Page 1

Service

Manual

For machine versions:

A1, A2, A3 and A4

Based on firmware version 3.0.0

& Mutoh CutServer version 3.0.0

For service technicians only!

Page 2

Page 3

Service manual Kona cutting plotter

Copyright notice

COPYRIGHT © 27/4/10 Mutoh Europe nv All rights reserved.

Mutoh Europe nv reserves the right to modify the information contained in this manual at any

time without prior notice.

This document may not be reproduced by any means, in whole or in part, without written

permission of the copyright owner.

Mutoh furnished this document to support the Kona cutting plotter series. In consideration of

the furnishing of the information contained in this document, the party to whom it is given,

assumes its custody and control and agrees to the following:

The information herein contained is given in confidence, and any part thereof shall not be

copied or reproduced without written consent of Mutoh Europe nv

This document or the contents herein under no circumstances shall be used in the

manufacture or reproduction of the article shown and the delivery of this document shall not

constitute any right or license to do so.

AP-74380 - Revision 1.0 3

Page 4

Service manual Kona cutting plotter

Parts replacement summary

The Service manual contains all necessary replacement procedures for every spare part

available for the Kona. Though, when replacing parts it might be possible that there are

additional actions necessary.

Please find below an overview:

1. Pen head replacement page44

Perform Y-Z measurement (diagnostics) page93

Adjust sheeting-off knife position page91

Perform EPOS calibration page103

2. Mainboard replacement page67

Before mainboard replacement

Take back-up parameters using the Mutoh CUTserver page98

After mainboard replacement

Uninstall and reinstall USB drivers on PC page96

Load firmware via USB. page94

Restore back-up parameters using the Mutoh CUTserver page99

If there are no back-up parameters available, you have to do the

following:

Calibrate X and Y distance accuracy using the Mutoh CUTserver page102

Perform Y-Z measurement (diagnostics) page93

Perform EPOS calibration page103

3. Y-motor or Y speed reduction belt replacement page35

Adjust speed reduction belt to 3.5 kg page87

4. X-motor replacement page33

Adjust belt tension to 3.5 kg page86

5. Pressure roller assembly replacement page61

Adjust pressure of pressure rollers to 5,5 kg page90

4 AP-74380 - Revision 1.0

Page 5

Service manual Kona cutting plotter

Table of contents

Chapter 1 Regulations and safety information . . . . . . . . . . . . . 9

1.1 Warnings, cautions and notes . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.2 Compliance with the following regulations . . . . . . . . . . . . . . 10

1.3 Important notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.4 Safety labels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Chapter 2 Product overview . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.1 Dimensions machine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.2 Installation environment requirements . . . . . . . . . . . . . . . . . . 14

Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Ambient conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Room conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.3 Part names and functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.4 Overview operation panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Main menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Settings or actions menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Adjust value menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.5 Menu overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

User mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Diagnostics mode 1 and 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2.6 Machine version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

AP-74380 - Revision 1.0 5

Page 6

Service manual Kona cutting plotter

Chapter 3 Part replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.1 Cover removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Side covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Y-rail cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Penhead cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Front platen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Rear platen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

3.2 X-motor and drive belt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

3.3 Y-motor assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Exploded view. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Y-motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Y-drive pulley and speed reduction belt . . . . . . . . . . . . . . . . . . . . . . 38

Y-return pulley . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

3.4 Penhead assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Exploded view. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Penhead FFC (flexible flat cable). . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Penhead assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Penhead drive belt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Sheet-off mechanism. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

EPOS sensor block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Y-origin flex PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

3.5 Grit shaft. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Exploded view. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Grit shaft and support rollers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

3.6 Pressure roller assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Exploded view. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Pressure roller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Pressure roller assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

3.7 Cutting mat. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

6 AP-74380 - Revision 1.0

Page 7

Service manual Kona cutting plotter

3.8 Electronics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Mainboard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

X and Y motor fuse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Penhead PCB. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Touchscreen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Vacuum fans. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Chapter 4 Adjustments and calibrations . . . . . . . . . . . . . . . . . 85

4.1 Mechanical adjustments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

X drive belt tension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Y drive belt tension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Penhead drive belt tension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Pressure roller pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Sheeting-off knife position. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

YZ measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

4.2 Software and drivers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Download latest software and drivers . . . . . . . . . . . . . . . . . . . . . . . . 94

Firmware installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

How to uninstall the USB drivers . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

How to install the USB drivers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

USB icon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

4.3 Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Backup parameters of machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Restore parameters of machine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

4.4 Mutoh CutServer tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Tracking test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

XY-distance accuracy test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

4.5 EPOS calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

AP-74380 - Revision 1.0 7

Page 8

Service manual Kona cutting plotter

Chapter 5 Diagnostics mode . . . . . . . . . . . . . . . . . . . . . . . . . . 105

5.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

5.2 How to start up in diagnostics mode 1 and 2 . . . . . . . . . . . . 106

Diagnostics 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Diagnostics 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

5.3 Menu overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Encoder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

PWM test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Defaults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

YZ profile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Tool Force . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Actuators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Aging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Chapter 6 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

6.1 Troubleshooting when no error is displayed . . . . . . . . . . . . 122

General troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Recoverable error messages with no error ID number. . . . . . . . . 126

6.2 Troubleshooting when an error is displayed . . . . . . . . . . . . 128

Errors with error number (ID 1009-6115) . . . . . . . . . . . . . . . . . . . . 128

Contourcutting errors and warnings (ID 6201-6271). . . . . . . . . . . 131

MGL errors (ID 4000-5000) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

BREVID_ERROR_HW_REVISION (6110-6120) . . . . . . . . . . . . . 139

FPGA ERRORS (6140 - 6150) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

RAM ERRORS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Other errors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

8 AP-74380 - Revision 1.0

Page 9

Service manual Kona cutting plotter

Regulations and safety information

Chapter1 Regulationsand

safetyinformation

Warnings, cautions and notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Compliance with the following regulations . . . . . . . . . . . . . . . . . . . . . . . 10

Important notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Safety labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1

AP-74380 - Revision 1.1 9

Page 10

Service manual Kona cutting plotter

Regulations and safety information

1.1 Warnings, cautions and notes

Safety terms in this manual and the contents of warning labels attached to the cutter are

categorized into the following three types, depending on the degree of risk (or the scale of

accident).

Read the following explanations carefully and follow the instructions in this manual.

Safety terms Details

Important Must be followed carefully to avoid death or serious bodily injury.

Caution

Notes

Must be observed to avoid bodily injury (moderate or light) or damage to

your equipment.

Contains important information and useful tips on the operation of your

cutter.

1.2 Compliance with the following regulations

The CE marking is a mandatory European marking for certain

product groups to indicate conformity with the essential health and

safety requirements set out in European Directives.

By affixing the CE marking, the manufacturer, his authorized

representative, or the person placing the product on the market or

putting it into service ensures that the item meets all the essential

requirements of all applicable EU directives and that the applicable

conformity assessment procedures have been applied.

This product is tested and approved by the Canadian Standards

Association (CSA), this to provide increased assurance of quality and

safety.

The product is tested according to IEC60950.

This standard tries to cover all safety aspects.

Mechanical, electrical

Choice of components

Choice of materials: flammability!

Connectors, cables …

Fire enclosure

…

This means the product is safe for users, service personnel and

production personnel.

CSA International certification is not a legal commitment but it

assures the quality and safety of the machine.

10 AP-74380 - Revision 1.1

Page 11

Service manual Kona cutting plotter

Regulations and safety information

Your product is designed and manufactured with high-quality

materials and components, which can be recycled and reused.

When this crossed-out wheeled bin submenu is attached to a

product, it means the product is covered by the European Directive

2002/96/EC - WEEE regulation.

Please inform yourself about the local separate collection system for

electrical and electronic products.

Please act according to local rules and do not dispose of your old

products with your normal household waste. The correct disposal of

your old product will help prevent potential negative consequences

for the environment and human health.

This equipment has been tested and found to comply with the limits

for a Class A digital device, pursuant to Part 15 of the FCC Rules.

These limits are designed to provide reasonable protection against

harmful interference when the equipment is operated in a commercial

FCC

ICES

environment. This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance with

the instruction manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is

likely to cause harmful interference in which case the user will be

required to correct the interference at his own expense.

This Class A digital apparatus complies with Canadian ICES-003.

1.3 Important notes

1

This machine has a double pole / neutral fusing.

Technical problems and maintenance, which require the cutter to be opened, can only be

done by qualified personnel who were trained to repair this type of machine.

Unauthorized removing of covers and/or overruling safety locks can be dangerous and will

result in your guarantee becoming void.

After powering OFF the machine, wait at least 10 seconds before powering ON again. Not

respecting this time interval could damage the machine.

The cutter must be connected to an earthed mains socket-outlet.

AP-74380 - Revision 1.1 11

Page 12

Service manual Kona cutting plotter

Regulations and safety information

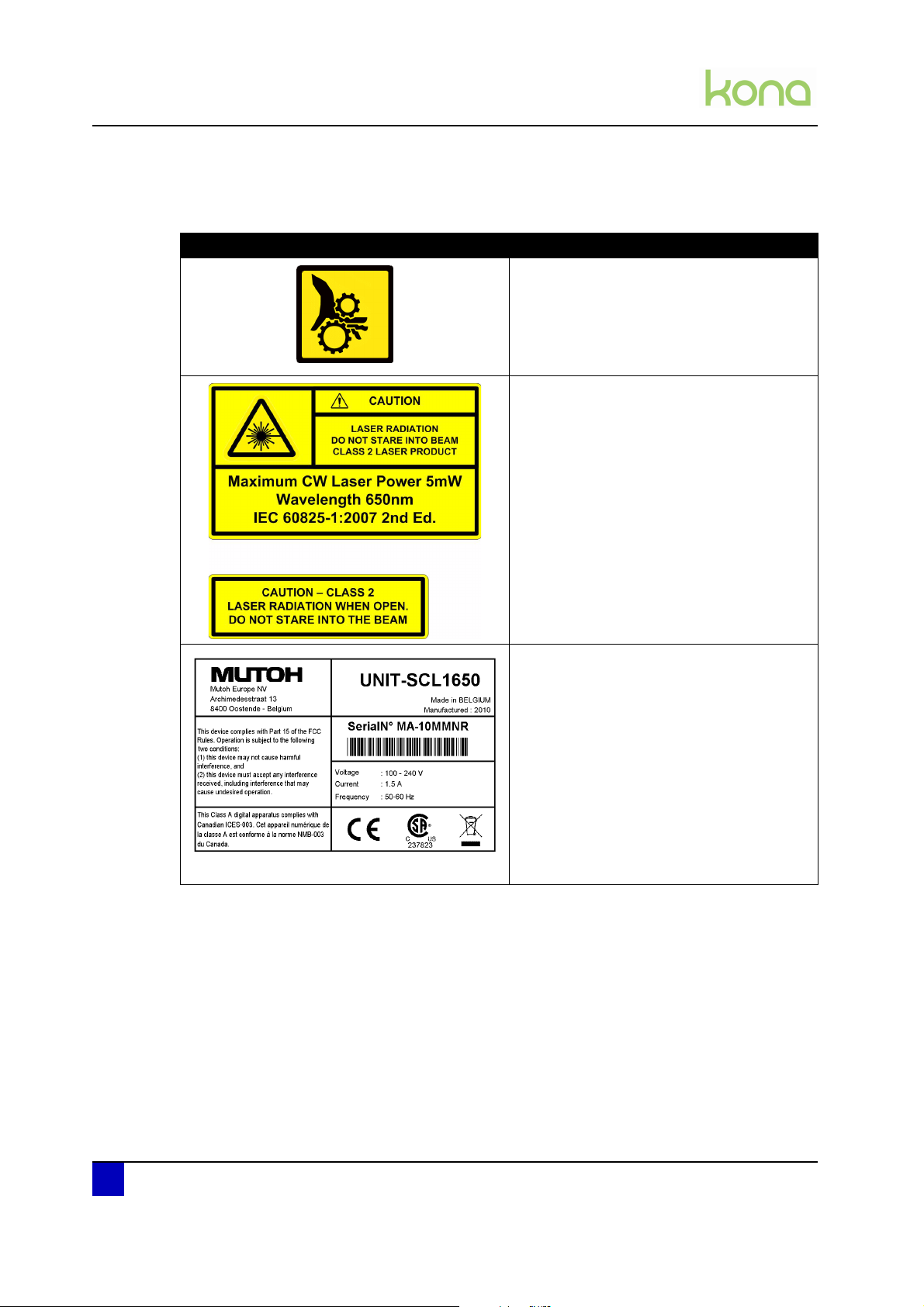

1.4 Safety labels

Label Description

Be careful not to get stuck between the

following moving parts:

Cutting head

Grit rollers

Be sure not to stare in the laser mounted

on the cutting head.

Serial number label providing you the

following information:

Serial number

Unit name

Power supply requirements

Regularisations

Class A product

Address Mutoh Europe n.v.

12 AP-74380 - Revision 1.1

Page 13

Service manual Kona cutting plotter

Product overview

Chapter 2 Product overview

Dimensions machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Installation environment requirements . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Ambient conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Room conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Part names and functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Overview operation panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2

Main menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Settings or actions menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Adjust value menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Menu overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

User mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Diagnostics mode 1 and 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Machine version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

AP-74380 - Revision 1.1 13

Page 14

Service manual Kona cutting plotter

Humidity (%)

10 16 32 35

35

70

75

Product overview

2.1 Dimensions machine

Kona 760 Kona 1400 Kona 1650

Width 1200 mm / 47,2” 1850 mm / 72,8” 2090 mm / 82.3”

Depth 260 mm / 10,2” 490 mm / 19,3” 490 mm / 19,3”

Height 275 mm / 10,8” 1150 mm / 45,3” 1150 mm / 45,3”

Weight (options excl.) 21 kg / 46,3 lb 48 kg / 105,8 lb 52 kg / 114,6 lb

Weight (options incl.)

Media support rolls

Media basket

Roll off system

40 kg / 88,9 lb 56 kg / 123,5 lb 63 kg / 138,9 lb

2.2 Installation environment requirements

2.2.1 Power supply

Voltage 100-240 V AC

Current 1,5 A

Frequency 50-60 Hz

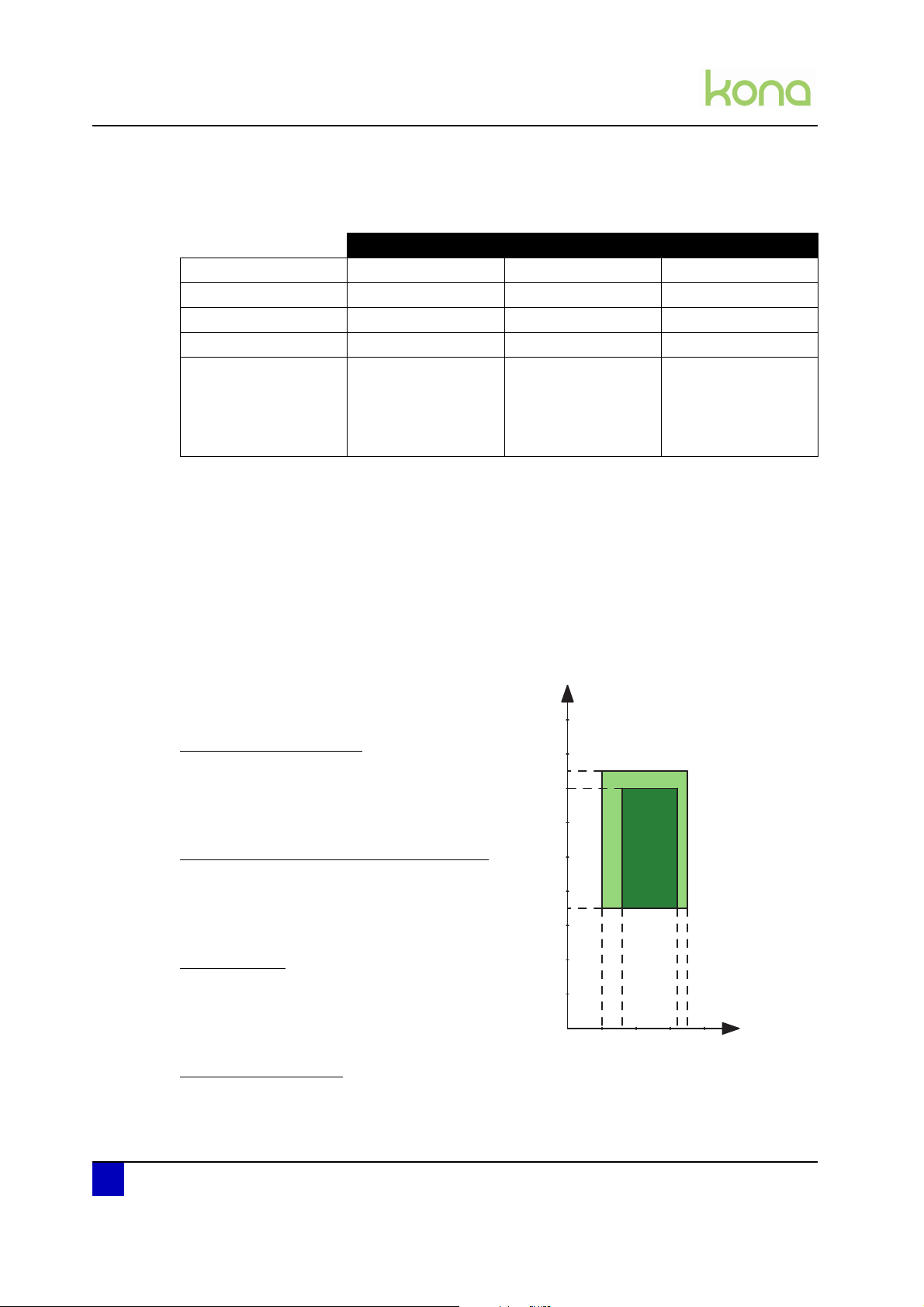

2.2.2 Ambient conditions

Operation environment

Temperature: 10°C - 35°C

Humidity: 35% - 75% non-condensing

Recommended environment (dark area)

Temperature: 16°C - 32°C

Humidity: 35% - 70% non-condensing

Variation rate

Temperature: 2°C per hour

Humidity: 5% per hour

T(°C)

Storage environment

Temperature: 0°C - 50°C

14 AP-74380 - Revision 1.1

Page 15

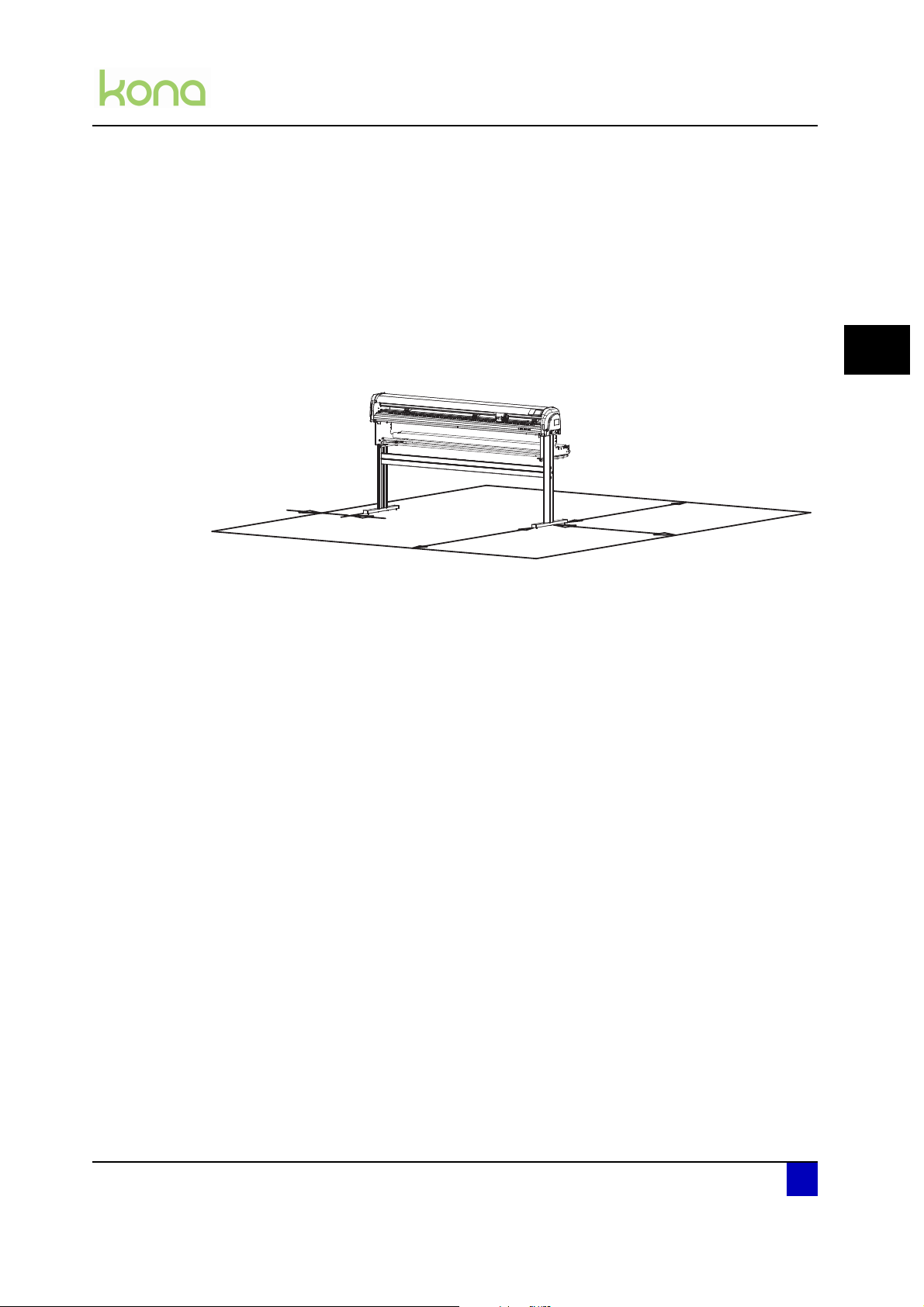

2.2.3 Room conditions

a

b

c

d

Please protect your cutter from moisture, dust, draughts and direct sunlight (to prevent

possible media detection and epos readout issues). It is best to keep your machine away

from open windows and air-conditioners.

See to it that there is an adequate space around the cutter so that ventilation is not

obstructed.

Avoid unnecessary vibrations and set up your cutter on a level surface.

Be sure to have some free space on each side of the Kona to ease the operating of it.

Service manual Kona cutting plotter

Product overview

2

a = at least 1 meter

b = at least 1 meter

c = at least 1 meter

d = at least 0,2 meter

AP-74380 - Revision 1.1 15

Page 16

Service manual Kona cutting plotter

Product overview

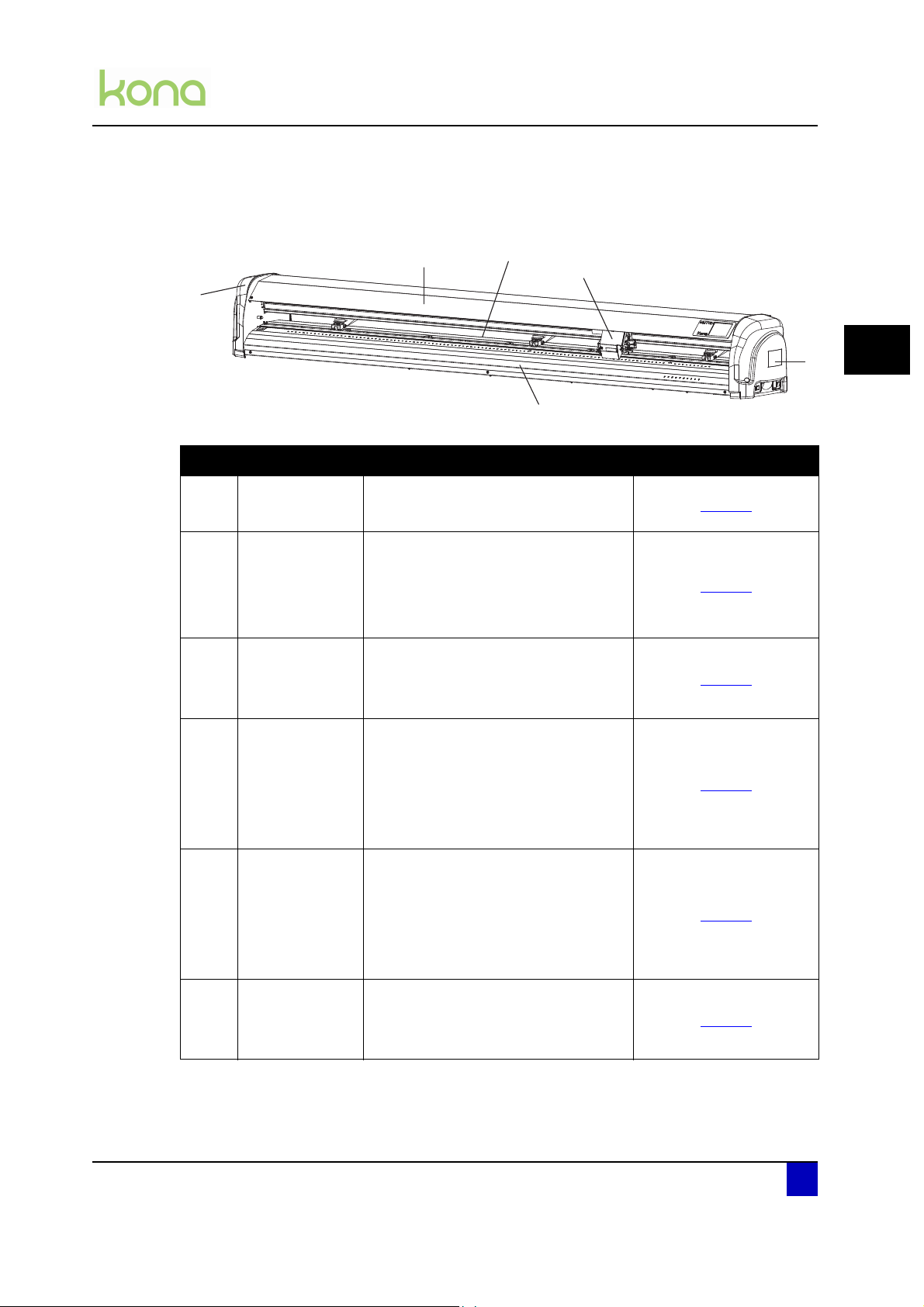

2.3 Part names and functions

N° Description Extended description

1 Pressure rollers To push the media against the grit rollers

2 Media guide

3 Cutting mat

4 Grit rollers

5 Control panel touch screen To make various settings before and during cutting

6 Cutting head

7 USB inlet To connect the USB cable

8 Power inlet and power switch To connect the power cable and power on the unit

9 Roll conveyor To support and roll-off the vinyl

10 Stand and wheels To move the cutter easily

11 Media bag To collect the media when sheeting off

12 Roll-off system To roll-off pre printed vinyl

A guiding platform with vacuum fans to transport

the media as flat as possible during cutting

Provides a reliable cutting surface and minimizes

damage to the knife tip

Rollers with a granular surface to move the media

front and backwards

Assembly of cutting knife, sheet-off mechanism and

EPOS sensor

13 Pressure roller lever To lower and raise the pressure rollers

16 AP-74380 - Revision 1.1

Page 17

2.4 Overview operation panel

2.4.1 Main menu

Service manual Kona cutting plotter

Product overview

2

N° Description Extended description

1 Settings button Open the settings menu 1/4

2 Actions button Open the actions menu 1/2

This icon will appear as from the

3 USB indication

4 Play / pause button Pause or resume a job

5 Cancel button Cancel a job

moment the Kona is connected via USB

to the computer AND the correct drivers

are installed.

AP-74380 - Revision 1.1 17

Page 18

Service manual Kona cutting plotter

Product overview

2.4.2 Settings or actions menu

N° Description Extended description

1 Home button Go back to the home menu (the menu shown above)

2 Settings button Open the settings menu 1/4

3 Actions button Open the actions menu 1/2

4 Back / cancel button Go back to the previous menu in the hierarchy

5 Previous button Go back to the previous page within a menu level

6 Next button Go to the next menu page within a menu level

7 Menu button Open the respective menu

18 AP-74380 - Revision 1.1

Page 19

2.4.3 Adjust value menu

Service manual Kona cutting plotter

Product overview

2

N° Description Extended description

1 Home button Go back to the home menu (the menu shown above)

2 Settings button Open the settings menu 1/4

3 Actions button Open the actions menu 1/2

4 Back / cancel button

5 Numeric keyboard Type the requested set value

6 Save button Save the new value

7 Decrease button Decrease the value with one digit

8 Increase button Increase the value with one digit

9 Erase button Delete the last digit

10 Erase all button Erase the complete value

Go back to the previous menu in the hierarchy and/or cancel

the settings change

Note

It is impossible to exceed a maximum value. The cutter will beep twice if you

try.

The value will be displayed in blue when the chosen value is smaller than the

minimum value.

AP-74380 - Revision 1.1 19

Page 20

Service manual Kona cutting plotter

Product overview

2.5 Menu overview

2.5.1 User mode

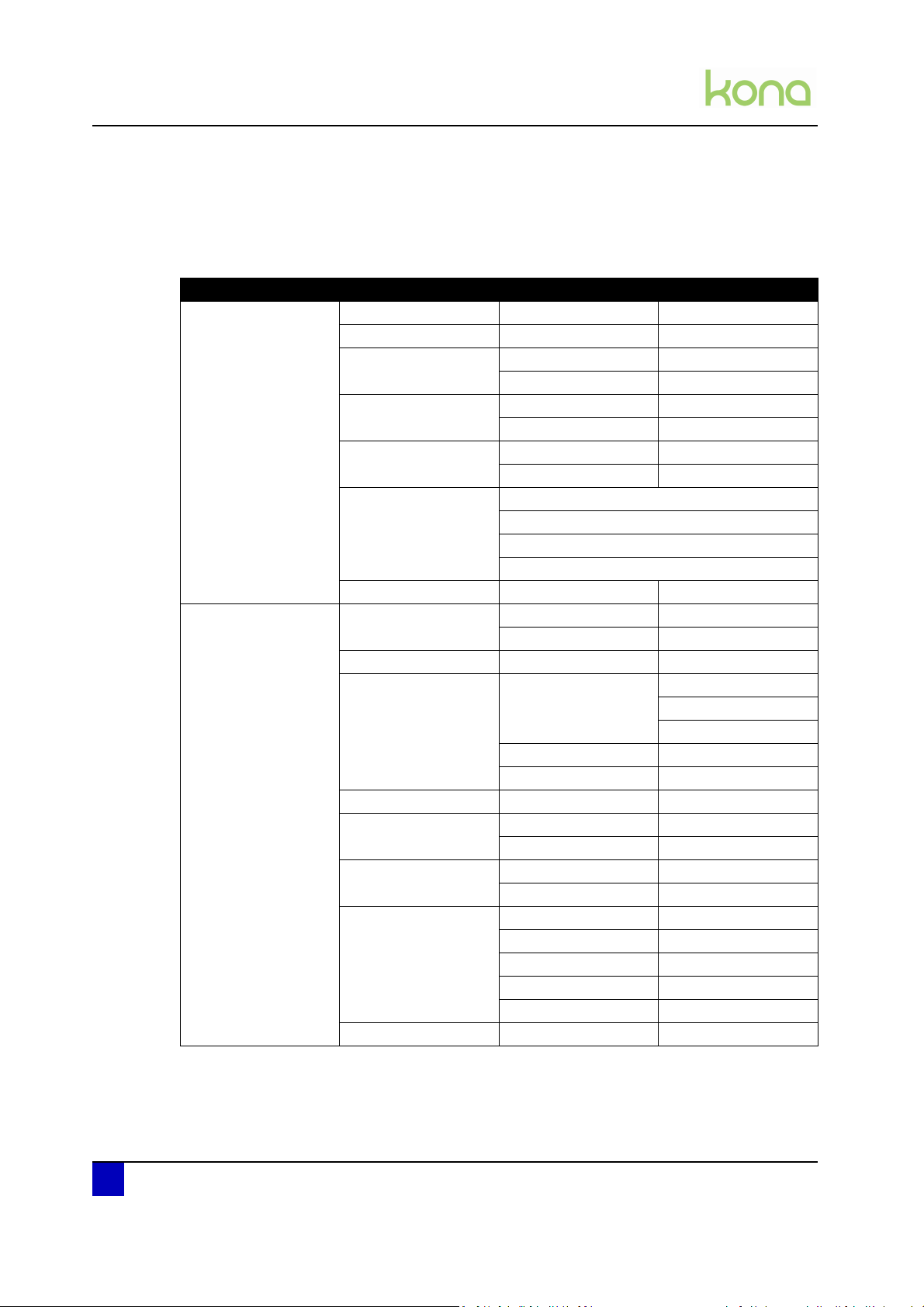

Main menu Sub menus BOLD = default value

Settings 1/4 Velocity Tool down 1 - 60 -100 cm/s

Offset Offset 0.1 - 0.5 - 1 mm

Force Force 20 - 100 - 450 g

To ol Drag knife

Load mode With front

Load Length 100 - 1000 - 10000 mm

Settings 2/4 Smoothing On

Prefeed 0 - 1000 - 10000 mm

Sheet off Mode Automatic

Max. length 0 - 2000 - 10000

Job Focus Accuracy

Auto shuffle On

Origin Center

Page Mode 0 - 1 - 2

Tool up 1 - 100 cm/s

Te st

Te st

Pen

Without front, uneven media

With front, uneven media

Without front

Off

Manual

Disabled

Margin 1 - 5 - 250 mm

Velocity 10 - 60 - 100 cm/s

Speed

Off

Lower right

Lower left

Upper right

Upper left

20 AP-74380 - Revision 1.1

Page 21

Service manual Kona cutting plotter

Product overview

Main menu Sub menus BOLD = default value

Settings 3/4 Epos Alignment Automatic

Manual

Language English

Greek

Polski

Portugues

Italiano

Espanol

Deutsch

Francais

Nederlands

Protocol Emulation HPGL2

HPGL

MHGL2

MHGL

VS/ZF/AS Accept

Ignore

Resolution 0.010 mm

0.025 mm

Swap Alert Singletool / multitool

Cut Through Velocity 1 - 15 - 100 cm/s

Force 20 - 250 - 450 g

Te st

Up Distance 0.1 - 2.0 mm

Down Distance 0 - 10 - 100 mm

Epos Alignment Automatic

Manual

Settings 4/4 Diagnostics

Screen Beep Off

Defaults Yes / No

Information Firmware

User

Refer to Diagnostics mode 1 and 2 on page23

On

Contrast 0 - 25 - 40%

Brightness 0 - 50 - 100%

Animation Wait Time

Play

Machine

Company

2

AP-74380 - Revision 1.1 21

Page 22

Service manual Kona cutting plotter

Product overview

Main menu Sub menus BOLD = default value

Actions 1/2 Jogging

Actions 2/2 Copies 0 - 1 - 100

Origin

Cut Through Trim poster Length

Width

Contour Cut Multi frame Single scan

Repeat mode

Single frame Single scan

Repeat mode

Manual Length

Width

Direction

EPOS Read

Sheet-off Yes / No

22 AP-74380 - Revision 1.1

Page 23

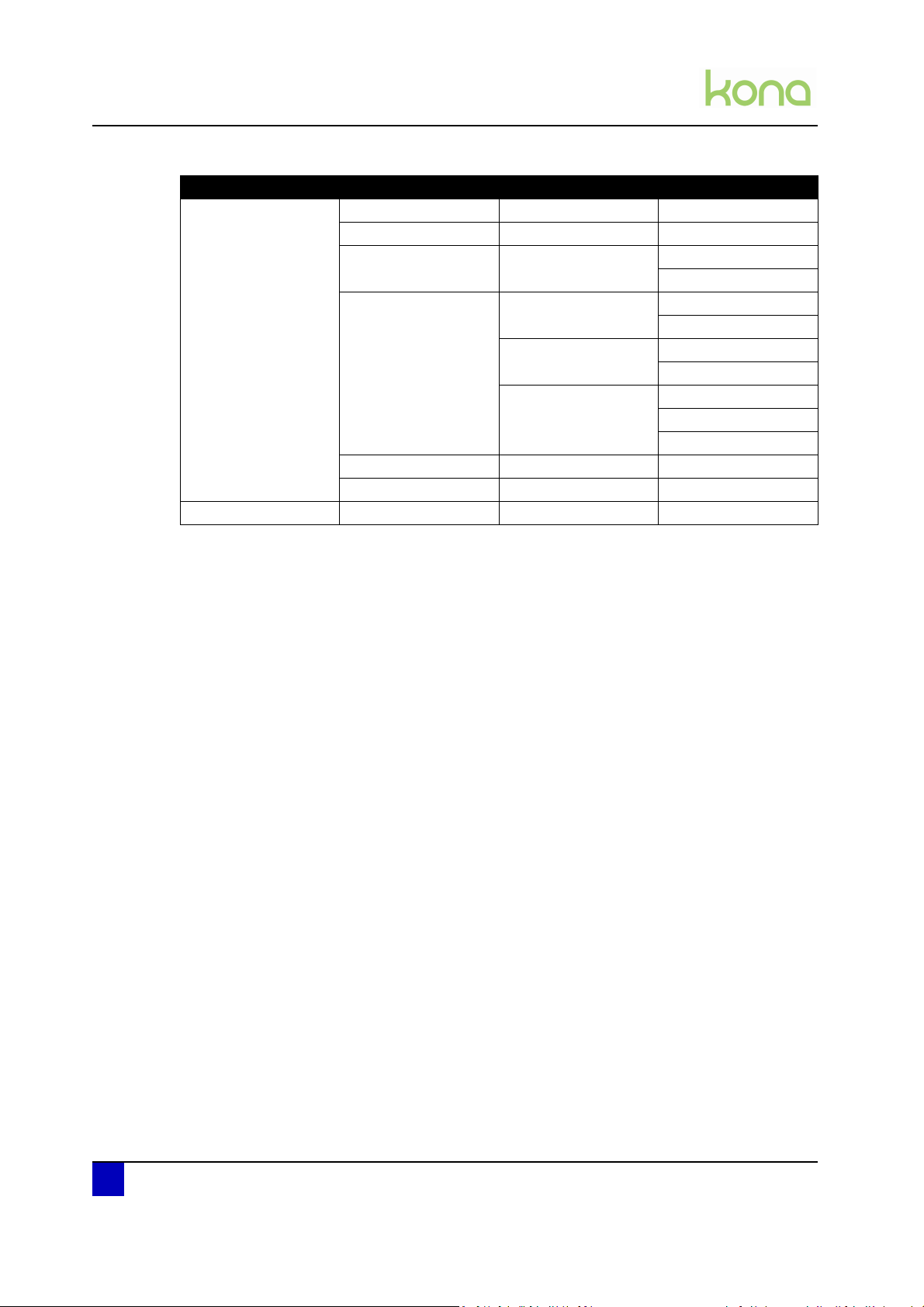

2.5.2 Diagnostics mode 1 and 2

Refer to Diagnostics mode on page105 for further details.

Connection

Encoder

PWM test

Defaults

Accuracy

Machine

X

Y

X

Y

Z

X

Y

Z

User

X

Y

Service manual Kona cutting plotter

Product overview

Availability

Diagnostics 1 Diagnostics 2

2

Too l Fo rc e

Actuators

Sensors

Aging

Screen

YZ profile

Measure

Verify

Laser

Fan

Buzzer

Leds

Media front left

Media front right

Media rear

Lever

Pinch flap

Dip switches

XY voltage

EPOS

Tool

Sheet off

Cut through

VCM

Touchfield

AP-74380 - Revision 1.1 23

Page 24

Service manual Kona cutting plotter

Product overview

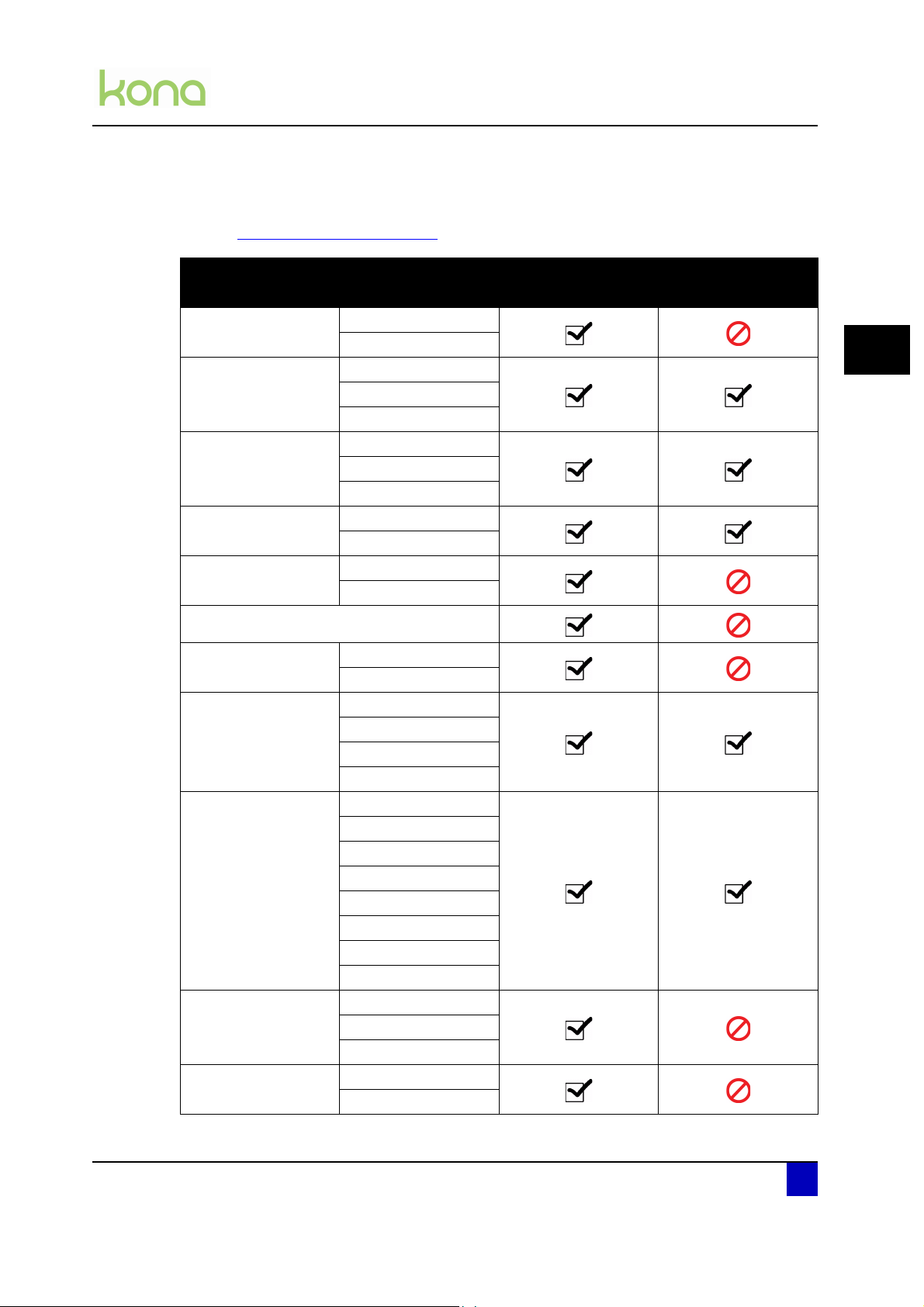

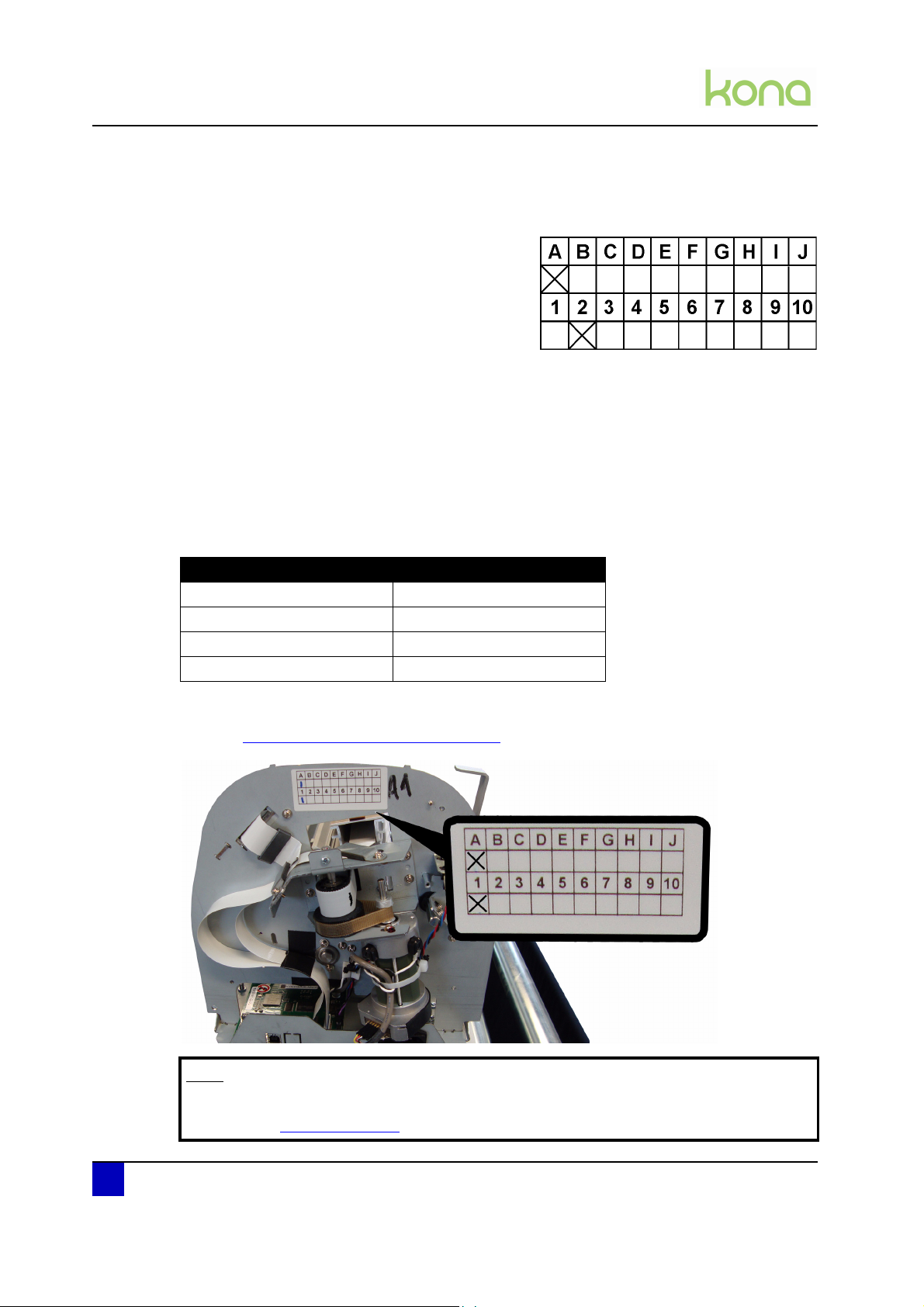

2.6 Machine version

Each machine has its own version number existing

out of a letter (version) and a number (revision),

e.g. A2.

Some parts integrated in a machine with a

higher version number, might not be

downwards-compatible with machines

containing a lower version number.

Example: Parts tagged with version C are NOT downwards compatible with machines

from version A and B

Some parts integrated in a machine with a higher revision number, are downwards

compatible with machines containing a lower revision number.

Parts that are different due to different version-numbers, will be tagged on the sparepart-list,

with a serial number. (refer to the table below)

When spare parts have to be ordered, please always verify the serial-number on the cutter,

with those on the sparepart-list, to ensure you use the correct part!

Serial numbers Machine version number

LA-1909xx A1

LA-1910xx and LA-1911xx A2

LA-1912xx A3

LA-1001xx to LA-1007xx A4

The version label of the machine can be found behind the right side cover.

Refer to Cover removal > Side covers on page 28

Note

The list of differences between the versions can be requested at our service

department (service@mutoh.eu

24 AP-74380 - Revision 1.1

).

Page 25

Service manual Kona cutting plotter

Part replacement

Chapter 3 Part replacement

Important

Before replacing parts, be sure to take the following precautionary measures:

Power OFF the cutter

Unplug the power cable

Disconnect all other cables

Only the parts described in this chapter may be replaced and are available as a

spare part.

Refer to the latest spare part price list and exploded views to find the correct

partnumber and price.

3

Cover removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Side covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Y-rail cover. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Penhead cover. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Front platen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Rear platen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

X-motor and drive belt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Y-motor assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Exploded view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Y-motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Y-drive pulley and speed reduction belt. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Y-return pulley . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Penhead assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Exploded view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Penhead FFC (flexible flat cable). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Penhead assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Penhead drive belt. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Sheet-off mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

EPOS sensor block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Y-origin flex PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

AP-74380 - Revision 1.1 25

Page 26

Service manual Kona cutting plotter

Part replacement

Grit shaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Exploded view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Grit shaft and support rollers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Pressure roller assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Exploded view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Pressure roller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Pressure roller assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Cutting mat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Electronics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Mainboard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

X and Y motor fuse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Penhead PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Touchscreen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Vacuum fans . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

26 AP-74380 - Revision 1.1

Page 27

3.1 Cover removal

1

2

3

4

5

6

N° Description Get access to the following parts Removal procedure

Service manual Kona cutting plotter

Part replacement

3

1

Left cover

2

Y-rail cover

3

Rear platen

4

Penhead cover

5

Right cover

Belt return pulley assy

Grit shaft drive pulley and belt

Penhead assembly

Head FFC (flex flat cable)

Pressure roller assembly

Touchscreen assembly

Rear paper sensor

Power supply

X-motor assembly

EPOS block

Sheet-off assembly

Penhead assembly

Penhead board

Y-origin flex PCB

Y-motor assembly

Speed reduction pulley

Pressure roller up/down sensor

Mainboard flatcables

Power inlet

page 28

page 29

page 32

page 30

page 28

6

Front platen

AP-74380 - Revision 1.1 27

Paper front sensors (2)

Mainboard

X-motor connector

page 28

Page 28

Service manual Kona cutting plotter

2x

Part replacement

3.1.1 Side covers

Tools necessary

P2 screwdriver

Removal procedure

Step 1: Remove the 2 screws fixing the side cover.

Step 2: Hook off the side covers.

Reassembling notes

When reinstalling the cover, hook it over the positioning points of the side frame.

28 AP-74380 - Revision 1.1

Page 29

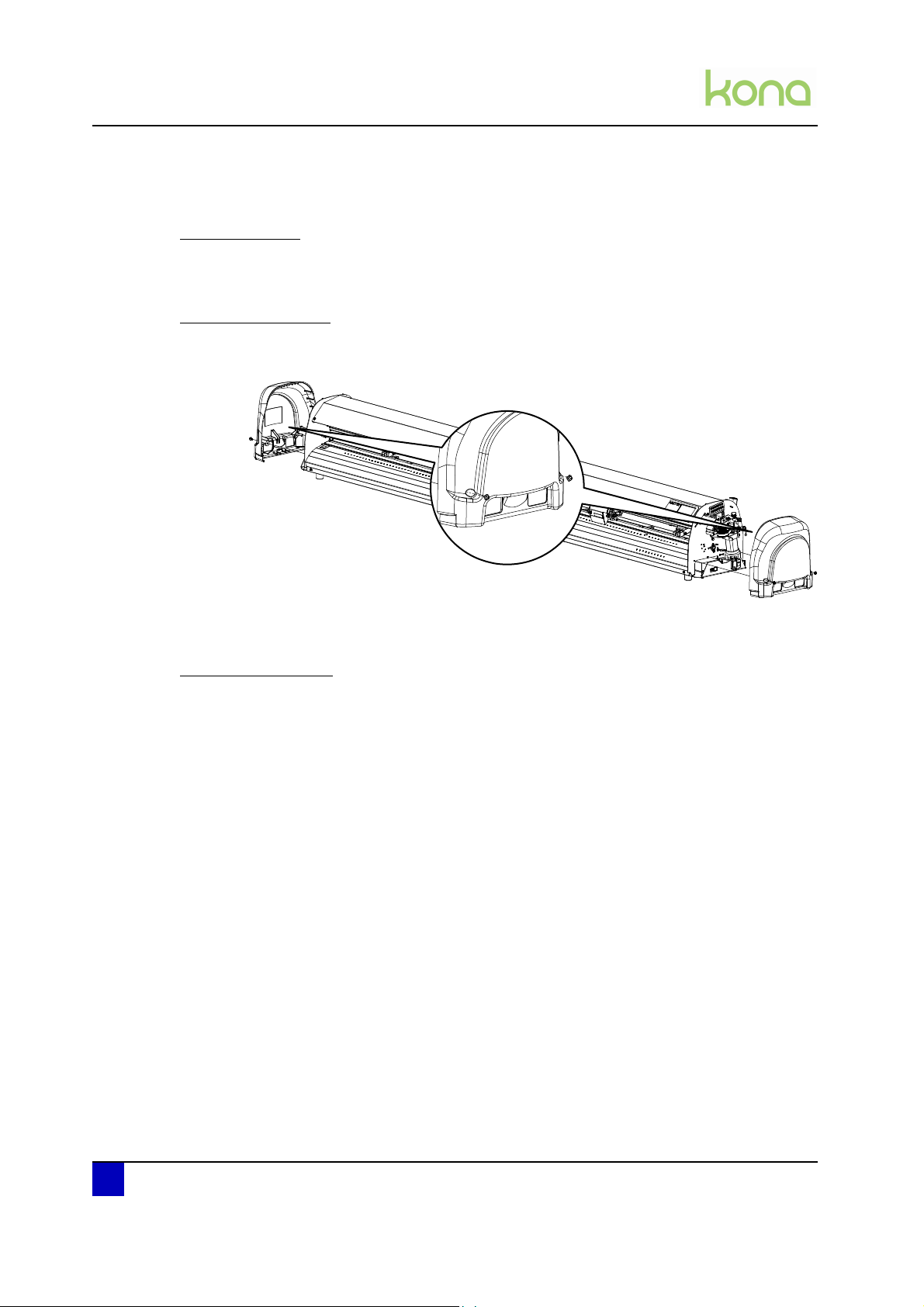

3.1.2 Y-rail cover

4x

Tools necessary

P2 screwdriver

Removal procedure

Service manual Kona cutting plotter

Part replacement

Step 1: Remove on of the side covers first.

Refer to Cover removal > Side covers on page 28

Step 2: Loosen the 4 screws fixing the Y-rail cover.

Step 3: Remove the Y-rail cover.

3

AP-74380 - Revision 1.1 29

Page 30

Service manual Kona cutting plotter

3x

Part replacement

3.1.3 Penhead cover

Tools necessary

P2 screwdriver

Removal procedure

Step 1: Remove side covers and Y-rail cover first

Refer to Cover removal > Y-rail cover on page 29

Step 2: Remove the 3 screws fixing the penhead cover.

Step 3: Remove the penhead cover.

30 AP-74380 - Revision 1.1

Page 31

3.1.4 Front platen

3x

Tools necessary

P2 screwdriver

Removal procedure

Service manual Kona cutting plotter

Part replacement

Step 1: Remove the side covers, Y-rail cover and penhead cover.

Refer to Cover removal > on page 27

Step 2: Remove the 3 screws fixing the front platen.

Step 3: Loosen the screw at the left and right side pushing down the front platen.

3

Step 4: Remove the front platen carefully. It might be necessary to move the penhead

during removal.

Reassembling notes

Step 1: Position the head in the middle of the print platform.

Step 2: Hook the front platen over the front sensors.

Step 3: Push the plate back in its original position and tighten the screws at the front and

then sides.

AP-74380 - Revision 1.1 31

Page 32

Service manual Kona cutting plotter

Part replacement

3.1.5 Rear platen

Tools necessary

P2 screwdriver

Removal procedure

Step 1: Remove the following covers first:

Side covers

Refer to Cover removal > Side covers on page 28

Y-rail cover

Refer to Cover removal > Y-rail cover on page 29

Step 2: Remove the 3 screws fixing the rear platen.

3x

Step 3: Lower the pressure rollers.

Step 4: Remove the rear platen.

32 AP-74380 - Revision 1.1

Page 33

3.2 X-motor and drive belt

Tools necessary

P2 screwdriver

Replacement procedure

Service manual Kona cutting plotter

Part replacement

Follow the procedure below to replace the X-motor and/or drive belt.

Step 1: Remove the following covers first:

Left cover

Refer to Cover removal > Side covers on page 28

Front platen

Refer to Cover removal > Front platen on page 31

Rear platen

Refer to Cover removal > Rear platen on page 32

Step 2: Remove the 2 screws fixing the X-motor assembly.

Step 3: Disconnect the cable at the front side of the cutter.

3

AP-74380 - Revision 1.1 33

Page 34

Service manual Kona cutting plotter

Part replacement

Step 4: Replace the motor and cable.

Step 5: Remove the grounding bracket.

Step 6: Replace the drive belt.

o

Adjustments necessary

After replacing this part, it is necessary to make the following adjustment.

N° Description Link

1 X drive belt tension Mechanical adjustments on page86

34 AP-74380 - Revision 1.1

Page 35

3.3 Y-motor assembly

rear

front

front

rear

1

2

3

4

3.3.1 Exploded view

Service manual Kona cutting plotter

Part replacement

3

N° Description Replacement procedure

1 Y-mo tor page 36

2 Y-drive pulley page 38

3 Speed reduction belt page 39

4 Y-return pulley page 39

AP-74380 - Revision 1.1 35

Page 36

Service manual Kona cutting plotter

Part replacement

3.3.2 Y-motor

Tools necessary

P2 screwdriver

Replacement procedure

Follow the procedure below to replace the Y-motor.

Step 1: Remove the following covers first:

Right cover

Refer to Cover removal > Side covers on page 28

Front platen

Refer to Cover removal > Front platen on page 31

Step 2: Remove the 2 screws fixing the Y-motor.

36 AP-74380 - Revision 1.1

Page 37

Step 3: Disconnect the following cables:

From motor to mainboard

From motor to lever up/down sensor

Step 4: Put the lever in the down position.

Step 5: Gently tilt out and replace the Y-motor.

Service manual Kona cutting plotter

Part replacement

3

Adjustments necessary

After replacing this part, it is necessary to make the following adjustment.

N° Description Link

1 Y drive belt tension Mechanical adjustments on page87

AP-74380 - Revision 1.1 37

Page 38

Service manual Kona cutting plotter

Part replacement

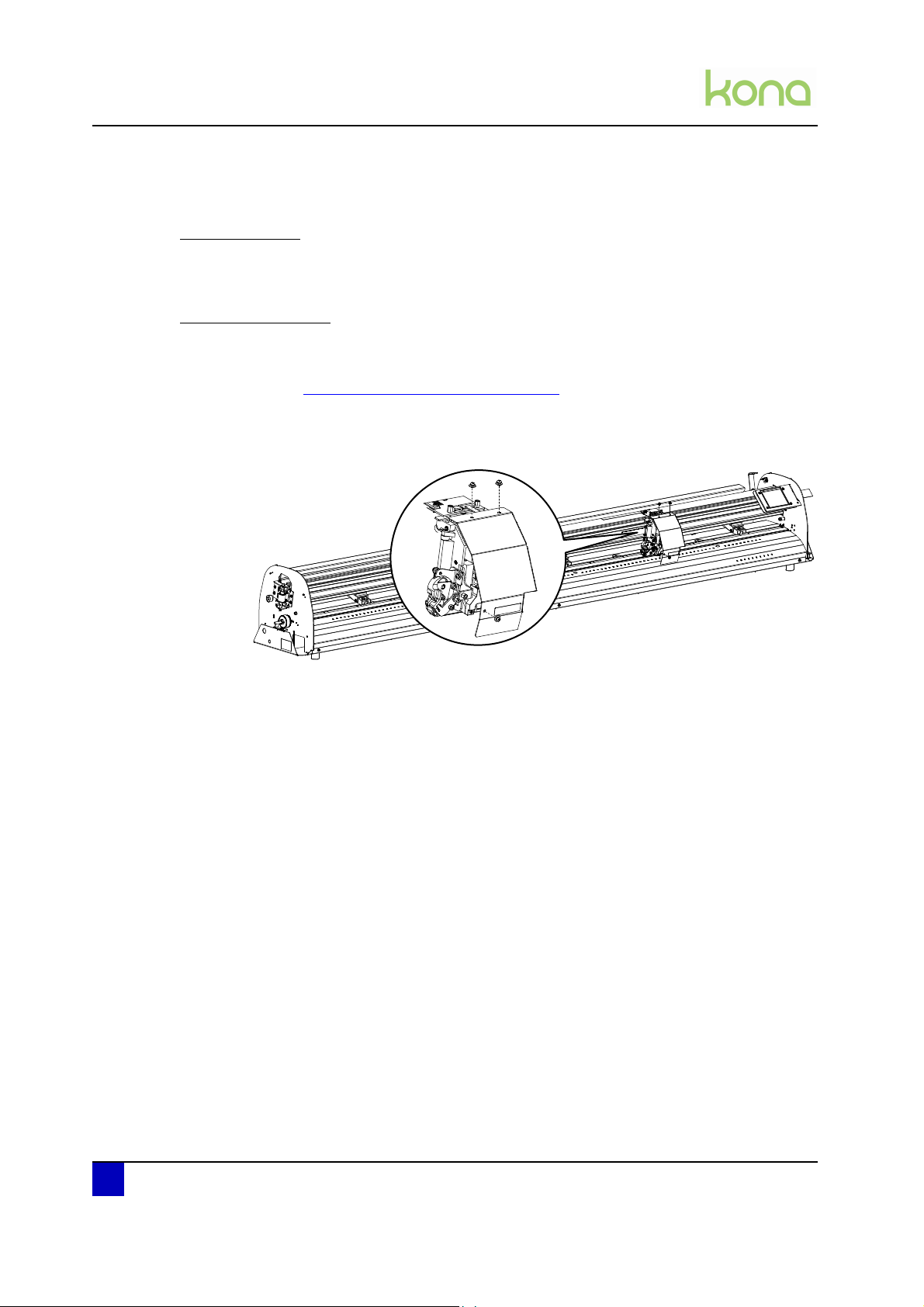

3.3.3 Y-drive pulley and speed reduction belt

Tools necessary

P1 and P2 screwdriver

Replacement procedure

Follow the procedure below to replace the Y-drive pulley and speed reduction belt.

Step 1: Remove all covers except the front and rear platen

Refer to Cover removal on page27

Step 2: Remove the penhead assembly

Refer to Penhead assembly > Penhead assembly on page 44

Step 3: Loosen penhead drive belt

Refer to Penhead assembly > Penhead drive belt on page 47

Step 4: Remove the Y-motor

Refer to Y-motor assembly > Y-motor on page 36

Step 5: Loosen the screw fixing the Y-drive pulley.

Step 6: Replace the Y-drive pulley and/or speed reduction belt.

Adjustments necessary

After replacing this part, it is necessary to make the following adjustment.

N° Description Link

1 Y drive belt tension Mechanical adjustments on page87

2 Penhead drive belt tension Mechanical adjustments on page88

38 AP-74380 - Revision 1.1

Page 39

3.3.4 Y-return pulley

Tools necessary

P2 screwdriver

Replacement procedure

Service manual Kona cutting plotter

Part replacement

Follow the procedure below to replace the Y-return pulley.

Step 1: Remove the following covers first:

Left cover

Refer to Cover removal > Side covers on page 28

Y-rail cover

Step 2: Remove the penhead assembly

Refer to Penhead assembly > Penhead assembly on page 44

Step 3: Loosen penhead drive belt

Refer to Penhead assembly > Penhead drive belt on page 47

Step 4: Loosen the 2 screws fixing the Y-return pulley.

3

Step 5: Turn the Y-return pulley shaft 90 degrees and remove the metal sockets.

Step 6: Remove and replace the Y-return pulley.

Adjustments necessary

After replacing this part, it is necessary to make the following adjustment.

N° Description Link

1 Penhead drive belt tension Mechanical adjustments on page88

AP-74380 - Revision 1.1 39

Page 40

Service manual Kona cutting plotter

1

2

3

4

5

6

Part replacement

3.4 Penhead assembly

3.4.1 Exploded view

N° Description Replacement procedure

1 Penhead FFC (flexible flat cable) page 41

2 Penhead PCB page 75

3 Penhead drive belt page 47

4 Sheet-off mechanism page 49

5 EPOS sensor block page 50

40 AP-74380 - Revision 1.1

6 Y-origin flex PCB page 52

Page 41

3.4.2 Penhead FFC (flexible flat cable)

Tools necessary

P2 screwdriver

Snap-off blade

Service manual Kona cutting plotter

Part replacement

Replacement procedure

Follow the procedure below to replace the penhead FFC.

Step 1: Remove the following covers first:

Right cover

Refer to Cover removal > Side covers on page 28

Y-rail cover

Refer to Cover removal > Y-rail cover on page 29

Penhead cover

Refer to Cover removal > Penhead cover on page 30

Step 2: Remove the 2 screws of the flatcable bracket.

3

Step 3: Disconnect the flatcable.

AP-74380 - Revision 1.1 41

Page 42

Service manual Kona cutting plotter

Part replacement

Step 4: Carefully loosen the flatcable guider (only for Kona 1400 and 1650). Be careful not

to bend the guider and to cut in the flatcable!

Step 5: Loosen the 2 brackets fixing the flatcable at the right side of the cutter.

Step 6: Unplug the flatcable from the mainboard and replace it.

42 AP-74380 - Revision 1.1

Page 43

Service manual Kona cutting plotter

Part replacement

Reassembling notes

Step 1: Move the penhead to the far left of the machine and press it against the pen until the

sheet-off knife is pushed out completely.

Step 2: Mount the flatcable to the penhead PCB and fix the flatcable bracket.

Step 3: Start guiding the flatcable in the gutter until you reach the middle (where no double

sided tape is installed).

Step 4: Adjust the flatcable position until it does not interfere with the Y-return pulley

bracket. If you do not install the flatcable correctly, it might be damaged during

cutting.

3

Step 5: Guide the flatcable through the cutter to the right side.

Step 6: Stick the flatcable onto the double side tape.

Step 7: Bend the flatcable in an angle of 90° and fix the flatcable bracket as shown below:

Step 8: Plug the flatcable in the mainboard. Be sure the flatcable is installed rectangularly.

AP-74380 - Revision 1.1 43

Page 44

Service manual Kona cutting plotter

Part replacement

3.4.3 Penhead assembly

Tools necessary

P2 screwdriver

Hexagon wrench 5,5 mm

Hexagon key 2,5 mm

Replacement procedure

Follow the procedure below to remove the penhead assembly.

Step 1: Remove the following covers first:

Step 2: Remove the following covers first

Side covers

Y-rail cover

Penhead cover

Refer to Cover removal on page27

Step 3: Disconnect the 3 flex cables.

Step 4: Loosen the two hexagon spacers.

Step 5: Move the penhead to the middle of the machine.

44 AP-74380 - Revision 1.1

Page 45

Service manual Kona cutting plotter

Step 6: Remove the screw fixing the penhead to the drive belt.

Step 7: Remove the screw on top of the penhead.

Part replacement

3

Step 8: Remove the leaf spring.

Step 9: Remove penhead assembly by tilting it of the Y-rail.

AP-74380 - Revision 1.1 45

Page 46

Service manual Kona cutting plotter

Part replacement

Adjustments necessary

After replacing/removing this part, it is necessary to make the following adjustment.

N° Description Link

1 EPOS calibration EPOS calibration on page103

2 YZ profile YZ measurement on page93

Reassembling notes

Pay attention to the order of the installation of the leaf spring, washer and screw.

Step 1: Install the leaf spring.

Step 2: Install the washer.

Step 3: Tighten the screw.

46 AP-74380 - Revision 1.1

Page 47

3.4.4 Penhead drive belt

Tools necessary

P2 screwdriver

Hexagon wrench 5,5 mm

Hexagon key 2,5 mm

Service manual Kona cutting plotter

Part replacement

Replacement procedure

Follow the procedures below to replace the penhead drive belt.

Step 1: Remove the following covers first

Side covers

Y-rail cover

Penhead cover

Refer to Cover removal on page27

Step 2: Remove the penhead assembly

Refer to Penhead assembly > Penhead assembly on page 44

Step 3: Loosen the 2 screws fixing the Y-return pulley equally. This will ease the adjustment

of the penhead drive belt afterwards.

3

Step 4: Turn the Y-return pulley shaft 90 degrees.

AP-74380 - Revision 1.1 47

Page 48

Service manual Kona cutting plotter

Part replacement

Step 5: Remove the 4 screws of the drive belt connection plate.

Step 6: Replace the penhead drive belt.

Adjustments necessary

After replacing this part, it is necessary to make the following adjustment.

N° Description Link

1 Penhead drive belt tension Mechanical adjustments on page88

2 EPOS calibration EPOS calibration on page103

48 AP-74380 - Revision 1.1

Page 49

3.4.5 Sheet-off mechanism

Tools necessary

P2 screwdriver

Replacement procedure

Service manual Kona cutting plotter

Part replacement

Step 1: Remove the 2 screws fixing the sheet-off mechanism.

Step 2: Replace the sheet-off mechanism.

Refer to the User’s Guide to know how to replace the sheet-off blade only.

Adjustments necessary

After replacing this part, it is necessary to make the following adjustment.

3

N° Description Link

1 Sheet-off knife position Mechanical adjustments on page91

AP-74380 - Revision 1.1 49

Page 50

Service manual Kona cutting plotter

Part replacement

3.4.6 EPOS sensor block

Tools necessary

P2 screwdriver

Replacement procedure

Follow the procedure below to replace the EPOS sensor block.

Step 1: Remove the following covers first:

Step 2: Remove the following covers first

Side covers

Y-rail cover

Penhead cover

Refer to Cover removal on page27

Step 3: Disconnect the EPOS sensor flatcable from the PCB board.

50 AP-74380 - Revision 1.1

Page 51

Step 4: Remove the screw fixing the EPOS sensor block.

Service manual Kona cutting plotter

Part replacement

3

Step 5: Replace the EPOS sensor block.

Adjustments necessary

After replacing this part, it is necessary to make the following adjustment.

N° Description Link

1 EPOS calibration EPOS calibration on page103

AP-74380 - Revision 1.1 51

Page 52

Service manual Kona cutting plotter

Part replacement

3.4.7 Y-origin flex PCB

Tools necessary

P2 screwdriver

Hexagon wrench 5,5 mm

Hexagon key 2,5 mm

Replacement procedure

Follow the procedure below to replace the Y-origin flex PCB.

Step 1: Remove the following covers first

Side covers

Y-rail cover

Penhead cover

Refer to Cover removal on page27

Step 2: Remove the penhead assembly.

Refer to Penhead assembly > Penhead assembly on page 44

Step 3: Loosen the 2 screws fixing the Y-origin flex PCB.

Step 4: Replace the Y-origin flex PCB.

Adjustments necessary

After replacing this part, it is necessary to make the following adjustment.

N° Description Link

1 EPOS calibration EPOS calibration on page103

52 AP-74380 - Revision 1.1

Page 53

3.5 Grit shaft

1

2

3

3.5.1 Exploded view

Service manual Kona cutting plotter

Part replacement

3

N° Description Replacement procedure

1 Grit shaft page 54

2 Grit shaft bearings page 54

3 Grit shaft support rolls page 58

AP-74380 - Revision 1.1 53

Page 54

Service manual Kona cutting plotter

Part replacement

3.5.2 Grit shaft and support rollers

Tools necessary

Paper sheets (A5 - A4)

Tape

P2 screwdriver

Hexagon key 1,5 mm

Loctite 641

Hammer

Replacement procedure

Follow the procedure below to replace the grit shaft and support rollers.

Step 1: Remove all the covers of the cutter

Refer to Cover removal on page27

Step 2: Be sure that the lever is in the UP position.

Step 3: Loosen the screws of the X-motor.

Step 4: Remove the screw fixing the grounding bracket

54 AP-74380 - Revision 1.1

Page 55

Service manual Kona cutting plotter

Part replacement

Step 5: Install a piece of paper between the grit shaft and each support roll assembly to

avoid damaging them when pulling out the shaft later on.

Step 6: Loosen the 2 setscrews of the speed reduction pulley.

3

Step 7: Remove the speed reduction pulley and white spacer.

Step 8: Remove the 2 screws fixing the left bearing of the grit roll shaft.

AP-74380 - Revision 1.1 55

Page 56

Service manual Kona cutting plotter

Part replacement

Step 9: Hammer out the grit shaft from the right side of the machine until the bearing at the

left comes out.

Step 10: Remove the grit shaft assembly.

Step 11: Remove the 2 screws fixing the right bearing of the grit roll shaft.

Step 12: Remove the bearing at the right side of the cutter.

Step 13: Remove all screws fixing a grit shaft support roll and remove them.

56 AP-74380 - Revision 1.1

Page 57

Service manual Kona cutting plotter

!

!

Left Right

Part replacement

Reassembling notes

1. The grit shaft support rolls can be mounted in two ways (as shown below). Be sure to

install them correctly. With the large collar of the bearing facing the screw.

3

2. When replacing the grit shaft, you will have to order a kit including the following items:

Grit shaft

2 bearings

A set of grit shaft support rolls (quantity depends on the machine size)

3. Reinstall the grit shaft as follows:

Step 1: Clean both ends of the grit shaft with isopropanol and let it dry completely!

Step 2: Clean the inside of the bearings with isopropanol and let it dry completely!

Step 3: Apply loctite 641 on the left side of the grit shaft. (refer to the picture above)

AP-74380 - Revision 1.1 57

Page 58

Service manual Kona cutting plotter

Part replacement

Step 4: Install a bearing and push it as far as possible.

Step 5: Remove the spoiled glue.

Step 6: Install the grit shaft from left to right. Be careful not to damage the grit sections when

moving it through the hole in the left end plate.

Step 7: Apply loctite 641 on the right side of the grit shaft and install the right bearing.

Step 8: Fix the bearings with each two screws.

Step 9: Remove the spoiled glue on the inside

Step 10: Reinstall all parts previously removed in reverse order.

Adjustments necessary

After replacing this part, it is necessary to make the following adjustment.

N° Description Link

1 X drive belt tension Mechanical adjustments on page86

58 AP-74380 - Revision 1.1

Page 59

3.6 Pressure roller assembly

1

2

3.6.1 Exploded view

Service manual Kona cutting plotter

Part replacement

3

N° Description Replacement procedure

1 Pressure roller assembly page 61

2 Pressure roller page 60

AP-74380 - Revision 1.1 59

Page 60

Service manual Kona cutting plotter

Part replacement

3.6.2 Pressure roller

Tools necessary

Small screwdriver

Replacement procedure

Follow the procedure below to replace the pressure roller.

Step 1: Be sure that the pressure rollers raised.

Step 2: Push on the pressure roller shaft (left and right) until the pressure roller clicks out of

its base.

Step 3: Push down the pressure roller at the back of the machine and remove the roller with

a screwdriver.

60 AP-74380 - Revision 1.1

Page 61

3.6.3 Pressure roller assembly

Tools necessary

P1 and P2 screwdriver

Hexagon wrench 5,5 mm

Hexagon key 2,5 mm

Service manual Kona cutting plotter

Part replacement

Replacement procedure

Follow the procedure below to replace the pressure roller assembly.

Step 1: Remove all the covers of the cutter

Refer to Cover removal on page27

Step 2: Remove the following parts first:

Part Procedure

Penhead Penhead assembly on page44

Penhead drive belt Penhead drive belt on page47

Y-mo tor Y-motor on page36

Speed reduction belt and pulley Y-drive pulley and speed reduction belt on page38

Touchscreen Touchscreen on page80

Step 3: Loosen all flatcable brackets at the right side and unplug the flatcables.

3

Note

Try not to bend the flatcables too much. Frequently folding the cables will

damage them.

AP-74380 - Revision 1.1 61

Page 62

Service manual Kona cutting plotter

Part replacement

Step 4: Remove the hexagon pressure roller shaft as follows:

Put the pressure rollers in the up position.

Remove the shaft stop and spacer (at the left side) by loosening the set screw.

Remove the two screws fixing the pressure roller lever.

Remove the screw fixing the torsion spring (at the right side)

Pay attention to the way the shaft is positioned at this moment. This to know how

to reinstall the shaft after replacing the pressure roller base.

62 AP-74380 - Revision 1.1

Page 63

Step 5: Remove Y-rail as follows:

Support the Y-rail so it can not fall when disassembling it.

Loosen the grounding strip avoiding static electricity on top of the Y-rail.

Service manual Kona cutting plotter

Part replacement

3

Remove the 4 screws fixing the Y-rail at both sides.

Insert the drive belt in the Y-rail.

Tilt out the Y-rail and be careful not to damage the flatcables.

Support the Y-rail when laying it down on a table.

AP-74380 - Revision 1.1 63

Page 64

Service manual Kona cutting plotter

Part replacement

Step 6: Mark the position of the end stop.

Step 7: Loosen the screw fixing the end stop and slide out the stop.

Step 8: Slide out the pressure roller assembly and replace it.

64 AP-74380 - Revision 1.1

Page 65

Service manual Kona cutting plotter

Part replacement

Reassembling notes

Be sure to push the Y-rail to the front against the positioning points on the side frames before

fixing the rail.

3

Be sure to guide and tighten the flatcables in the same way as shown on the picture below:

Adjustments necessary

After replacing this part, it is necessary to make the following adjustment.

N° Description Link

1 EPOS calibration EPOS calibration on page103

2 Penhead drive belt tension Mechanical adjustments on page88

3 Y drive belt tension Mechanical adjustments on page87

4 Pressure roller pressure Mechanical adjustments on page90

AP-74380 - Revision 1.1 65

Page 66

Service manual Kona cutting plotter

Part replacement

3.7 Cutting mat

Tools necessary

Isopropanol

Replacement procedure

Please follow the procedure below to replace the cutting mat.

Step 1: Remove the following covers first

Side covers

Y-rail cover

Penhead cover

Refer to Cover removal on page27

Step 2: Draw a line in front of the cutting mat and remove the worn cutting mat.

Step 3: Clean the platen using isopropanol.

Step 4: Install the new cutting mat in the same position as the previous one.

Step 5: Reinstall the covers.

Adjustments necessary

After replacing this part, it is necessary to make the following adjustment.

N° Description Link

1 YZ calibration YZ measurement on page93

66 AP-74380 - Revision 1.1

Page 67

3.8 Electronics

3.8.1 Mainboard

Tools necessary

P2 screwdriver

Set of pliers

USB cable

Mutoh CutServer and PC

Replacement procedure

Follow the procedure below to replace the mainboard.

Step 1: Store the current parameters using the Mutoh CutServer.

Service manual Kona cutting plotter

Part replacement

3

Refer to Parameters > Backup parameters of machine on page 98

Step 2: Remove the following covers first:

Right cover

Refer to Cover removal > Side covers on page 28

Front platen

Refer to Cover removal > Front platen on page 31

Step 3: Unplug all connectors and flatcables. Note that the touchscreen flatcable has a

special connector. You should push up the lip of the connector before removing it.

AP-74380 - Revision 1.1 67

Page 68

Service manual Kona cutting plotter

Part replacement

Step 4: Remove the 2 screws fixing the mainboard. (only for machine versions A1 and A2)

Refer to Machine version on page24

Step 5: Push in all studs with a set of pliers, remove the mainboard and replace it.

m

Reassembling notes

Follow the procedure below to replace the flatcables correctly.

Step 1: Be sure that the lip of touchscreen flatcable connector is in the up position.

Step 2: Insert the flatcable.

Step 3: Push down the lip of the connector to secure the cable.

Step 4: Also be sure that the flatcables or mounted rectangularly.

68 AP-74380 - Revision 1.1

Page 69

Service manual Kona cutting plotter

Adjustments necessary

After replacing this part, it is necessary to make the following adjustment.

