Page 1

Application

Guide

Mutoh CutServer and

Print and cut

Page 2

Page 3

Application Guide Kona / Kona apparel

Copyright notice

COPYRIGHT © 20/6/11 Mutoh Belgium nv. All rights reserved.

Mutoh Belgium nv reserves the right to modify the information contained in this manual at any

time without prior notice.

This document may not be reproduced by any means, in whole or in part, without written

permission of the copyright owner.

This document is furnished to support the Mutoh CutServer in combination with the Mutoh

cutting plotter. In consideration of the furnishing of the information contained in this document,

the party to whom it is given, assumes its custody and control and agrees to the following:

The information herein contained is given in confidence, and any part thereof shall not be

copied or reproduced without written consent of Mutoh Belgium nv.

This document or the contents herein under no circumstances shall be used in the

manufacture or reproduction of the article shown and the delivery of this document shall not

constitute any right or license to do so.

20 June 2011

Published: Mutoh Belgium nv, Archimedesstraat 13, B-8400 Oostende, BELGIUM

www.Mutoh.eu

AP-75381 - Revision 1.3 3

Page 4

Application Guide Kona / Kona apparel

Dear Customer,

The Mutoh Kona / Kona apparel drag knife cutting plotter is designed to be one of the most

user-friendly and versatile cutting plotters in the market.

As a stand-alone cutting plotter, the Kona / Kona apparel can cut and plot designs onto vinyl

and paper as required.

In combination with an inkjet printer, the Kona / Kona apparel cutting plotter is ready for

contour-cutting of pre-printed signs made with any printer capable of printing onto cutting

plotter compatible media. Contour-cutting is made possible via the integrated EPOS

(electronic positioning) technology and the in-the-box software.

On the one hand Mutoh offers “flagship” solutions, in which the complete workflow is

integrated in one software package: designing, ripping, printing, contour cutting and

stand-alone cutting. These flagship solutions are the latest Mutoh editions of EasySIGN

Power Pack and Scanvec-Amiable PhotoPRINT DX.

On the other hand, Mutoh also offers a “Workflow Integrity Solution” that keeps an existing

workflow largely intact but still introduces the flawless bar code option that behaves as a

unique job ticket along the print & cut process and minimizes errors. The workflow integrity

solution allows that the jobs are still designed, ripped and printed with the customer's existing

software packages. The sticker layout, bar code generation, cutting and contour cutting are in

that case handled with the standard Kona / Kona apparel in-the-box EasySIGN Power Pack

and the Mutoh CutServer.

In the following pages of this application guide the installation of the CutServer, the print and

cut workflow and some hints and tricks are captured.

Note

Please find the Kona / Kona apparel Installation CD as support for this manual

in-the-box.

4 AP-75381 - Revision 1.3

Page 5

Application Guide Kona / Kona apparel

Table of contents

Chapter 1 Compatibility overview. . . . . . . . . . . . . . . . . . . . . . . . 9

1.1 Cutter drivers and Mutoh software . . . . . . . . . . . . . . . . . . . . . . 9

1.2 RIP software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Chapter 2 Installing CutServer . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.2 Installing Mutoh CutServer . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Install the CutServer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Create and set a hot folder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Backup the machine settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.3 Details about Mutoh’s CutServer. . . . . . . . . . . . . . . . . . . . . . . 15

Main window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Menu items. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Toolbar icons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Available connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Chapter 3 Setting up your print and cut software. . . . . . . . . . 37

3.1 EasySIGN. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Update EasySIGN. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

EasySIGN driver installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Configuring EasySIGN for the CutServer . . . . . . . . . . . . . . . . . . . . 40

Synchronise your CutServer hotfolder in EasySIGN . . . . . . . . . . . 41

3.2 Scanvec Amiable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Configuring Scanvec Amiable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

3.3 Mutoh Grip + . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Installing a Kona driver. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

AP-75381 - Revision 1.3 5

Page 6

Application Guide Kona / Kona apparel

Chapter 4 Contourcutting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

4.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

4.2 Different alignment methods . . . . . . . . . . . . . . . . . . . . . . . . . . 48

4.3 Which alignment method to use? . . . . . . . . . . . . . . . . . . . . . . 49

Automatic alignment method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Manual alignment method. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

4.4 Bounding box details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Hints, tips and recommendations. . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Bounding box specifications

(without bar code, no cutserver application required) 54

4.5 Scanning routing of bounding box . . . . . . . . . . . . . . . . . . . . . 59

4.6 Kona / Kona apparel keyboard features . . . . . . . . . . . . . . . . . 61

Automatic. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

4.7 Print and cut with EasySIGN . . . . . . . . . . . . . . . . . . . . . . . . . . 67

4.8 Print and cut with Mutoh Grip (+). . . . . . . . . . . . . . . . . . . . . . . 71

4.9 Print and cut with Scanvec Amiable . . . . . . . . . . . . . . . . . . . . 75

Chapter 5 Cutting through. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

5.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

5.2 Setting up your cutter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Tools necessary on a Kona . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Tools necessary on a Kona apparel . . . . . . . . . . . . . . . . . . . . . . . . . 80

Toolswap settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Through cut settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

5.3 Through cutting workflow . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

5.4 Through cutting with EasySIGN. . . . . . . . . . . . . . . . . . . . . . . . 85

6 AP-75381 - Revision 1.3

Page 7

Application Guide Kona / Kona apparel

Convert shapes to cutthrough lines . . . . . . . . . . . . . . . . . . . . . . . . . 85

How to plot and setup your design . . . . . . . . . . . . . . . . . . . . . . . . . . 86

5.5 Through cutting with Mutoh Grip (+). . . . . . . . . . . . . . . . . . . . 88

Convert shapes to cutthrough lines . . . . . . . . . . . . . . . . . . . . . . . . . 88

Verify automatic detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Cutthrough tool configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

5.6 Throughcutting with Scanvec Amiable. . . . . . . . . . . . . . . . . . 90

5.7 Poster trimming workflow . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Chapter 6 Handling curled media . . . . . . . . . . . . . . . . . . . . . . . 95

Chapter 7 Hints, tips and tricks . . . . . . . . . . . . . . . . . . . . . . . . 99

7.1 How to create a cut contour around your images . . . . . . . . 101

For vector images . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

For bitmap images . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

7.2 How to connect your Kona / Kona apparel to your network 116

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

USB to network sharing box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Quick installation procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Make the following connections . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Software and driver installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Connecting your Kona / Kona apparel . . . . . . . . . . . . . . . . . . . . . . 121

Verify the new connection in your cut software / CutServer . . . . 121

Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

7.3 Did you know. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Print and cut workflow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

7.4 Frequently asked questions. . . . . . . . . . . . . . . . . . . . . . . . . . 130

Mutoh CutServer related FAQ. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

AP-75381 - Revision 1.3 7

Page 8

Application Guide Kona / Kona apparel

8 AP-75381 - Revision 1.3

Page 9

Application Guide Kona / Kona apparel

Compatibility overview

Chapter 1 Compatibility overview

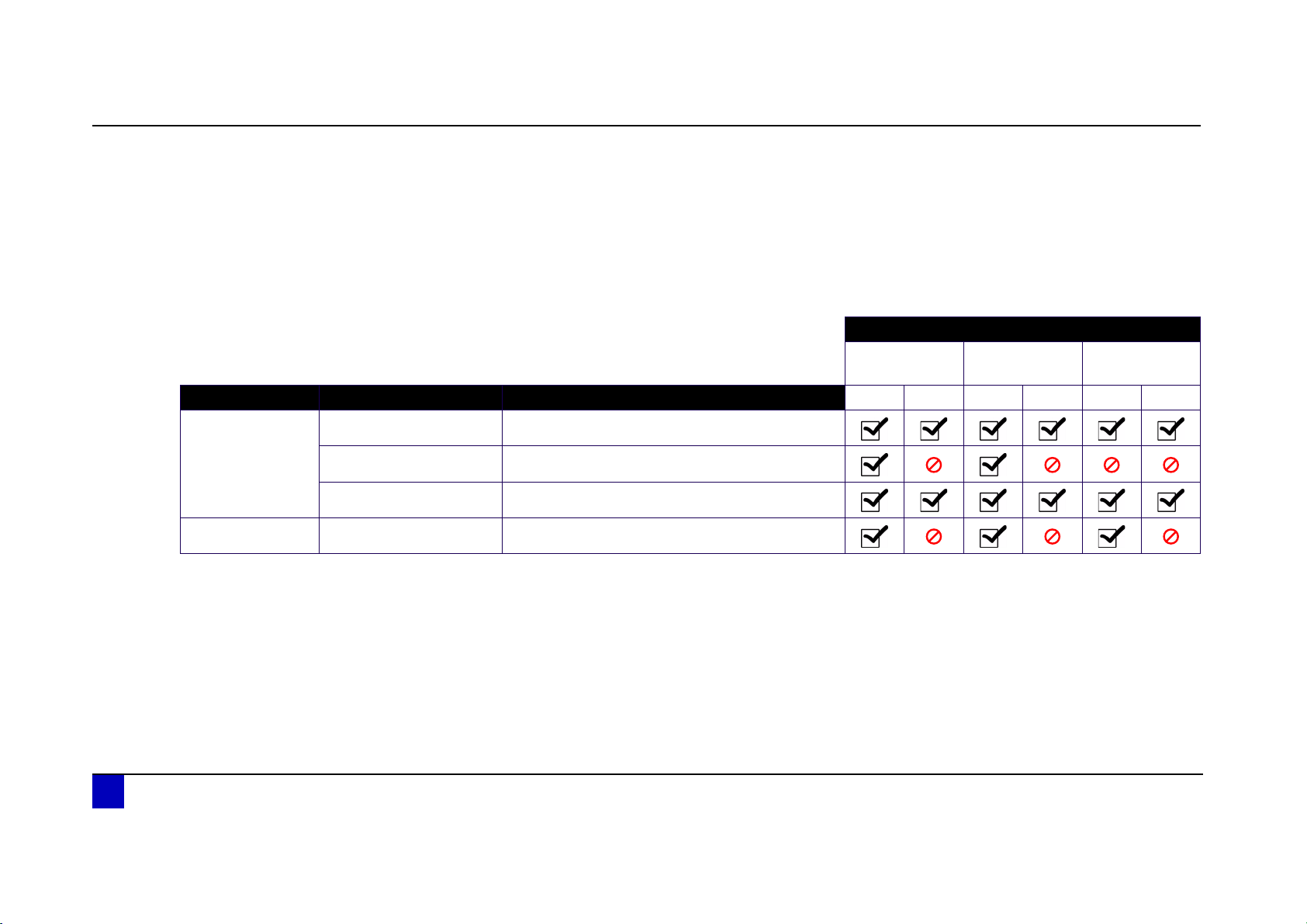

1.1 Cutter drivers and Mutoh software

Please find below an overview of the available drivers and software packages for the Kona cutter.

Windows XP

with SP2

Device Tool Driver / Software 32 bit 64 bit 32 bit 64 bit 32 bit 64 bit

USB driver USB_Drivers_2_0_0.zip

Kona

and

Kona apparel

CutServer 1.0.5 CutServer_setup_v1.0.5.exe

CutServer 4.1.0 -

Operating system

Windows Vista Windows 7

Kona EasySign 5.16 driver Mutoh.drv

9 AP-75381 - Revision 1.3

Page 10

Application Guide Kona / Kona apparel

Compatibility overview

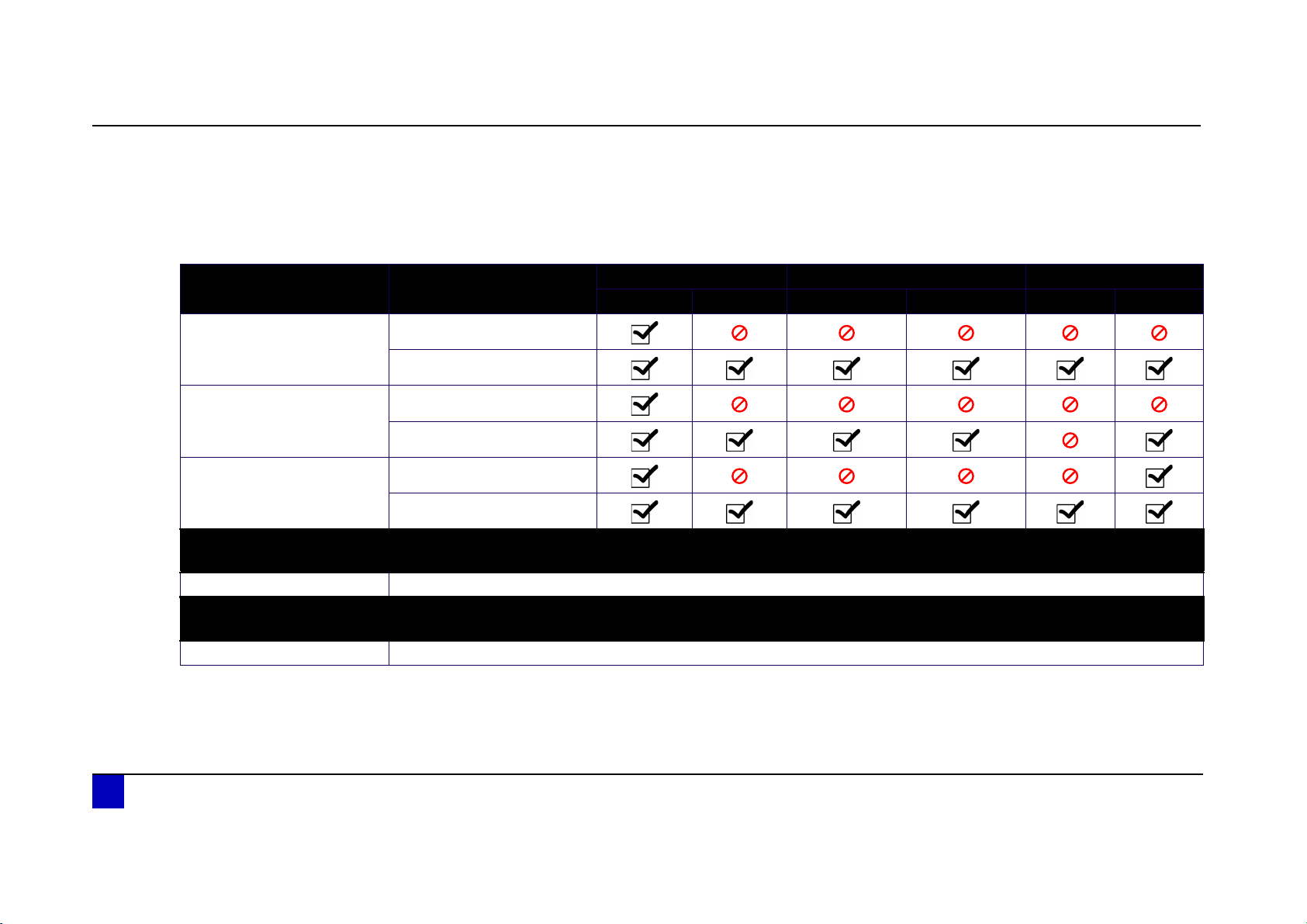

1.2 RIP software

Please find below an overview of the most common RIP software used in combination with Mutoh printers and their compatibility with Windows, Linux

or Mac.

