Page 1

Troubleshooting

Spitfire 65/90

Rockhopper 3

Page 2

Troubleshooting

2 AP-74700 – Rev. 1.0 – 10/03/2008

This page is intentionally left blank

Page 3

Troubleshooting

3 AP-74700 – Rev. 1.0 – 10/03/2008

Table of content

1 TROUBLESHOOTING PROCEDURE WHEN A MESSAGE IS DISPLAYED ..............5

1.1 OPERATING CONDITION DISPLAY ..................................................................................6

1.2 MESSAGE TYPE ERRORS .............................................................................................8

1.3 HEATING SYSTEM ERROR ..........................................................................................14

1.4 DATA ERROR............................................................................................................15

1.5 COMMAND ERRORS ..................................................................................................16

2 TROUBLESHOOTING WITH ERROR CODES...........................................................17

2.1 DRAM

ERRORS.......................................................................................................17

2.2 CPU

ERRORS..........................................................................................................18

2.2.1 E 016 error CPU Err(03) ..................................................................................18

2.3 PF - PAPER FEED ERRORS .......................................................................................19

2.4 CARRIAGE RELATED ERRORS.....................................................................................21

2.4.1 E066 - CR Motor Err ........................................................................................21

2.4.2 E068 - CR Encoder Err ....................................................................................21

2.4.3 E072 - CR OverCurrent ...................................................................................21

2.4.4 E070 - CR Timeout Error .................................................................................23

2.4.5 E073 - CR Origin Error.....................................................................................24

2.4.6 E074 - Cover Sensor Error...............................................................................24

2.4.7 E076 - PG Origin Err........................................................................................24

2.4.8 E078 - Head Cable Error .................................................................................25

2.5 LEVER & PRESSURE ROLLER ERRORS........................................................................26

2.5.1 E079 - Lever OverCurrent................................................................................26

2.5.2 E080 - Lever Sensor Err ..................................................................................26

2.6 CAPPING STATION ERRORS.......................................................................................27

2.6.1 E081 - Cap Sensor Err.....................................................................................27

2.6.2 Sensor diagnostics...........................................................................................27

2.6.3 Capping - Motor diagnostics ............................................................................27

2.6.4 E082 - Wiper Sensor Err..................................................................................27

2.6.5 Sensor diagnostics...........................................................................................28

2.6.6 Wiper - Motor diagnostics ................................................................................28

2.6.7 E097 - NVRAM Error .......................................................................................29

2.7 HEAD AND FLATCABLE RELATED ERRORS ....................................................................30

2.8 ETHERNET CARD ERRORS .........................................................................................31

2.9 M

AINBOARD RELATED ERRORS ..................................................................................31

2.9.1 E211 – Incompatible hardware ........................................................................31

2.9.2 E256 – Mode not found....................................................................................31

2.9.3 E257 – Mode not available ..............................................................................31

2.9.4 E258 – Mode Init problem................................................................................31

2.9.5 A259 – Hardware not found .............................................................................32

2.9.6 E260 – Incompatible Firmware ........................................................................33

2.9.7 E261 – Firmware Init Problem..........................................................................33

2.10 W

ALLET-SIMM-CARD ERRORS..................................................................................33

Page 4

Troubleshooting

4 AP-74700 – Rev. 1.0 – 10/03/2008

3 TROUBLESHOOTING WITHOUT ERROR CODE......................................................35

3.1 PARAMETER & PRINTING RELATED ISSUES .................................................................35

3.1.1 Parameters are not being saved during shutdown...........................................35

3.1.2 Unstable machine behaviour (CPU errors, machine crashes) .........................35

3.1.3 Printer doesn’t start printing, interrupts or intermittently stops during printing..36

3.1.4 Ink drops falling on media from heads during printing......................................37

3.2 PRINTING RELATED PROBLEMS ..................................................................................38

3.2.1 Complete nozzle-row (A or B-channel) is missing............................................38

3.2.2 Head is firing continuously ...............................................................................39

3.3 INITIAL MACHINE STARTUP-RELATED PROBLEMS ..........................................................40

3.3.1 Ink and cleaning compatibility-Chart ................................................................40

3.3.2 Only applicable 65” – 90” machines.................................................................42

3.4 PUMP INK AND CLEANING SUCTION PROBLEMS.............................................................42

3.4.1 The machine is completely dead – non responding.........................................43

3.4.2 Mainboard replacement procedure ..................................................................44

3.4.3 Media Feed – Distance adjustment basic principles ........................................44

3.4.3.1 Mechanical toleration: ...................................................................................44

3.4.3.2 Media toleration ............................................................................................45

Page 5

Troubleshooting

5 AP-74700 – Rev. 1.0 – 10/03/2008

Introduction

This chapter explains the procedures for troubleshooting this product.

When the product indicates a failure and an error message is also displayed on the control panel, refer to

"Troubleshooting procedures when a message has been displayed" and implement treatment. When the

product indicates failure but an error message has not been displayed, refer to "Troubleshooting procedures

when an error message has not been displayed" and implement treatment.

1 TROUBLESHOOTING PROCEDURE

WHEN A MESSAGE IS DISPLAYED

This chapter explains the messages displayed when the product is operating normally and when an error

occurs.

There are the following types of messages.

Priority level Message Type Description

1

Operating condition

display

Displayed when the product is operating normally

2 Heating system error Displayed when heating element errors occurs during operation.

3

Message type errors Message type errors are displayed when trouble occurs during

operation.

4

Data error Displayed when data communication trouble occurs between the

computer and this product.

5

Command errors Displayed when trouble occurs during analysis of the command

data that is sent to this product from the computer.

