Page 1

MC-SERIES MULTI-TOOL

CUTTING PLOTTERS

OPERATION

INSTRUCTIONS

MUTOH EUROPE N.V.

Part N°. AP-75020

Rev. 1.0 - 18/12/98

Page 2

Operation Instructions MC-Series cutting plotters

AP-75020, Rev. 1.0 - 18/12/98

Page 3

Operation Instructions MC-Series cutting plotters

COPYRIGHT NOTICE

COPYRIGHT 1998 Mutoh Europe N.V. All rights reserved.

This document may not be reproduced by any means, in whole or in part, without written

permission of the copyright owner.

This document is furnished to support the MUTOH MC Series cutting plotters. In

consideration of the furnishing of the information contained in this document, the party to

whom it is given assumes its custody and control and agrees to the following:

1. The information herein contained is given in confidence, and any part thereof shall not

be copied or reproduced without written consent of Mutoh Europe N.V.

2. This document or the contents herein under no circumstances, shall be used in the

manufacture or reproduction of the article shown and the delivery of this document shall

not constitute any right or license to do so.

FCC WARNING

This equipment complies with the requirements for a class A computing device in the FCC

rules, part 15, subpart J.

Operation of this device in a residential area may interfere with television reception or

operation of utilities.

Cutters generate weak radio signals and may interfere with television reception and

utilities. If the cutter does interfere with radio or TV reception, try the following:

•

Change the direction of your radio and TV reception antenna or feeder.

•

Change the direction of the cutter.

•

Move either the cutter or the receiving antenna so that there is more distance between

them.

•

Be sure the cutter and the receiving antenna are on separate power lines.

AP-75020, Rev. 1.0 - 18/12/98

Page 4

Operation Instructions MC-Series cutting plotters

AP-75020, Rev. 1.0 - 18/12/98

Page 5

Operation Instructions MC-Series cutting plotters

Congratulations with your new MUTOH cutting plotter !

We are happy to find you joining the ever rapidly growing family of MUTOH

computer peripherals users.

By purchasing an MC-series cutter, you have become the owner of one of the

most versatile multiple-tool cutters in the market. It is fast, reliable, of the

highest quality and has been assembled with the application of the most

stringent quality checks.

But even more important, it is easy to use, as the following guide will show

you.

Hereafter you will find all information necessary to set-up your MC-cutting

plotter in a trice.

ENJOY!

AP-75020, Rev. 1.0 - 18/12/98

Page 6

Operation Instructions MC-Series cutting plotters

AP-75020, Rev. 1.0 - 18/12/98

Page 7

Operation Instructions MC-Series cutting plotters

TABLE OF CONTENTS

MC-SERIES MULTI-TOOL CUTTING PLOTTERS OPERATION

INSTRUCTIONS

SETTING UP THE CUTTER........................................................................1

PREPARING THE CUTTING ENVIRONMENT............................................................ 1

UNPACKING THE CUTTER........................................................................................ 2

WHAT’S IN THE BOX ?............................................................................................... 2

GETTING TO KNOW THE CUTTER PARTS .............................................................. 3

ASSEMBLING THE PLOTTER.................................................................................... 5

CONNECTING THE CUTTER TO THE COMPUTER.................................................. 8

CONNECTING THE POWER CABLE ......................................................................... 9

COMMUNICATION SETTINGS................................................................................... 9

CHANGING THE SET-UP LANGUAGE OF YOUR CUTTER.................................... 10

PREPARING FOR A JOB..........................................................................11

LOADING MEDIA...................................................................................................... 11

ADJUSTING THE KNIFE DEPTH.............................................................................. 14

INSTALLING A TOOL................................................................................................ 16

SETTING THE CUTTING FORCE / TEST SQUARES............................................... 18

OFFSET PRINCIPLE................................................................................................. 19

OFFSET EFFECT...................................................................................................... 19

OFFSET ADJUSTMENT PROCEDURE.................................................................... 20

PERFORMING A TEST............................................................................................. 23

FIXED KNIFE SYSTEM............................................................................................. 25

UNDERSTANDING THE KEYBOARD & MENU STRUCTURE................28

GUIDED TOUR AROUND THE KEYBOARD............................................................. 28

KEYBOARD CONCEPT ............................................................................................ 33

MENU STRUCTURE - OVERVIEW........................................................................... 34

OVERVIEW GENERAL SETTINGS........................................................................... 37

AP-75020, Rev. 1.0 - 18/12/98

Page 8

Operation Instructions MC-Series cutting plotters

AP-75020, Rev. 1.0 - 18/12/98

Page 9

Setting up the cutter Operation Instructions MC-Series cutting plotters

SETTING UP THE CUTTER

PREPARING THE CUTTING ENVIRONMENT

The location where you set up your equipment is very important. Please see to it

that it meets following conditions :

♦

Power supply of 100 to 120 VAC 50/60 Hz or 200 to 240 VAC 50/60 Hz.

♦

Ambient Conditions :

•

Operating environment

- Temperature : 5° C to 40° C (41° F to 104° F).

- Humidity : 35% - 75% non-condensing.

•

Recommended environment

- Temperature : Room temperature 16°C to 32°C (61° F to 90° F).

- Humidity : 50% to 65%, non-condensing.

•

Variation rate

- Temperature : 2° C per hour.

- Humidity : 5% per hour.

•

Storage environment

- Temperature : 0° C to 50° C (32° F to 122° F).

♦

Please protect your cutter from moisture, dust, draughts and direct sunlight. It is

best to keep your machine away from open windows and air-conditioners.

♦

See to it that there is an adequate space around the cutter so that ventilation is

not obstructed.

♦

Avoid unnecessary vibrations and set up your cutter on a level surface.

When selecting a place for your cutter, leave at least 150 cm (60”) in front and 150

cm (60”) at the rear.

Page

1

AP-75020, Rev. 1.0 - 18/12/98

Page 10

Setting up the cutter Operation Instructions MC-Series cutting plotters

UNPACKING THE CUTTER

•

When unpacking the cutter, check whether all parts described in the parts

lists are included in the boxes. Consult your dealer if anything seems to be

missing.

•

Lifting the machine out of the box should be done by two persons.

•

Protect the plotter from firm shocks.

•

Do not dismantle the unit.

To unpack the cutter:

1. Lift the cutter unit out of the box and put it on a flat, stable surface.

2. Take out the accessories box.

3. Remove all plastic wrapping materials.

4. Remove the pieces of foam.

5. Unpack the stand.

WHAT’S IN THE BOX ?