RIP software compatible

with Windows

version 6 or lower

Onyx

version 7 / Onyx X

EasySign

version 5 with SP 15

Scanvec Amiable

RIP software compatible

with Mac

Scanvec Amiable

RIP software compatible

with Linux

Grip (+)

Bold = current version is sold by Mutoh

Version

version 4

version 5

version 6

Version

Windows XP Windows Vista Windows 7

32 bit 64 bit 32 bit 64 bit 32 bit 64 bit

10 AP-75381 - Revision 1.3

Page 11

Application Guide Kona / Kona apparel

Chapter 2 Installing

CutServer

Installing CutServer

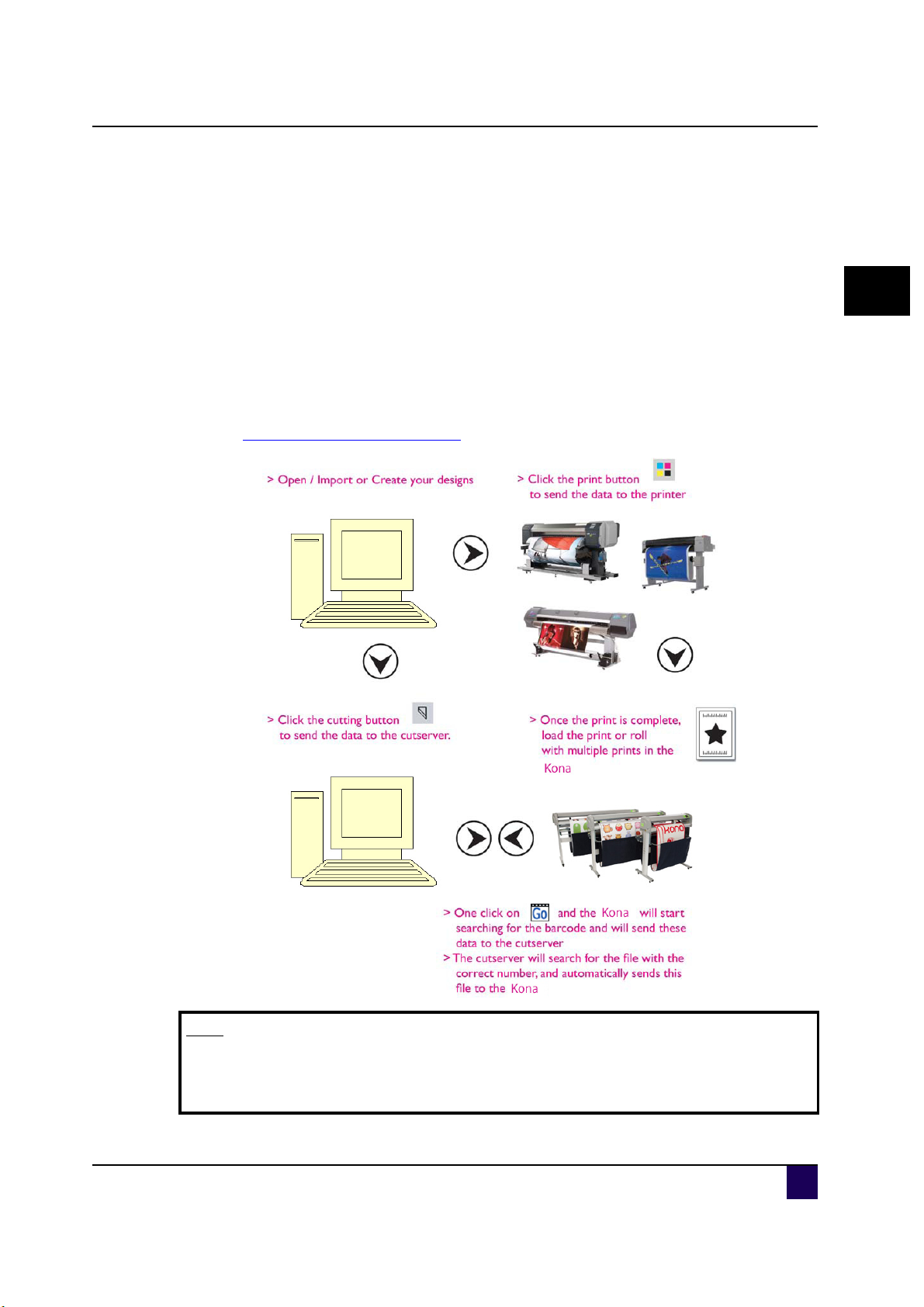

2.1 Introduction

In order to use the Automated Barcode workflow, an exclusive CutServer tool is developed by

Mutoh to pass on all generated alignment plot files from your software to the Kona / Kona

apparel. All print and cut plot files are gathered into a hot folder, linked to the CutServer

queue, in which the scanning command can be given to read the ID number of your printout.

Refer to

Compatibility overview on page9

2

Note

Rather than using the “Go” CutServer button, an alternative bar code scanning

sequence can be started as well. Press the Contour Cutting button on the LCD

and select your appropriate alignment system.

AP-75381 - Revision 1.3 11

Page 12

Application Guide Kona / Kona apparel

Installing CutServer

2.2 Installing Mutoh CutServer

In order to use the Automated Barcode workflow, an exclusive CutServer tool is

developed by Mutoh to pass on all generated alignment plot files from your software to the

cutter.

All print and cut plot files are gathered into a hot folder, linked to the CutServer queue,

in which the scanning command can be given to read the ID number of your printout.

2.2.1 Install the CutServer

Step 1: Download the CutServer from Mutoh’s member Site

Step 2: Install the Mutoh CutServer by double clicking on the exe installation file.

Step 3: Follow the instructions of the program.

Select Destination Location.

Select Start Menu Folder.

Decide whether to create a desktop icon or not.

Install the software.

Step 4: Open the Mutoh CutServer and set a hot folder.

Refer to Create and set a hot folder on page12

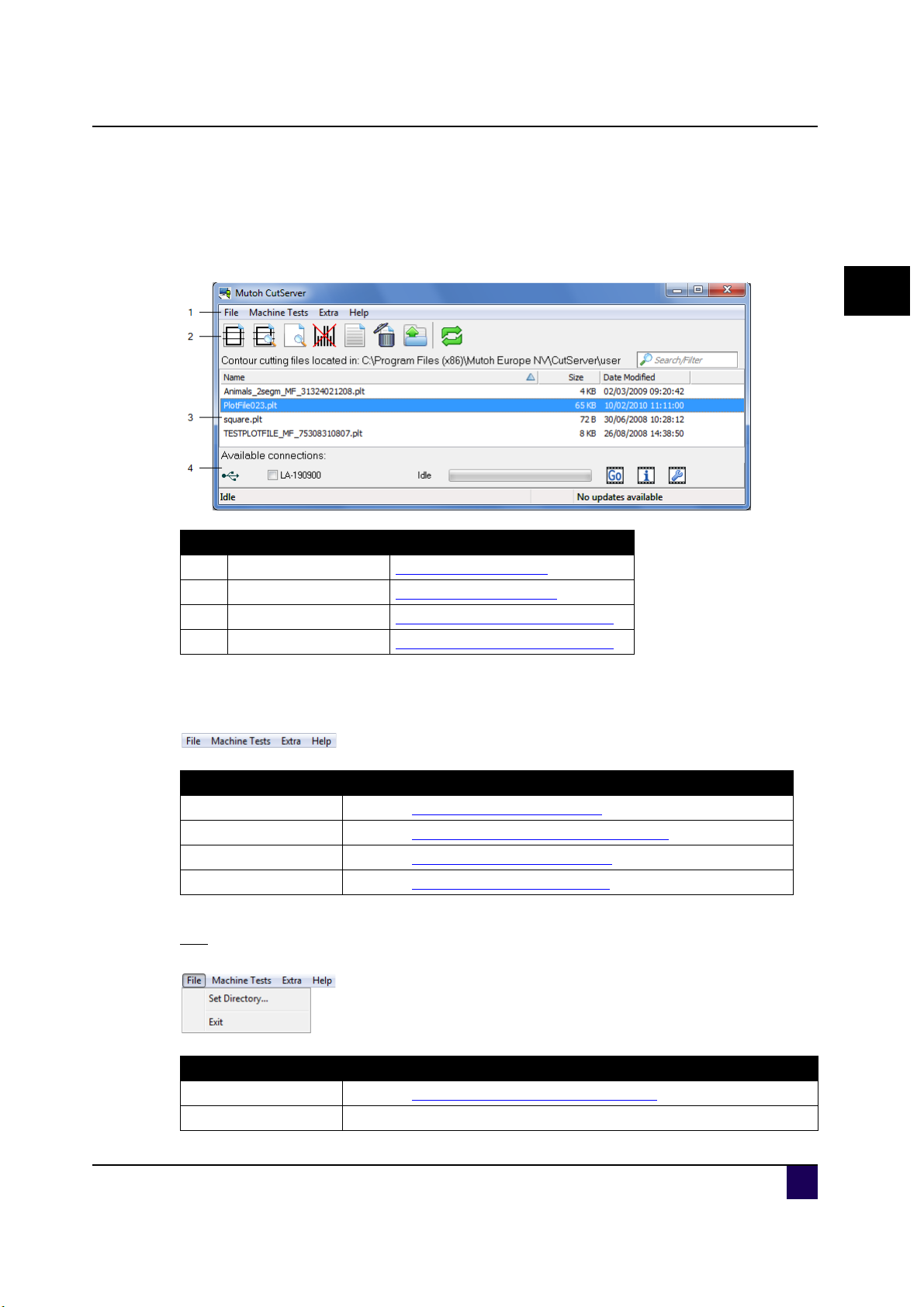

2.2.2 Create and set a hot folder

To be able to display all the jobs in the queue of the CutServer, a folder need to be made on

your local hard disk. This folder should be linked to the CutServer.

Step 1: Using your windows explorer, create a new empty folder on your Hard disk. (Any

name will do, for the example we will call the folder CutServer and place it directly

under C:\) or use the default folder C:\Program Files\Mutoh Europe Nv\CutServer

Step 2: Start the Mutoh CutServer.

Step 3:

Step 4: Browse to your hot folder and click OK.

Step 5: All the plotfiles gathered in this folder will now be displayed.

³Go to file and choose set directory.

.

12 AP-75381 - Revision 1.3

Page 13

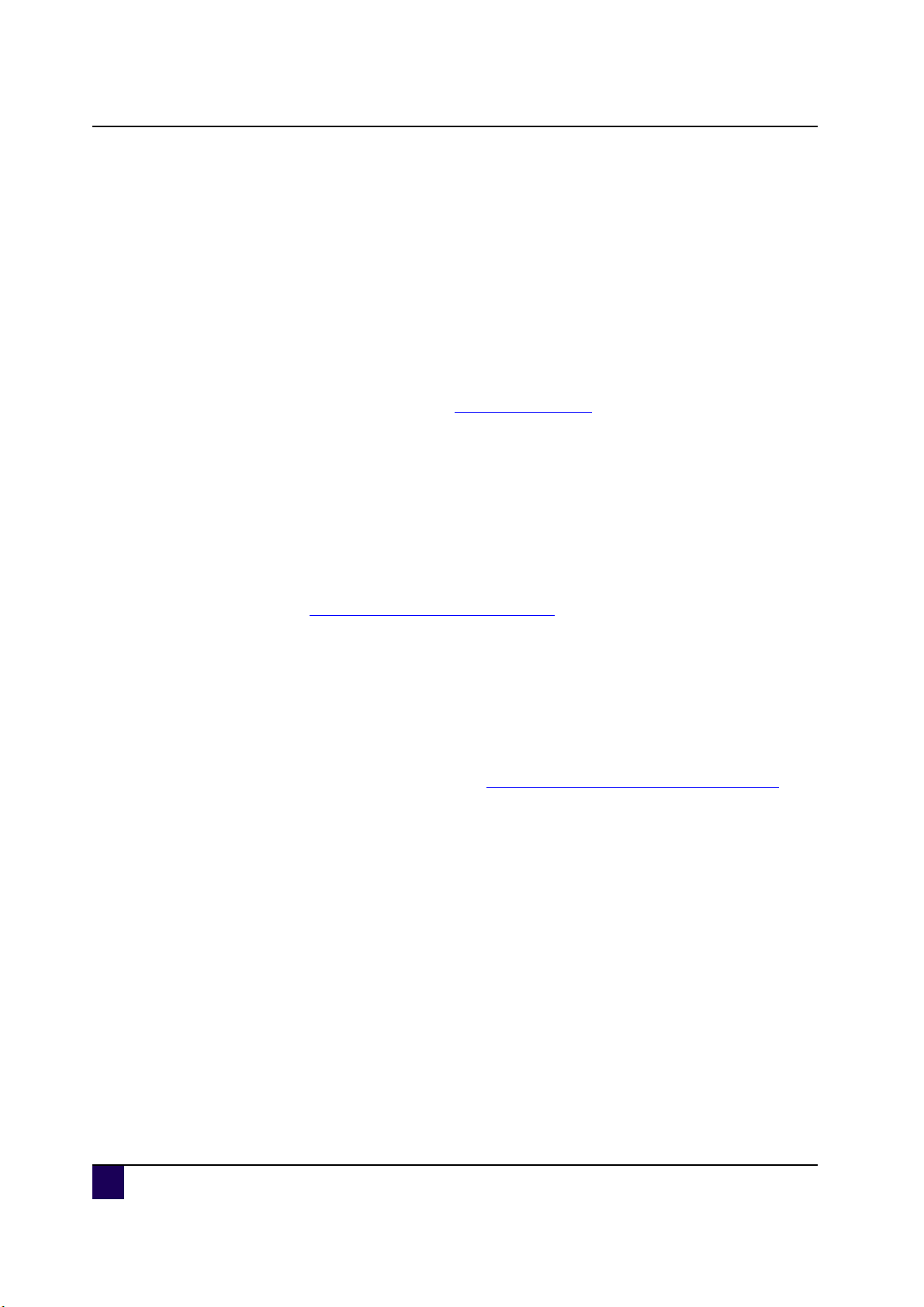

2.2.3 Backup the machine settings

When establishing problems with your cutter, it is very useful to be able to restore previous

settings and parameters. Therefore, when a machine is connected and starting up the

CutServer for the first time, an automatic back-up will be taken from the parameters.

After clicking OK, the CutServer will show a new window. This window enables you to save

the backup with a specific name or with the serial number.

Application Guide Kona / Kona apparel

Installing CutServer

2

It is recommended to store your parameters frequently. All back-ups are stored in the

following folder: C:\Program Files\Mutoh Europe NV\CutServer\backup

back up a recognizable name, including the serial number of the machine.

. Be sure to give your

Backup the settings manually as follows:

Step 1: Be sure that the cutter is connected via the CutServer and there are no cutting

operations busy.

Refer to Details about Mutoh’s CutServer > Available connections on page 34

Step 2: Right-click on a connection and choose to take a backup.

Step 3: The “Save Backup window” opens. Here you are able give the backup a specific

name or to save the backup using the serial number.

Step 4: The CutServer automatically creates a backup file and stores it in the installation

folder of the Mutoh Europe CutServer: C:\Program Files\Mutoh Europe

NV\CutServer\backup.

AP-75381 - Revision 1.3 13

Page 14

Application Guide Kona / Kona apparel

Installing CutServer

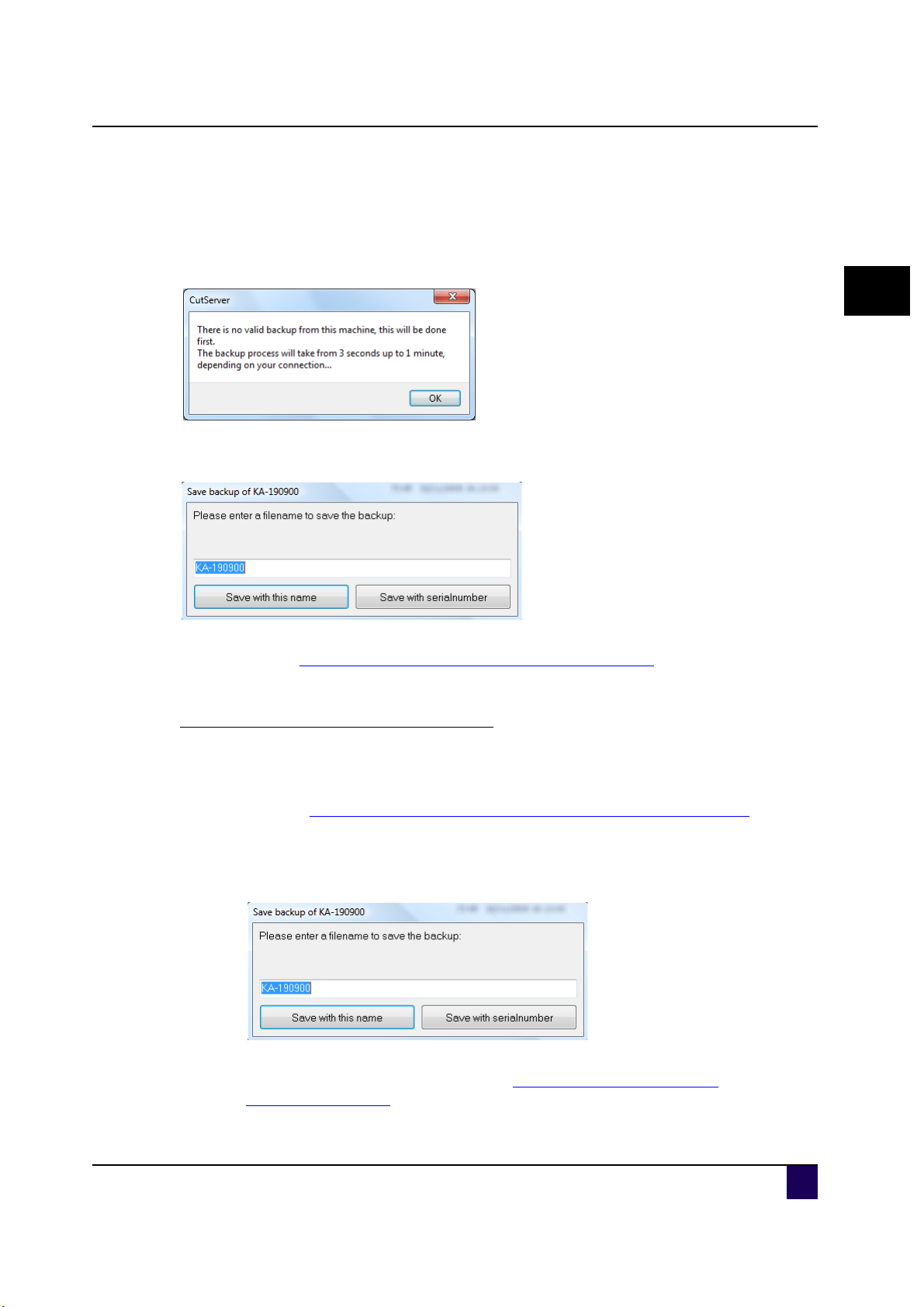

Restore the settings manually as follows

Step 1: Be sure that the cutter is connected via the CutServer

Refer to Details about Mutoh’s CutServer > Available connections on page 34

Step 2: Right-click on a connection and choose to restore a backup.