Page 6

Troubleshooting

6 AP-74700 – Rev. 1.0 – 10/03/2008

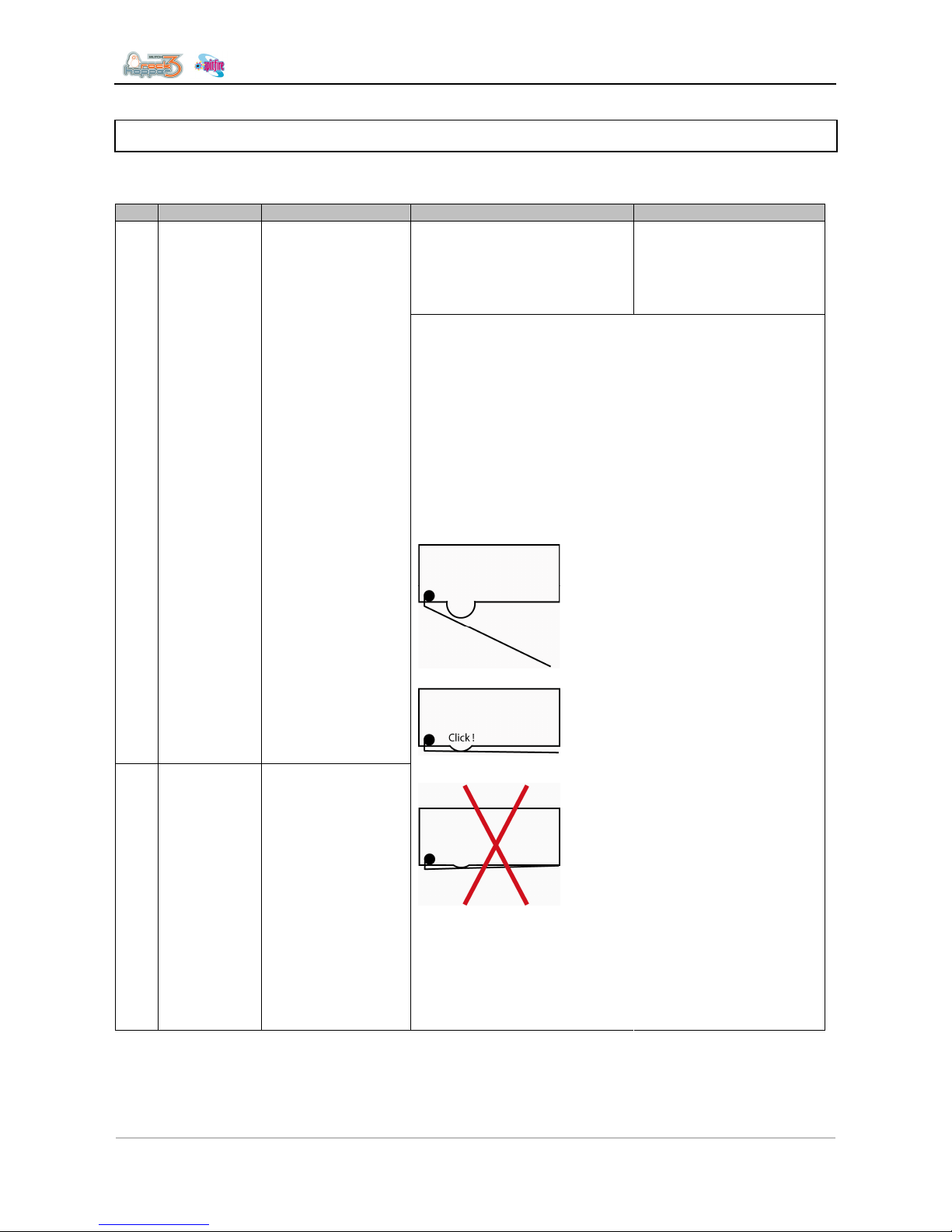

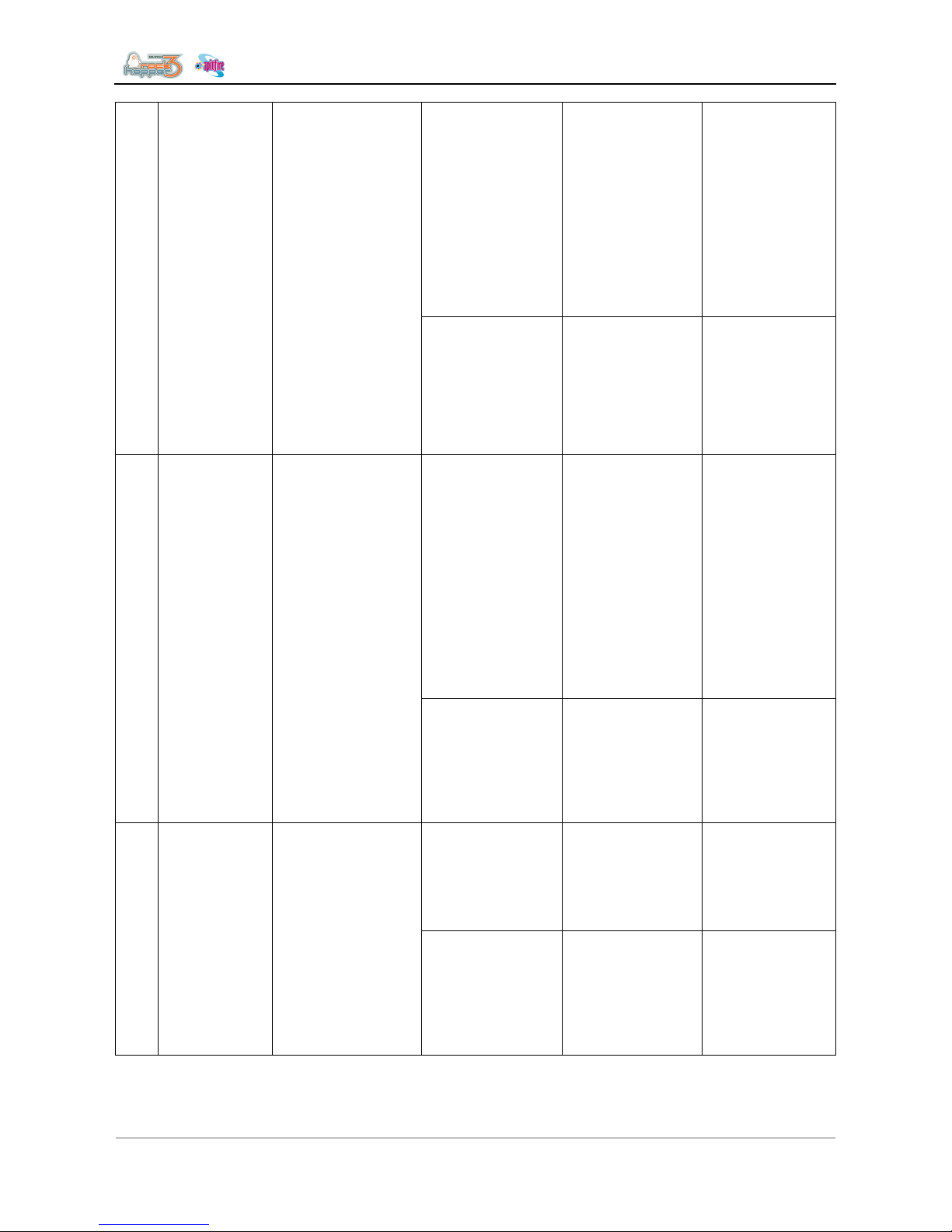

1.1 OPERATING CONDITION DISPLAY

This chapter explains how to proceed, when the following messages are displayed on your LCD-display.

No. Message Phenomenon Check point Action

(1) Verify the L/R cover sensor

via diagnostics:

Diagnostics Æ Test Æ Sensor

Æ Cover SW

• Replace the cover sensor

if the sensor is not

responding

(2) Open and close the cover,

check if all sensors are

“clicking”.

Ensure the sensor is properly

adjusted:

Adjust the sensor-bracket

or sensor-cam when

necessary

The cover-switch is a twoway switch. Or pin 1 and

2 or pin 2 and 3 are

closed.

Malfunction of the switch

might also result in the

following error:

“E068 CR Encoder Error”

Sensor state:

Pin 1 and 2 on the sensor

are closed, Pin 3 is open

(floating)

1 Cover Open The LCD indicates:

- The front cover is

open.

- One of the coverswitches is not

properly activated or

connected

Pin 2 and 3 on the sensor

are closed, Pin 1 is open

(floating)

!Attention!

Be careful when

adjusting the sensorbracket, the sensor-lip is

not fully stressed. This

will decrease life and

possibly damage the

sensor!

Adjust the sensor and

make sure there is a 0,5

to 1mm gap as

illustrated.

Page 7

Troubleshooting

7 AP-74700 – Rev. 1.0 – 10/03/2008

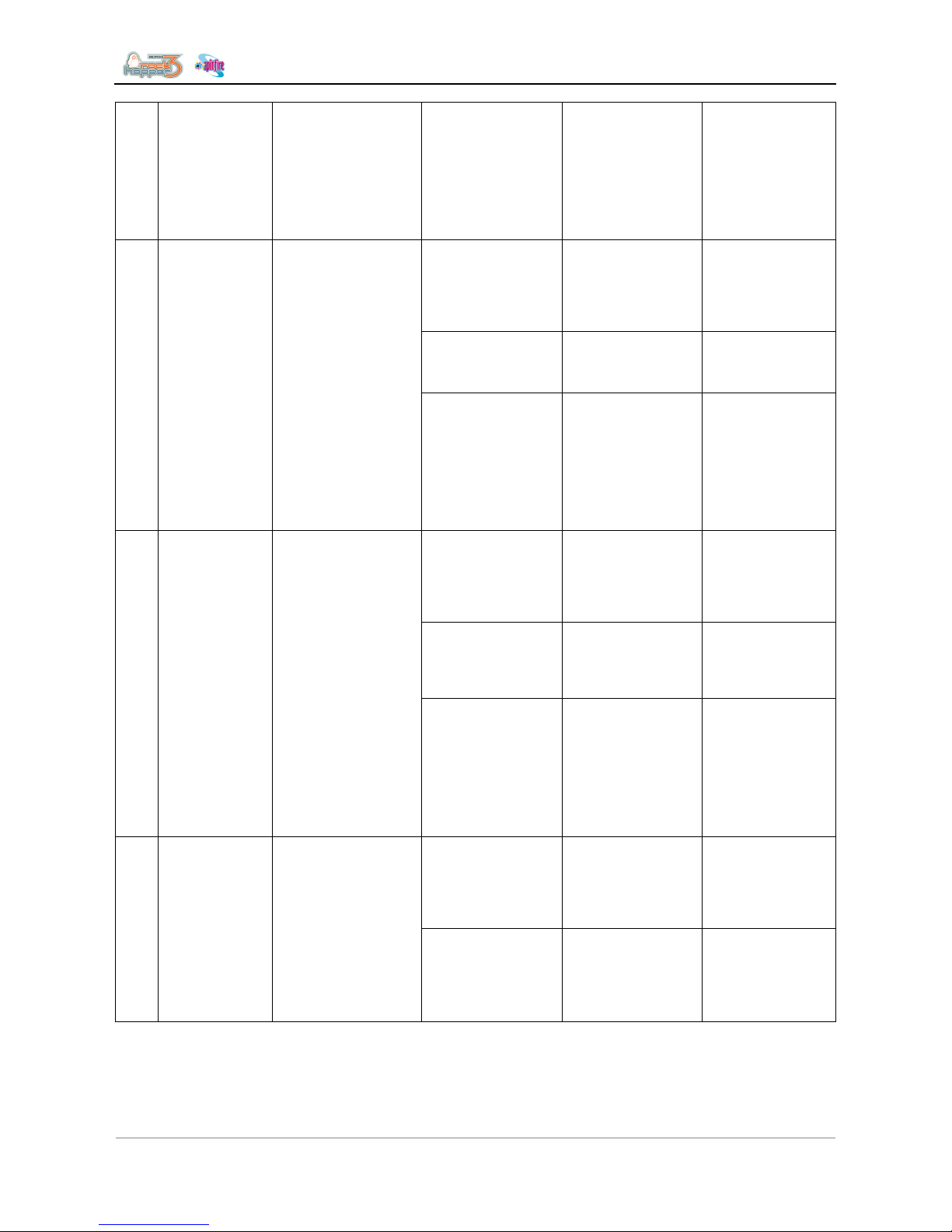

(3) If the cover switches are ok,

and the error persists

(4) The cover switch circuit IC’s

on the mainboard assembly

may have a problem

Verify the cover switch

connectors on the

mainboard, (J155 and

J156)

If no spare cover switches

are available, temporary

bypass on own risk is

possible, short circuiting

pins 1 and 2 for both

switches.

Replace the mainboard

assembly if after

bypassing the cover

switches, the mainboard is

still not recognizing a

closed cover switch.

(1) Try to put the lever down:

- Via the foot pedal

- Via the LCD display

If the lever is not

responding, try to short

circuit the 2 pins of the

lever foot pedal.

(2) Check the 2 sensors of the

lever UP / DOWN via

diagnostics:

Diagnostics Æ Test Æ Sensor

Æ Lever Sensor

If sensors are responding:

- Remove A heater platen.

Check if nothing is broken

in de Up/Down mechanism

- Replace the photo

sensor / sensor bracket if

the sensor is not

responding

(3) Verify if the 2 U-photo

sensors on the lever motor are

properly mounted.

• If the photo sensor is

detached or broken, fix or

replace when necessary.

(4) Check the 2 U-photo

sensors for dust or

contamination

• Clean the photo sensor

blowing compressed air

(5) Check if the sensors are

properly connected

• Check the connections

on the Mainboard assy at

connectors J123 and

J124.

2 Set Paper Indicates the lever—

sensor is in the UP

position.

The lever motor

should be the UP

position when

having this

message.

(7) If after replacement of the

sensors, the sensor still doesn’t

respond in diagnostics, the

Mainboard assembly may have

a problem.

• Replace the Mainboard

assembly.

(1) Check if both the

P_REAR_R and P_REAR_L

sensors are properly working:

Diagnostics Æ Test Æ Sensor

Æ PaperRear R and L.

When you cover the

sensor with paper, the

P_REAR sensor should

switch ON.

If the sensor is not

responding, check the

sensor alignment.

Replace if necessary.

3 Paper End There is no media

inside the printer.

The roll of media

has ended

(2) Check if the sensors are not

obstructed by dust, dirt or

media

Clean when necessary

Blow dirt and dust away

from sensor with

compressed air

Page 8

Troubleshooting

8 AP-74700 – Rev. 1.0 – 10/03/2008

(3) Check if both P_REAR

sensors are properly

connected.

Verify connections on

Mainboard assembly,

connectors J128 and

J129.

(4) The P_REAR sensor

assembly may be broken.

• Replace the P_REAR

sensor assembly.

(5) If after sensor replacement,

the problem still persists, the

Mainboard assembly may have

a problem.

• Replace the Mainboard

assembly.

1.2 MESSAGE TYPE ERRORS

Message type errors are displayed when trouble occurs during operation.

When message type errors occur, this product displays the following error messages on the operation panel

and stops the operation.

When the causes of errors are removed, message type errors are restored and the printing operation will be

restarted.

