Page 1

MAINTENANCE

MANUAL

Eco-Solvent Inkjet Printer

Rockhopper 46/62

Rockhopper: AP-74016, Rev:1.0

Page 2

CON1000

Model Name: Rockhopper-46/62

CON1000

Model Name:Rockhopper-46/62

Introduction

Introduction

This equipment is Class 1 communications equipment (communications equipment

to be used in commercial and industrial areas) and conforms to Voluntary

Communications Control Institute (VCCI) standards for data processing and other

equipment for the prevention of radio wave interference in commercial and industrial

areas.

Therefore, if it is used in or near a residential area, it may cause interference with

radio and television reception.

It should be used correctly in accordance with the operation manual.

■ Concerning interference with reception

Since this product emits weak radio waves, if it is not installed and used correctly

and is thought to be causing interference with radio and television reception, this

may be prevented by trying a combination of the following measures:

• Try changing the orientation of the receiving antenna and feeder.

• Try changing the orientation of this product.

• Change the distance between the receiver and this product.

• Try using different power supply systems for the receiver and this product.

■ Trademarks included in this manual

• MUTOH, Model Name:Rockhopper-46/62, MH-GL, MH-GL/2, MH-RTL

are trademarks or trade names of Mutoh Industries Ltd.

• HP, HP-GL, HP-GL/2, HP-RTL, HP759X, HP758X, C2848 are trademarks or

trade names of the Hewlett Packard Company.

• Centronics and Bitronics are trademarks or trade names of the Centronics Data

Computer Company.

• Windows 3.1, Windows 95, Windows NT 3.51, Windows NT 4.0, MS-DOS are

trademarks or trade names of the Microsoft Corporation

• Other names of products and companies are the trademarks or trade names of

each relevant company.

This manual contains basic technical details necessary for marketplace servicing to

maintain product quality and performance of Model Name:Rockhopper-46/62 printer.

Model Name:Rockhopper-46/62 printer is equipped with a self-diagnostic program

that will be of service for adjusting and checking whenever a fault is detected or

during maintenance.

This manual contains all the basic items but actual maintenance work should be

undertaken only after a thorough understanding of the functions, operations and

movements has been gained from the operation manual and by other means.

Please note that there may be occasions where the name of a part used in the

explanation in this manual differs from the name of that same part that is used in the

operation manual or in the parts list.

Published by Mutoh Europe,

Archimedesstraat 13, 8400 Oostende Belgium

Copyright February 2002, Mutoh Europe All rights reserved.

CAUTION:

• The details of this product and the contents of this manual are

protected by copyright held by this Company and, except for

legitimate use by individuals, unauthorized copying, reproduction

or distribution in whole or part is forbidden.

• Details contained in this manual may be subject to future alteration

without notice.

• Details contained in this manual are believed to be correct but

please contact this Company or a dealer if an error is suspected

or a point is not clear.

• In no event will this Company be responsible for the consequences

of using this product or this manual.

Page 3

CON1010

Model Name:Rockhopper-46/62

CON1010

Model Name:Rockhopper-46/62

Some Thoughts on Maintenance Work

Some Thoughts on Maintenance Work

1. Algunas ideas sobre el trabajo de Mantenciónn

La mantencion cae en dos categorias, Full mantencion y mantencion preventiva

, both of which are aimed at stable operation of the equipment that has been delivered to the user.

Las posibilidades de mantencion deben considerar.

• In principle, fault maintenance and protective maintenance are both carried out by the

one person.

• Both fault maintenance and protective maintenance involve the bringing of maintenance

parts.

• The cooperation of the user/operator is used effectively.

2. Protective maintenance work

La mantencion periodica esta designed to provide the user con mas estabilidad operation of the

equipment and involves the periodic cleaning and replacement of replacement parts. Basic

ideas on protective maintenance include:

• Adhere strictly to preventive maintenance periods.

• In a case of carrying out preventive maintenance, gain the approval of the user before-

hand.

• Don’t press preventive maintenance on the user.

3. Fault maintenance work

A fault will hold up the user’s work and must be remedied quickly. The following are some

basic ideas on fault maintenance:

3-1 If it is not solved by the primary consultation, take the necessary maintenance items

and make an on-site visit.

• Assemble the necessary maintenance parts from the matrix map

• At the user’s premises, first check the symptoms.

• Proceed with maintenance work in accordance with the fault tracing procedure.

• After the repair work is finished, be sure to check again by testing in accordance

with the test procedure.

3-2 If repair is not possible even though all the work has been done in accordance with

the fault tracing procedure:

• Contact the Sales Support Groups in your local distributor.

4. The need for user/operator cooperation

! CAUTION: The user cannot be compelled to do the following!

Asking the user/operator to cooperate is not a matter of having the user do the maintenance for you but it is necessary in order to have the equipment working more efficiently

and for having faults rectified quickly.

Actually, even when you do ask for the user’s cooperation, instead of a simple acknowledgement you will usually get doubts and quibbles such as “I’m paying for maintenance”,

“I’m not familiar with the equipment” and “it only benefits the manufacturer.”

However, you must try to persuade the user/operator to cooperate by explaining that doing

daily inspections will give better printing quality and giving you all the fine details of a fault

means that the fault will be rectified quickly.

The following explains the items you need in order to understand fault conditions in detail:

• Check error messages

• Check user’s usage conditions

• Output from diagnostic pattern

• Output from setup lists

• Retest after changing settings

• Probability of recovery by implementing daily inspections.

Page 4

CON2000

Model Name:Rockhopper-46/62

CON2000

Model Name:Rockhopper-46/62

Precautions For Maintaining This Printer

Precautions For Maintaining This Printer

PRECAUTION 1 Head Cleaning

Head cleaning (see REP1620) must be carried out when this printer is to be transported by truck (see CON6000) and when the following parts are to be replaced.

< Replacement parts > Head, Damper, Head Cable, Cartridge Frame Assembly,

Ink Tubes

PRECAUTION 2 Head Cleaning Jig

When the head cleaning jig is to be used, fill the jig’s 100 cc bottle with at least 50

cc of cleaning fluid and use it with the cap loosened.

If head cleaning is done with the cap tightened, ink will flow back into the 100 cc

bottle.

When you have finished head cleaning, return the remaining cleaning fluid from the

100 cc bottle to the 500 cc cleaning fluid bottle (JD-42054).

PRECAUTION 3 Printing After Initial Filling

On rare occasions, printing quality may be unstable if printing is carried out immediately after initial filling.

If this occurs, switch off the power and wait for at least 30 minutes before trying to

print again.

PRECAUTION 4 Thorough Waste Fluid Bottle Replacement

When the following tasks have been carried out,drain the waste fluid bottle.

1. After head cleaning and initial filling.

2. When it was not possible to capture main board assembly backup parameters.

PRECAUTION 6 Take Care When Inserting Head Cable and Y Cable

PRECAUTION 7 Ink and Cleaning Fluid Conduct Electricity

When the print head assembly, head board assembly and main board assembly

have been replaced, be careful to insert the head cable and Y cable straight to the

back and don’t forget to lock the connectors.

(The connectors fitted with locks are J207 and J208 on the head board.)

If the cables are inserted obliquely or power is applied without locking the connectors, there is a risk that the main board assembly may be damaged and it will be

impossible for ink to be ejected.

Ink and cleaning fluid will conduct electricity.

If there is ink or cleaning fluid on the connectors of the head or head cables when

power is applied, there will be a short circuit which may lead to all sorts of damage.

If there is ink on the contacts of the connector, wipe it off with alcohol or ethanol and

allow to dry thoroughly before reconnecting.

PRECAUTION 5 Maintenance Unit Tubes

If you can not lower the maintenance unit cap assembly and the cap assembly and

pump assembly have been replaced:

• When the two tubes from the pump assembly are being connected to the cap

assembly, turn them clockwise through 45 to 90 degrees as you insert them.

Page 5

CON3000

Model Name:Rockhopper-46/62

CON3000

Model Name:Rockhopper-46/62

Contents

Contents

Rockhopper-463 Rockhopper-62

Introduction CON 1000 CON 1000

Some Thoughts on Maintenance Work CON 1010 CON 1010

Precautions For Maintaining This Printer CON 2000 CON 2000

Contents CON 3001 ~ 3 CON 3007 ~ 9

How to use the Maintenance Manual CON 4000 CON 4000

Trouble-Shooting Lists TRB 0000 TR B 0000-3

Matrix Map MAP 0000 MAP 0000-3

Fault-Tracing Procedure EXA 0000 EXA 0000-3

Replacement and Adjustment Procedures REP 0000 REP 0000-3

Fundamental Knowledge GID 0000 GI D 0000-3

Stored Test Patterns PAT 0000 PAT 0000-3

Self-Diagnosis Functions BAC 0000 BAC 0000-3

Maintenance Parts CAT 0000 CAT 0000-3

Page 6

CON3001

Model Name: Rockhopper-46

Model Name: Rockhopper-46

Rockhopper-463 Contents 1

Rockhopper 46 inch

Trouble-Shooting Lists TRB0000

• When Message is Displayed TRB1000

- How to Use LEDs to Check CPU System and Mechanical System Faults TRB1001

• When Message is not Displayed

- Initialization, Media Feed, Printing TRB2000

- Noise, Media Cutting, Online, Others TRB2001

Matrix Map MAP0000

• When Message is Displayed

- Printer Status Messages MAP1000

- Data Errors MAP1200

- Command Errors MAP1250

- CPU System Faults MAP1500

- Mechanical System Faults MAP1700

• When Message is not Displayed

- Trouble with Initialization MAP2000

- Trouble with Media Feed MAP3000

- Trouble with Printing MAP4000

- Problem Involving Noise MAP5000

- Trouble with Media Cutting MAP6000

- Online/Function Problems MAP7000

- Other MAP8000

Fault-Tracing Procedure EXA0000

• When Message is Displayed

- Printer Status Messages EXA1000~

- Data Errors EXA1200~

- Command Errors EXA1250~

- CPU System Faults EXA1500~

- Mechanical System Faults EXA1700~

• When Message is not Displayed

- Trouble with Initialization EXA2000~

- Trouble with Media Feed EXA3000~

- Trouble with Printing EXA4000~

- Problem Involving Noise EXA5000~

- Trouble with Media Cutting EXA6000~

- Online/Function Problems EXA7000~

- Others EXA8000~

Heater System MAP9000

Heater System EXA9000

Heater System Faults EXA1800

Page 7

CON3002

CON3002

Rockhopper-463 Contents 2

Rockhopper-463 Contents 2

Replacement and Adjustment Procedures

Right and Left Covers REP 1010

Front Cover REP 1020

Panel Cover, Y Rail Cover REP 1030

Front Paper Guide and Rear Paper Guide REP 1040

Left Side Cap and Right Side Cap REP 1041

Control Box REP 1050

Head Cover REP 1060

X Motor Assembly REP 1070

Fan Assembly and Fan Cable REP 1080

X Speed Reduction Belt REP 1090

Lever Sensor Assembly REP 1100

Cover Switch Assembly REP 1110

Waste Fluid Box Sensor Assembly REP 1120

Switch Cable Assembly, DC Cable Assembly REP 1130

Main Board Assembly REP 1140

Power Supply Board Assembly REP 1150

Panel Board Assembly and Heater anel Board Assembly REP 1160

Panel Cable REP 1170

Extension Board Assembly REP 1180

XR Cable Assembly (Rear Paper Sensor) REP 1200

Pressure Assembly, Pressure Roller and Blade REP 1220

Pump Motor Assembly REP 1230

Cap Assembly REP 1240

Wiper REP 1250

Pump Assembly REP 1260

Maintenance Station Assembly REP 1270

Y Motor Assembly REP 1280

Steel Belt REP 1290

T Fence Assembly REP 1300

Cursor Plate Spring, Steel Flexible Guide Assembly REP 1310

Y Return Pulley Assembly REP 1320

Cartridge Frame Assembly REP 1330

Ink ID Sensor Assembly REP 1340

Detector Assembly REP 1350

Y Cable REP 1360

Ink Tubes REP 1370

Cutter Solenoid Assembly REP 1380

Print Head Assembly, Head Cable REP 1390

Edge Sensor Assembly REP 1410

Head Board Assembly REP 1420

Dampers REP 1430

Cursor Assembly REP 1440

Origin Sensor Assembly, Y Encoder REP 1450

Junction Board Assembly REP 1470

How to Adjust the Platen Height REP 1520

Tubes Guides Assemblies REP 1540

How to Adjust Steel Belt Tension REP 1550

How to Adjust X Speed Reduction Belt Tension REP 1560

How to Adjust the Tilt of the Print Head REP 1570

How to Capture and Install Backup Parameters REP 1590

How to Install a Program (Software Upgrade) REP 1600

Head Cleaning Procedure REP 1620

How to Clean the Head Nozzle Face REP 1660

Speed Reduction Pulley Assembly REP 1680

Grid Roller Assembly REP 1690

F Absorbent Assembly REP 1700

Front / Rear Heater (or heater sensors) (refer to)RE P 1040

Page 8

CON3003

Model Name: Rockhopper-46

CON3003

Model Name: Rockhopper-46

Rockhopper-463 Contents 3

Rockhopper-463 Contents 3

Fundamental Knowledge GID0000

• Basic Specifications GID1000

• System Block Diagram GID3000

• Operating Sequence

- Power On Sequence GID4010

- Power Off Sequence GID4020

- Media Detection Sequence GID4030

- Normal Standby Sequence GID4040

- Encoder Disconnected Check Sequence GID4050

- Origin Detection Sequence GID4060

- Media Cutting Sequence GID4070

- Printing Sequence (Including Flushing) GID4080

Stored Test Patterns PAT0000

• Presentation Pattern PAT1000

• Print quality adjustment pattern PAT3000

• Setup List PAT4000

Self-Diagnosis Functions BAC0000

• Examination BAC1000

- Memory (RAM) Capacity BAC1010

- Version BAC1020

- Panel BAC1030

- Sensors BAC1040

- Encoders BAC1050

- Fans BAC1060

- Ethernet Board BAC1065

- History: Last error message BAC1070

- History: Head nozzle ejection count check BAC1070

- Head Waveform BAC1080

• Adjustment BAC2000

- Capping Position Adjustment BAC2010

- Skew Verification BAC2030

- Head Rank Input (Include Initial filling) BAC2040

- Head Nozzle Verification BAC2050

- Left Head Tilt Verification BAC2060

- Right Head Tilt Verification BAC2070

- Repeatability Printing Positioning BAC2080

- CW Adjustment BAC2090

- Flush Pointer Adjustment BAC2110

- Media Feed Distance Compensation BAC2120

- Margin Adjustment BAC2130

- Rear Sensor Position Adjustment BAC2140

- Test Print BAC2150

- Head Wash BAC2160

• Cleaning BAC3000

- Normal BAC3000

- Powerful BAC3000

• Test Printing BAC4000

- Head Printing Verification BAC4000

- Adjustment Parameters BAC4000

• Parameters BAC5000

- Initialize BAC5010

- Update BAC5020

• Aging BAC6000

- Carriage Motor BAC6010

- Media Feed Motor BAC6020

- Cutter BAC6030

- Maintenance Unit BAC6040

- Head BAC6050

Maintenance Parts CAT0000

Maintenance Parts List CAT1000

Maintenance Tool List CAT2000

Lubrication Points CAT4000

Exploded View Drawing CAT5000

Page 9

CON3007

Model Name: Rockhopper-62

CON3007

Model Name: Rockhopper-62

Rockhopper-62 Contents 1

Rockhopper-62 Contents 1

Rockhopper 62 inch

Trouble-Shooting Lists TRB0000-3

• When Message is Displayed TRB1000

- How to Use LEDs to Check CPU System and Mechanical System Faults TRB1001

• When Message is not Displayed

- Initialization, Media Feed, Printing TRB2000

- Noise, Media Cutting, Online, Others TRB2001

Matrix Map MAP0000-3

• When Message is Displayed

- Printer Status Messages MAP1000

- Data Errors MAP1200

- Command Errors MAP1250

- CPU System Faults MAP1500

- Mechanical System Faults MAP1700-2

• When Message is not Displayed

- Trouble with Initialization MAP2000-2

- Trouble with Media Feed MAP3000-2

- Trouble with Printing MAP4000-2

- Problem Involving Noise MAP5000

- Trouble with Media Cutting MAP6000

- Online/Function Problems MAP7000

- Other MAP8000

Fault-Tracing Procedure EXA0000-3

• When Message is Displayed

- Printer Status Messages EXA1000~

(1020-2)