Step 3: Double-click on the backup you wish to restore.

Step 4: The CutServer asks for confirmation to restore the backup.

Step 5: The machine will reboot automatically after sending the backup.

Caution

Never restore a parameter backup from another cutter because there are some

machine dependant parameters such as the Y-Z profile.

When you do not have a parameter back-up, please contact our Mutoh Service

Department

Note

It is not advised to install an old parameter backup when using new firmware.

14 AP-75381 - Revision 1.3

Page 15

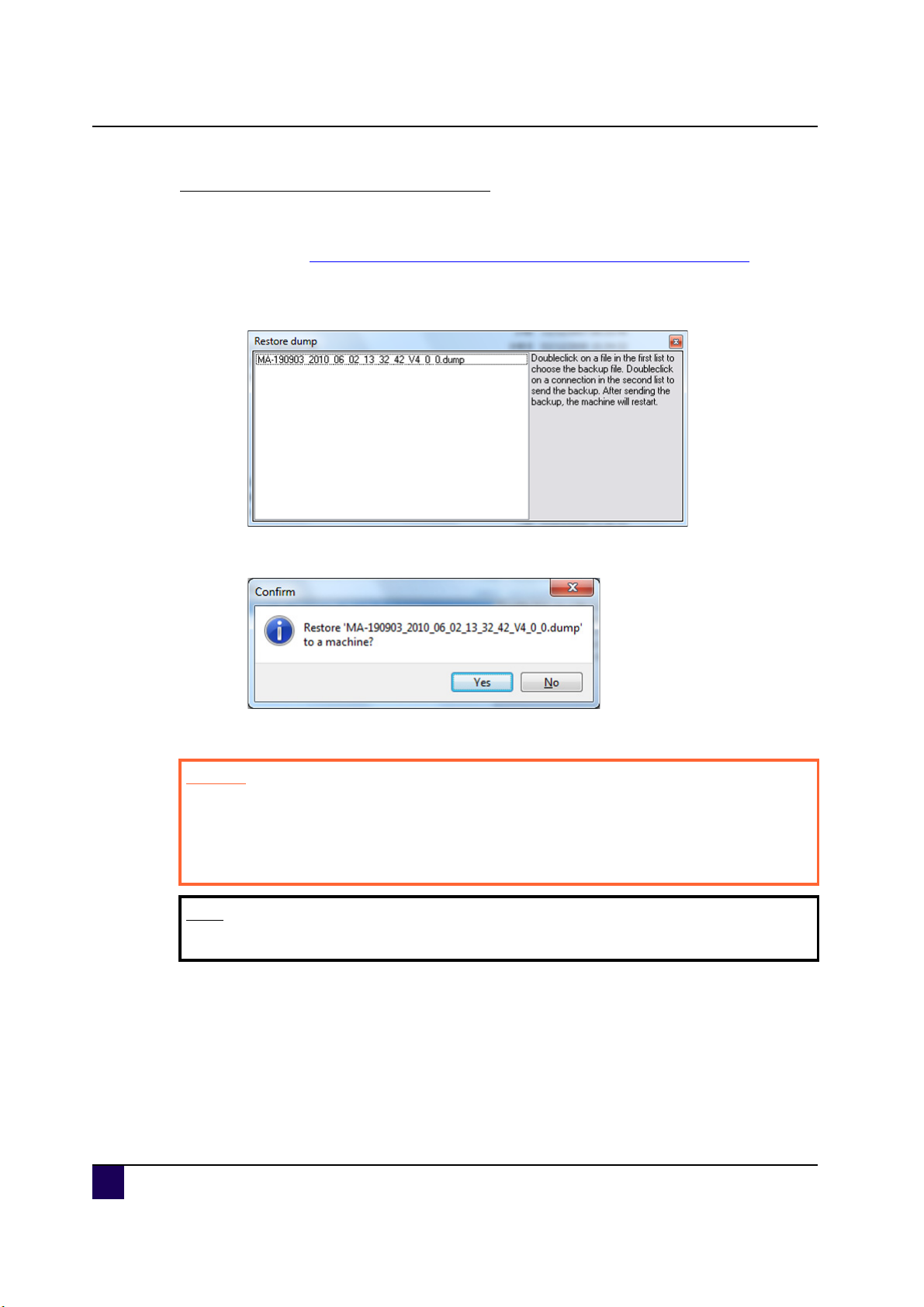

2.3 Details about Mutoh’s CutServer

2.3.1 Main window

Application Guide Kona / Kona apparel

Installing CutServer

2

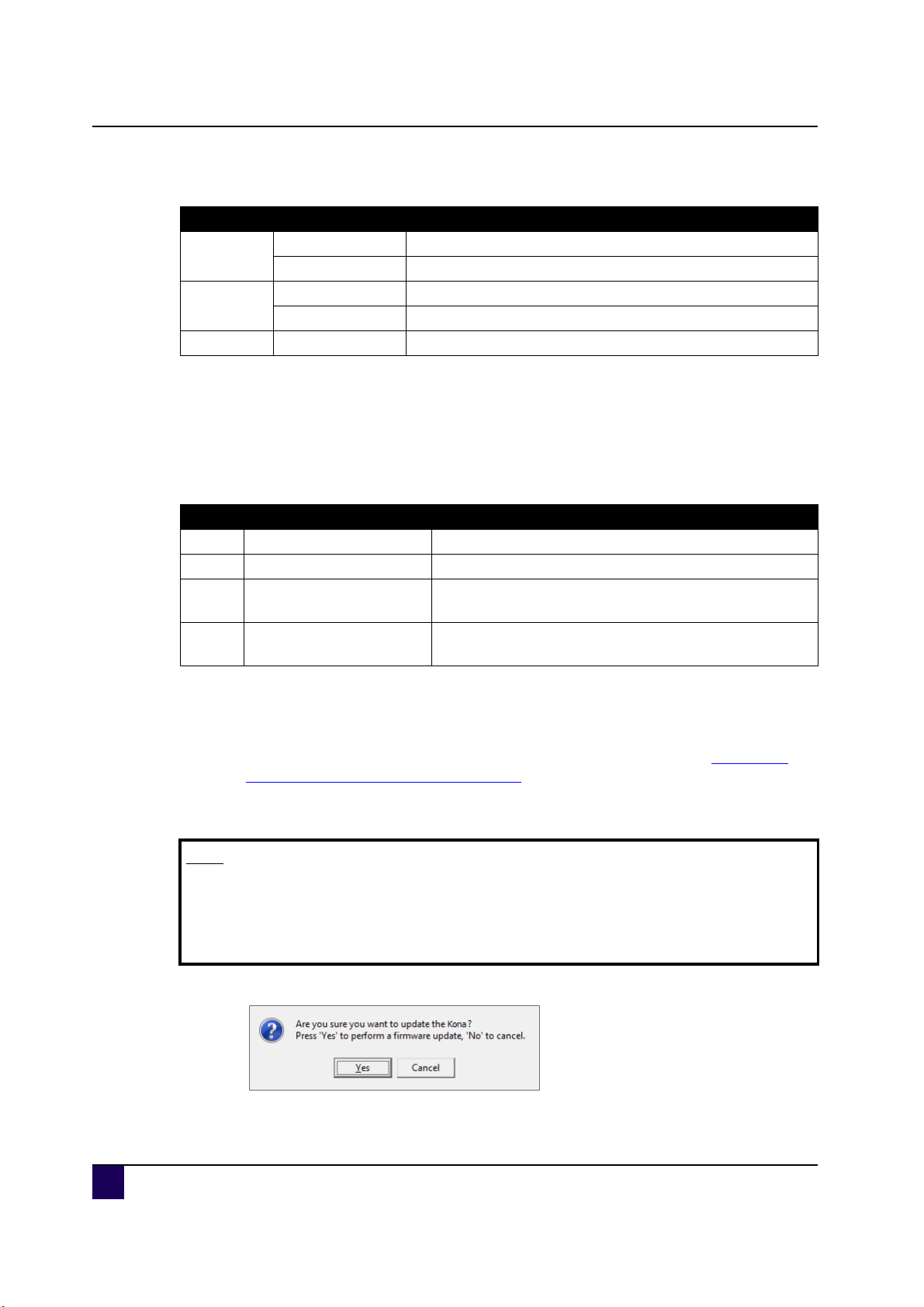

N° Description More info

1 Menu items Menu items on page15

2 Toolbar icons Toolbar icons on page28

3 Contour cutting files Available connections on page34

4 Available connections Available connections on page34

2.3.2 Menu items

Menu item More info

File Refer to Menu items > File on page 15

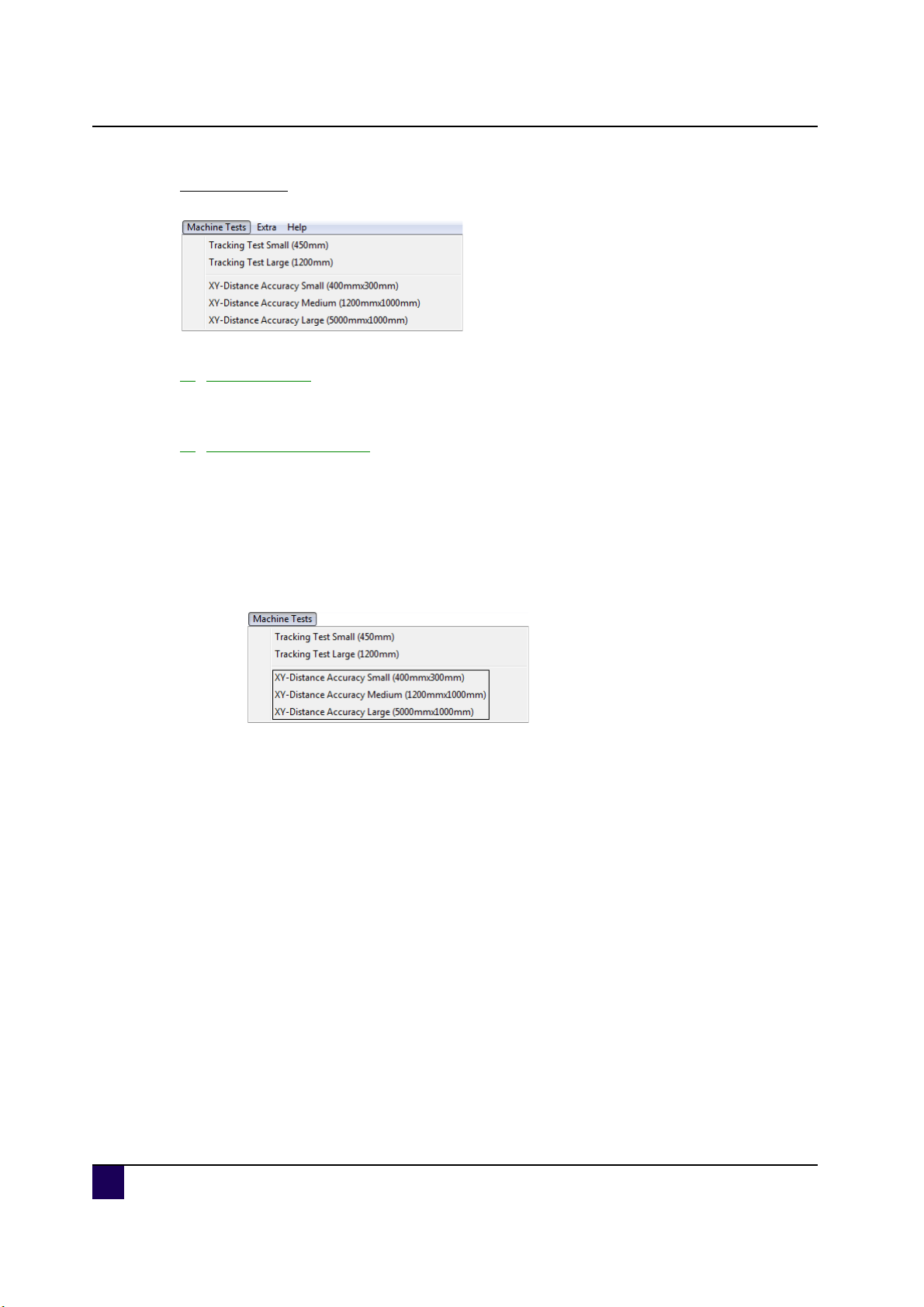

Machine test Refer to Menu items > Machine tests on page 16

Extra Refer to Menu items > Extra on page 18

Help Refer to Menu items > Help on page 25

File

Menu item More info

Set Directory... Refer to Create and set a hot folder on page12

Exit Close the application

AP-75381 - Revision 1.3 15

Page 16

Application Guide Kona / Kona apparel

Installing CutServer

Machine tests

1) Tracking tests

Reserved for authorized Mutoh technicians only.

2) XY-distance accuracy

The XY - Distance Accuracy tests are developed to check the actual X-Y cutting distance with

the sent vector data.

Please follow the procedure below to make the test:

Step 1: Launch Mutoh’s CutServer.

Step 2: Be sure that the cutter is connected with the Mutoh CutServer.

Step 3: Select which test to perform.

16 AP-75381 - Revision 1.3

Page 17

Application Guide Kona / Kona apparel

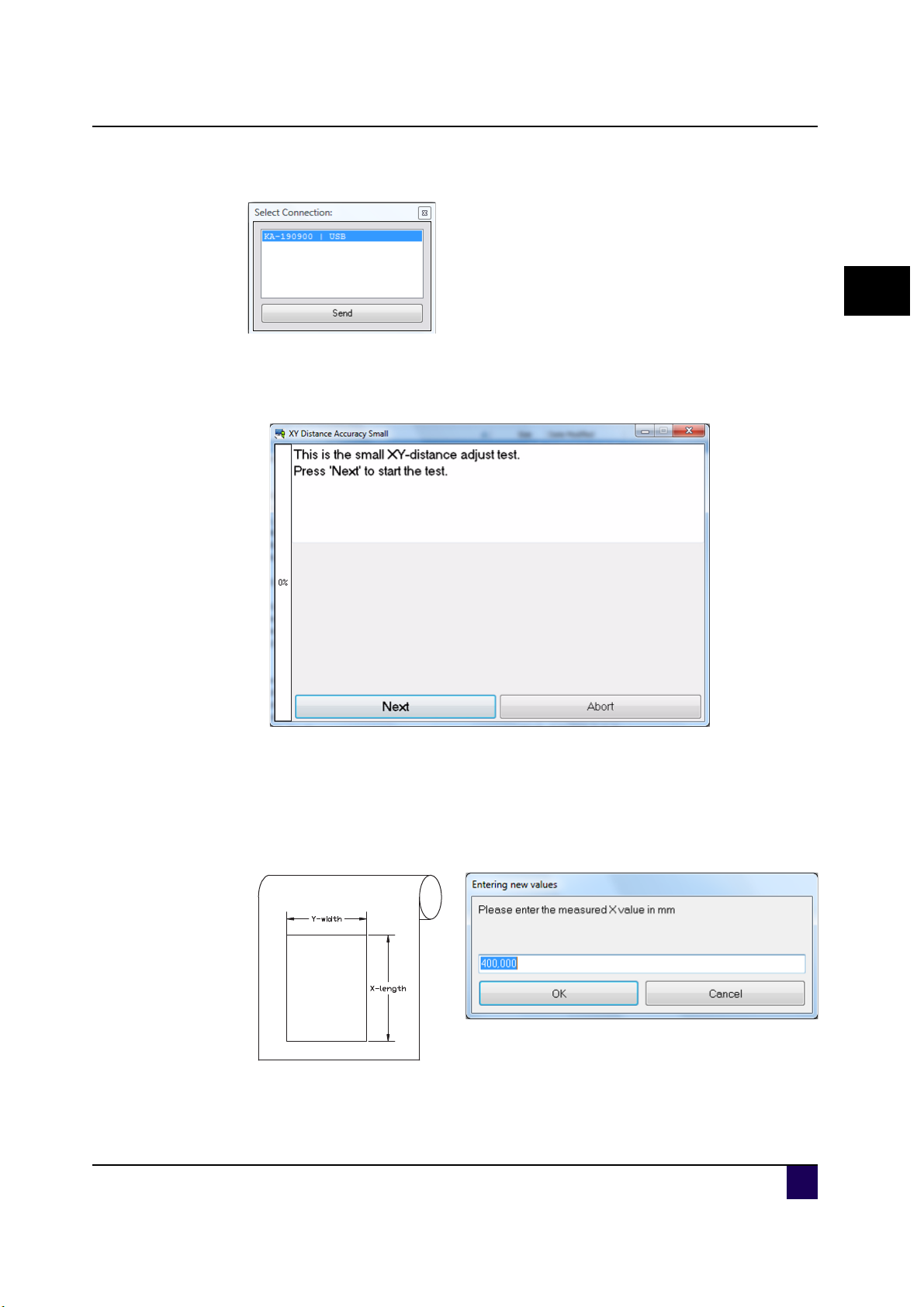

Step 4: Select the appropriate connection and click on it.

A new window appears. Do not press Next before:

media is loaded

a knife is loaded.

Installing CutServer

2

Step 5: If m

Step 6: Peel out the box.