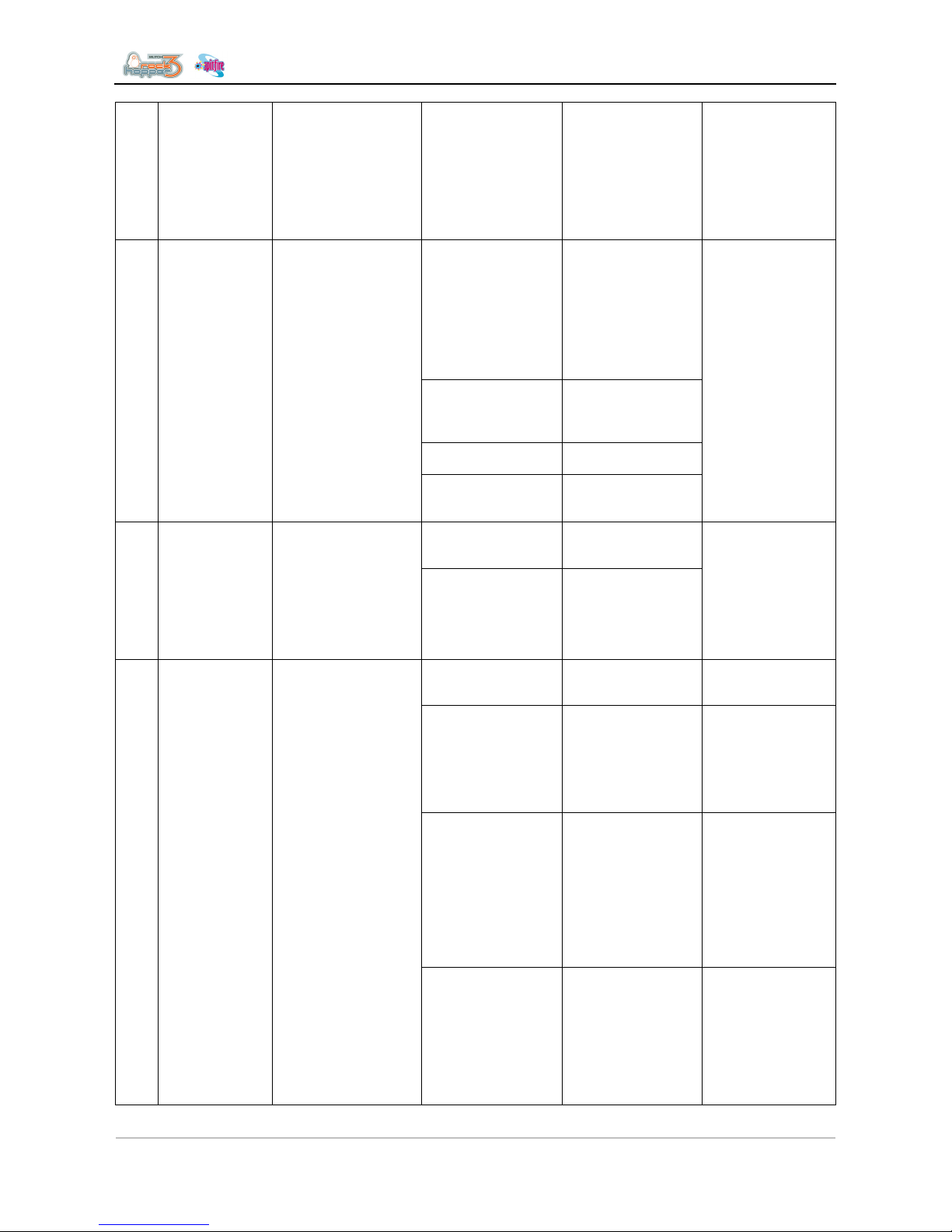

No. Message Phenomenon Check point Action Refer to

(1) Check the

operation of the

P_EDGE sensor via

“Test: Sensor” of the

self-diagnostic

function.

• If the sensor

responds to the

presence of the

paper, adjust the

sensor volume.

• If the sensor does

not respond to the

presence of the

paper, replace the

P_EDGE sensor

assembly

• Media sensor

sensitivity

adjustment

• Replacing the

P_EDGE

sensor

assembly.

(2) Make sure the

P_EDGE sensor

assembly connector

at the cursor is

securely connected.

• Securely connect

it to CR board

assembly

connector J234.

• Replacing the

Mainboard

assembly,

HDD_Extensio

n board

assembly,

HEAD_DRV

board

assembly and

cooling fan

assembly.

Undefined paper The printer failed to

detect the media.

(3) Make sure the

R_REAR sensor

assembly cables

underneath paper

guide R are securely

connected.

• Securely connect

the cables to

Mainboard

assembly

connectors J128

and J129.

• Replacing the

Mainboard

assembly,

HDD_Extensio

n board

assembly,

HEAD_DRV

board

assembly and

cooling fan

assembly.

Page 9

Troubleshooting

9 AP-74700 – Rev. 1.0 – 10/03/2008

(4) Check the

Flatcables for

skewed insertion.

• Redo the

connections of

the following

connectors :

• CR board : J201

– J216

• Mainboard : J137

– J152

• Replacing the

Mainboard

assembly,

HDD_Extensio

n board

assembly,

HEAD_DRV

board

assembly and

cooling fan

assembly.

(5) The Flatcables

from the mainboard

to the head board

may be damaged.

• Replace the

Flatcables.

• Replacing the

steel bearer,

tube guide,

Flatcable and

ink tube.

(6) The CR board

assembly may be

damaged.

• Replace the CR

board assembly.

• Replacing the

CR board

assembly.

(7) The Mainboard

assembly may be

damaged.

• Replace the

Mainboard

assembly.

• Replacing the

Mainboard

assembly,

HDD_Extensio

n board

assembly,

HEAD_DRV

board

assembly and

cooling fan

assembly.

2 Paper Slant The paper is fed

askew.

(1) Reset the paper

and check if the

condition recurs.

• If this is caused

by incorrect paper

setup, explain the

correct paper

setup procedure.

-

(1) Check the cutter

grooves for

accumulated paper

dust and slip.

• Remove the

accumulated

paper dust along

the direction of

the grooves.

• Please refer to

the User’s

Guide.

(2) Has the cutter

cap securely been

installed?

• Reset the cutter

cap securely

• Please refer to

the User’s

Guide.

(3) Check the

cutter’s up and down

sliding operation.

• If it does not rise

Go to step (4)

• If it rises : Go to

step (5)

3 Paper Cut Error Even though cutting

operation was

performed, the paper

was not completely cut

and removed.

(4) Check if the

cutter drops to the

bottom end under its

own weight when the

cutter has been

installed without the

cutter spring.

• If it drops: The

cutter spring may

have a problem.

Replace the

cutter spring while

referring to the

unfolded view.

• If it does not drop:

The cutter may

have a problem.

Replace the

cutter. If the

cutter does not

drop after

replaced, replace

the cutter holder.

→ Replacing the

cutter holder, cutter

spring, cutter cap,

solenoid assembly

and solenoid

spring.

Page 10

Troubleshooting

10 AP-74700 – Rev. 1.0 – 10/03/2008

(5) Check the up and

down operation of

the solenoid via

“Life/Cutter” of the

self-diagnostic

function.

a) The solenoid

moves up and down:

Check the cutter’s

down position

relative to the cutter

groove.

b) It does not move

up and down.

• OK: The cutter’s

service life is

reached or it is

damaged.

Replace the

cutter.

NG: Adjust the

position of the cutter

holder.

• The connectors

may have poor

contacts.

• Check the

connections of

the following

connectors :

CR board : J235

CR board : J201 –

J216

Mainboard : J137 –

J152

→ Please refer to

the User’s Guide

→ Cutter

adjustment

→ Replacing the

CR board

assembly.

→ Replacing the

Mainboard

assembly,

HDD_Extension

board assembly,

HEAD_DRV board

assembly and

cooling fan

assembly.

(6) Open CR cable,

faulty solenoid

assembly, faulty

board assembly,

etc., may be the

cause.

• Replace the

Flatcables.

• Replace the

solenoid

assembly

• Replace the CR

board assembly

• Replace the

Mainboard

assembly.

• Replacing the

steel bearer,

tube guide, CR

tapes power

cable and ink

tube.

• Replacing the

cutter holder,

cutter spring,

cutter cap,

solenoid

assembly and

solenoid spring

• Replacing the

CR board

assembly

• Replacing the

Mainboard

assembly,

HDD_Extensio

n board

assembly,

HEAD_DRV

board

assembly and

cooling fan

assembly.

4 End of Roll Displayed when the

end of the roll paper is

detected during the

use of roll paper. This

is released when the

lever has been set to

(1) Check if the

message is still

displayed after

turning the power off

and then back on

again.

If the message is

displayed : go to

step (2)

Page 11

Troubleshooting

11 AP-74700 – Rev. 1.0 – 10/03/2008

(2) Check the

P_REAR sensor

assembly for the

contact condition.

• Redo the

connections of

Mainboard

assembly

connectors J128

and J129. If the

paper is not

initialized, the

sensor may be

damaged.

• Replace the

P_REAR sensor

assembly.

→ Replacing the

Mainboard

assembly,

HDD_Extension

board assembly,

HEAD_DRV board

assembly and

cooling fan

assembly.

→ Replacing the

P_REAR_R sensor

assembly and

P_REAR_L sensor

assembly.

the up position.

(3) The Mainboard

may be damaged.

• Replace the

Mainboard

assembly.

→ Replacing the

Mainboard

assembly,

HDD_Extension

board assembly,

HEAD_DRV board

assembly and

cooling fan

assembly.

(1) Check the ink

end via “Test:

Sensor” of the selfdiagnostic function.

• Operate the lever

at the end

detecting element

of the ink sensor

assembly to

check if the ink

end indication

changes. (At this

time, the sensor

for detecting the

presence of

cartridges is set

to Yes.) If there is

no response,

replace the ink

sensor assembly.

→ Sensor menu

→ Replacing the I/H

(ink holder)

assembly

5

6

[ ] Near End

[ ] Ink End

The remaining amount

of ink is low. Printing

is still possible.

There is no more ink

left. Printing in

progress is interrupted

immediately.

(2) Check the ink

sensor connector for

the contact

conditions.

• Redo the

connections of

the following

connectors.

• Junction board :

J401 – J418

• Mainboard : J133

– J134

• Replacing the

Junction board

assembly.

(1) Check the ink

end ID via “Test:

Sensor” of the selfdiagnostic function.

