Page 1

1

Full Color Inkjet Printer

RJ-4100

RJ41-A-01

MAINTENANCE

MANUAL

Page 2

2

CON1000Model Name: RJ–4100

CON1000Model Name: RJ–4100

Introduction

Introduction

This equipment is Class 1 communications equipment (communications equipment

to be used in commercial and industrial areas) and conforms to Voluntary

Communications Control Institute (VCCI) standards for data processing and other

equipment for the prevention of radio wave interference in commercial and industrial

areas.

Therefore, if it is used in or near a residential area, it may cause interference with

radio and television reception.

It should be used correctly in accordance with the operation manual.

■ Concerning interference with reception

Since this product emits weak radio waves, if it is not installed and used correctly

and is thought to be causing interference with radio and television reception, this

may be prevented by trying a combination of the following measures:

• Try changing the orientation of the receiving antenna and feeder.

• Try changing the orientation of this product.

• Change the distance between the receiver and this product.

• Try using different power supply systems for the receiver and this product.

■ Trademarks included in this manual

• MUTOH, RJ-4100, MH-GL, MH-GL/2, MH-RTL, ESC/P2 are trademarks or trade

names of Mutoh Industries Ltd.

• HP, HP-GL, HP-GL/2, HP-RTL, HP759X, HP758X, C2848 are trademarks or

trade names of the Hewlett Packard Company.

• EPSON ESC/P is a trademark or trade name of the Seiko-Epson Company.

• Centronics and Bitronics are trademarks or trade names of the Centronics Data

Computer Company.

• Windows 3.1, Windows 95, Windows NT 3.51, Windows NT 4.0, MS-DOS are

trademarks or trade names of the Microsoft Corporation

• Other names of products and companies are the trademarks or trade names of

each relevant company.

This manual contains basic technical details necessary for marketplace servicing to

maintain product quality and performance of RJ-4100 printer.

RJ-4100 printer is equipped with a self-diagnostic program that will be of service for

adjusting and checking whenever a fault is detected or during maintenance.

This manual contains all the basic items but actual maintenance work should be

undertaken only after a thorough understanding of the functions, operations and

movements has been gained from the operation manual and by other means.

Please note that there may be occasions where the name of a part used in the

explanation in this manual differs from the name of that same part that is used in the

operation manual or in the parts list.

Published by Mutoh Industries Ltd., 1-3 Ikejiri 3-chome, Setagaya-ku, Tokyo

Copyright May 1999, Mutoh Industries Ltd. All rights reserved.

CAUTION:

• The details of this product and the contents of this manual are

protected by copyright held by this Company and, except for

legitimate use by individuals, unauthorized copying, reproduction

or distribution in whole or part is forbidden.

• Details contained in this manual may be subject to future alteration

without notice.

• Details contained in this manual are believed to be correct but

please contact this Company or a dealer if an error is suspected

or a point is not clear.

• In no event will this Company be responsible for the consequences

of using this product or this manual.

Page 3

CON1010Model Name: RJ–4100

CON1010Model Name: RJ–4100

Some Thoughts on Maintenance Work

Some Thoughts on Maintenance Work

1. Some ideas about maintenance work

Maintenance work falls into two major categories, fault maintenance and protective maintenance, both of which are aimed at stable operation of the equipment that has been delivered to the user.

The profitability of maintenance work must also be considered.

• In principle, fault maintenance and protective maintenance are both carried out by the

one person.

• Both fault maintenance and protective maintenance involve the bringing of maintenance

parts.

• The cooperation of the user/operator is used effectively.

2. Protective maintenance work

Periodic maintenance is designed to provide the user with more stable operation of the

equipment and involves the periodic cleaning and replacement of replacement parts. Basic

ideas on protective maintenance include:

• Adhere strictly to preventive maintenance periods.

• In a case of carrying out preventive maintenance, gain the approval of the user before-

hand.

• Don’t press preventive maintenance on the user.

3. Fault maintenance work

A fault will hold up the user’s work and must be remedied quickly. The following are some

basic ideas on fault maintenance:

3-1 Use the user/operator to obtain a more detailed grasp of the fault.

• Conduct a primary consultation by “inquiry sheet”, “fax” and “telephone”

• Select applicable symptoms from the trouble-shooting lists and make inquiries in

accordance with the primary consultation form. (Check error messages, check the

user’s operating conditions, test again with changed settings, output test patterns,

etc.)

3-2 If it is not solved by the primary consultation, take the necessary maintenance items

and make an on-site visit.

• Assemble the necessary maintenance parts from the matrix map

• At the user’s premises, first check the symptoms.

• Proceed with maintenance work in accordance with the fault tracing procedure.

• After the repair work is finished, be sure to check again by testing in accordance

with the test procedure.

3-3 If repair is not possible even though all the work has been done in accordance with

the fault tracing procedure:

• Contact the Sales Support Groups in Graphics Sales Section or Data Equipment

Sales Section of the Data Imaging Operations Division.

4. The need for user/operator cooperation

! CAUTION: The user can not be compelled to do the following!

Asking the user/operator to cooperate is not a matter of having the user do the maintenance for you but it is necessary in order to have the equipment working more efficiently

and for having faults rectified quickly.

Actually, even when you do ask for the user’s cooperation, instead of a simple acknowledgement you will usually get doubts and quibbles such as “I’m paying for maintenance”,

“I’m not familiar with the equipment” and “it only benefits the manufacturer.”

However, you must try to persuade the user/operator to cooperate by explaining that doing

daily inspections will give better printing quality and giving you all the fine details of a fault

means that the fault will be rectified quickly.

The following explains the items you need in order to understand fault conditions in detail:

• Check error messages

• Check user’s usage conditions

• Output from diagnostic pattern

• Output from setup lists

• Retest after changing settings

• Probability of recovery by implementing daily inspections.

3

Page 4

4

CON2000Model Name: RJ–4100

CON2000Model Name: RJ–4100

Precautions For Maintaining This Printer

Precautions For Maintaining This Printer

PRECAUTION 1 Head Cleaning

Head cleaning (see REP1620) must be carried out when this printer is to be transported by truck (see CON6000) and when the following parts are to be replaced.

< Replacement parts > Head, Damper, Head Cable, Cartridge Frame Assembly,

Ink Tubes

PRECAUTION 2 Head Cleaning Jig

When the head cleaning jig is to be used, fill the jig’s 100 cc bottle with at least 50

cc of cleaning fluid and use it with the cap loosened.

If head cleaning is done with the cap tightened, ink will flow back into the 100 cc

bottle.

When you have finished head cleaning, return the remaining cleaning fluid from the

100 cc bottle to the 500 cc cleaning fluid bottle (JD-42054).

PRECAUTION 3 Printing After Initial Filling

On rare occasions, printing quality may be unstable if printing is carried out immediately after initial filling.

If this occurs, switch off the power and wait for at least 30 minutes before trying to

print again.

PRECAUTION 4 Thorough Waste Fluid Box Replacement

When the following tasks have been carried out, install a new waste fluid box and

clear the waste fluid counter.

1. After head cleaning and initial filling.

2. When it was not possible to capture main board backup parameters.

PRECAUTION 6 Take Care When Inserting Head Cable and Y Cable

PRECAUTION 7 Ink and Cleaning Fluid Conduct Electricity

When the print head assembly, head board assembly and main board assembly

have been replaced, be careful to insert the head cable and Y cable straight to the

back and don’t forget to lock the connectors.

(The connectors fitted with locks are J207 and J208 on the head board.)

If the cables are inserted obliquely or power is applied without locking the connectors, there is a risk that the head board may be damaged and it will be impossible

for ink to be ejected.

Ink and cleaning fluid will conduct electricity.

If there is ink or cleaning fluid on cables or connectors when power is applied, there

will be a short circuit which may lead to all sorts of damage.

If there is ink on the contacts of the connector, wipe it off with alcohol or ethanol and

allow to dry thoroughly before reconnecting.

PRECAUTION 5 Maintenance Unit Tubes

If you can not lower the maintenance unit cap assembly and the cap assembly and

pump assembly have been replaced:

• When the two tubes from the pump assembly are being connected to the cap

assembly, turn them clockwise through 45 to 90 degrees as you insert them.

Page 5

CON3000Model Name: RJ–4100

CON3000Model Name: RJ–4100

Contents 1

Contents 1

History of Amendments CON0000

Introduction CON1000

Some Thoughts on Maintenance Work CON1010

Precautions For Maintaining This Printer CON2000

Contents CON3000

How to use the Maintenance Manual CON4000

Daily Care CON5000

How to Move the Printer Main Unit CON6000

Trouble-Shooting Lists TRB0000

• When Message is Displayed TRB1000

• How to Use LEDs to Check CPU System and Mechanical System Faults TRB1001

• When Message is not Displayed

• Initialization, Media Feed, Printing TRB2000

• Noise, Media Cutting, Online, Other TRB2001

Primary Consultation ENT0000

• When Message is Displayed

• Printer Status Messages ENT1000~

• Data Errors ENT1200~

• Command Errors ENT1250~

• CPU System Faults ENT1500~

• Mechanical System Faults ENT1700~

• When Message is not Displayed

• Trouble with Initialization ENT2000~

• Trouble with Media Feed ENT3000~

• Trouble with Printing ENT4000~

• Problem Involving Noise ENT5000~

• Trouble with Media Cutting ENT6000~

• Online/Function Problems ENT7000~

• Other ENT8000~

Matrix Map MAP0000

• When Message is Displayed

• Printer Status Messages MAP1000

• Data Errors MAP1200

• Command Errors MAP1250

• CPU System Faults MAP1500

• Mechanical System Faults MAP1700

• When Message is not Displayed

• Trouble with Initialization MAP2000

• Trouble with Media Feed MAP3000

• Trouble with Printing MAP4000

• Problem Involving Noise MAP5000

• Trouble with Media Cutting MAP6000

• Online/Function Problems MAP7000

• Other MAP8000

Fault-Tracing Procedure EXA0000

• When Message is Displayed

• Printer Status Messages EXA1000~

• Data Errors EXA1200~

• Command Errors EXA1250~

• CPU System Faults EXA1500~

• Mechanical System Faults EXA1700~

• When Message is not Displayed

• Trouble with Initialization EXA2000~

• Trouble with Media Feed EXA3000~

• Trouble with Printing EXA4000~

• Problem Involving Noise EXA5000~

• Trouble with Media Cutting EXA6000~

• Online/Function Problems EXA7000~

• Other EXA8000~

5

Page 6

CON3001Model Name: RJ–4100

CON3001Model Name: RJ–4100

Contents 2

Contents 2

Replacement and Adjustment Procedures

Right and Left Covers REP 1010

Front Cover REP 1020

Panel Cover REP 1030

Y Rail Cover REP 1030

Front Paper Guide and Right Paper Guide REP 1040

Control Box REP 1050

Head Cover REP 1060

X Motor Assembly REP 1070

Fan Assembly and Fan Cable REP 1080

X Speed Reduction Belt REP 1090

Lever Sensor Assembly REP 1100

Cover Switch Assembly REP 1110

Waste Fluid Box Detector Switch Assembly REP 1120

Switch Cable Assembly REP 1130

DC Cable Assembly REP 1130

Main Board Assembly REP 1140

Power Supply Board and Fuse REP 1150

Panel Board Assembly REP 1160

Panel Cable REP 1170

Mother Board Assembly REP 1180

Front Paper Sensor Assembly REP 1190

Rear Paper Sensor Assembly REP 1200

Grid Roller Assembly and Coupling Assembly REP 1210

Pressure Assembly, Pressure Roller and Blade REP 1220

Pump Motor Assembly REP 1230

Cap Assembly REP 1240

Wiper REP 1250

Pump Assembly REP 1260

Maintenance Station GA Assembly REP 1270

Y Motor Assembly REP 1280

Steel Belt (A0) REP 1290

T Fence Assembly (A0) REP 1300

Cursor Plate Spring REP 1310

Steel Flexible Guide A0 Assembly REP 1310

Y Return Pulley Assembly REP 1320

Cartridge Frame Assembly REP 1330

Ink ID Sensor Assembly (Black) (Yellow) (Magenta) (Cyan) REP 1340

Detector Assembly (Black) (Yellow) (Magenta) (Cyan) REP 1350

Y Cable (A0) REP 1360

Ink Tubes (A0) REP 1370

Cutter Solenoid Assembly REP 1380

Print Head Assembly(Black) REP 1390

Print Head Assembly (Color) REP 1400

Head Cable (Black) REP 1390

Head Cable (Color) REP 1400

Y Paper Sensor Assembly REP 1410

Head Board Assembly REP 1420

Dampers (Black) REP 1430

Dampers (Color) REP 1430

Cursor Assembly REP 1440

Origin Sensor Assembly REP 1450

Waste Fluid Box REP 1460

Junction Board Assembly REP 1470

Network Interface Board REP 1480

Extended Memory (8 MB) (16 MB) (32MB) REP 1490

A0 Scroller REP 1500

Cutter Holder REP 1510

How to Adjust the Platen Height REP 1520

O-rings (Small) and (Large) REP 1530

Tubes Guides A0 Assemblies REP 1540

How to Adjust Steel Belt Tension REP 1550

How to Adjust X Speed Reduction Belt Tension REP 1560

How to Adjust the Tilt of the Print Head (Black) REP 1570

How to Adjust the Tilt of the Print Head (Color) REP 1580

How to Capture and Install Backup Parameters REP 1590

How to Install a Program (Software Upgrade) REP 1600

How to Measure the Y Rail Fitting Precision REP 1610

Head Cleaning Procedure REP 1620

How to Check the Power Supply Voltages/100 V AC REP 1630

How to Check the Power Supply Voltages/5 V DC REP 1640

How to Check the Power Supply Voltages/24 V DC and 42 V DC REP 1650

How to Clean the Head Nozzle Face REP 1660

Ink ID Sensor REP 1670

6

Page 7

CON3002Model Name: RJ–4100

CON3002Model Name: RJ–4100

Contents 3

Contents 3

Test Procedures TST0000

• Test 1 Printing from User's Host Computer TST1000

• Test 2 Print a Test Print TST1000

• Test 3 Skew Check TST1000

• Test 4 Head Movement Aging Test TST1001

• Test 5 Media Feed Aging Test TST1001

• Test 6 Cutter Aging Test TST1001

• Test 7 Maintenance Unit Aging Test TST1002

• Test 8 Head (Black/Color) Aging Test TST1002

• Test 9 Sensor Test TST1002

• Test 10 Panel Test TST1003

• Test 11 Fan Operating Test TST1003

Fundamental Knowledge GID0000

Basic Specifications GID1000

Interface Specifications GID1010

Name of Parts GID1100

Explanation of Operating Principles and Mechanisms GID2000

Explanation of Printing Operation GID2100

System Block Diagram GID3000

Explanation of Boards GID3010

Connector Layout Diagram GID3020

Operating Sequence GID4000

• Power On Sequence GID4010

• Power Off Sequence GID4020

• Media Detection Sequence GID4030

• Normal Standby Sequence GID4040

• Encoder Disconnected Check Sequence GID4050

• Origin Detection Sequence GID4060

• Media Cutting Sequence GID4070

• Monochrome Printing Sequence (Including Flushing) GID4080

• Color Printing Sequence (Including Flushing) GID4090

Stored Test Patterns PAT0000

• Presentation Pattern PAT1000

• Color palette PAT2000

• Print quality adjustment pattern PAT3000

• Setup List PAT4000

Self-Diagnosis Functions BAC0000

• Examination BAC1000

• Memory Capacity BAC1010

• Version BAC1020

• Panel BAC1030

• Sensors BAC1040

• Encoders BAC1050

• Fans BAC1060

• History: Last error message BAC1070

• History: Head nozzle ejection count check BAC1070

• Adjustment BAC2000

• Capping Position Adjustment BAC2010

• Skew Verification BAC2030

• Head Rank Input (Include Initial filling) BAC2040

• Head Nozzle Verification BAC2050

• Black Head Tilt Verification BAC2060

• Color Head Tilt Verification BAC2070

• Reciprocal Printing Positioning BAC2080

• CW Adjustment BAC2090

• Flush Pointer Adjustment BAC2110

• Media Feed Distance Compensation BAC2120

• Front-to-Head, Cutter-to-Head Distances Adjustment BAC2130

• Rear Sensor Position Adjustment BAC2140

• Test Print BAC2150

• Head Cleaning BAC2160

7

Page 8

CON3003Model Name: RJ–4100

CON3003Model Name: RJ–4100

Contents 4

Contents 4

• Cleaning BAC3000

• Normal BAC3000

• Powerful BAC3000

• Test Printing BAC4000

• Head Printing Verification BAC4000

• Adjustment Parameters BAC4000

• Parameters BAC5000

• Initialize BAC5010

• Update BAC5020

• Aging BAC6000

• Carriage Motor BAC6010

• Media Feed Motor BAC6020

• Cutter BAC6030

• Maintenance Unit BAC6040

• Head BAC6050

Maintenance Parts CAT0000

Maintenance Parts List CAT1000

Maintenance Tool List CAT2000

Adhesives and Tapes CAT3000

Lubrication Points CAT4000

Exploded View Drawing CAT5000

8

Page 9

9

CON4000Model Name: RJ–4100

CON4000Model Name: RJ–4100

How to use the Maintenance Manual

How to use the Maintenance Manual

How to use the Maintenance Manual

How to use the Maintenance Manual CON4010

How to use the Trouble-Shooting Lists (TRB) CON4020

How to use Primary Consultation (ENT) CON4030

How to use the Matrix Map (MAP) CON4040

How to use the Fault-Tracing Procedure (EXA) CON4050

How to use Replacement and Adjustment Procedure (REP) CON4060

How to use Test Procedure (TST) CON4070

Page 10

10

CON4010Model Name: RJ–4100

CON4010Model Name: RJ–4100

How to use the Maintenance Manual

How to use the Maintenance Manual

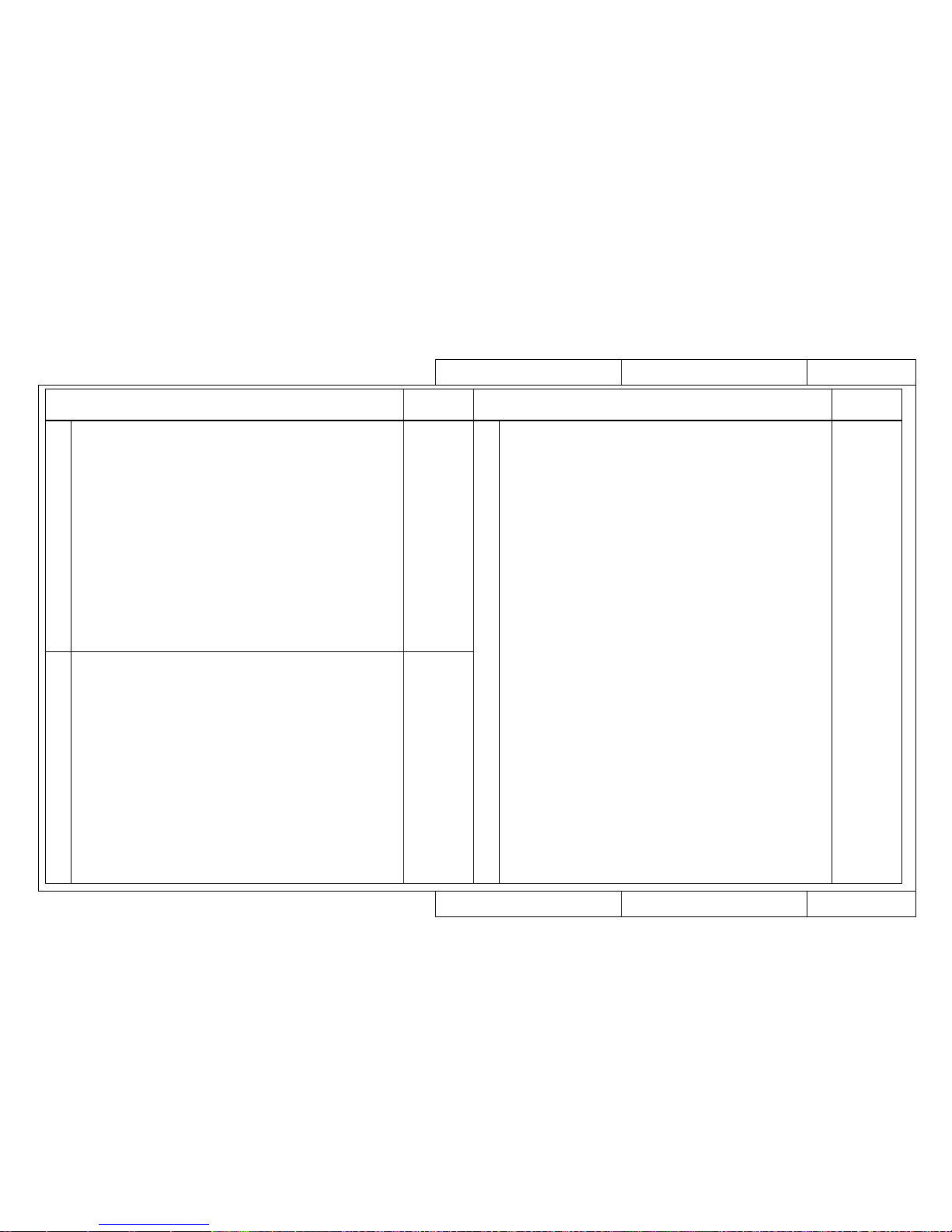

■ Fault maintenance work procedures and how to use the Maintenance Manual

When a user reports an equipment fault, use the following procedure to carry out fault recovery tasks.

A fault occurs

Task Page Details Reference materials

Check fault circumstances,

select fault details from

Trouble-Shooting Lists

Trouble-Shooting List

TRB❉❉❉❉

Check circumstances by “fax” or “telephone”. Check error

messages, check user usage conditions, retry after changing settings, output

diagnostic pattern, etc. Select fault symptoms produced by user from

the Trouble-Shooting List.

Conduct a consultation by “fax” or “telephone”.

Check possibility of user error or recovery by daily inspection. Check error

messages, check user usage conditions, output diagnostic pattern, output

setup list. Retry after changing settings, etc.

Primary Consultation

ENT❉❉❉❉

Operation Manual, basic

knowledge, daily care, periodic maintenance/

inspection/cleaning

Task Page Details Reference materials

Gather the necessary

maintenance parts

Matrix Map

MAP❉❉❉❉

Gather the necessary maintenance parts Maintenance Parts list, Maintenance Tools list,

Exploded views

Conduct a tracing inquiry Fault Tracing Procedures

EXA❉❉❉❉

Conduct an inquiry to trace the cause of the fault Basic knowledge

Replace parts and adjust Replacement and Adjustment

Procedures REP❉❉❉❉

Replace or readjust parts suspected to be faulty.

Carry out adjustments after replacing parts.

Basic knowledge

Final check Test Procedures

TST❉❉❉❉

Separate causes of faults and check operation after faults have been

rectified.

Conduct a primary

consultation with the user

• If you are unable to resolve the fault at this point, take the necessary maintenance parts and make an on-site visit.

Page 11

11

CON4020Model Name: RJ–4100

CON4020Model Name: RJ–4100

How to use the Trouble-Shooting Lists (TRB)

How to use the Trouble-Shooting Lists (TRB)

1. How to look up trouble-shooting tables

■ When a user has reported a fault, first select the applicable details from the trouble-shooting lists (TRB) and jump to the specified primary consultation (ENT).

• Faults are broadly classified as those which cause a message to appear in the printer LCD and those which do not.

• For troubles that cause a message to be displayed, select the message as it is.

• Troubles with no message display are classified into the 10 blocks shown below. First select the block then select the appropriate fault details from that block.

2. Definitions of groupings in the case of faults that produce no message display

When Message is Displayed TRB1000

• Printer Status Messages, Data Errors, Command Errors

• CPU System Faults, Mechanical System Faults

When Message is Not Displayed

TRB2000 to TRB2001

•

Trouble with Initialization: Troubles that occur when unpacking immediately after delivery are grouped here.

Check this group for a similar trouble occurring other than immediately after delivery.

Troubles concerning the series of operations up to the enabling of printing are grouped here.

•

Trouble with Plotting: This group concerns printing quality problems.

•

Trouble with Media Feed: This group concerns problems with the media path.

•

Trouble with Media Cutting: Cutter section problems are grouped here.

Plotting precision problems are grouped here.

•

Problem Involving Noise: Troubles that produce abnormal noise from the driving section.

• Online/Function Problems: Online plotting function problems.

Troubles involving driver software, consumable items, peripheral devices are grouped here.

• Other: Troubles concerning the series of operations up to the enabling of printing are grouped here.

Page 12

12

CON4030Model Name: RJ–4100

CON4030Model Name: RJ–4100

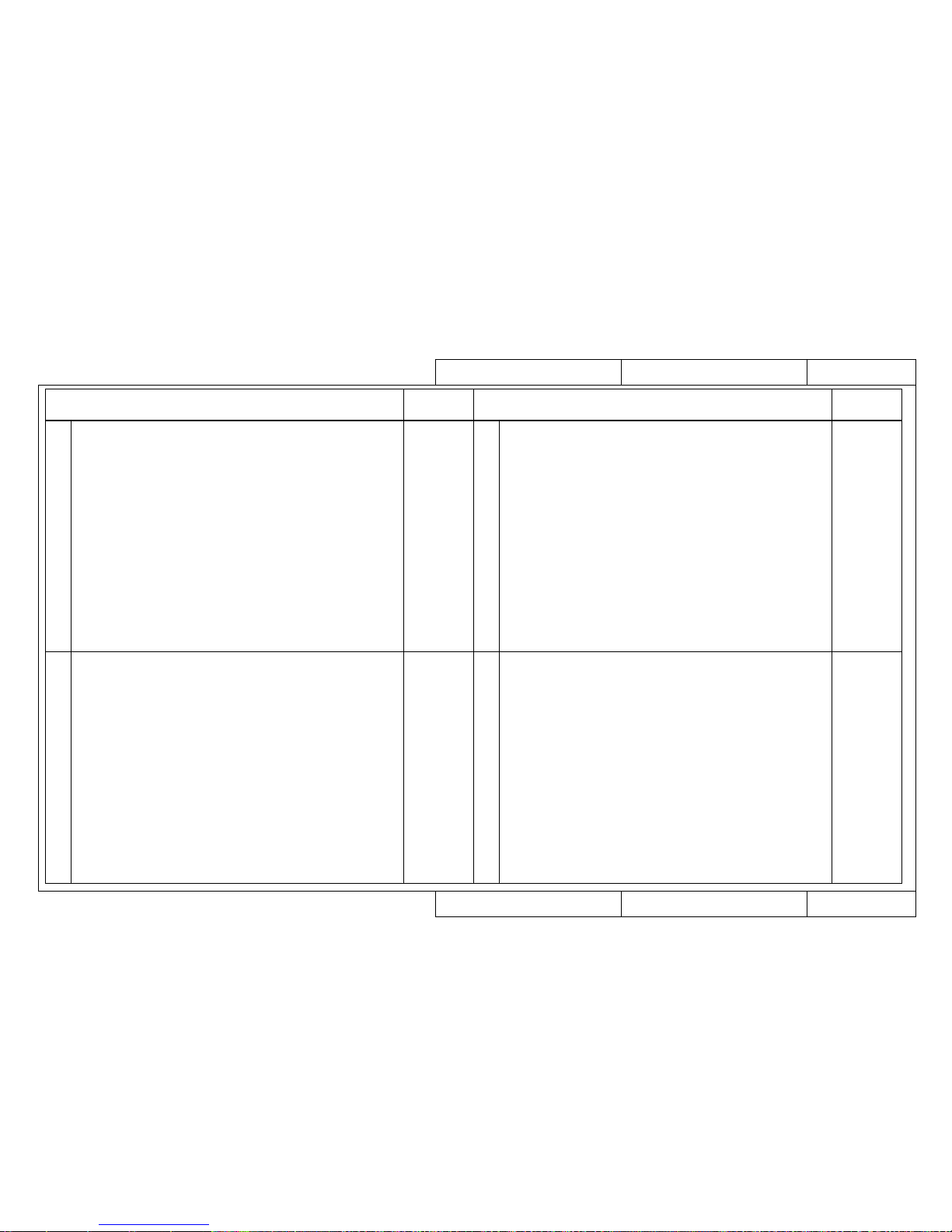

How to use Primary Consultation (ENT)

How to use Primary Consultation (ENT)

■ When a user has reported a fault, first select the applicable details from the trouble-shooting lists (TRB) and then check the conditions in detail by asking questions in

accordance with the primary consultation (ENT) shown below.

• Ask the questions in order, beginning with 1-1, and move to the next question if there is nothing abnormal. If an abnormality is revealed, carry out the task indicated by

the arrow [→].

• If all questions produce nothing abnormal, then jump to the specified matrix map (MAP).

ENT2000Model Name: RJ–4100

ENT2000Model Name: RJ–4100

Trouble with Initialization

When No Error is Displayed on the Printer's Liquid Crystal Display

12• No power

• Faulty liquid crystal display (no display/unstable display)

1-1

1-2

1-3

1-4

1-5

1-5

1-6

1-7

1-8

1-9

• Has the power plug come away from the outlet?

→ Plug the cord all the way into the socket.

• Has the cord come away from the printer inlet?

→ Plug the cord all the way into the printer socket and try again.

• Is power available at the power outlet?

→ Check the power supply.

• Is the AC power supply securely earthed? (grounding)

→ Make sure it is connected to a 100 V or 200 V ground and confirm by testing the display again.

• With the cord inserted into the power outlet, is the prescribed voltage available at the end of the cord?

→ Switch off the printer, leave it for ten minutes then try switching on again.

• The overcurrent detector circuit in the printer's power supply may have tripped.

→ Leave it for 10 minutes then try switching on again.

• Are there any large power-consuming peripheral devices, such as a copier, on the same outlet?

→ Take power from a separate power source.

• Is there any equipment near the printer that is producing strong noise?

→ Separate the power supplies of nearby equipment and try increasing their distance from the printer.

• Is the power cable broken?

→ It's no good connecting a broken cable. Replace the power cable.

• Is the LCD unit damaged?

→ It needs to be repaired by the Serviceman.

Please request repair.

❈ If the above procedures do not improve the symptoms, the main unit has probably developed a fault for

some reason.

Go to MAP2000

No. Symptom

Sequence

Items to be Confirmed

When No Error is Displayed on the Printer's Liquid Crystal Display

Trouble with Initialization

Whether an error message is displayed

Fault details

Questioning sequence

If all questions

produce no

abnormality,

jump to the

specified matric

map (MAP)

Major classification of fault details

Page specified by

trouble-shooting

list (TRB)

Page specified by

trouble-shooting

list (TRB)

Page 13

13

CON4040Model Name: RJ–4100

CON4040Model Name: RJ–4100

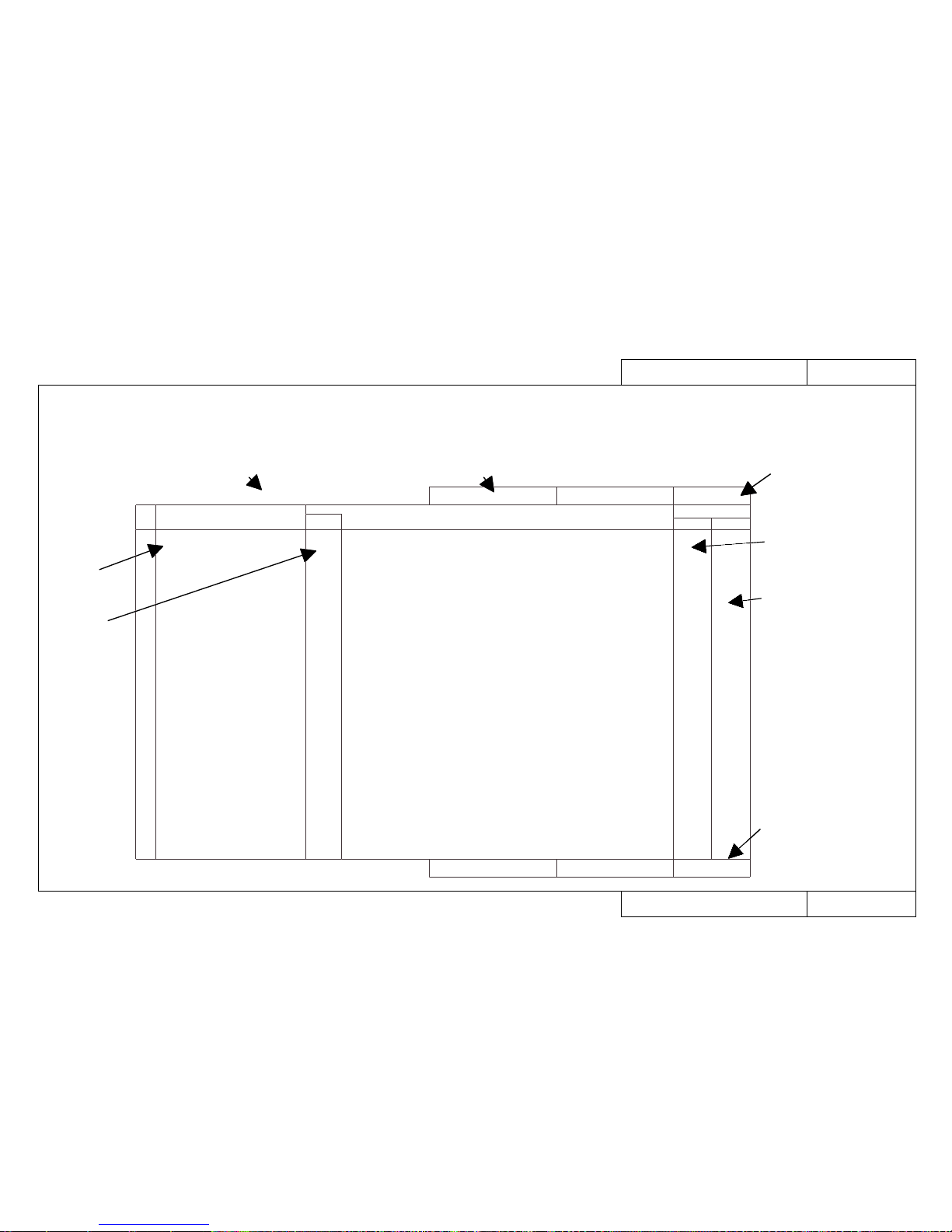

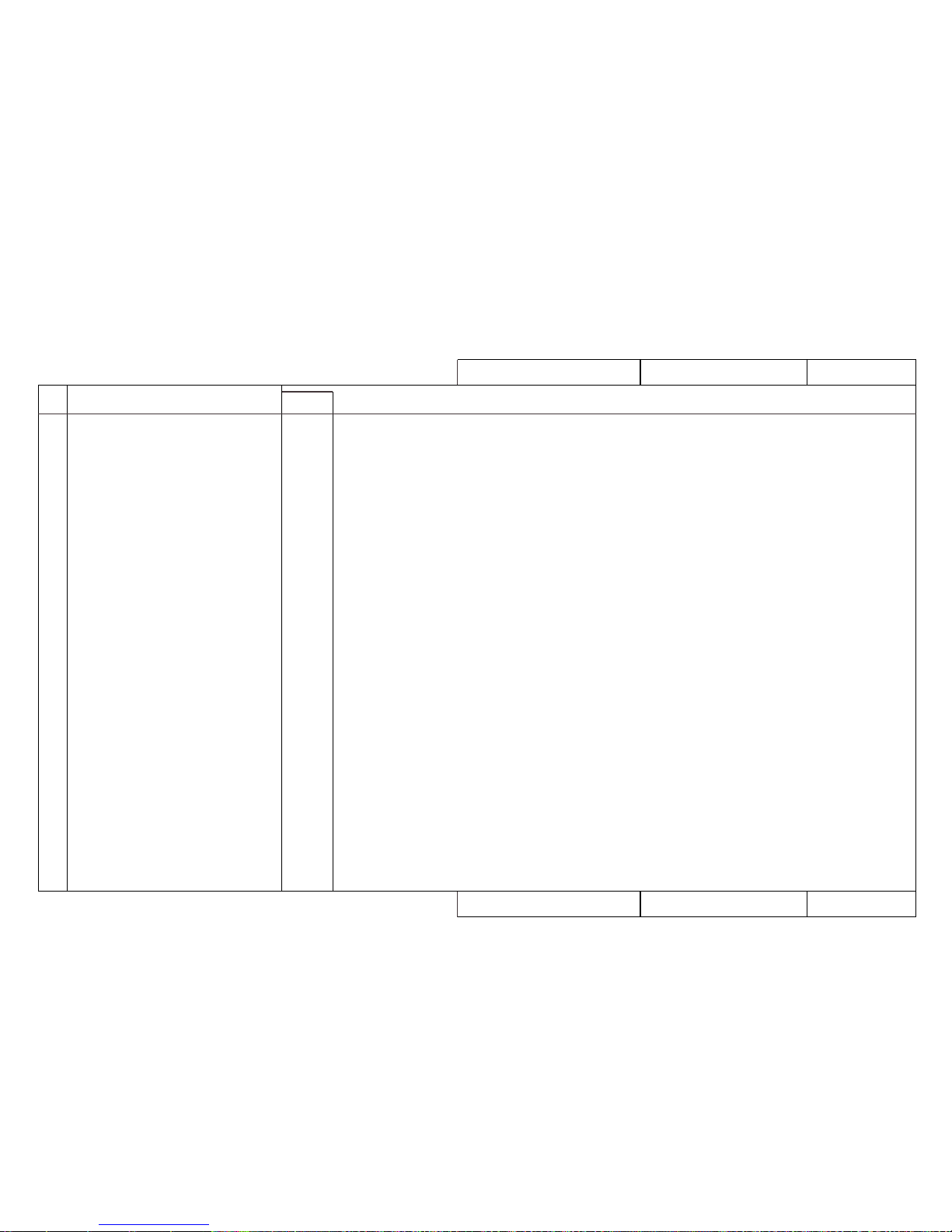

How to use the Matrix Map (MAP)

How to use the Matrix Map (MAP)

■ When the primary consultation (ENT) has not revealed any anomaly, gather the necessary maintenance parts according to the matrix map (MAP) shown below and visit

the user.

Major classification of fault details

ENT number

selected from

trouble-shooting

list (TRB)

Whether an error message is displayed

Major classification

of fault details and

range of ENT numbers

Fault

details

Replacement

and adjustment

procedure page

Names and drawing numbers of

required parts

Page specified

by primary

consultation (ENT)

Page specified

by primary

consultation (ENT)

Fault-tracing

procedure

(EXA) page

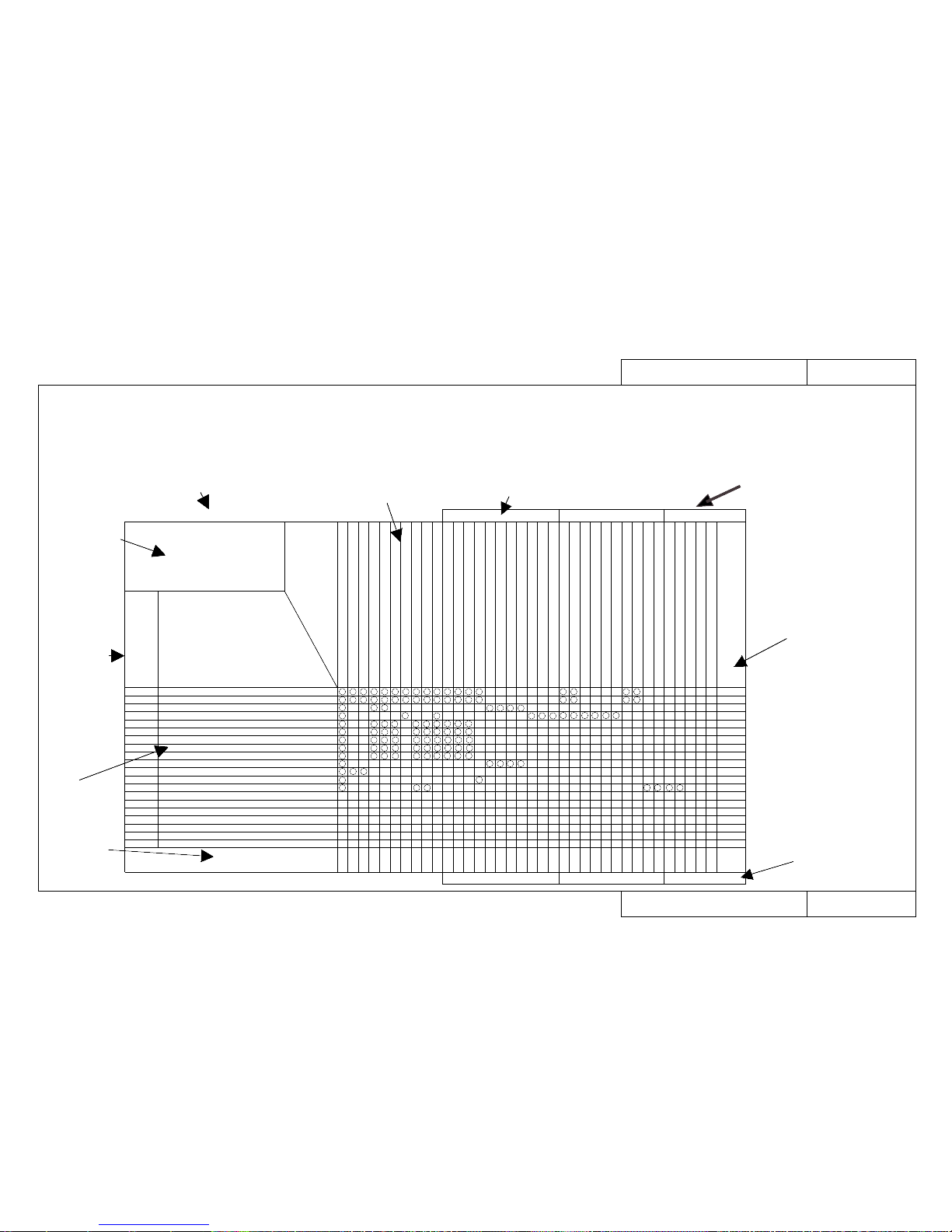

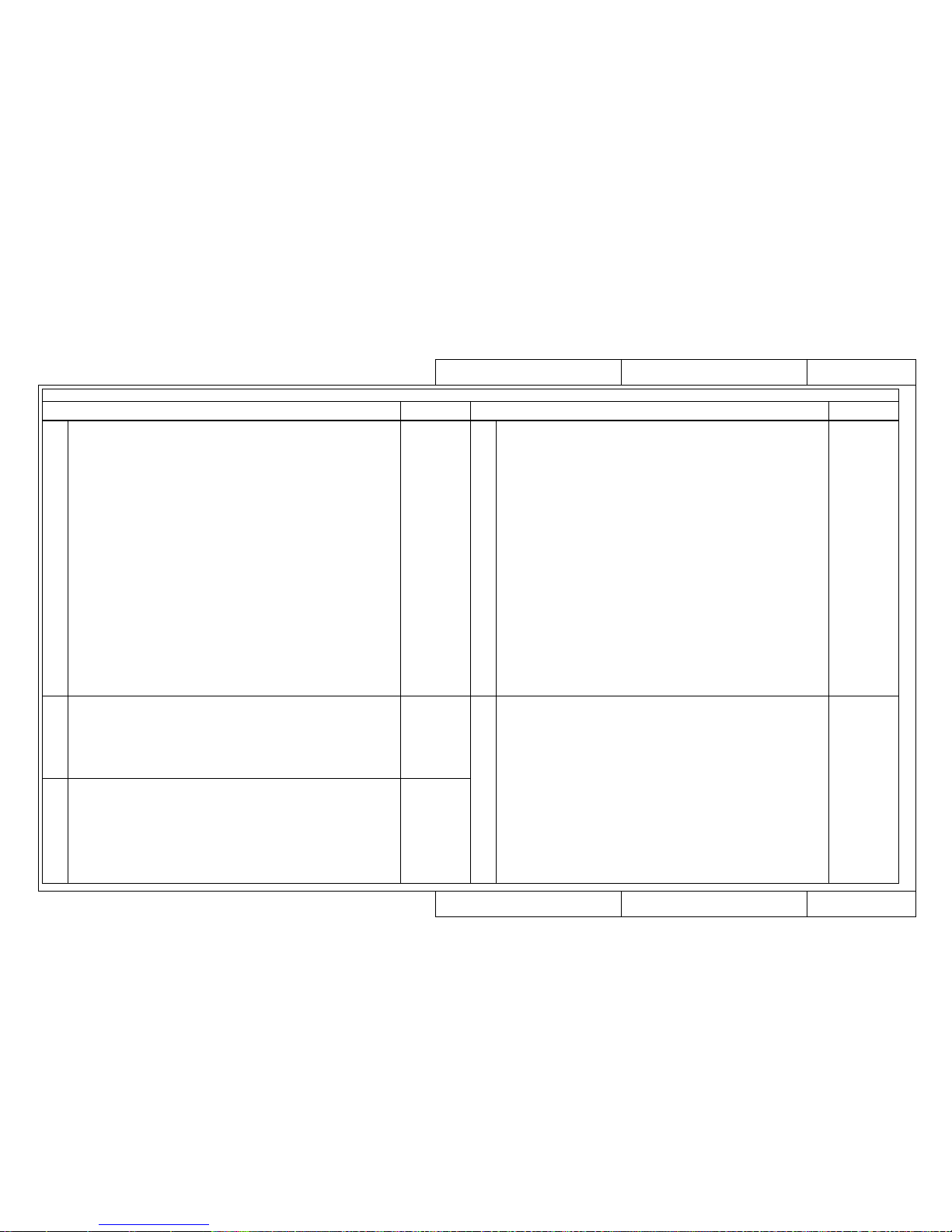

When Message is Not Displayed Trouble with Initialization Model Name: RJ-4100 MAP2000

Trouble with Initialization Model Name: RJ-4100 MAP2000

When Message is Not Displayed

Trouble with Initialization

ENT2000 to ENT2070

TroubleShooting

List

ENT. No.

Problem

- Power supply does not come on

- LCD faulty (no display/erratic display)

- Initial filling of inks failed

- Initial filling is completed but no ink comes out

- After power is switched on, nothing works

- When power is applied, “Initializing” appears and then a reset is executed.

- After mounting media, initial operation fails

- Printer does not work even with the cover closed

- Printer does not stop even with the cover opened

- Ink cartridges are installed but not recognized

- Can not make entries from the operating panel

- Data is received but not plotted

- Media is not suction

Replacement and Adjustment Procedure REP. No.

Name and Diagram Number of

Replacement Part

DF-41524 Main Board Assembly

DF-40097 Panel Board Assembly

DF-40114 Panel Cable

DF-40100 Cover Switch Assembly

DF-40099 Lever Sensor Assembly

DF-40108 Paper Sensor Y Assembly

DF-41525 Head Board Assembly

DF-40102 Paper Sensor F Assembly

DF-40103 Paper Sensor R Assembly

DF-40118 Y Cable (A0) x 1

DF-40115 Switch Cable Assembly

DF-40095 Power Board Assembly

DF-41535 DC Cable Assembly

RJ8-ETH13 Network Interface Board (Supply item)

DF-40106 Detector Assembly (Black)

DF-40107 Detector Assembly (Y)

DF-40146 Detector Assembly (M)

DF-40147 Detector Assembly (C)

DF-40123 Cap Assembly

DF-40124 Pump Assembly

DF-40126 Maintenance Station Assembly

DF-40119 Head Cable (Black)

DF-40120 Head Cable (Color)

DF-40121 Print Head Assembly (Black)

DF-40122 Print Head Assembly (Color)

DF-40488 O-rings (Large)

DF-40487 O-rings (Small)

DF-40101 Waste Fluid Box Detector Switch Assembly

SIM8M, SIM16M, SIM32M Extended Memory (32 MB)(Supply item)

DF-40173 Vacuum Fan Assembly

DF-40174 Fan Cable A Assembly

DF-40132 Fan Cable B Assembly

DF-40133 Fan Cable C Assembly

1140

1160

1170

1110

1100

1410

1420

1190

1200

1360

1130

1150

1130

1480

1350

1350

1350

1350

1240

1260

1270

1400

1400

1390

1390

1530

1530

1120

1490

1080

1080

1080

1080

Fault-Tracing Procedure EXA No.

2000

2000

2010

2020

2030

2030

2030

2030

2030

2040

2050

2060

2070

2000

2000

2010

2020

2030

2030

2030

2030

2030

2040

2050

2060

2070

Page 14

14

CON4050Model Name: RJ–4100

CON4050Model Name: RJ–4100

How to use the Fault-Tracing Procedure (EXA)

How to use the Fault-Tracing Procedure (EXA)

■ Gather the parts specified by the matrix map (MAP), visit the user and carry out the task of recovery in accordance with the fault-tracing procedure (EXA) shown below.

• First, check again on-site that there was no mistake about the primary consultation. (EXA and ENT page numbers are the same)

• Carry out the checking tasks in order, beginning with 1-1, and move to the next task if there is nothing abnormal. If an abnormality is revealed, carry out the task indi-

cated by the arrow [→].

EXA2000Model Name: RJ–4100

EXA2000Model Name: RJ–4100

Trouble with Initialization

When No Error is Displayed on the Printer's Liquid Crystal Display

12• No power

• Faulty liquid crystal display (no display/unstable display)

1-1

1-2

1-3

1-4

1-5

1-6

1-7

1-8

• Is there a broken or shorted lead in the switch cable assembly (between the switch and

power supply board)?

Use a tester to check for broken or shorted leads.

→ Replace the switch cable assembly.

• Do the "Power supply voltage check 100 V AC"

• Do the "Power supply voltage check 5 V DC"

• Do the "Power supply voltage check 24, 42 V DC"

• Check the panel cable connectors on the panel board and main board.

Are they inserted obliquely? Are they securely locked?

Check Main board J113 (PANEL), panel board J301 (MAIN)

→ Reconnect the connectors.

• The panel cable may be faulty.

→ Replace it.

• Is there a fault in the panel board assembly liquid crystal display?

→ Replace the panel board assembly.

• The main board assembly may be damaged.

→ Replace it.

No. Symptom

Sequence

Items to be Confirmed

When No Error is Displayed on the Printer's Liquid Crystal Display

Trouble with Initialization

1130

1630

1640

1650

1170

1160

1140

REP BAC

GO TO Ref. Pages

Whether an error message is displayed

Fault details

Fault-tracing

sequence

Major classification of fault details

Page specified by

matrix map (MAP)

Page specified by

matrix map (MAP)

