Page 1

Maintenance Manual

SC CUTTING PLOTTER

MUTOH EUROPE N.V. AP-74030, Rev./ B

Page 2

2 AP-74030, Rev / B

Page 3

3 AP-74030, Rev / B

COPYRIGHT NOTICE

COPYRIGHT © 2001 Mutoh Europe N.V. all rights reserved.

This document may not be reproduced by means, in whole or in part, without written permission of the

copyright owner.

This document is furnished to support the Mutoh SC-series cutting plotter. In consideration of the furnishing

of the information contained in this document, the party to whom it is given assumes its custody and control

and agrees to the following :

1) The information herein contained is given in confidence, and any part thereof shall not be copied or

reproduced without written consent of Mutoh Europe N.V.

2) This document or the contents herein under no circumstances, shall be used in the manufacture or

reproduction of the article shown and delivery of this document shall not constitute any right or license to

do so.

FCC WARNING

This equipment complies with the requirements for a class A computing device in the FCC rules, part 15,

subpart J.

Operation of this device in a residential area may interfere with television or operating utilities.

Cutters generate weak radio signals and may interfere with television reception and utilities. If the cutter

does interfere with radio or TV reception, try the following :

· Change the direction of your radio and TV reception antenna or feeder.

· Change the direction of the cutter.

· Move either the cutter or the receiving antenna so that there is more distance between them.

· Be sure the cutter and the receiving antenna are on separate power lines.

.

Page 4

4 AP-74030, Rev / B

Page 5

5 AP-74030, Rev / B

TABLE OF CONTENTS

Maintenance Manual................................................................................................1

1. SPECIFICATIONS.................................................................................................9

1.1. Mutoh SC-series Cutting Plotter............................................................................................... 9

1.2. SC cutting plotter, environment.............................................................................................. 10

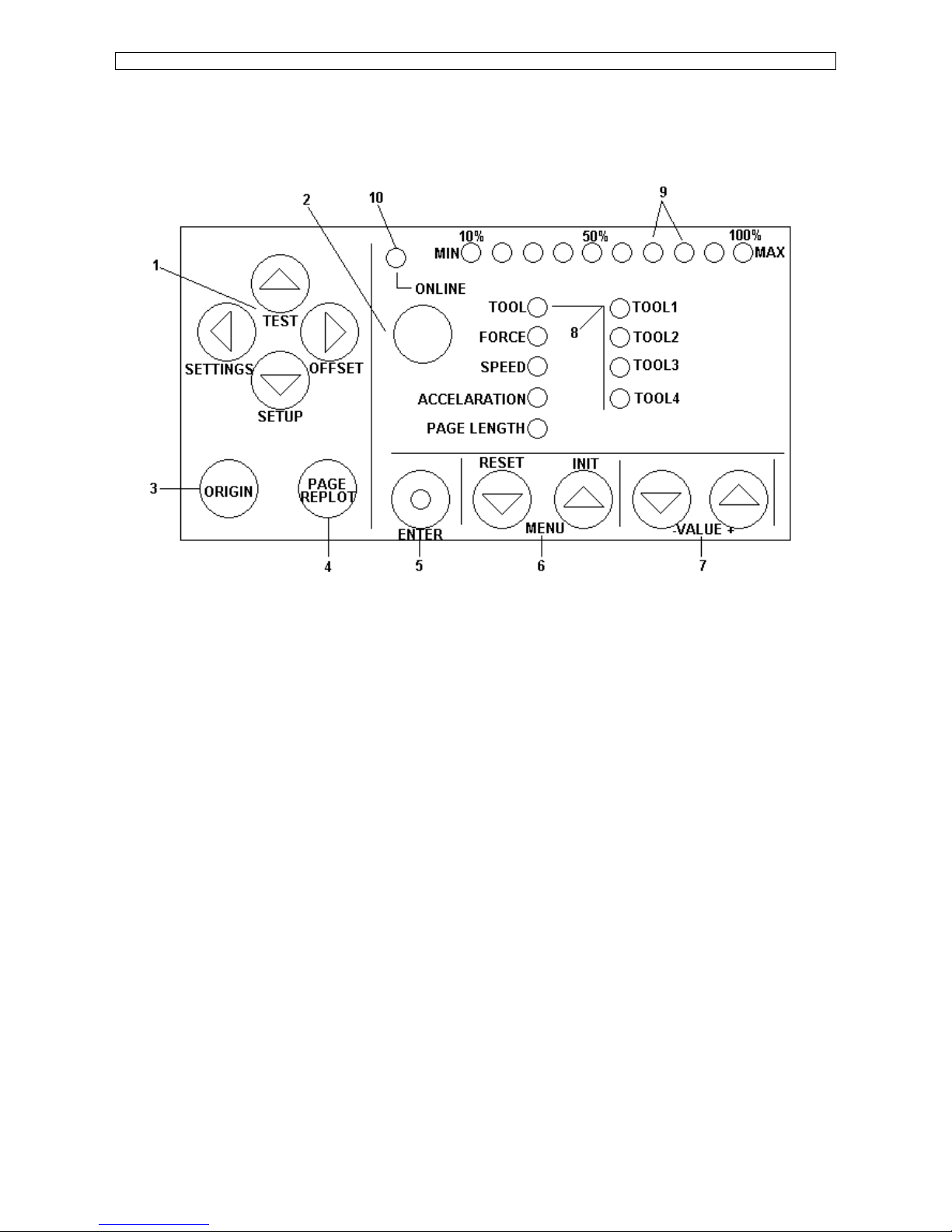

1.3. Function keys. .........................................................................................................................11