(This is limited to

when smart chips

are set.)

• If the type of the

installed cartridge

does not match

the displayed

type, the ink ID

sensor may be

damaged.

• Sensor menu

7 Not Original Ink

(2) Check the ink ID

sensor connector for

the contact

conditions.

• Redo the

connections of

the following

connectors

• Junction board :

J401 – J418

• Mainboard : J133

– J134

→ Replacing the

JUNCTION board

assembly.

Page 12

Troubleshooting

12 AP-74700 – Rev. 1.0 – 10/03/2008

(3) The Mainboard

may be damaged.

• Replace the

Mainboard

assembly.

→ Replacing the

Mainboard

assembly,

HDD_Extension

board assembly,

HEAD_DRV board

assembly and

cooling fan

assembly.

(1) Check if the

message is still

displayed after

turning the power off

and then back on

again.

• When a message

is displayed : Go

to step (2)

-

(2) The amount of

waste ink inside the

tank reached the

specified level.

• Dispose of the

waste ink in the

waste bottle.

-

8 Warning Waste

INK Tank

The waste tank will

soon be full.

(3) If initialization

does take effect

when the waste ink

is disposed of and

waste ink history is

initialized, the

Mainboard may be

damaged.

• Replace the

Mainboard

assembly.

→ Replacing the

Mainboard

assembly,

HDD_Extension

board assembly,

HEAD_DRV board

assembly and

cooling fan

assembly.

(1) Check if the

message is still

displayed after

turning the power off

and then back on

again.

• When a message

is displayed : Go

to step (2)

-

(2) The number of

times the ink tube

was used reached

the maximum

allowable times.

• Replace the ink

tube.

• Initializing CR

motor history.

→ Replacing the

steel bearer, tube

guide, Flatcable

and ink tube.

9 Warning Waste

INK Tank

The service life of the

ink tube will soon be

reached.

(3) If initialization

does take effect

when the CR motor

history is initialized

after the ink tube is

replaced, the

Mainboard may be

damaged.

• Replace the

Mainboard

assembly.

→ Replacing the

Mainboard

assembly,

HDD_Extension

board assembly,

HEAD_DRV board

assembly and

cooling fan

assembly.

(1) Check if the

message is still

displayed after

turning the power off

and then back on

again.

• When a message

is displayed :

refer to step (2)

10 (Warning Head

Life)

The service life of the

print head will soon be

reached.

(2) The number of

times the print head

was used reached

the maximum

allowable times.

• Replace the print

head assembly.

• Initialize the head

unit.

→ Replacing the

print head

assembly and head

tape power cable.

→ Counter

initialization menu.

Page 13

Troubleshooting

13 AP-74700 – Rev. 1.0 – 10/03/2008

(3) If initialization

does not take effect

when the head unit is

initialized, the

Mainboard assembly

may be damaged.

• Replace the

Mainboard

assembly.

→ Replacing the

Mainboard

assembly,

HDD_Extension

board assembly,

HEAD_DRV board

assembly and

cooling fan

assembly

(1) Check the

connections of

connectors.

• Redo the

connections of

the following

connectors.

• Mainboard : J102

• power source

board (small)

assembly : CN51

– CN52

(2) The

HDD_MOTHER

board assembly may

be damaged.

• Replace the ink

tube.

• Initializing CR

motor history.

(3) Hard disk may be

damaged.

• Replace the hard

disks.

11 Hard disk status

connect error

There is a problem in

the hard disk

connections.

(4) The Mainboard

assembly may be

damaged.

• Replace the

Mainboard

assembly.

→ Replacing the

Mainboard

assembly,

HDD_Extension

board assembly,

HEAD_DRV board

assembly and

cooling fan

assembly.

→ Replacing the

power source board

assembly.

(1) The PCI_LINUX

board assembly may

be damaged.

• Replace the

PCI_LINUX board

assembly.

12 Network

initialize error

There is a problem in

the network board.

(2) The Mainboard

assembly may be

damaged.

• Replace the

Mainboard

assembly.

→ Replacing the

Mainboard

assembly,

HDD_Extension

board assembly,

HEAD_DRV board

assembly and

cooling fan

assembly.

(1) Check if the

waste bottle has

been installed.

• Install the waste

bottle correctly.

-

(2) Check the

operation of the

waste box sensor

assembly via

“Sensor/Waste Bin”

of the self-diagnostic

function.

• Replace the

waste box sensor

assembly.

-

(3) Check the

connections of the

connectors.

• Check if the

waste box sensor

connectors are

connected to the

rear side cap R.

• Redo the

connections of

the following

connectors.

• Mainboard : J120

→ Replacing the

Mainboard

assembly,

HDD_Extension

board assembly,

HEAD_DRV board

assembly and

cooling fan

assembly.

13 Waste ink tank

sts. No

The waste tank is not

installed.

(4) The Mainboard

assembly may be

damaged.

• Replace the

Mainboard

assembly.

→ Replacing the

Mainboard

assembly,

HDD_Extension

board assembly,

HEAD_DRV board

assembly and

cooling fan

assembly.

Page 14

Troubleshooting

14 AP-74700 – Rev. 1.0 – 10/03/2008

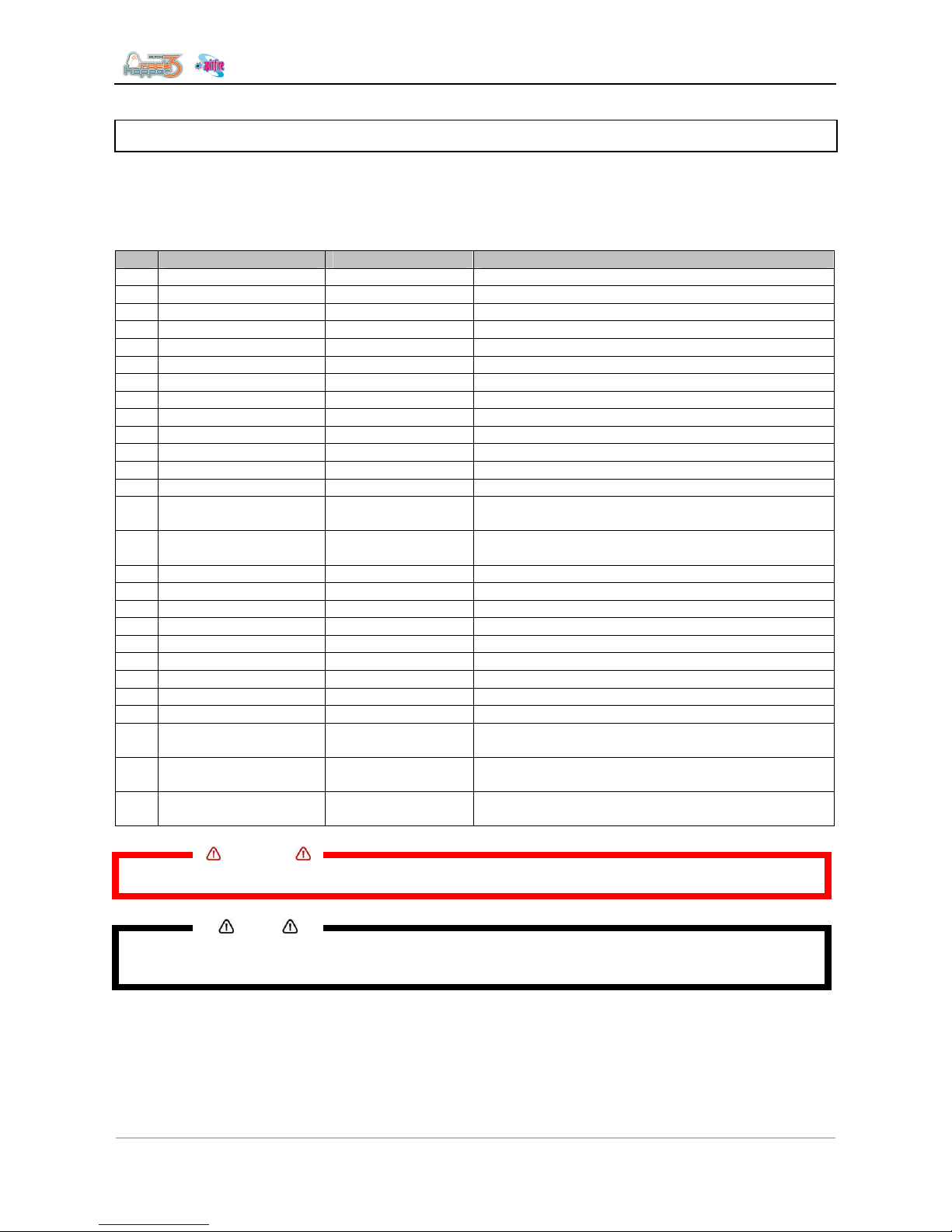

1.3 HEATING SYSTEM ERROR

Heating system errors are displayed when communication trouble occurs between the heater strips and this

product.

If heating system error occurs, the following error messages are displayed and the printer stops.

Solve the problem to delete the error message and restart the printer.

No Message Check point Action

1 AC not present AC connector. Check AC connector

2 Error sensors A Sensors A Check if the sensors are connected properly.

3 Error sensor A Sensor A Check if the sensors are connected properly.

4 Conn. err. Left A Sensor A Check if the left sensor is connected properly.

5 Conn. err. Right A Sensor A Check if the right sensor is connected properly.

6 Error sensors D1 Sensors D1 Check if the sensors are connected properly.

7 Error sensor D1 Sensor D1 Check if the sensors are connected properly.

8 Conn. err. Left D1 Sensor D1 Check if the left sensor is connected properly.

9 Conn. err. Right D1 Sensor D1 Check if the right sensor is connected properly.

10 Error sensors D2 Sensors D2 Check if the sensors are connected properly.

11 Error sensor D2 Sensor D2 Check if the sensors are connected properly.

12 Conn. err. Left D2 Sensor D2 Check if the left sensor is connected properly.

13 Conn. err. Right D2 Sensor D2 Check if the right sensor is connected properly.

14 Couldn't reach temp Heater strip After 10 minutes, temperature is not reached. Check

the heater strips.

15 Err: Temp > 85°C! Heater strip Temperature comes higher then the limit. Check the

heater strips.