Step 7: Measure the X length and Y width and enter them. Be sure to enter the values in

AP-75381 - Revision 1.3 17

edia and a knife are loaded, click Next.

A box is cut.

mm!

Page 18

Application Guide Kona / Kona apparel

Installing CutServer

Step 8: If the correct values are entered, the following message appears and the test is

done.

A new message appears warning you that an EPOS calibration is recom-

mended.

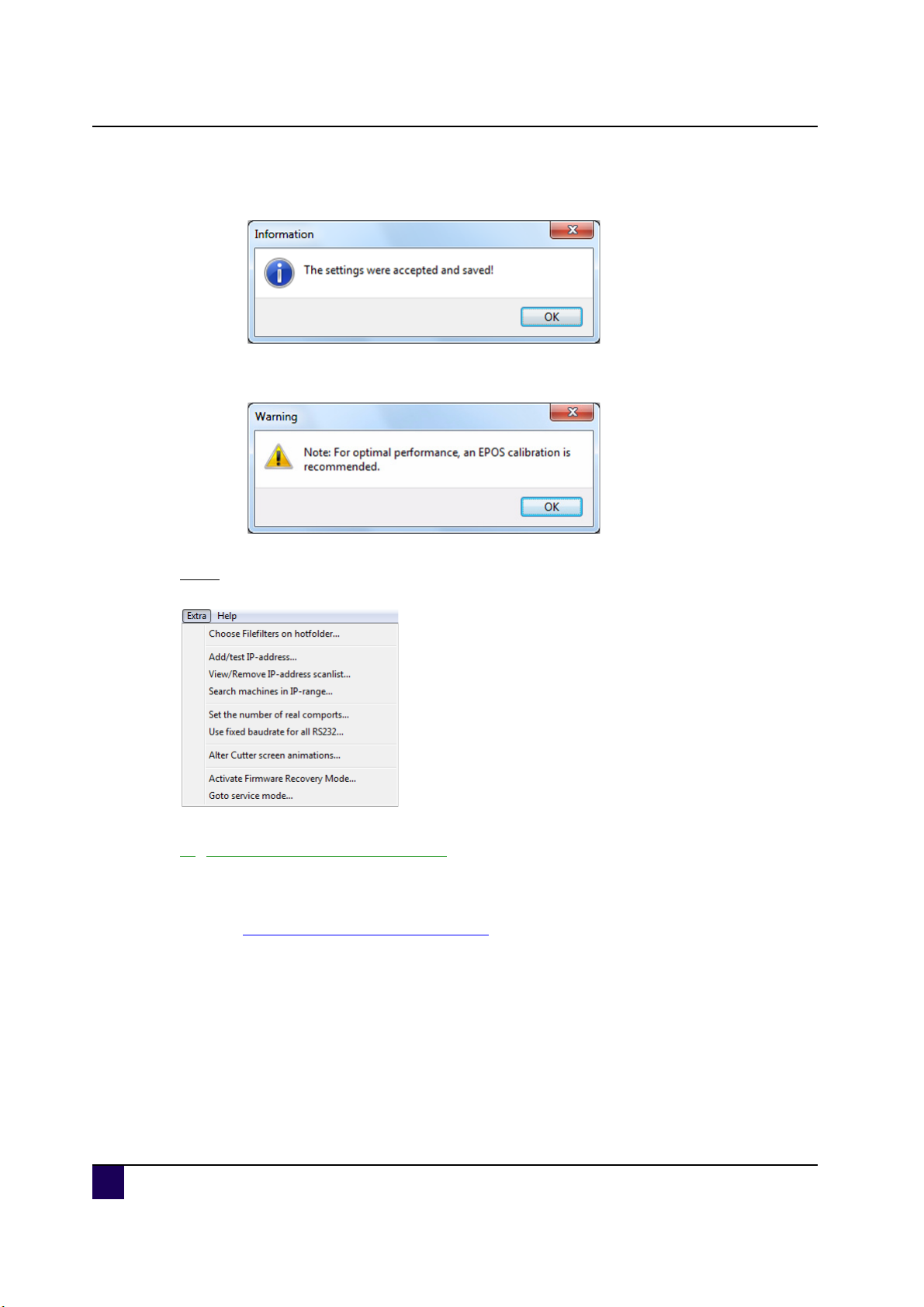

Extra

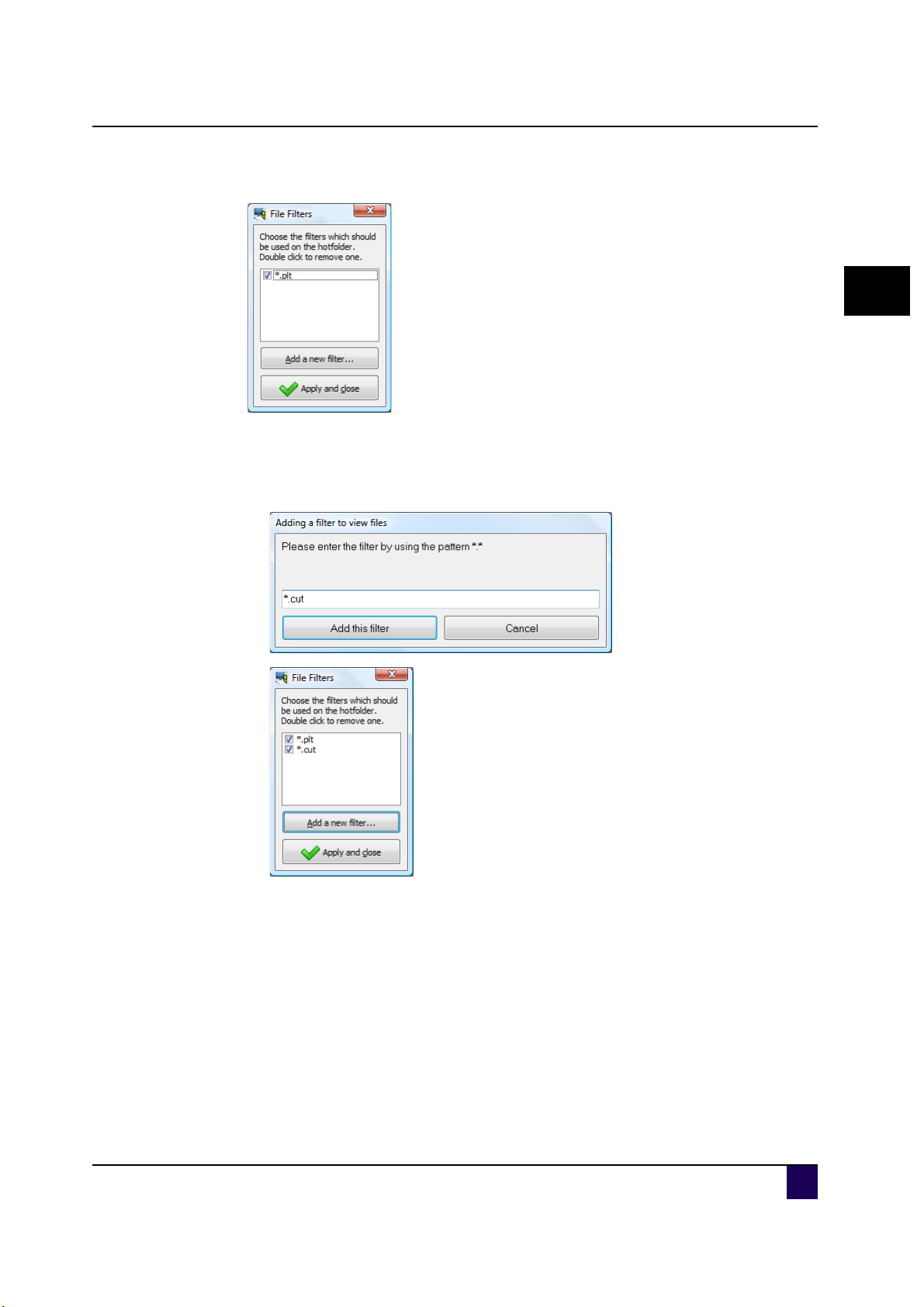

1) Choose File filters and hotfolder

As described earlier, the files in the hot folder are displayed in a queue. This folder can

include different kind of files.

Refer to

Standard, only PLT files are displayed in the queue. However, it is possible to create cut files

via the RIP for example with another extension (e.g. CUT). These file types will not automatically be displayed and should be added to the filter list as described below.

Note that the file name should be build up similar to the PLT files, which means:

Name_alignment method_barcode.extension

Step 1: Select extra > Choose Filefilters and hotfolder.

Create and set a hot folder on page12

e.g. Job1_MF_14587652131.cut

18 AP-75381 - Revision 1.3

Page 19

Step 2: The following screen is displayed:

Step 3: Now you can do one of the following actions:

Select the checkbox of the file type which should be displayed.

Add a new file type (filter), e.g. *.cut.

Application Guide Kona / Kona apparel

Installing CutServer

2

Remove a filetype by double clicking on it.

Apply your changes and close this screen.

Step 4: The filter is applied to the queue.

AP-75381 - Revision 1.3 19

Page 20

Application Guide Kona / Kona apparel

Installing CutServer

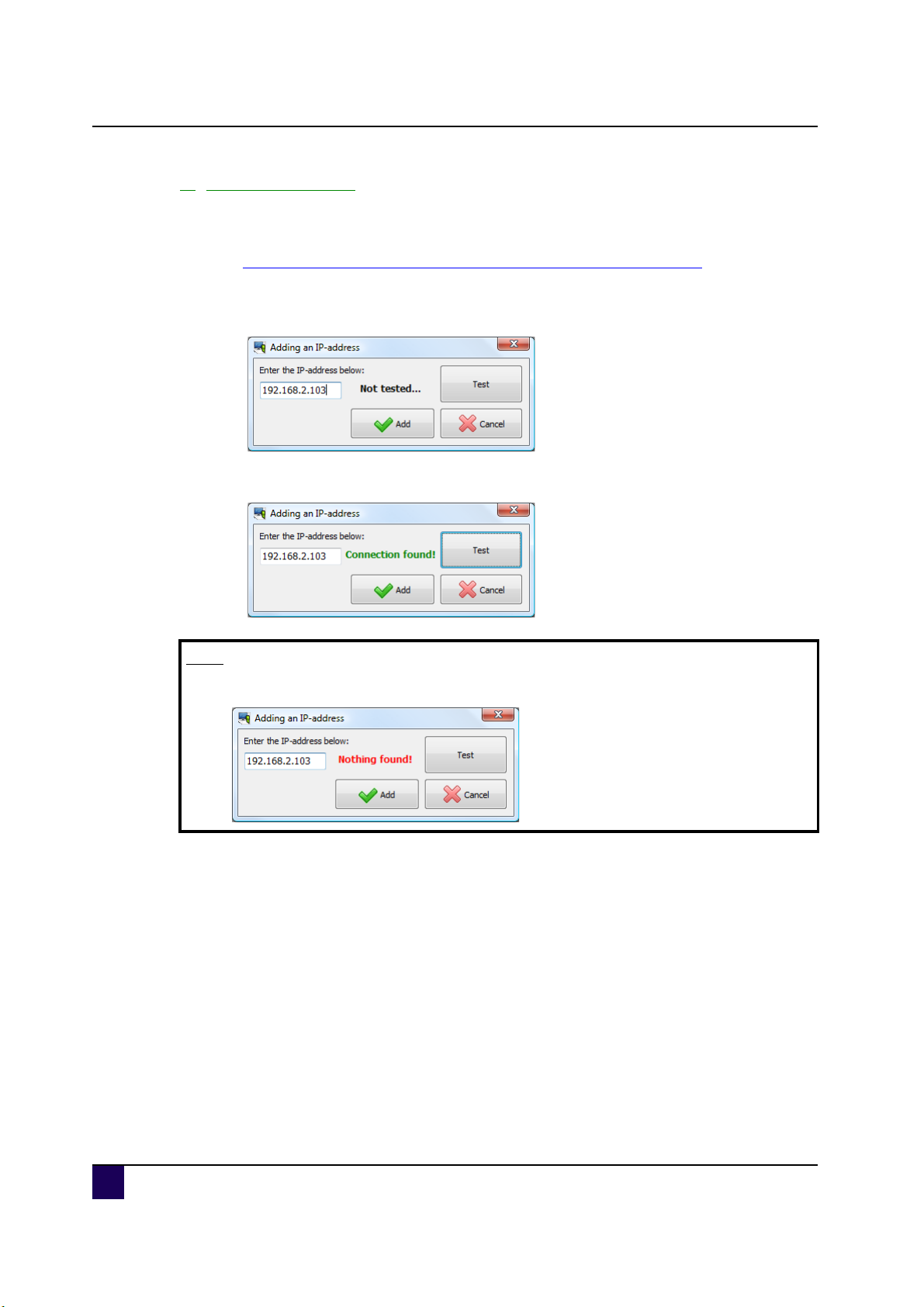

2) Add/test IP address

When your cutter is connected to your local area network it is possible to add your cutter by

providing the IP address of the cutter.

Refer to How to connect your Kona / Kona apparel to your network on page116

Step 1: Select extra > Add/test IP address.

Step 2: Fill in the IP address of the cutter.

Step 3: Click on test to check the connection. Make sure that the cutter is powered ON.

Note

In case the IP address is not found, following message is displayed:

Step 4: Click on add to verify the IP address or cancel this action.

20 AP-75381 - Revision 1.3

Page 21

Application Guide Kona / Kona apparel

Installing CutServer

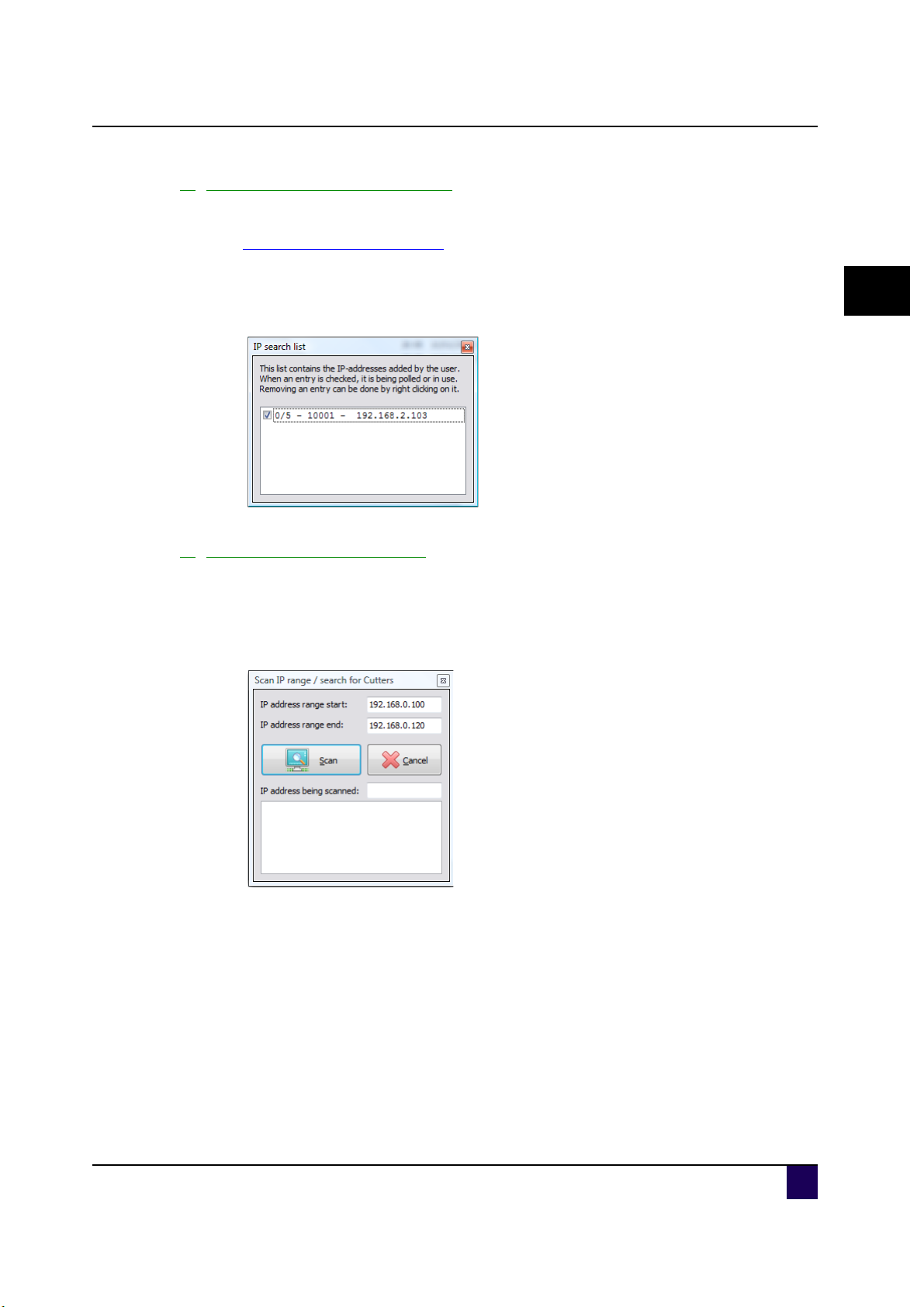

3) View/remove IP address scanlist

The list will display the IP-address added by the user.