- Data Errors EXA1200~

- Command Errors EXA1250~

- CPU System Faults EXA1500~

- Mechanical System Faults EXA1700~

• When Message is not Displayed

- Trouble with Initialization EXA2000~

(2070-2)

- Trouble with Media Feed EXA3000~

(3000-2)

- Trouble with Printing EXA4000~

(4050-2)

(4100-2)

(4130-2)

- Problem Involving Noise EXA5000~

- Trouble with Media Cutting EXA6000~

- Online/Function Problems EXA7000~

- Others EXA8000~

(8050-2)

Heater System MAP9000

Heater System EXA9000-2

Heater System Faults EXA1800-2

Page 10

CON3008

Model Name: Rockhopper-62

CON3008

Model Name: Rockhopper-62

Rockhopper-62 Contents 2

Rockhopper-62 Contents 2

Replacement and Adjustment Procedures REP0000-2

Right and Left Covers REP 1010

Front Cover REP 1020

Panel Cover, Y Rail Cover REP 1030

Front Paper Guide and Rear Paper Guide REP 1040-2

Left Side Cap and Right Side Cap REP 1041

Control Box REP 1050

Head Cover REP 1060

X Motor Assembly REP 1070

Fan Assembly and Fan Cable REP 1080-2

X Speed Reduction Belt REP 1090

Lever Sensor Assembly REP 1100

Cover Switch Assembly REP 1110

Waste Fluid Box Sensor Assembly REP 1120

Switch Cable Assembly, DC Cable Assembly REP 1130

Main Board Assembly REP 1140

Power Supply Board Assembly REP 1150

Panel Board Assembly REP 1160

Panel Cable REP 1170

Extension Board Assembly REP 1180

XR Cable Assembly (Rear Paper Sensor) REP 1200

Pressure Assembly, Pressure Roller and Blade REP 1220

Pump Motor Assembly REP 1230

Cap Assembly REP 1240

Wiper REP 1250

Pump Assembly REP 1260

Maintenance Station Assembly REP 1270

Y Motor Assembly REP 1280

Steel Belt REP 1290

T Fence Assembly REP 1300

Cursor Plate Spring, Steel Flexible Guide Assembly REP 1310-2

Y Return Pulley Assembly REP 1320

Cartridge Frame Assembly REP 1330

Ink ID Sensor Assembly REP 1340

Detector Assembly REP 1350

Y Cable REP 1360-2

Ink Tubes REP 1370-2

Cutter Solenoid Assembly REP 1380

Print Head Assembly, Head Cable REP 1390

Edge Sensor Assembly REP 1410

Head Board Assembly REP 1420

Dampers REP 1430

Cursor Assembly REP 1440

Origin Sensor Assembly, Y Encoder REP 1450

Junction Board Assembly REP 1470

How to Adjust the Platen Height REP 1520

Tubes Guides Assemblies REP 1540-2

How to Adjust Steel Belt Tension REP 1550

How to Adjust X Speed Reduction Belt Tension REP 1560

How to Adjust the Tilt of the Print Head REP 1570

How to Capture and Install Backup Parameters REP 1590

How to Install a Program (Software Upgrade) REP 1600

Head Cleaning Procedure REP 1620

How to Clean the Head Nozzle Face REP 1660

Speed Reduction Pulley Assembly REP 1680

Grid Roller Assembly REP 1690

F Absorbent Assembly REP 1700

Waste Fluid Bottle Assembly REP 1710

Front / Rear Heater (or heater sensors) (refer to)RE P 1040-2

Page 11

CON3009

Model Name: Rockhopper-62

CON3009

Model Name: Rockhopper-62

Rockhopper-62 Contents 3

Rockhopper-62 Contents 3

Fundamental Knowledge GID0000-3

• Basic Specifications GID1000-3

• System Block Diagram GID3000

• Operating Sequence

- Power On Sequence GID4010

- Power Off Sequence GID4020

- Media Detection Sequence GID4030

- Normal Standby Sequence GID4040

- Encoder Disconnected Check Sequence GID4050

- Origin Detection Sequence GID4060

- Media Cutting Sequence GID4070

- Printing Sequence (Including Flushing) GID4080

Stored Test Patterns PAT0000-3

• Presentation Pattern PAT1000

• Print quality adjustment pattern PAT3000

• Setup List PAT4000

Self-Diagnosis Functions BAC0000-3

• Examination BAC1000

- Memory (RAM) Capacity BAC1010

- Version BAC1020

- Panel BAC1030

- Sensors BAC1040

- Encoders BAC1050

- Fans BAC1060

- Ethernet Board BAC1065

- History: Last error message BAC1070

- History: Head nozzle ejection count check BAC1070

- Head Waveform BAC1080

• Adjustment BAC2000

- Capping Position Adjustment BAC2010

- Skew Verification BAC2030

- Head Rank Input (Include Initial filling) BAC2040

- Head Nozzle Verification BAC2050

- Left Head Tilt Verification BAC2060

- Right Head Tilt Verification BAC2070

- Repeatability Printing Positioning BAC2080

- CW Adjustment BAC2090

- Flush Pointer Adjustment BAC2110

- Media Feed Distance Compensation BAC2120

- Margin Adjustment BAC2130

- Rear Sensor Position Adjustment BAC2140

- Test Print BAC2150

- Head Wash BAC2160

• Cleaning BAC3000

- Normal BAC3000

- Powerful BAC3000

• Test Printing BAC4000

- Head Printing Verification BAC4000

- Adjustment Parameters BAC4000

• Parameters BAC5000

- Initialize BAC5010

- Update BAC5020

• Aging BAC6000

- Carriage Motor BAC6010

- Media Feed Motor BAC6020

- Cutter BAC6030

- Maintenance Unit BAC6040

- Head BAC6050

Maintenance Parts CAT0000-3

Maintenance Parts List CAT1000-3

Maintenance Tool List CAT2000

Lubrication Points CAT4000

Exploded View Drawing CAT5000

Page 12

CON4000

CON4000

Model Name: Rockhopper-46/62

How to use the Maintenance Manual

How to use the Maintenance Manual

How to use the Maintenance Manual

Como usar el Manual de Mantenimientol CON4010

How to use the Trouble-Shooting Lists (TRB) CON4020

How to use the Matrix Map (MAP) CON4040

How to use the Fault-Tracing Procedure (EXA) CON4050

Procedimiento de Reemplazo y Ajustes (REP) CON4060

Model Name: Rockhopper-46/62

Page 13

CON4010

Model Name: Rockhopper-46/62

CON4010

Model Name: Rockhopper-46/62

How to use the Maintenance Manual

How to use the Maintenance Manual

■ Fault maintenance work procedures and how to use the Maintenance Manual

When a user reports an equipment fault, use the following procedure to carry out fault recovery tasks.

A fault occurs

Task Page Details Reference Materials

Check fault circumstances,

select fault details from

Trouble-Shooting Lists

Trouble-Shooting List

TRB❉❉❉❉

Check circumstances by “fax” or “telephone”. Check error

messages, check user usage conditions, retry after changing settings, output

diagnostic pattern, etc. Select fault symptoms produced by user from

the Trouble-Shooting List.

Conduct a consultation by “fax” or “telephone”.

Check possibility of user error or recovery by daily inspection. Check error

messages, check user usage conditions, output diagnostic pattern, output

setup list. Retry after changing settings, etc.

Manual de Operaciones, Conocimiento

báasico, Cuidados diarios, Mantencion periodica/

inspeccion/Limpieza

Task Page Details Reference Materials

Gather the necessary

maintenance parts

Matrix Map

MAP❉❉❉❉

Gather the necessary maintenance parts Maintenance Parts list, Maintenance Tools list,

Exploded views

Conduct a tracing inquiry Fault Tracing Procedures

EXA❉❉❉❉

Conduct an inquiry to trace the cause of the fault Basic knowledge

Replace parts and adjust Replacement and Adjustment

Procedures REP❉❉❉❉

Replace or readjust parts suspected to be faulty.

Carry out adjustments after replacing parts.

Basic knowledge

Final check Separate causes of faults and check operation after faults have been

rectified.

Conduct a primary

consultation with the user

• If you are unable to resolve the fault at this point, take the necessary maintenance parts and make an on-site visit.

Page 14

CON4020

Model Name: Rockhopper-46/62

CON4020

Model Name: Rockhopper-46/62

How to use the Trouble-Shooting Lists (TRB)

How to use the Trouble-Shooting Lists (TRB)

1. How to look up trouble-shooting tables

■ When a user has reported a fault, first select the applicable details from the trouble-shooting lists (TRB) and jump to the specified primary consultation (ENT).

• Faults are broadly classified as those which cause a message to appear in the printer LCD and those which do not.

• For troubles that cause a message to be displayed, select the message as it is.

• Troubles with no message display are classified into the 10 blocks shown below. First select the block then select the appropriate fault details from that block.

2. Definitions of groupings in the case of faults that produce no message display

When Message is Displayed TRB1000

• Printer Status Messages, Data Errors, Command Errors

• CPU System Faults, Mechanical System Faults

When Message is Not Displayed

TRB2000 to TRB2001

•

Trouble with Initialization: Troubles that occur when unpacking immediately after delivery are grouped here.

Check this group for a similar trouble occurring other than immediately after delivery.

Troubles concerning the series of operations up to the enabling of printing are grouped here.

•

Trouble with Printing: This group concerns printing quality problems.

•

Trouble with Media Feed: This group concerns problems with the media path.

•

Trouble with Media Cutting: Cutter section problems are grouped here.

Printing precision problems are grouped here.

•

Problem Involving Noise: Troubles that produce abnormal noise from the driving section.

• Online/Function Problems: Online printing function problems.

Troubles involving driver software, consumable items, peripheral devices are grouped here.

• Other: Troubles concerning the series of operations up to the enabling of printing are grouped here.