16 Connection err. A Rear Heater (A) Check the connector of the rear heater.

17 Connection err. D1 Dryer (D1) Check the connector of the front heater (D1).

18 Connection err. D2 Dryer (D2) Check the connector of the front heater (D2).

19 Error sensor B1 Fixer (B1) Check the sensor of the fixer 1 (B1).

20 Error sensor C Post fixer (C) Check the sensor of the fixer (C).

21 Connection err. B1 Fixer (B1) Check the connector of the fixer 1 (B1).

22 Connection err. C Post fixer (C) Check the connector of the post fixer (c).

23 Error sensor B2 Fixer (B2) Check the sensor of the fixer 2 (B2)

24 Connection err. B2 Fixer (B2) Check the connector of the fixer 2 (B2).

25 Error D group Heaters D Temperature difference higher than 15°C between

the sensors of the D heaters.

26 Error A group Heaters A Temperature difference higher then 15°C between

the sensors of the A heaters.

27 Error B group Heaters B Temperature difference higher then 15°C between

the sensors of the B heaters.

Important

• Before checking the connectors, please power off the unit and remove the power cable.

Notes

• Check if the connectors are properly connected to the power board.

• Check if the sensors are connected onto the right connector.

Page 15

Troubleshooting

15 AP-74700 – Rev. 1.0 – 10/03/2008

1.4 DATA ERROR

Data errors are displayed when data communication trouble occurs between the computer and this product.

If data error display occurs, the following error messages are displayed and the printer stops.

Solve the problem to delete the error message and restart the printer.

No. Message Phenomenon Check point Action Refer to

1 I 15-1 error

command [ ]

Online frame error

2 I 15-2 error

command [ ]

Overrun error

3 I 15-3 error

command [ ]

Online parity error

4 I 15-4 error

command [ ]

Sum check error

5 I 15-5 error

command [ ]

ESC parameter

6 I 15-6 error

command [ ]

Undefined ESC

7 I 15-7 error

command [ ]

Incorrect letters

ESC

8 I 15-8 error

command [ ]

Numeral character

ESC

9 I 15-9 error

command [ ]

Parameter error

ESC

10 I 15-10 error

command [ ]

Buffer overflow

Check the printing

data for contents

that may be judges

as an error.

Mainboard

assembly may be

defective?

• Try a different

drive for the

application.

• Replace

Mainboard

assembly

• Replacing the

Mainboard

assembly

• HDD_Extensi

on board

assembly

• HEAD_DRV

board

assembly

• cooling fan

assembly

Notes

• The command codes for errors may be indicated between brackets [ ].

Page 16

Troubleshooting

16 AP-74700 – Rev. 1.0 – 10/03/2008

1.5 COMMAND ERRORS

Command errors are displayed when trouble occurs during analysis of the command data that is sent to this

product from the computer.

If a command error occurs, the following error messages are displayed and the printer stops.

Solve the problem to delete the error message and restart the printer.

No. Message Phenomenon Check point Action Refer to

1 MH01 error

command [ ]

Undefined ESC: A

command that has

not been defined in

command modes

was analyzed.

2 MH02 error

command [ ]

Parameter error:

Number of

parameters

following command

is incorrect.

3 MHO3 error

command [ ]

Numeric error:

Number of

parameters

following command

is incorrect.

4 MH04 error

command [ ]

Undefined letter set:

Letter sets that

should not exist (do

exist).

5 MH05 error

command [ ]

Buffer overflow:

Polygon buffer or

downloadable

character buffer

overflows.

Check the printing

data for contents

that may be judged

as an error.

The Mainboard

assembly may

have a problem.

• Try a different

drive for the

application

• Replace

Mainboard

assembly

• Replacing the

Mainboard

assembly

• HDD_Extensi

on board

assembly

• HEAD_DRV

board

assembly

• cooling fan

assembly

Notes

• The command codes for errors may be indicated between brackets [ ].

• For the settings on a computer, refer to the computer's operation manual.

Page 17

Troubleshooting

17 AP-74700 – Rev. 1.0 – 10/03/2008

2 TROUBLESHOOTING WITH ERROR

CODES

2.1 DRAM ERRORS

E001 - DRAM Error

E002 - Opt. DRAM Error

The RAM memory module is not or badly recognised on the mainboard.

• Be sure RAM memory contacts are clean

• Make sure you us an Original Mutoh Memory Module ONLY.

• 3

rd

party memory-modules will not work properly. Never use these!

Page 18

Troubleshooting

18 AP-74700 – Rev. 1.0 – 10/03/2008

2.2 CPU ERRORS

These errors can appear when internally the machine detected an illegal software command in the central

microprocessor-circuitry inside the mainboard.

This can happen due to:

• Illegal header-commands might be sent from the rip-computer Æ Make sure the rip is always updated to

the latest version!

Also make sure the latest printer-driver from the Mutoh-website!

If the problem is still occurring:

o Try another rip computer or use a pre-ripped (demo-) file provided by Mutoh.

o Try to rip to a different (analog) Mutoh-printer, whenever available.

o Try to rip an internal job, e.g. print a palette or distance adjust test

• A power drop or spike on the power supply Æ Reboot machine

Check if the problem reoccurs. Also always check for a good, stable power connection + properly

grounded.

• Generally when a permanent-occurring CPU-error appears on your LCD display, every time after

restarting the machine several times, there are possible clues:

• Install always the latest and correct firmware-version!

SX for new-generation RoHS-compliant mainboards

SP for the previous non-RoHS-compliant mainboards

o The onboard offline-memory may be corrupt. Reset the NVRAM and re-insert all the parameters

manually (not with a backup-flashcard or via Ethernet) via the LCD Display. Manual input avoids

copying corrupted data back.

o With the installed firmware – Always install the correct and the latest firmware version!

o Try with a different Mutoh memory-module.

o If this error still reoccurs after these actions, replacing the mainboard and re-inserting the parameters

manually is the last solution. Same reason again, why inserting parameters manually, is to avoid

copying possible NVRAM data to the new mainboard.

• For printers equipped with an older non-RoHs mainboard can, you can also try the following procedure:

o Load the Falcon II v1.26 firmware

o Load directly afterwards, back the latest firmware applicable for your machine

o Re-insert the parameters via the LCD display (to avoid copying corrupt parameters)

o Test if the machine is working properly and try to print

o If the problem still persists after this, the mainboard might need to be replaced

• For printer equipped with a RoHs-mainboard (Revision A or later), this described test is not applicable as

no Falcon II machines exist with these boards. So just make sure you use the latest firmware-version!

Some more specific CPU errors:

2.2.1 E 016 error CPU Err(03)

Data boundary exception errors. Trouble occurred in the data boundary in its internal memory.

• Make sure you us an Original Mutoh Memory Module ONLY.

• 3

rd

party memory-modules will not work reliably!

Page 19

Troubleshooting

19 AP-74700 – Rev. 1.0 – 10/03/2008

2.3 PF - PAPER FEED ERRORS

¾ E065 - PF Motor Err

¾ E067 - PF Encoder Err

¾ E069 - PF Timeout Err

¾ E071 - PF OverCurrent

¾ E083 - PF2 OverCurrent

The Paper-Feed motor is failing or the electronics doesn’t receive an encoder-signal from the PF sensor

correctly.

The electronics wants to move the Paper Feed system (PF). The driver IC on the mainboard provides power

to the X-motor (1). Therefore the X-motor starts to turn, resulting in a PF movement (2). PF movement is

detected via the encoder-sensor (3), and gives feedback, back to the electronics.

This closed-loop system is fully controlled in the electronic circuit of the mainboard. It regulates the direction,

electrical current and the speed of the carriage extremely precisely.

Mainboard

PF-X-motor

X-Encoder

Forward movement

Grid Roller

Backward movement

Grid Roller

PF Encoder Disk

2

1

3

Step 1 : Power supply to motor from electronics

Step 2 : Mechanical movement X encoder

Step 3 : X encoder gives feedback to mainboard

Page 20

Troubleshooting

20 AP-74700 – Rev. 1.0 – 10/03/2008

If anything goes wrong in this process, the following parts inside this loop needs to be verified:

1)

Verify the encoder signal of the Paper Feed system

Diagnostic Æ test Æ encoder Æ PF

If the Hex counter changes near PF, when turning the grid-roll shaft, the encoder is ok.

If not ok:

• Be assured that the PF encoder sensor is properly adjusted and positioned

• Check if the encoder disk is clean and not scratched. Clean with Isopropyl alcohol and a fibre-free

tissue only!

Verify the X-motor functionality via the aging procedure

Diagnostics Æ Life Æ PF Motor

If the motor is not responding:

• Go to step 3, verify the driver + cable connections

• If still not OK, replace the X-motor

2) Check the X motor driver-IC.

The driver chip is located on the mainboard on U94 for old board revisions. New board

revisions (RoHS) the driver chip is the U109. The following pins should be measured:

• Between pin 1 and 10

•

Between pin 2 and 11

The measurement value should be approx. 2 to 3 Meg Ohms. If this is not the case, the driver is broken,

replace the mainboard

Page 21

Troubleshooting

21 AP-74700 – Rev. 1.0 – 10/03/2008

2.4 CARRIAGE RELATED ERRORS

2.4.1 E066 - CR Motor Err

2.4.2 E068 - CR Encoder Err

2.4.3 E072

- CR OverCurrent

The mainboard is not receiving an encoder-signal, from the CR encoder sensor. Even though, the

mainboard sends a signal to the CR-motor to move the carriage.

Basic principles of the CR-Driving and Encoder-system:

Mainboard

Y-motor

Y-Encoder

CW-Movement

= Carriage moves left

CCW-Movement

= Carriage moves right

1

2

3

Step 1 : Power supply to motor

Step 2 : Mechanical movement moves Y encoder

Step 3 : Y encoder gives feedback to the mainboard

The electronics wants to move the carriage. The driver IC on the mainboard provides power to the Y-motor

(1). Therefore the Y-motor starts to turn, resulting in carriage-movement (2). Carriage movement is

detected via the encoder-sensor (3), back to the electronics.

This closed-loop system is fully controlled in the electronic circuit of the mainboard. It regulates the direction,

electrical current and the speed of the carriage extremely precisely.

Page 22

Troubleshooting

22 AP-74700 – Rev. 1.0 – 10/03/2008

If anything goes wrong in this process, the following parts inside this loop needs to be verified:

1) Check the encoder sensor

Go to diagnostics Æ test Æ encoder

If the Hex counter changes near CR_ENC, when moving the carriage, the encoder signal is OK. To be able

to move the carriage freely, the front cover (incl. cover sensors) must be opened.

2) Check the cover switches + connectors

The cover switches make contact with a relay. This relay physically connects/disconnect the Y-motor from

the Y-motor power circuitry. Pin 1 and 2 will measure 0 ohms.