Refer to Add/test IP address on page20

When checking an entry, it is being polled or in use. Removing an entry is done by

right-clicking on it.

Step 1: Select extra > View/remove IP address scanlist.

2

4) Search machines in IP range

Use this function when you do not know the exact IP address of the cutter but you know in

which range it should be.

Step 1: Select extra > Search machines in IP range.

Step 2: Fill in the range start and end.

Step 3: Click on scan.

AP-75381 - Revision 1.3 21

Page 22

Application Guide Kona / Kona apparel

Installing CutServer

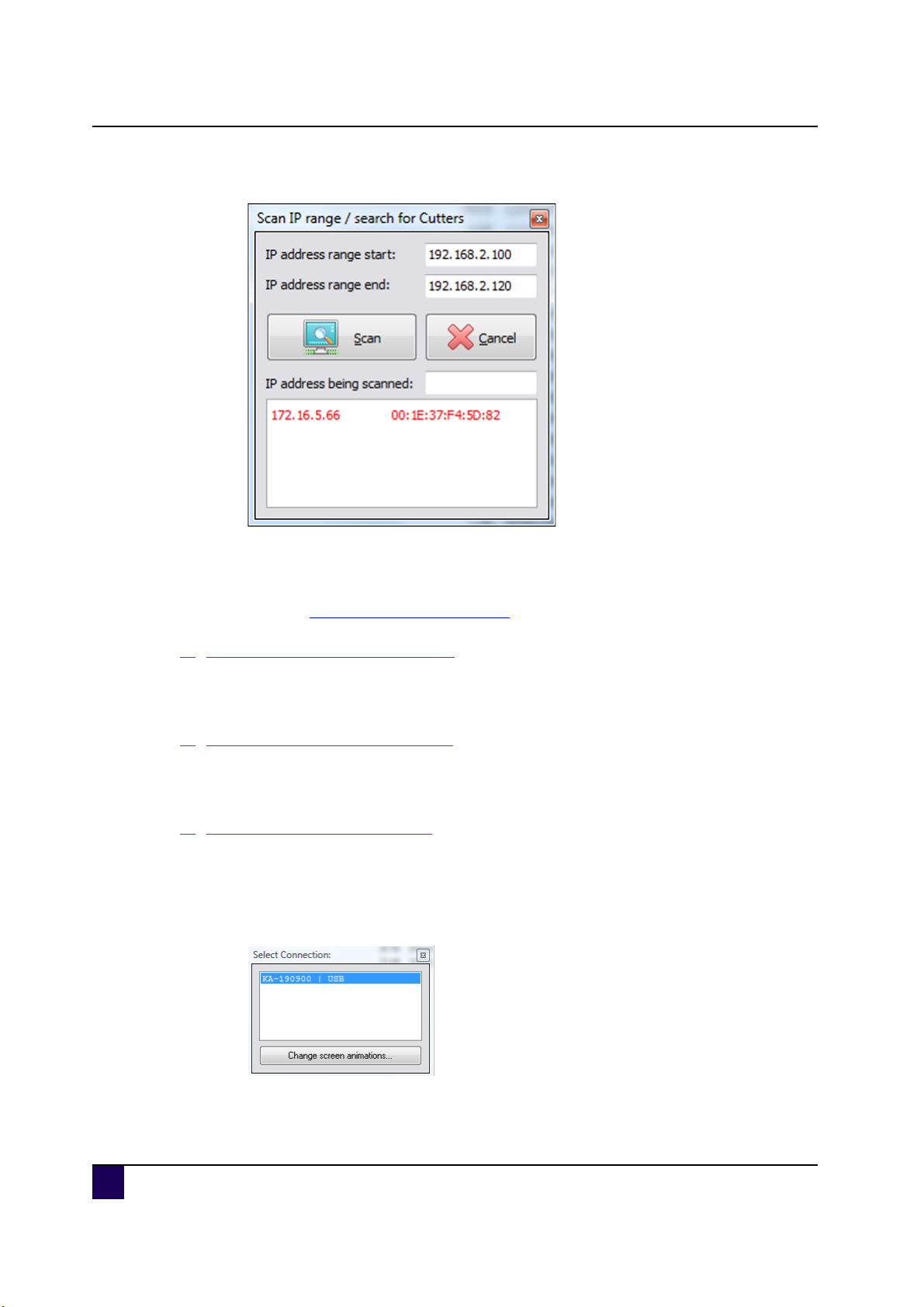

Step 4: All the devices connected to your network within this range are displayed:

Step 5: Select the IP address of your demand and copy it.

Step 6: Follow the procedure mentioned below to add this IP address to your list.

Refer to

Add/test IP address on page20

5) Set the number of real com ports

If you want to use a virtual com port (e.g. COM3) you can change the settings here. However,

it is recommended to use the USB connection.

6) Use fixed baudrate for all RS232

This function has no effect on a Kona / Kona apparel cutter, because the baudrate is irrelevant if you use a virtual com port.

7) Alter cutter screen animations

This function enables you to store images onto your Kona / Kona apparel so that you can

modify the screen saver as you whishes.

Step 1: Select Alter cutter screen animation.

Step 2: Select the connection and press Change screen animation.

22 AP-75381 - Revision 1.3

Page 23

Application Guide Kona / Kona apparel

Installing CutServer

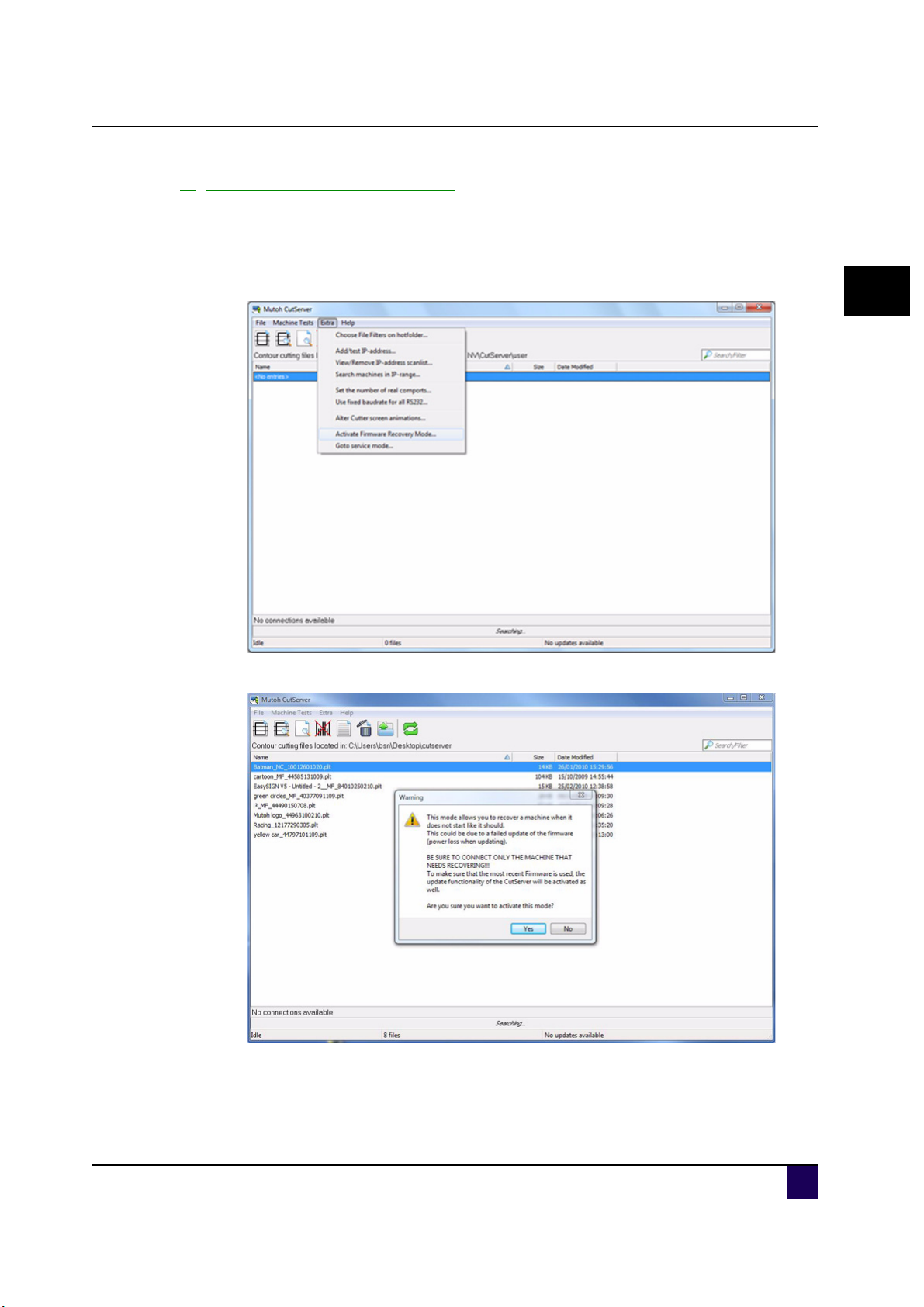

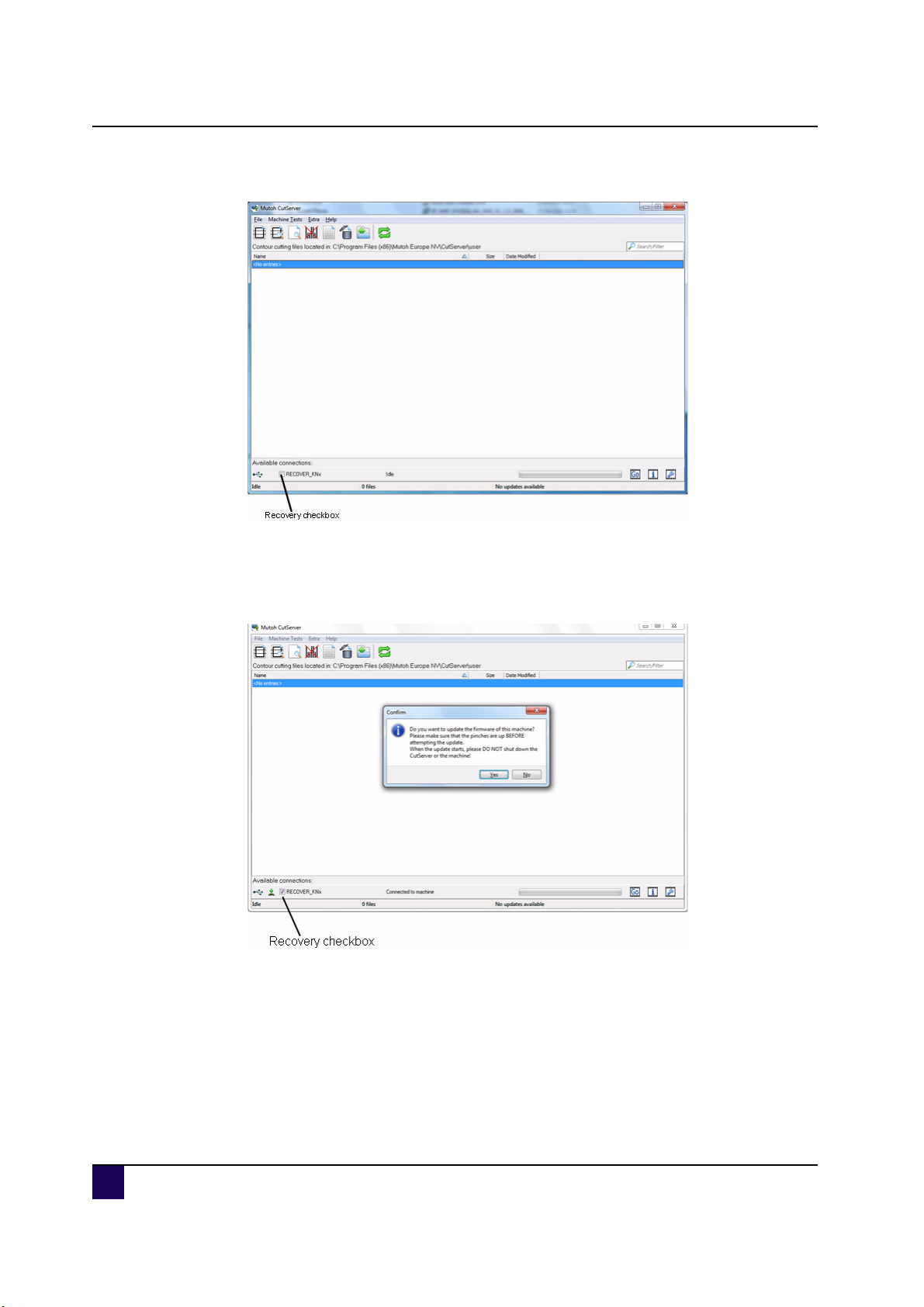

8) Activate firmware recovery mode

Step 1: It might happen that a firmware update is not performed correctly. In that case, you

are able to recover the firmware update. To do so, proceed as follows.

Step 2: Start the CutServer.

Step 3: In the CutServer, click the Extra tab and select Activate Firmware Recovery Mode.

2

Step 4: A ne

w screen appears asking if you are sure. Select Yes.

AP-75381 - Revision 1.3 23

Page 24

Application Guide Kona / Kona apparel

Installing CutServer

Step 5: In the statusbar, a recover connection becomes available.

Step 6: Se

Step 7: The recovery button appears next to the checkbox. When selecting this button, a

Step 8: T

Step 9: After the recovery, restart the CutServer or restart the cutter.

lect this recover connection.

confirmation window appears asking if you are sure you want to proceed. Select

yes.

he firmware is being recovered.

24 AP-75381 - Revision 1.3

Page 25

Application Guide Kona / Kona apparel

Installing CutServer

9) Go to service mode

For authorized Mutoh technicians only.

Help

1) Show Backup Files

When taking a backup of your parameters, a dump file is created. Use this function to browse

to the following folder C:\Program Files\Mutoh Europe NV\CutServer\backup/

2

Refer to Backup the machine settings on page13 also.

2) Show version history

This menu allows the user to get know-how about the CutServer history topics.

3) Configure update

It is possible to check for new updates using the Mutoh CutServer. Please follow the procedure below to configure the update function.

Step 1: Select help > configure update.

Step 2: The following screen will pop-up.

AP-75381 - Revision 1.3 25

Page 26

Application Guide Kona / Kona apparel

Installing CutServer

Step 3: Here you can set the following update options:

Item Option Description

Automatic

update

Periodical

check

Disable Never check if there are updates available

Enable Check if there are updates available

At start-up Check for updates every time you start-up the CutServer

Every 3 months Check for updates every 3 months

Check now Immediately check for updates

Follow the procedure below to download and install the updates (if available).

Step 1: Run the Mutoh CutServer.

Step 2: Be sure that the automatic updates are enabled.

Step 3: Check the status of the updates in the lower right corner.

Option Status Description

A Nothing available You have the latest version of firmware and software.

B Updates available There are new updates available.

Updates & Installs /

C

Upgrades available

Installs / Upgrades

D

available

You have downloaded an update which can be

installed and there are still updates available.

You have downloaded the upgrades, but not yet

installed.

Step 4: Double click on the status if there are upgrades or installs available (option B-C-D)

Step 5: Select the checkbox of the upgrade you want to download.

Step 6: When your computer is connected to the internet, the file(s) are automatically

downloaded. The downloaded files can be found in following folder: C:\Program

Files\Mutoh Europe NV\CutServer\updates

Step 7: When displaying the message "Installs/Upgrades" available, you can install the

upgrades by selecting the checkbox ones again.

Note

Be sure that there are no running jobs when installing the new CutServer

version.

Be sure that there is a connection between the CutServer and Kona / Kona

apparel when you want to install the new firmware.

Step 8: An installation window will pop-up.

26 AP-75381 - Revision 1.3

Page 27

Application Guide Kona / Kona apparel

Step 9: Press yes and continue the installation procedure.

Refer to Installing firmware>Normal procedure on page17

Refer to Installing Mutoh CutServer on page12

Installing CutServer

Important

Do NOT power OFF the cutter and computer during installation.

If the installation fails, follow the procedure here

Refer to Installing firmware>Recovery procedure on page18

4) CutServer Help

Press F1 to open this manual in a help format.

5) About

Shows you can see the CutServer version, the build and the loaded libraries.