•

MC plotter unit with roll support system, 2 conveyor rolls and

small guiding flanges

•

Cutting plotter stand

•

Mutoh MC-Series User’s Guide

•

Knife holder with depth indication (+ 1 cutting blade)

•

Set of 2 spare cutting blades 45°

•

Set of 2 water-based fibre tip pens

•

Spare cutting mat

•

Power Cord

•

RS-232 Serial interface cable

•

3” core roll media guiding flanges (2 pcs)

Page

2

AP-75020, Rev. 1.0 - 18/12/98

Page 11

Setting up the cutter Operation Instructions MC-Series cutting plotters

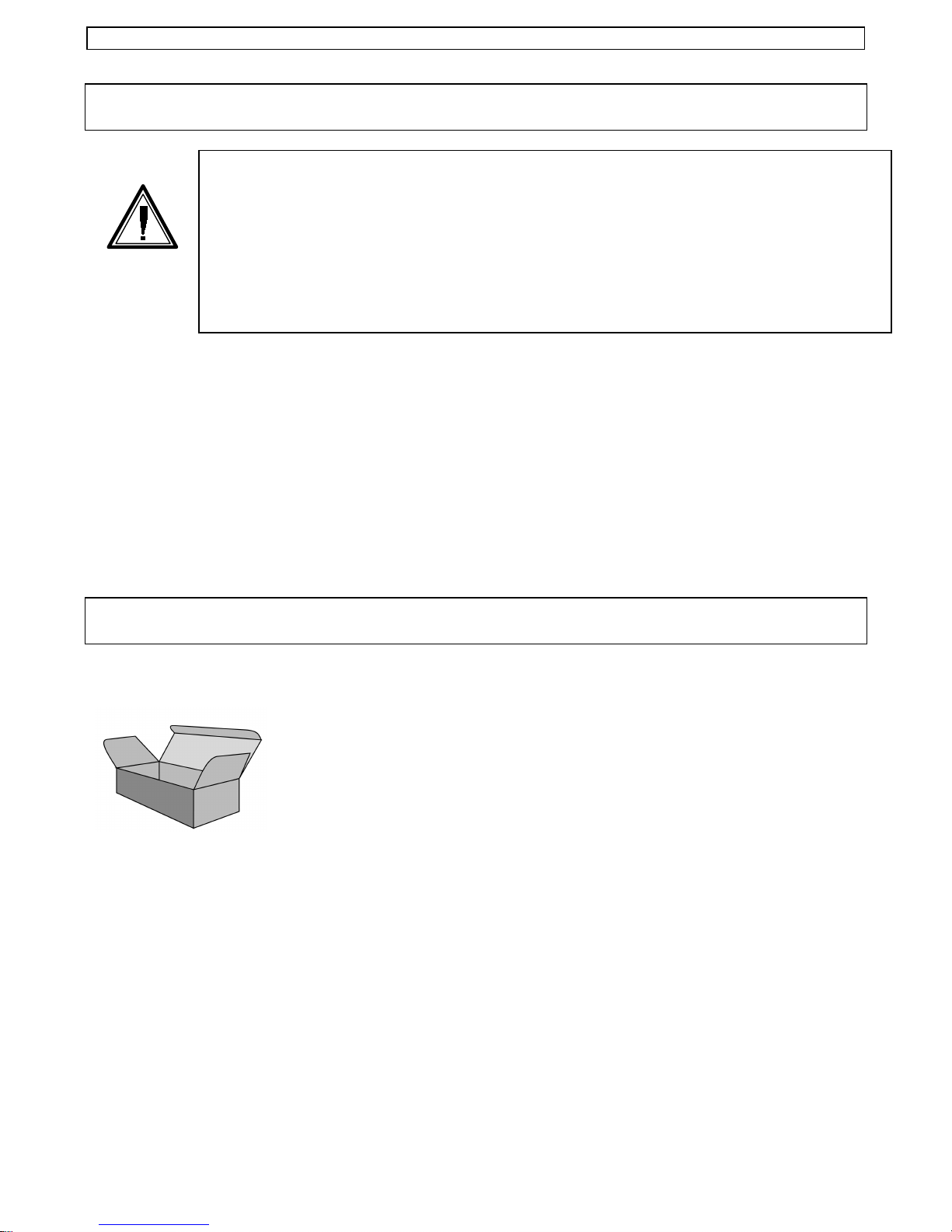

GETTING TO KNOW THE CUTTER PARTS

N° Part Description

1. Control Panel

2. Power Switch

3. Carriage Cover

Panel with Liquid Crystal Display (4 lines by 16

characters), indicator LEDs and control keys.

Turns the plotter ON or OFF.

For safety reasons, the cutter will not work while the

cover is open. The cover will also prevent objects from

falling into the cutting zone.

Page

3

AP-75020, Rev. 1.0 - 18/12/98

Page 12

Setting up the cutter Operation Instructions MC-Series cutting plotters

4. Conveyor Roll Support

Brackets

5. Conveyor Rolls

6. Media Guiding Rings

7. Hold Lever

8. Platen & Grid Cover

9. Cutting Mat

10. Serial Interface

Connector

11. Parallel Interface

Connector

12. Power Connector

These brackets carry the conveyor rolls.

2 pieces - these rolls carry the roll media.

These rings are placed alongside the roll media.

Raises and lowers the pressure rollers. Lowering the

pressure rollers will press the media against the drive

rollers (grid rolls).

Supports the media and guides the movement of the

media along the X-axis.

Provides a reliable cutting surface and minimises damage

to the knife tip.

RS-232 serial interface connector to connect the cutter to

the host computer.

Centronics parallel connector to connect the cutter to the

host computer’s printer port for fast data transfer.

Connector for the power cord, which plugs into the main

power supply of the cutter.

13. Tool head for Cutting /

Marking / Plotting

14. Carousel / Stocker &

Stocker Housing

15. Drive Rollers or Grid

Rolls

16. Pressure Rollers

17. Media Alignment

Stripes

18. Soft Media Collection

Bag

19. Caster Wheels

All available tools such as knife holders, drawing pens

and wide tip pens are automatically picked from the 8-tool

carousel. The tool head moves along the Y-axis to locate

the cutting position.

The carousel can hold up to 8 different tools, allowing

flexible switching from one application to another. It can

be easily removed to install and/or remove tools.

Move the cutting media along the X-axis.

Hold the media against the drive rollers during cutting.

Indication marks to facilitate loading of cut-sheets.

Attached to the stand, the media collection bag will

prevent finished designs from being dropped on the

ground.(*)

The cutting plotter’s legs are equipped with 4 pre-installed

caster wheels, two of which have a lock switch.

20. Slip Ring

(*) = Optional item, only when ordered separately.

The slip ring is placed onto the conveyor roll and prevents

undesirable movements of the roll media.

Page

4

AP-75020, Rev. 1.0 - 18/12/98

Page 13

Setting up the cutter Operation Instructions MC-Series cutting plotters

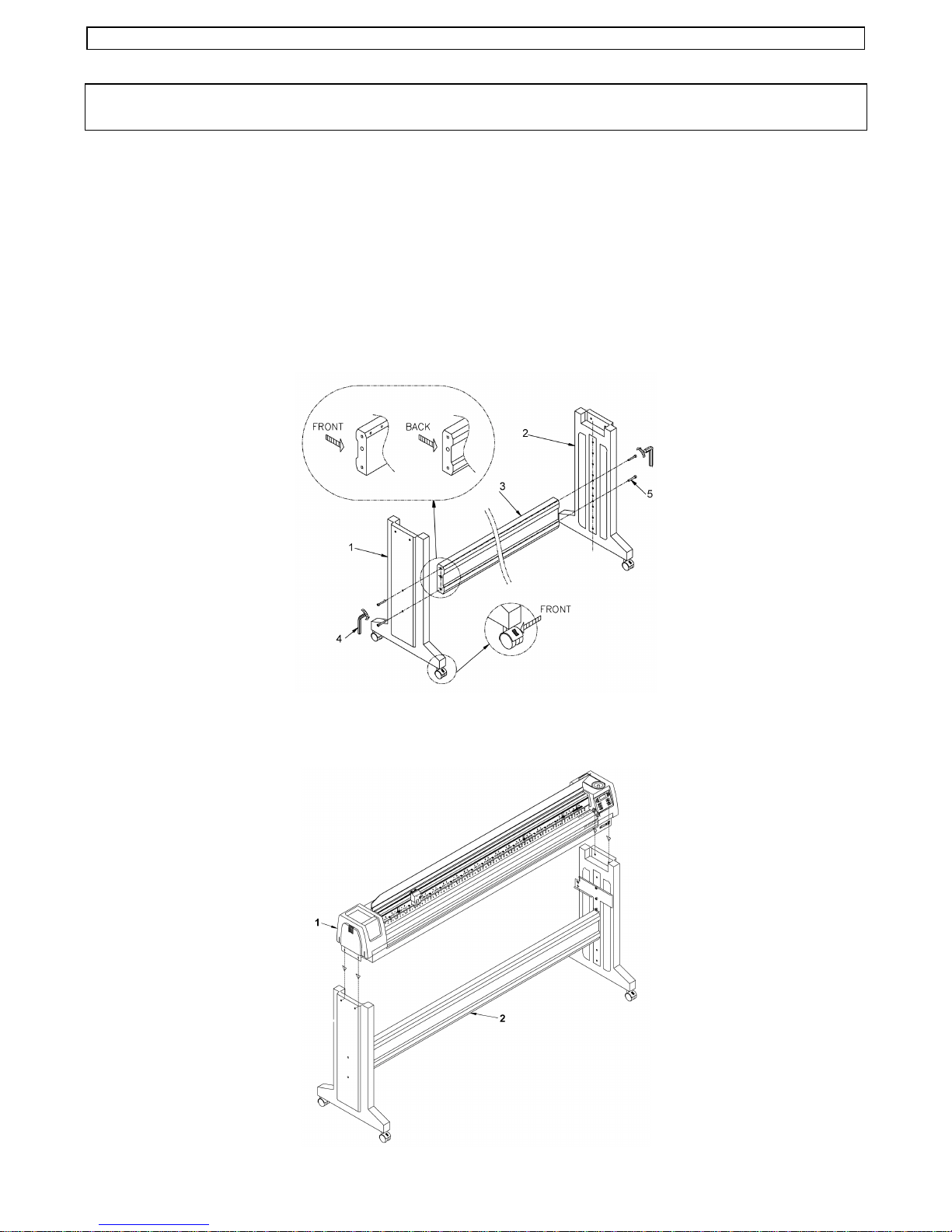

ASSEMBLING THE PLOTTER

After you have selected a suitable location for your cutting plotter, some assembly is

necessary before the plotter is ready for use. This section describes how to

stand

, how to

attach the plotter body to the stand

media collection bag

.

and how to

mount the optional

1. Use the hex wrench (4) to fix the stand side stays (1)(2) firmly to the cross beam (3)

with the hex bolts M8, long type (5). As indicated in the illustration, the caster wheels

with locking switch have to be on the front side. Also, the cross beam’s flat side has to

be on the back side.

assemble the

2. Place the cutting plotter body (1) onto the stand (2).

Page

5

AP-75020, Rev. 1.0 - 18/12/98

Page 14

Setting up the cutter Operation Instructions MC-Series cutting plotters

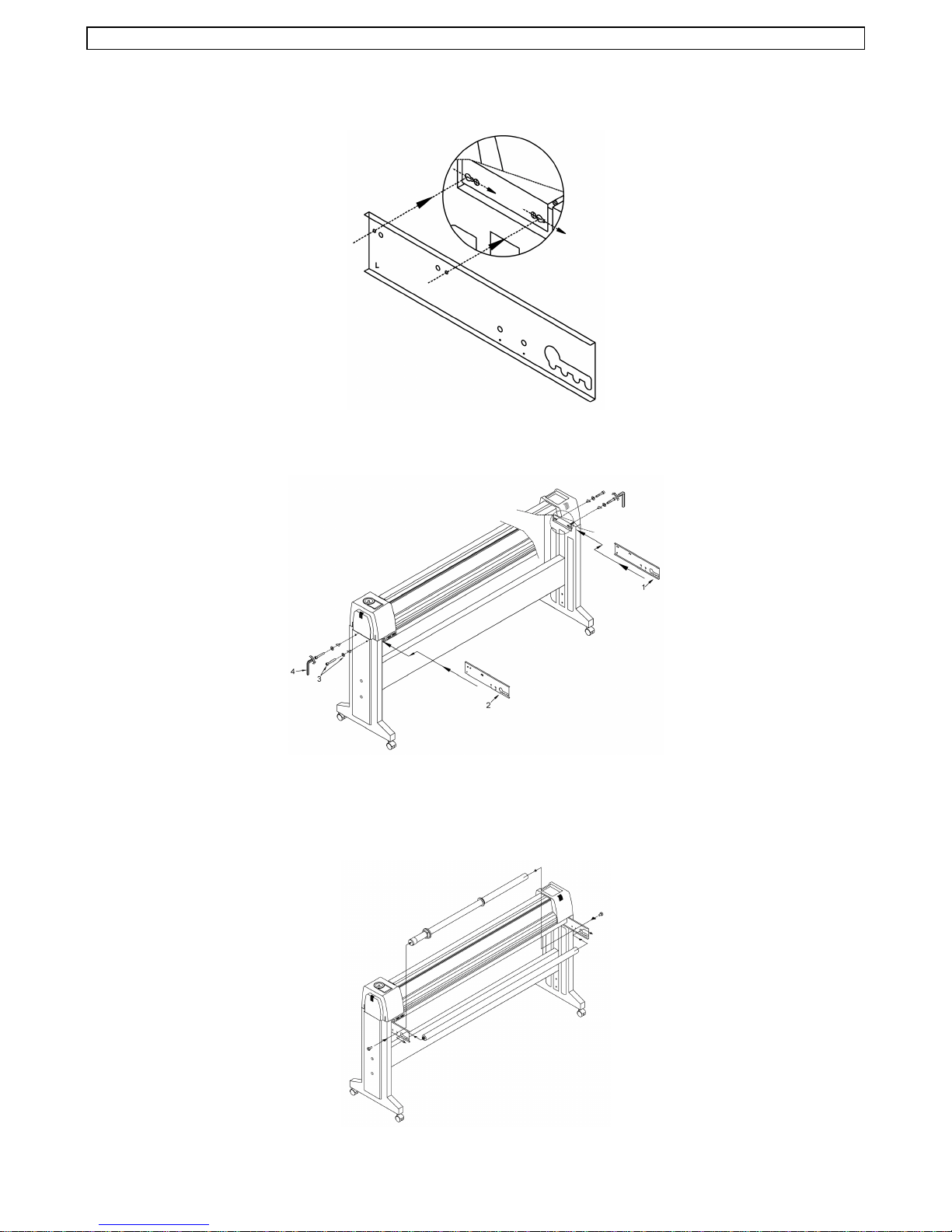

3. Hook the MC conveyor roll support brackets Left (1) and Right (2) in the key holes of

the body (see detail).

4. Attach the plotter body with the brackets to the stand using 4 hex bolts M6 + washers (3).

5. Fix the conveyor roll which is closest to the plotter body to the support brackets, using

two short M8 bolts and a spacer (see illustration).