If one of both cover switches are open, the relay will disconnect. Instead the cover switch must close

contacts 2 and 3. In this way the /COVER-detection lines integrated inside the electronics, will recognise

that the cover is open and inform the operator.

• Check if the connector J156 is bridged

between pin 1 and 2 on the mainboard

(applicable for SPFR100 only)

• Make sure J155 is properly connected to

the cover switch

Important

• 28 Volts is directly connected to the cover switches! Therefore the switches are properly

insulated. Be aware removing the covers, the chassis is not touching the insulation and

breaking so it hits the contacts. This will result in a broken main board!

• Shutting-down the printer while removing the covers is strongly recommended!

The sensor can also be checked via the “test sensor” inside diagnostics.

3) Check the relay RY1 on the mainboard

On the picture, you can see that the relay can switch the Y motor on/off. If the cover is being closed (= both

switches closes too), you should hear the relay clicking.

If the relay RY1 is NOT clicking after closing, verify if the cover switch is really closed. Measure pin 1 and 2

of the connector of J155 and J156. Both pins should be 0 ohms!

If the switches are OK, the relay or the driver of the relay on the mainboard might be is broken. In that case

replace the mainboard

Page 23

Troubleshooting

23 AP-74700 – Rev. 1.0 – 10/03/2008

4) Check the Y motor driver-IC.

The driver chip is located on the mainboard on U97 for old board revisions. New board revisions (RoHS) the

driver chip is the U112. The following pins should be measured:

• Between pin 1 and 10

• Between pin 2 and 11

The measurement value should be approx. 2 to 4 Meg Ohms.

If this is not the case, the driver is broken, replace the mainboard

5) Verify the Y-motor, make sure the carriage is running smoothly and the motor makes no noise.

Make endurance tests via: Diagnostics Æ Life Æ PF Motor

If the motor is not responding:

• Go to step 4, verify the driver + cable connections (white cable is +, black cable is -)

• If still not OK, replace the X-motor

6) Check the steel belt pressure. A wrong steel belt pressure will result in frictioning. Therefore the

“controlled loop feedback”-system will fail.

Blizzard 65” = 1 Newton (100 gr) – Blizzard 90” = 0,9 Newton (90 gr)

If you are sure all previous parts are ok, check the steel belt pressure; check the ‘smoothness’ of the

carriage. Verify the Y-motor and if necessary, replace it.

Verify if the Y-motor belt. Same reason as for the steel belt.

• Verify if the belt is in good shape and properly greased

• Verify the belt’s pressure Æ 35 Newton (3,5 kg)

Verify the carriage movement. The carriage should run smoothly over the whole length.

• The carriage should also run smoothly without steel belt. If not check the carriage-bearings.

• Both steel-belt pulleys should run smoothly

2.4.4 E070 - CR Timeout Error

This error occurs when the carriage didn’t move to the expected, correct position within a certain amount of

time.

1) Verify the Carriage movement with aging tests

Diagnostics Æ Life Æ CR motor

2) Verify the linear encoder strip. Clean the encoder strip with Isopropyl Alcohol if necessary.

Check if the encoder strip isn’t scratched.

3) Verify the encoder sensor

Diagnostics Æ Sensor Æ encoder Æ CR

Move the carriage and check if the HEX-counter on the LCD-display is going up and down over the

complete length of the Y-rail.

Page 24

Troubleshooting

24 AP-74700 – Rev. 1.0 – 10/03/2008

2.4.5 E073 - CR Origin Error

The origin sensor of the printer Carriage cannot be detected.

Step 1 : Verify the U-pot sensor on top of the Y-rail Check if the U-photo sensor is properly aligned and

the carriage-flag activates it. The U-sensor can be tested by putting some non-transparent

material inside to activate.

Diagnostics Æ Test Æ Sensor Æ CR Home position

Step 2 : Verify cable connections on sensor and mainboard

Step 3 : If sensor is not responding, replace sensor + verify, eventually replace cabling

Step 4 : If still no response after sensor replacement, the mainboard might be defect (replace mainboard)

2.4.6 E074 - Cover Sensor Error

Step 1 : Verify all cover sensors as described in error E068.

Step 2 : Verify cover sensors in Diagnostics Æ Test Æ Sensor Æ Cover switches

Step 3 : Verify if the front cover is closing all the switches properly

Step 4 : Verify sensor cable connections, try to bypass sensors by short-circuiting pins 1 and 2

Step 5 : If still not ok, replace mainboard + cover switches

2.4.7 E076 - PG Origin Err

Step 1 : Verify if the optical sensor is working by putting something a piece of material before it. The

sensor can be tested via:

Diagnostic Æ sensor Æ HD_SLIDE sensor

Step 2 : The optical headheight home-sensor (HD_SLIDE) can not be detected.

Apply some non-reflective and non-transparent black tape on the right carriage headheight

adjustment-bracket. This will improve the performance of the optical sensor (which only detects

black/white transitions) to detect the hole in the adjustment-wheel of the headheight assembly.

Step 3 : Verify the headheight homing sensor and the Up-Down motor via:

Diagnostics Æ Life Æ Head U/D

Step 4 : If the motor is not running, replace the motor

Step 5 : If still not ok, verify cable connections.

Step 6 : If all previous steps did not help you any further and a replacement sensor also doesn’t give any

response, only then replace the mainboard.

Page 25

Troubleshooting

25 AP-74700 – Rev. 1.0 – 10/03/2008

2.4.8 E078 - Head Cable Error

The flatcable of head number 1 is not properly connected. This is applicable on as well 4 as 8 heads

machines.

Head 1 MUST always be connected, as the head contains a temperature probe. The machine will always try

to retrieve the temperature during start-up. If you get this error, it indicates, a flatcable is not connected

properly. Verify all flatcable connections. Please refer to flatcable treatment.

In future firmware releases, this error can as well be a fatal error or a non-fatal error (warning message).

Please check the flatcable-treatment chapter for more information how to solve the problem.

Page 26

Troubleshooting

26 AP-74700 – Rev. 1.0 – 10/03/2008

2.5 LEVER & PRESSURE ROLLER ERRORS

2.5.1 E079 - Lever OverCurrent

Step 1 : The lever motor is drawing too much power. Replace the lever motor.

Step 2 : Verify for any short circuits in the motor wiring between the motor and the mainboard.

Step 3 : Check the Y motor driver-IC.

The driver chip is located on the mainboard on Uxx for old board revisions. New board revisions

(RoHS) the driver chip is the Uxxx.

The following pins should be measured:

• Between pin 1 and 10

• Between pin 2 and 11

The measurement value should be approx. 2 to 3 Meg Ohms.

If this is not the case, the driver is broken, replace the mainboard

2.5.2 E080 - Lever Sensor Err

The lever up / down sensor of the lever motor did not respond within a certain time or the Up-Down sensor is

failing.

Step 1 : Verify the Up / Down sensors

Diagnostics Æ Test Æ Sensor Æ Lever Up / Down

• Verify if both sensors are clean

• Verify the cable connections on the sensors and the mainboard

Step 2 : Verify if the gear-wheel / sensor flag of the pinch rollers is properly activating both sensors

Step 3 : Verify if the lever-motor is working and properly geared. Therefore you need to remove the A-

heater platen to be able to verify this.

Step 4 : Check the Y motor driver-IC.

The driver chip is located on the mainboard on U109 for old board revisions. New board revisions

(RoHS) the driver chip is the U123.

The following pins should be measured:

• Between pin 1 and 10

• Between pin 2 and 11

The measurement value should be approx. 2 to 3 Meg Ohms.

If this is not the case, the driver is broken, replace the mainboard

Page 27

Troubleshooting

27 AP-74700 – Rev. 1.0 – 10/03/2008

2.6 CAPPING STATION ERRORS

2.6.1 E081 - Cap Sensor Err

The cap sensor detects if the capping station-assy is in the downward position. It’s a photo sensor that is

fixed inside the capping-station.

2.6.2 Sensor diagnostics

Step 1 : Verify if the sensor is working properly. Insert a non-transparent piece of material inside the

optical U-sensor to activate the sensor. The default value is OFF and should switch ON.

Menu location:

Start up in diagnostics – Test – Sensor – Cap

Step 2 : Push the capping station down and turn the stepper motor to keep it down. Check if the Cap-

sensor goes into the U-sensor properly + verify in sensor diagnostics (see previous step)

Step 3 : Verify if the sensor is properly mounted on the capping-station assembly.

Step 4 : Verify if the optical U-sensor is clean and not covered with ink or contamination

Step 5 : Check the U-sensor cable connection on the sensor and the mainboard

2.6.3 Capping - Motor diagnostics

Step 1 : Verify if the Capping stepper motor is working properly in diagnostics

Motor functionality can be verified multiple times with the Ageing menu.

Menu location:

Start up in diagnostics – Test – Life – Head Lock – Select Wiper U/D off

Step 2 : If the stepper motor is not working properly or loosing torque, verify if the gears and plastic parts

are properly lubricated/greased.

Step 3 : If the stepper motor is not responding at all:

• Verify the stepper motor, replace if necessary

• Replace the mainboard

2.6.4 E082 - Wiper Sensor Err

The wiper sensor, located below the wiper assembly was not activated when the heads were being wiped.

Page 28

Troubleshooting

28 AP-74700 – Rev. 1.0 – 10/03/2008

2.6.5 Sensor diagnostics

Step 1 : Verify if the sensor is working properly. Unlock the carriage from the capping station, using the

Head Unlock in Diagnostics. Move the head on the side. Remove the wiper plate assembly.

Insert a non-transparent piece of material inside the optical U-sensor to activate the sensor. The

default value is OFF and should switch ON.

Menu location:

Start up in diagnostics – Test – Sensor – Wiper

Step 2 : Mount the wiper plate assembly back on the capping station. Move the wiper assy to the outer

position to activate the U-sensor. Check if the Cap-sensor goes into the U-sensor properly and if

the value on the display switches ON and OFF.

Step 3 : Verify if the sensor is properly mounted on the capping-station assembly.

Verify if the sensor-flag properly activates the sensor, check if the flag goes deep enough inside

the sensor.

Step 4 : Verify if the optical U-sensor is clean and not covered with ink or contamination

Step 5 : Check the U-sensor cable connection on the sensor and the mainboard.

2.6.6 Wiper - Motor diagnostics

Step 1 : Verify if the Capping stepper motor is working properly in diagnostics

Motor-functionality can be verified multiple times with the Ageing menu.