Replacement and

adjustment procedure

(REP) page reference

Hidden diagnostic

procedure page

reference

Page 15

15

CON4060Model Name: RJ–4100

CON4060Model Name: RJ–4100

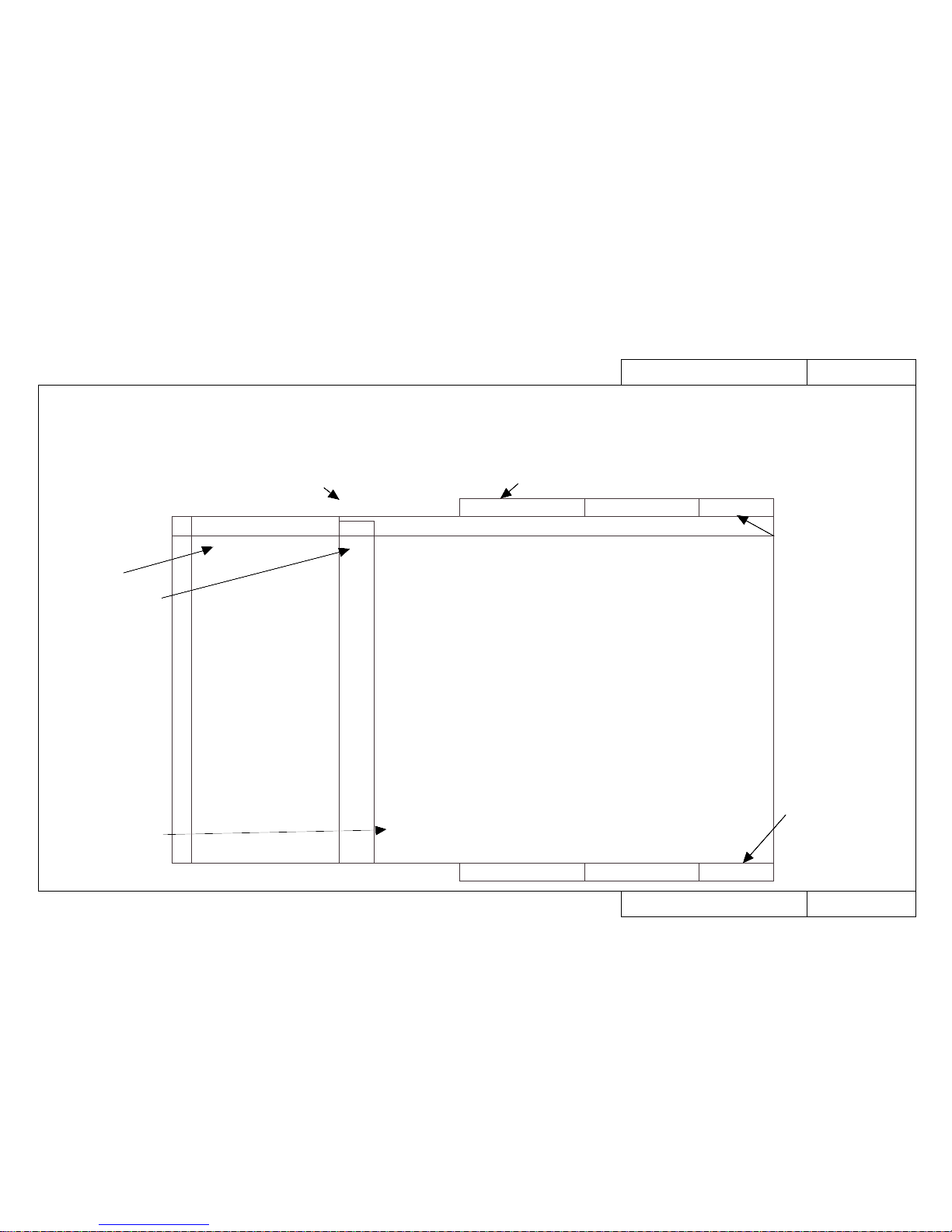

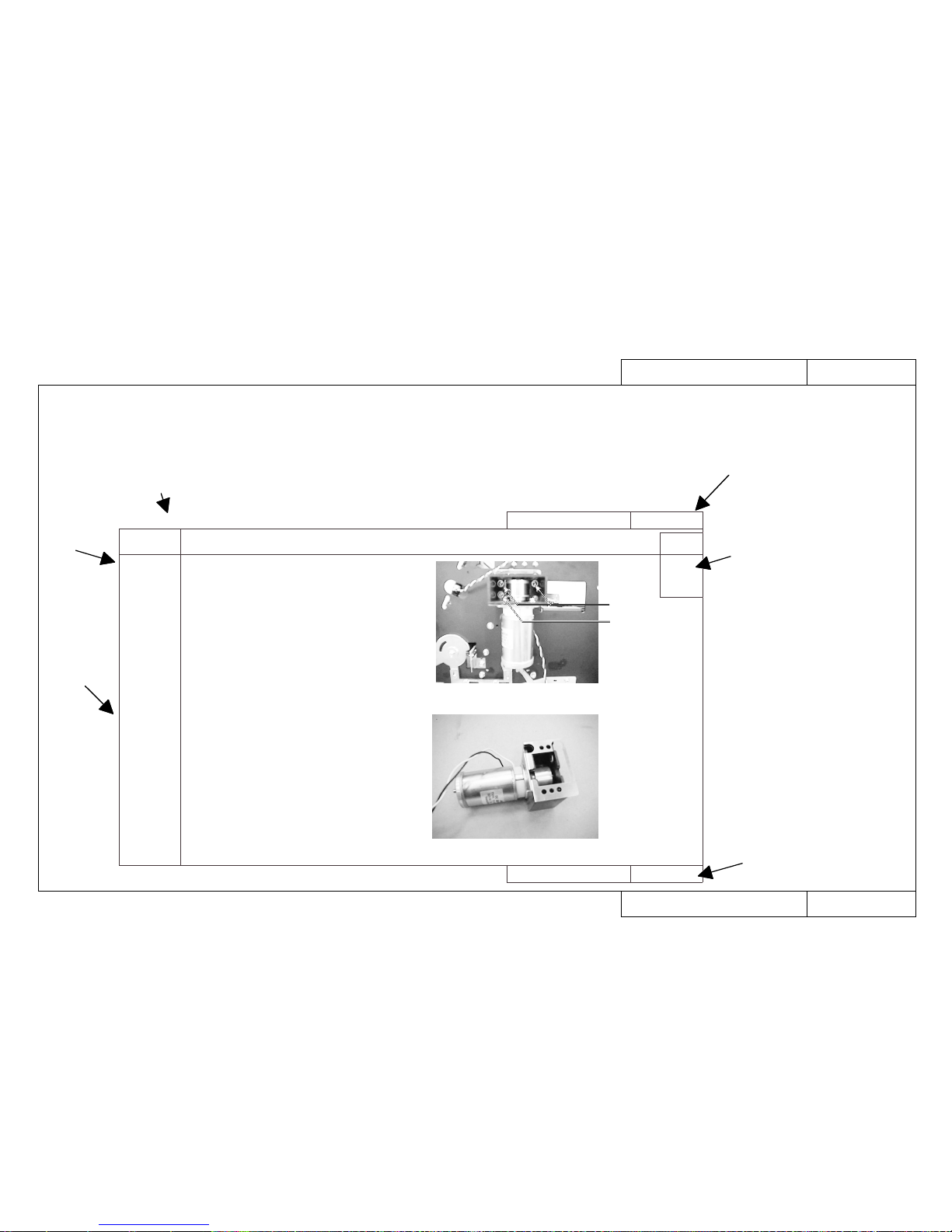

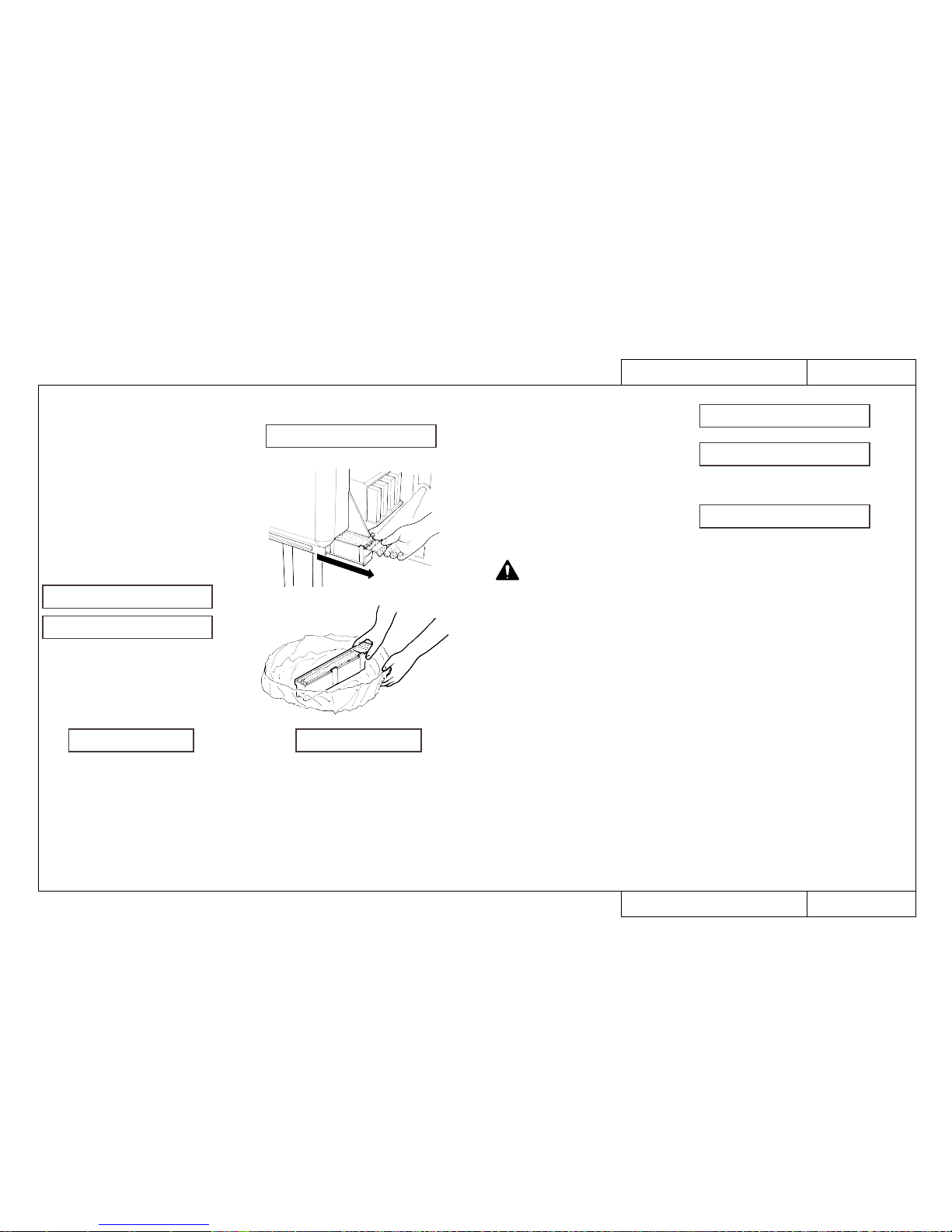

How to use Replacement and Adjustment Procedure (REP)

How to use Replacement and Adjustment Procedure (REP)

■ If the fault-tracing procedure (EXA) has produced a replacement task, carry out the work of replacement and adjustment in accordance with the replacement and adjustment procedure (REP) shown below.

• If you don’t know how to go about the removal of covers involved in replacing a part, refer to REP1010 to REP1060.

• If there is a page listed in the top right “GO TO TEST No.” column, you must jump to the test page and carry out a final check.

Y Motor Assembly

Screws

Screw

REP1280Model Name: RJ–4100

REP1280Model Name: RJ–4100

How to replace the Y Motor Assembly

How to replace the Y Motor Assembly

GO TO

TEST NO

1001

TEST4

Item Replacement and Adjustment Procedure

1. Replacement

Procedure

2. Adjustment

and

Examination

Procedure

Replace the Y Motor Assembly

1. Remove the Left and Right Covers. (Refer to REP1010)

2. Remove the Rear Paper Guide. (Refer to REP1040)

3. Remove the Steel Belt. (Refer to REP1290)

4. Open the Control Box. (Refer to REP1050)

5. Disconnect connector J119 (YMOT) from the Main Board

Assembly.

6. Remove the Y Motor Assembly (3 fastening screws).

7. Assembling is the reverse of the removal procedure.

Reference: Since the Y Motor Assembly Cable passes below

the Cartridge Unit, the work will be easier if you

remove the two Cartridge Base screws and push

it back.

1. Carry out the Steel Belt Tensioning Adjustment. (Refer to

REP1550)

Replacement and adjustment item

Replacement

procedure

Adjustment

procedure

and items to

be checked

Page specified by

the fault-tracing

procedure (EXA)

Page specified by

the fault-tracing

procedure (EXA)

Test procedure (TST) page.

You must go to this page

Page 16

16

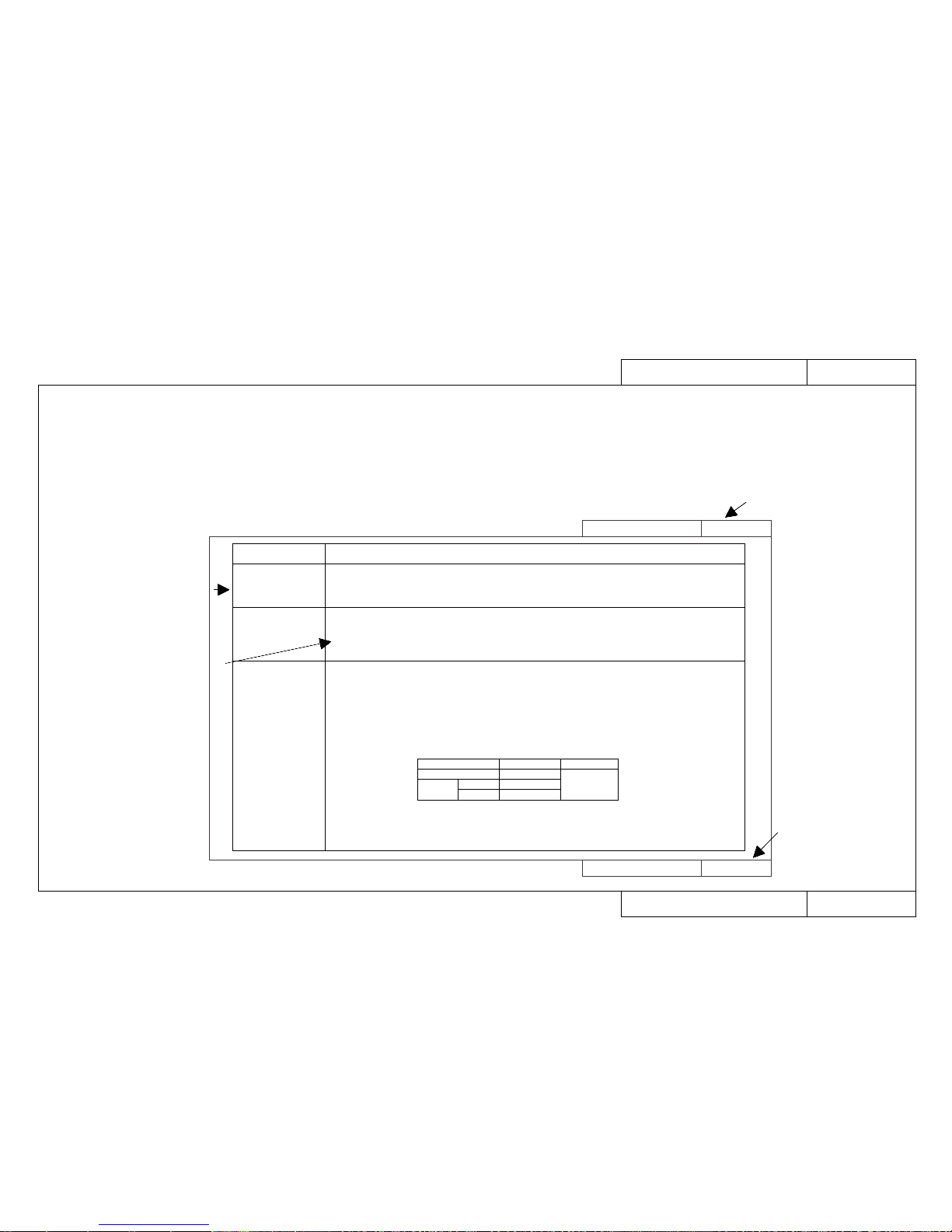

CON4070Model Name: RJ–4100

CON4070Model Name: RJ–4100

How to use Test Procedure (TST)