Page 15

CON4040

Model Name: Rockhopper-46/62

CON4040

Model Name: Rockhopper-46/62

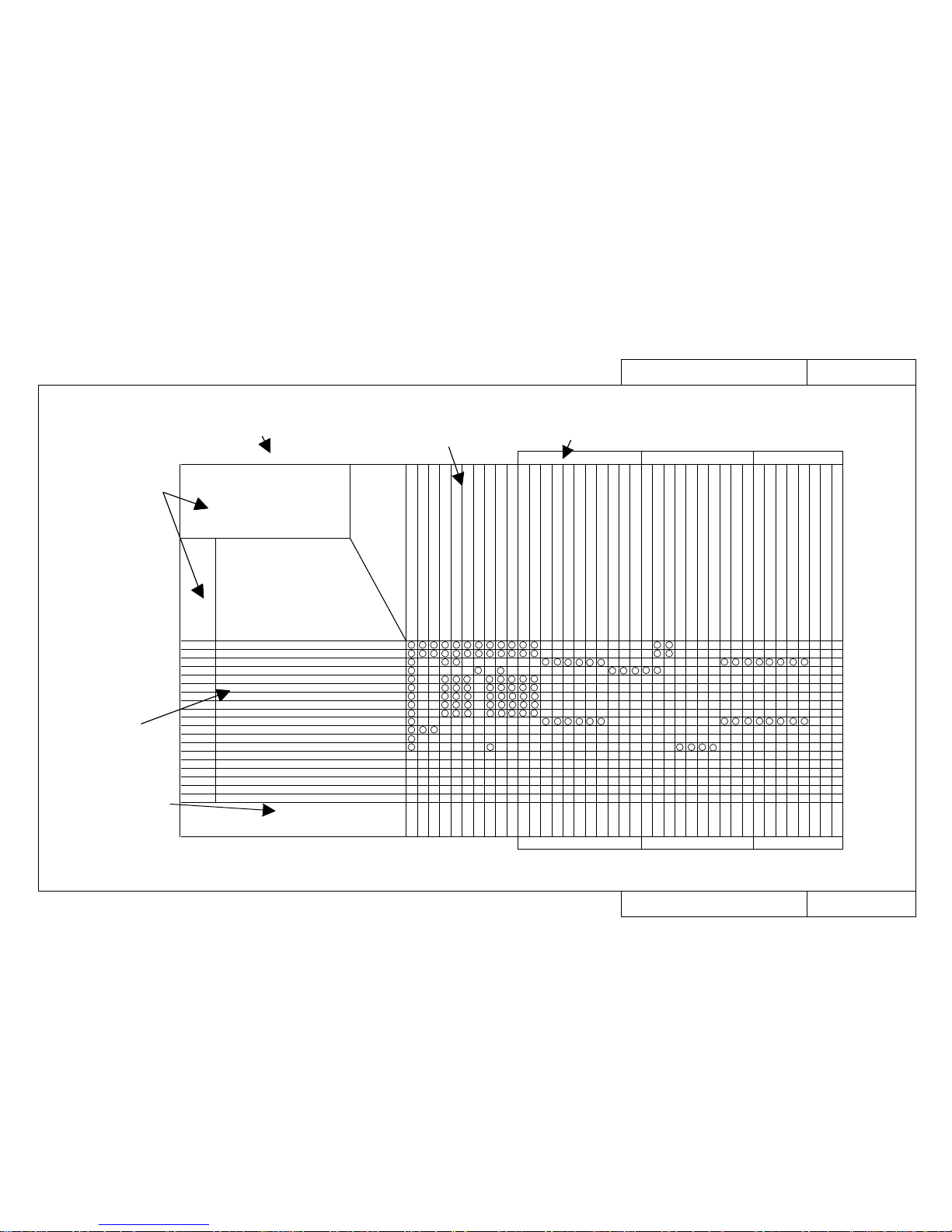

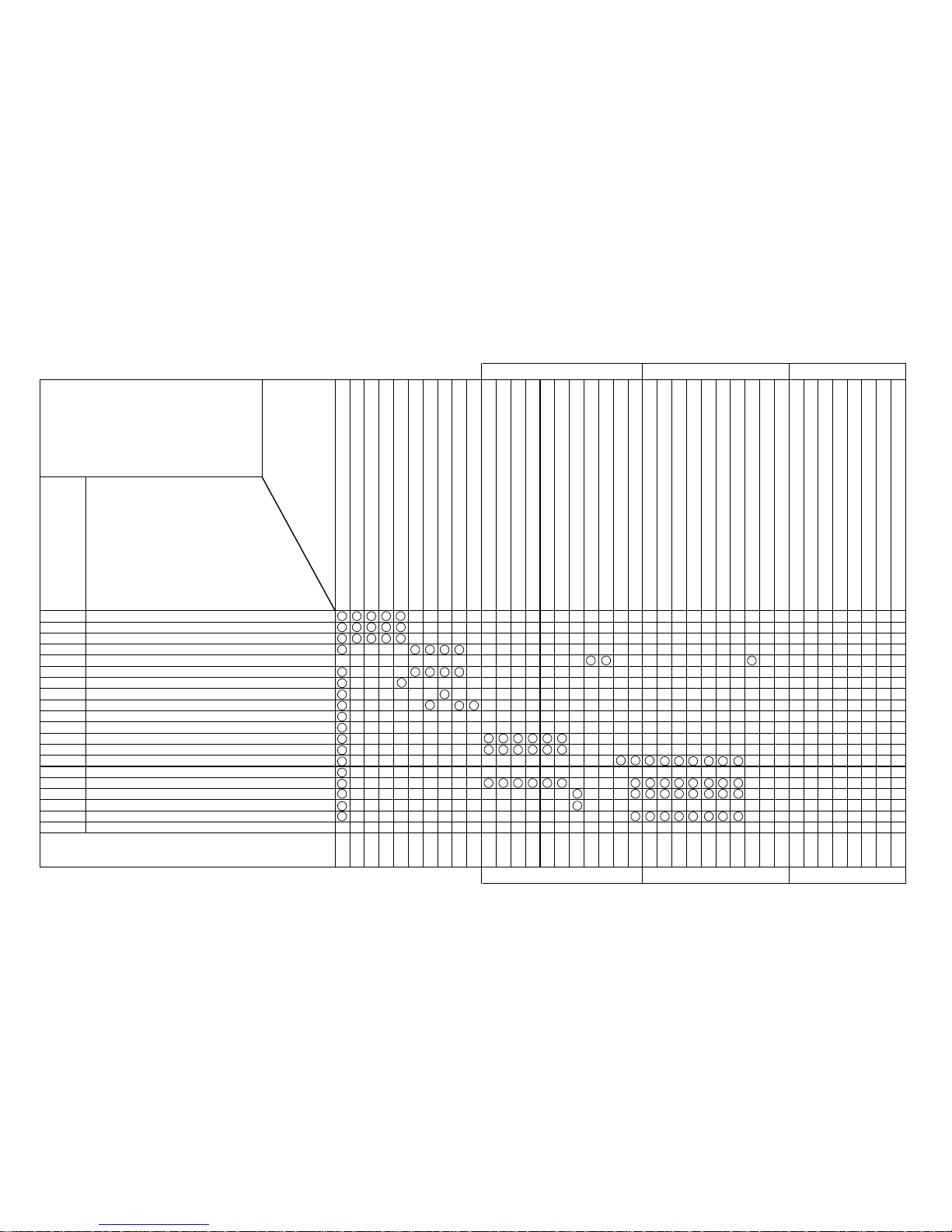

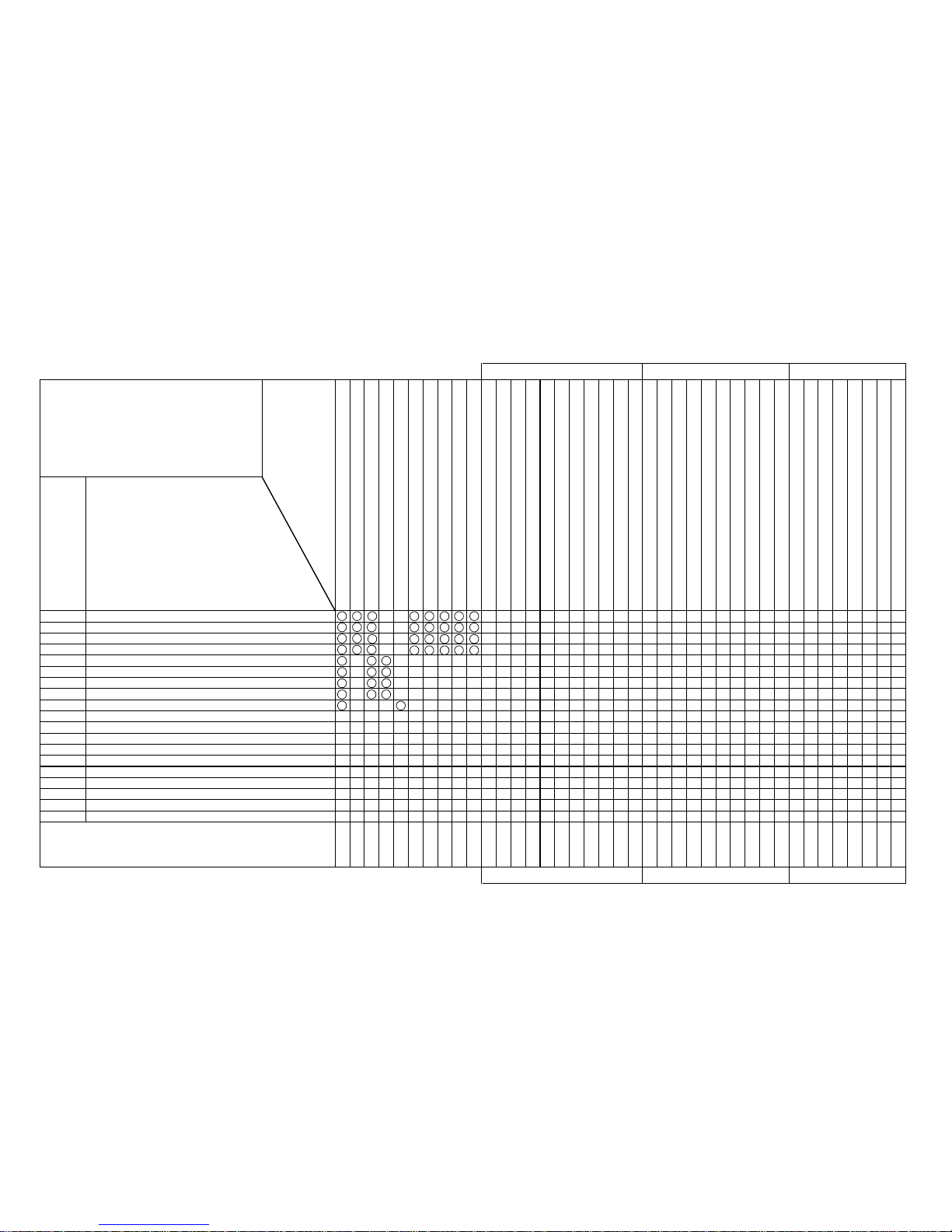

How to use the Matrix Map (MAP)

How to use the Matrix Map (MAP)

■ When the primary consultation (ENT) has not revealed any anomaly, gather the necessary maintenance parts according to the matrix map (MAP) shown below and visit

the user.

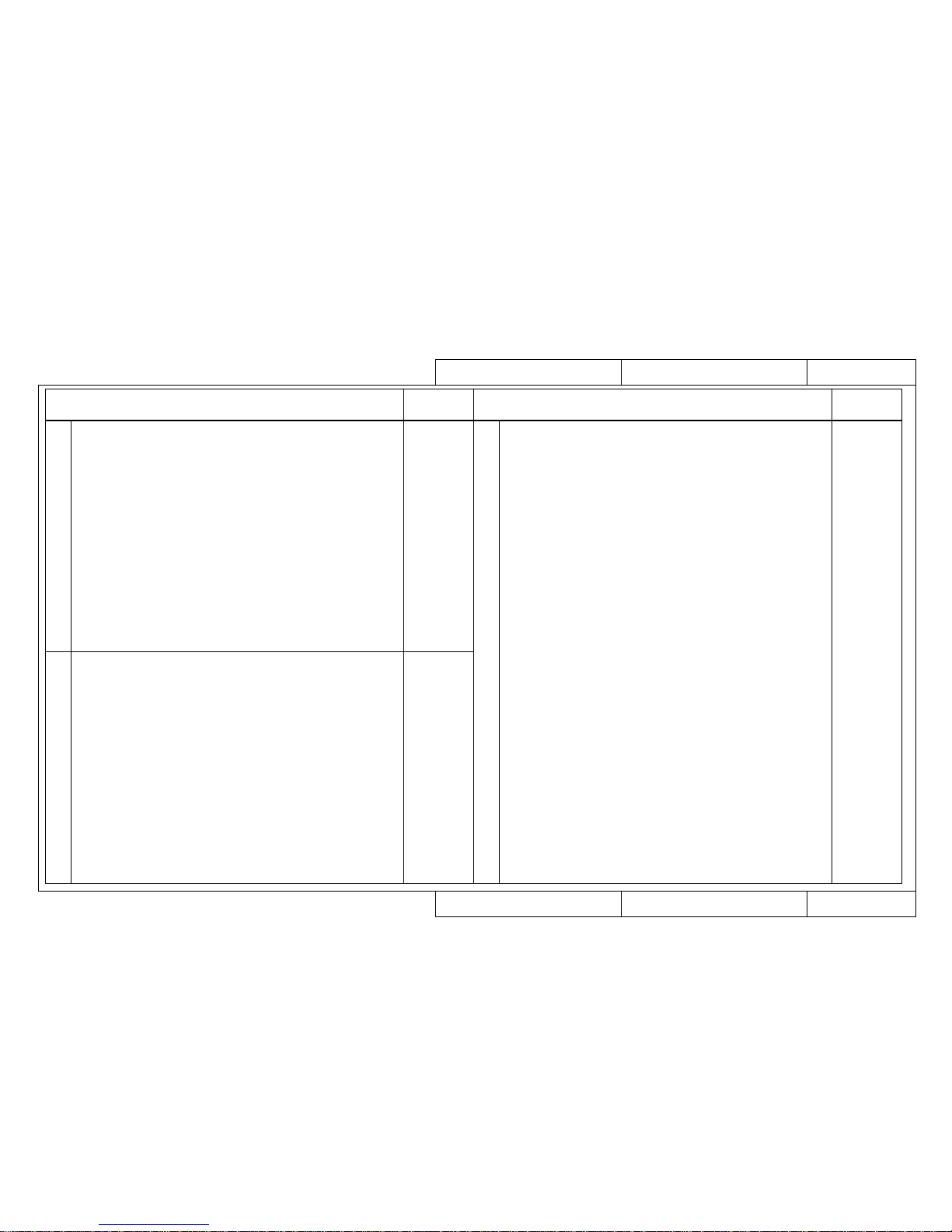

Major classification of fault details

Whether an error message is displayed

Major classification

of fault details and

range of EXA

numbers

Fault

details

Replacement

and adjustment

procedure page

Names and drawing numbers of

required parts

When Message is Not Displayed Trouble with Initialization

Trouble with Initializatio Model Name: 463

MAP2000

When Message is Not Displayed

When Message is Not Displayed

[Trouble with Initialization]

EXA2000 to EXA2070

Problem

- Power supply does not come on

- LCD faulty (no display/erratic display)

- Initial filling of inks failed

- Initial filling is completed but no ink comes out

- After power is switched on, nothing works

- When power is applied, “Initializing” appears and then a reset is executed.

- After mounting media, initial operation fails

- Printer does not work even with the cover closed

- Printer does not stop even with the cover opened

- Ink cartridges are installed but not recognized

- Can not make entries from the operating panel

- Data is received but not plotted

- Media is not suction

Replacement and Adjustment Procedure REP. No.

Name and Diagram Number of

Replacement Part

DF-41586 Main Board Assembly

DF-40097 Panel Board Assembly

DF-41617 Panel Cable

DF-41590 Cover Switch Assembly

DF-41589 Lever Sensor Assembly

DF-41595 Edge Sensor Assembly

DF-41588 Head Board Assembly

DF-41592 XR Cable Assembly (Paper Sensor R)

DF-41600 Y Cable

DF-41619 Switch Cable Assembly

DF-41587 Power Board Assembly

DF-41468 DC Cable Assembly

DF-41593 Detector 1 Assembly

DF-41594 Detector 2 Assembly

DF-40106 Detector Assembly (Black)

DF-40107 Detector Assembly (Y)

DF-40146 Detector Assembly (M)

DF-40147 Detector Assembly (C)

DF-41602 Cap Assembly

DF-41603 Pump Assembly

DF-41604 Maintenance Station Assembly

DF-40690 Print Head Assembly (Colour)

DF-41601 Head Cable

DF-41591 Waste Fluid Box Sensor

DF-40173 Vacuum Fan Assembly

DF-41620 Fan Extension Cable 1 Assembly

DF-41621 Fan Extension Cable 2 Assembly

DF-41622 Fan Extension Cable 3 Assembly

DF-41609 INK ID Sensor 1 Assembly

DF-41610 INK ID Sensor 2 Assembly

DF-41611 INK ID Sensor 3 Assembly

DF-41612 INK ID Sensor 4 Assembly

DF-41613 INK ID Sensor 5 Assembly

DF-41614 INK ID Sensor 6 Assembly

DF-41615 INK ID Sensor Cable

DF-41536 Junction Board Assembly

1140

1160

1170

1110

1100

1410

1420

1200

1360

1130

1150

1130

1350

1350

1350

1350

1350

1350

1240

1260

1270

1390

1390

1120

1080

1080

1080

1080

1340

1340

1340

1340

1340

1340

1470

1470

2000

2000

2010

2020

2030

2030

2030

2030

2030

2040

2050

2060

2070

FaultTracing

Procedure

EXA No.