Menu location:

Start up in diagnostics – Test – Life – Head Lock – Select Wiper U/D on

Step 2 : If the stepper motor is not working properly or loosing torque, verify if the gears and plastic parts

are properly lubricated/greased.

Step 3 : If the stepper motor is not responding at all:

• Verify the stepper motor, replace if necessary

• Replace the mainboard

Page 29

Troubleshooting

29 AP-74700 – Rev. 1.0 – 10/03/2008

2.6.7 E097 - NVRAM Error

Diagnostics Æ Test Æ NVRAM

Free space: bytes free

Max block: largest block free (bytes)

If an error occurs, problems occur or the free space for parameters is very low (<100) try the following:

Diagnostics – MOD Level – Reset to 0, reboot the machine and wait until completed.

Then repeat the diagnostics. If still not ok, clear NVRAM, reboot.

If the test is still failing Æ Replace mainboard

E100 - 28V P. Supply Err

E101 - 42V P. Supply Err

The machine is not detecting 28 or 48 Volts from the power supply.

Possible reasons:

• Bad contact power connectors

• Short circuit somewhere inside the machine

1) Try to disconnect all possible boards (network card, slave boards, print heads, etc.) to exclude

any shortcircuits. It works; reconnect every board step-by-step to find the possible cause.

Pin out to measure the main power supply connected to J101 on the mainboard:

Pin out of the supplemental 12V power supply connected to J102 on the mainboard:

Pin 1 & 2 = 12V

Pin 5 & 6 = GND

Pin 4 = Power On

Pin 5 = 5V

Remark: The machine contains a switching power supply and must always be measured when it is under

load. (This means: connected on the mainboard)

Page 30

Troubleshooting

30 AP-74700 – Rev. 1.0 – 10/03/2008

2.7 HEAD AND FLATCABLE RELATED ERRORS

E102 - Fuse 1 Error

E103 - Fuse 2 Error

E104 - Fuse 3 Error

E105 - Fuse 4 Error

E106 - Fuse 5 Error

E107 - Fuse 6 Error

E108 - Fuse 7 Error

E109 - Fuse 8 Error

E077 - Head OverHeat (Somewhere between head 1 and 8)

Æ Applicable on old mainboards (< Rev. W) only

E110 - Head Overheat 1

E111 - Head Overheat 2

E112 -Head Overheat 3

E113 - Head Overheat 4

E114 -Head Overheat 5

E115 - Head Overheat 6

E116 - Head Overheat 7

E117 - Head Overheat 8

The fuses protect the electronic driver components on the mainboard. Every ink-channel has a separate

fuse, so every printhead have 2 fuses, located on the main board below the Head Driver Board.

Old revision mainboards need some soldering, to remove the old fuse and to put a new one.

New revision boards (RoHS) do not need soldering. The fuse can easily be replaced as it is socketed.

Important

• ONLY USE THE FUSE DEFINED IN THE SPAREPARTS FROM MUTOH. DO NOT USE ANY OTHER FUSE AS WE

CANNOT GUARANTEE THE CORRECT TYPE USED

.

• P

LEASE REFER TO TIB 188 FOR MORE INFORMATION

Page 31

Troubleshooting

31 AP-74700 – Rev. 1.0 – 10/03/2008

2.8 ETHERNET CARD ERRORS

E128 – ONLINE Error

E129 – EthROM error

E130 – EthRAM error

E131 – EthBank RAM error

E132 – EthNIC chip error

E133 – EthLback error

The Ethernet card is failing Æ Replace Ethernet card

2.9 MAINBOARD RELATED ERRORS

2.9.1 E211 – Incompatible hardware

Recent firmwares are always compatible with all mainboard-revisions.

• Always use the correct firmware version for the correct hardware:

o Non-Rohs mainboards have the extension SP (e.g. 3.00sp)

o Rohs-compliant mainboards have the extension SX (e.g. 3.00sx)

• Always use the latest firmware-version. Older firmware-versions might possibly not compatible

with newer hardware.

2.9.2 E256 – Mode not found

Problems related to the SIMM card or wallet system.

• Check the specific error-number via diagnostics mode > Chipmgr

• Proceed to the SIMM-Card diagnostics chapter

2.9.3 E257 – Mode not available

Invalid machine settings

Contact the Mutoh service department

2.9.4 E258 – Mode Init problem

Contact the Mutoh service department.

Page 32

Troubleshooting

32 AP-74700 – Rev. 1.0 – 10/03/2008

2.9.5 A259 – Hardware not found

This is a smart-chip, wallet or CLIB-related problem, including flatcable connection to the mainboard. As this

can be a very complicated problem, the analysis needs to be followed step-by-step.

2 possibilities:

• One smart-chip inside the cartridge-reader, is interfering the cartridge-smartchips or the internal wallet-

SIMM card. All the smart-chips are connected to 1 serial bus. This communication-bus can be

disturbed, preventing some of all smart chips and the wallet, to be ‘read’.

• The simm card or simm card reader is not available or defect. Verify if:

o The Card-reader is properly connected

o The SIMM-card is inserted in it’s socket properly

o The CLIB board is not properly properly functioning or badly connected

Verify flatcable connections thoroughly!

Step 1 : Verify if the SIMM card and the SIMM card reader is functional:

• Remove all the cartridges that has a smart-chip.

• Reboot the machine, go to diagnostics mode > Chipmgr

• Verify the chip-status. If the SIMM-chip is ok, go to step 2.

• If the SIMM card is NOT ok:

o And taking into account, all the cartridges have been removed, following parts

can be faulty:

¾ The SIMM chip is broken, proceed to the service-chip procedure. Check

the specific error-number via diagnostics mode > Chipmgr

¾ The CLIB board is improperly connected to the Mainboard. Try to swap

the 2 flatcables on both sides, to see if the problem ‘shifts’ to other

cartridges or becomes OK.

Step 2 : Go to user-mode, menu “Ink Status”, verify ink status of all cartridge-smartchips separately

• Insert every cartridge one-by-one

• Verify with each inserted cartridge, if the smartchip is properly recognised. Cartridges with non-

readable smartchips should be reinserted several times to be sure it’s not bad contact. Check the

smart-chip issues documentation.

If the smartchip remains unreadable, try another analog cartridge or swap cartridges located on

another location inside the cartridge-station. Check if the smartchip can be ‘read’ on this other

location. If still not ok, the chip might be defect.

• Verify the 2 flatcables if they are properly connected, swap the 2 flatcables to verify if the problem

‘shifts’ to another location.

Step 3 : If cartridge smartchips and wallet can ALL properly be read and the same problem still re-occurs

after rebooting:

• Remove all the cartridges again

• Insert all cartridges one by one, for each inserted cartridge, reboot again. Where the problem

possibly reoccurs, remove the cartridge. Retry with another cartridge. If still not ok:

o The CLIB board might be improperly connected to the Mainboard via the 2

flatcables.

o Try to swap the 2 flatcables on both sides, to see if the problem ‘shifts’ to other

cartridges or another problem appears.

Page 33

Troubleshooting

33 AP-74700 – Rev. 1.0 – 10/03/2008

2.9.6 E260 – Incompatible Firmware

Check and make sure that the correct firmware is installed on the correct machine, eg. Spitfire firmware on

Spitfire machine. Blizzard firmware on the blizzard, etc.

2.9.7 E261 – Firmware Init Problem

Contact the Mutoh service department.

2.10 WALLET-SIMM-CARD ERRORS

Wallet-SIMM errors can be analysed inside the diagnostics-menu:

ChipMgr -> Status

In normal circumstances the chip should indicate, everything is ok and the amount of ml should be visible.

Possible status information when the chip might have a problem:

[E1] Printer chip is broken Æ Install a service chip

[E2] Printer chip is broken Æ Install a service chip

[E10] Invalid chip Æ Install a service chip

[E32] Invalid chip operation occurred Æ Restart machine

Other errors:

[E….] Chip all chip connections

SIMM-card errors can be due to the Wallet-SIMM card, mounted inside the machine.

However, problems might also occur due to the printer cartdridges (e.g. “Not Original Ink”). In fact, in this

case it’s the smart-chips that might be causing this issue. The internal SIMM and the smart-chip

management system (8 smartchip-cartridge-readers) are al interconnected. One chip can interfere with the

others and potentially give an error.

So when you know, cartridges with smart-chips are inside the machine and an [Exx]-error occurs, the error

can be caused by 2 possible reasons:

• The internal SIMM Card

• One of the 8 cartridges with smart-chips

Page 34

Troubleshooting

34 AP-74700 – Rev. 1.0 – 10/03/2008

To make an accurate diagnose of the problem, execute the following steps:

Step 1 : Shutdown the machine and remove all cartridges with smartchips

Step 2 : Check flatcables between mainboard and cassette led interface board (CLIB)

Step 3 : Check all connections on the CLIB board

Step 4 : Check all connections on SIMM-wallet PCB

Step 5 : Check all connections on the CLIB expander board (SPFR100 only)

Step 6 : Restart the machine without any cartridges, verify if the error still occurs Æ if not, check TIB252

Step 7 : If the error doesn’t occur, insert every cartridge back one-by-one and verify if every cartridge is

properly recognised in “ink status”

Step 8 : If non of above helps, install a service chip

Step 9 : Follow the service chip activation procedure

In the case, that cassette-smart-chips are responsible for causing an [Exx]-error, you can try the following

topics:

• If the internal wallet is used, the smart-chips on the cartridges can be removed. The credits can be

downloaded inside the printer. Beware that there is no glue or self-adhesive remaining on the smart-chip

or cartridge. This to avoid contamination of the smart-chip reader!

o Ink end will always be detected as this is a physical switch detection

o Ink levels per cartridge will not be readable when using the internal wallet. Only the total ink amount

charged inside the wallet, will be readable.

• If smart-chips are used, follow the TIB252, flowchart “not original ink”.