2

AP-75381 - Revision 1.3 27

Page 28

Application Guide Kona / Kona apparel

Installing CutServer

2.3.3 Toolbar icons

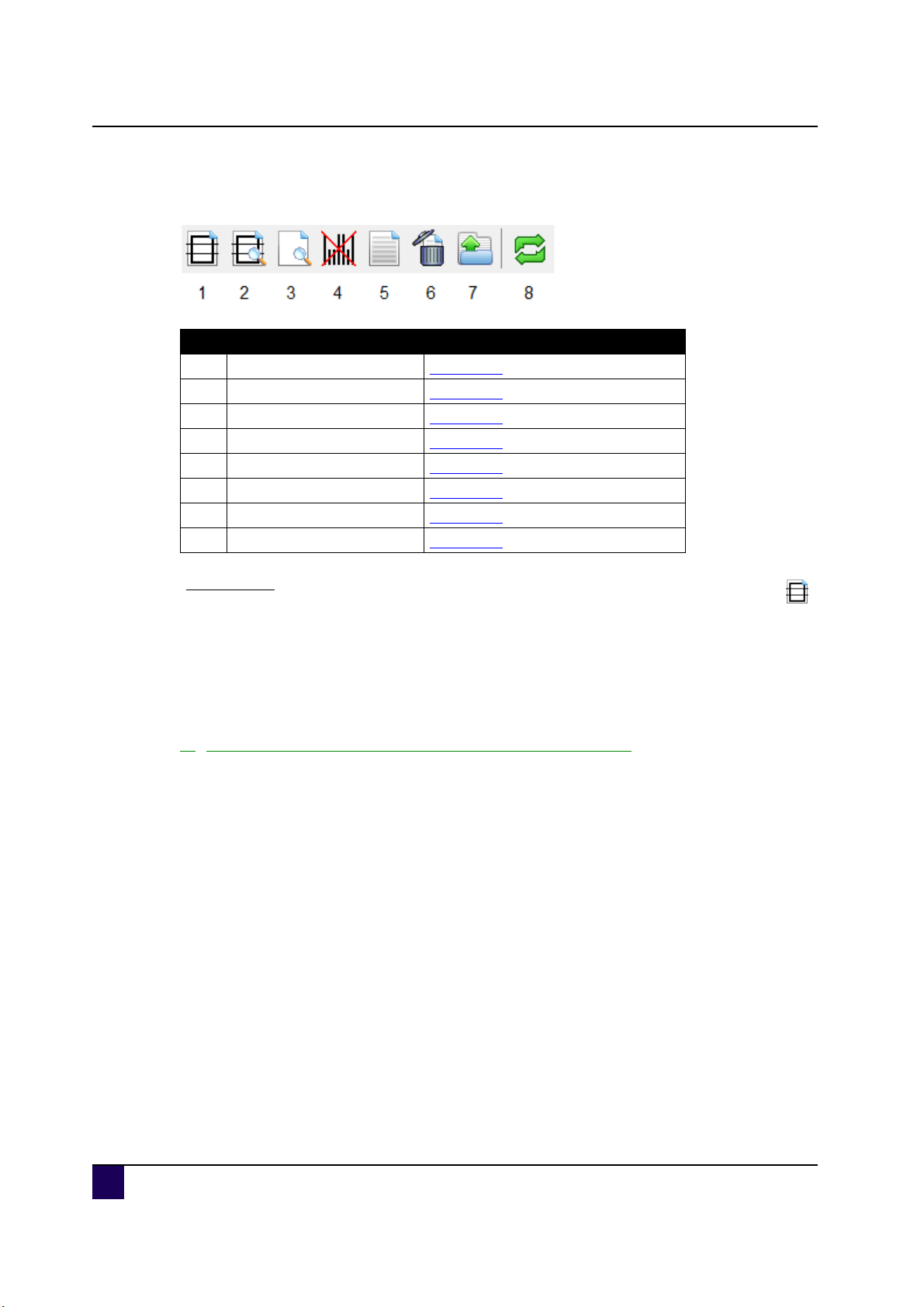

N° Icon More info

1 Clip the file on page 28

2 View/clip the selected file on page 30

3 View file data on page 31

4 Send EPOS job on page 32

5 View file info on page 32

6 Delete file on page 33

7 Set CutServer directory on page 33

8 Refresh the file list on page 33

Clip the file

Some software manufacturers do not divide or clip the standard multi frame contour data into

separated segments. In general, they will generate unsegmented contour data, carrying a NC

label (Not Clipped) in its file name. The CutServer will then be responsible to convert the

contour data into numerous segments. There are 2 possibilities:

1) Full automatic approach - DEFAULT - RECOMMENDED

The CutServer build offers the user the ability to fully convert the clipping of the unsegmented

contour data (NC file) ON THE FLY, without any user intervention. Only one condition should

be suffered from: the presence of the NC file in the CutServer Queue.

Step 1: NC file in CutServer Queue?

Step 2: Check your CutServer settings for the appropriate multipoint mode (multi frame).

Step 3: Press Go → bar code scanning → CutServer receives the ID number detected by

the Kona / Kona apparel.

Step 4: Searches for the proper bar code ID, and notifies a non-clipped ID number.

28 AP-75381 - Revision 1.3

Page 29

Application Guide Kona / Kona apparel

Installing CutServer

Step 5: Automatically, the NC → MF conversion will take place and the CutServer will only

respond with the clipped MF file

Filename_NC_41010220205.plt

Filename_MF_41010220205.plt

2

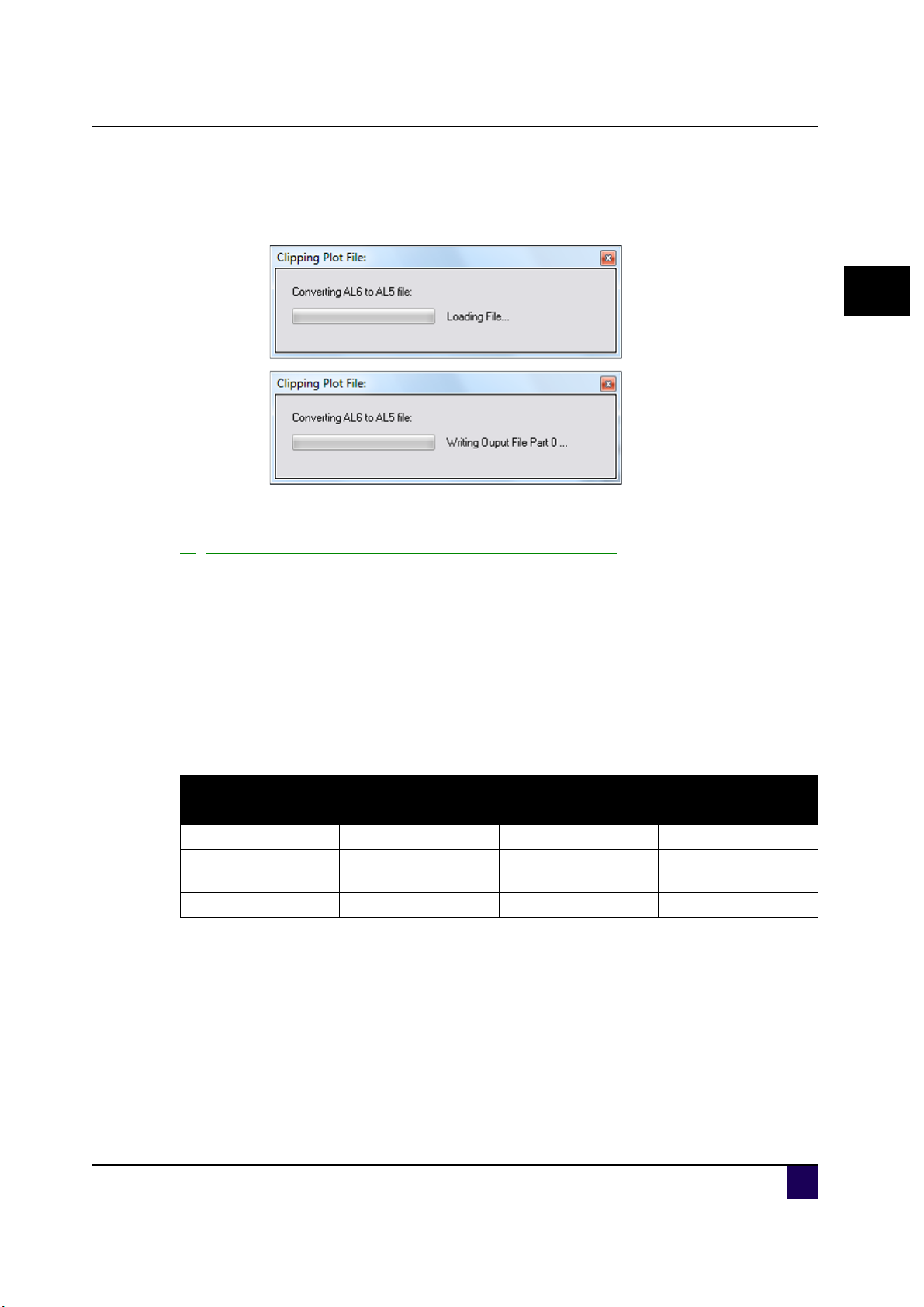

2) A manual approach - Click the Clip the file toolbar icon

Step 1: Search and select the appropriate ID file (NC label) in the Mutoh CutServer Queue.

Step 2: Press the Clip the file toolbar icon.

Step 3: Converting busy.

Step 4: The end of the CutServer clipping will result in a similar filename with MF extension.

Step 5: Check your CutServer settings for the appropriate multipoint mode (multi frame).

Step 6: Press Go → Bar code scanning → CutServer receives the ID number.

Step 7: CutServer selects the MF extension and replies with the segmented plot file.

Step 8: Segment plotting on Kona / Kona apparel.

Software manufac-

turer

EasySIGN EasySIGN NO YES

Scanvec Amiable

Caldera Grip + NO NO

(*) NC: not clipped

(**) MF: multi frame

Software bundle

PhotoPRINT SE or

DX Mutoh Edition

NC compatible (*) MF compatible (**)

Clipping method

NO YES

AP-75381 - Revision 1.3 29

Page 30

Application Guide Kona / Kona apparel

Installing CutServer

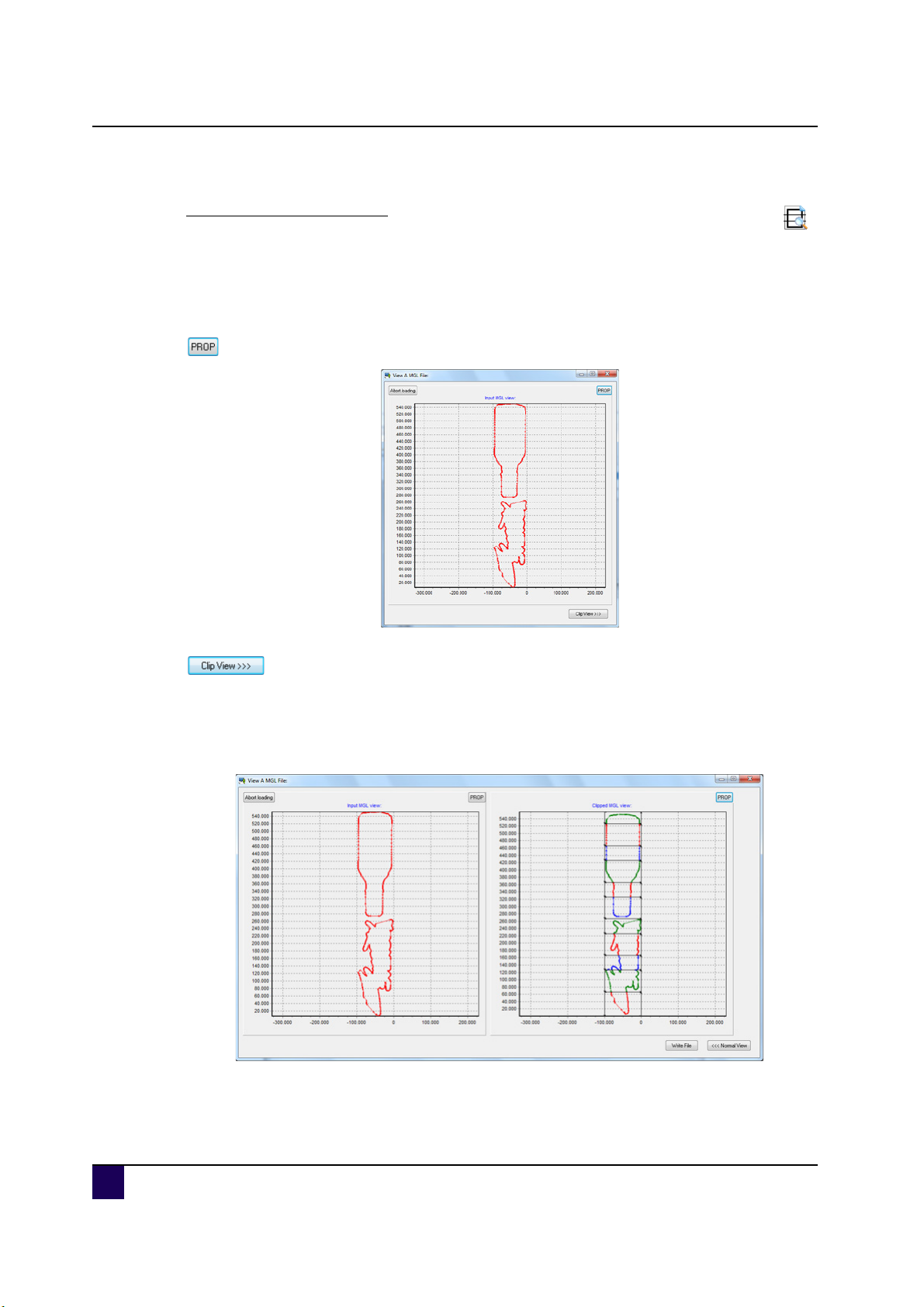

View/clip the selected file

Identical like previous clip icon, however a graphical interface will represent both NC and MF

files. For a large amount of data, it is not recommended to use this time consuming viewing

method. Nevertheless, it is always possible to abort.

Uses proportional window scaling

Views your clipping result - extend your window

Left: Input MGL view

Right: Clipped MGL view

Each colour represents a clipped segment of the entire contour alignment

file - type multi frame mode.

The files above do not show the contour boxes because they come together with the sides

of the diagram.

30 AP-75381 - Revision 1.3

Page 31

Application Guide Kona / Kona apparel

Installing CutServer

Writes a clipping file by one single click (manual method)

Before: Filename_NC_41010220205.plt (NC: Not Clipped)

After: Filename_MF_41010220205.plt (MF: Multi Frame)

Switches back to the classic normal input view

Note

Both MF and NC files will still be present in your Mutoh CutServer queue list

after completing the segment dividing / clipping.

View file data

To view the MGL plot data, the file contents can be displayed (no editing possible).

To edit the file, browse for the hot folder and correct the file as required.

2

AP-75381 - Revision 1.3 31

Page 32

Application Guide Kona / Kona apparel

Installing CutServer

Send EPOS job

In case reading errors occur during the Kona / Kona apparel's bar code detection sequence, a

manual workaround for damaged bar code strings or faulty readings is available. Search for

the correct alignment file in Mutoh's CutServer Queue, and press the Send Epos Job button.

To directly send the EPOS file without reading the bar code, the media load direction needs

to be provided (0° or 180° degrees rotated?).

As soon as a confirmation is given, the frame scanning command is adapted to bypass the

bar code reading, and immediately the registration marks of the bounding box and the vector

data are broadcasted.

View file info

In order to get know-how of certain file properties, additional information can be obtained by

double clicking each contour cutting file listed in the CutServer Queue. Furthermore, rather

than using the quick shortcut icons from the toolbar, a number of relevant file functionalities

were reproduced once more by means of an extra set of buttons.

Clip only Refer to Clip the file on page28

View/clip Refer to View/clip the selected file on page30

Start EPOS Refer to Send EPOS job on page32

32 AP-75381 - Revision 1.3

Page 33

Application Guide Kona / Kona apparel

Installing CutServer

It might be possible that you only want to cut the first segment of a

multi frame job. Via this option you can choose which segment(s) to

cut by selecting or clearing the checkboxes.

Be ware that all segments will be measured.

Choose Segments

Send Raw Data Sends out the cutting file, after asking the target communication port.

View Data Refer to View file data on page31

Close Close the window

Delete file

The recycle bin icon removes the selected file from the CutServer Queue and its hot folder!

Set CutServer directory

2

Refer to Installing Mutoh CutServer > Create and set a hot folder on page 12

Refresh the file list

The hotfolder should auto refresh automatically. However, it might be possible that the job list

is not up-to-date after adding a plot file in the CutServer hot folder. If you notice this, press the

Refresh button.

Note

In case refreshing the list does not work, restart the cutserver.

AP-75381 - Revision 1.3 33

Page 34

Application Guide Kona / Kona apparel

Installing CutServer

2.3.4 Available connections

All the cutters installed earlier are displayed in a list. The CutServer can be connected with

each cutter listed below.

Refer to Install USB drivers on page11 to know how to install your cutter properly.

Right-click on one of the connections to backup or restore parameters

Refer to Machine tests on page16

Refer to Restore the settings manually as follows on page14

N° Description Extended description

Connection type

USB

1

LAN

Serial

on page 34

2 Connection checkbox on page 35

Serial number Kona / Kona apparel /

3

machine type

on page 35

4 Status connection on page 35

5 Progress bar on page 35

6 Go button on page 35

7 Machine info button on page 35

8 Settings button on page 36

Connection type

Depending on the type of the connection, another icon is visualised.

USB connection

Network connection

Serial connection

34 AP-75381 - Revision 1.3

Page 35

Application Guide Kona / Kona apparel

Installing CutServer

Connection checkbox

Select the checkbox to make a connection with the cutter.

Clear the connection checkbox before rebooting the machine. Select the box once again

when the cutter is rebooted successfully.

Note

The connection between the PC and cutter does not disappear due to a reset. It

only disappears if the power is off.

Serial number Kona / Kona apparel

The serial number and the machine type are displayed here.

Status connection

Displays the status of varies connections e.g.

Idle

Connected to the machine

Updating firmware

...

Progress bar

Displays the progress of the sent data.

2

Go button

To identify the loaded contour job, pressing Go will start a bar code scanning sequence.

If selecting the checkbox “Show this window when I click Go”, the communication & machine

settings window opens.

Refer to Settings button on page36

Machine info button

Supplementary, a list of machine information can be obtained.

AP-75381 - Revision 1.3 35

Page 36

Application Guide Kona / Kona apparel

Installing CutServer

Settings button

When clicking this button, the following window will pop-up.

1) EPOS mode

After clicking Go, these settings are used. You can set the following:

Number of jobs to perform in 1 run

Sheeting off settings

Perform a sheet-off after the complete run is done

Perform a sheet-off between every job during this run

Note

Be sure to have the latest firmware version installed to be able to benefit from

these settings. Firmware version KN 3.0.0 is the first one supporting this

feature.

2) Terminal properties

A DOS look-alike terminal window allows you to get knowledge of certain command interactions (MGL commands) between the Kona / Kona apparel and CutServer. Every time making

a new port connection, a new corresponding terminal window is created. Selecting the relevant checkbox in the bottom section of the CutServer to activate / deactivate the plotter, will

also open such a terminal, if set to ON. As an end-user, you will normally not need to set this

option. It can be useful, however during installation or when a problem occurs, in order to test

and / or debug communication issues between the plotter and the software.

3) Autoshow settings

It might be interesting that this setup window pops-up when clicking on Go to point you on the

settings which are used during this run.

36 AP-75381 - Revision 1.3

Page 37

Application Guide Kona / Kona apparel

Setting up your print and cut software

Chapter 3 Setting up your

print and cut

software

Note

Please be aware that this chapter is for Kona only.

3

3.1 EasySIGN

3.1.1 Update EasySIGN

Please be sure to always have the latest service pack of EasySIGN installed on your

computer.

Refer to Compatibility overview on page9 to know which versions of EasySIGN are

compatible with the Kona / Kona apparel and CutServer.

There is a special driver update required when working with the Kona / Kona apparel series

cutters. This file ( Mutoh.drv ) can be found on Mutoh’s FTP

existing Mutoh.drv.

3.1.2 EasySIGN driver installation

When installing the cutter, you might need to install the driver twice. Once for the CutServer

and once for direct cutting (com port).

Once via the CutServer (to be used with the auto-align barcode workflow) and once via the

virtual com port (created by the Kona / Kona apparel USB driver) for normal sign cutting jobs.

Step 1: Start EasySIGN.

and should be copied over the

AP-75381 - Revision 1.3 37

Page 38

Application Guide Kona / Kona apparel

Setting up your print and cut software

Step 2: Go to file, device setup and click on the 'Add Plotter' Wizard. The “add plotter” window

appears. Choose Mutoh Kona and click on next,

Step 3: The Select Port window appears. Choose the virtual com port (in this case, COM3)

and click on next.

Refer to (Un)Install USB drivers>Check COM port used on page14

38 AP-75381 - Revision 1.3

Page 39

Application Guide Kona / Kona apparel

Setting up your print and cut software

Step 4: The port settings window appears, leave it on windows defaults, and click on next.

Step 5: Click on finish.The driver is now being installed.

3

AP-75381 - Revision 1.3 39

Page 40

Application Guide Kona / Kona apparel

Setting up your print and cut software

3.1.3 Configuring EasySIGN for the CutServer

Before you are able to print and cut, the software needs to be configured as follows:

Step 1: Start EasySIGN

Step 2: Go to file, device setup and click on the 'Add Plotter' Wizard. The add plotter window

appears. Choose Mutoh Kona and click on next.

Step 3: The Select Port window appears. Choose the Mutoh CutServer.

Step 4: Click on finish.The driver is now being installed.

40 AP-75381 - Revision 1.3

Page 41

Application Guide Kona / Kona apparel

Setting up your print and cut software

3.1.4 Synchronise your CutServer hotfolder in EasySIGN

EasySIGN should automatically find the directory that is used by the CutServer via the

windows registry. In case this does not happen, start via windows the production manager of

EasySIGN, go to spooler settings and change the directory.

3

Note that the directory of the CutServer is automatically changed when changing it in the

Mutoh CutServer itself after restarting EasySIGN.

AP-75381 - Revision 1.3 41

Page 42

Application Guide Kona / Kona apparel

Setting up your print and cut software

3.2 Scanvec Amiable

3.2.1 Configuring Scanvec Amiable

Before you are able to print and cut, the software needs to be configured as follows:

Step 1: Click on Setup > Add Setup or ctrl+N

Step 2: Select

Vinyl Cutters

Mutoh

Kona

Step 3: Click next

42 AP-75381 - Revision 1.3

Page 43

Application Guide Kona / Kona apparel

Setting up your print and cut software

Step 4: Choose a name and COM port and finish the setup.

Refer to (Un)Install USB drivers>Check COM port used on page14

3

AP-75381 - Revision 1.3 43

Page 44

Application Guide Kona / Kona apparel

Setting up your print and cut software

3.3 Mutoh Grip +

3.3.1 Installing a Kona driver

Step 1: Select the settings tab and press config.

Step 2: In th

Step 3: A

new application window appears. Select cutter in the type drop down list, enter a

name + press the configure button.

e applications bar, press new.

44 AP-75381 - Revision 1.3

Page 45

Application Guide Kona / Kona apparel

Setting up your print and cut software

Step 4: The cutters configuration window appears. Press new.

Step 5: In the Cutter parameters window select the correct model and press OK.

3

Step 6: In the sof

tware configuration window press restart.

AP-75381 - Revision 1.3 45

Page 46

Application Guide Kona / Kona apparel

Setting up your print and cut software

46 AP-75381 - Revision 1.3

Page 47

Application Guide Kona / Kona apparel

Chapter 4 Contourcutting

4.1 Introduction

Contour cutting is a very popular feature of the Mutoh cutters.

This feature is made to cut pre-printed signs on vinyl for sticker production as shown on this

picture:

Contourcutting

4

Please read this chapter carefully.

AP-75381 - Revision 1.3 47

Page 48

P4 P2

P3 P1

00000000000

00000000000

Application Guide Kona / Kona apparel

Contourcutting

4.2 Different alignment methods

There are some different approaches to cut your signs which also implicate a different

alignment method.

Manual alignment Single frame alignment Multi frame alignment

N° Description Info

1 Manual

2 Single Frame

3 Multi Frame

Manual alignment method

Manually set the size of the paper and 4 corners of the box

Alignment with barcode and single frame

Only 1 bounding box

Alignment with barcode and multi-segment frame.

Multiple segments in 1 bounding box

(for long files to guarantee precision).

48 AP-75381 - Revision 1.3

Software Manual Single frame

EasySIGN

Scanvec

Amiable

Mutoh Grip (+)

Mutoh

CutServer

Multi frame

(clipped)

Multi frame

(not clipped)

Page 49

Application Guide Kona / Kona apparel

4.3 Which alignment method to use?

4.3.1 Automatic alignment method

Single frame alignment method

This is a fully-automated alignment system, with a barcode printed on the sign. This method

should be used in combination with Mutoh’s CutServer.

This method can be used in case you are creating multiple different contour signs. It allows

you to make all your prints at once (overnight printing for example), and then load the roll with

images in the CutServer.

If each sign on the roll has a barcode and if all plot files are in the Mutoh CutServer, set the

amount of jobs and click on Go in the Mutoh CutServer and every sign on the roll will be cut,

without the need for user intervention (make sure you’ve enabled auto-sheet-off in EasySIGN

for each contour-sign).

The reason for the two barcodes is to make it possible for the CutServer to auto-detect if the

image is loaded upside-down or correctly. There is no need for you to search the plot file for

each image; the CutServer and the Mutoh CutServer will do this fully-automatically, until the

complete roll with signs is finished.

We do not recommend this method over 2 m job length, although there is no real limit to the

length that can be used.

Contourcutting

4

Refer to the CutServer application guide for all details about Mutoh’s CutServer and

the Print&Cut workflow.

Multi frame alignment method

The Mutoh Multi frame alignment method offers all advantages of the previous one but it will

split the image in multiple segments. This is to enhance precision over long length. This

method should be used in combination with Mutoh’s CutServer. With this method, it is

possible to make signs of 10m or longer, and the CutServer will measure segment per

segment, and cut segment per segment. This method gives you more accuracy than the

previous method.

Refer to the CutServer application guide for all details about Mutoh’s CutServer and

the Print&Cut workflow.

AP-75381 - Revision 1.3 49

Page 50

Application Guide Kona / Kona apparel

Contourcutting

Note

When working with EasySign, check the corners to see if you are using a

Single frame or multi frame alignment box.

Single Frame alignment box

Multi Frame alignment box

50 AP-75381 - Revision 1.3

Page 51

4.3.2 Manual alignment method

Single frame alignment method

This is a manually alignment system, with a barcode printed on the sign. This method should

be used in combination with Mutoh’s CutServer.

This method can be used in case the bounding box cannot be read by the cutter. In this case,

user intervention is necessary. This means the user needs to fill in the barcode number, how

the print job is loaded in the cutter and if a sheet off action is necessary once the job is done.

Once all these parameters are set, you need to jog the knife tip to some predetermined

coordinates. As soon as the cutter knows these coordinates, the cutting procedure starts

(make sure you’ve enabled auto-sheet-off in EasySIGN for each contour-sign).

We do not recommend this method over 2 m job length, although there is no real limit to the

length that can be used.

Multi frame alignment method

Application Guide Kona / Kona apparel

Contourcutting

4

Is the same as the single frame alignment method but for multi frame jobs.

This method should be used in combination with Mutoh’s CutServer. With this method, it is

possible to make signs of 10m or longer.

Once you have set all parameters and positioned the knife tip over the predetermined

coordinates, the CutServer will start and cut segment per segment. This method gives you

more accuracy than the previous method. We do not recommend this method for signs

smaller than 1,2m.

Refer to the CutServer application guide for all details about Mutoh’s CutServer and

the Print&Cut workflow.

Manual alignment method

The Mutoh Manual Alignment Method is a non-automatic method.

Its advantage is that the cropmark system is very small (for small sized jobs), and that this

method can be used in case of vinyl that do not reflect the EPOS laser light (meaning, the

laser would not be capable of measuring the cropmarks automatically).

Refer to EPOS read on page138

The user has to use the jog keys on the keyboard to measure each cross manually before

contour cutting can start.

Refer to the CutServer application guide for all details about Mutoh’s CutServer and

the Print&Cut workflow.

AP-75381 - Revision 1.3 51

Page 52

Application Guide Kona / Kona apparel

Contourcutting

Note

When working with EasySign, check the corners to see if you are using a

Single frame or multi frame alignment box.

Single Frame alignment box

Multi Frame alignment box

52 AP-75381 - Revision 1.3

Page 53

Indicates the max

working width when

working with a

Kona Apparel

4.4 Bounding box details

4.4.1 Hints, tips and recommendations

To use the automatic alignment procedure, the pre-printed sheet contains a bounding box

around the design to be cut.

Note that the bounding box around your design(s) is printed. Before contour-cutting the

EPOS technology will search for the bounding box and measure the position of the

design(s).

Be sure that there is 5 mm of white space between the image and the bounding box.

Be sure that the bounding box has a dark colour (recommended: black) in order to have

enough contrast with the vinyl.

The minimum thickness of the bounding box is 3 mm. However, when printing the

print&cut file on an Osprey or Toucan, it is recommended to raise this value to at least 5

mm.

Make sure that the bounding box fits within the margins of the maximum cutting width of

your cutting plotter.

On a Kona apparel the maximum width is marked by the 2 extra holes at both the left and

right side of the platform.

Application Guide Kona / Kona apparel

Contourcutting

4

Be sure that the media has been sheeted off straight. If not, the cutter will have

problems measuring the media.

Note

The position of the design with the bounding box compared to the page edges

is defined in the print-software.

The creation of an image should be done in a graphics application software

(e.g. CorelDraw, Adobe Illustrator, Adobe Photoshop or Macromedia Freehand)

or in origin software with design functionalities (EasySIGN Power Pack Pro

Mutoh Edition or Scanvec Amiable PhotoPRINT DX Mutoh Edition)

Do not forget to create the cutting line around your image. The default cutting

line is a “magenta hairline” or “spotcolor” with <CutContour> swatch name (in

the CMYK pallet).

Thickness line = hairline (or 0.25)

Colour = 100% magenta

For more details, please refer to the CutServer Application Guide.

AP-75381 - Revision 1.3 53

Page 54

1

2

3

4

5

6

7

Sheet

Bounding box

Pressure roller

Application Guide Kona / Kona apparel

Contourcutting

4.4.2 Bounding box specifications (without bar code, no cutserver application required)

For automatic alignment Type 1

The frame bounding box printed or generated around the contour cut data should respect the

guidelines below.

N° Description Minimum Maximum

White edge at the rear side

Sheet

1

Between 2 boxes

75 mm

50 mm

-

1200 mm

Add extra space (50mm) when working with curled

media

White edge at the front side

2

Add extra space (50mm) when working with curled

media

3 bounding box thickness 3 mm 20 mm

25 mm 1200 mm

4 bounding box width 250 mm -

5 bounding box height 250 mm 10 m

6 Margin between image and bounding box 6 mm -

7 Distance between pressure roller and bounding box 1 mm -

54 AP-75381 - Revision 1.3

Page 55

1

2

3

4

5

6

11

Sheet

Bounding box

Pressure roller

7

10

9

93908130410

93908130410

8

Application Guide Kona / Kona apparel

Contourcutting

For automatic alignment Type 2

(With barcode & with CutServer)

The frame bounding box printed or generated around the contour cut data should respect the

guidelines below.

4

N° Description Minimum Maximum

White edge at the rear side

Sheet

1

Between 2 boxes

75 mm

50 mm

250 mm

250 mm

Add extra space (50 mm) when working with curled

media

White edge at the front side

2

Add extra space (50 mm) when working with curled

20 mm 300 mm

media

3 bounding box thickness 3 mm 20 mm

4 bounding box width 250 mm -

5 bounding box height 250 mm 10 m

6

7

8

Vertical distance between image (or bottom part of

your ID number) and bounding box edge

Horizontal distance between bottom part of your

bar code and bounding box edge

Vertical distance between bottom part of your bar

code and bounding box edge

2 mm 6 mm

40 mm 100 mm

6 mm 12 mm

AP-75381 - Revision 1.3 55

Page 56

Application Guide Kona / Kona apparel

Contourcutting

N° Description Minimum Maximum

9 Bar code height 20 mm 20 mm

10 Bar code width 246 mm -

Distance between pressure roller and bounding

11

box

Note

Upper and lower postnet barcodes do have an identical margin setup

Make sure to respect the minimum margin setup (6) when adding your postnet

ID number too

1 mm -

56 AP-75381 - Revision 1.3

Page 57

1

2

3

5

6

13

Sheet

Bounding box

Pressure roller

4

9

7

12

11

93908130410

93908130410

8

10

Application Guide Kona / Kona apparel

Contourcutting

For automatic alignment Type 3

(With barcode & with CutServer)

The frame bounding box printed or generated around the contour cut data should respect the

guidelines below.

4

N° Description Minimum Maximum

White edge at the rear side

Sheet

1

Between 2 boxes

75 mm

50 mm

250 mm

250 mm

Add extra space (50mm) when working with curled

media

White edge at the front side

2

Add extra space (50mm) when working with curled

20 mm 300 mm

media

3 bounding box thickness 3 mm 20 mm

4 In between marker length 10 mm 60 mm

5 bounding box width 250 mm -

6 bounding box height 250 mm 10 m

7 Start / stop bounding box height 125 mm 125 mm

Vertical distance between image (or bottom part of

8

your ID number) and bounding box edge

Horizontal distance between bottom part of your

9

bar code and bounding box edge

2 mm 6 mm

6 mm 12 mm

AP-75381 - Revision 1.3 57

Page 58

Application Guide Kona / Kona apparel

Contourcutting

N° Description Minimum Maximum

Vertical distance between bottom part of your bar

10

code and bounding box edge

11 Bar code height 20 mm 20 mm

12 Bar code width 246 mm -

Distance between pressure roller and bounding

13

box

Note

Upper and lower postnet barcodes do have an identical margin setup

Make sure to respect the minimum margin setup (8) when adding your postnet

ID number too

40 mm 100 mm

1 mm -

58 AP-75381 - Revision 1.3

Page 59

1

2

3

4

Application Guide Kona / Kona apparel

1

2

34

scan 1

4.5 Scanning routing of bounding box

The bounding box is measured by the Epos sensor during a fast scan routine. It is interesting

to know the principle behind this innovative scanning method.

The scanning routine will go through the following steps:

Contourcutting

4

1 The laser will be activated to detect the background colour. This value will be used to

recognize the difference between background and box during the scanning procedure.

2 A diagonal scan will be executed at the set cutting speed in the firmware (user controlled).

3 A horizontal scan will be executed at maximum speed.

4 The head goes back over the scanned path to verify.

As from the moment the scan cycle detects 4 points, the position of the barcode is known

(situation 1 and 2). When there are less than 4 points detected, an intelligent feed of media

will be done and the same type of scan will be performed a second time (situation 3).

Situation 1 = Bottom and side of frame detected (4 points)

AP-75381 - Revision 1.3 59

Page 60

Application Guide Kona / Kona apparel

1

2

3

4

scan 1

scan 2

scan 1

1’

2’

3’

4’

1

2

Contourcutting

Situation 2 = Both sides detected (4 points)

2nd scan > bottom and side of frame detected (4 points)

Situation 3

1st scan > both sides detected (2 points)

feed of media to start second fast scan

When the cutter establishes a slight difference between the thickness of the frame in one or

more corners, a re-measuring will be performed at the respective side of the frame but slightly

higher or lower. If there is still a dissimilarity, a warning message will be displayed on the

panel and a cross will be cut in the lower right corner.

Afterwards, the cutter starts reading out the barcode. As from the moment the barcode is

recognized, the corresponding job is launched from the Mutoh CutServer.

Note

The same principle of scanning is also used on the top and centre of the

bounding box. Due to the use of this measurement system it is possible to

measure bounding boxes with a small print step error.

60 AP-75381 - Revision 1.3

Page 61

Application Guide Kona / Kona apparel

4.6 Kona / Kona apparel keyboard features

4.6.1 Automatic

When performing a single or multi-frame contour cut job, start the job via the Go button on

Mutoh’s CutServer. It is also possible to launch the job directly from the cutter itself, only on

the condition that the cutter is connected with Mutoh’s CutServer. In fact, this function

replaces the Go button.

Start a single or multi-frame contour cutting job as follows:

Step 1: Press the following buttons in order:

Actions

Contour Cut

Contourcutting

4

Automatic

Step 2: Sele

ct whether the job loaded is a single or multi-frame contour cut.

AP-75381 - Revision 1.3 61

Page 62

Application Guide Kona / Kona apparel

Contourcutting

Step 3: Set the number of jobs to perform

Press Jobs

Fill in the number of jobs.

Step 4: Press

p 5: Press the Sheet off between button.

Ste

Decide if you want to perform a sheet off action between two jobs or not.

Step 6: Press the Sheet off afterwards button.

Decide if you want to perform a sheet off action after the jobs or not.

Step 7: Press the start key.

Step 8: The cutter

will start scanning the bounding box and reading out the barcode.

Step 9: As from the moment the barcode is recognized, the corresponding job is launched

from the Mutoh CutServer.

62 AP-75381 - Revision 1.3

Page 63

4.6.2 Manual

When you want to start a contour cut job of which for example the bounding box is not printed

clearly, the automatic alignment option will not work. In this case the manual mode needs to

be chosen.

Start a manual contour cutting job as follows:

Step 1: Press the following buttons in order:

Application Guide Kona / Kona apparel

Contourcutting

Actions

Contour Cut

4

Manual

Step 2: De

cide whether the job loaded is a single or multi-frame contour cut.

AP-75381 - Revision 1.3 63

Page 64

Application Guide Kona / Kona apparel

Contourcutting

Step 3: Fill in the bar code number

Press Barcode

Fill in the barcode.

Step 4: Press

p 5: Fill in how the job is loaded

Ste

Press Direction

Set whether the media is loaded Reverse or Non Reverse.

Step 6: Press

64 AP-75381 - Revision 1.3

Page 65

Application Guide Kona / Kona apparel

Step 7: Decide if a sheet off operation is necessary once the job is done.

Press ShtOff Aft.

Select Yes or NO.

Contourcutting

4

Step 8: Press st

The CutServer will now look in the CutServer queue for the correct file. Once the

art.

file is received, the cutter asks to move the knife tip to predefined coordinates.

Step 9: Once all coordinates are determined, the cutter will start the job.

When you want to start a contour cutting job without using the automatic alignment option, or

if no automatic detection is possible, the manual mode needs to be chosen. This could be

useful when you have loaded very reflective media which cannot be detected by the cutter.

Start a manual contour cutting job as follows:

Step 1: Press the following buttons in order:

Actions

Contour Cut

Manual

Manual

Step 2: Se

t the exact length and width of the bounding box.

AP-75381 - Revision 1.3 65

Page 66

Application Guide Kona / Kona apparel

X Length

Y Width

P1

P3

P2

P4

Contourcutting

Step 3: Set the roll direction.

Non-reverse: When standing in front of the cutter, the data sent should not be

rotated.

Reverse: When standing in front of the cutter, the data sent should be rotated.

Step 4: Press start.

Step 5: M

ove the penhead using the jog keys until the knife point is positioned above P1

and press OK when done. Then select P2 - P3 - P4.

Step 6: The knife will pause near point P1

Step 7: Send the relative (NOT absolute) plot data to the cutter to start the job.

66 AP-75381 - Revision 1.3

Page 67

4.7 Print and cut with EasySIGN

Please follow the steps below to perform a print and cut workflow with NCD EasySIGN.

Step 1: Create your contour design with hairline identification.

Application Guide Kona / Kona apparel

Contourcutting

4

Step 2: Set your import settings in EasySIGN.

Step 3: Import your designs.

AP-75381 - Revision 1.3 67

Page 68

Application Guide Kona / Kona apparel

Contourcutting

Step 4: Enable cropmark settings in the menu which comes on the screen when pushing the

right mouse button.

Step 5: Select appropriate alignment system:

Mutoh Manual Align

Mutoh Auto Align

Mutoh Auto Align (barcode)

Mutoh Auto Align (Multiframe)

Set number of segments or select “0” if you want to make EasySIGN decide

itself.

Refer to Different alignment methods on page48

Step 6: Do you have EasySIGN Power Pack Pro?

Yes >> Print via EasySIGN

No >> Export and import into your rip bundle

Step 7: Do you want a barcode?

No >> [A] Direct plotting (Mutoh Manual Align, Mutoh Auto Align)

Yes >> [B] Plot file via Mutoh CutServer (Mutoh Auto Align (barcode), Mutoh

Auto Align (Multiframe))

68 AP-75381 - Revision 1.3

Page 69

Application Guide Kona / Kona apparel

Step 8: [A] Direct Plotting (Mutoh Manual Align, Mutoh Auto Align)

Contourcutting

4

AP-75381 - Revision 1.3 69

Page 70

Application Guide Kona / Kona apparel

Contourcutting

Step 9: [B] Plot file via Mutoh CutServer (Mutoh Auto Align (barcode), Mutoh Auto Align

(Multiframe))

Set EasySIGN link with Mutoh CutServer and verify the location of the hot folder

(Spooler Production Manager) and match with the CutServer.

Refer to EasySIGN > Configuring EasySIGN for the CutServer on page 40

Refer to EasySIGN > Synchronise your CutServer hotfolder in EasySIGN on page 41

Plot Print & Cut lines to Mutoh CutServer

Step 10: Send plot job via Mutoh CutServer to Kona / Kona apparel

Press the Go Button in the Mutoh CutServer or launch the job directly via the

Kona / Kona apparel

Refer to Available connections > Go button on page 35

Refer to Kona / Kona apparel keyboard features on page61

70 AP-75381 - Revision 1.3

Page 71

Application Guide Kona / Kona apparel

4.8 Print and cut with Mutoh Grip (+)

Please follow the steps below to perform a print and cut workflow with Mutoh's Grip(+).

Step 1: Create your contour design in Illustrator. Be sure that

The Swatch Name is CutContour

It is a spotcolor

ColorMode is CMYK

The colour is 100% magenta

The swatch has a thickness of 0.1 mm

Contourcutting

4

Step 2: Import the job in Grip(+). If everything is correct, a scissor is displayed in the

preview pane.

Step 3: Drag your file to the desired printer.

Step 4: Click the following button to open the preferences.

AP-75381 - Revision 1.3 71

Page 72

Application Guide Kona / Kona apparel

Contourcutting

Step 5: Go to the Cutting tab and enable Cutting Contour and Print registration marks.

Note

It is not recommended to mark the “Print bar code” and “Print Identification

number” box. This is NOT the Postnet barcode and job number which the

CutServer uses, but only the Grip(+). The original barcode will automatically be

printed.

Step 6: After making the above settings, close the screen and print the job.

Step 7: As soon the job is printed, it is queued in the Grip(+) CutServer.

Step 8: Double click on your Kona / Kona apparel cutter and press the Configure… key.

72 AP-75381 - Revision 1.3

Page 73

Application Guide Kona / Kona apparel

Contourcutting

Step 9: Fill in the link type (USB) and verify if your cutter is well connected by pressing on

the detect cutter key.

4

Step 10: Set positioning, sheeting off mode and cutter step as you wish.

Note

Be sure to set the cutter step in Grip(+) the same as the program step on the

cutter. If not, the image will be cut 2,5 time bigger or smaller.

Alignment

method

Full Automatic

Single

Full Automatic

Repeat

Blind cut

None

More info

The Postnet barcode printed is scanned to identify the job. The cutter will

stop once the job is finished.

The Postnet barcode printed is scanned to identify the job. The cutter will

continue with the next box until the complete roll is finished.

You need to select the job you want to cut in the software and manually

align the bounding box. Once the bounding box is determined, the cut

job will start without reading the bar code.

Means there will be no positioning, the job will be cut immediately (useful

for cutting in coloured vinyl for example).

AP-75381 - Revision 1.3 73

Page 74

Application Guide Kona / Kona apparel

Contourcutting

Step 11: For each contour type, a tool setup should be available. Add or edit the knife

settings accordingly.

Step 12: Press the OK button.

Step 13: Press the Cut key to start cutting sequence.

74 AP-75381 - Revision 1.3

Page 75

Application Guide Kona / Kona apparel

4.9 Print and cut with Scanvec Amiable

Please follow the steps below to perform a print and cut workflow with Scanvec Amiable.

Step 1: Create your contour design in Illustrator. Be sure that:

The Swatch Name is CutContour

It is a spotcolor

ColorMode is CMYK

The colour is 100% magenta

The swatch has a thickness of 0.1 mm

Contourcutting

4

Step 2: Click on the printer TAB and add your design.

Step 3: Double click on the job in the hold list to see the job properties.

AP-75381 - Revision 1.3 75

Page 76

Application Guide Kona / Kona apparel

Contourcutting

Step 4: Click on the workflow tab and be sure to select the "Send cut job" checkbox!

76 AP-75381 - Revision 1.3

Page 77

Application Guide Kona / Kona apparel

Contourcutting

Step 5: Click on the labels and marks tab and select the requested alignment method.

Mutoh Mark: Single frame

Mutoh Single segment: Multi frame with only 1 segment

Mutoh Multiple segments: Multi frame with multiple segments

4

Step 6: Rip and Print the contour job.

Step 7: After printing the job, the plot data will automatically be added to CutServer (Mutoh

or Scanvec, depending on your settings).

Refer to Configuring Scanvec Amiable on page42

Step 8: Now you can cut the job.

AP-75381 - Revision 1.3 77

Page 78

Application Guide Kona / Kona apparel

Contourcutting

78 AP-75381 - Revision 1.3

Page 79

Application Guide Kona / Kona apparel

1

2

Cutting through

Chapter 5 Cutting through

5.1 Introduction

Working with the through cut setting consists out of two major parts.

The first part is when working with the Kona.

When the contour of your file is completed, single sticker samples (basic shapes) are often to

be isolated (e.g. if making 100 stickers, you want to be able to get out every sticker

separately).

The second part is when working with the Kona apparel.

When you have written the text you want, or drawn the design you wanted, you are able to cut

out the design using the through cut setting.

5

AP-75381 - Revision 1.3 79

Page 80

Application Guide Kona / Kona apparel

Cutting through

5.2 Setting up your cutter

5.2.1 Tools necessary on a Kona

Through cutting is a combination of firmware and software features, the correct settings and

tools. Be sure to have the following firmware, software and tool(s) to perform a through cut.

Firmware - program - tool To have at least ...

Kona / Kona apparel cutter

firmware

EasySIGN

Mutoh Grip (+) 8.00

Standard knife Angle = 45° and offset = 0,50 mm

Cut through knife

Spare cutting mat Partnumber: KY-15305

KN 1.0.0 or higher

service pack v 5.12

There is a special driver update required when working with

the Kona / Kona apparel series cutters. This file ( Mutoh.drv )

can be found on Mutoh’s FTP

existing Mutoh.drv

Angle = 45° and offset = 0,50 mm

Depending on the material you are using, the angle might be

different.

and should be copied over the

5.2.2 Tools necessary on a Kona apparel

Through cutting is a combination of firmware and software features, the correct settings and

tools. Be sure to have the following firmware, software and tool(s) to perform a through cut.

Firmware - program - tool To have at least ...

Kona / Kona apparel cutter

firmware

Standard knife Angle = 60°

Spare cutting mat Partnumber: KY-15305

KN 1.0.0

80 AP-75381 - Revision 1.3

Page 81

5.2.3 Toolswap settings

Step 1: Press the following buttons in order:

Settings

Tool

next page

Swap alert

Application Guide Kona / Kona apparel

Cutting through

5

Step 2: M

On or Off, if swap alerts is set to off, an automatic switch between tools is

ake your preferred choice:

performed without tool swap notifications.

AP-75381 - Revision 1.3 81

Page 82

Application Guide Kona / Kona apparel

Cutting through

5.2.4 Through cut settings

It is however not easy to match an ideal tool configuration setup in which the media weakness

suffers not radically from the multiple cut through samples accomplished. Therefore a perfect

harmony between your tool down force and tool up distance needs to be synchronised.

Via this menu, you can set the desired cut through parameters.

Parameter Description

Tool Select the tool you want to use for the cut through operation.

Vel ocity

Force

Tool Down Distance (1)

Tool Up Distance (2)

The speed of which the cut through routine is cut.

Default: 10 cm/s

The force on the tool during the cut through routine.

Default: 250 gram

The distance of cutting through the vinyl.

Default: 10 cm

The quantity of vinyl left uncut to hold the sticker fixed to the

media. Default: 0,1 cm

Note

Be aware that Software such as EasySign overrules your settings. Therefore it

is best to verify the settings in the used software as well.

Note

EasySign uses always SP2 and its own Cut Through parameters.

The user can define his own tool in the user interface (default tool 2) however,

these settings are overruled by the EasySign settings.

After setting these values, it is also possible to test if they match your needs

Follow the procedure below to the velocity and force:

82 AP-75381 - Revision 1.3

Page 83

Step 1: Press the following buttons in order:

Settings

Cut through

Click tool

Select the tool you want to use and confirm with

Set the values for the velocity and force.

Application Guide Kona / Kona apparel

Cutting through

Step 2: Enter the desired values and confirm with

Step 3: Press the test key to verify the quality of the through cutting settings.

Step 4: Se

t the values for the tool up and tool down distance.

Go to the next sub page

Select Up Dist. and/or Down. Dist.

Step 5: Enter the desired values and confirm with

Step 6: Press the test key to verify the quality of the through cutting settings.

Step 7: Check

if it is easy to push out the cut patterns. If not, try to increase the force and

knife depth or to decrease the tool down distance.

Step 8: Be sure to perform a sheet-off after the test because the pushed-out squares/circles

will uncover the paper sensor which could lead to an error.

5

Refer to

Toolswap settings on page81

AP-75381 - Revision 1.3 83

Page 84

Application Guide Kona / Kona apparel

Cutting through

5.3 Through cutting workflow

Basically, 4 cut through parameters are required:

Cut through speed

Cut through force

Tool down & tool up distance

Cut the vectors in following order:

1st Standard cut lines

2nd Print and cut lines

3rd Cut through lines

Cut through specifications:

reduce your speed to 10 cm/s

increase your force to 250 g

use all pressure rollers

On a Kona 760 ==> 2 pressure

rollers

On a Kona 1400 and Kona 1650 ==> 3 pressure rollers.

lower your cut through media width dimension

choose your in between margins for cut through stickers sufficient enough

minimal vinyl movement

plot order important (first > contour data, second > cut through data)

VS/ZF/AS menu = accept (new header per line type)

When accepting you will use the software settings and not the parameters you set.

Therefore you need to set your preferred settings in the software.

easy cut through shapes (rectangles, circles, squares)

NO multi-frame alignment systems advised (multi-segment)

NO repeat mode recommend

For cut through reasons, it is better to have this dashing technique configured at the end of

your vector data group. The sorting routine of your software should therefore automatically

configure these vector paths at the end of your file output.

Cut Through compatible alignments are:

Manual Alignment

Automatic Alignment

Automatic Alignment with bar code

Automatic multi - frame alignment with bar code (# segments)

Cut Through incompatible alignments are:

Multi - frame splitting done by the CutServer

Refer to Tools necessary on a Kona on page80 to know which software are compatible.

84 AP-75381 - Revision 1.3

Page 85

5.4 Through cutting with EasySIGN

5.4.1 Convert shapes to cutthrough lines

After importing your design into EasySign, it is possible to convert your lines to cutthrough

lines as follows:

Step 1: Select the lines, right-click and select Convert to > Line type > Cut through line.

Application Guide Kona / Kona apparel

Cutting through

5

Step 2: The basic shape is converted to a dashed blue line.

AP-75381 - Revision 1.3 85

Page 86

Application Guide Kona / Kona apparel

Cutting through