Page 16

CON4050

Model Name: Rockhopper-46/62

CON4050

Model Name: Rockhopper-46/62

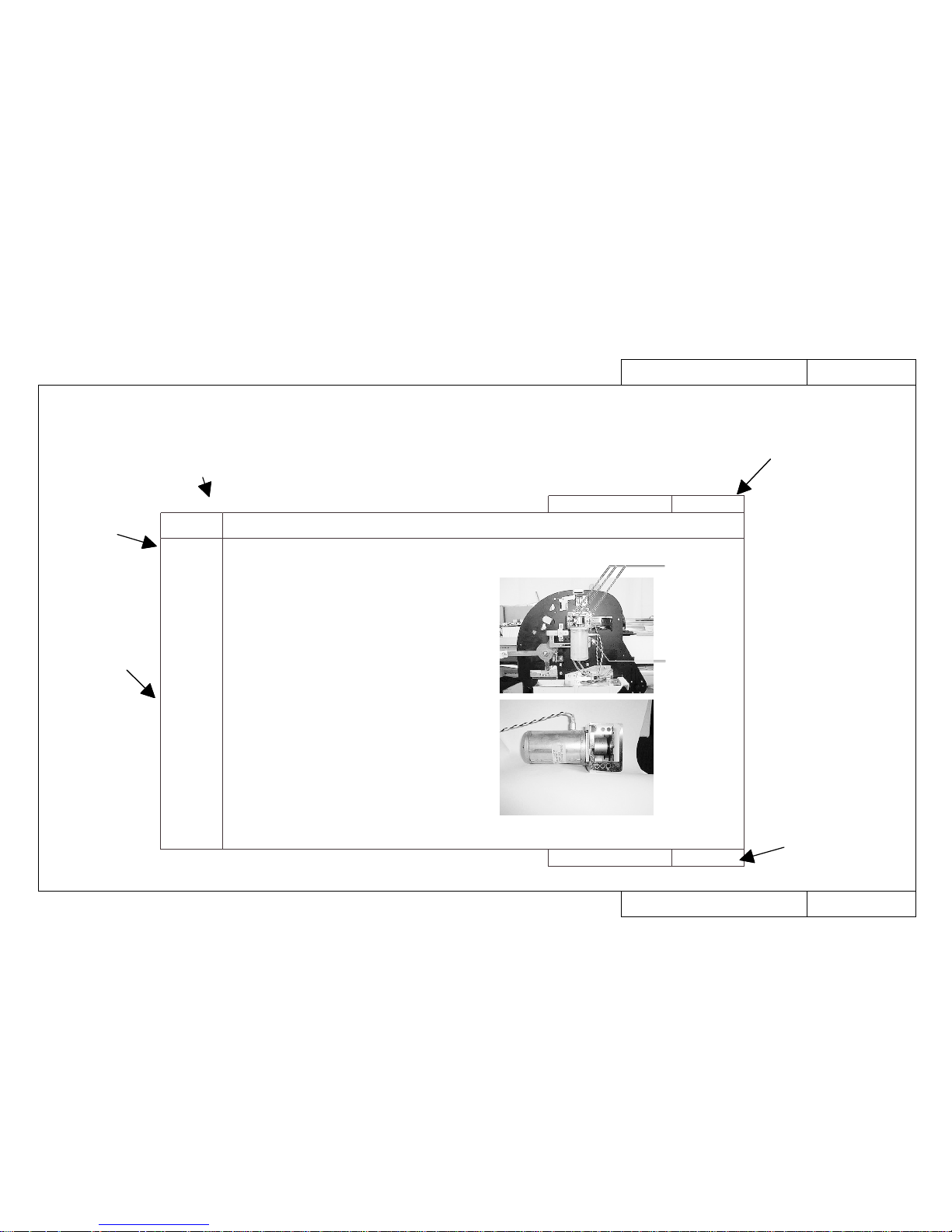

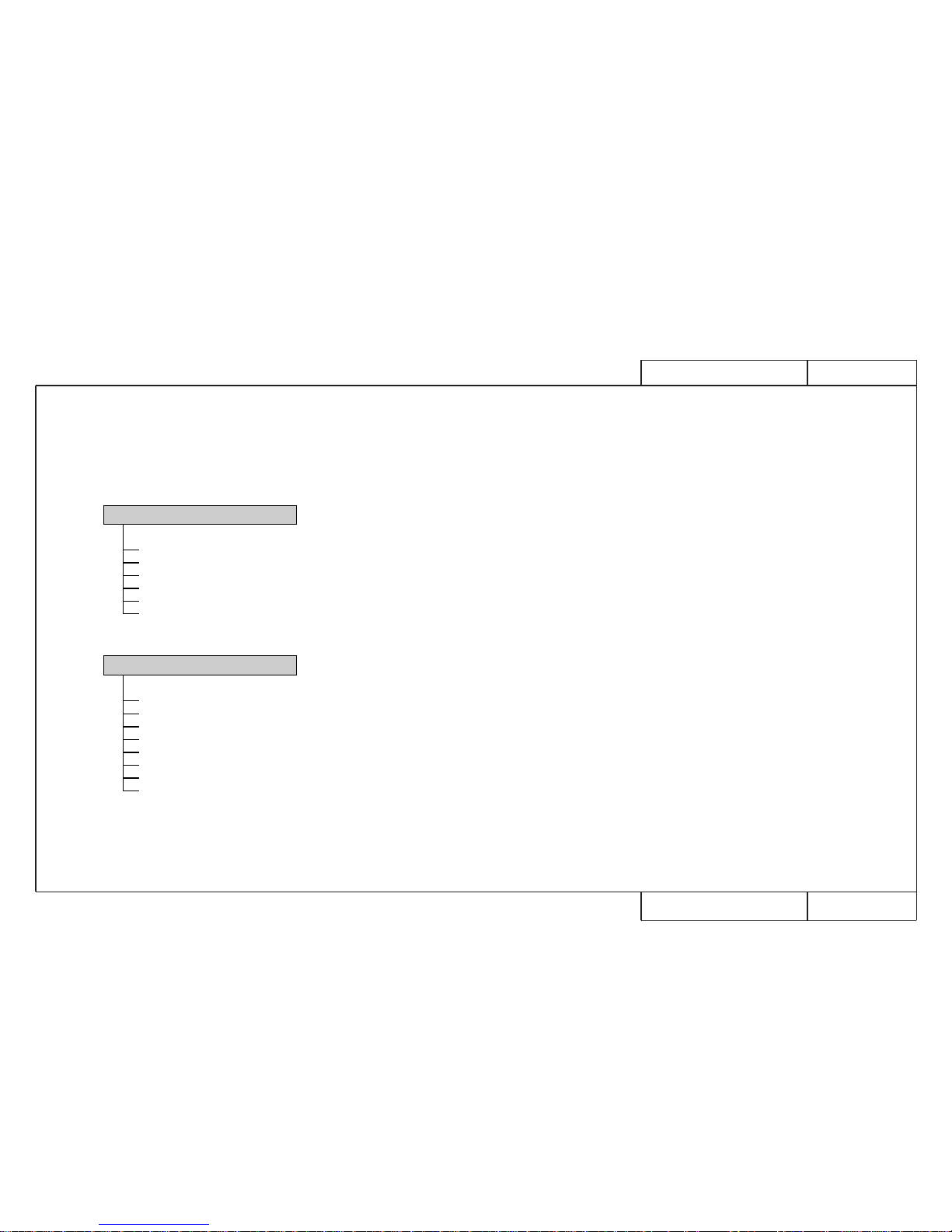

How to use the Fault-Tracing Procedure (EXA)

How to use the Fault-Tracing Procedure (EXA)

■ Gather the parts specified by the matrix map (MAP), visit the user and carry out the task of recovery in accordance with the fault-tracing procedure (EXA) shown below.

• First, check again on-site that there was no mistake about the primary consultation. (EXA and ENT page numbers are the same)

• Carry out the checking tasks in order, beginning with 1-1, and move to the next task if there is nothing abnormal. If an abnormality is revealed, carry out the task indi-

cated by the arrow [→].

EXA2021

Model Name: Rockhopper-46/62

EXA2021

Model Name: Rockhopper-46/62

Trouble with Initialization

When No Error is Displayed on the Printer's Liquid Crystal Display

1 • Initial filling is completed but no ink

comes out

(Initial filling means to fill the head

with ink to enable it to print.)

1-10

1-11

1-12

1-13

1-14

1-15

1-16

1-17

• Are there any breaks, cuts or air leaks in the ink tubes?

→ Change each ink tube, cleaning each time and checking that ink flows during cleaning.

• Check that connectors J207 (HEAD C1) and J208 (HEAD C2) on the head board assembly, and

head cables on the print head are not inserted obliquely, and they are locked securely.

→ Insert the connectors again.

• Is there a broken lead in head cables?

→ Replace head cables.

• Is the print head assembly damaged?

→ Replace the print head assembly.

• Is the head board assembly damaged?

→ Replace it.

• Check that the Y cable connector is connected securely and not inserted obliquely.

→ Reconnect head board assembly connectors J201 (MAIN1) and J202 (MAIN2) and main board

assembly connectors J111 (HEAD1) and J112 (HEAD 2).

• Is there a broken lead in Y cables?

→ Replace Y cables.

• The main board assembly may be damaged.

→ Replace it.

No. Symptom

Sequence

Items to be Confirmed

When No Error is Displayed on the Printer's Liquid Crystal Display

Trouble with Initialization

1370

1400

1390

1420

1360

1140

REP BAC

GO TO Ref. Pages

CAUTION: Power must be off when connectors are being disconnected or reconnect-

ed, otherwise you may be injured or a board may be damaged.

The main board assembly will certainly be damaged if power is applied

with main board assembly connectors J111 (HEAD) and J112 (HEAD2) and

head board connectors J201 (MAIN1) and J202 (MAIN2) inserted with

oblique FFP.

Whether an error message is displayed

Fault details

Fault-tracing

sequence

Major classification of fault details

Page specified by

matrix map (MAP)

Page specified by

matrix map (MAP)

Replacement and

adjustment procedure

(REP) page reference

Hidden diagnostic

procedure page

reference

Page 17

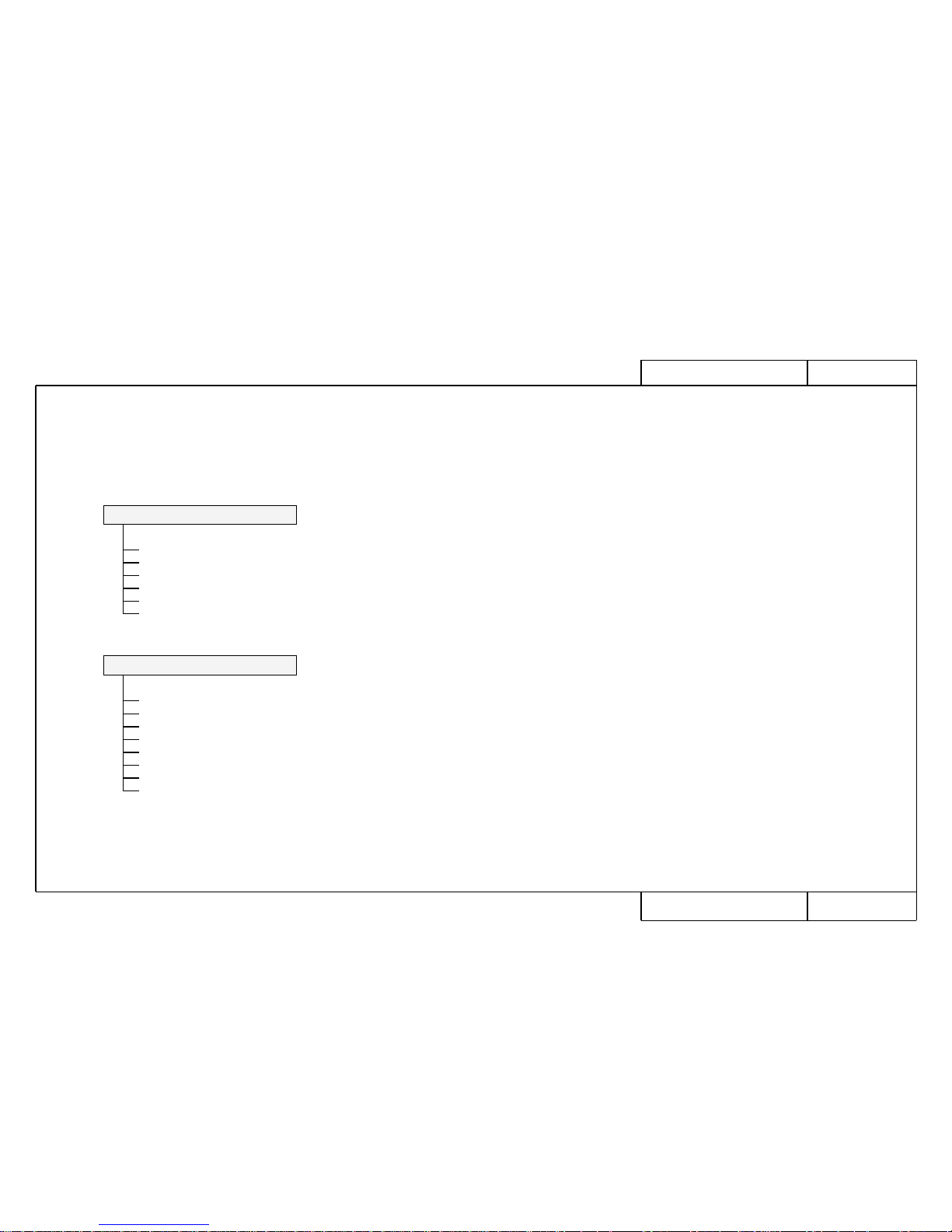

CON4060

Model Name: Rockhopper-46/62

CON4060

Model Name: Rockhopper-46/62

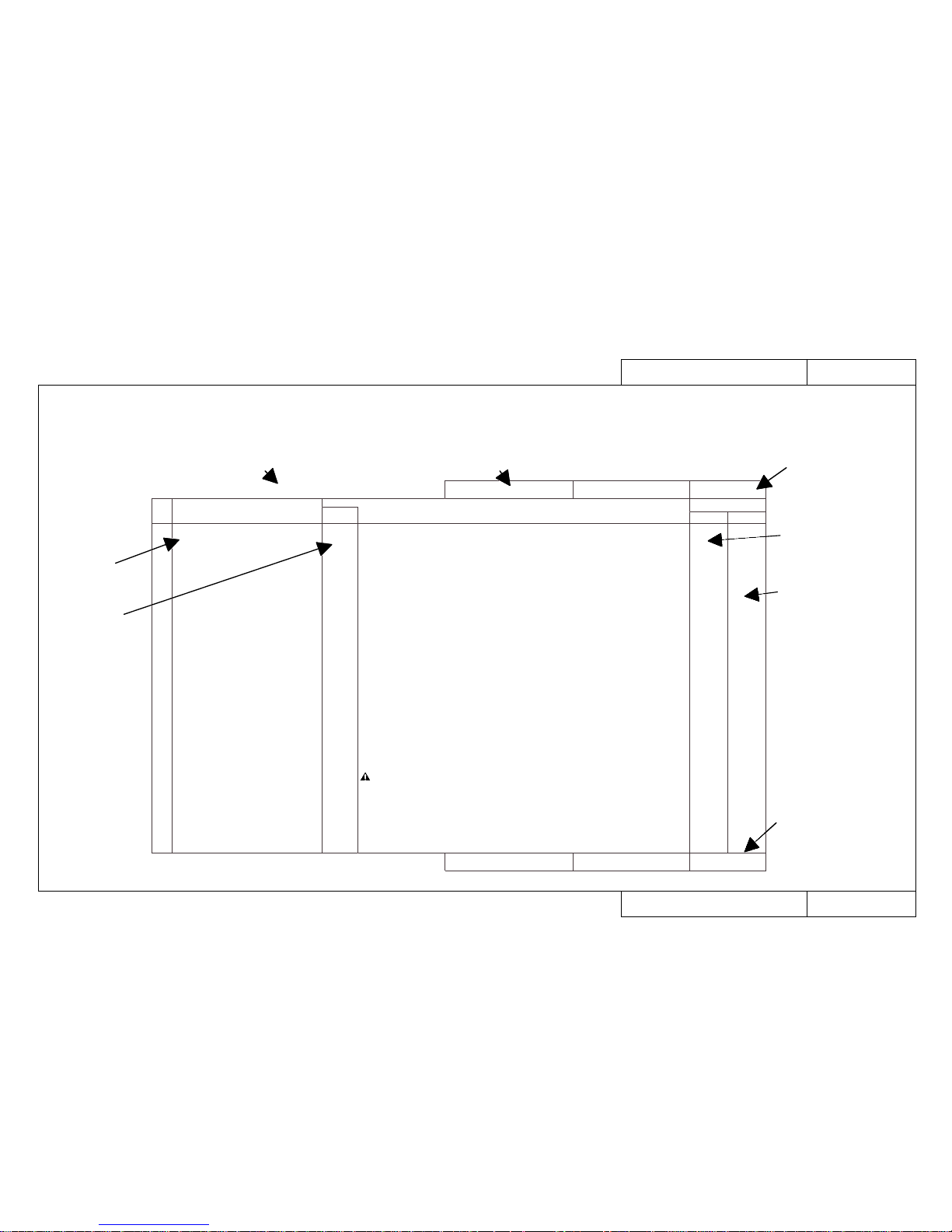

How to use Replacement and Adjustment Procedure (REP)

How to use Replacement and Adjustment Procedure (REP)

■ If the fault-tracing procedure (EXA) has produced a replacement task, carry out the work of replacement and adjustment in accordance with the replacement and adjustment procedure (REP) shown below.

• If you don’t know how to go about the removal of covers involved in replacing a part, refer to REP1010 to REP1060.

Screws

Y motor cable terminal

Y motor assembly

REP1280

Model Name: Rockhopper-46/62

REP1280

Model Name: Rockhopper-46/62

How to replace the Y Motor Assembly

How to replace the Y Motor Assembly

Item Replacement and Adjustment Procedure

1. Replacement

Procedure

2. Adjustment

and

Examination

Procedure

« REFERENCE » If there is to be no replacement that

includes the Y motor assembly, steps 2, 4

and 5 are not necessary.

Replace the Y Motor Assembly

1. Remove the Left and Right Covers.

2. Remove the Rear Paper Guide.

3. Remove the Steel Belt.

4. Open the Control Box.

5. Disconnect connector J120 (YMOT) from the Main Board

Assembly.

6. Remove the Y Motor Assembly. (3 fastening screws)

7. Assembling is the reverse of the removal procedure.

« REFERENCE » Since the Y Motor Assembly Cable pass-

es below the Cartridge Unit, the work will

be easier if you remove the two Cartridge

Base screws and push it back.

1. Carry out the Steel Belt Tensioning Adjustment.

Replacement and adjustment item

Replacement

procedure

Adjustment

procedure

and items to

be checked

Page specified by

the fault-tracing

procedure (EXA)

Page specified by

the fault-tracing

procedure (EXA)

Page 18

TRB0000

Model Name: Rockhopper-46

TRB0000

Model Name: Rockhopper-46

Rockhopper-463 Trouble-Shooting Lists

Rockhopper-43 Trouble-Shooting Lists

Trouble-Shooting Lists

When Message is Displayed

Printer Status Messages TRB1000

Data Errors TRB1000

Command Errors TRB1000

CPU System Faults TRB1000

Mechanical System Faults TRB1000

When Message is Not Displayed

Trouble with Initialization TRB2000

Trouble with Printing TRB2000

Trouble with Media Feed TRB2000

Trouble with Media Cutting TRB2001

Problem Involving Noise TRB2001

Online/Function Problems TRB2001

Others TRB2001

Heater System TRB2001

How to Use LEDs to Check CPU System TRB1001

and Mechanical System Faults

Heaters System Faults TRB1000

Page 19

TRB0000-3

Model Name: Rockhopper-62

TRB0000-3

Model Name: Rockhopper-62

Rockhopper-62 Trouble-Shooting Lists

Rockhopper-62 Trouble-Shooting Lists

Trouble-Shooting Lists

When Message is Displayed

Printer Status Messages TRB1000

Data Errors TRB1000

Command Errors TRB1000

CPU System Faults TRB1000

Mechanical System Faults TRB1000

When Message is Not Displayed

Trouble with Initialization TRB2000

Trouble with Printing TRB2000

Trouble with Media Feed TRB2000

Trouble with Media Cutting TRB2001

Problem Involving Noise TRB2001

Online/Function Problems TRB2001

Others TRB2001

Heater System TRB2001

How to Use LEDs to Check CPU System TRB1001

and Mechanical System Faults

Heaters System Faults TRB1000

Page 20

When Message is Displayed

When Message is Displayed

TRB1000

Model Name: Rockhopper-46/62

TRB1000

Model Name: Rockhopper-46/62

Trouble-Shooting 1/3 (List of Faults)

Trouble-Shooting 1/3 (List of Faults)

Cases where an error message is displayed on the liquid crystal display of the main printer unit

GO TO EXA No.Minor Faults CPU System/Mechanical System Faults GO TO EXA No.

Printer Status Messages

CPU System Faults

• Cover Open

• Lever Up

• Cover and Lever

• Undefined Media

• Media Skew Error

• [User 1] Media End

• Remove Media

• Roll Media End

• Media Cut Error

• Not enough memory SIMM 12 MB

• Insert Special Cartridge

• [ ∗ ] Ink Low

• [ ∗ ] No Ink

• [ ∗ ] No Cartridge

• Capping position not specified

• Not Filled

• No Waste Fluid Box

• Wrong Ink Type

EXA1000

EXA1000

EXA1000

EXA1010

EXA1020

EXA1030

EXA1040

EXA1050

EXA1060

EXA1070

EXA1080

EXA1090

EXA1090

EXA1100

EXA1110

EXA1120

EXA1130

EXA1150

• E001 Error DRAM (Standard DRAM error)

• E002 Error Opt.DRAM (Optional DRAM error)

•E016CPUErr[00] (Interrupt exception error)

•E016CPUErr[02] (Command boundary exception error)

•E016CPUErr[03] (Data boundary exception error)

•E016CPUErr[04] (Address error exception)

(Load or command fetch)

•E016CPUErr[05] (Address error exception) (Store)

•E016CPUErr[06] (Bus error exception) (Command fetch)

•E016CPUErr[07] (Bus error exception) (Data load)

•E016CPUErr[08] (System call exception error)

•E016CPUErr[09] (Break point exception error)

•E016CPUErr[10] (Reserved command exception error)

•E016CPUErr[11] (Unable to use coprocessor exception error)

•E016CPUErr[12] (Operation overflow exception error)

•E016CPUErr[13] (Trap exception error)

•E016CPUErr[15] (Floating point exception error)

•E016CPUErr[22] (Watch exception error)

•E016CPUErr[32] (Watchdog timeout exception error)

•E016CPUErr[33] (Abort error)

• Error E237 Transfer memory (Transfer memory error/Transfer memory

access error)

• Error E129 NVRAM

EXA1500

EXA1500

EXA1510

EXA1510

EXA1510

EXA1510

EXA1510

EXA1510

EXA1510

EXA1510

EXA1510

EXA1520

EXA1520

EXA1520

EXA1520

EXA1520

EXA1520

EXA1520

EXA1520

EXA1520

EXA1530

Mechanical System Faults

• E065 Error X Motor

• E069 Error X Encoder

• E071 Error X Timeout

• E073 Error X Overcurrent

• E066 Error Y Motor

• E070 Error Y Encoder

• E072 Error Y Timeout

• E074 Error Y Overcurrent

• E075 Error Sensor Fault

EXA1700

EXA1700

EXA1700

EXA1700

EXA1710

EXA1710

EXA1710

EXA1710

EXA1720

Data Errors

• Network Detection Error

• Network Initialization Error

EXA1230

EXA1230

Command Errors

• MH01 Error (Undefined Command)

• MH02 Error (Parameter Error)

• MH03 Error (Numerical Error)

• MH04 Error (Undefined Character Set)

• MH07 Error (Buffer Overflow)

EXA1250

EXA1250

EXA1250

EXA1250

EXA1250

Heater System Faults EXA1800

Page 21

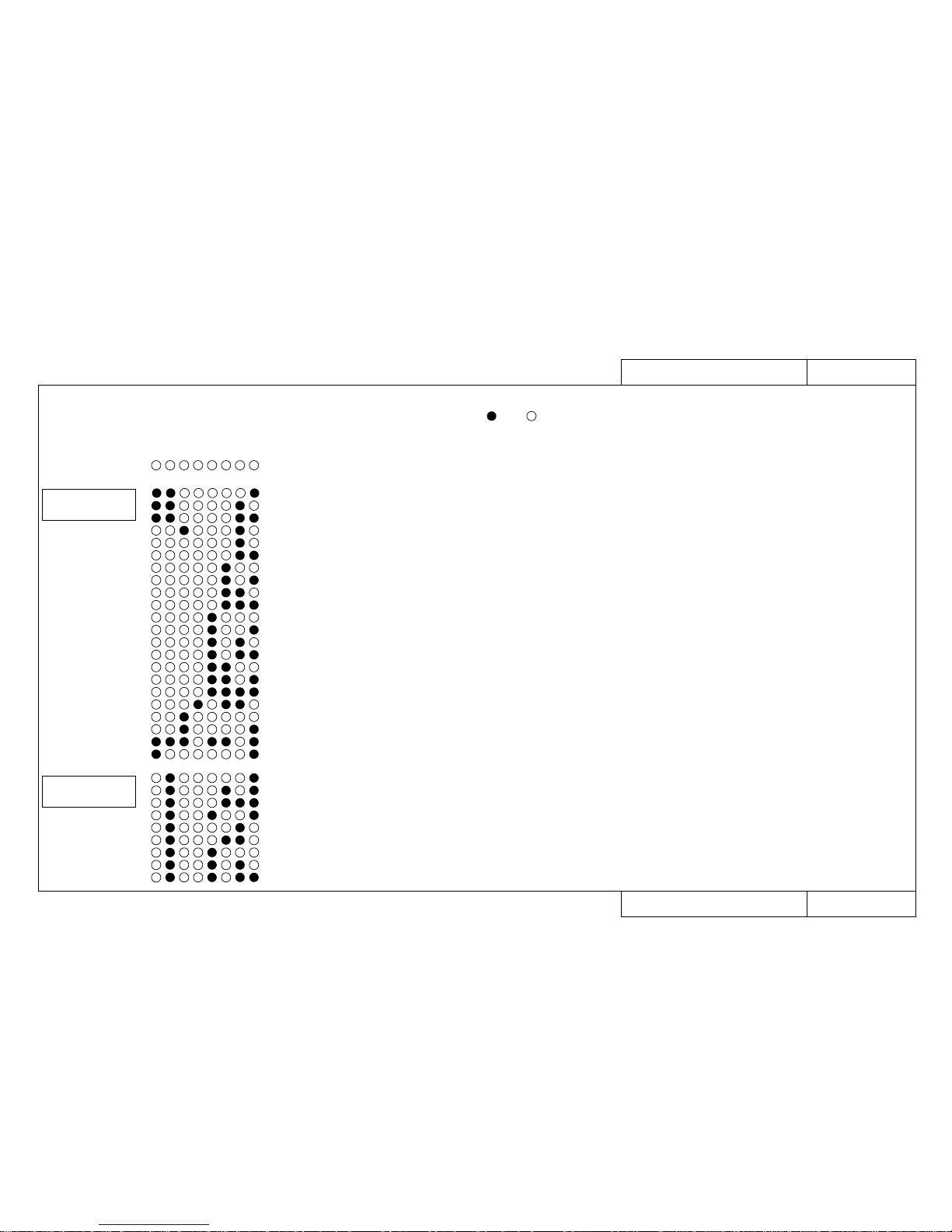

TRB1001

Model Name: Rockhopper-46/62

TRB1001

Model Name: Rockhopper-46/62

How to Use LEDs to Check CPU System and Mechanical System Faults

How to Use LEDs to Check CPU System and Mechanical System Faults

• When the printer stops working and nothing appears on the liquid crystal display (LCD),

a fault has probably occurred in the CPU system or the mechanical system.

In that case, open the control box and check the error by the LEDs on the main board assembly. is on, is off.

LED display

12345678

• E001 Error DRAM

Fallas Sistema CPU

Details of Error

• E002 Error Opt.DRAM

• E002 Error Opt.DRAM

• E016CPUErr[00]

• E016CPUErr[02]

• E016CPUErr[03]

• E016CPUErr[04]

• E016CPUErr[05]

• E016CPUErr[06]

• E016CPUErr[07]

• E016CPUErr[08]

• E016CPUErr[09]

• E016CPUErr[10]

• E016CPUErr[11]

• E016CPUErr[12]

• E016CPUErr[13]

• E016CPUErr[15]

• E016CPUErr[22]

• E016CPUErr[32]

• E016CPUErr[33]

• E237 Error Transfer memory

• E129 Error NVRAM

(Standard DRAM error)

(Optional DRAM 1 error)

(Optional DRAM 2 error)

(Interrupt exception error)

(Command boundary exception error)

(Data boundary exception error)

(Address error exception) (Load or command fetch)

(Address error exception) (Store)

(Bus error exception) (Command fetch)

(Bus error exception) (Data load)

(System call exception error)

(Break point exception error)

(Reserved command exception error)

(Unable to use coprocessor exception error)

(Operation overflow exception error)

(Trap exception error)

(Floating point exception error)

(Watch exception error)

(Watchdog timeout exception error)

(Abort error)

(Transfer memory error/Transfer memory access error)

EXA1500

Fault-Tracing Procedure

EXA page

EXA1500

EXA1500

EXA1510

EXA1510

EXA1510

EXA1510

EXA1510

EXA1510

EXA1510

EXA1510

EXA1510

EXA1520

EXA1520

EXA1520

EXA1520

EXA1520

EXA1520

EXA1520

EXA1520

EXA1520

EXA1530

• E065 Error X Motor

• E066 Error Y Motor

• E069 Error X Encoder

• E070 Error Y Encoder

• E071 Error X Timeout

• E072 Error Y Timeout

• E073 Error X Overcurrent

• E074 Error Y Overcurrent

• E075 Error Sensor Fault

EXA1700

EXA1700

EXA1700

EXA1700

EXA1710

EXA1710

EXA1710

EXA1710

EXA1720

FALLAS SISTEMA

MECANICO

Page 22

TRB2000

Model Name: Rockhopper-46/62

TRB2000

Model Name: Rockhopper-46/62

Trouble-Shooting 2/3 (List of Faults)

Trouble-Shooting 2/3 (List of Faults)

When Message is Not Displayed

When Message is Not Displayed

GO TO

EXA No.