Page 35

Troubleshooting

35 AP-74700 – Rev. 1.0 – 10/03/2008

3 TROUBLESHOOTING WITHOUT ERROR

CODE

3.1 PARAMETER & PRINTING RELATED ISSUES

3.1.1 Parameters are not being saved during shutdown

Step 1 : Be assured to use the latest firmware-version

Step 2 : Check available NVRAM

Diagnostics Æ Test Æ NVRAM

Free space: bytes free

Max block: largest block free (bytes)

If an error occurs, problems occur or the free space for parameters is very low (<100), proceed

to the next step

Step 3 : Go to diagnostics – and change MOD-level to 0

(MOD-level defragments internal parameters, clearing memory for additional data, can be reverified with Test Æ NVRAM)

Step 4 : If still not ok:

a. Try to reset the parameters

b. Try to clear the NVRAM

Step 5 : If the problem still persists, the NVRAM might be damaged Æ replace mainboard

3.1.2 Unstable machine behaviour (CPU errors, machine crashes)

If this behaviour still proceeds, after replacing a main-board and restoring the parameter-backup, in some

rare cases, it can happen that something inside the parameters becomes corrupt but we cannot see. This

results mostly in strange machine-behaviour (unknown cpu errors, crashes).

Æ In that case a parameter backup should not be taken because when you restore it, you might literally

‘restore the problem’ on another board.

In this situation, the clearance of the NVRAM may be proceeded.

Before proceeding to this try to print out the machine setup and parameters to insert everything with the

same values afterwards.

Important

• BEFORE PROCEEDING WITH THIS PROCEDURE, ALWAYS USE THE LATEST FIRMWARE VERSION. IF THIS IS NOT

DONE

, YOU MIGHT LOOSE THE SETTINGS AND WILL MAKE YOUR MACHINE TOTALLY UNUSABLE. IN THIS CASE

MAINBOARD REPLACEMENT IS THE ONLY OPTION

.

This procedure takes much more time and is more complicated (the machine doesn’t know if there is ink

inside, eco ink or mid solvent ink, or cleaning, the serial number is gone, head adjustments in parameters

must be re-programmed, distance adjust, etc…). This manual programming, will take much more labourtime… (up to a few hours)

So, in this situation, manual parameter might anyway still be useful…

Page 36

Troubleshooting

36 AP-74700 – Rev. 1.0 – 10/03/2008

3.1.3 Printer doesn’t start printing, interrupts or intermittently stops

during

printing

Step 1 : Try to launch an internal printer test, e.g.

Testprint – Palette

Æ If this is working, proceed to the next point

Step 2 : Verify network connections

• Verify if the IP-address is ok on Machine, computer and Rip-software

• Check if you can ping the IP-address from the computer command window

• Assure that the IP-address is set-up properly according to ‘normal circumstances’. Make a

testconnection by configuring both devices into a mini-class C-network (192.168.x.x subnet

255.255.0.0)

• Disable any computer-firewalls as they might block, interrupt or slow down the printer

• Make sure the network-cabling is ok, always respect the following guidelines:

o Only use stranded UTP-cables, stranded cables have a very high flexibility because it has

multiple copper fibres per cable when for connecting printers to wall sockets, computers,

switches and mounting onto RJ45 connectors.

o Rigid UTP-cables have 1 thick copper core per curve and are designed for fixed wall-mounting

and inside sockets only and are NOT suitable as patchcables

! Never use that kind of cables,

between the printer and a computer or wall-socket! Mounting RJ45 connectors on that kind of

cables will guarantee bad contacts with signal-quality loss, network problems resulting in printing

problems.

o Make a direct connection between rip-computer and printer with a cross-cable. This ensures

maximum data-transfer without network-interference.

o The newest generation printers require high quality cables. Thus Cat 5E cables are suitable for

Gigabit networking, however CAT6 cables are strongly recommended for optimum signal-quality!

Step 3 : Try to connect to another computer, try to print with a pre-ripped file (e.g. Mutoh adjustment-files)

Step 4 : If still not ok, replace the Network-card and try again

Step 5 : If still identical, replace the mainboard and try again

Page 37

Troubleshooting

37 AP-74700 – Rev. 1.0 – 10/03/2008

3.1.4 Ink drops falling on media from heads during printing

Step 1 : Never remove cartridges out of the printer when it’s uncapped!

If cartridges are removed when the machine is not on it’s capping station, ink will leak out from

heads and air will be sucked through the cartridge-needle.

Step 2 : Once air-bubbles inside the tubing, the risk of smudging and destroying the print is possible!

Step 3 : To solve: proceed with ink load to remove all ink-bubbles from the tubing

Inkmanager Æ Ink load

Step 4 : Avoid dust particles below the printer heads by any means. 1 piece of dust on the nozzle-plate

will suck out ink from the heads resulting in ink drops.

Avoid placing the printer in dirty and dusty environments. Clean the machine on a regular basis.

Step 5 : Verify if wipers are in good shape. After wipe action, before printing, verify if the nozzle-plate

around the nozzles, is 100% clean. If not, clean the wipers. If the wipers are not straight

anymore, replace wipers.

Step 6 : The printer is a high-precision instrument that needs care and maintenance, this due to the

nature of the solvent inks.

Be sure to respect the recommended daily maintenance procedures according to the ink used, to

assure optimum performance.

Step 7 : Respect the environmental conditions as described in the installation guide. During winter-time

and cold periods, low environmental humidity will decrease print performance.

Step 8 : Place the machine in an antistatic location. Antistatic flooring is recommended.

Step 9 : All electronical equipment (printer + computer) must be properly earthed.

Step 10 : Very Low environmental humidity also causes plastic materials like banner and vinyl’s to charge

statically. Statically charged materials might cause printing anomalies like:

• Ink drops

• Nozzle inaccuracy and deflection

• Bad printing quality

Step 11 : Printing materials need to be climatized in the same environment as the printer for at least 8

hours, before being ready for printing.

Step 12 : Always use the latest released Firmware version.

Page 38

Troubleshooting

38 AP-74700 – Rev. 1.0 – 10/03/2008

3.2 PRINTING RELATED PROBLEMS

3.2.1 Complete nozzle-row (A or B-channel) is missing

Step 1 : Try if you can recover, performing a cleaning (powerful)

Step 2 : If nozzles still do NOT appear after a cleaning, try to connect a seringe and suck with the

seringe instead, be assured that the seringe is making a proper vacuum.

If a vacuum cannot be created with the seringe, verify:

• If the damper is properly connected to the head’s nipple

• If the damper is intact and the membrane is not punctured

• If the ink-tubing is properly connected from cartridge up to damper. Make sure there is an air-tight

connection between every tube and O-ring.

• If the ink-cartridge is not empty (..and the empty-flag is not being detected properly)

• If the nipple of the printing head is not leaking or broken-off

If a vacuum can be created with the seringe, verify:

• If flatcables are properly connected to the head

• If the fuse on the mainboard is still intact

• If the nozzle-row or the damper is not blocked / dried out

Page 39

Troubleshooting

39 AP-74700 – Rev. 1.0 – 10/03/2008

3.2.2 Head is firing continuously

With continuous firing we define the following:

One head or one colour-channel is firing continuously over the whole print-length, over the whole length of

the movement of the carriage, as well over the edge of the media, as on the print platform.

In this situation, firing will occur starting from the flushing-box, over the print platform and over the edge of

the media up till where the carriage stops.

First of all, be assured, the latest firmware-version is installed in the machine!

This can also give an indication, that there might be problems with the fuse of this head- or colour-channel.

Possible indications are (in order of most to less important reason):

• Short flatcables badly connected

• Long flatcables badly connected

• HEAD_DRV board

• Mainboard (mainly checking and/or replacing fuses)

• Print head itself

When that kind of problem is reported it’s always recommended to have at least these spares available for

replacement.

To solve this problem, following the instructions described in TIB188 (Flat Cable Treatment) is strongly

recommended! Flatcables must be in perfect condition

and must be connected 100% perfectly!

Notes

• Fuses on the mainboard can be easily measured with an Ohm-meter. A fuse in good

condition, should have approx 0 Ohms resistance. Fuses on non-RoHS mainboards must be

re-soldered with a new one, when broken. Fuses on a RoHS mainboard, can easily be

replaced with a tweezer.

Important

• When replacing fuses, always remove the power-cord and discharge the machine, to

avoid static charge and damage to electronics!

Page 40

Troubleshooting

40 AP-74700 – Rev. 1.0 – 10/03/2008

3.3 INITIAL MACHINE STARTUP-RELATED PROBLEMS

A simplified, automatic procedure for loading the appropriate cleanings and inks has been developed and is

executed via firmware.

This makes it easier for the customer to load the correct liquids inside the printer. The big advantage of the

smart-chip management system is that it can identify, if the correct cartridge inserted. It also assures that

the correct procedure is followed like described in the user’s manual. So there is a double security!

This procedure is of utmost importance as not all solutions and inks are directly compatible. If notcompatible solutions and inks are mixed, the heads and ink tubings inside the printer might block resulting in

replacement and a lot of work.

3.3.1 Ink and cleaning compatibility-Chart

Water-based solution STL-Liquid (Eco Solvent Cleaning) ECO Solvent Ink

Water-based

solution

Compatible Compatible

NOT Compatible

STL-Liquid (Eco

Solvent CLN)

Compatible Compatible Compatible

Mild Solvent

Cleaning

NOT Compatible

Compatible

NOT Compatible

Mild Solvent Ink

NOT Compatible NOT Compatible NOT Compatible

As you can see in the chart, ECO-Solvent Inks, are also NOT compatible with either water-based, either,

Mild solvent Cleanings or Ink. So avoid the mixture of these solutions in any case inside the machine’

tubings and heads!

Brand-new machines are shipped are standard delivered with a water-based solution:

• Inside the ink-tubings

• Inside the dampers

• Inside the heads

The chart shows that water-based solution and solvent inks are NOT compatible!

When Solvent inks are mixed with water-based solution, the pigments of the ink will decay and it will block:

• The ink tubings

• The dampers

• The heads

To avoid this, multiple cleaning cycles are required to convert the machine into the correct configuration.

Page 41

Troubleshooting

41 AP-74700 – Rev. 1.0 – 10/03/2008

• There are 3 status-flags in the machine. Each flag describes in which state the machine is at this

moment. Depending of the flag-status, the machine will execute a specific action when starting-up. All

the possible combinations are described here below:

Ink Load Cycle – Spitfire – Blizzard

Mild solvent inks

Ink Load Cycle – RHIII – Blizzard

ECO solvent inks

Status flags brand-new machine:

• Ink fill flag = RESET

• SMS flag = RESET

• SolPrepare flag = SET

Machine will automatically proceed to:

1

st

phase:

Water-Based Æ STL-Liquid

Status flags after loading ECO-cleaning:

• Ink fill flag = RESET

• SMS flag = RESET

• SolPrepare flag = SET

Machine will automatically proceed to:

2

nd

phase

STL-Liquid Æ Mild Solvent Cleaning

Machine will automatically detect MS-Cleaning: