Page 1

Maintenance Manual

MUTOH EUROPE N.V.

AP-74065, Rev 1.2: , 27/09/2004

Page 2

Rockhopper II series printers – Maintenance Manual

3

AP-74065, Rev. 1.2, 27/09/04

MUTOH INDUSTRIES LTD.

Tel.:81-(0)3-54867145

Fax.:81-(0)3-54867163

E-mail:ibd@mutoh.co.jp

http://www.mutoh.co.jp

MUTOH EUROPE N.V.

Tel.:32-(0)59-561400

Fax:32-(0)59-807117

E-mail:mutoh@mutoh.be

http://www.mutoh.be

MUTOH DEUTSCHLAND GmbH.

Tel.:49-(0)2159 913430

Fax.:49-(0)2159 913456

E-mail:Mutoh-Sales@t-online.de

MUTOH AMERICA INC.

Tel.: (480) 968-7772

Fax: (480) 968-7990

E-mail:Sales@mutoh.com

http://www.mutoh.com

Page 3

Rockhopper II series printers – Maintenance Manual

4

AP-74065, Rev. 1.2, 27/09/04

Page 4

Rockhopper II series printers – Maintenance Manual

5

AP-74065, Rev. 1.2, 27/09/04

COPYRIGHT NOTICE

COPYRIGHT © 2004 Mutoh Europe N.V. All rights reserved.

This document may not be reproduced by any means, in whole or in part, without written permission of the

copyright owner.

This document is furnished to support the Mutoh’s Rockhopper II series Printer. In consideration of the

furnishing of the information contained in this document, the party to whom it is given, assumes its custody

and control and agrees to the following:

The information herein contained is given in confidence, and any part thereof shall not be copied or

reproduced without written consent of Mutoh Europe N.V.

This document or the contents herein under no circumstances shall be used in the manufacture or

reproduction of the article shown and the delivery of this document shall not constitute any right or license to

do so.

September 2004

Published: Mutoh Europe N.V., Archimedesstraat 13, B-8400 Oostende, BELGIUM

Page 5

Rockhopper II series printers – Maintenance Manual

6

AP-74065, Rev. 1.2, 27/09/04

Page 6

Rockhopper II series printers – Maintenance Manual

7

AP-74065, Rev. 1.2, 27/09/04

Important Notice

This product has been tested and found to comply with the limits for a Class A digital device, pursuant to Part

15 of FCC Rules. These limits are designed to provide reasonable protection against harmful interference

when the product is operated in a commercial environment.

This product generates, uses, and can radiate radio frequency energy and if not installed and used in

accordance with this manual, may cause harmful interference to radio communications. Operation of this

product in a residential area is likely to cause harmful interference in which case the user will be required to

correct the interference at his expense.

1. Radio interfere

Product generates weak radio signals and may interfere with television reception and utilities. If a

product does interfere with radio or TV reception, try following:

¾ Change the direction of your radio and TV reception antenna or feeder.

¾ Change the direction of the product.

¾ Move either the product or the receiving antenna so there is more distance between them.

¾ Be sure the product and the receiving antenna are on separate power lines.

2. Trademark mentioned in this manual.

¾ MUTOH, Rockhopper II, Eco-Solvent Plus, MH-GL, MH-GL2, MH-RTL are registered trademarks or

product names of MUTOH INDUSTRIES LTD.

¾ Centronics and Bitronics are registered trademarks or product names of Centronics Data Computer

Corporation.

¾ Windows 95, Windows 98, Windows Me, Windows XP, Windows NT4.0, Windows2000, and

MSDOS are registered trademarks or product names of Microsoft Corporation.

¾ DOS/V is registered trademark and product name of International Business Machine Corporation

(IBM).

¾ Other company and product names may be registered trademarks or product names.

No part of this product or publication may be reproduced, copied or transmitted in any form or by any means,

except for personal use, without the permission of MUTOH EUROPE N.V.

The product and the contents of this publication may be changed without prior notification.

MUTOH EUROPE N.V. has made the best efforts to keep this publication free from error, but if you find any

uncertainties or misprints, please call us or the shop where you bought this equipment.

MUTOH EUROPE N.V. shall not be liable for any damages or troubles resulting from the use of this

equipment or this manual.

Page 7

Rockhopper II series printers – Maintenance Manual

8

AP-74065, Rev. 1.2, 27/09/04

Page 8

Rockhopper II series printers – Maintenance Manual

9

AP-74065, Rev. 1.2, 27/09/04

TABLE OF CONTENTS

1. Safety Instructions.......................................................................................................15

1.1. Introduction .......................................................................................................................... 15

1.2. Warnings, Cautions and Note .............................................................................................. 15

1.3. Important safety instructions ................................................................................................ 15

1.3.1. Warning......................................................................................................................................... 15

1.3.2. Caution.......................................................................................................................................... 16

1.4. Warning labels ..................................................................................................................... 17

1.4.1. Handling the operation procedure labels...................................................................................... 17

1.4.2. Locations and types of operation procedure labels ...................................................................... 17

1.5. Operation procedure labels.................................................................................................. 20

2. Product Overview ........................................................................................................21

2.1. Introduction .......................................................................................................................... 21

2.2. Features............................................................................................................................... 21

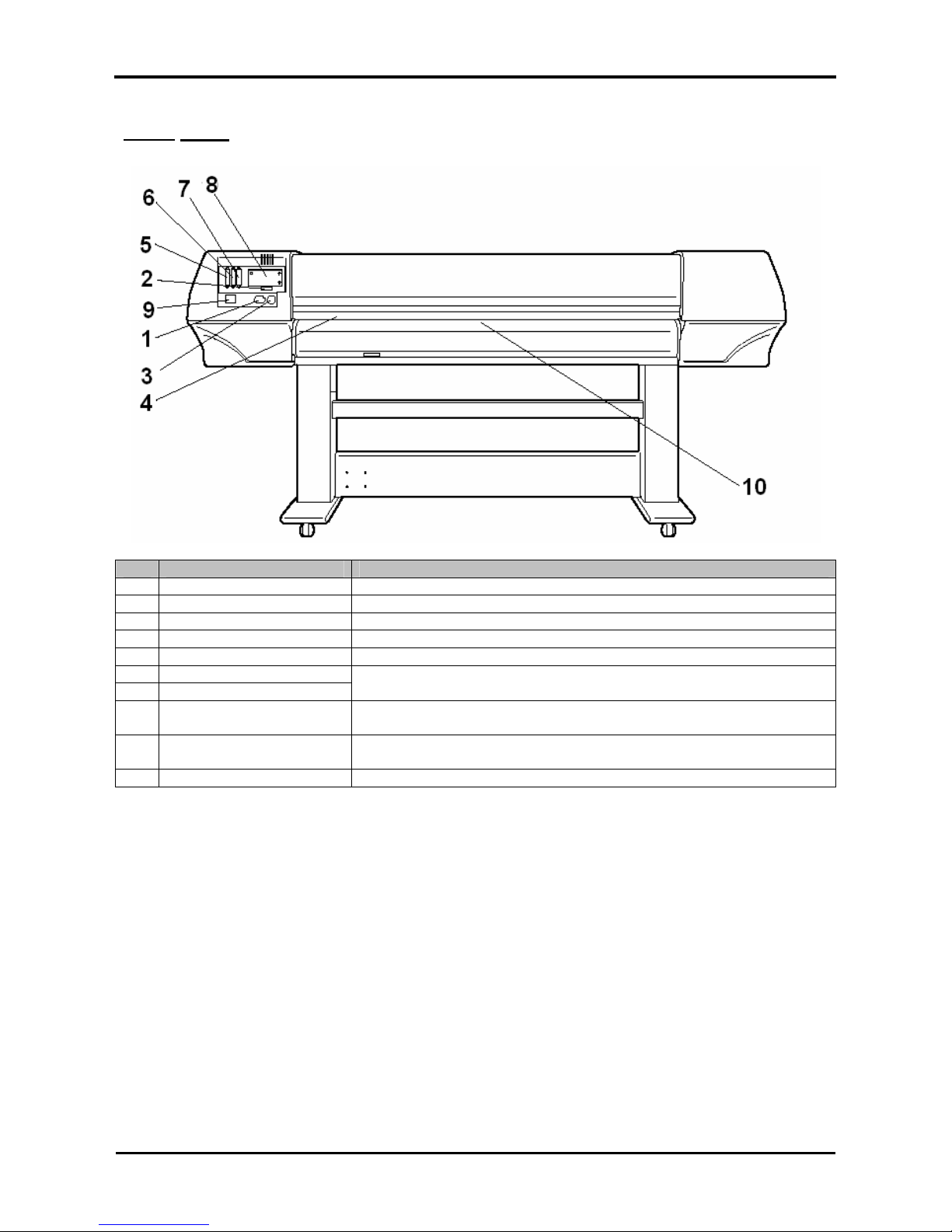

2.3. Part names and functions .................................................................................................... 22

2.3.1. Front.............................................................................................................................................. 22

2.3.2. Back .............................................................................................................................................. 23

2.3.3. Operation panel ............................................................................................................................ 24

2.4. Printer status........................................................................................................................ 26

2.4.1. Normal........................................................................................................................................... 26

2.4.2. Setup menu display ...................................................................................................................... 26

2.4.3. Self-diagnosis Function Display.................................................................................................... 26

2.4.4. Maintenance Mode Display .......................................................................................................... 26

2.4.5. Selecting Language ...................................................................................................................... 27

2.5. Position and function of the heating elements ..................................................................... 28

2.5.1. Rockhopper II 2 heater printers .................................................................................................... 28

2.5.2. Rockhopper II 4 heater printers .................................................................................................... 28

2.5.3. 2 or 4 heater.................................................................................................................................. 29

3. Specifications ..............................................................................................................31

3.1. Introduction .......................................................................................................................... 31

3.2. Product Specifications ......................................................................................................... 31

3.3. Interface Specifications........................................................................................................ 33

3.3.1. Centronics Bidirection Parallel Interface:IEEE1284) .................................................................... 33

3.3.2. Network Interface (Optional) Specifications.................................................................................. 34

3.4. Installation............................................................................................................................ 35

3.4.1. Conditions of the installation environment.................................................................................... 35

4. Parts Replacement ......................................................................................................37

4.1. Introduction .......................................................................................................................... 37

4.2. Removing the cover ............................................................................................................. 38

4.2.1. Removing the I/H cover ................................................................................................................ 39

4.2.2. Removing side cover R................................................................................................................. 40

4.2.3. Removing side cover L ................................................................................................................. 42

4.2.4. Removing the front cover.............................................................................................................. 44

4.2.5. Removing the carriage cover........................................................................................................ 46

4.2.6. Removing the panel unit assembly............................................................................................... 47

4.2.7. Removing the Y rail cover............................................................................................................. 48

4.2.8. Removing front paper guide ......................................................................................................... 50

4.2.9. Removing rear paper guide .......................................................................................................... 52

4.2.10. Removing the head cover........................................................................................................... 53

4.2.11. Removing the maintenance cover .............................................................................................. 54

Page 9

Rockhopper II series printers – Maintenance Manual

10

AP-74065, Rev. 1.2, 27/09/04

4.3. Replacement of the heater element..................................................................................... 55

4.3.1. Rockhopper II 2 heaters : Heater elements.................................................................................. 55

4.3.2. Rockhopper II 4 heaters : Heater elements.................................................................................. 59

4.4. Replacing Board Bases........................................................................................................ 65

4.4.1 Replacing the Mainboard assembly, HDD_Extension board assembly, HEAD_DRV board

assembly, PCI_Linux board assembly and cooling fan assembly.......................................................... 65

4.4.2. Replacing the power source board assembly............................................................................... 70

4.4.3. Replacing the inlet assembly, inlet board assembly and lever foot SW cable assembly............. 72

4.4.4. Replacing the JUNCTION board assembly .................................................................................. 73

4.5. Replacing the PF Actuator ................................................................................................... 74

4.5.1. Replacing the PF motor assembly................................................................................................ 74