Cases where no error message is displayed

on the liquid crystal display of the main printer unit

GO TO

EXA No.

Cases where no error message is displayed

on the liquid crystal display of the main printer unit

Trouble with Initialization

Trouble with Printing

• No power

• Faulty liquid crystal display (no display/unstable display)

• Initial filling of inks failed

• Initial filling is completed but no ink comes out

• After power is switched on, nothing works

•

When power is applied, “Initializing” appears and then a reset is executed.

• Media is mounted but the initialization operation is not done

• Printer does not work even with the cover closed

• Printer does not stop even with the cover opened

• Ink cartridges are installed but not recognized

• No se puede entrar al Panel de Operaciones

• Data is received but not printed

• Media is not suction

EXA2000

EXA2000

EXA2010

EXA2020

EXA2030

EXA2030

EXA2030

EXA2030

EXA2030

EXA2040

EXA2050

EXA2060

EXA2070

EXA3000

EXA3000

EXA3000

EXA3000

EXA3000

EXA3010

EXA3010

• No imprime en forma continua

• There is an extra feed after printing is finished

• Dots are missing from the printing

• Cleaning does not cure blockage

• No imprime nada

• No imprime un color especifico

• La superficie entera se imprime en negro

• Printing becomes shaded

• The image contains blurs

• Transverse lines appear to be split

• AParecen lineas blancas y negras en la impresion

• Orillas de la impresion aparecen borrosas

• Many satellites (unwanted dots)

• The printing has whiskers

• Printed lines appear blurred (printing is dirty)

• Mixed colour lines do not overlap

• Black and colour positions are offset

•

Inaccurate line length in the direction of head movement (Main scanning direction)

• Inaccurate straight line in the direction of head movement (straightness)

•

Inaccurate line distance in the direction of media feed (Subsidiary scanning distance)

• Inaccurate straight line in the direction of media feed (joining precision Y)

• Bad right angle precision

EXA4000

EXA4010

EXA4020

EXA4020

EXA4030

EXA4030

EXA4040

EXA4050

EXA4050

EXA4050

EXA4050

EXA4060

EXA4070

EXA4070

EXA4070

EXA4080

EXA4080

EXA4090

EXA4100

EXA4110

EXA4120

EXA4130

Trouble with Media Feed

• The media comes off when it is initialized or during printing

• The media is skewed or meanders when it is initialized or during printing

• The media becomes wrinkled when it is initialized or during printing

• The media jams when it is initialized or during printing

• The media tears when it is initialized or during printing

• The media size is different after media mounting and initialization

• Tracing paper and thin media cannot be detected

Page 23

TRB2001

Model Name: Rockhopper-46/62

TRB2001

Model Name: Rockhopper-46/62

Trouble-Shooting 3/3 (List of Faults)

Trouble-Shooting 3/3 (List of Faults)

When Message is Not Displayed

When Message is Not Displayed

GO TO

EXA No.

Cases where no error message is displayed

on the liquid crystal display of the main printer unit

GO TO

EXA No.

Cases where no error message is displayed

on the liquid crystal display of the main printer unit

Problem Involving Noise

Online/Function ProblemsOthers

• Abnormal noise when media is sucked down

• Abnormal noise when standing by ready to print

• Abnormal noise when head is moving left and right

• Abnormal noise when media is fed

• Abnormal noise when cutting

EXA5000

EXA5010

EXA5020

EXA5030

EXA5040

EXA6000

EXA6010

EXA6020

EXA6020

EXA6030

EXA6040

EXA6050

EXA6050

EXA7000

EXA7000

EXA7020

EXA7020

EXA7020

EXA7020

EXA7030

EXA7040

EXA7050

EXA7060

• The printer hangs up

• Power shutdown during printing

• The ink cartridges will not go in

• Ink has overflowed from the waste fluid box

• Ink overflows from flushing box

• Ink is split around the X-rail

• Cannot connect normally with Centronics

• Cannot connect normally with Network

• The scale function does not work correctly

• The rotate function does not work correctly

• The mirror function does not work correctly

• Other functions are not working correctly

• Printing position is offset

• Some data are not printed (omitted)

• Text and printing data are garbled (extra lines appear)

• There is an extra feed after printing is finished

EXA8000

EXA8010

EXA8020

EXA8050

EXA8050

EXA8050

Trouble with Media Cutting

• Does not cut normally

• Cutting occurs during printing

• The cutting operation is normal but the media is not cut

• The cutting is bad and the media jams

• The cutting operation is normal but the media does not fall out

• Inaccurate media cutting

• Cutting is delayed for some time after printing has ended

• White paper is cut (Blank print)

Sistema Calefactores EXA9000

Page 24

MAP0000

MAP0000

Rockhopper-463 Matrix Map

Rockhopper-463 Matrix Map

Matrix Map

When Message is Displayed

Printer Status Messages MAP1000

Data Errors MAP1200

Command Errors MAP1200

CPU System Faults MAP1500

Mechanical System Faults MAP1700

When Message is Not Displayed

Trouble with Initialization MAP2000

Trouble with Printing MAP4000

Trouble with Media Feed MAP3000

Trouble with Media Cutting MAP6000

Problem Involving Noise MAP5000

Online/Function Problems MAP7000

Other MAP8000

Model Name: Rockhopper-46

Model Name: Rockhopper-46

Heater System MAP9000

Heaters Fault MAP1800

Page 25

MAP0000-3

MAP0000-3

Rockhopper-62 Matrix Map

Rockhopper-62 Matrix Map

Matrix Map

When Message is Displayed

Printer Status Messages MAP1000-3

Data Errors MAP1200

Command Errors MAP1200

CPU System Faults MAP1500

Mechanical System Faults MAP1700-2

When Message is Not Displayed

Trouble with Initialization MAP2000-2

Trouble with Printing MAP4000-2, 4001-3

Trouble with Media Feed MAP3000-3

Trouble with Media Cutting MAP6000-2

Problem Involving Noise MAP5000-3

Online/Function Problems MAP7000-2

Other MAP8000-2

Model Name: Rockhopper-62

Model Name: Rockhopper-62

Heater System MAP9000-2

Heaters Fault MAP1800-2

Page 26

When Message is Displayed Printer Status Messages Model Name: Rockhopper463 MAP1000

Printer Status Messages Model Name: Rockhopper463 MAP1000

1000

1000

1000

1010

1020

1030

1040

1050

1060

1070

1080

1090

1090

1100

1110

1120

1130

1150

1140

1160

1110

1170

1100

1410

1420

1200

1360

1380

1350

1350

1350

1350

1350

1350

1120

1220

1220

1330

1340

1340

1340

1340

1340

1340

1470

1470

1690

When Message is Displayed

When Message is Displayed

[Printer Status Display]

EXA1000 to EXA1150

Problem

- Cover open

- Lever up

- Cover & Lever

- Undefined Media

- Media Skew Error

- [User 1] Media End

- Remove Media

- Roll Media End

- Media Cut Error

- Not enough memory SIMM12MB

- Insert Special Cartridge

- [✼✼] Ink Low

- [✼✼] No Ink

- [✼✼] No Cartridge

- Capping position not specified

- Not Filled

- No Waste Fluid Box

- Wrong Ink Type

Replacement and Adjustment Procedure REP. No.

Name and Diagram Number of

Replacement Part

DF-41586 Main Board Assembly

DF-40097 Panel Board Assembly

DF-41590 Cover Switch Assembly

DF-41617 Panel Cable

DF-41589 Lever Sensor Assembly

DF-41595 Edge Sensor Assembly

DF-41588 Head Board Assembly

DF-41592 XR Cable Assembly (Paper Sensor R)

DF-41600 Y Cable

DF-40113 Cutter Solenoid Assembly

DF-41593 Detector1 Assembly

DF-41594 Detector2 Assembly

DF-40106 Detector Assembly (Black)

DF-40107 Detector Assembly (Y)

DF-40146 Detector Assembly (M)

DF-40147 Detector Assembly (C)

DF-41591 Waste Fluid Box Sensor Assembly

DF-41529 Pressure Assembly

DF-41530 Pressure Roller

DF-40127 Cartridge Frame Assembly

DF-41609 Ink ID Sensor1 Assembly

DF-41610 Ink ID Sensor2 Assembly

DF-41611 Ink ID Sensor3 Assembly

DF-41612 Ink ID Sensor4 Assembly

DF-41613 Ink ID Sensor5 Assembly

DF-41614 Ink ID Sensor6 Assembly

DF-41615 Ink ID Cable

DF-41536 Junction Board Assembly

DF-41840 Grid Roller Assembly

FaultTracing

Procedure

EXA No.

Page 27

When Message is Displayed Printer Status Messages Model Name: Rockhopper62 MAP1000-3

Printer Status Messages Model Name: Rockhopper62 MAP1000-3

1000

1000

1000

1010

1020-2

1030

1040

1050

1060

1070

1080

1090

1090

1100

1110

1120

1130

1150

1140

1160

1110

1170

1100

1410

1420

1200

1360-2

1380

1350

1350

1350

1350

1350

1350

1120

1220

1220

1330

1340

1340

1340

1340

1340

1340

1470

1470

1690

1690

When Message is Displayed

When Message is Displayed

[Printer Status Display]

EXA1000 to EXA1150

Problem

- Cover open

- Lever up

- Cover & Lever

- Undefined Media

- Media Skew Error

- [User 1] Media End

- Remove Media

- Roll Media End

- Media Cut Error

- Not enough memory SIMM12MB

- Insert Special Cartridge

- [✼✼] Ink Low

- [✼✼] No Ink

- [✼✼] No Cartridge

- Capping position not specified

- Not Filled

- No Waste Fluid Box

- Wrong Ink Type

Replacement and Adjustment Procedure REP. No.

Name and Diagram Number of

Replacement Part

DF-41586 Main Board Assembly

DF-40097 Panel Board Assembly

DF-41590 Cover Switch Assembly

DF-41617 Panel Cable

DF-41589 Lever Sensor Assembly

DF-41595 Edge Sensor Assembly

DF-41588 Head Board Assembly

DF-41592 XR Cable Assembly (Paper Sensor R)

DF-41600 Y Cable

DF-40113 Cutter Solenoid Assembly

DF-41593 Detector1 Assembly

DF-41594 Detector2 Assembly

DF-40106 Detector Assembly (Black)

DF-40107 Detector Assembly (Y)

DF-40146 Detector Assembly (M)

DF-40147 Detector Assembly (C)

DF-41591 Waste Fluid Box Sensor Assembly

DF-41529 Pressure Assembly

DF-41530 Pressure Roller

DF-40127 Cartridge Frame Assembly

DF-41609 Ink ID Sensor1 Assembly

DF-41610 Ink ID Sensor2 Assembly

DF-41611 Ink ID Sensor3 Assembly

DF-41612 Ink ID Sensor4 Assembly

DF-41613 Ink ID Sensor5 Assembly

DF-41614 Ink ID Sensor6 Assembly

DF-41615 Ink ID Cable

DF-41536 Junction Board Assembly

DF-41840 Grid Roller Assembly

FaultTracing

Procedure

EXA No.

Page 28

When Message is Displayed Data Errors, Command Errors MAP1200

Data Errors, Command Errors Model Name: Rockhopper-46/62

Model Name: Rockhopper-46/62

MAP1200

1230

1230

1250

1250

1250

1250

1250

1140

When Message is Displayed

When Message is Displayed

[Data Errors, Command Errors]

EXA1230 to EXA1250

Problem

- Network Detection Error

- Network Initialization Error

- MH01 Error (Undefined Command)

- MH02 Error (Parameter Error)

- MH03 Error (Numerical Error)

- MH04 Error (Undefined Character Set)

- MH07 Error (Buffer Overflow)

Replacement and Adjustment Procedure REP. No.

Name and Diagram Number of

Replacement Part

DF-41586 Main Board Assembly

FaultTracing

Procedure

EXA No.

Page 29

When Message is Displayed CPU System Faults MAP1500

CPU System Faults Model Name: Rockhopper-46/62

Model Name: Rockhopper-46/62

MAP1500

1500

1500

1510

1510

1510

1510

1510

1510

1510

1510

1510

1520

1520

1520

1520

1520

1520

1520

1520

1520

1530

1140

When Message is Displayed

When Message is Displayed

[CPU System Faults]

EXA1500 to EXA1530

Problem

- E001 Error DRAM (Standard DRAM error)

- E002 Error Opt.DRAM (Optional DRAM error)

- E016 CPUErr[00] (Interrupt exception error)

- E016 CPUErr[02] (Command boundary exception error)

- E016 CPUErr[03] (Data boundary exception error)

- E016 CPUErr[04] (Address error exception load)

- E016 CPUErr[05] (Address error exception store)

- E016 CPUErr[06] (Bus error exception check)

- E016 CPUErr[07] (Bus error exception load)

- E016 CPUErr[08] (System call exception)

- E016 CPUErr[09] (Break point exception)

- E016 CPUErr[10] (Reserved command exception)

- E016 CPUErr[11] (Processor usage denial exception)

- E016 CPUErr[12] (Operation overflow exception)

- E016 CPUErr[13] (Trap exception)

- E016 CPUErr[15] (Floating point exception)

- E016 CPUErr[22] (Watch exception)

- E016 CPUErr[32] (Watchdog timeout error)

- E016 CPUErr[33] (Abort error)

- E237 Error Transfer memory (Transfer memory error/access error)

- Error E129 NVRAM (Backup memory error)

Replacement and Adjustment Procedure REP. No.

Name and Diagram Number of

Replacement Part

DF-41586 Main Board Assembly

FaultTracing

Procedure

EXA No.

Page 30

When Message is Displayed Mechanical System Faults Model N.:Rockhopper-463 MAP1700

Mechanical System Faults Model N.: Rockhopper-463 MAP1700

1140

1070

1280

1290

1450

1150

1080

1080

1080

1080

When Message is Displayed

When Message is Displayed

[Mechanical System Faults]

EXA1700 to EXA1720

Problem

- Error E065 X Motor

- Error E069 X Encoder

- Error E071 X Timeout

- Error E073 X Overcurrent

- Error E066 Y Motor

- Error E070 Y Encoder

- Error E072 Y Timeout

- Error E074 Y Overcurrent

- Error E075 Sensor Abnormal

Replacement and Adjustment Procedure REP. No.

Name and Diagram Number of

Replacement Part

DF-41586 Main Board Assembly

DF-41597 X Motor Assembly

DF-41598 CR Motor Assembly (Y Motor)

DF-41607 T Fence

DF-40109 Origin Sensor Assembly

DF-41587 Power Board Assembly

DF-40173 Vacuum Fan Assembly

DF-41620 Fan Extension Cable 1 Assembly

DF-41621 Fan Extension Cable 2 Assembly

DF-41622 Fan Extension Cable 3 Assembly

1700

1700

1700

1700

1710

1710

1710

1710

1720

FaultTracing

Procedure

EXA No.

Page 31

When Message is Displayed Mechanical System Faults Model Name: Rockhopper 62 MAP1700-2

Mechanical System Faults Model Name: Rockhopper 62 MAP1700-2

1140

1070

1280

1290

1450

1150

1080-2

1080-2

1080-2

1080-2

1080-2

When Message is Displayed

When Message is Displayed

[Mechanical System Faults]

EXA1700 to EXA1720

Problem

- Error E065 X Motor

- Error E069 X Encoder

- Error E071 X Timeout

- Error E073 X Overcurrent

- Error E066 Y Motor

- Error E070 Y Encoder

- Error E072 Y Timeout

- Error E074 Y Overcurrent

- Error E075 Sensor Abnormal

Replacement and Adjustment Procedure REP. No.

Name and Diagram Number of

Replacement Part

DF-41586 Main Board Assembly

DF-41597 X Motor Assembly

DF-41598 CR Motor Assembly (Y Motor)

DF-41607 T Fence

DF-40109 Origin Sensor Assembly

DF-41587 Power Board Assembly

DF-40173 Vacuum Fan Assembly

DF-41620 Fan Extension Cable 1 Assembly

DF-41621 Fan Extension Cable 2 Assembly

DF-41622 Fan Extension Cable 3 Assembly

DF-41993 Fan Extension Cable 4 Assembly

1700

1700

1700

1700

1710

1710

1710

1710

1720

FaultTracing

Procedure

EXA No.

Page 32

When Message is Displayed d Heater System Faultsr Model N:Rockhopper46 3 MAP1800

Heater System Faultsr Model N:Rockhopper46 3 MAP1800

When Message is Displayed

When Message is Displayed

[Heater system]

EXA1800

Problem

- Err : F.R.T. Sensor

Replacement and Adjustment Procedure REP. No.

Name and Diagram Number of

Replacement Part

Front Right Heater Sensor

Front Left Heater Sensor

Rear Right Heater Sensor

Rear Left Heater Sensor

1040

104

0

1040

1040

1800

FaultTracing

Procedure

EXA No.

- Err : F.L.T. Sensor

1800

- Err : R.L.T. Sensor

1800

- Err : R.R.T. Sensor

1800

- Err : FRFLT Sensor

1800

- Err : FRRLT Sensor

1800

- Err : FRRRT Sensor

1800

- Err : FLRLT Sensor

1800

- Err : FLRRT Sensor

1800

- Err : RRRLT Sensor

1800

- Err : 2FRLT Sensor

1800

- Err : 2FRRT Sensor

1800

- Err : FR2RT Sensor

1800

- Err : FL2RT Sensor

1800

- Err : All T. Sensor

1800

- Err : Heater Stop

1800

Heater System

1040

Page 33

When Message is Displayed d Heater System Faultsr Model N:Rockhopper62 3 MAP1800-2

Heater System Faultsr Model N:Rockhopper62 3 MAP1800-2

When Message is Displayed

When Message is Displayed

[Heater system]

EXA1800

Problem

- Err : F.R.T. Sensor

Replacement and Adjustment Procedure REP. No.

Name and Diagram Number of

Replacement Part

Front Right Heater Sensor

Front Left Heater Sensor

Rear Right Heater Sensor

Rear Left Heater Sensor

1040 -2

104

0 -2

1040 -2

1040 -2

1800

FaultTracing

Procedure

EXA No.

- Err : F.L.T. Sensor

1800

- Err : R.L.T. Sensor

1800

- Err : R.R.T. Sensor

1800

- Err : FRFLT Sensor

1800

- Err : FRRLT Sensor

1800

- Err : FRRRT Sensor

1800

- Err : FLRLT Sensor

1800

- Err : FLRRT Sensor

1800

- Err : RRRLT Sensor

1800

- Err : 2FRLT Sensor

1800

- Err : 2FRRT Sensor

1800

- Err : FR2RT Sensor

1800

- Err : FL2RT Sensor

1800

- Err : All T. Sensor

1800

- Err : Heater Stop

1800

Heater System

1040 -2

Page 34

When Message is Not Displayed Trouble with Initialization Model N. :Rockhopper463 MAP2000

Trouble with Initialization Model N. : Rockhopper463 MAP2000

When Message is Not Displayed

When Message is Not Displayed

[Trouble with Initialization]

EXA2000 to EXA2070

Problem

- Power supply does not come on

- LCD faulty (no display/erratic display)

- Initial filling of inks failed

- Initial filling is completed but no ink comes out

- After power is switched on, nothing works

- When power is applied, “Initializing” appears and then a reset is executed.

- After mounting media, initial operation fails

- Printer does not work even with the cover closed

- Printer does not stop even with the cover opened

- Ink cartridges are installed but not recognized

- Can not make entries from the operating panel

- Data is received but not plotted

- Media is not suction

Replacement and Adjustment Procedure REP. No.

Name and Diagram Number of

Replacement Part

DF-41586 Main Board Assembly

DF-40097 Panel Board Assembly

DF-41617 Panel Cable

DF-41590 Cover Switch Assembly

DF-41589 Lever Sensor Assembly

DF-41595 Edge Sensor Assembly

DF-41588 Head Board Assembly

DF-41592 XR Cable Assembly (Paper Sensor R)

DF-41600 Y Cable

DF-41619 Switch Cable Assembly

DF-41587 Power Board Assembly

DF-41468 DC Cable Assembly

DF-41593 Detector 1 Assembly

DF-41594 Detector 2 Assembly

DF-40106 Detector Assembly (Black)

DF-40107 Detector Assembly (Y)

DF-40146 Detector Assembly (M)

DF-40147 Detector Assembly (C)

DF-41602 Cap Assembly

DF-41603 Pump Assembly

DF-41604 Maintenance Station Assembly

DF-40690 Print Head Assembly (Colour)

DF-41601 Head Cable

DF-41591 Waste Fluid Bottle Sensor

DF-40173 Vacuum Fan Assembly

DF-41620 Fan Extension Cable 1 Assembly

DF-41621 Fan Extension Cable 2 Assembly

DF-41622 Fan Extension Cable 3 Assembly

DF-41609 INK ID Sensor 1 Assembly

DF-41610 INK ID Sensor 2 Assembly

DF-41611 INK ID Sensor 3 Assembly

DF-41612 INK ID Sensor 4 Assembly

DF-41613 INK ID Sensor 5 Assembly

DF-41614 INK ID Sensor 6 Assembly

DF-41615 INK ID Sensor Cable

DF-41536 Junction Board Assembly

1140

1160

1170

1110

1100

1410

1420

1200

1360

1130

1150

1130

1350

1350

1350

1350

1350

1350

1240

1260

1270

1390

1390

1120

1080

1080

1080

1080

1340

1340

1340

1340

1340

1340

1470

1470

2000

2000

2010

2020

2030

2030

2030

2030

2030

2040

2050

2060

2070

FaultTracing

Procedure

EXA No.

Page 35

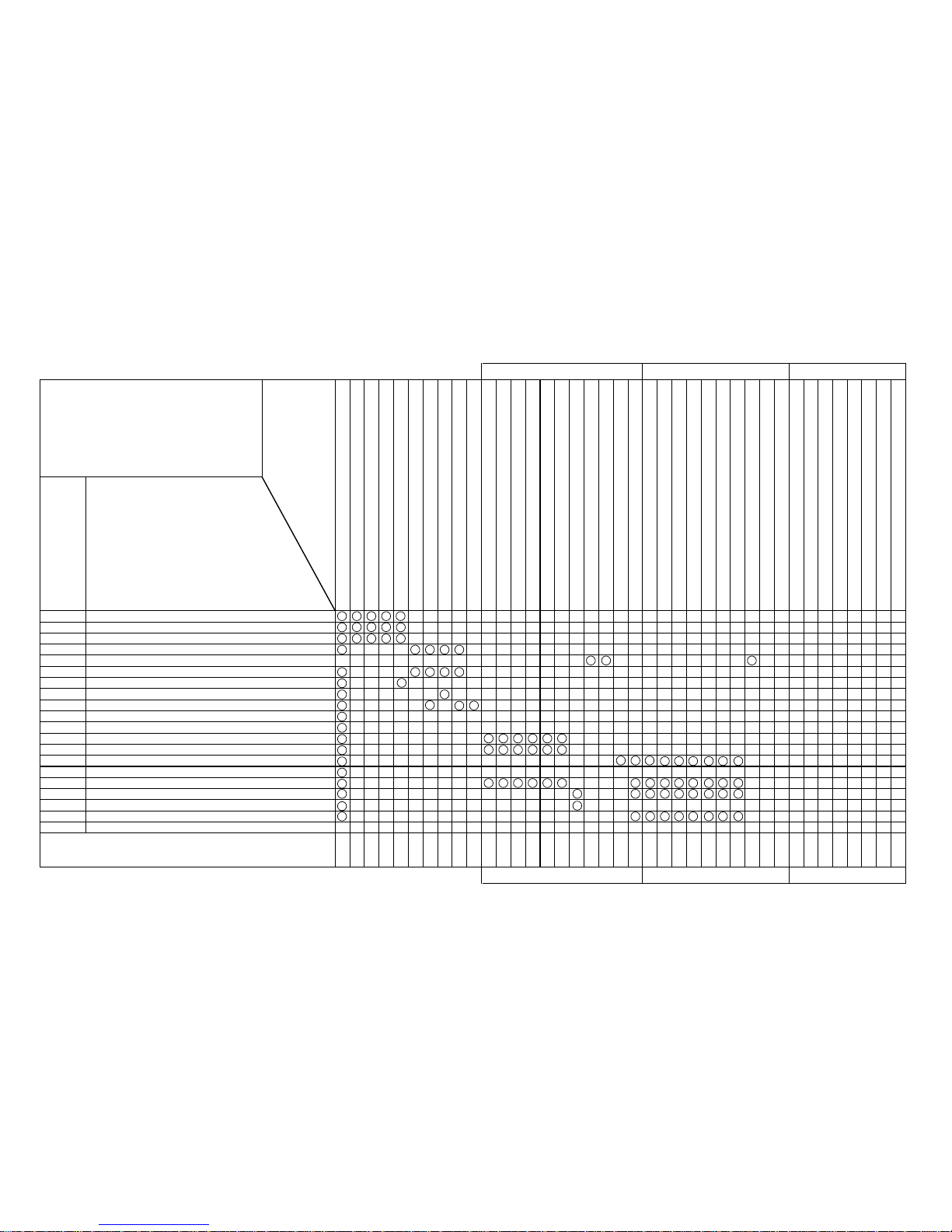

When Message is Not Displayed Trouble with Initialization Model Name: Rockhopper 62 MAP2000-2

Trouble with Initialization Model Name: Rockhopper 62 MAP2000-2

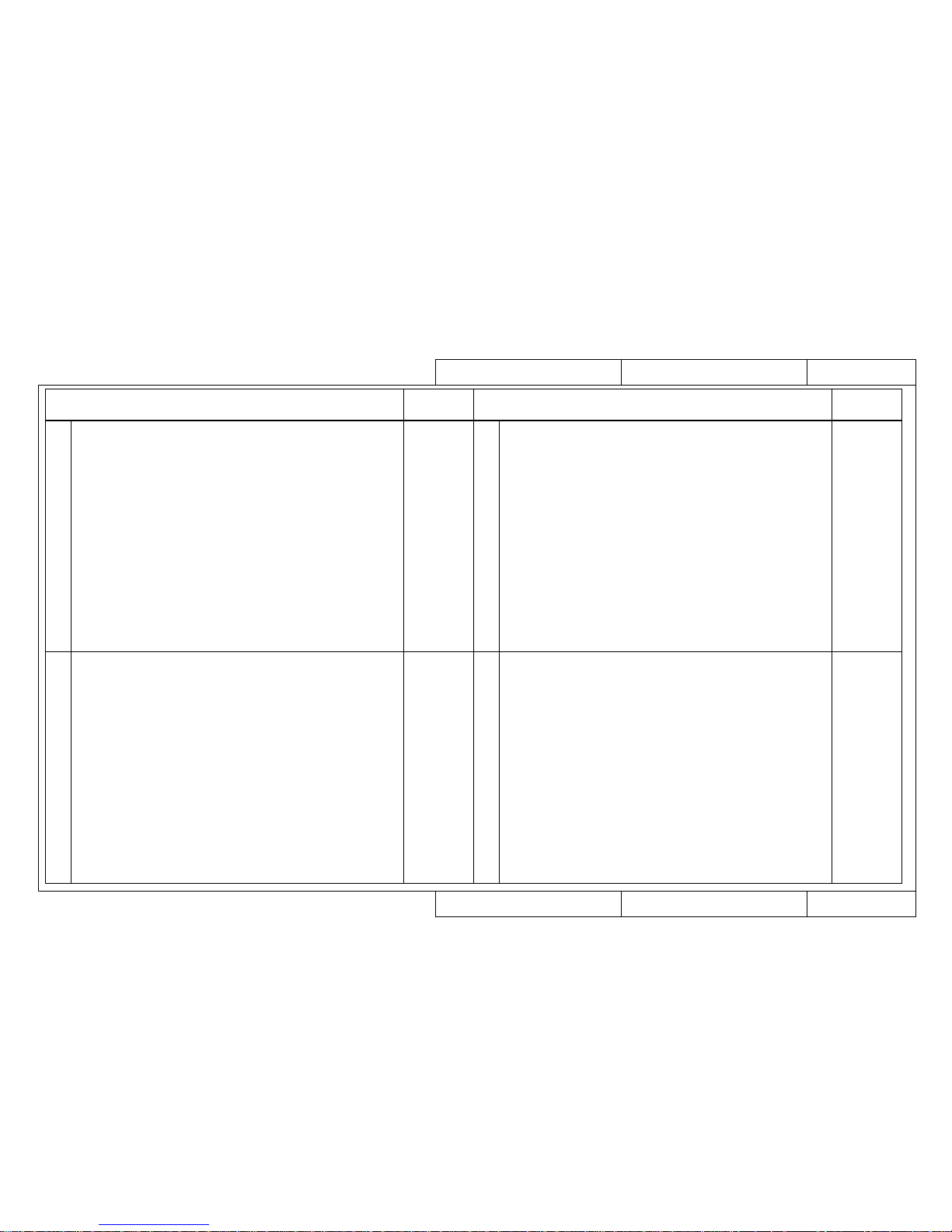

When Message is Not Displayed

When Message is Not Displayed

[Trouble with Initialization]

EXA2000 to EXA2070-2

Problem

- Power supply does not come on

- LCD faulty (no display/erratic display)

- Initial filling of inks failed

- Initial filling is completed but no ink comes out

- After power is switched on, nothing works

- When power is applied, “Initializing” appears and then a reset is executed.

- After mounting media, initial operation fails

- Printer does not work even with the cover closed

- Printer does not stop even with the cover opened

- Ink cartridges are installed but not recognized

- Can not make entries from the operating panel

- Data is received but not plotted

- Media is not suction

Replacement and Adjustment Procedure REP. No.

Name and Diagram Number of

Replacement Part

DF-41586 Main Board Assembly

DF-40097 Panel Board Assembly

DF-41617 Panel Cable

DF-41590 Cover Switch Assembly

DF-41589 Lever Sensor Assembly

DF-41595 Edge Sensor Assembly

DF-41588 Head Board Assembly

DF-41592 XR Cable Assembly (Paper Sensor R)

DF-41600 Y Cable

DF-41619 Switch Cable Assembly

DF-41587 Power Board Assembly

DF-41468 DC Cable Assembly

DF-41593 Detector 1 Assembly

DF-41594 Detector 2 Assembly

DF-40106 Detector Assembly (Black)

DF-40107 Detector Assembly (Y)

DF-40146 Detector Assembly (M)

DF-40147 Detector Assembly (C)

DF-41602 Cap Assembly

DF-41603 Pump Assembly

DF-41604 Maintenance Station Assembly

DF-40690 Print Head Assembly (Colour)

DF-41601 Head Cable

DF-41591 Waste Fluid Bottle Sensor

DF-40173 Vacuum Fan Assembly

DF-41620 Fan Extension Cable 1 Assembly

DF-41621 Fan Extension Cable 2 Assembly

DF-41622 Fan Extension Cable 3 Assembly

DF-41993 Fan Extension Cable 4 Assembly

DF-41609 INK ID Sensor 1 Assembly

DF-41610 INK ID Sensor 2 Assembly

DF-41611 INK ID Sensor 3 Assembly

DF-41612 INK ID Sensor 4 Assembly

DF-41613 INK ID Sensor 5 Assembly

DF-41614 INK ID Sensor 6 Assembly

DF-41615 INK ID Sensor Cable

DF-41536 Junction Board Assembly

1140

1160

1170

1110

1100

1410

1420

1200

1360-2

1130

1150

1130

1350

1350

1350

1350

1350

1350

1240

1260

1270

1390

1390

1120

1080-2

1080-2

1080-2

1080-2

1080-2

1340

1340

1340

1340

1340

1340

1470

1470

2000

2000

2010

2020

2030

2030

2030

2030

2030

2040

2050

2060

2070-2

FaultTracing

Procedure

EXA No.

Page 36

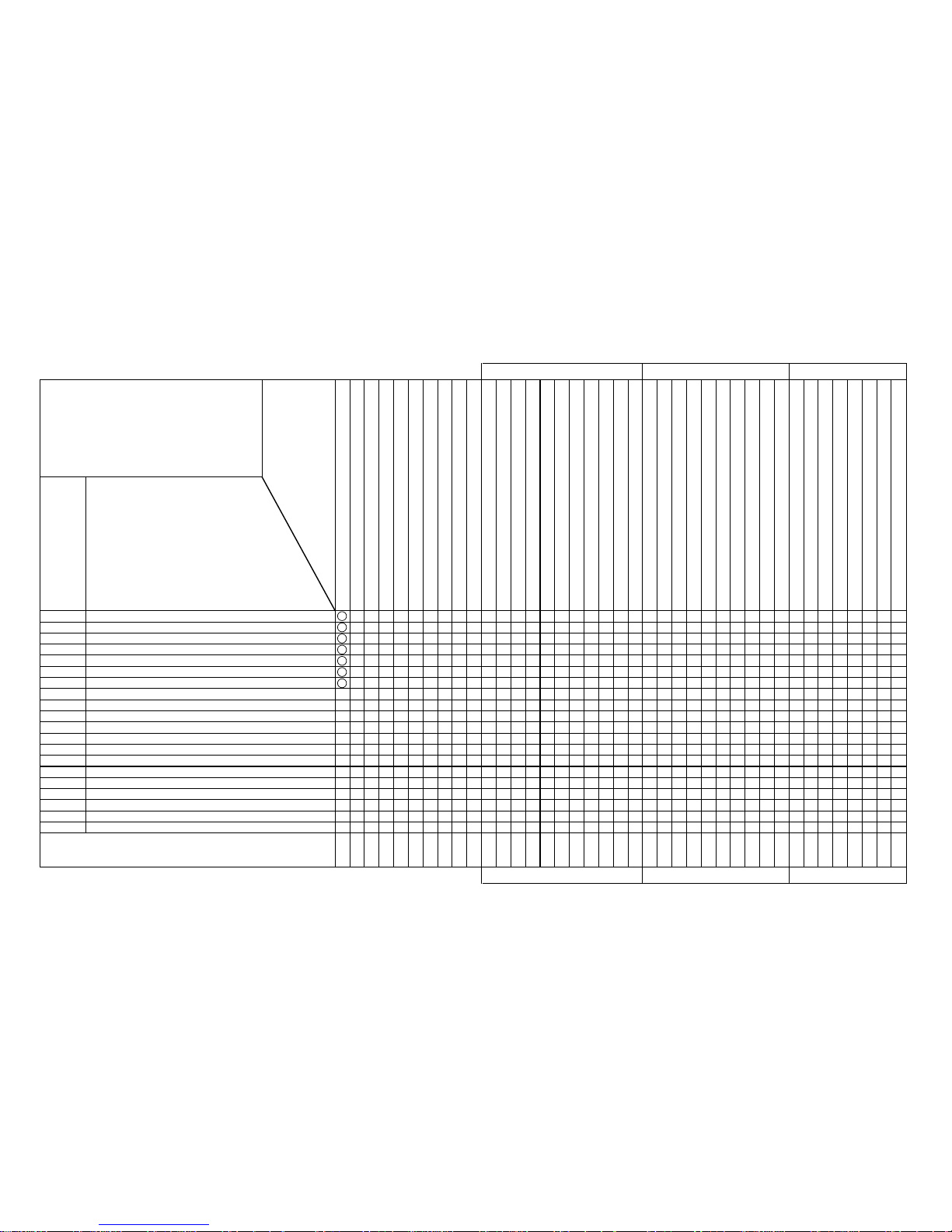

When Message is Not Displayed Trouble with Media Feed Model N. :Rockhopper463 MAP3000

Trouble with Media Feed Model N. :Rockhopper463 MAP3000

When Message is Not Displayed

When Message is Not Displayed

[Trouble with Media Feed]

EXA3000 to EXA3010

FaultTracing

Procedure

EXA No.

Problem

- The media comes off when it is initialized or during printing

- The media is skewed or meanders when it is initialized or during printing

- The media becomes wrinkled when it is initialized or during printing

- The media jams when it is initialized or during printing

- The media tears when it is initialized or during printing

- The media size is different after media mounting and initialization

- Tracing paper and thin media cannot be detected

Replacement and Adjustment Procedure REP. No.

Name and Diagram Number of

Replacement Part

DF-41586 Main Board Assembly

DF-40173 Vacuum Fan Assembly

DF-41620 Fan Extension Cable 1 Assembly

DF-41621 Fan Extension Cable 2 Assembly

DF-41622 Fan Extension Cable 3 Assembly

DF-41529 Pressure Assembly

DF-41595 Edge Sensor Assembly

DF-41592 XR Cable Assembly (Paper Sensor R)

DF-41600 Y Cable

DF-41840 Grid Roller Assembly

1140

1080

1080

1080

1080

1110

1410

1200

1360

1690

3000

3000

3000

3000

3000

3010

3010

Page 37

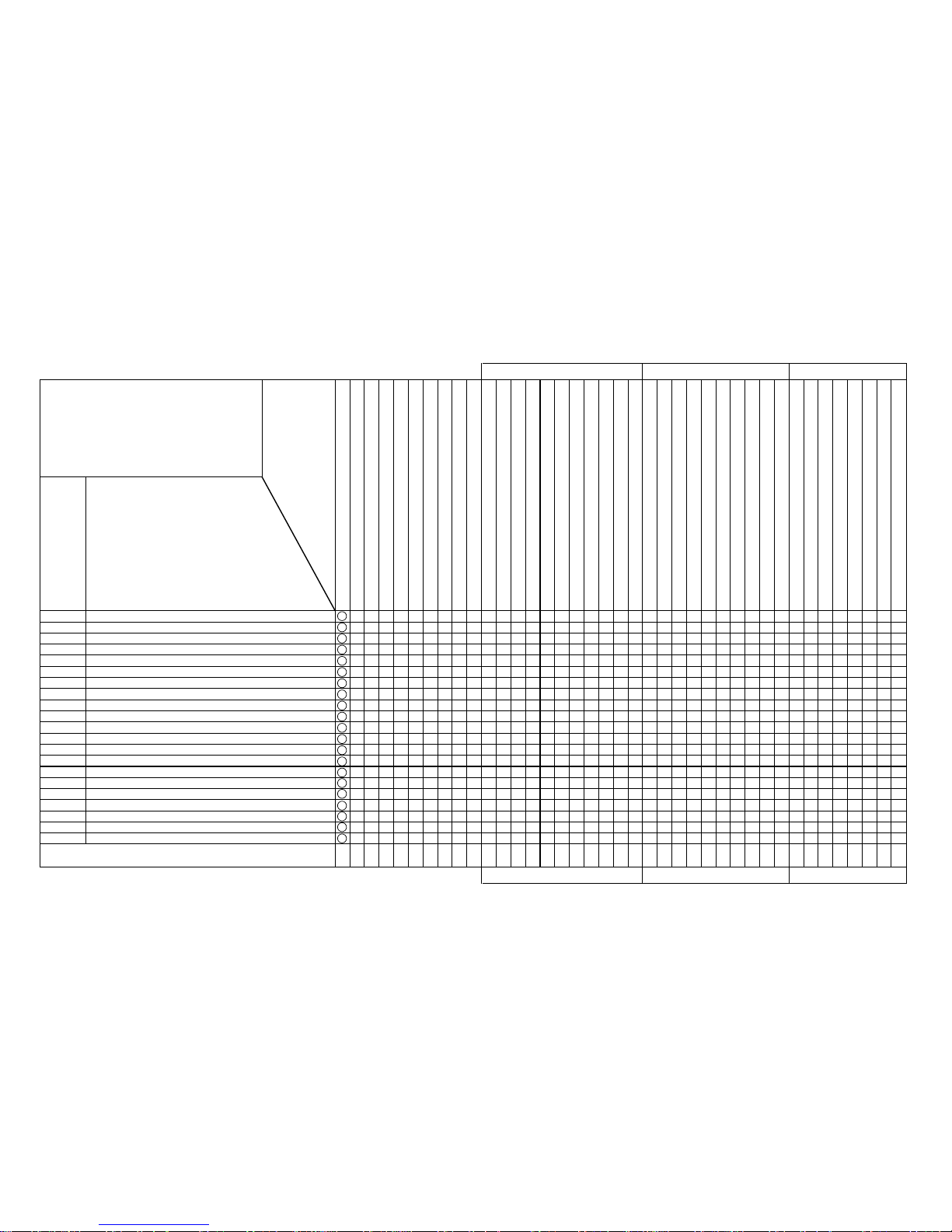

When Message is Not Displayed Trouble with Media Feed Model N. : Rockhopper-62 MAP3000-3

Trouble with Media Feed Model N. : Rockhopper-62 MAP3000-3

When Message is Not Displayed

When Message is Not Displayed

[Trouble with Media Feed]

EXA3000-2 to EXA3010

FaultTracing

Procedure

EXA No.

Problem

- The media comes off when it is initialized or during printing

- The media is skewed or meanders when it is initialized or during printing

- The media becomes wrinkled when it is initialized or during printing

- The media jams when it is initialized or during printing

- The media tears when it is initialized or during printing

- The media size is different after media mounting and initialization

- Tracing paper and thin media cannot be detected

Replacement and Adjustment Procedure REP. No.

Name and Diagram Number of

Replacement Part

DF-41586 Main Board Assembly

DF-40173 Vacuum Fan Assembly

DF-41620 Fan Extension Cable 1 Assembly

DF-41621 Fan Extension Cable 2 Assembly

DF-41622 Fan Extension Cable 3 Assembly

DF-41993 Fan Extension Cable 4 Assembly

DF-41529 Pressure Assembly

DF-41595 Edge Sensor Assembly

DF-41592 XR Cable Assembly (Paper Sensor R)

DF-41600 Y Cable

DF-41840 Grid Roller Assembly

1140

1080-2

1080-2

1080-2

1080-2

1080-2

1110

1410

1200

1360-2

1690

3000-2

3000-2

3000-2

3000-2

3000-2

3010

3010

Page 38

When Message is Not Displayed Trouble with Printing Model N. : Rockhopper-463 MAP4000

Trouble with Printing Model N. : Rockhopper-463 MAP4000

When Message is Not Displayed

When Message is Not Displayed

[Trouble with Printing]

EXA4000 to EXA4130

(EXA4110 to EXA4130 → See MAP4001)

Problem

- Does not print continuously

- There is an extra feed after printing is finished

- Dots are missing from the printing

- Cleaning does not cure blockage

- Does not print at all or does not print a specific colour

- The entire surface is printed black

- Printing becomes shaded

- The image contains blurs

- Transverse lines appear to be split

- Black and white lines appear in the printed image

- Edges of printing are blurred

- Many satellites (unwanted dots)

- The printing has whiskers

- Printed lines appear blurred

- Mixed colour lines do not overlap

- Black and colour positions are offset

-

Inaccurate line length in the direction of head movement (Main scanning direction)

- Inaccurate straight line in the direction of head movement (straightness)

Replacement and Adjustment Procedure REP. No.

Name and Diagram Number of

Replacement Part

DF-41586 Main Board Assembly

DF-40173 Vacuum Fan Assembly

DF-41620 Fan Extension Cable 1 Assembly

DF-41621 Fan Extension Cable 2 Assembly

DF-41622 Fan Extension Cable 3 Assembly

DF-41605 Ink Tube

DF-41601 Head Cable

DF-41600 Y Cable

DF-41607 T Fence

DF-41602 Cap Assembly

DF-41603 Pump Assembly

DF-41599 Pump Motor Assembly

DF-40125 Wiper

DF-41604 Maintenance Station Assembly

DF-40690 Print Head Assembly (Colour)

DF-41588 Head Board Assembly

DF-41593 Detector 1 Assembly

DF-41594 Detector 2 Assembly

DF-40106 Detector Assembly (Black)

DF-40107 Detector Assembly (Y)

DF-40146 Detector Assembly (M)

DF-40147 Detector Assembly (C)

DF-41592 XR Cable Assembly (Paper Sensor R)

DF-41587 Power Board Assembly

1140

1080

1080

1080

1080

1370

1390

1360

1290

1240

1260

1230

1250

1270

1390

1420

1350

1350

1350

1350

1350

1350

1200

1150

4000

4010

4020

4020

4030

4040

4050

4050

4050

4050

4060

4070

4070

4070

4080

4080

4090

4100

FaultTracing

Procedure

EXA No.

Page 39

When Message is Not Displayed Trouble with Printing Model Name: Rockhopper 62 MAP4000-2

Trouble with Printing Model Name: Rockhopper 62 MAP4000-2

When Message is Not Displayed

When Message is Not Displayed

[Trouble with Printing]

EXA4000 to EXA4130-2

(EXA4110 to EXA4130-2 → See MAP4001-2)

Problem

- Does not print continuously

- There is an extra feed after printing is finished

- Dots are missing from the printing

- Cleaning does not cure blockage

- Does not print at all or does not print a specific colour

- The entire surface is printed black

- Printing becomes shaded

- The image contains blurs