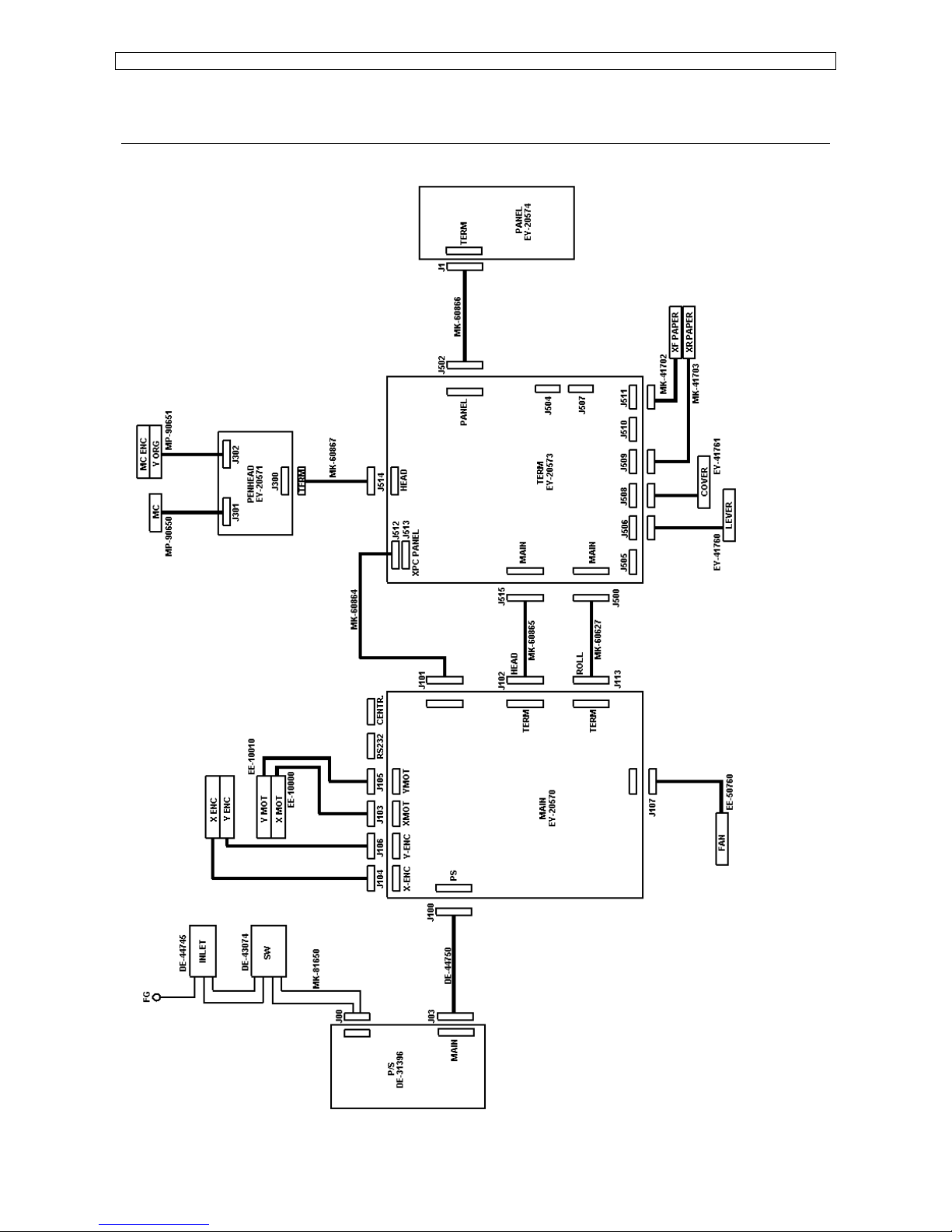

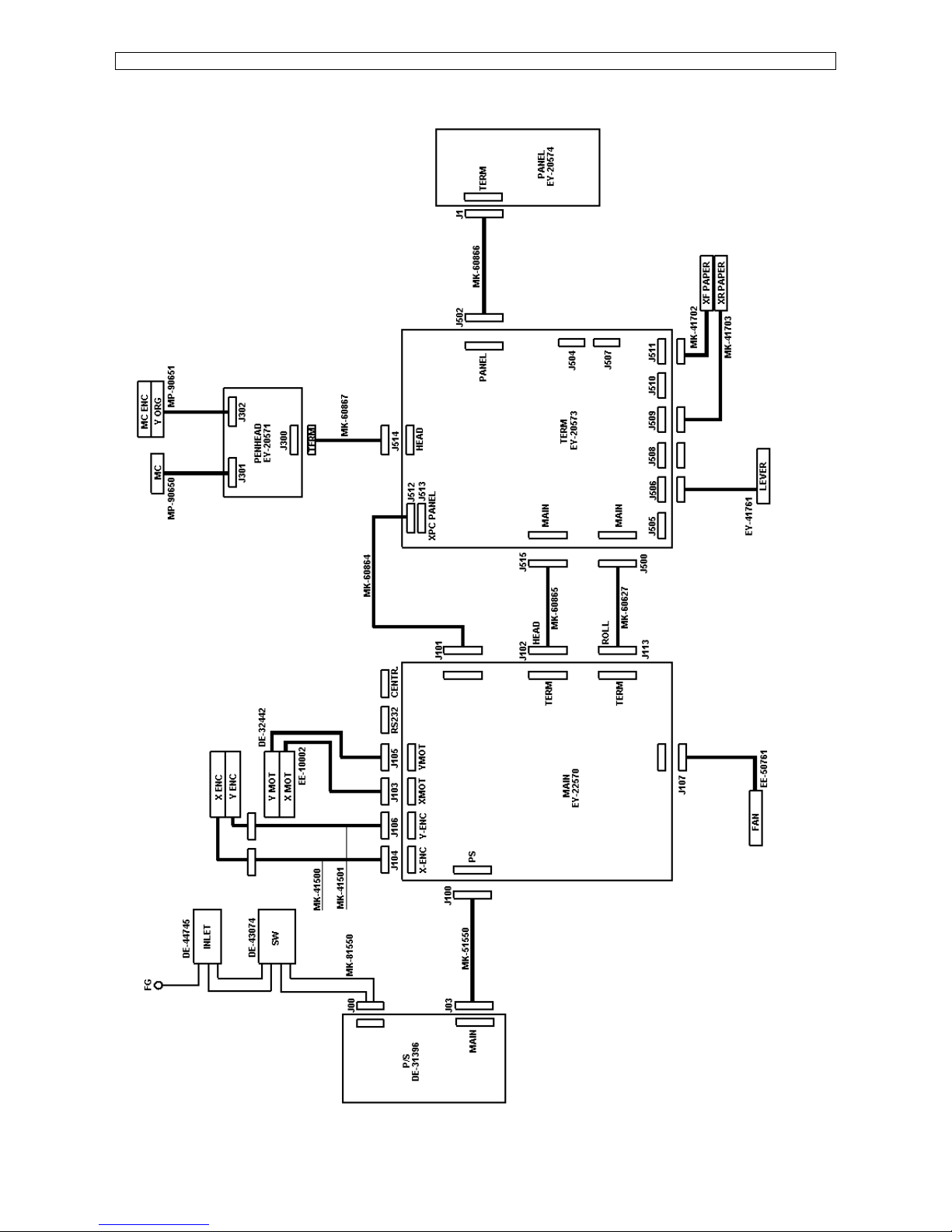

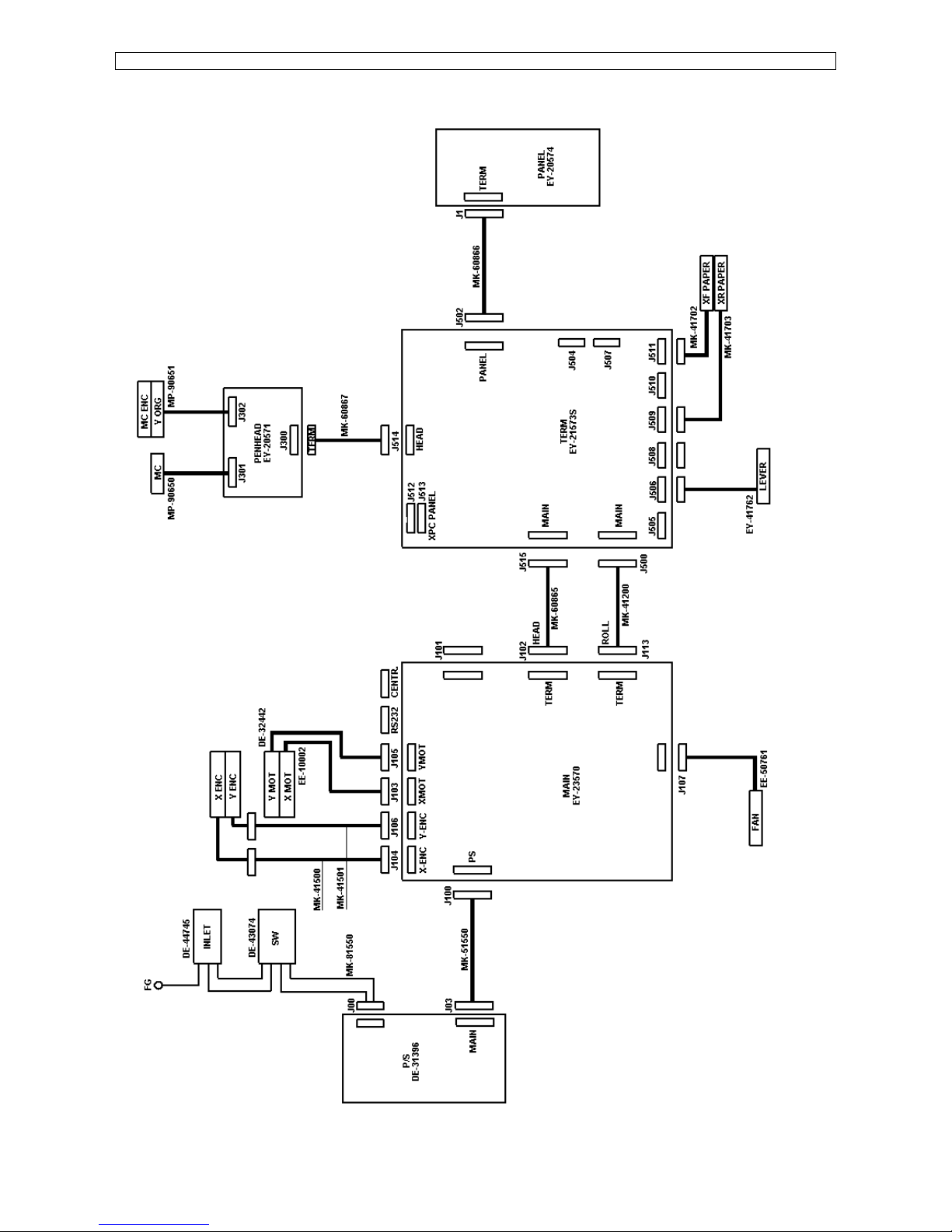

2. SYSTEM BLOCK DIAGRAM. ...............................................................13

2.1. Block diagram SC-series (1st version). ...................................................................................13

2.2. Block diagram SC-series (2nd version)....................................................................................14

2.3. Block diagram SC-550 (1

st

version)........................................................................................15

2.4. Block diagram SC-550 (2

nd

version)....................................................................................... 16

3. INTERFACES............................................................................................................ 17

3.1. Serial interface RS-323C (standard). ......................................................................................17

3.1.1. RS-232C pin configuration. .............................................................................................18

3.1.2. Serial cable configuration. ...............................................................................................18

3.2. Centronics interface (Standard). .............................................................................................19

3.2.1. Centronics interface Pin configuration. ...........................................................................19

4. TROUBLESHOOTING...................................................................................21

4.1. Recoverable errors. .................................................................................................................21

4.1.1. RECOVERABLE SYSTEM ERRORS ...........................................................................21

4.1.2. COMMUNICATION ERRORS ......................................................................................22

4.1.3. LANGUAGE ERRORS...................................................................................................23

4.2. Unrecoverable errors............................................................................................................... 24

4.2.1. Processor errors................................................................................................................24

4.2.2. X – Y Servo errors. ..........................................................................................................24

4.2.3. Cutting head errors...........................................................................................................25

4.2.4. Other errors. .....................................................................................................................25

4.3. Problem symptoms and suggested actions.............................................................................. 26

4.3.1. Processor errors................................................................................................................26

4.3.2. X- Y Servo errors............................................................................................................. 26

4.3.3. Cutting head errors...........................................................................................................27

4.3.4. Other errors. .....................................................................................................................27

5. SPECIALIZED DIAGNOSTICS............................................................29

5.1. Diagnostics overview.............................................................................................................. 29

5.1.1. Diagnostics with SC-keyboard.........................................................................................29

5.1.2. Diagnostics with optional LCD keyboard........................................................................ 30

5.2. Diagnostics with SC-keyboard................................................................................................32

5.2.1. Initialising the EEPROM. ................................................................................................32

5.2.2. Aging................................................................................................................................ 33

5.2.3. Drawings for quality check. .............................................................................................33

5.2.4. Measuring the CUTTING MAT height. ..........................................................................34

Page 6

6 AP-74030, Rev / B

5.2.5. Adjusting the SHEET OFF system. .................................................................................34

5.2.6. Backup plots (on paper only). ..........................................................................................35

5.3. Diagnostics with optional LCD keyboard............................................................................... 36

5.3.1. Diagnost 1. .......................................................................................................................37

5.3.2. Diagnost. 2 .......................................................................................................................38

5.3.3. Diagnost. 3 .......................................................................................................................39

5.3.4. Diagnost. 4 .......................................................................................................................40

5.3.5. Diagnost. 5 .......................................................................................................................40

5.3.6. Diagnost. 6 .......................................................................................................................42

5.3.7. Adjust. 7........................................................................................................................... 42

5.3.8. Adjust. 8........................................................................................................................... 42

5.3.9. Adjust. 9........................................................................................................................... 43

5.3.10. Adjust. 10....................................................................................................................... 46

6. PARTS REPLACEMENT AND ADJUSTMENT................ 47

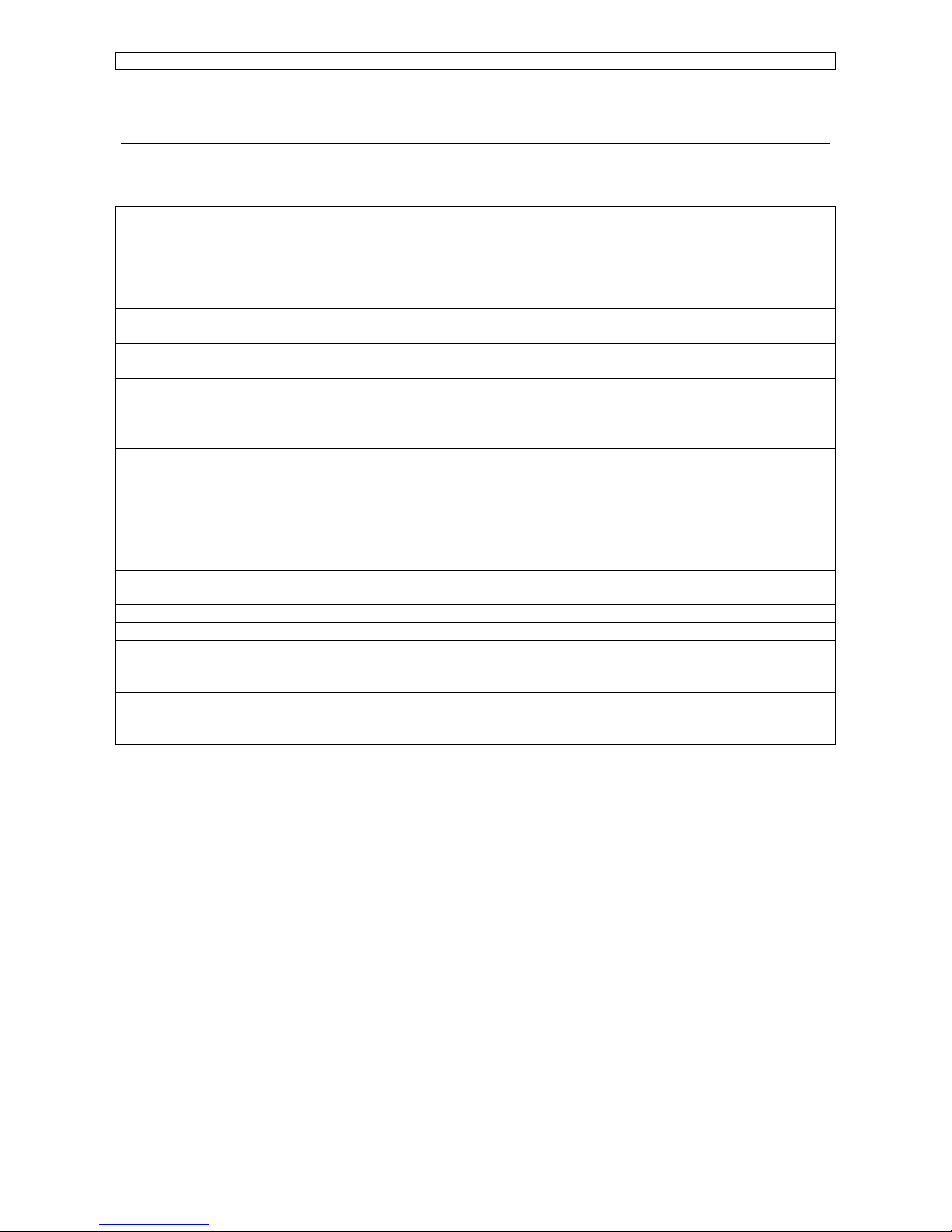

6.1. Maintenance access table for parts replacement. ....................................................................47

6.2. Mechanical parts. ....................................................................................................................48

6.2.1. Covers Left and Right : removal and installation. ...........................................................48

6.2.2. Transparent cover : Removal and installation..................................................................49

6.2.3. PCB box :open and close. ................................................................................................50

6.2.4. Y-rail cover : Removal and installation. ..........................................................................51

6.2.5. Grid cover : Removal and installation. ............................................................................51

6.2.6. Cutting head : Removal and installation.......................................................................... 53

6.2.7. Grid rollers : removal and installation. ............................................................................54

6.2.8. Y-drive belt (long) : removal and installation.................................................................. 55

6.2.9. Pressure roller pressure adjustment.................................................................................. 58

6.2.10. Sheeting off mechanism : mechanical alignment. .........................................................59

6.3. Electronical parts.....................................................................................................................60

6.3.1. Main PC board : Removal and installation. .....................................................................60

6.3.2. Main and terminal PCB SC-550 : Removal and installation. ..........................................61

6.3.3. Dip switch settings on Main PC board.............................................................................62

6.3.4. EEPROM initialisation and replacement. ........................................................................63

6.3.5. Power supply board : removal and installation................................................................ 64

6.3.6. Power supply board SC-550 : removal and installation................................................... 65

6.3.7. Power supply output connections. ...................................................................................65

6.3.8. Terminal Board : removal and installation. .....................................................................66

6.3.9. Keyboard : removal and installation. ...............................................................................67

6.3.10. X-motor and drive belt : removal and installation. ........................................................68

6.3.11. Y-motor and drive belt : removal and installation. ........................................................68

6.3.12. Head flex cable : removal and installation.....................................................................69

6.3.13. Paper sensors : removal and installation. ....................................................................... 70

6.3.14 Transparent cover sensor : removal and installation.......................................................70

6.3.15. Pressure roller UP/DOWN sensor : removal and installation........................................ 71

6.3.16. Pressure roller UP/DOWN sensor SC-550 : removal and installation........................... 71

6.3.17. Fan motors : removal and installation............................................................................72

7. JIG TOOL LIST.......................................................................................................73

7.1. Jig tool list...............................................................................................................................73

7.2. Special glue. ............................................................................................................................ 73

Page 7

7 AP-74030, Rev / B

8. PARTS LISTS SC-SERIES.......................................................................... 75

8.1. Body and Covers.....................................................................................................................75

8.2. Cover right + keyboard assy. ..................................................................................................77

8.3. Cover left assy......................................................................................................................... 78

8.4. Transparent cover assy............................................................................................................79

8.5. PCB box. .................................................................................................................................80

8.6. Head flex cable assy................................................................................................................ 81

8.7. Pressure roller UP/DOWN mechanism................................................................................... 82

8.8. X-motor assy. .......................................................................................................................... 84

8.9. X-rail assy. ..............................................................................................................................85

8.10. Y-motor assy. ........................................................................................................................ 87

8.11. Y-rail assy. ............................................................................................................................88

8.12. Y-axis drive belt assy............................................................................................................ 89

8.13. Y-drive pulley assy + mounting bracket. .............................................................................. 90

8.14. Y-axis return pulley assy....................................................................................................... 91

8.15. Pressure roller assy................................................................................................................92

8.16. Cutting head assy. .................................................................................................................94

8.17. Sideplate left (ME-20599). ...................................................................................................99

8.18. Sideplate right (ME-20600). ...............................................................................................100

9. PARTS LISTS SC-550.................................................................................... 101

9.1. Body and covers SC-550.......................................................................................................101

9.2. Cover right + keyboard assy SC-550. ...................................................................................102

9.3. Cover left assy SC-550. ........................................................................................................103

9.4. PCB box left and right SC-550. ............................................................................................104

9.5. Penhead flex cable assy SC-550. ..........................................................................................106

9.6. X-motor Assy SC-550........................................................................................................... 107

9.7. X-rail assy SC-550. ............................................................................................................... 108

9.8. Y-MOTOR Assy SC-550......................................................................................................109

9.9. Y-axis drive belt assy SC-550............................................................................................... 110

9.10. Y-drive pulley assy + mounting bracket SC-550................................................................ 111

9.11. Y-axis return pulley assy SC-550. ......................................................................................112

9.12. Y-rail assy SC-550. ............................................................................................................. 113

9.13. Pressure roller UP/DOWN mechanism SC-550. ................................................................114

9.14. Pressure roller assy SC-550. ...............................................................................................115

9.15. Cutting head assy SC-550. .................................................................................................. 117

Page 8

8 AP-74030, Rev / B

Page 9

Maintenance Manual – SC Cutting Plotter

9 AP-74030, Rev / B

1. SPECIFICATIONS.

1.1. Mutoh SC-series Cutting Plotter

Cutting area SC-550 : 100 – 540 mm x 4 m

SC-650 : 100 – 630 mm x 12 m

SC-750 : 100 – 780 mm x 12 m

SC-1000 : 100 – 1030 mm x 12 m

SC-1300 : 100 – 1200 mm x 12 m

Max. addressable cut length 50 meter

Maximum media thickness 1.2 mm (1 mm for SC-550)

Drive mechanism Friction

Knife / Cut type / principle Drag

Mechanical resolution 0.005 mm

Accuracy 0.15 % (0.20 % for SC-550)

Repeatability 0.15 mm / m

Knife types 30°, 45° 60° Offset 0.3 & 0.5 mm

Speed 1000 mm / s (600 mm / s for SC-550)

Acceleration 4G (pen UP), 3G (pen DOWN)

2G for SC-550

PEN UP / DOWN cycles 40 / sec.

Pressure range 20 – 500 g

Interface (standard) RS – 232 / centronics

Input buffer 1 Mb standard / 4 Mb optional

No optional buffer on SC-550

Graphic languages MHGL, MHGL/2, HGL/2 compatible

& MCGL (Calcomp compatible)

Configurable origin Yes

Offset adjustment range

0 ® 1 mm

Integrated intelligence Fuzzy logic / Vector look-ahead / Curve & Arc

smoothing

Auto sheet off function Yes (not on SC-550)

Replot function Up to 100 copies

Power requirements 100 to 120 VAC 50/60 Hz

200 to 240 VAC 50/60 HZ

Page 10

Maintenance Manual – SC Cutting Plotter

10 AP-74030, Rev / B

1.2. SC cutting plotter, environment.

The location where you set up your equipment is very important. Please see to it that it meets following

conditions :

q Power supply of 100 to 120 VAC 50/60 Hz or 200 to 240 VAC 50/60 Hz.

q Ambient conditions :

o Operating environment

§ Temperature : 5°C to 40°C (41°F to 104°F)

§ Humidity : 35% - 75% non-condensation

o Recommended environment

§ Temperature : room temperature 16°C to 32°C (61°F to 90°F)

§ Humidity : 50% to 65% non-condensation

o Variation rate

§ Temperature : 2°C per hour

§ Humidity : 5% per hour

o Storage environment

§ Temperature : 0°C to 50°C (32°F to 122°F)

q Please protect your cutter from moisture, dust, draughts and direct sunlight. It is best to keep

your machine away from open windows and air-conditioners.

q See to it that there is an adequate space around the cutter so that ventilation is not obstructed.

q Avoid unnecessary vibrations and set up your cutter on a level surface.

q When selecting a place for your cutter, leave at least 90 cm in front and 90 cm at the rear.

Page 11

Maintenance Manual – SC Cutting Plotter

11 AP-74030, Rev / B

1.3. Function keys.

Using the control panel, you can access different modes and alter several settings, in order to fine-tune the

cutter to match all your needs.

1)

JOG – keys

: Keys for manual movement of the tool head.

2)

ON-LINE

: Key to switch between OFF-LINE and ON-LINE mode.

3)

ORIGIN

: When this key is pressed, a new origin is set at the present location of

the tool head. Using the ORIGIN key, you can also activate the

alignment function.

4)

PAGE

: Performs media pre-feed cycle and gives access to the replot / copy

function and starts the automatic sheet-off function.

5)

ENTER

: To confirm changes and accept settings. The enter key, marked with a

blue dot, also gives access to special functions indicated by the blue text

on the control panel.

6)

MENU Selection Keys

: To select the parameter you want to alter.

7)

Value + & - Keys

: To change a parameter’s value or setting.

8)

LED indicator for plotter parameters and tool selection indication.

9)

LED bar for value indicators, error messages and function confirmation.

10)

ONLINE-LED indicator

Page 12

Maintenance Manual – SC Cutting Plotter

12 AP-74030, Rev / B

Page 13

Maintenance Manual – SC Cutting Plotter

13 AP-74030, Rev / B

2. SYSTEM BLOCK DIAGRAM.

2.1. Block diagram SC-series (1st version).

Page 14

Maintenance Manual – SC Cutting Plotter

14 AP-74030, Rev / B

2.2. Block diagram SC-series (2nd version).

Page 15

Maintenance Manual – SC Cutting Plotter

15 AP-74030, Rev / B

2.3. Block diagram SC-550 (1st version).

Page 16

Maintenance Manual – SC Cutting Plotter

16 AP-74030, Rev / B

2.4. Block diagram SC-550 (2nd version).

Page 17

Maintenance Manual – SC Cutting Plotter

17 AP-74030, Rev / B

3. INTERFACES.

3.1. Serial interface RS-323C (standard).

1) Baud rate (software selectable).

- 19200 bps

- 9600 bps

- 4800 bps

- 2400 bps

- 1200 bps

2) Data length (software selectable).

- 7 bits

- 8 bits

3) Stop bits (software selectable).

- 1 bit

- 2 bits

4) Parity (software selectable).

- Odd

- Even

- None

5) Error detection.

- Parity error

- Framing error

- Overrun error

6) External connector.

- DB-25S (equivalent)

7) RS-232C driver / receiver IC.

- driver : 75188 (TI, ± 12V power supply)

- receiver : 75189A

Page 18

Maintenance Manual – SC Cutting Plotter

18 AP-74030, Rev / B

3.1.1. RS-232C pin configuration.

PIN #

SIGNAL Abbr. Signal direction

1 Frame ground FG 2 Transmit data TXD OUT

3 Receive date RXD IN

4 Request to send RTS OUT

5 Clear to send CTS IN

6 Data set ready DSR IN

7 Signal ground SG 8 Carrier detect CD IN

9 ® 14

Not used

15 Transmitter signal

Element timing

ST IN

16 Not used

17 Receiver signal

Element timing

RT IN

18 Data terminal ready DTR OUT

19 Not used

20 Data terminal ready DTR OUT

21 ® 25

Not used

3.1.2. Serial cable configuration.

1) 9 pins ® 25 pins connector.

2) 25 pins ® 25 pins connector.

Page 19

Maintenance Manual – SC Cutting Plotter

19 AP-74030, Rev / B

3.2. Centronics interface (Standard).

- Uni-directional (Receiving only)

- Data length : 8 bit parallel

- Signal level : TTL

- Transmission distance : maximum 5 meters

3.2.1. Centronics interface Pin configuration.

PIN #

SIGNAL SIGNAL Signal direction

1 Strobe (*) Strobe input In

2 ® 9 DATA 1 ® 8

Parallel Data input In

10 ACK (*) Acknowledge Output Out

11 BUSY Busy Out

12 PAPER END Paper end Out

13 SELECTED Selected Out

16 SG Signal ground 17 FG Frame ground 18 HIGH High level Out

19 ® 30

SG Signal ground 31 - Not used 32 FAULT Error Out

33 SG Signal ground -

NOTE : - Other pins are put in NC (no contact) status.

- Asterix (*) indicates negative logic.

Page 20

Maintenance Manual – SC Cutting Plotter

20 AP-74030, Rev / B

Page 21

Maintenance Manual – SC Cutting Plotter

21 AP-74030, Rev / B

4. TROUBLESHOOTING.

When errors occurring during cutting or after powering on the machine, some LED code may appear on the

LED bar to inform you about the kind of error.

In general 2 different types of error messages may occur :

4.1. Recoverable errors.

Recoverable errors can be recognized by some flashing LED’s on the LED bar. Sometimes the machine

continue to work while LED’s are flashing. Sometimes it stops but continue again after correction of the

error.

Recoverable errors are mostly related to communication problems or user mistakes.

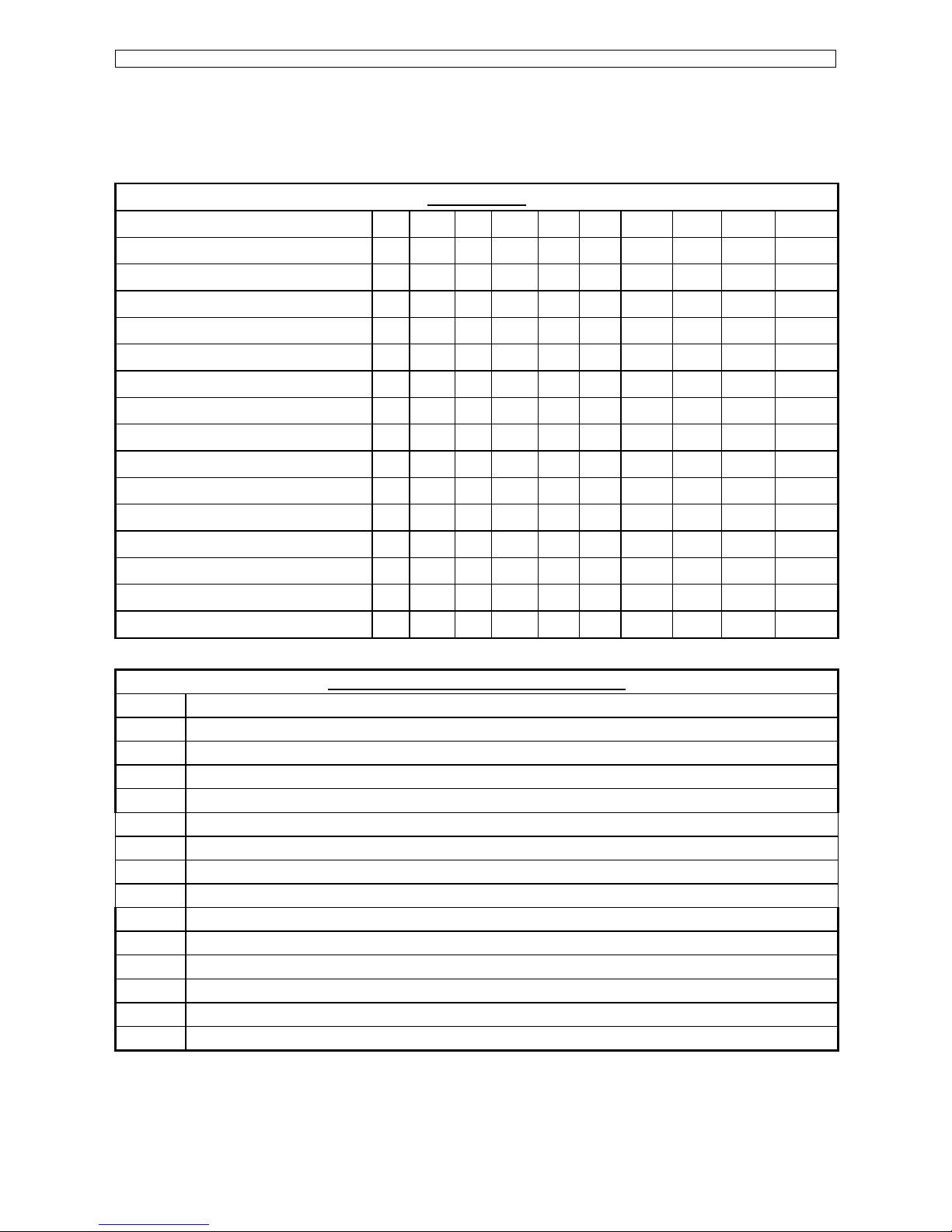

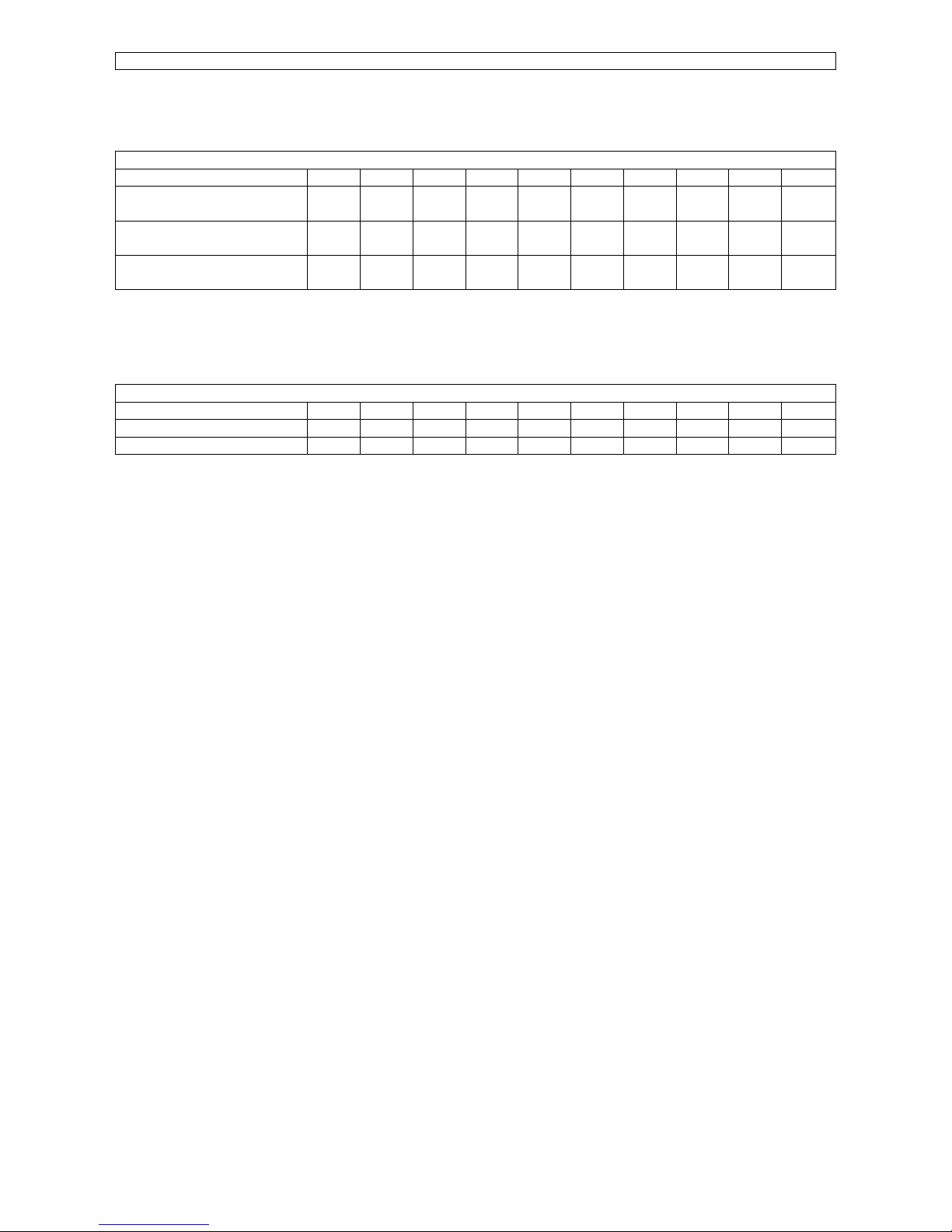

4.1.1. RECOVERABLE SYSTEM ERRORS

ERROR CODE

10% 20% 30% 40% 50% 60% 70% 80% 90% 100%

IMPOSSIBLE AUTOON-LINE RECOG (S02)

G. LANGUAGE NOT

CORRESPONDING (S03)

MEDIA DETECT ERROR (S05)

ROLL MEDIA END (S06)

CANNOT AUTO-CONNECT (S07)

AUTO CUT ERROR (S08)

CHANGE MEDIA (S28)

KANJI ROM SUM ERROR (S29)

POSSIBLE CAUSE & SUGGESTED ACTION

S02 Communication difficulties – Check cables.