N° Description Link

Uninstall and reinstall USB drivers on

1

the PC

Software and drivers on page96

Part replacement

2 Load firmware Software and drivers on page94

Restore parameters Restore parameters of machine on page99

If there are no parameters available,

either perform the additional

adjustments mentioned below or

contact our service department

3

(service@mutoh.eu

X - Y distance accuracy Mutoh CutServer tests on page102

Y - Z measurement Mechanical adjustments on page93

EPOS calibration EPOS calibration on page103

)

3

AP-74380 - Revision 1.1 69

Page 70

Service manual Kona cutting plotter

Part replacement

Board diagnostics

70 AP-74380 - Revision 1.1

Page 71

Service manual Kona cutting plotter

Connector overview

Connector and function

J1 (+48V) (fans)

J2 (rev A mainboards) or J12 (rev C mainboards) (to headboard)

J3 (to LCD)

J7 (X-motor and encoder)

J8 (Y-motor and encoder)

J9 (Power supply)

J10 (Sensors)

J1 (+48V) (fans)

Pin Pin name

1 + 48V

3GND

Part replacement

3

J2 (rev A mainboards) or J12 (rev C mainboards) (to headboard)

Pin Pin name

1 AI_5V0_EPOS2

2 AI_5V0_EPOS1

3GND

4 +5V0_FIL

5 DO_5V_OUT3

6GND

7IN5

8GND

9 DI_5V0_ENC3B

10 GND

11 DI_5V0_ENC3A

12 GND

13 GND

14 DO_48V_OUT2

15 DO_48V_MOTOR316 DO_48V_MOTOR3+

AP-74380 - Revision 1.1 71

Page 72

Service manual Kona cutting plotter

Part replacement

J7 (X-motor and encoder)

Pin Pin name

1V+

3+5V

4 ENC_A

5V-

7GND

8 ENC_B

J8 (Y-motor and encoder)

Pin Pin name

2V+

3+5V

4 ECN_A

6V-

7GND

8 ENC_B

J9 (Power supply)

Pin Pin name

1+48V

2+48V

3GND

4GND

J10 (Sensors)

Pin Pin name

1+5V0

2 nRear Paper

3GND

4+5V0

5 nFront Paper

6GND

7+5V0

8nMid Paper

9GND

72 AP-74380 - Revision 1.1

Page 73

Pin Pin name

10 +5V0

11 nLever

12 GND

LED summary

LED Function

LD1 G +48 V

LD2 R Error LED 2

LD3 R Error LED 1

LD4 R Error LED 3

LD5 R Error LED 4

LD6 Y Alive

LD14 R X motor (V-)

LD15 R Y motor (V-)

LD16 Y X motor (V+)

LD17 Y Y motor (V+)

Service manual Kona cutting plotter

Part replacement

3

Fuses summary

Connector Function LED

FU1 X Motor

FU2 Y Motor

Switch summary

Switch Function

SW1 RESET

DIP Switch summary

DIP Switch Function

DIP1 -

LD16 Y

LD17 Y

AP-74380 - Revision 1.1 73

Page 74

Service manual Kona cutting plotter

Part replacement

3.8.2 X and Y motor fuse

Tools necessary

P2 screwdriver

Pair of tweezers

Replacement procedure

Follow the procedure below to replace the X or Y motor fuse

Step 1: Remove the following covers first

Side covers

Y-rail cover

Penhead cover

Front platen

Refer to Cover removal on page27

Step 2: Remove the fuse with a pair of tweezer and replace it.

Note

Fuse type

Manufacturer: Littlefuse

Serie: Slo-Blo Fuse 452/454

Partnumber: R452002

2A

74 AP-74380 - Revision 1.1

Page 75

3.8.3 Penhead PCB

Tools necessary

P2 screwdriver

Hexagon wrench 5,5 mm

Service manual Kona cutting plotter

Part replacement

Replacement procedure

Follow the procedure below to replace the penhead PCB.

Step 1: Remove the following covers first:

Side covers

Y-rail cover

Penhead cover

Refer to Cover removal on page27

Step 2: Disconnect the 3 flex cables.

Step 3: Loosen the two hexagon spacers.

3

Step 4: Remove the 2 screws of the flatcable bracket and disconnect the flatcable.

Step 5: Replace the penhead PCB.

AP-74380 - Revision 1.1 75

Page 76

Service manual Kona cutting plotter

Part replacement

Board diagnostics

Connector overview

Connector and function

J1 (to mainboard)

J2 is not used

J3 (EPOS)

J4 (Y-origin)

J5 (PenHead)

J1 (to mainboard)

Pin Pin name

1COIL+

2COIL3 DO_48V_OUT2+

4 DO_48V_OUT25GND

6 CHA

7GND

8 CHB

9GND

10 DI_5V0_IN5

11 GND

12 DO_5V_OUT3

13 +5V0

76 AP-74380 - Revision 1.1

Page 77

Pin Pin name

14 GND

15 AI_5V0_EPOS1

16 AI_5V0_EPOS2

J3 (EPOS)

Pin Pin name

1+5V0

2 AI_5V0_EPOS2

3GND

4 AI_5V0_EPOS1

5GND

6 DO_5V_OUT3

J4 (Y-origin)

Service manual Kona cutting plotter

Part replacement

3

Pin Pin name

1GND

2 nY-Origin

3GND

4+5V

J5 (PenHead)

Pin Pin name

1 CHB

2+5V0

3 CHA

4GND

5GND

6COIL+

7COIL8GND

9GND

10 GND

11 GND

12 GND

AP-74380 - Revision 1.1 77

Page 78

Service manual Kona cutting plotter

Part replacement

3.8.4 Power supply

Important

Be sure to remove the power cable before servicing the power supply!

Tools necessary

P2 screwdriver

Replacement procedure

Follow the procedure below to replace the power supply.

Step 1: Remove the following covers first:

Side covers

Y-rail cover

Penhead cover

Rear platen

Refer to Cover removal on page27

Step 2: Unplug all connectors.

Step 3: Remove the 2 plugs to get access to the 2 rear screws.

78 AP-74380 - Revision 1.1

Page 79

Service manual Kona cutting plotter

Part replacement

Step 4: Depending on the machine version, a protective cover has been installed above the

power supply. Remove it before replacing the power supply.

3

Step 5: Remove the 4 screws fixing the power supply.

Step 6: Replace the power supply.

AP-74380 - Revision 1.1 79

Page 80

Service manual Kona cutting plotter

Part replacement

3.8.5 Touchscreen

Tools necessary

P2 screwdriver

Replacement procedure

Follow the procedure to replace the touchscreen.

Step 1: Remove the following covers first:

Right cover

Refer to Cover removal > Side covers on page 28

Y-rail cover

Refer to Cover removal > Y-rail cover on page 29

Step 2: Remove the screw fixing the touchscreen bracket.

Step 3: Remove the 2 screws fixing the touchscreen plastic cover.

Step 4: Unplug the flat touchscreen data cable.

Step 5: Replace the touchscreen or data cable.

80 AP-74380 - Revision 1.1

Page 81

3.8.6 Sensors

Tools necessary

P2 screwdriver

Pressure roller lever sensor

Service manual Kona cutting plotter

Part replacement

Follow the procedure below to replace the lever sensor.

Step 1: Remove the right cover.

Refer to Cover removal > Side covers on page 28

Step 2: Disconnect the sensor cable.

Step 3: Remove the two screws fixing the sensor bracket.

3

Step 4: Replace the optical U-sensor.

AP-74380 - Revision 1.1 81

Page 82

Service manual Kona cutting plotter

Part replacement

Front and middle paper sensor

Follow the procedure below to replace the front and middle paper sensor.

Step 1: Remove the front platen.

Refer to Cover removal > Front platen on page 31

Step 2: Disconnect the sensor cable.

Step 3: Remove the screw fixing the sensor.

Step 4: Replace the paper sensor.

Rear paper sensor

Follow the procedure below to replace the rear paper sensor.

Step 1: Remove the rear platen.

Refer to Cover removal > Rear platen on page 32

Step 2: Disconnect the sensor cable.

Step 3: Remove the screw fixing the sensor.

Step 4: Replace the paper sensor.

82 AP-74380 - Revision 1.1

Page 83

3.8.7 Vacuum fans

Tools necessary

P2 screwdriver

New cutting mat

Service manual Kona cutting plotter

Part replacement

Replacement procedure

Follow the procedure below to replace the vacuum fans.

Step 1: Remove the following covers first:

Side covers

Y-rail cover

Rear platen

Refer to Cover removal on page27

Step 2: Remove the cutting mat.

Refer to Cutting mat on page66

Step 3: Disconnect the fan cable.

Step 4: Remove the 4 screws fixing the vacuum fan.

3

Step 5: Replace the fan.

Step 6: Install new cutting mat.

Refer to Cutting mat on page66

Adjustments necessary

After replacing this part, it is necessary to make the following adjustment.

N° Description Link

1 YZ calibration YZ measurement on page93

AP-74380 - Revision 1.1 83

Page 84

Service manual Kona cutting plotter

Part replacement

84 AP-74380 - Revision 1.1

Page 85

Service manual Kona cutting plotter

Adjustments and calibrations

Chapter 4 Adjustments and

calibrations

Mechanical adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

X drive belt tension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Y drive belt tension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Penhead drive belt tension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Pressure roller pressure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Sheeting-off knife position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

YZ measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Software and drivers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Download latest software and drivers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Firmware installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

How to uninstall the USB drivers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

How to install the USB drivers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

USB icon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Backup parameters of machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Restore parameters of machine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

4

Mutoh CutServer tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Tracking test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

XY-distance accuracy test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

EPOS calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

AP-74380 - Revision 1.1 85

Page 86

Service manual Kona cutting plotter

Adjustments and calibrations

4.1 Mechanical adjustments

4.1.1 X drive belt tension

After replacing the following parts:

Part Link

X motor and drive belt replacement X-motor and drive belt on page33

Grit shaft replacement Grit shaft on page53

Adjustment procedure

Follow the procedure below to adjust the tension of the X drive belt.

Step 1: Loosen the 2 screws fixing the X-motor assembly.

Step 2: Attach a piece of rope around the motor body, through the hole as close as possible

to the side plate.

Step 3: Pull the bar tension gauge (range 5kg) in the direction of the slotholes for and

tighten the 2 screws when reaching the value: 3.5 kg ± 0.05 kg.

86 AP-74380 - Revision 1.1

Page 87

4.1.2 Y drive belt tension

After replacing the following parts:

Part Link

Y motor replacement Y-motor on page36

Service manual Kona cutting plotter

Adjustments and calibrations

Y-drive pulley and speed reduction belt Y-drive pulley and speed reduction belt on page38

Pressure roller assembly replacement Pressure roller assembly on page61

Adjustment procedure

Follow the procedure below to adjust the tension of the Y-drive belt.

Step 1: Loosen the 2 screws fixing the Y-motor assembly.

Step 2: Attach a piece of rope around the motor body as close as possible to the side plate.

4

Step 3: Pull the bar tension gauge (range 5kg) perpendicularly for 3.5 kg ± 0.05 kg.

Step 4: Move the cutting head manually left and right a few times before fixing the motor

screws while holding the tension gauge under a constant pressure of 3.5 kg.

AP-74380 - Revision 1.1 87

Page 88

Service manual Kona cutting plotter

Adjustments and calibrations

4.1.3 Penhead drive belt tension

After replacing the following parts:

Part Link

Y-drive pulley and speed reduction belt Y-drive pulley and speed reduction belt on page38

Y return pulley replacement Y-return pulley on page39

Penhead drive belt replacement Penhead drive belt on page47

Pressure roller assembly replacement Pressure roller assembly on page61

Adjustment procedure

Follow the procedure below to adjust the tension of the penhead drive belt.

Step 1: Move the penhead from the far left to the far right of the machine. The penhead

drive belt position on the Y-return pulley should remain the same. If it is moving up

and down, adjust the two screws fixing the Y-return pulley.

Step 2: Park the penhead at the left side of the machine.

88 AP-74380 - Revision 1.1

Page 89

Service manual Kona cutting plotter

Adjustments and calibrations

Step 3: Measure with a bar tension gauge (range: 500 g) the tension of the belt in the

middle of the Y-rail. Push the belt with the bar tension until it touches the rail and

release gently the pressure on the gauge. When the belt starts to release from the

rail is the moment of reading the value on the bar tension gauge. The tension

depends of the size of the Kona.

For Kona 760 the value should be 200 g ± 5 g.

For Kona 1400 the value should be 130 g ± 5 g.

For Kona 1650 the value should be 95 g ± 5 g.

4

Step 4: If the value is out of range, turn the two screws of the Y-return pulley an equal

amount to the left or right.

AP-74380 - Revision 1.1 89

Page 90

Service manual Kona cutting plotter

Adjustments and calibrations

4.1.4 Pressure roller pressure

After replacing the following parts:

Part Link

Pressure roller assembly replacement Pressure roller assembly on page61

Adjustment procedure

Follow the procedure below to adjust the pressure of the pressure roller assembly.