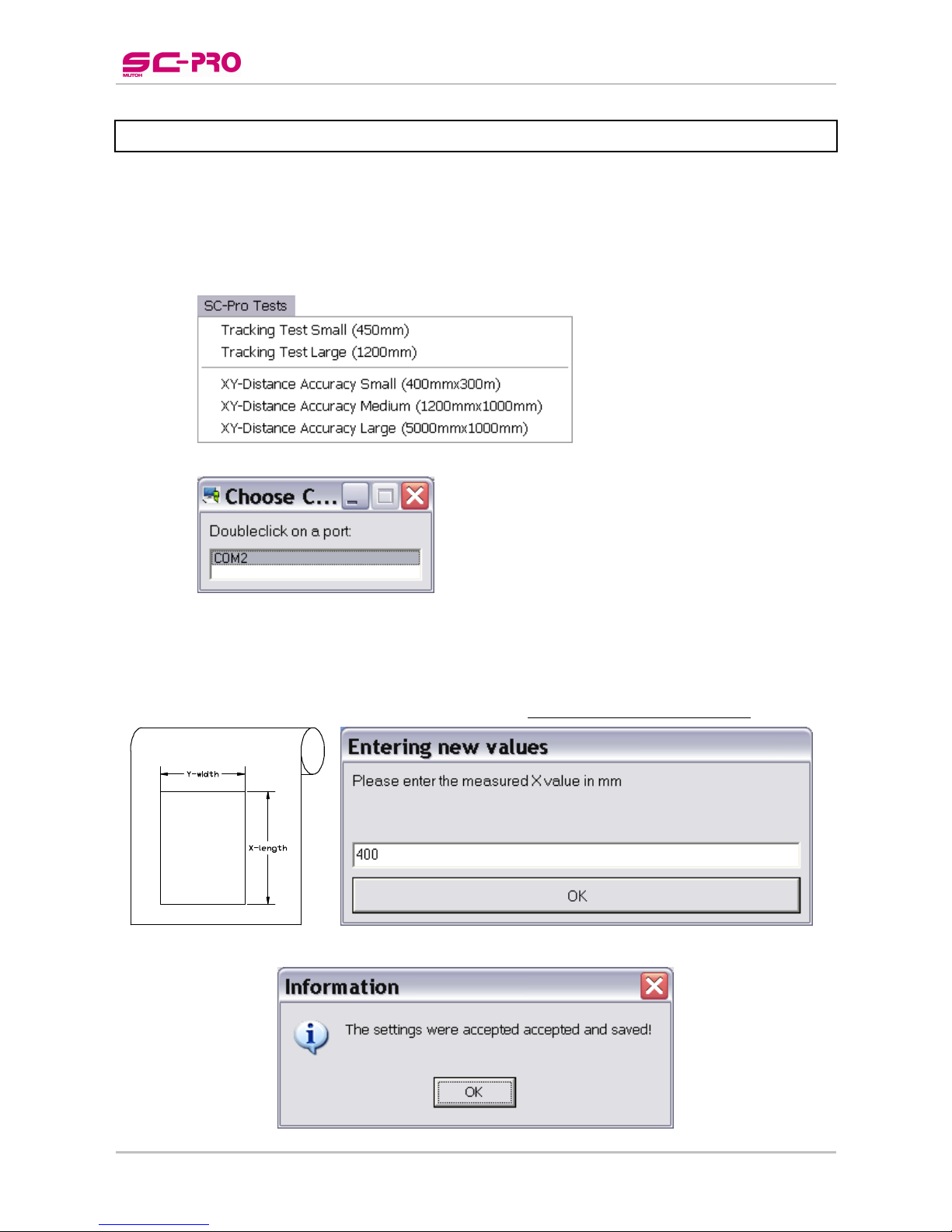

- keys and confirm once again with the [ ] – key.