S03 Select other graphics language. (Chapter 3 - Language Settings )

S05 Media detection impossible.

Too much or too little light, incorrect pressure roll position.

S06 Load a new sheet or roll.

S07 Communication difficulties – Check cables.

S08 Error during auto-sheet-off sequence.

Check media and auto-cut knife.

S28 Change or reload media.

Page 22

Maintenance Manual – SC Cutting Plotter

22 AP-74030, Rev / B

4.1.2. COMMUNICATION ERRORS

Communication errors are caused by a problem in the communication between the cutter and the host

computer. They can be caused by errors related to the communication conditions, errors due to a defective

handshake or command format errors in the ESCAPE sequences.

ERROR CODE

10% 20% 30% 40% 50% 60% 70% 80% 90% 100%

ERROR ON-LINE FRAME (C01)

ERROR ON-LINE OVERRUN (C02)

ERROR ON-LINE PARITY (C03)

ERROR BIAS VALUE (C04)

ERROR SUM CHECK (C05)

ERROR DATA BLOCK (C06)

FEW PARAMETER ESC (C07)

FEW PARAMETER ESC (C08)

COMMUNICATION BUSY (C09)

UNDEFINED ESC (C10)

ILLEGAL ESC (C11)

ERROR VALUE ESC (C12)

MANY PARAMETERS ESC (C13)

COMMUNICATION ERROR (C14)

BUFFER OVERFLOW (C15)

POSSIBLE CAUSE & SUGGESTED ACTION

C01 A framing error occurred. Check the communication settings. Chapter 3.

C02 Overrun error. Check the communication settings. Chapter 3.

C03 Parity error. Check the communication settings. Chapter 3.

C04 Bias is less than EOB code. Check the communication settings. Chapter 3.

C05 Check-sum difference cutter vs. host. Check the communication settings. Chapter 3.

C06 Data between bias and EOB too large. Check the communication settings. Chapter 3.

C07 Not enough ESC-parameters. Check the communication settings. Chapter 3.

C08 Not enough ESC-parameters. Check the communication settings. Chapter 3.

C09 Change the computer program to prevent the cutter from returning double data.

C10 Undefined ESCAPE sequence. Check the ESCAPE command setup.

C11 Illegal character used for MH-GL ESC-sequence. Check the ESCAPE command setup.

C12 Illegal character in ESC-sequence parameter. Check the ESCAPE command setup.

C13 Too many ESC-sequence parameters. Check the ESCAPE command setup.

C14 Communication error. Restart the cutter.

C15 Buffer overflow. Restart the cutter.

Page 23

Maintenance Manual – SC Cutting Plotter

23 AP-74030, Rev / B

4.1.3. LANGUAGE ERRORS

Language errors occur when command data entered from the host computer does not match the data

format of the command mode currently activated on the cutter’s side. The error can be caused by a

difference in command type or by a syntax error.

ERROR CODE

10% 20% 30% 40% 50% 60% 70% 80% 90% 100%

UNDEFINED XX (E01)

ERROR PARAMETER (E02)

ERROR VALUE (E03)

UNKNOWN CHAR (E05)

BUFFER OVERFLOW (E07)

POSSIBLE CAUSE & SUGGESTED ACTION

E01 Undefined MH-GL command. Verify computer and cutter language settings.

E02 Incorrect number of parameters was transmitted.

E03 Parameter out of range was transmitted. Verify computer and cutter language settings.

E05 Character unknown to MH-GL was sent. Verify computer and cutter language settings.

E07 Polygon and character buffer overflow. Verify computer and cutter language settings.

Page 24

Maintenance Manual – SC Cutting Plotter

24 AP-74030, Rev / B

4.2. Unrecoverable errors.

Unrecoverable errors can be recognized when all LED’s are flashing and the machine has stopped working.

After pressing the [ENTER] key VERY SHORT (just touch it ones) the error code appears on the LED bar

(NOT flashing).

To clear the error message, the machine needs to be powered OFF and ON again. (Wait ± 7 seconds

between power OFF/ON).

Refer to the following chart for error code explanation :

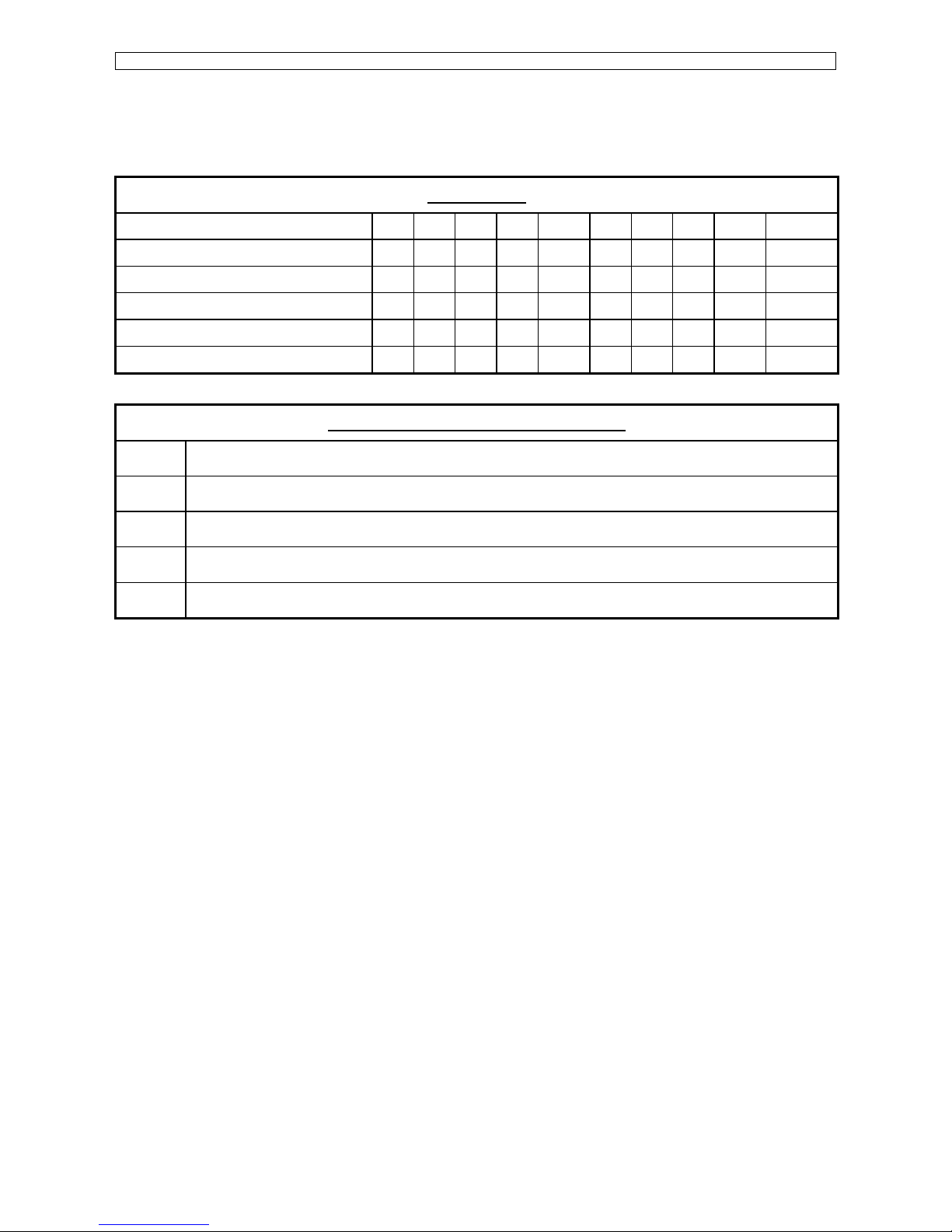

4.2.1. Processor errors.

ERROR CODE

10% 20% 30% 40% 50% 60% 70% 80% 90% 100%

Error Code 0 X

Watch dog time out X

Bus trap error X X

Address trap error X

Illegal instruction

(MC68020)

X X

Zero divide X X

General processor failure X X X

EPROM check-sum error X

Interrupt failure X X

1010 CPU failure X X X

1111 CPU failure X X X X

DRAM error X X X

SRAM error X X

Extended RAM error X X X X

EEPROM error X X X

EEPROM error X X

4.2.2. X – Y Servo errors.

ERROR CODE

10% 20% 30% 40% 50% 60% 70% 80% 90% 100%

OUT of SYNC X X X X

OUT of SYNC Y X X X

X POSITION timeout X X X X

Y POSITION timeout X

X Over current X X

Y Over current X X

X Encoder fail X X X

Y Encoder fail X X

X Overload X X X X

Y Overload X X X X X

Driver failure X X X X

Encoder failure X X X X X

Page 25

Maintenance Manual – SC Cutting Plotter

25 AP-74030, Rev / B

4.2.3. Cutting head errors.

ERROR CODE

10% 20% 30% 40% 50% 60% 70% 80% 90% 100%

POSITION

Timeout MC

X X X

OVER CURRENT

Moving Coil

X X X X

A/D failure

Moving Coil

X X X X

4.2.4. Other errors.

ERROR CODE

10% 20% 30% 40% 50% 60% 70% 80% 90% 100%

ILLEGAL Mainboard rev. X X X X X

ILLEGAL Mainboard TYPE X X X

Page 26

Maintenance Manual – SC Cutting Plotter

26 AP-74030, Rev / B

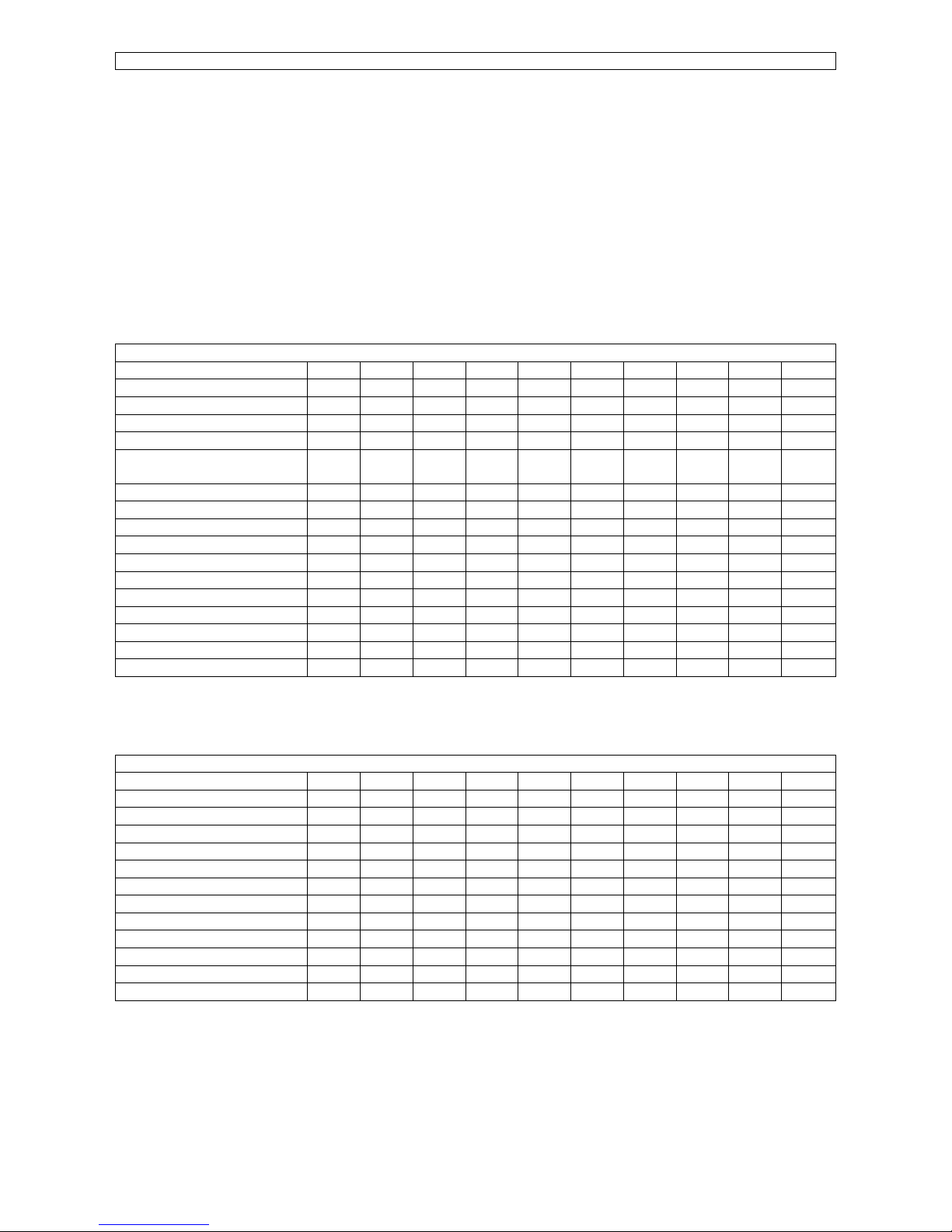

4.3. Problem symptoms and suggested actions.

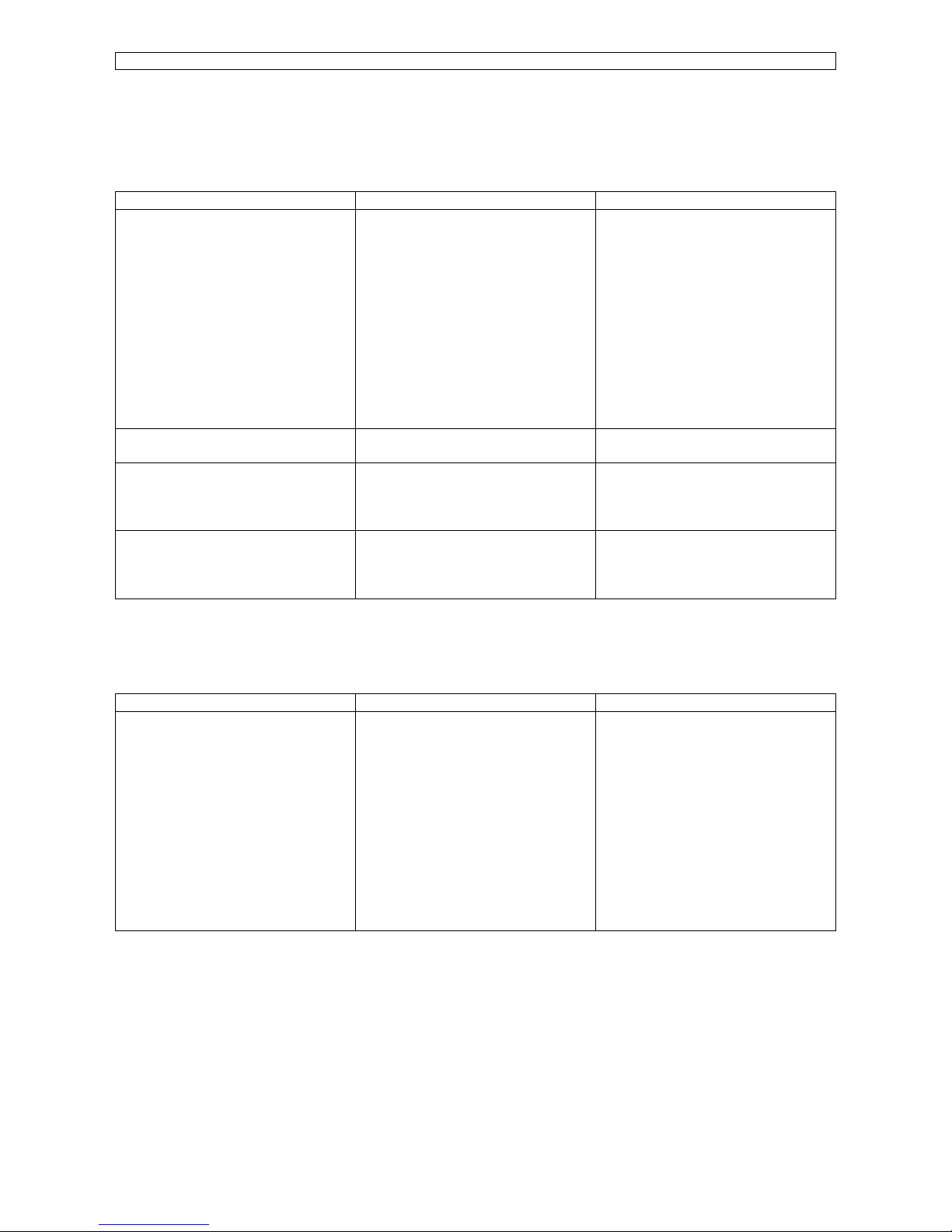

4.3.1. Processor errors.

PROBLEM SYMPTOM POSSIBLE CAUSE SUGGESTED ACTIONS

- Error code 0

- Watch dog timeout

- Bus trap error

- Address trap error

- Illegal instruction (MC68020)

- Zero divide

- General processor failure

- Interrupt failure

- 1010 CPU failure

- 1111 CPU failure

- DRAM error

- SRAM error

- Poor connection between

main and terminal board.

- Bad EPROM’s

- Bad EEPROM

- Mainboard failure

- Check cable and connection

- Check pins and position of

EPROM and EEPROM.

Reinstall EPROM and

EEPROM.

- Replace Mainboard

- EPROM checksum error

- EPROM data is changed

- Replace EPROM set

- EEPROM error

- EEPROM data is changed

- Perform INIT 1

- Perform INIT 2

- Replace EEPROM

-

- Extended RAM error

- Poor extended RAM

connection

- Bad extended RAM

-

- Check connection

- Replace extended RAM

4.3.2. X- Y Servo errors.

PROBLEM SYMPTOM POSSIBLE CAUSE SUGGESTED ACTIONS

- OUT of SYNC X

- OUT of SYNC Y

- X position Timeout

- Y position Timeout

- X over current

- Y over current

- X overload

- Y overload

- X Encoder fail

- Y Encoder fail

- Encoder failure

- Driver failure

- Defective motor / encoder

- Loose drive pulley

- Failure in drive circuit

- Poor connection of motor/

encoder

- Too much friction in X or Y

axis

- Replace motor / encoder

- Fix pulley or replace motor /

encoder

- Replace main PC board

- Check cables and

connections

- Check X and Y movement

Page 27

Maintenance Manual – SC Cutting Plotter

27 AP-74030, Rev / B

4.3.3. Cutting head errors.

PROBLEM SYMPTOM POSSIBLE CAUSE SUGGESTED ACTIONS

- Position Timeout Moving Coil

(MC)

- OVER CURRENT Moving Coil

(MC)

- A/D failure Moving Coil (MC)

- Nose piece of knife holder

(XPC model) not fixed

- Blade is too far out

- Sheet off mechanism blocks

UP/DOWN movement (Not on

SC-550)

- Head flex cable bad or poor

connection

- Bad cutting head

- Failure in drive circuit

-

- Check knife holder

- Check blade depth

- Check sheet off mechanism

(Not in SC-550)

- Check connections or replace

head flex cable

- Replace cutting head

- Replace main PC board

4.3.4. Other errors.

PROBLEM SYMPTOM POSSIBLE CAUSE SUGGESTED ACTIONS

System is dead :

- No movement

- No LED’s lighted

- Power failure

- Defective Power supply (P/S)

- Defective Mainboard

- Check power cord

- Check wall outlet

- Check fuse on P/S

- Check LEDs on P/S

- Replace P/S

- Replace mainboard

Some LED’s lighted but no

movement of the motors and

cutting head.

- Defective EPROM’s

- Defective EEPROM

- Defective mainboard

- Poor connection between

main and terminal board

- Replace EPROM’s

- Replace EEPROM

- Replace mainboard

- Check cable connections

- Plotter powers on, head

UP/DOWN initialises but no

movement of motors.

- Transparent cover is not

closed

- Transparent cover switch

defective

- Close the cover

- Check or replace cover switch

Plotter does not shuffle media. - Pressure roller lever is not

DOWN

- Bad lever sensor

- Both media sensors are not

covered

- Media sensors dusty or bad

- Lower the lever

- Check the lever sensor

- Load media properly

- Clean or replace media

sensors

Illegal mainboard revision (LED

code on LED bar)

- Mainboard version is not

compatible

- Use correct mainboard

Wrong mainboard (LED code on

LED bar)

- Mainboard from SC-550 is

used in SC-series or vice

versa

- Use correct mainboard

Page 28

Maintenance Manual – SC Cutting Plotter

28 AP-74030, Rev / B

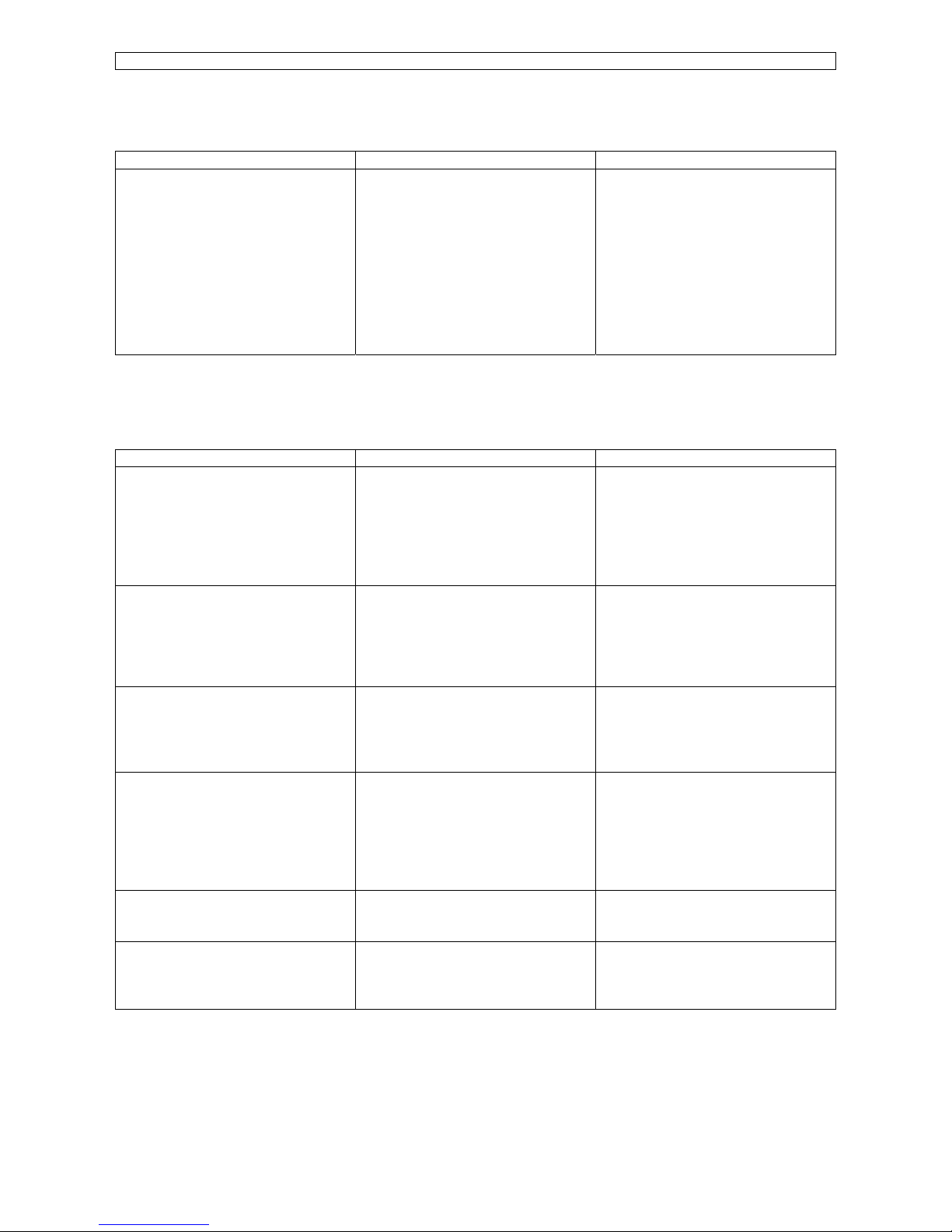

PROBLEM SYMPTOM POSSIBLE CAUSE SUGGESTED ACTIONS

Plotter has shuffled media but

does not respond to data

- Plotter is OFF-line

- Interface cable not connected

or bad

- Wrong plotter driver

- Wrong interface parameters

- Bad interface port

- Put plotter in ON-line

- Check interface cable

- Check plotter driver

- Check interface parameters

- Check port or replace main

PC board

Plotter is responding to data, but

error messages appear on the

LED bar (See User’s guide)

- Wrong interface parameters

- Wrong cable configuration

- Check interface parameters

(See User’s Guide)

- Check interface cable

Plotter is cutting but quality is not

acceptable

- Blade worn or broken

- Blade is not turning smooth

- Offset is not correct

- Blade is too far out

- Cutting force is too high

- Cutting mat worn

- Wrong plotter driver

- Play on cutting head

- Drive belt tension not correct

- X or Y motor defective

- Replace blade

- Check or replace knife holder

- Perform offset procedure (See

User’s Guide)

- Adjust knife depth

- Reduce cutting force

- Replace cutting mat

- Select correct plotter driver

- Check or replace cutting head

- Check or adjust belt tensions

- Replace X or Y motor

Media tracking problems

Media skews during cutting or

loading..

- Media is not loaded straight in

the machine

- Grid rollers dirty

- Grid rollers or pressure rollers

worn

- Speed or acceleration too

high

- Pressure roller pressure not

correct

- Media backing is very slippery

(Teflon based)

- Load media as described in

the User’s Guide

- Clean grid rollers

- Replace grid rollers or

pressure rollers

- Decrease

o Cutting speed

o Pen/UP speed

o Cutting acceleration

o Pen/UP acceleration

- Adjust pressure roller

pressure

- Change media type or

decrease speed acceleration

Page 29

Maintenance Manual – SC Cutting Plotter

29 AP-74030, Rev / B

5. SPECIALIZED DIAGNOSTICS.

5.1. Diagnostics overview.

Two different types of specialized diagnostics are available on the SC-series cutting plotter :

Þ Diagnostics with normal SC-keyboard

Þ Diagnostics with optional keyboard with LCD display. (Keyboard from XP-C cutting

plotter).

The most important adjustments can be performed with the standard SC-series keyboard. However to take

advantage of all the features of the complete diagnostics menu, an optional XP-C keyboard (Partnumber EY6200-50010) is required.

Caution :

The specialized diagnostics built into the SC-series cutting plotters are designed only for

maintenance purposes and may only be used by authorized MUTOH technicians.

Entering the Diagnostics Menu’s by non qualified people may result in damage of the

machine.

5.1.1. Diagnostics with SC-keyboard.

The following diagnostics are available with normal SC-keyboard :

q Initialising EEPROM

Ø INIT 1

Ø INIT 2

q Aging

Ø X axis

Ø Y axis

Ø X & Y axes simultaneously

q Drawing for Quality check

q Measuring the CUTTING MAT height

q Adjusting the SHEET OFF system (Not on SC-550)

q Backup plot User parameters

q Backup plot Adjustment values

Page 30

Maintenance Manual – SC Cutting Plotter

30 AP-74030, Rev / B

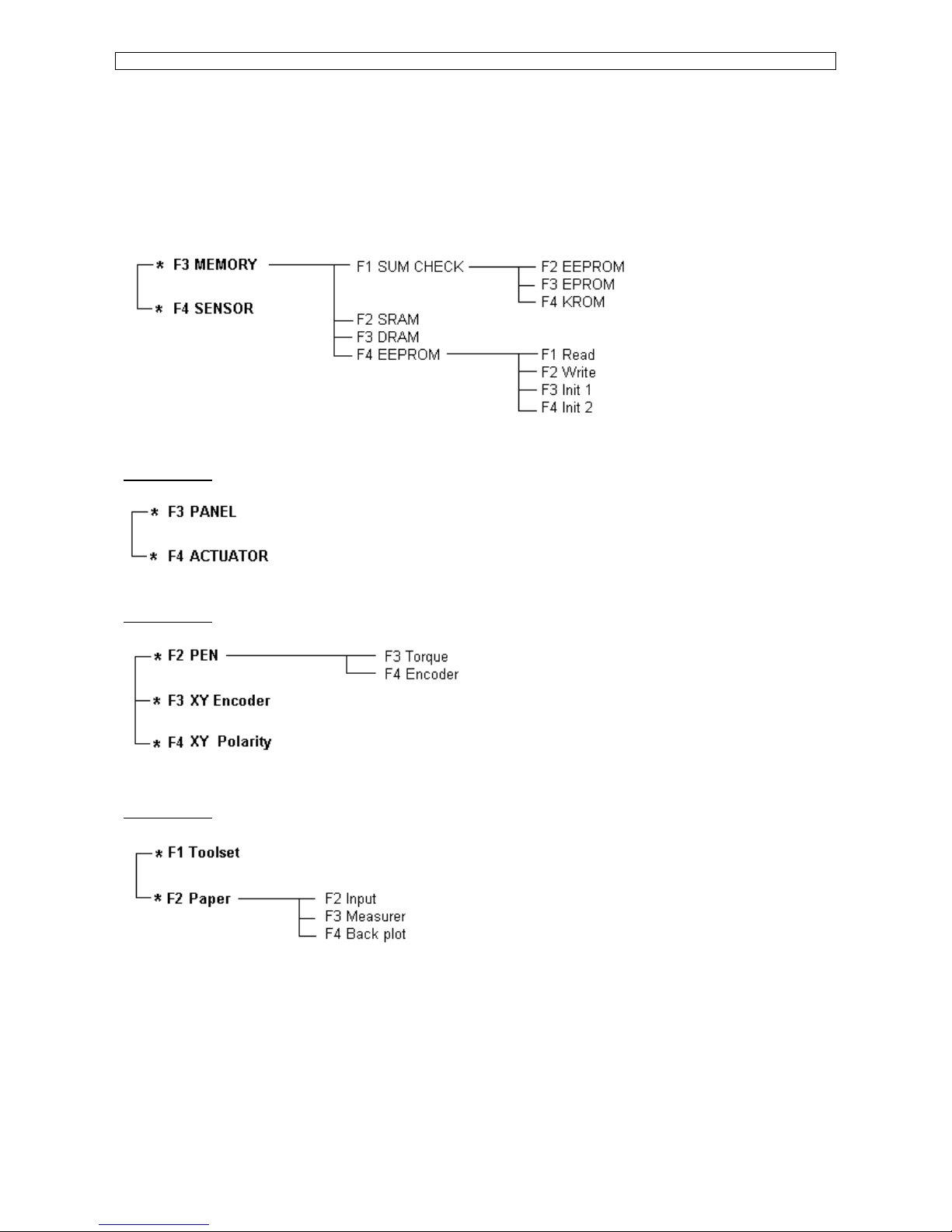

5.1.2. Diagnostics with optional LCD keyboard.

By using the optional keyboard with LCD, you can access all the existing diagnostics. Ten diagnostics

pages as follows :

DIAGNOST 1

DIAGNOST 2

DIAGNOST 3

DIAGNOST 4

Page 31

Maintenance Manual – SC Cutting Plotter

31 AP-74030, Rev / B

DIAGNOST 5

DIAGNOST 6

Reserved for future use.

ADJUST 7

Reserved for future use.

ADJUST 8

ADJUST 9

ADJUST 10

Page 32

Maintenance Manual – SC Cutting Plotter

32 AP-74030, Rev / B

5.2. Diagnostics with SC-keyboard.

While pressing and holding the [MENU ], [VALUE ¯] and [VALUE ] keys simultaneously, turn the machine

on.

Now all LED’s, except the ONLINE MLED, are on.

If you have pressed a wrong key, or other LED’s are on or off, switch off the machine and try again.

5.2.1. Initialising the EEPROM.

Caution :

Before initialising the EEPROM, perform the

· Backup plot with user parameters

· Backup plot with adjustment parameters

(Please refer to 5.2.6.Backup plots (on paper only))

This will give you a hard copy with all the current settings and adjustment values.

1) INIT 1 :

Caution :

INIT 1 initialises the USER PARAMETERS back to DEFAULT VALUES.

Step 1 : Power on the unit in diagnostics mode.

Step 2 : Press :

· ORIGIN until 10 % LED is on.

· [VALUE ¯], [VALUE ], [VALUE ¯], [VALUE ]

Step 3 : Power OFF.

2) INIT 2 :

Caution :

INIT 2 initialises all adjustment values back to DEFAULT VALUES.

After INIT 2 the unit needs to be RECALIBRATED, and this requires a LCD

keyboard and can only be performed by MUTOH qualified people.

NEVER start this procedure unless you are sure it is really necessary and you

have the tools to recalibrate the unit.

Step 4 : Power on the unit in diagnostics mode.

Step 5 : Press :

· ORIGIN until 10 % LED is on.

· [VALUE ¯], [VALUE ], [VALUE], [VALUE ¯]

Step 6 : Power OFF.

Page 33

Maintenance Manual – SC Cutting Plotter

33 AP-74030, Rev / B

5.2.2. Aging.

This test makes the plotter continuously moving in the X-/Y- axis.

This test can be performed without media or with media loaded.

Step 1 : Power on the plotter in diagnostics mode.

Step 2 : Press the [ORIGIN] key until 50 % LED is on.

Step 3 : Press the [VALUE ¯] key. (Unit starts initialising, wait until finished)

Step 4 : Press [MENU ] key.

Step 5 : The [NEXT/+] or [LAST/-] key keys will determine what axis is to be aging.

· [MENU ] will continuous move the X and Y axis.

· [VALUE ¯] will continuous move the X axis only.

· VALUE ] will continuous move the Y axis only.

Note :

Press the [VALUE ¯] key to start / pause aging.

Press the [VALUE ] key to end aging and select another axis to be aged if

desired.

Step 6 : Power OFF.

5.2.3. Drawings for quality check.

Step 1 : Power on the unit in Diagnostics mode.

Step 2 : Put a pen in the head and load some paper.

Step 3 : Press the [ORIGIN] key until 50% LED is on.

Step 4 : Press the [VALUE ¯] key (Unit starts initialising and loads medium if lever is down. Wait until

finished)

Step 5 : Press the [VALUE ] key.

Step 6 : The next key will determine the kind of drawing to be made.

· [MENU ¯] for ZIG ZAG test

· [MENU ] for 45° test

· [VALUE ¯] for DASH LINE test

· [VALUE] for circles test

Now you have to position the tool (pen) on the desired place on the medium by using the JOG

keys (arrow keys).

Note :

Press the [VALUE ¯] key to start / pause the test drawing.

Press the [VALUE ] key to end and select another drawing

Page 34

Maintenance Manual – SC Cutting Plotter

34 AP-74030, Rev / B

Step 7 : When finished power off the machine.

5.2.4. Measuring the CUTTING MAT height.

Caution :

This adjustment routine requires a special tool!

DO NEVER start this routine without this tool.

Step 1 : Place TOOL JD-44140 (adjustment pen) in head.

Step 2 : Power on the unit in diagnostic mode. (No medium loaded)

Step 3 : Press the [ORIGIN] key until 80% LED is on.

Step 4 : Press the [VALUE ] key. (Unit starts initialising, wait until finished)

Step 5 : Press the [VALUE ¯] and [ENTER] key. (Unit starts measuring the cutting mat height on several

places, wait until finished.)

Step 6 : Press the [ENTER] key. (The values are now stored in EEPROM)

Step 7 : Power off.

5.2.5. Adjusting the SHEET OFF system.

(NOT for SC-550)

Step 1 : Power on the unit in diagnostic mode (No medium loaded).

Step 2 : Press the [ORIGIN] key until 90% LED is on.

Step 3 : Press the [VALUE ] (Unit starts initialising, wait until finished).

Step 4 : Press the [VALUE ¯] and [ENTER] key.

The head moves to the left hand side and stops approximately 60 mm before the left hand side of

the machine.

Open the transparent caver and move the head manually to the utmost left position. The correct

position is that the head is at the left as much as possible but that the knife catch bracket is still

free to move UP/DOWN. Check that the head can catch the bracket and hold it firmly.

Step 5 : With the cover still open (!!! IMPORTANT !!!), press the [ENTER] key twice. The value is stored

now in the EEPROM.

Step 6 : After closing the cover, the head will move to the right.

Step 7 : Power off.

Page 35

Maintenance Manual – SC Cutting Plotter

35 AP-74030, Rev / B

5.2.6. Backup plots (on paper only).

Step 1 : Power on the unit in diagnostic mode.

Step 2 : Press the [ORIGIN] key until 50% LED is on.

Step 3 : Put a pen in the head and load some paper (Min. A3 size).

Step 4 : Press the [VALUE ] key (Unit will start initialising, wait until finished).

Step 5 : Pres the [VALUE ] key.

Step 6 : The next key will determine the kind of plot.

· [VALUE ¯] selects USER PARAMETERS backup.

· [VALUE ] selects ADJUSTMENT VALUES backup.

· [VALUE ¯] (Unit will start plotting, wait until finished.)

Step 7 : When finished 1 of the 2 plots, you can change the sheet and select the other one without

powering off the machine.

Þ Press the [VALUE ] key

Þ Select with the [VALUE ¯] and [VALUE ] key the desired plot.

Þ Press the [VALUE ¯] key (Unit will start plotting, wait until finished).

Step 8 : Power off.

Page 36

Maintenance Manual – SC Cutting Plotter

36 AP-74030, Rev / B

5.3. Diagnostics with optional LCD keyboard.

To have access to the complete range of specialised diagnostics, an optional keyboard

With LCD from the MUTOH XP-C series is required. The partnumber for the keyboard is EY-6200-50010.

To enter the specialised diagnostics mode, proceed as follows :

Step 1 : Open the PC-board box from the back of the machine. (On SC-550 remove the right cover.)

Step 2 : On the terminal board (board to the left in the box when you are behind the machine) you must

plug in the optional keyboard in connector J513. (On SC-550 terminal board is board on top of

mainboard.)

Step 3 : Depending on the type of keyboard, power ON the machine with the following buttons pressed

simultaneously :

· New style keyboard : [PAGE] and [ORIGIN]

(P/Nr : EY-6200-50100)

· Old style keyboard : 0 and Decimal (.) and Minus (-)

(P/Nr : EY-5005-50100)

Step 4 : The following screen appears on the display :

** DIAGNOSTICS **

** MODE **

TYPE : SC - xxx

Step 5 : If you are planning to make a lot of tests and / or adjustments in the diagnostic mode, you can

avoid above ‘power on’ procedure as follows :

· On the Main PC board (board in the middle), look for the DIP switches (in front of LED’s)

and put switch 1 in the ON position.

· Now the unit will always power on in diagnostic mode until you change switch 1 to the OFF

position again.

Page 37

Maintenance Manual – SC Cutting Plotter

37 AP-74030, Rev / B

5.3.1. Diagnost 1.

Caution :

Before running these diagnostics, be sure to perform the

· Backup plot user parameters (Please refer to 5.2.6. Backup plots)

· Backup plot adjustment values (Please refer to 5.2.6. Backup plots)

This will give you a hard copy of all the current settings and adjustment values.

1) Memory :

* Diagnost –1 *

Memory Sensor

Press F3

MEMORY CHECK

SUM CHECK SRAM

DRAM EEPROM

Press F1

F3

* SUM *

EEPROM

EPROM KROM

F2

F4

Press F2 : Checksum EEPROM (Version EEPROM)

Press F3 : Checksum EPROM set

Press F4 : Checksum KanjiROM

The Checksum and Version value of EEPROM is of no importance.

The Checksum of EPROM is related to the version. The calculated sum should be equal to the

programmed one.

If this is not the case, EPROM set has to be replaced.

The STATIC RAM test (F2) and DYNAMIC RAM test (F3) are of no importance for maintenance and

repair.

MEMORY CHECK

SUM CHECK SRAM

DRAM EEPROM

F4

Press F4

F1

F3

EEPROM TEST

Read Write

Init1 Init2

F2

F4

Read (F1) and Write (F2) are of no importance for maintenance and repair.

Page 38

Maintenance Manual – SC Cutting Plotter

38 AP-74030, Rev / B

Init1 (F3) initialises all user parameters to default

values.

Init2 (F4) initialises all adjustment values to default

values.

Caution :

After INIT, the following adjustments need to be performed

· X axis length adjustment (ADJ.08)

· Cutting Mat height adjustment (ADJ.-08)

· Pen force calibration (ADJ.-09)

· Sheet-off system adjustment (ADJ.09)

(Not for SC-550)

2) Sensor

* Diagnostic-1 *

Memory Sensor

Press F4

Press F1/F3

Front : Open

Middle : Open

Rear : Open

Lever : Up

Cover : Closed

Y Org :

Sensors ‘Front’, Middle’ and ‘Rear’ are paper sensors located on the plotter bed.

‘Lever’ sensor detects if pressure rollers are UP/DOWN.

‘Cover’ sensor detects if safety cover is OPEN/CLOSED.

(Not for SC-550)

‘Y Org’ sensor is the sensor on the back of the penhead that detects the position of the pressure rollers.

5.3.2. Diagnost. 2

1) Panel test.

F3

* Diagnost-2 *

Panel Actuator

F4

Press F3

F1

LED and KEY test

< >

Key :

Press EXIT

F2

Pressing F1/F2 actuates the LED’s on the SC-keypad and shows the corresponding position on

the LCD.

Keys pressed on the SC-keypad are indicated on the LCD.

Page 39

Maintenance Manual – SC Cutting Plotter

39 AP-74030, Rev / B

5.3.3. Diagnost. 3

1) Actuator.

F3

* Diagnost – 3 *

Pen

XY-enc XY-polar

F2

F4

Press F2

F3

* PEN TEST *

Torque Encoder

F4

Test (F3) Torque tests the moving coil and drive circuit.

Pressing F2/F4 makes the MC move UP/DOWN step by step and puts more/less force on the

head.

Test (F4) Encoder shows the readout of the penhead encoder. (Move the head manually

up/down).

2) XY-encoder test.

F3

* Diagnost-3 *

Pen

XY-enc XY-polar

F2

F4

Press F3

* XY Encoder *

X : 0000 Y :0000

0.00 0.00

Press EXIT

This test shows the readout of the X/Y encoders when manually moving the head or the

gridrollers.

3) XY-polarity test

F3

* Diagnost-3 *

Pen

XY-enc XY-polar

F2

F4

Press F4

* XY-Polarity *

X axis : OK

Y axis : Ok

Press EXIT

This test checks the drive circuit of X and Y motors. One current pulse is sent to the motors and

the direction of the movement is checked by the encoders.

Page 40

Maintenance Manual – SC Cutting Plotter

40 AP-74030, Rev / B

5.3.4. Diagnost. 4

1) Toolset

F1

* Diagnost-4 *

TOOLSET Paper

F2

Press F1

F3

* Select TOOL *

< Pen1 >

Press ENTER/EXIT

F4

This diagnostic allows you to change from tool to pen or the reserve by pressing F3/F4.

2) Paper.

This test / adjustment is of no importance.

5.3.5. Diagnost. 5

1) Time and Distance.

F1

F3

* Diagnost – 5 *

TIME DISTANCE

XY-move General

F2

F4

(F1) TIME displays the actual working time of the machine.

(F2) DISTANCE displays the actual distance that the machine has been cut.

Page 41

Maintenance Manual – SC Cutting Plotter

41 AP-74030, Rev / B

2) X-Y Move.

* Diagnost – 5 *

TIME DISTANCE

XY-move General

Press F3

F3

* XY MOVE *

Aging

Shift Quality

F2

F4

Press F2

F3

* Aging *

XY

X Y

F2

F4

With this test you can make the plotter

continuously moving in the X-/Y- axis or

both axes together and the time of operation

is displayed

Press F3

F3

* Paper shift *

Start Finish

F4

For this test a SHEET of paper need to be

loaded. This test checks the if the tracking

of the media remains correct during

operation

Press F4

F1

F3

* Quality *

Blocks Line45

Dashline Circle

F2

F4

For this test a SHEET of paper and a pen

need to be loaded.

This test is used to check the overall plot

quality of the machine

Before you press (F3) ‘START’, you have to position the pen to the desired place on the paper by

using the jog keys.

Press (F1) to activate the ZIG ZAG test.

Press (F2) to activate the 45° test.

Press (F3) to activate the Dash line test.

Press (F4) to activate the Circles test.

3) General (Backup plots).

F1

F3

* Diagnost – 5 *

TIME DISTANCE

XY-move General

F2

F4

Press F4

This plot requires Min A3 size paper and a pen.

F3

* Total Plot *

Backup Adjust

F4

(F3) ‘Backup’ plots the USER parameters.

(F4) ‘Adjust’ plots the adjustment values.

Page 42

Maintenance Manual – SC Cutting Plotter

42 AP-74030, Rev / B

5.3.6. Diagnost. 6

Reserved for future use.

5.3.7. Adjust. 7

Reserved for future use.

5.3.8. Adjust. 8

1) X-axis Length Adjustment.

Caution :

The MUTOH SC-series plotters are calibrated before shipping from the factory. Do

not perform this adjustment except when obviously worsens.

An accurate reference scale is required to perform this calibration.

F3

* Adjust – 08 *

Xaxis adj Roller

F4

Press F3

F1

F3

Axis correction

500mm 20inch

Robot1 Robot2

F2

F4

The X-axis length calibration compensates tolerance on the

GRID roller diameters causing incorrect length of the X-axis

movement.

Press F1

F3

Axis 500mm

Plot Input

F4

Load a A1-size paper or a larger and a pen.

Select (F1) or (F2) depending if you want to calibrate metric or

imperial.

Press (F3) Plot then (F3) start : The plotter will draw a square of 500mm (or 20 Inch).

Remove the paper from the machine and measure the length of the X-axis lines as accurate as

possible.

Press (F4) Input : Now you can enter the real (measured) value.

F1/F3 selects the digit that you want to change.

F2/F4 changes the value.

Press ENTER to confirm.

Press exit.

Page 43

Maintenance Manual – SC Cutting Plotter

43 AP-74030, Rev / B

Caution :

You cannot check if the calibration is correct by internal test from the plotter.

Check the calibration by sending a file from the computer.

If you perform the 500mm (20Inch) square again, it will be plotted as before

WITHOUT calibration.

2) Cutting mat height calibration (roller).

This test measures unevenness of the cutting mat on ± every 40 mm and stores this data in

EEPROM. This data is used to compensate the pen height on this particular places.

F3

* Adjust – 08 *

Xaxisadj Roller

F4

Without paper loaded, put the Special Adjustment pen

Press F4

JD-41440 in the penholder.

Press (F4) Roller.

Press (F3) Measure.

F3

* Roll height *

Measure Display

F4

Press ENTER to start the test.

The plotter starts to measure the cutting mat height on

every ± 40mm.

Press ENTER to save data.

Note :

It is recommended to performed the cutting mat height calibration after

replacement of the cutting mat.

(F4) Display is of no importance.

5.3.9. Adjust. 9

1) Pen force calibration.

F3

* Adjust – 09 *

PenForce Cutter

F4

Press F3

F3

* Pen Force *

Plot

Adjustment Check

F2

F4

(F2) Plot is of no importance.

Press F3

For Pen Force adjustment

Put Pen in the head

Close cover and press

ENTER.

Put Adjustment pen JD-41440 in penhead.

Press ENTER

Page 44

Maintenance Manual – SC Cutting Plotter

44 AP-74030, Rev / B

Pen Force : 40 g

F2 change : DOWN

Press ENTER to

Input value

F2 (F2) toggles pen UP/DOWN.

Attach bar tension gauge of 50g to pen and read the value

when the pen tip lifts from the paper.

Press F2 (DOWN)

Press ENTER

F1

F3

* Pen Force Input *

1g ® 40g

F2

F4

F1/F3 changes the digit

F2/F4 changes the value.

Enter the measured value

Press ENTER

Pen Force : 450g

F2 change : DOWN

Press ENTER to

Input value

F2 (F2) toggles pen UP/DOWN

Attach a bar tension gauge of 500 g to pen and read the

Press F2down

Press ENTER

value when the pen tip lifts from the paper.

F1

F3

Pen Force Input

1g ® 450g

F2

F4

F1/F3 changes the digit

F2/F4 changes the value.

Enter the measured value

Press ENTER

Confirm Input

40 ® 40 , 450 ® 450

Press Enter

Press ENTER

Press ENTER

2) Pen force Verify.

F3

* Pen Force *

Plot

Adjustment Check

F2

F4

(F2) Plot is of no importance

(F4) to verify the pen force calibration.

Press F4

Put Pen in the

Head Close cover

and press ENTER

Put adjustment pen JD-41440 in penhead.

Press ENTER

F1

F3

Pen Force :

10g : DOWN

DOWN / UP

F2

F4

With F1/F3 you can select different pen forces.

With F4 you can toggle UP/DOWN.

Attach a bar tension gauge to the pen and verify the value.

Press EXIT, Press ENTER.

Page 45

Maintenance Manual – SC Cutting Plotter

45 AP-74030, Rev / B

3) CUTTER (Sheet – Off system).

(Not for SC-550)

A) Adjustment of the Sheet-Off system.

This calibration stores the position in the EEPROM where the penhead makes the knife catch

bracket grabbing the sheet-off knife.

F3

* Adjust – 09 *

PenForce Cutter

F4

Press F4

F3

Cutter

Adjust Aging

Select or EXIT

F4

Press F3

Wait until

Finished then

Press ENTER

Press ENTER

Place Pen head

so that it can

take the knife

and press ENTER

The head moves to the left hand side and stops approx.

60mm before the left side of the machine.

Open the transparent cover and move the head manually to

the utmost left position.

Press ENTER

The correct position is that the head is at the left as much

as possible but that the knife catch bracket is still free to

move UP/DOWN. Check that the head can catch the

The adjusted

value = -XX.XX

Press ENTER to

save or EXIT

Bracket and can hold it firmly.

With the cover still open (VERY IMPORTANT) press

ENTER and ENTER after closing the cover the head will

travel to the right.

Page 46

Maintenance Manual – SC Cutting Plotter

46 AP-74030, Rev / B

B) Cutter aging (Testing the Sheet – Off system).

This test makes the machine sheeting – off as many times as you have selected.

F3

Cutter

Adjust Aging

Select or EXIT

F4

Load a sheet of vinyl.

Press F4

F3

Aging

How many times ?

< 1 X >

Enter to confirm

F4

With F3/F4 select how many times you want to sheet – off.

F3

Aging

Cut length

< 1 X >

Enter to confirm

F4

With F3/F4 select the length of the sheets.

Press ENTER.

5.3.10. Adjust. 10

Not used for maintenance and repair.

Page 47

Maintenance Manual – SC Cutting Plotter

47 AP-74030, Rev / B

6. PARTS REPLACEMENT AND ADJUSTMENT.

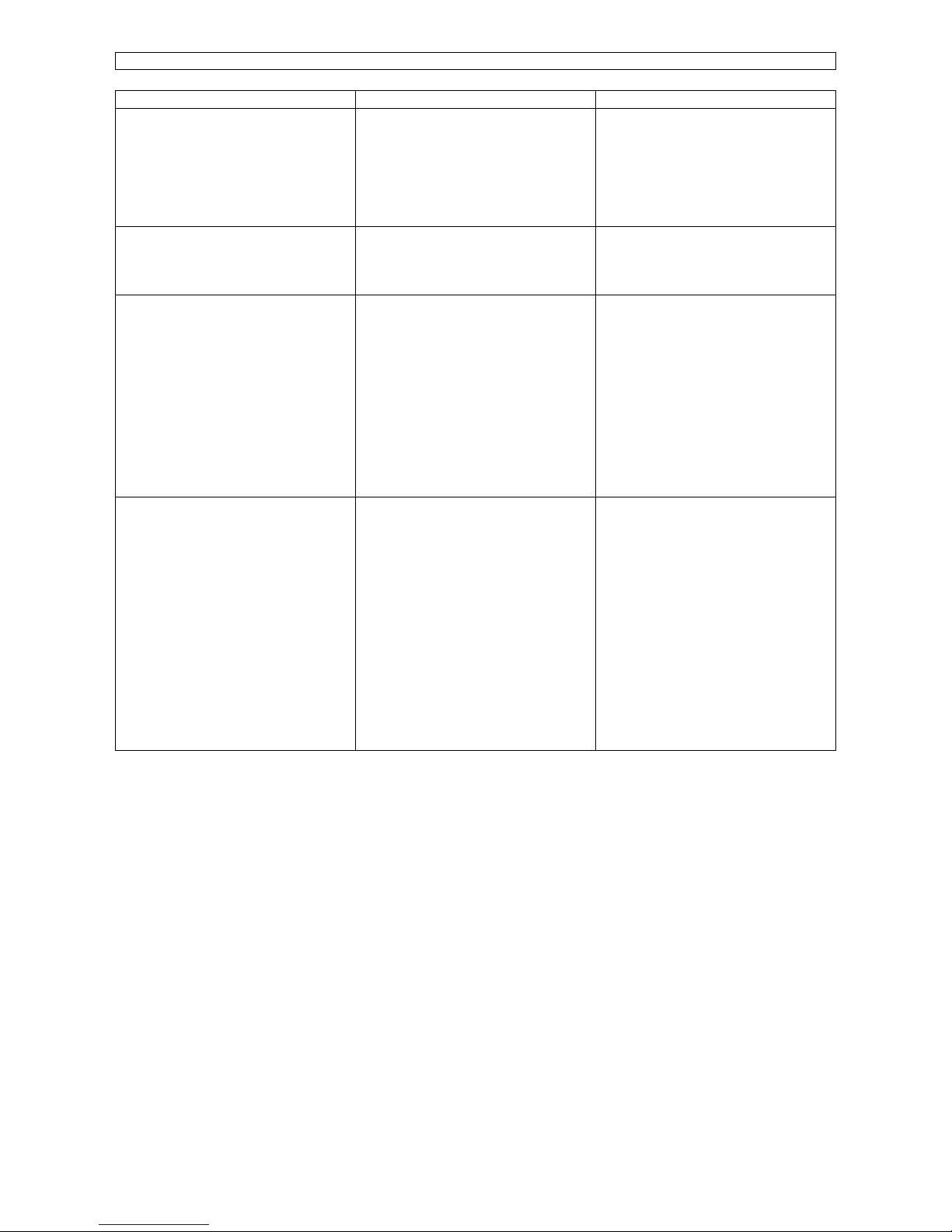

6.1. Maintenance access table for parts replacement.

Removal of the following cover gives access to the following part or mechanical adjustment :

COVER

Gives access to

Transparent

Cover

(Not on SC-550)

Cutting head

Auto sheet-off system (Not on SC-550)

Pressure rollers

Cutting mat

Left cover Y-axis return pulley assy

Y-axis drive belt tension adjustment

Power supply board (SC-550 only)

Right cover Y-motor

Y-drive pulley assy

Y-drive belt (short) tension adjustment

Pressure roller UP/DOWN sensor

Pressure roller UP/DOWN mechanism

Keyboard assy

X-drive belt

Main/driver board (SC-550 only)

EPROM set (SC-550 only)

EEPROM (SC-550 only)

Terminal board (SC-550 only)

Y-rail cover Pressure roller assy

Acrylic cover switch (Not on SC-550)

Y-rail assy

Penhead flex cable assy

Pressure roller pressure adjustment

PCB-box

(Not on SC-550)

X-motor cover

(SC-550 only)

Main/driver board assy

EPROM set

EEPROM

Power supply board assy

Terminal board assy

X-motor assy

X-drive belt tension adjustment

Fan motor

Grid cover Grid rollers

Paper sensors

Page 48

Maintenance Manual – SC Cutting Plotter

48 AP-74030, Rev / B

6.2. Mechanical parts.

6.2.1. Covers Left and Right : removal and installation.

Step 1 : Remove screw 9 (6X) (Please refer to the figure mentioned below).