The second conveyor roll can be installed easily via the back of the support brackets

(see illustration).

Page

6

AP-75020, Rev. 1.0 - 18/12/98

Page 15

Setting up the cutter Operation Instructions MC-Series cutting plotters

Only in case the

optional media collection basket was ordered

, follow steps 6 to 8 to

install it.

6. Using 4 hex bolts, short type, fix the bag frame components ( type B ) to the stand.

7. Insert the bag frame components ( type A ) into the bag sleeves.

8. Complete the media collection bag assembly by connecting the frame parts type A and

type B, as shown in the illustration. Attach the tension springs connecting the bag with

the lower frame part.

Page

7

AP-75020, Rev. 1.0 - 18/12/98

Page 16

Setting up the cutter Operation Instructions MC-Series cutting plotters

y

CONNECTING THE CUTTER TO THE COMPUTER

To make the

possibilities

connection between the cutter and the computer

. The first possibility is a

Centronics interface

high-speed unidirectional 8-bit parallel

. The second possibility is a

2-way RS-232C serial interface

, you are offered

two

. Of

course, it is also possible to connect two different computers to the cutter, the first one

using the serial interface, the second one using the parallel interface. The cutter will

automatically determine on which port data is coming in and will handle the jobs one by

one.

PARALLEL INTERFACE

All you need to make this connection is

a parallel printer cable.

The serial RS-232C interface enables

the cutter to be connected to and

SERIAL INTERFACE

controlled by an RS-232C compatible

host computer system. The cutter is

equipped with a standard RS-232C DB-25P connector on the rear panel

and requires a standard RS-232C dB25S mating connector.

a) Make sure both the cutter and the computer are turned off. Connect one end of the

parallel interface cable /

serial interface connector

serial interface cable

to the parallel interface connector /

at the back side of the cutting plotter.

b) Secure the lock pins to the

connector.

c) Connect the other end of the

parallel printer cable to your

computer.

•

Please be advised that the

means that the cutter can receive data from the computer but cannot send any

information to the computer. Consequently, software polling for media size will

not be available when using parallel communication.

•

Using the

data

serial communication

from the computer, but will also be able to

computer (media size, ...).

•

For proper operation of the serial communication, it will be necessary to match

the computer settings to the plotter settings !

b) Fasten the screws to secure the

connector.

c) Connect the other end of the serial

cable to your computer.

parallel interface

, your cutter will not only be able to

Page

8

only

works one-wa

send information

AP-75020, Rev. 1.0 - 18/12/98

. This

receive

to the

Page 17

Setting up the cutter Operation Instructions MC-Series cutting plotters

CONNECTING THE POWER CABLE

1. Make sure the plotter’s power switch

is turned OFF.

2. Plug the plotter-end of the power

cable into the connector at the back

of the plotter.

3. Plug the other end of the power cable

into an electrical outlet of the correct

voltage and with a proper grounding.

COMMUNICATION SETTINGS

In order for your plotter to be able to communicate well with your host computer, the

communication settings on both machines have to match exactly. Please refer to the

manual of your software to determine which communication settings will be used by your

software. Your cutter is able to be set up to use any settings necessary.

You can proceed in two ways:

•

You can check which of the 5 possible defaults matches your software and enable this

particular default setting.

•

You can set all communication parameters yourself. In this case, for communication,

select USER DEFINED.

Communication DEFAULT 1 DEFAULT 2 DEFAULT 3 DEFAULT 4 DEFAULT 5 USER

DEFINED

BAUDRATE

DATABITS

PARITY

STOPBITS

9600 9600 9600

787

EVEN NONE EVEN

111

9600

8

NONE

1

9600 Adjustable

8 Adjustable

EVEN Adjustable

2 Adjustable

SOFTWARE

HANDSHAKE

DTR-Pin

CTS-Pin

RTS-Pin

OFF OFF Xon/Xoff

ON ON OFF

OFF OFF OFF

ON ON ON

The factory default settings are shown in

Bold

Page

-face.

9

Xon/Xoff

OFF

OFF

ON

OFF Adjustable

ON Adjustable

OFF Adjustable

ON Adjustable

AP-75020, Rev. 1.0 - 18/12/98

Page 18

Setting up the cutter Operation Instructions MC-Series cutting plotters

CHANGING THE SET-UP LANGUAGE OF YOUR CUTTER

It is possible to change the user language of your cutter, thus changing the set-up sheet

language. Changing the set-up language can be done by pressing two keys simultaneously

during power-up. See table below for an overview.

LANGUAGE KEY COMBINATION

American

English

(dimensions in inches)

German

French

(dimensions in metric units)

Japanese

ENTER + JOG-DOWN

ENTER + JOG-UP

ENTER + JOG-RIGHT

ENTER + JOG-LEFT

ENTER + ONLINE

Page

10

AP-75020, Rev. 1.0 - 18/12/98

Page 19

Preparing for a Job Operation Instructions MC-Series cutting plotters

PREPARING FOR A JOB

This section covers the tasks you should perform as you prepare to run a job:

•

Loading the media

•

Adjusting the knife depth

•

Installing a tool

•

Offset principle, effect & adjustment routine

•

Performing a test

•

Using the fixed knife system

LOADING MEDIA

Page

11

AP-75020, Rev. 1.0 - 18/12/98

Page 20

Preparing for a Job Operation Instructions MC-Series cutting plotters

y

You can load either

cut sheet

or

roll material

into the cutter.

CUT SHEET MEDIA ROLL MEDIA

1. Close the

safet

media hold lever (3)

switch (5)

ON.

cover (1)

, put the

pressure rollers (2)

, make sure the

stocker (4)

in the “up” position using the

is into place and turn the

a) The cutting plotter performs an initialisation routine and the display shows the

initialisation menu.

b) The

c) The

2. Open the

stocker (4)

tool head (6)

protective cover (1)

the cut sheet media into the cutter. On

the

platen (7), marker lines (8)

been affixed for alignment purposes. It is

rotates about 2 times to perform tool identification.

moves to the rightmost position.

and insert

2. Open the

protective cover (1)

the media through to be able to choose

have

the best possible position for the

pressure rollers (2)

.

best to position the media so that half of it

hangs in front and half of it hangs at the

back of the cutter.

power

and pull

3. Depending on the width of the MC cutting plotter you have purchased, it is equipped

with 3 or 4 pressure rollers. You can use as many pressure rollers as you think are

necessary for good media handling.

a) In any case, at least 2 pressure rolls are needed. To disable one or more

rolls (2)

drive roller (9)

b) Adjust the position of the

drive rollers (9)

, they are to be placed at the leftmost side of the plotter, beyond the leftmost

.

pressure rollers (2)

in use, so that they align well with the

. Always make sure that the leftmost and rightmost pressure rollers

pressure

in use are at least 5 mm (0.2”) inside the media. It is not recommendable that the

rollers run on the very edge of the material.

4. Doing this, you are helped by the tactile and audible click system for the left pressure

rollers. The rightmost pressure roller’s movement is limited so that it can never be

malpositioned.

Always make sure that all pressure rollers in

use are completely inside the sheet of

media you want to load. Especially when

you use a cut sheet of which the corners are

not perfectly square, it is best to put the

pressure rollers well inside the media, as

the width of the sheet may vary.

5. Put the

hold lever (3)

in the

DOWN position (3

To ensure good & straight transport of the

roll media, see to it that there is an even

tension across the whole width of the roll

as you lower the media hold lever ( 3

3’).

Page

12

3’) and close the cover.

Î

Î

AP-75020, Rev. 1.0 - 18/12/98

Î

Î

Page 21

Preparing for a Job Operation Instructions MC-Series cutting plotters

g

y

Please do not use the marker lines to

ali

n a roll of media !

They are for use with

cut sheets onl

!

Rolls can only be correctly installed using

the

EQUAL TENSION METHOD.

Î

6. Lowering the lever (3

3’) will initialise

the media loading sequence, during

which the cutter will measure the loaded

sheet. Depending on the current

SHUFFLE / PRE-FEED settings, the

sheet will be moved back and forth,

enabling the cutter to determine the

media size and enabling you to verify the

media transport.

The cut sheet will only be recognised as

being a cut sheet if the shuffle length is

6. Lowering the lever (3 Î 3’) will initialise

the media loading sequence, during

which the cutter will measure the media

width and pull off a user-selectable prefeed length, called the shuffle length. At

the same time you are able to check the

media transport. The SHUFFLE / PREFEED settings allow the user to interfere

with the pre-feed length as well as with

the speed at which the media is pulled off

the roll.

set to a value which is larger than the cut

sheet length. If this is not the case, the

cut sheet will be treated as being a roll.

Default shuffle length is 1 metre.

7. After finishing the media loading sequence, the tool head will be parked at the origin

position and the cutter will be in ON-LINE mode, ready to receive data from the host

computer.

Please notice that the pressure rollers cannot be moved when the media hold

lever is in the DOWN position.

Page

13

AP-75020, Rev. 1.0 - 18/12/98

Page 22

Preparing for a Job Operation Instructions MC-Series cutting plotters

ADJUSTING THE KNIFE DEPTH

Two types of high-quality knife holders are available for the MUTOH cutting plotters.

No matter which type of knife holder you are using, adjusting the knife depth is a very

important parameter when it comes to making high-quality outputs. Always make sure that

the knife blade protrudes enough from the holder to cut through the vinyl and glue layer,

but not the backing.

When you adjust the knife depth, refer to the illustration below for guidance.

1. Knife Holder

2. Media to be cut

3. Cutting mat or material backing

4. Cutting blade

TO ADJUST THE KNIFE DEPTH, PROCEED AS FOLLOWS :

KNIFE HOLDER WITHOUT NONIUS KNIFE HOLDER WITH NONIUS

1) Hold the body (2) in one hand and

adjust the depth by using the set screw

(3).

1) Loosen the base part of the knife

holder. To do this, take the base part

in your left hand and twist the ring

slightly.

Page

14

AP-75020, Rev. 1.0 - 18/12/98

Page 23

Preparing for a Job Operation Instructions MC-Series cutting plotters

g

g

KNIFE HOLDER WITHOUT NONIUS KNIFE HOLDER WITH NONIUS

2) Turning the set screw (3) clockwisely

will make the blade protrude out of

the edge of the base part (1). Turning

the set screw (3) counterclockwisely

2) Take the base part and the ring in your left

hand and twist the shaft until the knife tip

protrudes about 0.2 mm (0.008”) out of the

edge of the base part.

will retract the blade.

For a first test, turn out the blade until

it protrudes about 0.2 mm (0.008”) out

of the base part.

Tighten the ring firmly against the base part.

This will prevent the cutting blade from

coming loose during cutting.

3) Make a manual test-cut on a small piece of media, of the same type that you will be

using.

When cutting

material with no backin

, verify that the media is just cut through. The

blade should only protrude as much as the thickness of the material you are cutting.

When cutting

material with backin

adjust the blade depth so that the top layer is

completely cut through and that you can see a slight scratch on the backing when

weeding off the top layer.

4) Repeat steps 2 and 3 until the correct depth is obtained.

Page

15

AP-75020, Rev. 1.0 - 18/12/98

Page 24

Preparing for a Job Operation Instructions MC-Series cutting plotters

INSTALLING A TOOL

For your MC-series cutting plotter, a number of different tools are available. Each of these

carries a unique identification mark called the

rings either in Silver or Black, which allow the cutter’s automatic tool recognition system to

determine which types of tools are available in the cutter’s stocker/carousel. Once a tool

has been recognised, the cutter can automatically use the appropriate values for

and

FORCE

jobs, should of course be fine-tuned by the user. Once set, the plotter will remember them

and automatically use them when the tool in question is selected.

. Settings which are media-dependent such as

tool ID-mark

. The ID-mark consists of 4

SPEED

KNIFE OFFSET

for cutting

Parameters such as

Some parameters such as

if a

KNIFE

1. Loading tools into the stocker

The stocker can accommodate up to 8 different tools. When a marking, cutting or plotting

tool is needed, the plotter will take it from the carousel. After finishing the job, the tool will

be returned to the stocker.

Before placing tools in the stocker, always verify that they are in working order and/or well

adjusted. In case of using ink pens, check whether they are correctly assembled and that

the ink is flowing smoothly. In case you are loading knife holders, first verify the blade

depth on a piece of media of the same type of the one which you will be using.

To load tools in the carousel, please proceed as follows :

or a

SPEED

PUNCHING TOOL

6

5

and

FORCE

OFFSET

are always used regardless of the tool-type.

or

PUNCHING GAP (DOT SPACE)

is selected.

a) Hold the

finger, press down one of the

caps (3)

are only activated

stocker (1)

.

and with one

pen

4

3

3

1

2

Page

16

b) With the other hand, gently push

the

tool (2)

clip (4)

See to it that the

below the

c) Release the

into the spring-loaded

in the stall.

tool collar (5)

disk (6)

.

pen cap (3)

AP-75020, Rev. 1.0 - 18/12/98

.

is

Page 25

Preparing for a Job Operation Instructions MC-Series cutting plotters

y

Please check whether the tools are loaded correctly.

Incorrectly installed tools may cause picking and/or replacing

problems.

When loaded correctly, the tool

is securely held; it is straight

and its tip is inside the pen

cap.

Correctl

installed tool Incorrectly installed tool

2. Installing the stocker

The stocker fits into the stocker housing situated at

the right side of the plotter.

•

Hold the stocker by the handle and slide it over

the spindle in the housing.

•

When inserting the carousel into the stocker

base, it should start an initialisation turn. If it does

not, turn it gently until it drops into place and

starts the initialisation routine.

•

To remove the stocker, lift it straight off the

spindle.

Page

17

AP-75020, Rev. 1.0 - 18/12/98

Page 26

Preparing for a Job Operation Instructions MC-Series cutting plotters

SETTING THE CUTTING FORCE / TEST SQUARES

In order to get excellent cutting quality, it is important to take good care to adjust the

cutting force. A design should always be cut with the lowest possible pressure. This

minimises blade wear and gives better quality.

To adjust the Force and cut a test square, proceed as follows:

1. Make sure the cutting plotter is OFF-LINE.

2. Press the FORCE key to enter the FORCE Adjustment menu.

3. Press the TOOL key to select the tool for which you want to adjust the FORCE.

4. Adjust the FORCE using the UP / DOWN keys.

5. If media is loaded and a knife-holder with correctly adjusted blade depth is installed in

the carousel, you can immediately cut a test square by pressing the TEST key.

The test square normally is positioned automatically. If you desire to do so, you can also

position the test square using the JOG keys.

In case a test square is cut, the new FORCE settings are saved automatically.

6. Press ENTER to accept the new FORCE value. Press EXIT to exit force set-up and

leave everything unchanged. Pressing ENTER is not required in case a test square was

cut in step 5.

Page

18

AP-75020, Rev. 1.0 - 18/12/98

Page 27

Preparing for a Job Operation Instructions MC-Series cutting plotters

OFFSET PRINCIPLE

One of the most important factors to obtain good quality, but unfortunately also one of the

factors that is easily forgotten, is the offset.

1

1: Cutter blade

2: Theoretical Offset

2

•

As you can see in the above figure, the knife offset (2) is the distance between

the knife centre and the knife tip.

•

Accurate measurement of the OFFSET to be used is very difficult and requires

specialised equipment. You should therefore adjust the offset (2) by checking real

cutting results on the media you will use. MUTOH helps you doing this by way of

a semi-automatic offset adjustment routine, which has been integrated into your

cutter.

OFFSET EFFECT

The selected Offset value is larger than

the optimum knife offset.

In this case, a square corner will be cut as

follows :

The selected Offset value is smaller than

the optimum knife offset.

In this case, a square corner will be cut as

follows :

The cutting direction is indicated by the

arrow. The corners are not well formed.

The cutter cuts too far in the angular

points.

The cutting direction is indicated by the

arrow. The corners are not well formed. The

cutter did not cut far enough in the angular

points.

Page

19

AP-75020, Rev. 1.0 - 18/12/98

Page 28

Preparing for a Job Operation Instructions MC-Series cutting plotters

y

OFFSET ADJUSTMENT PROCEDURE

In order to obtain perfect quality, MUTOH recommends you to perform

an offset adjustment routine

switch to another type of media

each time

.

ou change cutting blades or

To

perform offset adjustment

FINE TUNE

•

Base tune

•

Fine tune

.

is a

allows a

semi-automatic fine-tuning

limited adjustment

, you can select

, only setting the typical blade offset.

two offset modes

, called

BASE TUNE &

. In this mode, the plotter automatically

creates test patterns with different offsets allowing the user to choose the best result.

By factory default, the semi-automatic fine-tuning is activated.

Page

20

AP-75020, Rev. 1.0 - 18/12/98

Page 29

Preparing for a Job Operation Instructions MC-Series cutting plotters

SEMI-AUTOMATIC OFFSET ADJUSTMENT PROCEDURE

(Only if OFFSET MODE is set to

Fine Tune

)

1. Make sure the cutter is ready to start with a cutting job. Media has to be loaded and a

knife holder with well adjusted blade depth has to be available in the tool carousel.

2. Press

OFFSET

to initiate the offset procedure.

3. A menu will appear on the cutter display, indicating the BASE-OFFSET value. The

indicated value can range from 0.1 mm ( 0.004” ) to 1 mm ( 0.04” ).

*Offset Adjust*

TOOL: Knife1

À

Base: 0.50 mm

¿

Save with ENTER

4. Use the UP ¿ / DOWN À keys to set the correct BASE OFFSET value. This value is

indicated on the box in which the blades are packed. For the blades which are shipped

with the unit, this value is 0.50 mm ( 0.02” ).

5. Press ENTER to confirm the BASE OFFSET value. Press EXIT in case you want to

quit the offset adjustment procedure.

6. The cutter will now cut a series of test patterns with varying offset values.

If the base offset was set to 0.50 mm ( 0.02” ), the generated offsets will vary from 0.46

mm ( 0.018” ) up to 0.55 ( 0.022” ).

7. When the test cuts are completed, the cutter will advance the media for you to check

the patterns and to determine which of them gives best quality.

Especially look for good quality of the corners and closure of the circles.

Using the JOG-keys Õ/Ö you can move the TOOL-HEAD digitally to indicate the

square with the best quality. When the head is moved, the media is partially retracted,

but in such way that the test squares remain visible for the user.

The offset value is shown on the display:

Select best cut

JOG JOG

Õ

0.48 mm

Ö

Save with ENTER

8. Press ENTER to confirm the new settings. Press EXIT to quit the offset adjustment

procedure.

Page

21

AP-75020, Rev. 1.0 - 18/12/98

Page 30

Preparing for a Job Operation Instructions MC-Series cutting plotters

LIMITED OFFSET ADJUSTMENT PROCEDURE

(Only if OFFSET MODE is set to

To

perform

the

limited offset adjustment procedure

semi-automatic offset procedure

•

The

LIMITED OFFSET ADJUSTMENT PROCEDURE

OFFSET MODE is set to

.

Base Tune

Base Tune

.

follow

)

steps 1 to 5

from the

is only possible if the

Page

22

AP-75020, Rev. 1.0 - 18/12/98

Page 31

Preparing for a Job Operation Instructions MC-Series cutting plotters

PERFORMING A TEST

In your cutting/drawing plotter, two test plots have been integrated. Both of them are

available via the TEST button. Following tests are available:

•

Test Square :

•

DEMO-Cut :

To

perform one of the test plots

To perform a small test cut to check cutting force and offset.

To perform a test cut.

, please proceed as follows :

1. Load the media on which you will work into the plotter. The internal demo-cut is

automatically scaled, so the size of the media you load is not important in that case.

2. The plotter will only execute the plots if the correct tools are loaded into the stocker.

The plotter’s display will tell you which tools are to be loaded and where they should be

located in the stocker

3. Switch the plotter to OFF-LINE (ON-LINE LED should be OFF).

4. Press the TEST key

5. The display will change as follows :

DISPLAY

TEST MENU

Ð

SQUARE

Ï

ENTER to start

6. Using the ARROW-UP or ARROW-DOWN key, you can select between SQUARE and

DEMOCUT.

TEST SQUARE

The test square is very useful to check

cutting quality, cut force and offset

adjustment.

Please note that this test is intended for

media with backing. It should not be used

for tests on paper.

CUTTER TEST PLOT

Make sure that a knife is loaded into the tool

carousel.

7. Select TEST SQUARE 7. Select DEMO-CUT

Page

23

AP-75020, Rev. 1.0 - 18/12/98

Page 32

Preparing for a Job Operation Instructions MC-Series cutting plotters

8. Using the JOG-keys place the tool head

where you want the test square to be

located. In case you do not use the JOG

keys to indicate the position, the squares

you generate will be automatically

positioned, starting from the origin

position (Lower Right by default).

9. When pressing ENTER, a (new) test

square will be cut.

After generating a test square, you can

readjust FORCE settings and cut another

test square until the result is satisfactory.

8. When ENTER is pressed, cutting will

start. The following test plot will be cut.

Page

24

AP-75020, Rev. 1.0 - 18/12/98

Page 33

Preparing for a Job Operation Instructions MC-Series cutting plotters

FIXED KNIFE SYSTEM

When using thicker media such as sandblast or harder material such as reflective film, you

will get better cutting quality when using the

fixed knife system

To use the Fixed Knife System, you will need the fixing bracket which is part of your cutting

plotter’s accessories kit.

The procedure below explains how to start using the fixed knife option:

a) Let the cutting plotter finish the current job and verify that the tool in use is returned to

the stocker.

b) Switch the plotter into OFF-LINE mode (On-Line LED should be OFF) and open the

protective cover.

c) Press the TOOL button repeatedly, until the display shows that “FIXED” is selected.

d) Adjust the blade depth of the tool you are going to use.

.

e) Hold back the locking clip of the tool head and insert the knife holder in the tool head as

shown in the illustration (1). Verify that the tool collar fits nicely into the groove of the

tool head, as is shown in illustration (2) & detail drawing.

f) Insert the locking bracket into the tool head (3).

Page

25

AP-75020, Rev. 1.0 - 18/12/98

Page 34

Preparing for a Job Operation Instructions MC-Series cutting plotters

g) The bracket should hinge easily (4) and you should be able to close it and tighten the

screw (5) so that the tool is locked firmly into place.

h) The illustrations below show exactly at which height the tool should be inserted into the

head.

i) Press ENTER.

j) Now you can adjust FORCE, SPEED and OFFSET for the FIXED KNIFE tool.

k) You are now ready to use the FIXED TOOL option.

When you decide to stop using the FIXED TOOL OPTION, proceed

as follows:

•

Switch the plotter to Off-Line.

Page

26

AP-75020, Rev. 1.0 - 18/12/98

Page 35

Preparing for a Job Operation Instructions MC-Series cutting plotters

•

Open the protective cover, loosen and remove the locking screw.

Put it into a safe place for future use.

•

Remove the Tool (Knife) from the tool head.

•

Set a new Tool selection (Automatic, Knife 1,…) by pressing the

TOOL button.

•

Press ENTER.

•

Go back to On-Line.

Page

27

AP-75020, Rev. 1.0 - 18/12/98

Page 36

Understanding the Control Panel Operation Instructions MC-Series cutting plotters

UNDERSTANDING THE KEYBOARD & MENU

STRUCTURE

GUIDED TOUR AROUND THE KEYBOARD

In this section, we shall get acquainted with following items :

•

General description of each key.

•

Available menus.

•

The general concept of the keyboard.

•

The way to proceed when performing any of the necessary keyboard operations.

(;,7

3$*(

25,*,1

5(3/27

$/,*10(17

'$7$ 5(&(,9(

287 2) 5$1*(

3$5$0(7(5

25,*,1

$/,*10(17

'$7$ 5(&(,9(

287 2) 5$1*(

3$5$0(7(5

25,*,1

$/,*10(17

63(('

7(67

(17(5

21/,1(

)25&(

722/

2))6(7

5(6(7

Page

28

AP-75020, Rev. 1.0 - 18/12/98

Page 37

Understanding the Control Panel Operation Instructions MC-Series cutting plotters

N° Key Description

1. ENTER

2. EXIT

3. UP / NEXT

4. DOWN / PREVIOUS

To

confirm actions

settings

.

, requested changes and

store new

To enter a next menu level when changing settings.

To

cancel actions

To

increase values

the next item

To

decrease values

select the previous item

or

return to previous menu levels

during adjustment procedures or

in a list of available items.

during adjustment procedures or

in a list of available items.

.

select

5. ONLINE

6. REPLOT

The ON-LINE button is used to switch between the ON-

LINE and the OFF-LINE mode of your plotter.

Possible actions from the user in ON-LINE mode are:

setting a new origin

•

initiating a sheet-off action

•

Furthermore the JOG-keys are activated and the

RESET/CLEAR function is available.

In OFF-LINE mode the user has the possibility to alter all

possible cutter settings.

In case multiple copies of a specific design are needed,

you can use the replot function.

This function will replot the last set of data which was sent

to the cutting plotter.

Page

29

AP-75020, Rev. 1.0 - 18/12/98

Page 38

Understanding the Control Panel Operation Instructions MC-Series cutting plotters

y

g

j

y

y

j

j

g

7. PAGE

8. SPEED

9. FORCE

10. TOOL

The

PAGE ke

manual or automatic sheet-off function

is used to

initiate the media feed

.

and the

(Sheet-off only works with a knife installed in stocker

position 8)

Gives

Gives

The

direct access to speed functions

direct access to force functions

TOOL key

has a

double function:

.

.

11. TEST

12. OFFSET

•

It allows the user to specify

plotter has to use.

•

During

select the tool t

adjustment

Gives

The

ad

ustment procedures

pe for which you want to make the

.

direct access to test cut/plot functions.

OFFSET ke

gives

direct access to knife offset

adjustment.

To

perform offset ad

ustment

BASE TUNE & FINE TUNE

•

Base tune

allows a

limited ad

typical blade offset.

which tool the cuttin

, the tool key is used

you can

select between

.

ustment

, only setting the

to

•

Fine tune

is

a semi-automatic fine-tunin

. In this

mode, the plotter automatically creates test patterns with

different offsets allowing the user to choose the best

result.

Page

30

AP-75020, Rev. 1.0 - 18/12/98

Page 39

Understanding the Control Panel Operation Instructions MC-Series cutting plotters

g

y

g

guag

g

g

13. RESET Resets all parameters

14. SETTINGS

The

settin

s ke

allows the user to view or

number of special settings

when setting up the cutting plotter for the first time or when

reconfiguring the plotter for a special application.

The settings are divided in 4 groups:

Communication:

To view and/or modify the serial

communication settings.

Default 1, Default 2, Default 3, Default 4,

(

Default 5, User Defined

Lan

To view and/or modify the plotter

e:

graphics language emulation settings.

MH-GL : Plot Unit, VS-AS-FS, Bézier

(

Error or MC-GL

and

clears the buffer

chan

, most of which are only used

).

)

.

e a

15. ORIGIN

Miscellaneous:

To view and/or plot all the cutting plotter’s

system settings and internal information.

Settings Plot, Initialisation, Firmware

(

General Settin

To view and/or fine-tune specific settings

s:

which influence the plotter’s reactions to

commands or tasks sent by the computer

or initiated via the control panel.

Page Mode, Sheeting Off, Default

(

Origin, Smoothing, Front Clip, Offset

Adjust, Alignment, Plot Mode, Dot Space,

Dash Space, Dash line, Speed Control,

PG, FR, EC, AF/AH, NR, Axis Mode, IP

convert, Roll limit, Buzzer setting

•

The

ORIGIN

can start cutting on the media

determines the

position where the plotter

. By default, the origin is

located at the lower right.

•

The

ORIGIN

point, if media has been loaded

key allows the user to

. A new ORIGIN point

re

ister a new origin

can be set in OFF-LINE as well as in ON-LINE mode.

)

)

Page

31

AP-75020, Rev. 1.0 - 18/12/98

Page 40

Understanding the Control Panel Operation Instructions MC-Series cutting plotters

y

y

16. JOG-keys

17. SHUFFLE

18. ALIGNMENT

•

The

JOG-ke

are

s

always active

(ON-LINE / OFF-LINE

/ protective cover open / closed).

•

The

JOG-ke

tool head and the media

enable the user to

s

. This can be necessary in

manually move the

order to examine specific details of the sign or to set a

new origin.

•

Please note that in case no media is loaded, only the

Õ

(Left) and Ö (Right) Jog keys will be active.

Gives direct access to the cutter’s media pre-feed / page

length and media pull-off speed settings.

The alignment feature allows the user to (retro)fit media

into the plotter, either to finish a design which was started

before or to continue working on media that was pre-printed

on another unit, possibly an inkjet machine.

There are 2 possible alignment routines which can be

used on your plotter. They are called 3-point alignment and

2-point alignment.

By factory default, 3-point alignment is enabled.

19. ON-LINE LED Lights up when the cutter is ON-LINE.

Blinks when going OFF-LINE.

20. DATA RECEIVE LED Lights up when data is coming in.

21. OUT OF RANGE LED Lights up when the tool head is being moved beyond the

media with the JOG-keys or when data is sent beyond

the plotting / cutting area.

22. PARAMETER LED

Reserved for future use.

23. ORIGIN LED Lights up when the origin is set manually.

24. ALIGNMENT LED Lights up when internal alignment is activated.

Page

32

AP-75020, Rev. 1.0 - 18/12/98

Page 41

Understanding the Control Panel Operation Instructions MC-Series cutting plotters

KEYBOARD CONCEPT

In order to limit the amount of keystrokes to perform plotter adjustments directly from the

keyboard, your plotter control panel has been equipped with a number of keys, each one of

them giving direct access to a specific function or parameter.

To change parameter values, proceed as follows :

1. Press the key which corresponds to the function or parameter you wish to alter.

2. A menu will appear which is built up as indicated in the examples below :

¿

À

MENU TITLE

Item / Parameter

Value

Exit Message

¿

À

a)

b)

c)

d)

À

MENU TITLE

Item / Parameter

Value

Exit Message

¿

a) The menu title shows the menu currently activated. The available menus are shown

in the diagrams on the following pages.

b) The second line of the display will show the selected item or parameter. In case

more than one item or parameter is available, you can select the next item with the

UP-key.

c) The current value or setting is shown in the third line. It can be altered using the

DOWN-key. In case only one item or parameter is available for the selected menu,

you will be able to alter the current setting/value by using both the UP & DOWN

keys.

d) Always press ENTER to confirm the requested changes or EXIT to quit the menu

without changing any values.

Page

33

AP-75020, Rev. 1.0 - 18/12/98

Page 42

Understanding the Control Panel Operation Instructions MC-Series cutting plotters

MENU STRUCTURE - OVERVIEW

On the next pages you will find a

operating modes. The three modes which we distinguish are :

•

REMOTE MODE

•

•

Primary menus

panel. In the menu organisation chart, they are indicated by the drop-shadowed boxes.

Secondary menus, items and / or settings

À

(previous) keys. In the menu organisation chart, they are indicated by the regular boxes.

are directly accessible by pressing one of the function keys on the control

Primary menu

accessible by pressing the

corresponding key.

OFF

OFF

-

-

LINE

LINE

menu organisation chart

: Media loaded and cutter

with no

with

, directly

media loaded

media loaded

, if any, are available using the ¿(next) /

.

.

for each of the 3 available

On-Line

Secondary menu

available menu items,

submenus or functions.

.

,

R emote M od e

( M edia Load ed / C utter O n-Lin e )

* O N - LINE *

PAGE

ORIGIN

JOG

Jog - Left Jog - Right

Jog - U p Jog - Down

RESET

ON - LINE

Page

34

AP-75020, Rev. 1.0 - 18/12/98

Page 43

Understanding the Control Panel Operation Instructions MC-Series cutting plotters

OFF-LINE WITH NO MEDIA LOADED

* OF F - LIN E *

No Media Loaded

Leng th Sp eed

Sp eed Tool

Force Tool

PAGE

SHUFFLE

SPEED

FORCE

SETTINGS

Communication

De fau lt 1 ... 5

Us er D efine d

Lan guag e

MH - G L ( H P G L / 2 )

Plot Unit

VS-AS-FS

Bézier Error

PG

FR

EC

AF/AH

NR

AXIS Mod e

IP C onver t

Slow Down Mode

Roll Limit Mode

TOOL

SETTINGS

Communication Language

Miscellaneou s General Settings

RESET

JOG - KEYS

Jog - Left Jog - Right

MC - G L

Miscellaneous

Se tting s Plo t

In it ial is at io n

Version

General Settings

Page Mode

Sheeting O ff

De fau lt O rig in

Smoothin g

Front Clip

O ffse t Ad ju st

Alignment

Plot Mode

Dot Space

Dash Space

Dash Line

Speed Control

Beeper

Init ial Mo de

Knife Align Pos

Rollup Device

Frame Len g th

Page

35

AP-75020, Rev. 1.0 - 18/12/98

Page 44

Understanding the Control Panel Operation Instructions MC-Series cutting plotters

OFF-LINE WITH MEDIA LOADED

* O F F - LIN E *

Media Loaded

PAGE

SHUFFLE

Leng th Speed

SPEED

Speed Tool

FORCE

Force Tool

TOOL

SETTINGS

Communication Language

SETTINGS

Communication

De fau lt 1 ... 5

Us er D efine d

Lan guag e

MH - G L ( H P G L / 2 )

Plot Unit

VS-AS-FS

Bézier Error

PG

FR

EC

AF/AH

NR

AXIS Mod e

IP C onver t

Slow Down Mode

Roll Limit Mode

Miscellan eous General Settings

RESET

JOG - KEYS

Jog - Left Jog - Righ t

Jog - Up Jog - Down

ORIGIN

ALIGNM ENT

TEST

Democut Square

OFFSET

REPLO T

ON - LINE

MC - G L

Miscellaneous

Se tting s Plo t

In it ial is at io n

Version

General Settings

Page Mode

Sheeting O ff

De fau lt O rig in

Smoothin g

Front Clip

O ffse t Ad ju st

Alignment

Plot Mode

Dot Space

Dash Space

Dash Line

Speed Control

Beeper

Init ial Mo de

Knife Align Pos

Rollup Device

Frame Len g th

Page

36

AP-75020, Rev. 1.0 - 18/12/98

Page 45

Understanding the Control Panel Operation Instructions MC-Series cutting plotters

OVERVIEW GENERAL SETTINGS

In the following table you will find an overview of the General Settings.

Table : General Settings

Parameter Available settings & defaults

Page Mode

Sheeting Off

Default Origin

Smoothing

Front Clip

Offset Adjust

Alignment

Plot Mode

Dot Space

Dash Space

Dash line

Speed Control

PG

FR

Mode 1 Mode 2

LR

Mode 0

Enabled

Disabled

LL UR UL Centre

OFF

10 mm

50 mm 100 mm

Base-Tune

2-Point Method

Solid

1 mm 2 mm 3 mm 4 mm

0.1

0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0

5 mm

6 mm 7 mm 8 mm 9 mm 10 mm

1mm ➪ 100 mm adjustable per mm. Default is

HIGH MEDIUM

OFF

OFF

ON

Fine-Tune

3-Point Method

Dashed

10 mm

LOW

ON

ON

EC

AF / AH

NR

AXIS Mode

OFF

PLOTTER

IP convert

Roll Limit

UNLIMITED

Buzzer

OFF

OFF

HPGL2

OFF

ON

(Bold values = factory defaults)

Page

37

ON

ON

MUTOH

CUTTER

ON

SHUFFLE LENGTH

OFF

AP-75020, Rev. 1.0 - 18/12/98

Loading...

Loading...