4.5.2. Replacing the PF_ENC assembly and PF scale assembly.......................................................... 75

4.5.3. Replacing the PF deceleration pulley assembly........................................................................... 76

4.5.4. Replacing the PF deceleration belt............................................................................................... 77

4.5.5. Replacing the P_REAR_R sensor assembly and P_REAR_L sensor assembly ......................... 78

4.5.6. Replacing the suction fan assembly ............................................................................................. 79

4.5.7. Replacing the lever motor assembly and the arm motor installation board.................................. 80

4.5.8. Replacing the transmission photosensor...................................................................................... 82

4.5.9. Replacing the flushing box assembly ........................................................................................... 84

4.6. Replacing the CR Actuator................................................................................................... 85

4.6.1. Replacing the CR motor assembly ............................................................................................... 85

4.6.2. Replacing the steel belt................................................................................................................. 86

4.6.3. Replacing the SLIDE motor assembly, HD_SLIDE sensor assembly, and slide motor installation

board ....................................................................................................................................................... 88

4.6.4. Replacing the T fence................................................................................................................... 89

4.6.5. Replacing the CR slave pulley assembly...................................................................................... 91

4.6.6. Replacing the CR actuator pulley and the CR deceleration belt .................................................. 92

4.6.7. Replacing the steel bearer, tube guide, CR tape power cable and ink tube ................................ 93

4.6.8. Replace the cover R sensor assembly and the cover L sensor assembly................................... 95

4.7. Replacing the Cursor ........................................................................................................... 96

4.7.1. Replacing the cutter holder, cutter spring, cutter cap, solenoid assembly and solenoid spring... 96

4.7.2. Replacing the print head assembly and head tape power cable.................................................. 98

4.7.3. Replacing the H ink tube, tube branch and damper assembly................................................... 100

4.7.4. Replacing the CR board assembly ............................................................................................. 101

4.7.5. Replacing the CR_ENC assembly.............................................................................................. 103

4.7.6. Replacing the P_EDGE sensor assembly .................................................................................. 104

4.7.7 Replacing black tape on platform ............................................................................................... 105

4.7.8. Replacing the CR cursor assembly ............................................................................................ 107

4.7.9. Replacing the cursor roller assembly.......................................................................................... 108

4.8. Replacing the Maintenance Area....................................................................................... 112

4.8.1. Replacing the maintenance assembly ........................................................................................ 112

4.8.2. Replacing the wiper and wiperarm ............................................................................................. 115

4.8.3. Replacing the SLIDE motor assembly (wiper arm)..................................................................... 118

4.8.4. Replacing the transmission photosensor (wiper home position and maintenance home position)

.............................................................................................................................................................. 119

4.9. Replacing the Pump Area .................................................................................................. 120

4.9.1. Replacing the pump assembly.................................................................................................... 120

4.9.2. Replacing the pump assembly.................................................................................................... 121

4.9.3. Replacing the pump motor assembly ......................................................................................... 122

4.10. Replacing the Cartridge Area........................................................................................... 123

4.10.1. Replacing the I/H (ink holder) assembly ................................................................................... 123

4.11. Replacing Supports and Scroller...................................................................................... 127

4.11.1. Replacing the waste fluid bottle assembly (Rockhopper II 2H) ................................................ 127

4.11.2. Replacing the waste fluid bottle assembly (Rockhopper II 4H) ................................................ 128

4.11.3. Replacing the waste bottle box sensor assembly (RH II 2H) ................................................... 129

4.11.4. Replacing the waste bottle box sensor assembly (RH II 4H) ................................................... 131

4.11.5. Replacing the scroller R assembly ........................................................................................... 133

4.10.6. Replacing the scroller L assembly ............................................................................................ 135

Page 10

Rockhopper II series printers – Maintenance Manual

11

AP-74065, Rev. 1.2, 27/09/04

5. Self-Diagnosis Function............................................................................................137

5.1. Introduction ........................................................................................................................ 137

5.2. Preparation ........................................................................................................................ 137

5.2.1. Preparations on Machine............................................................................................................ 137

5.2.2. Starting Up .................................................................................................................................. 138

5.3. Operations in Self-Diagnosis Mode.................................................................................... 139

5.3.1. Operating Self-Diagnosis Mode.................................................................................................. 139

5.3.2. Diagnosis Items in Self-Diagnosis Menu .................................................................................... 141

5.4. Test / Inspection Menu....................................................................................................... 142

5.4.1. RAM Capacity Menu ................................................................................................................... 143

5.4.2. Version Menu.............................................................................................................................. 143

5.4.3. Operation Panel Menu................................................................................................................ 144

5.4.4. Sensor Menu............................................................................................................................... 145

5.4.5. Encoder Menu............................................................................................................................. 146

5.4.6. Fan Menu.................................................................................................................................... 147

5.4.7. History Menu............................................................................................................................... 147

5.4.8. Head Signal Menu ...................................................................................................................... 149

5.5. Adjustment Menu ............................................................................................................... 150

5.5.1. Skew Check Menu ...................................................................................................................... 151

5.5.2. Head rank input menu................................................................................................................. 152

5.5.3 Head Nozzle Check Menu .......................................................................................................... 153

5.5.4. Head Slant Check Menu............................................................................................................. 155

5.5.5. Repeatability Adjustment (Bi-Directional) ................................................................................... 164

5.5.6. CW adjustments (Uni-Directional) .............................................................................................. 165

5.5.7. Band Feed Correction Menu (X Length)..................................................................................... 166

5.5.8. Top & bottom adjustment menu.................................................................................................. 168

5.5.9. P_REAR sensor position adjustment menu................................................................................ 169

5.5.10. Test print menu ......................................................................................................................... 170

5.5.11. Head wash menu ...................................................................................................................... 171

5.5.12. Software Counter Initialization Menu........................................................................................ 173

5.5.13. Feed Pitch Check Menu............................................................................................................ 174

5.5.14. Fill printing menu....................................................................................................................... 174

5.6. Purge Menu ....................................................................................................................... 175

5.7. Sample Printing Menu........................................................................................................ 176

5.8. Parameter Menu ................................................................................................................ 177

5.8.1. Parameter Initialization Menu ..................................................................................................... 177

5.8.2. Parameter Update Menu............................................................................................................. 178

5.9. Endurance Running Menu ................................................................................................. 185

5.9.1. CR Motor Endurance Menu ........................................................................................................ 186

5.9.2. PF Motor Endurance Menu......................................................................................................... 187

5.9.3. Cutter Endurance menu.............................................................................................................. 188

5.9.4. Head Up/Down Endurance Menu............................................................................................... 189

5.9.5. Head Lock Endurance menu ...................................................................................................... 190

5.9.6. Pump Endurance menu .............................................................................................................. 191

5.9.7. Lever Motor Endurance Menu .................................................................................................... 192

5.9.8. Sequential Printing Endurance Menu ......................................................................................... 193

5.9.9. General Endurance Menu........................................................................................................... 194

5.9.10. Endurance Running Check Menu............................................................................................. 195

5.10. Head Lock Menu.............................................................................................................. 196

5.11. Heater System menu ....................................................................................................... 197

5.11.1. Heater Status Menu.................................................................................................................. 197

5.11.2. Heater Temperature Menu ....................................................................................................... 197

5.11.3. Heater Test 30 Menu ................................................................................................................ 198

5.11.4. Heater Test 50 Menu ................................................................................................................ 198

5.11.5. Heater Test Max Menu ............................................................................................................. 198

5.11.6. Heater Version Menu................................................................................................................ 199

5.11.7. Heater Adjust Menu .................................................................................................................. 199

5.12. Eco Prepare menu ........................................................................................................... 200

5.13. Machine size select menu................................................................................................ 201

Page 11

Rockhopper II series printers – Maintenance Manual

12

AP-74065, Rev. 1.2, 27/09/04

6. Maintenance Mode.....................................................................................................203

6.1. Introduction ........................................................................................................................ 203

6.2. Operating Maintenance Mode............................................................................................ 203

6.2.1. Starting Up Maintenance Mode .................................................................................................. 203

6.2.2. Operating Maintenance Mode .................................................................................................... 203

6.3. Maintenance Menu ............................................................................................................ 204

6.3.1. Counter Display Menu ................................................................................................................ 204

6.3.2. Counter Initialization Menu ......................................................................................................... 206

6.3.3. MAC address write enable menu................................................................................................ 207

6.3.4 Head Voltage ............................................................................................................................... 208

7. Adjustments ...............................................................................................................209

7.1. Introduction ........................................................................................................................ 209

7.2. Adjustment ......................................................................................................................... 209

7.3. Parameter backup.............................................................................................................. 212

7.3.1. Tools required for work ............................................................................................................... 212

7.3.2. Procedure for creating backup parameters ................................................................................ 213

7.3.3. Backup parameter installation procedure ................................................................................... 214

7.4. Firmware installation .......................................................................................................... 215

7.4.1. Tools required for work ............................................................................................................... 215

7.4.2. Installation procedure.................................................................................................................. 215

7.5. Steel belt tension adjustment............................................................................................. 218

7.5.1. Tools required for work ............................................................................................................... 218

7.5.2. Adjustment Procedure ................................................................................................................ 218

7.6. PF deceleration belt tension adjustment............................................................................ 220

7.6.1. Tools required for work ............................................................................................................... 220

7.6.2. Adjustment Procedure ................................................................................................................ 220

7.7. Head precision adjustment (slant)...................................................................................... 221

7.7.1 Head slant adjustment ................................................................................................................. 221

7.7.2. Front and back of head adjustment ............................................................................................ 225

7.8. Repeatability Adjustment (Bi-Directional)........................................................................... 230

7.9. CW adjustments (Uni-Directional)...................................................................................... 231

7.10. CR deceleration belt tension adjustment ......................................................................... 232

7.10.1. Tools required for work ............................................................................................................. 232

7.10.2. Adjustment Procedure .............................................................................................................. 232

7.11. Cover sensor adjustment ................................................................................................. 233

7.12. Head height adjustment ................................................................................................... 234

7.12.1. Tools required for work ............................................................................................................. 234

7.12.2. Adjustment Procedure .............................................................................................................. 234

7.13. Media sensor sensitivity adjustment ................................................................................ 236

7.13.1. Tools required for work ............................................................................................................. 236

7.13.2. Adjustment Procedure .............................................................................................................. 236

7.14. Cutter adjustment............................................................................................................. 239

7.15. Pump tubing layout for pump assembly........................................................................... 240

7.15.1 Pump tubing layout - Rockhopper 4 heater ............................................................................... 240

7.15.2. Pump tubing layout - Rockhopper 2 heater .............................................................................. 243

7.16. Board checklist................................................................................................................. 248

7.16.1. Power supply board. ................................................................................................................. 248

7.16.2. Control board. ........................................................................................................................... 249

7.16.3. Power board.............................................................................................................................. 250

7.16.4. Heater Elements ....................................................................................................................... 250

7.16.5. Checklist ................................................................................................................................... 252

7.17 Flushing box height position adjustment........................................................................... 253

Page 12

Rockhopper II series printers – Maintenance Manual

13

AP-74065, Rev. 1.2, 27/09/04

8. Maintenance ...............................................................................................................257

8.1. Introduction...................................................................................................................................... 257

8.2. Cleaning............................................................................................................................. 258

8.3. Periodical Services ............................................................................................................ 259

8.3.1. Service by end-user .................................................................................................................... 259

8.3.2. Service by authorised Mutoh technician ..................................................................................... 260

8.4. Part Life Information........................................................................................................... 261

8.5. Jig and Tool List................................................................................................................. 262

8.5.1. Required Tools............................................................................................................................ 262

8.6. Lubrication/Bonding ........................................................................................................... 263

8.7. Transportation of Machine ................................................................................................. 265

9. Troubleshooting ........................................................................................................267

9.1. Introduction ........................................................................................................................ 267

9.2. Troubleshooting procedures when a message has been displayed .................................. 267

9.2.1. Operating condition display ........................................................................................................ 268

9.2.2. Message type errors ................................................................................................................... 270

9.2.3. Heating system error................................................................................................................... 277

9.2.4. Data error.................................................................................................................................... 278

9.2.5. Command errors......................................................................................................................... 279

9.2.6. Errors requiring restart................................................................................................................ 280

9.3. Troubleshooting procedures when errors are not displayed.............................................. 291

9.3.1. Problems relating to initial operation........................................................................................... 291

9.3.2. Problems relating to paper feed.................................................................................................. 296

9.3.3. Problems relating to the printing operation................................................................................. 297

9.3.4. Problems relating to noise .......................................................................................................... 309

9.3.5. Problems relating to the paper cutting operation........................................................................ 311

9.3.6. Problems relating to online and functions................................................................................... 314

9.3.7. Other problems ........................................................................................................................... 316

10. Appendix...................................................................................................................317

10.1. Introduction ...................................................................................................................... 317

10.2. Wiring Diagram Rockhopper II 2H ................................................................................... 317

10.3. Wiring Diagram Rockhopper II 4H ................................................................................... 318

10.4. Rockhopper II : Service Parts List/Exploded Views/Configuration Diagrams .................. 318

Page 13

Rockhopper II series printers – Maintenance Manual

14

AP-74065, Rev. 1.2, 27/09/04

Page 14

Rockhopper II series printers – Maintenance Manual

15

AP-74065, Rev. 1.2, 27/09/04

1. SAFETY INSTRUCTIONS

1.1. INTRODUCTION

This chapter explains the meaning of safety terms for personnel who operate this equipment, important

safety instructions and the positions of the warning labels.

Important :

• Be sure to follow all instructions and warnings in this manual when using the

equipment.

1.2. WARNINGS, CAUTIONS AND NOTE

Safety terms in this manual and the contents of warning labels attached to the printer are categorized into

the following three types depending on the degree of risk (or the scale of accident).

Read the following explanations carefully, and follow the instructions in this manual.

Safety terms Details

Important Must be followed carefully to avoid death or serious bodily injury.

Caution Must be observed to avoid bodily injury (moderately or lightly) or damage to your

equipment.

Note Contains important information and useful tips on the operation of your printer.

1.3. IMPORTANT SAFETY INSTRUCTIONS

General safety instructions that must be observed to use the equipment safely are explained below.

1.3.1. Warning

¾ Do not place the printer in following areas. Doing so may result in the printer falling over and causing

injury.

Angled place.

Areas subject to vibration by other equipment.

Do not stand on the printer or place heavy objects on the printer.

¾ Do not sit on the printer. Doing so may cause the printer to fall and injure people.

¾ Do not cover the ventilation hole of the printer with cloth, such as a blanket or table cloth. Doing so

could obstruct ventilation and cause fire.

¾ Do not place the printer in humid and dusty areas. Doing so may result in electrical shock or fire.

¾ Be sure that the following is performed before replacing parts.

Turn the printer off.

Disconnect the power cable from the electric outlet. Not doing so may cause electric shock or

damage to the electric circuit.

Unplug the cables connected to the printer.

Page 15

Rockhopper II series printers – Maintenance Manual

16

AP-74065, Rev. 1.2, 27/09/04

1.3.2. Caution

¾ Assembling and disassembling the printer are possible only for the parts shown in the operation manual.

Do not disassemble any frame parts or parts of which disassembling procedures are not shown in the

manual. Doing so may cause trouble that cannot be restored, as the printer is originally assembled in

the factory with a high accuracy of 1/100 mm.

¾ Do not touch the elements on the circuit board with bare hands. Doing so may cause static electricity

and break the elements.

¾ Do not press down the transparent film on the sides of the damper assembly with your hands. The

damper assembly is filled with ink and pressing on the film will make the ink spurt out.

¾ Be careful not to scratch the transparent film on the sides of the damper assembly.

¾ Be careful not to touch the surface of the print head’s nozzles or to let dirt adhere to them.

¾ There is some remaining ink in the tubes. Be careful that the ink is not spilled from the tube onto the

printer or objects close to the printer.

¾ If you need to operate the printer with the cover removed for maintenance, be careful not to get hurt by

the moving parts.

¾ Do not oil the printer mechanism with oil other than the oil designated by MUTOH. Doing so may

damage the parts or shorten the lifetime.

¾ If the power substrate assembly needs to be removed, disconnect the power cable and wait for at least 5

minutes before taking it out. This will discharge the residual electrical charge of the electrolytic capacitor.

Touching the substrate before the capacitor discharges may cause electric shock.

¾ When connecting or disconnecting the FFC type cable from the connector of the main substrate

assembly, be sure to connect or disconnect the cable straight out from the connector. Connecting or

disconnecting at a slant angle may damage, break or short-circuit the inner terminal of the connector.

That may damage the elements on the substrate.

¾ When connecting or disconnecting the FFC type cable from the connector of the CR substrate, be sure

to connect or disconnect the cable straight out from the connector. Connecting or disconnecting at a

slant angle may damage, break or short-circuit the inner terminal of the connector. That may damage

the elements on the substrate.

¾ Before replacing parts, be sure to adjust the capping position. When the capping position adjustment

has not been implemented, the cleaning position and other operational positions can exit the alignment

and normal operations become impossible.

¾ Pay attention to the following points when performing the cutter endurance operation.

Install an available ink cartridge.

Make sure that media initialization has been completed.

¾ Make sure that the power of the printer is OFF before performing the parameter backup. Performing the

parameter backup with the power ON may damage the main substrate or data may not be properly

installed.

¾ Make sure that the power of the printer is OFF before installing the firmware. Installing the firmware with

the power ON may damage the main substrate assembly or data may not be properly installed.

¾ Ensure there is sufficient space around the printer when performing maintenance work.

¾ Maintenance must be done by more than one person for :

detaching the printer from the stand or attaching it.

packing the printer for transportation.

¾ Be sure to directly clean when spoiling RH Cleaning Liquid. Because this liquid could damage the paint.

Page 16

Rockhopper II series printers – Maintenance Manual

17

AP-74065, Rev. 1.2, 27/09/04

1.4. WARNING LABELS

The handling, attachment locations, and types of warning labels are explained below.

Warning labels are attached to areas to which attention should be paid. Read and understand the positions

and contents thoroughly.

1.4.1. Handling the operation procedure labels

Notes :

¾ Make sure that all labels can be recognized. If text or illustrations are invisible,

clean or replace the label.

¾ When cleaning labels, use a cloth with water or neutral detergent. Do not use a

solvent or gasoline.

¾ If a warning label has been damaged, lost or cannot be recognized, replace the

label.

1.4.2. Locations and types of operation procedure labels

The locations of warning labels are shown below.

(1) Front Part

Page 17

Rockhopper II series printers – Maintenance Manual

18

AP-74065, Rev. 1.2, 27/09/04

No. Type

1

CAUTION VORSICHT ATTENTION

> Do not open the front cover or touch the media during printing.This will result in poor image quality.

> If no printing is to be done for some time, remove the media and put the hold lever in the up

position. Otherwise the media may lift up and become wrinkled and you will not be able to obtain

good printing results.

> Öffnen Sie wärhend des Druckens die Frontabdeckung nicht und berü hren Sie das

Druckmaterial nicht.

> Wenn Sie wärhend lä ngere Zeit den Drucker nicht benutzen, nehmen Sie das Druckmaterial

heraus und stellen Sie den Halthebel in die obersten Position. Sonst kann sich das Druckmaterial

aufheben und zerknittern und demzufolge erzielen Sie keine gute Druckergebnisse mehr.

> N'ouvrez pas le couvercle quand l'imprimante est en train d'imprimer. Ne touchez pas non plus

le papier afin d'éviter que la qualité s'aggrave.

> Si vous ne comptez pas imprimer pendant un certain temps, retirez le papier et mettez le levier

en position levé e. Sinon, le support risque de se soulever et de se froisser et vous n'obtiendrez

pas de bonne qualité d'impression.

2 Only on a Rockhopper II 2H printer

CAUTION VORSICHT ATTENTION

> To avoid injury, keep fingers away from the

cutter blade.

> Um Verletzungen zu vermeiden, berü rhen Sie das

Schneidemesser nicht.

> Ne touchez pas la lame afin d'éviter des blessures.

> To avoid injury, do not touch the edge of the

steel belt.

> Um Verletzungen zu vermeiden, berü hren Sie den

Stahl-Antriebsriemen nicht .

> Ne touchez pas la courroie de transmission en

acier afin d'éviter des blessures.

A Only on a Rockhopper II 4H printer

Page 18

Rockhopper II series printers – Maintenance Manual

19

AP-74065, Rev. 1.2, 27/09/04

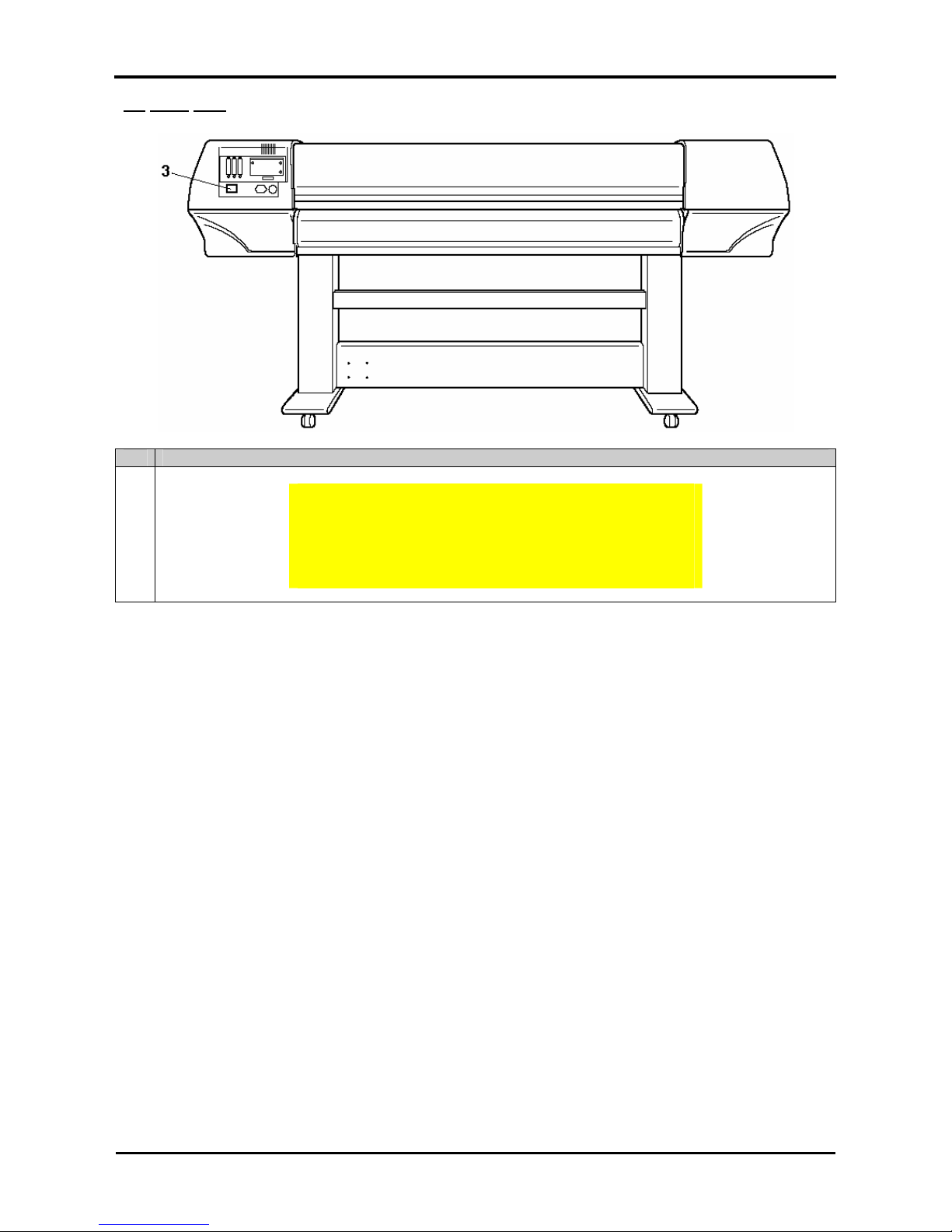

(2) Back Part

No. Type

3

CAUTION

THIS UNIT HAS TWO POWER SUPPLY CORDS

STANDARD. TO REDUCE THE RISK OF ELECTRICAL

SHOCK, DISCONNECT ALL POWER SUPPLY CORDS

BEFORE SERVICING.

Page 19

Rockhopper II series printers – Maintenance Manual

20

AP-74065, Rev. 1.2, 27/09/04

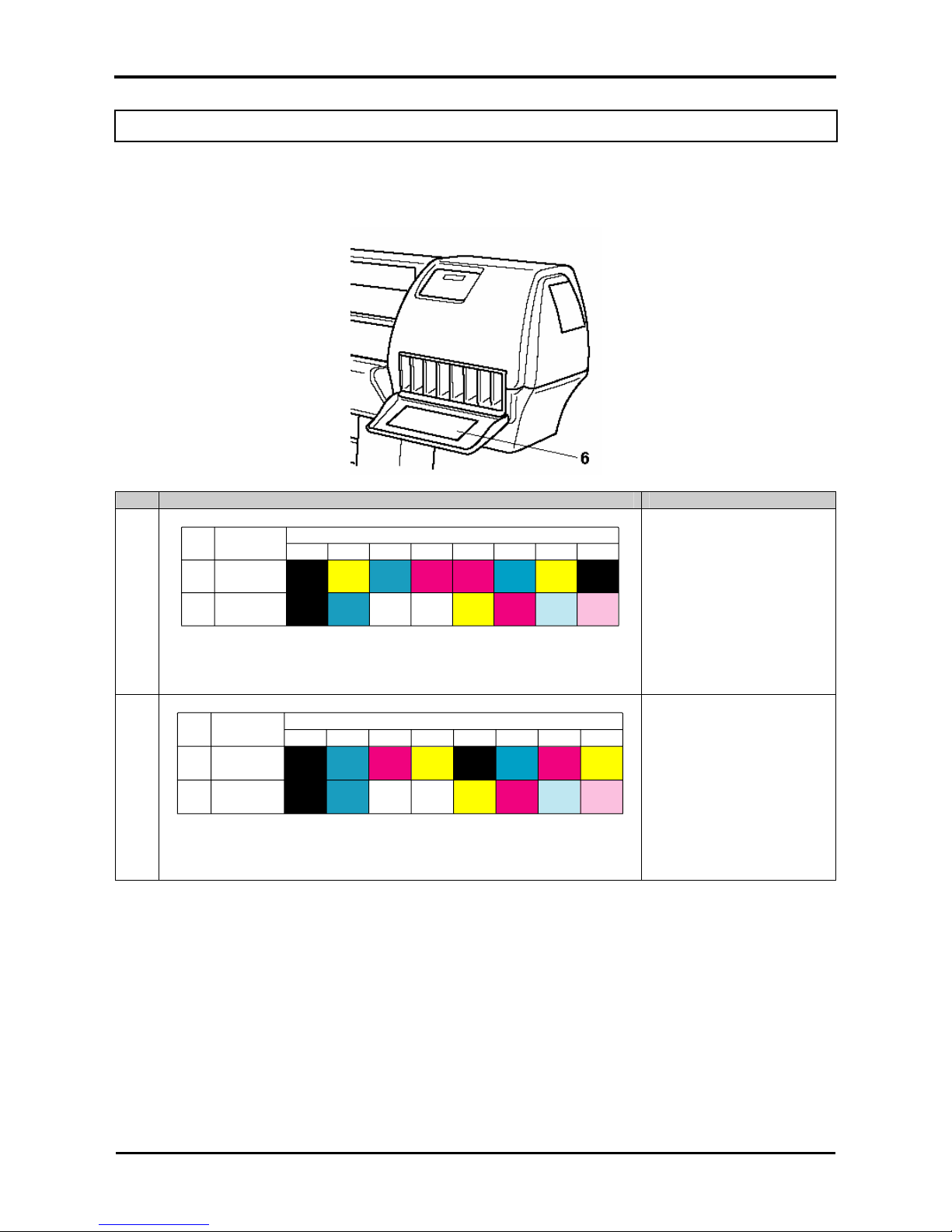

1.5. OPERATION PROCEDURE LABELS

The handling, attachment locations and types of operation procedure labels are explained below.

Your printer has labels, which give simple explanations of operations that require particular care. Read and

understand the locations and contents of these labels thoroughly before performing your work.

No. Type Refer to

6

Yellow

Magenta

Cyan

Black

Transition

Magenta

Liquid

Light

Magenta

Light

Cyan

Magenta

Cyan

Yellow

Yellow

Black

Ink Type

Slot Number of Ink Cartridge

1

2

3

4

56

7

8

Number

of the

Colours

4

6

Eco Solvent

2x4 colours

Eco Solvent

1x6 colours

Black

Transition

Liquid

Cyan

Æ Refer to the User’s

Guide “Installing ink

cartridges”

Please note that ink

cassettes order is different

for 87” printers versus 50”

and 64” printers.

(Label 50” and 64” printer)

6

Yellow

Black

Magenta

Cyan

Black

Transition

Magenta

Liquid

Light

Magenta

Light

Cyan

Cyan

Cyan

Yellow

Yellow

Black

Ink Type

Slot Number of Ink Cartridge

1

2

3

4

56

7

8

Number

of the

Colours

4

6

Eco Solvent

2x4 colours

Eco Solvent

1x6 colours

Transition

Liquid

Magenta

Æ Refer to the User’s

Guide “Installing ink

cartridges”

Please note that ink

cassettes order is different

for 87” printers versus 50”

and 64” printers.

(Label 87” printer)

Page 20

Rockhopper II series printers – Maintenance Manual

21

AP-74065, Rev. 1.2, 27/09/04

2. PRODUCT OVERVIEW

2.1. INTRODUCTION

This chapter explains the features, part names, and functions of the printer.

2.2. FEATURES

The features of the printer are explained below.

(1) High speed output

Both models feature new print heads and achieve high speed printing.

They also offer printing widths up to 1263 mm in 50-inch, 1643 mm in 64-inch and 2230 mm in 87-inch spec

possible.

(2) Wide variety of compatible media

Adjustable head height can adapt to various media thickness from 0.08 up to 1.1 mm.

(3) Vibrant Colour Reproduction

To reproduce sharp and vivid colour, 4, 6 and 8 ink colours are used for printing. The 220ml large

capacity ink tank is equipped with an IC chip. This unit can automatically detect the ink quantity,

significantly improving productivity.

(4) Effective usage of media

A JOG feature is provided to allow setting of the printing position as required. Because printing

can be performed on media on which was already printed, excess space can be used effectively.

(5) RIP

Software Starter Pack included in-the-box. (To be defined with the order.)

Page 21

Rockhopper II series printers – Maintenance Manual

22

AP-74065, Rev. 1.2, 27/09/04

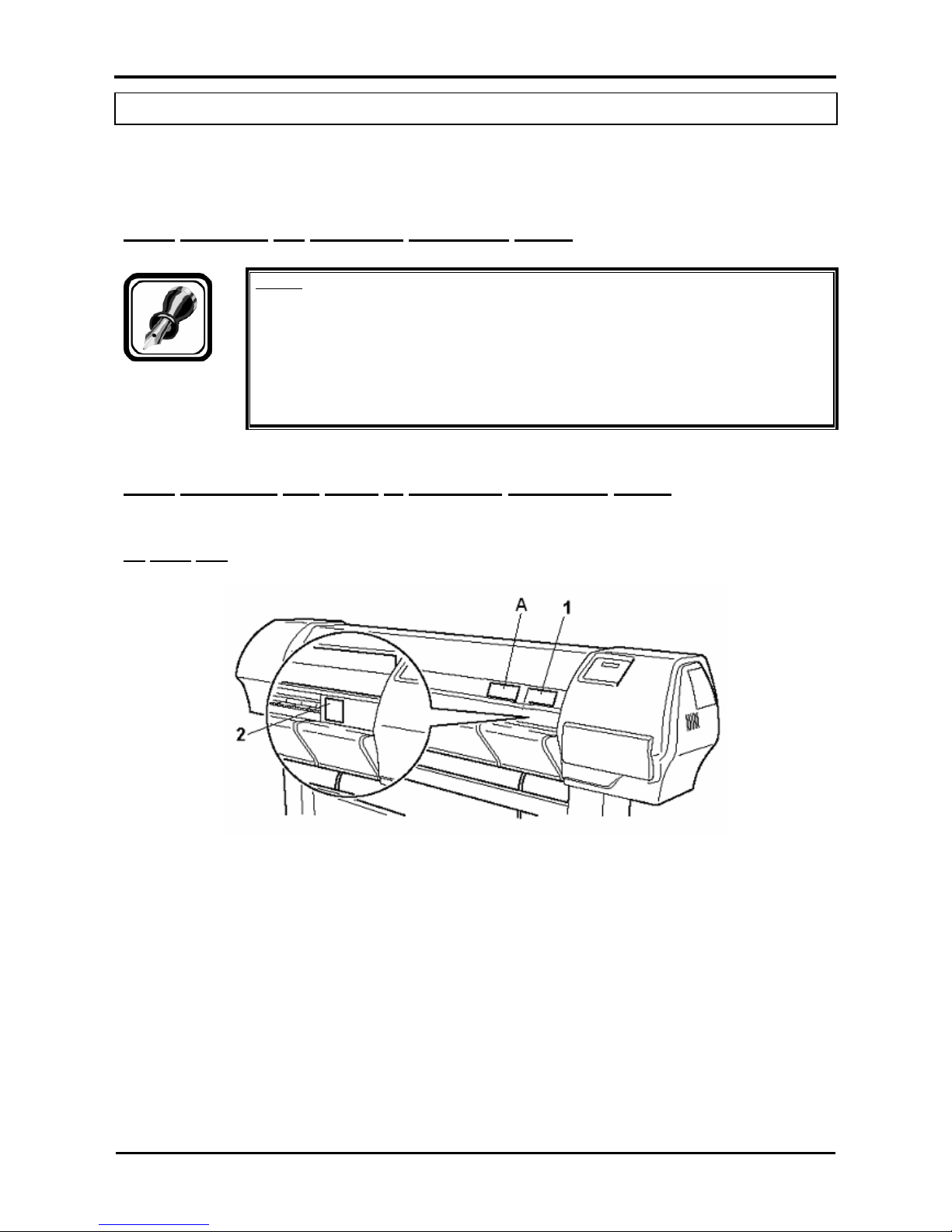

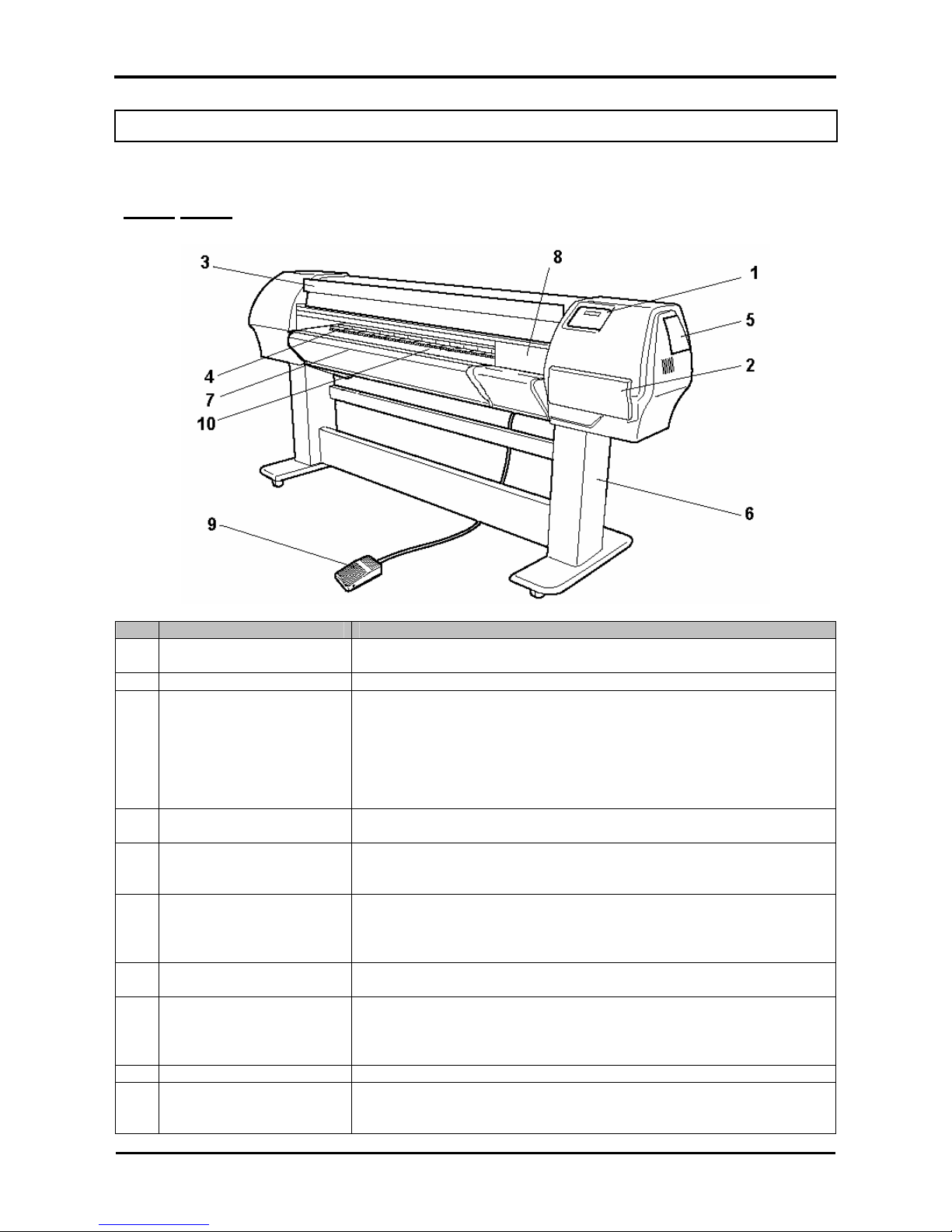

2.3. PART NAMES AND FUNCTIONS

Part names and functions are explained below.

2.3.1. Front

No. Name Function

1 Operation panel This panel is used to set operational conditions, the status of the printer,

and other functions.

2 Ink compartment This is the place for installing ink cartridges.

3 Front cover This cover keeps the operator safe from the drive parts of the printer

while it is operating. Only open and/or close the cover to perform

following operations:

¾ Media setting and replacement

¾ Cutter blade replacement

¾ Cleaning the cleaning wiper

¾ In case of media jam.

4 Pressure rollers This roller is used to press the media from above and keep it flat when

printing.

5 Maintenance cover This protects users from electric shocks caused by touching the internal

electrical parts. The cover is opened when expansion memory

(optional) has to be installed, and is closed for normal use.

6 Stand This stand is used to install the printer on a surface flat floor.

The following options are available for installation.

¾ Take-up system + scroller receiver

¾ Motorized roll-off / roll-up system

7 Media cut groove Only onto the Rockhopper II 4H printer !

Used to cut the media straight when it is cut manually.

8 Carriage cover Only onto the Rockhopper II printer !

This is a cover to protect the user from the internal components of the

unit. This is opened during following operation :

¾ When cleaning the cleaning wiper

9 Foot switch This switch is used to raise and lower the pressure rollers.

10 Paper Guide Support the media during printing

In the Rockhopper II it houses post-heater (dryer).

In the Rockhopper II 4H it houses the fixer, post-fixer and dryer.

Page 22

Rockhopper II series printers – Maintenance Manual

23

AP-74065, Rev. 1.2, 27/09/04

2.3.2. Back

No. Name Function

1 AC inlet This is the inlet interface to which the power plug is connected.

2 Interface connector This is the connector to which the interface cable is connected.

3 Foot switch connector This is the connector to which the foot switch cable is attached.

4 Insertion slot This is the slot for inserting media when loading it.

5 Interface slot 1 The network interface board attaches here.

6 Interface slot 2

7 Interface slot 3

This is not used for this printer.

Close it with the cover.

8 Hard disk slot The hard disk attaches here. When not using a hard disk, keep the

cover closed.

9 Nameplate rating The type, name, serial number, rating and other details of the printer are

labelled here.

10 Rear Heater Supports the media during printing and houses the pre-heaters.

Page 23

Rockhopper II series printers – Maintenance Manual

24

AP-74065, Rev. 1.2, 27/09/04

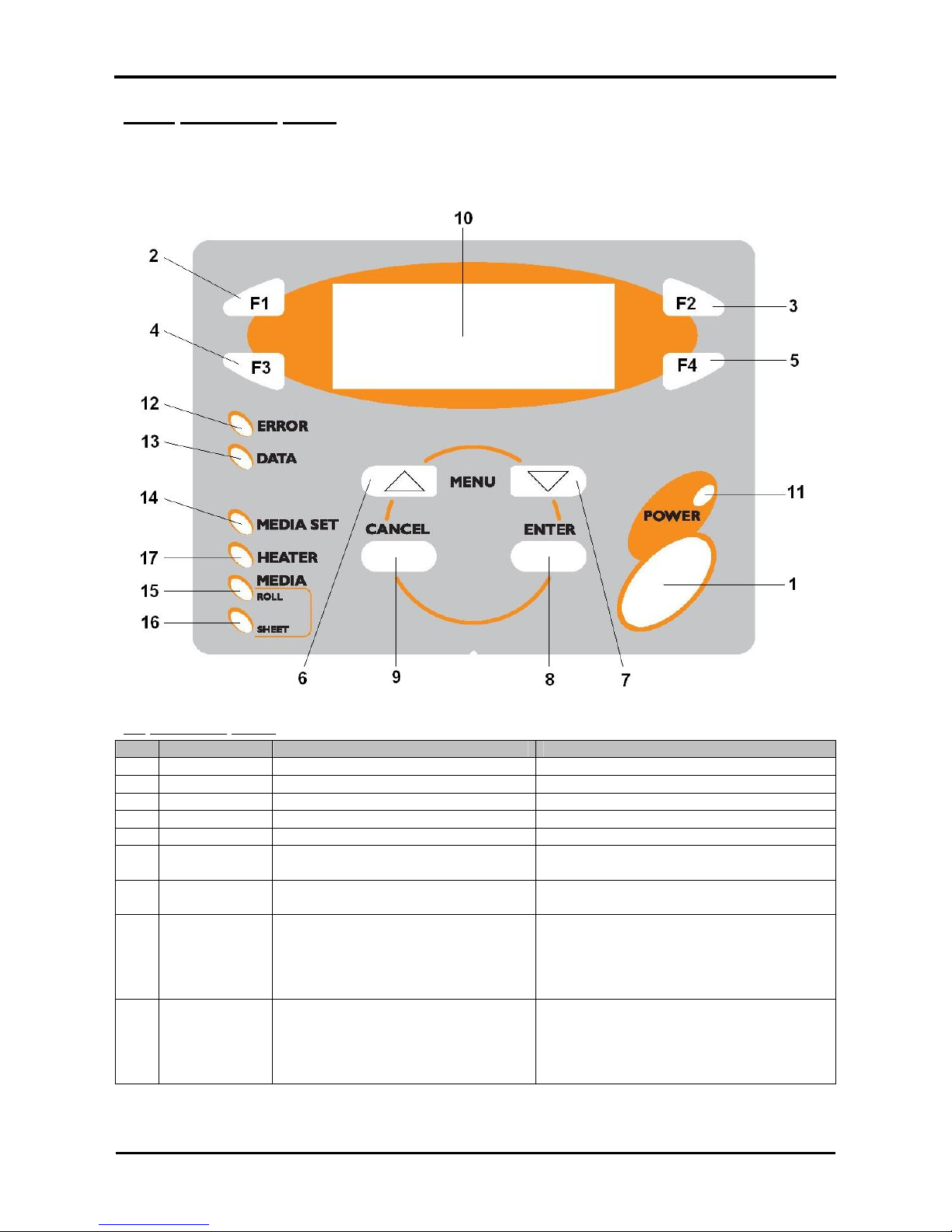

2.3.3. Operation panel

The operation panel is used to set operation conditions, display the status of the printer and set other

functions.

The names and functions of the operation keys and status lamps are explained below.

(1) Operation Keys.

No. Name Normal Setup menu display

1 [POWER] key Turns the printer on and off. Turns the printer on and off.

2 [F1] key Executes the function assigned to F1. Executes the function assigned to F1.

3 [F2] key Executes the function assigned to F2. Executes the function assigned to F2.

4 [F3] key Executes the function assigned to F3. Executes the function assigned to F3.

5 [F4] key Executes the function assigned to F4. Executes the function assigned to F4.

6

[MENU ↑] key

Changes the LCD monitor display to

setup menu status.

Changes the menu in reverse order.

7

[MENU ↓] key

Changes the LCD monitor display to

setup menu status.

Changes the menu in forward order.

8 [ENTER] key Displays the print mode currently set. Determines the new parameter value and

changes the LCD monitor display to the

next menu. Sets the parameter value and

changes the LCD monitor display to the

next menu.

9 [CANCEL] key - Cancels the new parameter value and

changes the LCD monitor display to the

next menu. Clears the parameter value

and changes the LCD monitor display to

the next menu.

Page 24

Rockhopper II series printers – Maintenance Manual

25

AP-74065, Rev. 1.2, 27/09/04

(2) LCD monitor and status lamps.

No. Name Colour Status Function

10 LCD monitor - - The monitor displays the operation status and error

messages of the printer.

ON The printer is on. 11 POWER lamp Green

OFF The printer is off.

Flashing An error has occurred. The contents will be displayed on

the LCD monitor.

12 ERROR lamp Red

OFF Either there is no error or the power is off.

ON The printer is receiving print data.

Flashing The printer is analysing receiving data.

13 DATA lamp Orange

OFF The printer is waiting to receive print data.

ON ¾ The pressure rollers are in the release position.

¾ Media is not set.

14 MEDIA SET lamp Orange

OFF ¾ The pressure rollers are in secured position.

¾ The media is set.

ON The media type is set to roll media. 15 ROLL lamp Orange

OFF The media type is set to sheet media.

ON The media type is set to sheet media. 16 SHEET lamp Orange

OFF The media type is set to roll media.

ON The temperature of the heating elements is the requested

temperature.

The real temperature is the same as the requested

temperature.

Flashing The heating elements are warming up.

The real temperature is different as the requested

temperature.

17 HEATER lamp Orange

OFF The heating elements are powered OFF.

Page 25

Rockhopper II series printers – Maintenance Manual

26

AP-74065, Rev. 1.2, 27/09/04

2.4. PRINTER STATUS

The status of the printer is explained below.

2.4.1. Normal

Indicates that the printer can print when media is loaded.

You can also make settings using the operation panel.

Notes :

¾ Refer to the User’s Guide.

2.4.2. Setup menu display

Indicates that you can make settings using the operation panel.

Operations for printing can be conducted with the operation panel.

Notes :

¾ Refer to the User’s Guide.

2.4.3. Self-diagnosis Function Display

Indicates that you can make settings concerning adjusting the printer using the operation panel. Keys of the

operation panel have the same names and functions as the display status of the setup menu.

Notes :

¾ Refer to the chapter “Self-Diagnosis function”.

2.4.4. Maintenance Mode Display

Indicates that you can make settings concerning the life of the printer. Keys of the operation panel have the

same names and functions as the display status of the setup menu.

Notes :

¾ Refer to the chapter “Maintenance mode”.

Page 26

Rockhopper II series printers – Maintenance Manual

27

AP-74065, Rev. 1.2, 27/09/04

2.4.5. Selecting Language

This chapter explains how to select the language on the display.

Japanese or English is selectable for the display language of the printer.

Follow the steps below to select the display language.

Step 1 : Press the [POWER] key while pressing the [CANCEL] key on the operation panel.

Step 2 : Press the [F1] key or [F2] key on the operation panel to change the parameter.

Step 3 : Press the [POWER] key, and then press the [POWER] key again.

Page 27

Rockhopper II series printers – Maintenance Manual

28

AP-74065, Rev. 1.2, 27/09/04

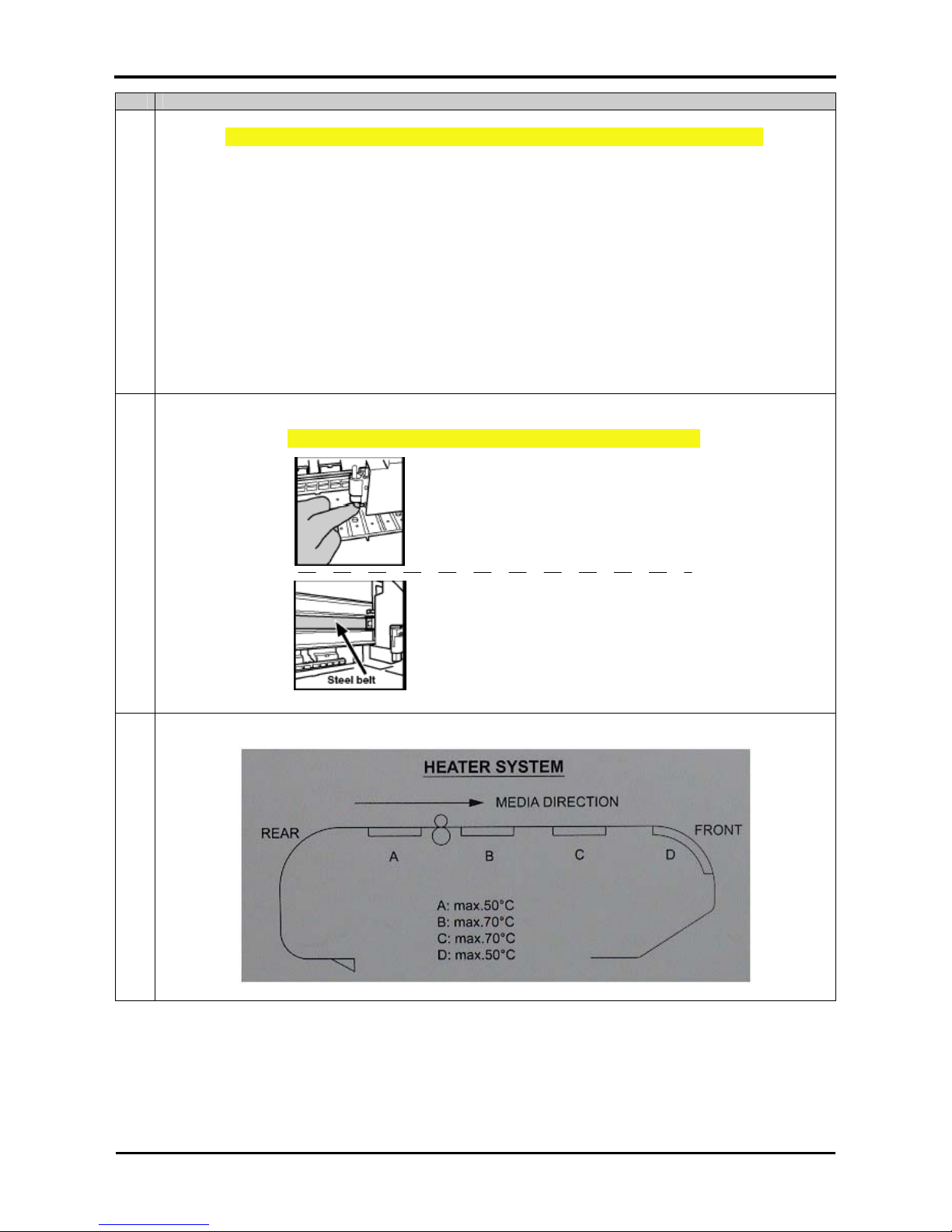

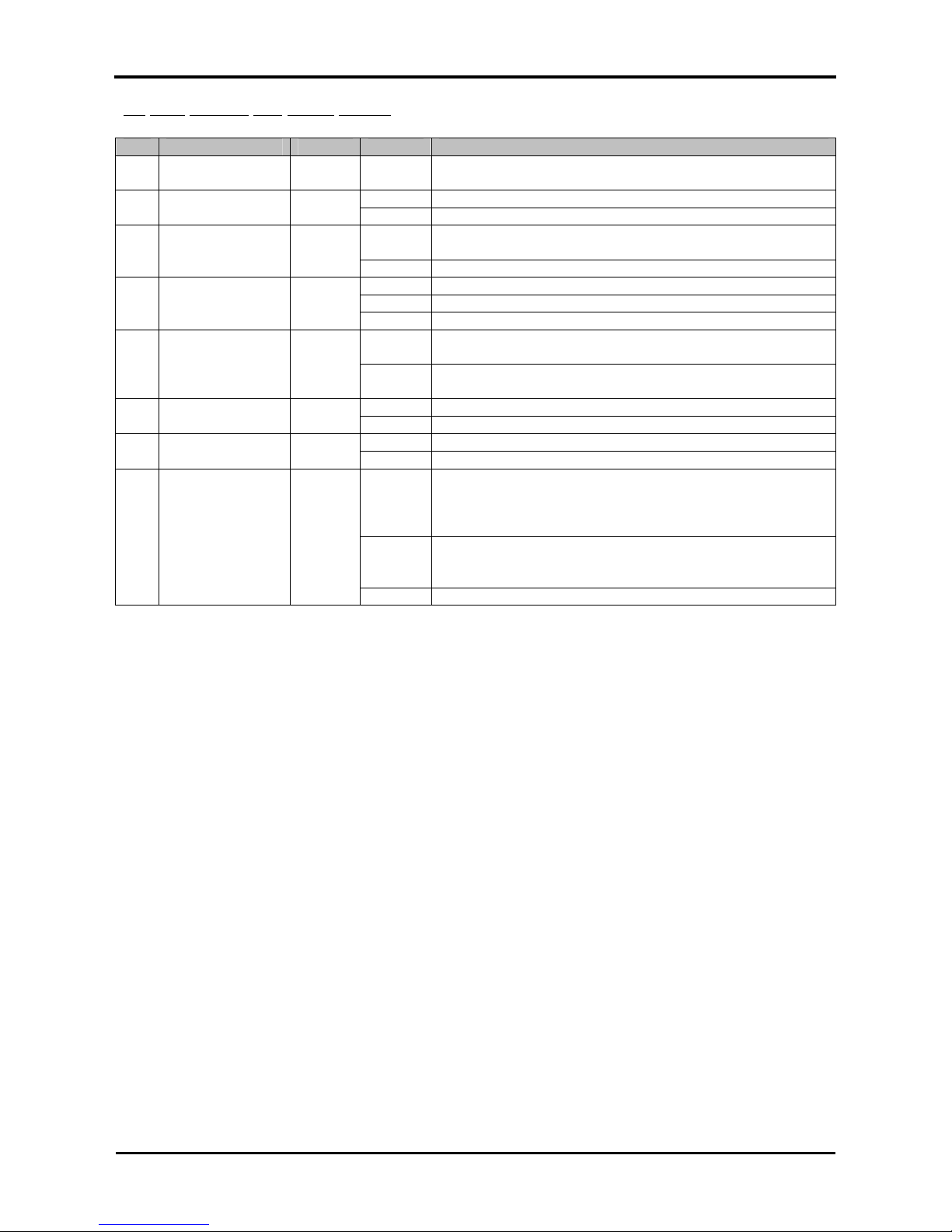

2.5. POSITION AND FUNCTION OF THE HEATING ELEMENTS

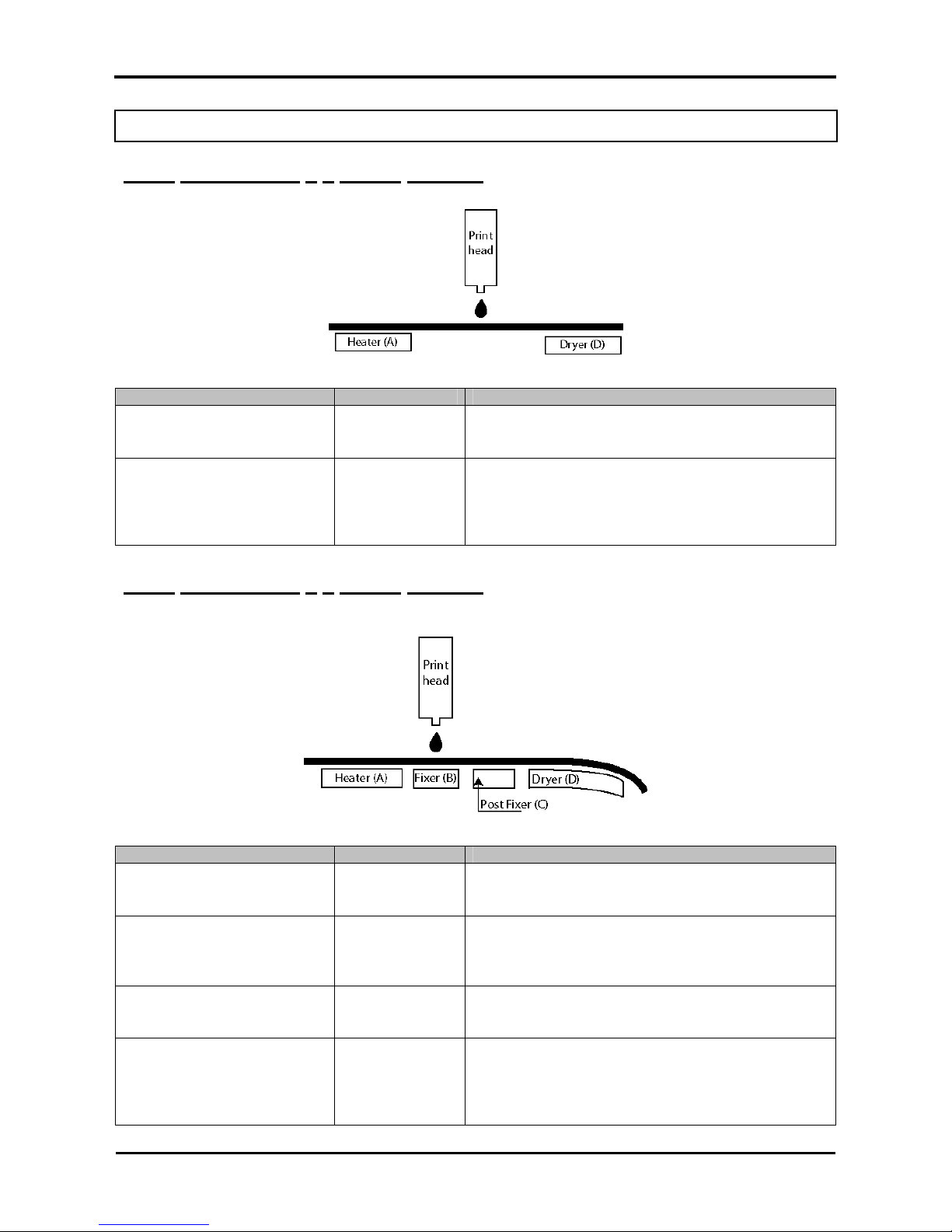

2.5.1. Rockhopper II 2 heater printers

Heater element Temperature Function

Pre-heater (Heater A) 20 – 50°C

→ Open the pores to make the media more receptive

for eco-solvent or eco-solvent plus™ ink.

Dryer (Heater D) 20 – 50°C

→ Applying heating immediately after printing

improves ink/media anchorage.

→ The dryer helps to make the media touch-dry before

it reaches the automatic take-up system.

2.5.2. Rockhopper II 4 heater printers

Heater element Temperature Function

Pre-heater (Heater A) 20 – 50°C

→ Open the pores to make the media more receptive

for eco-solvent or eco-solvent plus™ ink.

Fixer (Heater B) 20 – 70°C

→ To establish optimum fixation onto the media

(coated and uncoated).

→ Optimizes the dot gain control.

Post-Fixer (Heater C) 20 – 70°C

→ The post-fixer finalizes the fixation process and

helps to make the prints touch-dry.

Dryer (Heater D) 20 – 50°C

→ The dryer completes the drying for compatibility

with the take-up in combination with higher output

speeds.

→ Stickiness of printed banner materials is improved.

Page 28

Rockhopper II series printers – Maintenance Manual

29

AP-74065, Rev. 1.2, 27/09/04

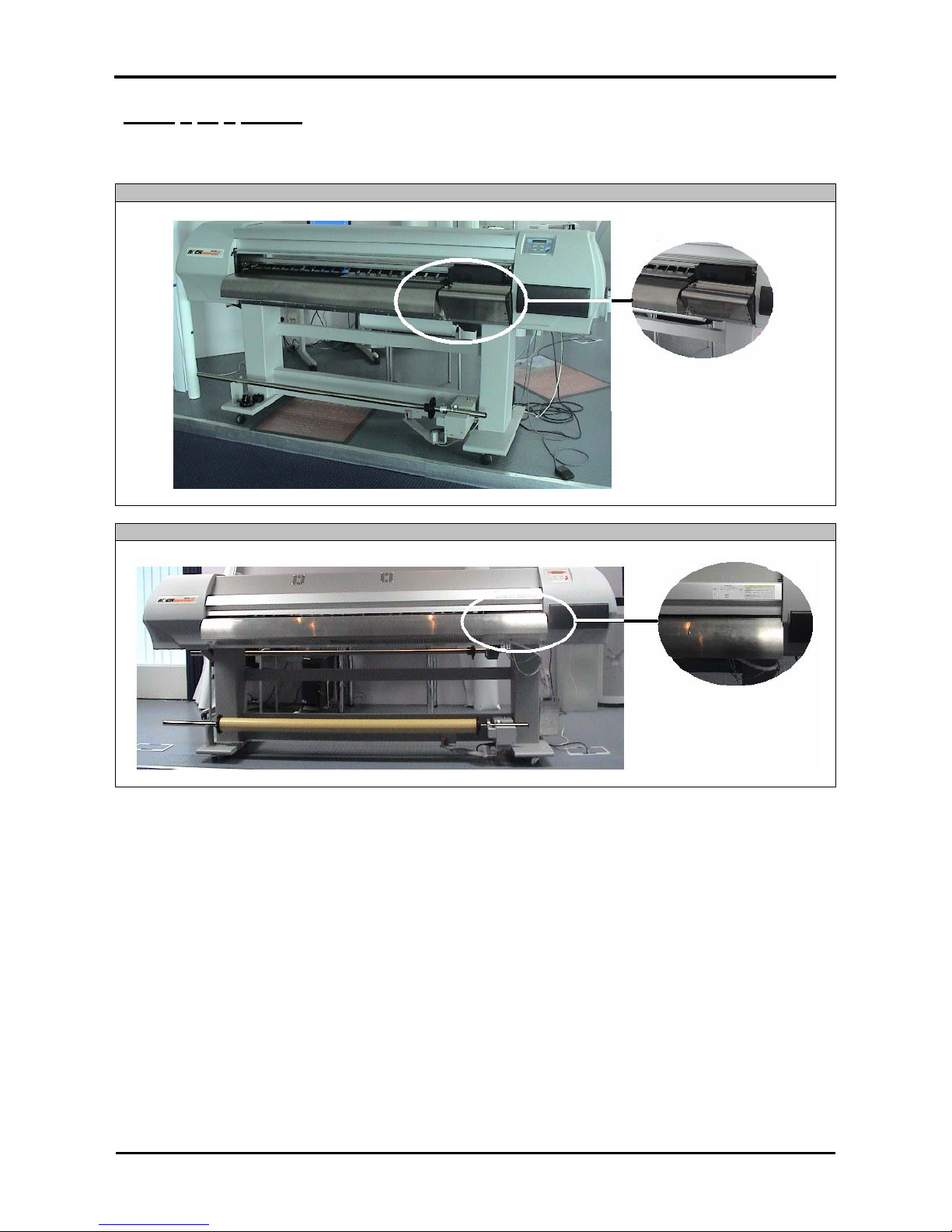

2.5.3. 2 or 4 heater

To verify if your printer is equipped with 2 or 4 heaters, please refer to the photo’s mentioned below.

Rockhopper II 2 heater printer

Rockhopper II 4 heater printer

Page 29

Rockhopper II series printers – Maintenance Manual

30

AP-74065, Rev. 1.2, 27/09/04

Page 30

Rockhopper II series printers – Maintenance Manual

31

AP-74065, Rev. 1.2, 27/09/04

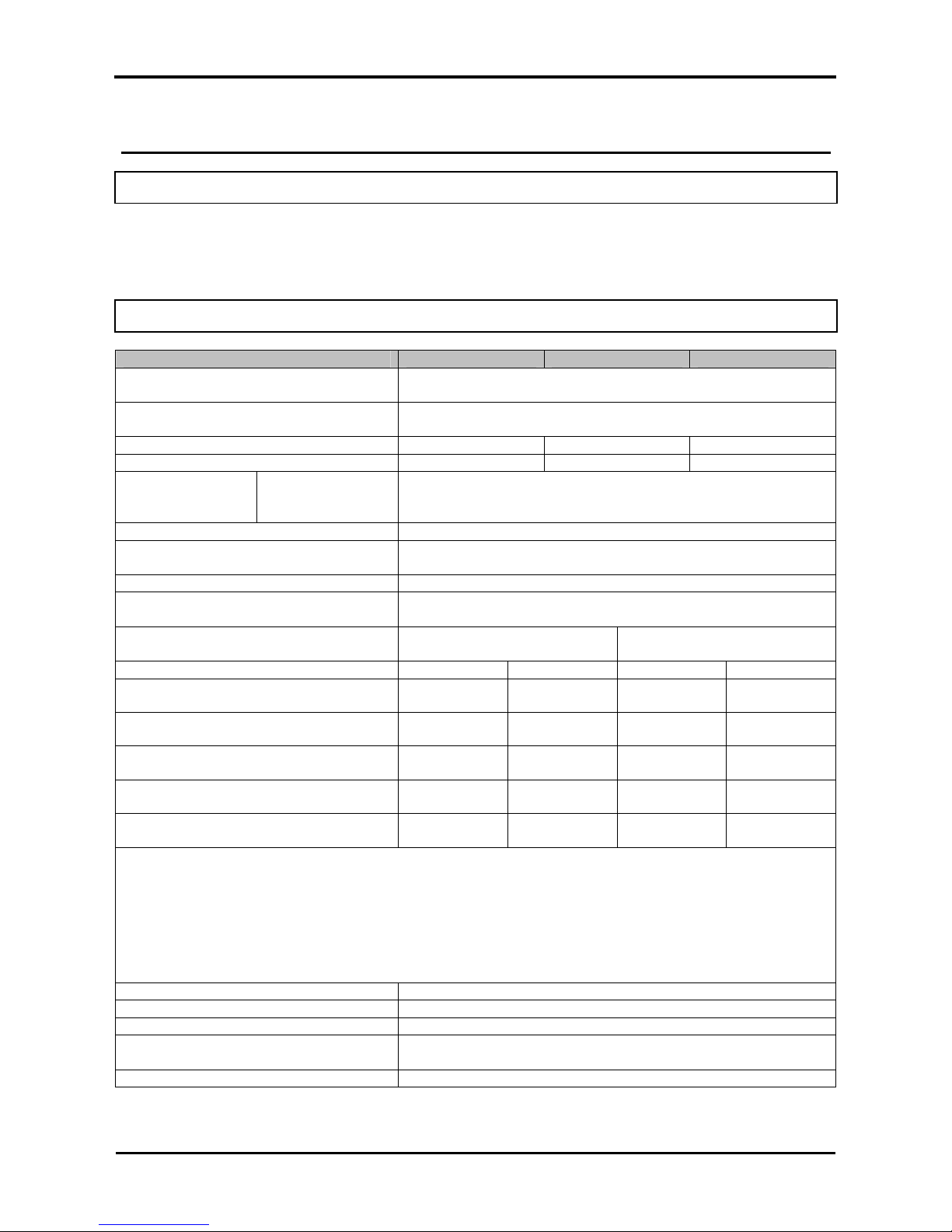

3. SPECIFICATIONS

3.1. INTRODUCTION

This section explains the specifications, optional parts and supplies, installation

procedures for optional parts, and user support for this printer.

3.2. PRODUCT SPECIFICATIONS

Printers 50”- model 64”- model 87”- model

Technology Drop-on-demand Micro Piezo Inkjet Technology.

Variable drop mass output between 5.4 ng and 41.5 ng

Media Thickness Compensation Automatic media thickness compensation.

Variable – RIP controlled – Head Height

Maximum Media Widths 1273 mm 1653 mm 2240 mm

Maximum Print Widths 1263 mm 1643 mm 2230 mm

Media Thickness

Diameter / Core

Weight

Range: 0.08 mm – 1.1 mm

Maximum: 150 mm / 2” & 3” for 50,64 and 3” for 87

Maximum: 50 kg

Colour Channels 8 colour channels – 4 or 6 process colour output

Inks

Eco-Solvent Plus 2xCMYK speed set-up

Eco-Solvent Plus CMYKLcLm photo tone rendering set-up

Ink Cassette Capacity / Type 220 ml / smart chip ink type & order sensing

Print Modes & Panel Control Options Uni & Bi-directional output, Interweaving, Mirror Output, Multi

Copy, Ink Status, Origin Control

Speed Overview Table ( * )

914mm (36”) wide output

50 & 64 87

Ink Set-Up 2 x 4 Colours 6 Colours 2 x 4 Colours 6 Colours

360 x 360

{{{ {

5.7 – 37.7 2.9 – 19.6 5.7 – 37.7 3.9 – 27.7

720 x 360

{

5.8 – 22.8 2.9 – 11.5 5.9 – 23.1 5.3 – 20.6

720 x 720

{{{ {

2.9 – 11.4 1.4 – 5.6 2.9 – 11.5 2.6 – 10.2

1440 x 720

{

2.9 – 5.9 1.4 – 2.8 3.0 – 6.0 2.6 – 5.2

1440 x 1440

{

1.4 – 2.9 0.7 – 1.5 1.5 – 3.0 1.3 – 2.6

Output speeds are given for 914 mm (36”) output.

50” output is 7 % faster, 64” output is 12 % faster and 87” output is 18 % faster.

For each mode, the minimum (Super High Quality) and maximum speed (Super Draft) are given.

Mode dependent, there are between 2 and 6 speed levels per mode, accessible via print direction selection

and interweave control from the RIP software.

Top speeds indicated are super draft modes and do not guarantee production output quality on all media

types.

{{{ Variable Drop Compatible { Fixed Drop Compatible

LCD Display Backlight LED – 4 lines x 20 characters

Take-up System (standard) Automated

Roll Media Core 2” & 3” for 50 & 64 and 3”” for 87

Interface Centronics, IEEE 1284 compatible / Network, High Speed

Interface (standard high-speed interface card – 4 Mb/s).

Graphics Command Language RTL-PASS, MH-GL, MH-GL/2

Page 31

Rockhopper II series printers – Maintenance Manual

32

AP-74065, Rev. 1.2, 27/09/04

Printers 50”- model 64”- model 87”- model

Power Consumption 1100 VA

80 VA in stand-by

mode

1300 VA

80 VA in stand-by

mode

1400 VA

100 VA in stand-by

mode

External Dimensions in mm (W x D x H)

Weight

2700 x 750 x 1250

170 kg

3100 x 750 x 1250

195 kg

3700 x 750 x 1250

215 kg

Noise Level Operating: 54 dB or less

Standard VCCI (Class A), FCC (Class A), UL, CE, CCIB

Standard Items Hard Disk: 20.3 GB – Stores 16 jobs – Up to 99 copies/job –

PostScript RIP included

Optional Item Extra Scroller Bars – Take-up System – Roll-off / roll-up system

50” model 11.7 m² or larger. Frontage of 4.3 m or greater.

64” model 12.7 m² or larger. Frontage of 4.7 m or greater.

Area

87” model 14.3 m² or larger. Frontage of 5.3 m or greater.

Floor loading capability 2490Pa (300kg/m²) or over

Voltage AC100V - 120V or AC220V – 240V

Frequency 50/60Hz±1Hz

Electrical

Capacity AC100V - 120V: 3A or more

AC220V - 240V: 1.5A or more

Recommended

working environment

Temperature: 25°C

Humidity: 40% to 60%, without condensation

Operational

conditions

Temperature: 18°C to 35°C

Humidity: 40% to 60%, without condensation

Rate of change Temperature: No more than 2°C per hour

Humidity: No more than 5% per hour

Environmental

Storage environment Temperature: -20°C to 60°C

Humidity: 5% to 85%, without condensation (When ink has been

discharged.)

Specifications are liable to changes without prior notice. All trademarks mentioned are property of their

respective owners.

Page 32

Rockhopper II series printers – Maintenance Manual

33

AP-74065, Rev. 1.2, 27/09/04

3.3. INTERFACE SPECIFICATIONS

This section explains the specifications for the interfaces supported by this product.

3.3.1. Centronics Bidirection Parallel Interface:IEEE1284)

(1) Interface Specifications

Item Specifications

Transmission modes Compatible , Nibble , ECP Mode

Data length 8 bits

Transmission direction Unidirectional (receiving only), Bidirectional

Connector pin number

(2) Table of parallel interface pin numbers and signals

Pin

number

Connection

signal

Signal direction Pin

number

Connection signal Signal

direction

1 STROBE To printer Å 19 SG

2 DATA1 To and from printer Å Æ 20 SG

3 DATA2 To and from printer Å Æ 21 SG

4 DATA3 To and from printer Å Æ 22 SG

5 DATA4 To and from printer Å Æ 23 SG

6 DATA5 To and from printer Å Æ 24 SG

7 DATA6 To and from printer Å Æ 25 SG

8 DATA7 To and from printer Å Æ 26 SG

9 DATA8 To and from printer Å Æ 27 SG

10 ACK From printer Æ 28 SG

11 BUSY From printer Æ 29 SG

12 P ERROR From printer Æ 30 SG

13 SELECTED From printer Æ 31 INIT To printer Å

14 AUTOFD To printer Å 32 FAULT From printer Æ

15 Not connected 33 Not connected

16 SG 34 Not connected

17 FG 35 Not connected

18 +5V 36 SELECTIN To printer Å

(3) Recommended Centronics cable specifications

Item Specifications

Interface Dual-direction Parallel Interface:IEEE1284

Structure AWG28×18 (twisted pair wiring)

Shield construction Metallic tape + weaving (double shielded cable)

Characteristic impedance

62 Ω

Page 33

Rockhopper II series printers – Maintenance Manual

34

AP-74065, Rev. 1.2, 27/09/04

3.3.2. Network Interface (Optional) Specifications

Item Specifications

Network Type Ethernet IEEE802.3

Network I/F 10 Base-T,100 Base-TX

(RJ-45 connector, twisted pair cable)

* Automatic switching

Protocol TCP/IP

Mode

• ftp

• lpr

• socket

Functions

• Automatic protocol recognition

• Transmission speed up to 4 MB/s

• Network environment setting by Web.

Page 34

Rockhopper II series printers – Maintenance Manual

35

AP-74065, Rev. 1.2, 27/09/04

3.4. INSTALLATION

The Installation of the unit is explained below.

3.4.1. Conditions of the installation environment

Important :

Do not place the printer in following areas. Doing so may result in the printer

falling over and causing injury.

Unstable surfaces

Slanted place

Where vibration of other machines is transmitted.

Do not sit on the printer or put heavy things on the printer. Doing so may cause

the printer to fall and injure people.

Do not cover the ventilation hole of the printer with cloth, such as a blanket or

table cloth. Doing so could obstruct ventilation and cause fire.

Do not place the printer in humid and dusty areas. Doing so may result in

electrical shock or fire.

(1) Conditions of the installation environment

Select the place to install this unit according to the environmental condition in the table below.

50” model 11.7 m² or larger. Frontage of 4.3 m or greater.

64” model 12.7 m² or larger. Frontage of 4.7 m or greater.

Area

87” model 14.3 m² or larger. Frontage of 5.3 m or greater.

Floor loading capability 2490Pa (300kg/m²) or over

Voltage AC100V - 120V or AC220V – 240V

Frequency 50/60Hz±1Hz

Electrical

Capacity AC100V - 120V: 3A or more

AC220V - 240V: 1.5A or more

Recommended

working environment

Temperature: 25°C

Humidity: 40% to 60%, without condensation

Operational conditions Temperature: 18°C to 35°C

Humidity: 40% to 60%, without condensation

Rate of change Temperature: No more than 2°C per hour

Humidity: No more than 5% per hour

Environmental

Storage environment Temperature: -20°C to 60°C

Humidity: 5% to 85%, without condensation (When ink has

been discharged.)

Page 35

Rockhopper II series printers – Maintenance Manual

36

AP-74065, Rev. 1.2, 27/09/04

Notes :

Avoid the following places with regard to temperature or humidity. If doing so, it may

affect the printing result.

Places where the temperature of humidity may rapidly change even though it is within

the correct range.

Places where there is direct sunlight or strong light.

Places where there is direct air from the air conditioner.

It is recommended to install the printer in an environment where the air conditioning is

adjustable for temperature and humidity.

(2) Installation space

Install on a horizontal place that satisfies following conditions.

The floor has the sufficient strength to sustain the weight of the printer and the stand.

Notes :

Refer to ‘product specifications’.

a = 1500 mm

b = 1500 mm

c = 2500 mm

d = 600 mm

e = 1250 mm

Page 36

Rockhopper II series printers – Maintenance Manual

37

AP-74065, Rev. 1.2, 27/09/04

4. PARTS REPLACEMENT

4.1. INTRODUCTION

This chapter explains the procedures for replacing and removing maintenance parts.

Important :

¾ Before replacing parts, be sure to perform following operations.

Turn the power OFF.

Remove the electrical cable from the socket. Otherwise, you may

suffer electric shock or the machine’s electric circuits may be

damaged.

Disconnect all cables from the machine. Not doing so could cause

damage to the printer.

Caution :

¾ Assembling and disassembling the printer is only allowed for the parts for which

disassembling procedures are shown in the operation manual.

¾ Do not disassemble any frame parts or parts for which disassembling procedures

are not shown in the manual.

¾ Doing so may cause trouble that cannot be restored, as the printer is originally

assembled in the factory with a high accuracy of 1/100 mm.

Notes :

¾ After replacing the parts, perform necessary lubrication/bonding according to

"Lubrication/Bonding".

Page 37

Rockhopper II series printers – Maintenance Manual

38

AP-74065, Rev. 1.2, 27/09/04

4.2. REMOVING THE COVER

When replacing any of the parts inside the printer, it is necessary to remove all covers.

The procedures for removing the covers are given below.

1 = I/H cover 5 = Panel unit assembly

2 = Side cover R 6 = Y-rail cover

3 = side Cover L 7 = Front paper guide

4 = Front cover

8 = Rear paper guide

Page 38

Rockhopper II series printers – Maintenance Manual

39

AP-74065, Rev. 1.2, 27/09/04

4.2.1. Removing the I/H cover

Step 1 : Remove the ink cartridge.

Step 2 : Open the I/H cover lid.

Step 3 : Remove the 4 screws fixing the I/H cover.

Step 4 : Remove the I/H cover and I/H cover lid.

1 = Screws (M3x12) fixing the I/H cover

Step 5 :

Remove the 2 screws fixing the ink cover sensor.

Step 6 :

Remove the ink cover sensor.

1 = Ink cover sensor 2 = Screws (M2x10) fixing the ink cover sensor

Step 7 :

Replace the parts inside the printer.

Step 8 :

Reinstall all parts in the opposite order of the removal procedure.

Page 39

Rockhopper II series printers – Maintenance Manual

40

AP-74065, Rev. 1.2, 27/09/04

4.2.2. Removing side cover R

Step 1 : Remove the screw from the upper part of the side cover R.

1 = Screws (M4x12) on the upper part of the side cover R

Step 2 : Remove the 2 screws from the bottom of side cover R.

1 = Screws (M4x16) on the side of the bottom of side cover R

Step 3 : Remove the 3 screws from the back of the bottom of side cover R.

1 = Screws (M4x16) on the back of the bottom of side cover R

Page 40

Rockhopper II series printers – Maintenance Manual

41

AP-74065, Rev. 1.2, 27/09/04

Step 4 : Remove the top of the side cover R.

Step 5 : Remove the 4 bolts from the front and back of the inner surface on the bottom of side cover R

and the front cover nut.

1 = Hexagon socket head cap screws (M4x16) 2 = Cover nut

Step 6 : Remove the 6 bolts from the front and back of the bottom surface on the bottom of the side cover

R.

Step 7 : Remove the bottom of side cover R.

1 = Hexagon socket head cap screws (M5x18)

Step 8 : Replace the parts inside the printer.

Step 9 : Reinstall all parts in the opposite order of the removal procedure.

Page 41

Rockhopper II series printers – Maintenance Manual

42

AP-74065, Rev. 1.2, 27/09/04

4.2.3. Removing side cover L

Step 1 : Remove the screw from the side of the upper part of side cover L.

1 = Screws (M4x12) on the side of the upper part of the side cover L

Step 2 : Remove the 2 screws from the front of the bottom of side cover L.

1 = Screws (4x16) on the back of the bottom of side cover L

Step 3 : Remove the 3 screws from the back of the bottom of side cover L.

1 = Screws (M4x16) on the rear of the bottom part of the side cover L

Page 42

Rockhopper II series printers – Maintenance Manual

43

AP-74065, Rev. 1.2, 27/09/04

Step 4 : Remove the 4 bolts and cover nut from the front and back of the inner surface on the bottom of

side cover L.

1 = Hexagon socket head cap screws (M4x16) 2 = Cover nut

Step 5 : Remove the 6 bolts from the front and back of the bottom surface on the bottom of side cover L.

1 = Hexagon socket head cap screws (M5x18)

Step 6 : Remove the bottom of side cover L.

Step 7 : Replace the parts inside the printer.

Step 8 : Reinstall all parts in the opposite order of the removal procedure.

Page 43

Rockhopper II series printers – Maintenance Manual

44

AP-74065, Rev. 1.2, 27/09/04

4.2.4. Removing the front cover

Step 1 : Open the front cover.

Step 2 : Remove the E ring on the left side.

Step 3 : Remove the 4 screws on the left and right cover spindles.

1 = E ring 2 = Screws (M3x8) on the left and right cover spindles

Step 4 : If the machine is a 50-inch model, remove cover spindle L, and then slide and remove the front

cover.

1 = Cover spindle L

Page 44

Rockhopper II series printers – Maintenance Manual

45

AP-74065, Rev. 1.2, 27/09/04

Step 5 : If the machine is 64 or 87-inch model, remove the E ring and the sensor cam, push the cover

spindle L to the origin side and then slide and remove the front cover.

1 = Cover spindle L 2 = Sensor cam

3 = E ring

Step 6 : Reinstall all parts in the opposite order of the removal procedure.

Page 45

Rockhopper II series printers – Maintenance Manual

46

AP-74065, Rev. 1.2, 27/09/04

4.2.5. Removing the carriage cover

Caution :