Step 2 : Remove screw 8 (3X) (please refer to the picture mentioned below) and screw 7 (1X) (Cover right

only) and remove the cover.

Step 3 : (Cover right only)

Be careful with the flat cable. If the cover need to be removed completely, pull the flat cable out

of the connector on the side of the keyboard PC board. (Please refer to nr 3 and 4 in the picture

mentioned below.)

Note :

To reinstall covers left and right perform above steps in reversed order.

Page 49

Maintenance Manual – SC Cutting Plotter

49 AP-74030, Rev / B

6.2.2. Transparent cover : Removal and installation.

Note :

Transparent cover does not exist on SC-550.

Step 1 : Open the transparent cover assy.

Step 2 : On the left side of the cover unscrew screws 7 (2) one (1) turn and slide the shaft 3 inside the rail

while holding the cover. (Please refer to picture mentioned below.)

Step 3 : Remove the cover and fix the 2 screws temporary to avoid falling out of the rail.

Note :

To reinstall the transparent cover perform above steps in reversed order.

Page 50

Maintenance Manual – SC Cutting Plotter

50 AP-74030, Rev / B

6.2.3. PCB box :open and close.

Note :

PCB box does not exist on SC-550.

Step 1 : If the unit is on a stand skip to step 2.

If the unit is on a table remove the pressure roller (UP/DOWN knob first with one screw.

Turn the unit with the front side on the table.

It is recommended to put some soft material (foam, cloth) on the table first to avoid scratches on

the machine or the table.

Step 2 : On the back of the machine remove screws #19 (Please refer to the picture mentioned below.)

while holding the PCB box.

Step 3 : Turn open the PCB box gently and be careful not to harm any cables or wires.

Note :

Close the PCB box by performing the above steps in reversed order.

Page 51

Maintenance Manual – SC Cutting Plotter

51 AP-74030, Rev / B

6.2.4. Y-rail cover : Removal and installation.

Step 1 : Remove the transparent cover (Please refer to 6.2.2. Transparent cover).

Step 2 : Remove 2 screws on top of the cover and 2 screws at the back.

Step 3 : Remove the Y-rail cover.

Note :

To reinstall the Y-rail cover perform above steps in reversed order.

6.2.5. Grid cover : Removal and installation.

Step 1 : Remove covers left and right (Please refer to 6.2.1. Covers left and right).

Step 2 : Remove the transparent cover (Please refer to 6.2.2. Transparent cover).

Step 3 : Remove the Y-rail cover (Please refer to 6.2.4.Y-rail cover).

Step 4 : Open the PCB box (Please refer to 6.2.3. PCB box).

Step 5 : Remove the rear paper guide with 4 screws. 2 screws on each side of the machine (Please refer

to #30 and #31 on the picture mentioned below). Lift the platen a little and pull it straight out

between the side plates.

Step 6 : Remove the small hexagon screws that fix the gridcover.

Use L-shaped hex-key of 1.27 / 1/20”.

Push the gridcover about 3mm to the back, lift the cover and remove it to the rear side of the

machine.

Page 52

Maintenance Manual – SC Cutting Plotter

52 AP-74030, Rev / B

Note :

To reinstall the grid cover perform above steps in reversed order.

Page 53

Maintenance Manual – SC Cutting Plotter

53 AP-74030, Rev / B

6.2.6. Cutting head : Removal and installation.

Step 1 : Remove the transparent cover (Please refer to 6.2.2. transparent cover).

Step 2 : Remove the Y-rail cover (Please refer to 6.2.4. Y-rail cover).

Step 3 : Remove the head cover by removing the screw in the middle of the cover and unscrew the

bottom screw a few turns.

The head cover can be removed by sliding upwards.

Step 4 : Open the 2 white connectors by sliding them to the front and pull away the 2 flex cables from the

connectors.

Remove the head PCB on top of the head by 2 screws ‘C’ (Please refer to picture mentioned

below) and lay it somewhere on the Y-rail where the flex cable cannot be damaged.

Step 5 : Remove the ‘A’ that fix the cutting head to the drive belt.

It is strongly recommended to use a magnetised –screwdriver in order not to drop the screw

inside the head.

Step 6 : Remove the screw ‘B’ on the top of the head and slide away the blade spring.

Step 7 : Move the head manually to the utmost right position, turn over the top rollers to the front, lower

the head a little and remove it in the front direction.

Caution :

It is really important to move the head to the utmost right position as on another position

it is impossible to remove the head from the Y-rail.

Note :

To reinstall the cutting head perform above steps in reversed order.

Page 54

Maintenance Manual – SC Cutting Plotter

54 AP-74030, Rev / B

Caution :

After replacement of the cutting head the following electronically adjustments have to be

performed :

· Cutting mat height measurement (Please refer to 5. Diagnostic menu

with SC-board or with optional LCD keyboard).

· Adjusting the sheeting off system (Please refer to 5. Diagnostic menu

with SC-keyboard or with optional LCD keyboard) (Not for SC-550)

· Pen force calibration (Please refer to 5.3. Diagnostic menu with

optional LCD keyboard).

6.2.7. Grid rollers : removal and installation.

Step 1 : Remove the grid cover (Please refer to 6.2.5. Grid cover).

Step 2 : Unscrew the two screws from the X-motor a few turns and remove the X-drive belt.

Step 3 : Unscrew all the grid rollers (with 1.5mm hex-key) and pull out gently the shaft out of the machine.

In this way every grid roller can be removed from the shaft.

Caution :

q Never replace only one grid roller but always the whole set. Replacement of only

one grid roller may result in noticeable deviation of media tracking!

q Before unscrewing the grid rollers, mark the position of every roller on the shaft.

This will simplify the reinstallation.

q NEVER unscrew or change the position of the bearing blocks on the X-rail as this

will result in misalignment of the grid roller shaft!

Note :

To reinstall the grid rollers perform above steps in reversed order.

Caution :

After reinstallation of the grid rollers, the X-drive belt tension should be adjusted (lease

refer to the adjustment of the X-drive belt).

Page 55

Maintenance Manual – SC Cutting Plotter

55 AP-74030, Rev / B

6.2.8. Y-drive belt (long) : removal and installation.

Step 1 : Remove the cutting head (Please refer to 6.2.6. Cutting head).

Step 2 : Remove covers left and right (Please refer to 6.2.1. Covers left and right).

Step 3 : On the left hand side of the machine, unscrew both screws #5 (2) ± 5 turns in order to get the

tension of the belt (Please refer to picture mentioned below).

Step 4 : Remove two screws #4 and one plate #3 from the belt connection assy and pull the belt complete

out of the Y-rail.

1) Y-drive belt (long) : Installation and adjustment.

Step 1 : Hold the belt in front of the machine and push one end trough the slit of the right side plate. Turn

the belt around the pulley and push it in the second slit to enter the at the back of the Y-rail.

Turn the belt around the pulley and push it in the second slit to enter the at the back of the Y-rail.

Push it as far as it goes and then use a flash light and look into the slit at the left side of the

machine.

With a pair of tweezers try to grab the belt and pull it through the slit.

Turn the belt around the return pulley and push it through the front slit to arrive at the starting

point of the belt again.

Page 56

Maintenance Manual – SC Cutting Plotter

56 AP-74030, Rev / B

Step 2 : Close the belt with the connection plate assy and be sure that all the teeth of the connection plate

are used to hold the belt.

Step 3 : Turn the 2 screws on the return pulley an equal amount of turns in CW (Clockwise) in order to get

a little tension on the belt.

Step 4 : Install the cutting head (Please refer to 6.2.6. Cutting head).

Step 5 : Move the head manually from the left to the right and look for the tracking of the belt on the return

pulley.

If the belt moves upwards, turn the top screw CW or the bottom screw CCW (counter-clockwise).

If the belt moves downwards, turn the top screw CCW or the bottom screw CW.

The target is that the tension of the belt stays stable at the surface of the return pulley on the

complete range of the cutting head.

Step 6 : Similar to step 5 check the track of the belt on the drive pulley.

If the belt moves upwards turn the screw 9 (Please refer to the picture mentioned below) CW.

If the belt moves downward turn screw 9 CCW.

Page 57

Maintenance Manual – SC Cutting Plotter

57 AP-74030, Rev / B

Caution :

Pay attention to the tension on the belt during this alignment.

The tension should stay between acceptable values (Please refer to step 7).

Step 7 : Move the head to the right end of the Y-rail and measure with a bar tension gauge (range : 500g,

MUTOH Part# JD-41446B) the tension of the belt in the middle of the Y-rail (Please refer to

picture mentioned below).

Push the belt with the bar tension gauge (with steel belt tension attachment MUTOH part# JD-

41565) to touch the rail and release gently the pressure on the gauge.

The movement that the belt starts to release from the rail is the moment of reading the value on

the bar tension gauge.

The values are different for each size machine :

SC-550

SC-650 SC-750 SC-1000 SC-1300

205 ± 5 g 205 ± 5 g 180 ± 5 g 150 ± 5 g 125 ± 5 g

The tension can be adjusted by turning the screws on the return pulley CW for more tension and

CCW for less tension.

Caution :

While adjusting the tension, keep on checking the track of the belt on the

return pulley (Please refer to step 5).

Page 58

Maintenance Manual – SC Cutting Plotter

58 AP-74030, Rev / B

6.2.9. Pressure roller pressure adjustment.

Step 1 : Switch off the machine and place the pressure rollers on top of a grid roller.

Step 2 : Remove the transparent cover (Please refer to 6.2.2. Transparent cover).

Step 3 : Remove the Y-rail cover (Please refer to 6.2.4. Y-rail cover).

Step 4 : Take a piece of polyester film of ± 300 cm long, 2.5 mm wide (12” X 1”) and put it between the

grid roller and the pressure roller (Please refer to the picture mentioned below).

Attach the bar tension gauge (range 5 kg, MUTOH Part# JD-41446C) to the pressure roller shaft

with a piece of rope or with the pressure measurement attachment JD-41563 and pull

simultaneously the film and the tension gauge under 90° angle.

The moment that the film is slipping between the rollers, is the moment to read the value on the

tension gage.

The value should be 3.5 kg ± 0.1 kg.

To adjust the pressure, change the spring tension by turning the nuts A (Please refer to the figure

mentioned below) CW to increase or CCW to decrease the pressure on the rollers.

Page 59

Maintenance Manual – SC Cutting Plotter

59 AP-74030, Rev / B

6.2.10. Sheeting off mechanism : mechanical alignment.

(Not for SC-550)

Note :

It is recommended to check the mechanical alignment of the sheeting off mechanism

before running the electronic adjustment procedure.

Step 1 : Make sure the machine is powered off.

Step 2 : Open the transparent cover and remove the head cover.

Step 3 : Check if lever #2 (Please refer to picture mentioned below) can move freely up/down and

front/backwards. The lever should return always to the Up position and to the backwards position

by the spring tension.

Also check if the blade moves up and down freely and returns in the up position by the spring

tension.

Step 4 : With your right hand move the tool holder to the most up position, with your left hand push the

lever (#2) inside and check the clearance between bracket #3 and lever “2. (Please refer to the

picture mentioned below)

This distance should be 1 mm –0.5 mm.

If this is not the case, use a small pair of pliers and bend the bracket #3 until the correct

clearance is obtained.

Step 5 : Install the head cover and make the electronic alignment in diagnostic mode.

Page 60

Maintenance Manual – SC Cutting Plotter

60 AP-74030, Rev / B

6.3. Electronical parts.

6.3.1. Main PC board : Removal and installation.

Note :

This procedure is valid for all SC-series except for SC-550. For the Main PC board SC550, please refer to 6.3.2.

Step 1 : Open the PCB box (Please refer to 6.2.3. PCB box).

Step 2 : Unplug all the connectors, remove all screws from the board and remove the board. Do not

forget to remove the screws from the parallel and serial communication connector.

Note :

Pay attention to the position of all connectors and the proper place of all the cables.

This will simplify the installation.

To reinstall the Main PC board perform above steps in reversed order.

Warning :

Check the DIP Switch settings on the board.

The position of the DIP switches determines the type of machine where the board

will be used in. (Please refer to 6.3.3. Dip Switch settings on Main PC board)

Page 61

Maintenance Manual – SC Cutting Plotter

61 AP-74030, Rev / B

6.3.2. Main and terminal PCB SC-550 : Removal and installation.

Step 1 : Remove the right side cover (Please refer to 6.2.1. Right and left cover).

Step 2 : Remove all the cables connected to the Terminal board.

Note :

Pay attention to the position of all connectors and the proper place of all the

cables.

This will simplify the installation.

Step 3 : Remove the Terminal board assy (including fixing brackets) by removing the 4 screws on the side

of the PCB box.

Step 4 : Remove all cable connected to the Main PC board.

Step 5 : Remove the power switch (just press it to the outside, no need to disconnect the wires).

Remove the power inlet connector with 2 screws on the back. (No need to disconnect the wires).

Step 6 : Remove the screws from the board and from the communication connectors (also remove the 2

clips from the centronics connector) and take out the board.

Note :

To reinstall the Main PC board perform above steps in reversed order.

Warning :

Check the DIP switch setting on the board.

The position of the DIP switches determines the type of machine where the board

will be used in. (Please refer to 6.3.3. Dip Switch settings on Main PC board)

Page 62

Maintenance Manual – SC Cutting Plotter

62 AP-74030, Rev / B