How to use Test Procedure (TST)

■ After completing replacement and adjustment in accordance with the replacement and adjustment procedure (REP), if “GO TO TEST No.” is specified, carry out a final

check in accordance with the following test procedure.

• If you do not understand how to go about the testing operation, refer to the reference pages in the text.

TST1000Model Name: RJ–4100

TST1000Model Name: RJ–4100

Test Procedures (Test 1 to Test 3)

Test Procedures (Test 1 to Test 3)

Item Test Procedure

Test 1:

Printing from User's Host

Computer

Test 2 :

Print a Test Print

Test 3:

Skew Check

1. With the cooperation of the user/operator, have the user's data printed in the user's operating environment.

2. Check that the printing is normal.

1. Load A3 size media in the printer.

2. Print a “Test Print”. Press the [Resolution] key while you hold down the [Shift] key.

3. Check that the printing is normal. (Refer to PAT1000 for checking printing quality)

1. Load roll media in the printer (thick coated paper).

2. Select “Adjustments/Skew Verification” from the self-diagnostics menu. (Refer to BAC2030)

3. When “Please input paper feed length [m] (default 1.0 m)” is displayed, set the paper feed length

using the “Setting Value +” key to increase the setting or “Setting Value -” key to decrease the setting.

4. End if “Measurement result ± ✼.✼✼✼, ± ✼.✼✼✼” (skew values on left and right sides of the media) are both within

the standard values shown below.

5. Switch off the power when the test is completed.

Standard values

Within ±1.5 mm

Within ±2.5 mm

Within ±10 mm

Roll Media

Cut Media

Conditions

7m

50m

Standard values

Specified Media

Thick

coated

paper

Test number

and name of

test

Test procedure

and items to be

checked

Page specified by replacement

and adjustment procedure (REP)

Page specified by

replacement and

adjustment procedure

(REP)

Page 17

17

CON5000Model Name: RJ–4100

CON5000Model Name: RJ–4100

Daily Care

Daily Care

Daily Care

This section explains the details of daily maintenance (including cleaning, ink cartridge replacement, cutter replacement, etc.)

How to Clean the Printer Main Unit CON5010

How to Clean the Printer Main Unit CON5011

How to Replace Ink Cartridges CON5020

How to Replace the Cutter CON5030

How to Replace the Waste Fluid Box CON5040

Page 18

18

CON5010Model Name: RJ–4100

CON5010Model Name: RJ–4100

How to Clean the Printer Main Unit

How to Clean the Printer Main Unit

RJ-4100 printer should be wiped free of dirt with a dry

soft cloth.

Plotting Board

Cutting Groove

Use a soft damp cloth to wipe away

any paper fluff adhering to the printing board and cutting groove.

♦ The power switch of the RJ-4000 series printer should be switched off

during cleaning.

♦ Don’t use solvents such as thinners or benzene that will damage the finish.

♦ Covers that are fixed with screws contain electrical components and

must not be opened during cleaning.

♦ Paper dust which is produced when the printer is working should be

removed periodically. Make sure that it does not get blown around.

♦ Stubborn dirt that is difficult to remove may be removed with a lint-free

cloth dampened with alcohol.

CAUTION:

♦ Paper dust and fluff will accumulate with long term use and stick to

the plotting board and cutter groove and may cause printing quality and

cutting performance to deteriorate.

They must be cleaned periodically.

IMPORTANT:

Brush

Grid Roller

Use a soft damp cloth to wipe away

any paper dust sticking to the pressure roller.

Clean the grid roller with a nylon

brush.

♦ Paper fluff sticking to the pressure roller and movable roller may prevent

normal feeding of the media and produce a “Skew Check Error”.

They must be cleaned periodically.

IMPORTANT:

Page 19

19

CON5011Model Name: RJ–4100

CON5011Model Name: RJ–4100

How to Clean the Printer Main Unit

How to Clean the Printer Main Unit

Use a cotton bud to wipe away any dust and paper fluff from the front and back

paper sensor covers in two places.

Paper Sensor Cover

♦ Progressive soiling will affect the sensitivity of the sensors and faulty

detection of the media in the initial operation may cause a “Skew Check

Error”. They must be cleaned periodically.

IMPORTANT:

Page 20

20

When a RJ-4100 Series printer is displaying “No ink” or “No cartridge”, the cartridge

should be replaced or filled without delay. Also, ink cartridges should be prepared

when “[YMCK] Ink Near End” is displayed.

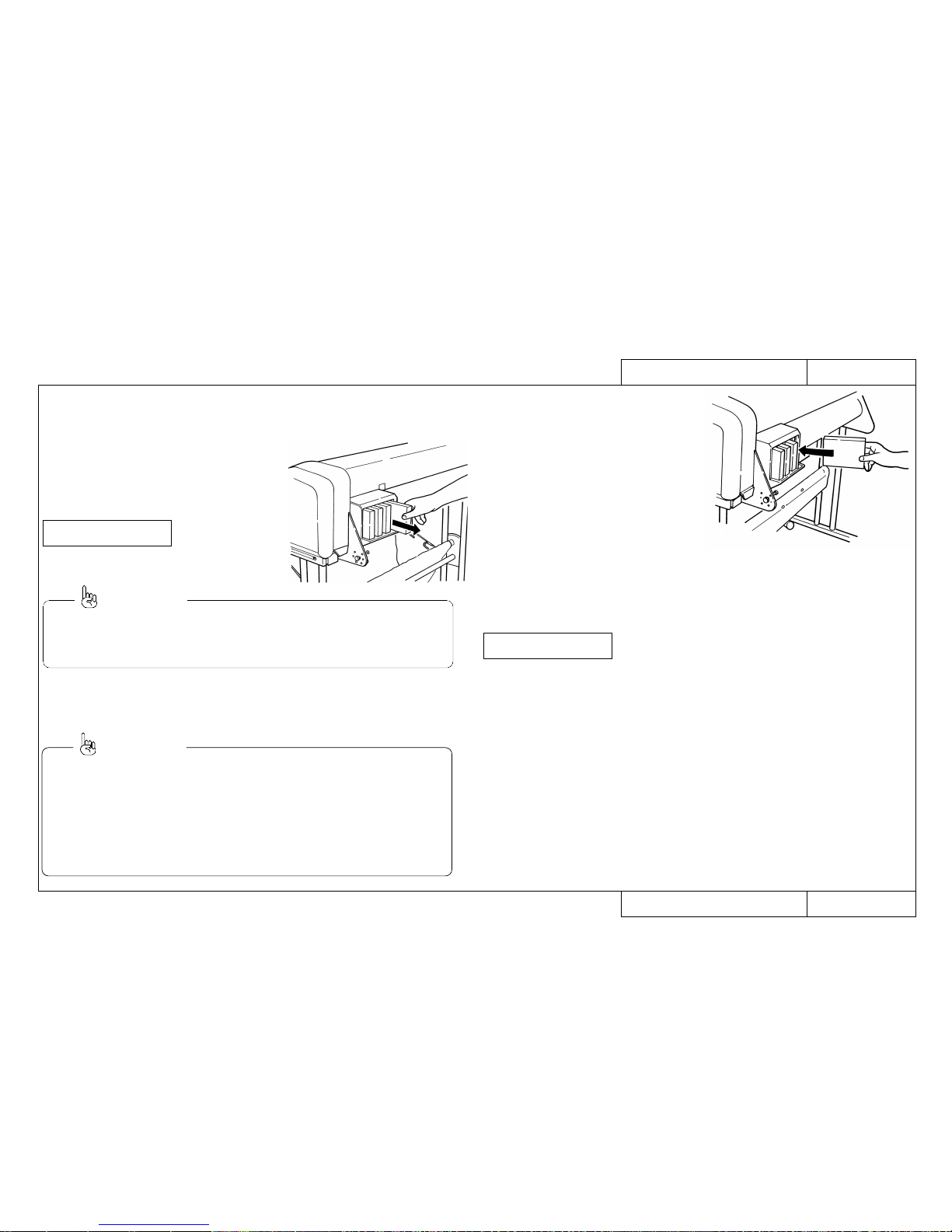

Step 1

If “No ink” appears in the message display section, when there is no printing operation in

progress, from the back of the printer, pull out

the ink cartridge whose color is indicated.

Step 2

Open the new ink cartridge packet.

[YMCK] cartridge

♦ Each letter Y, M, C, K in the display indicates a color: “Y” (yellow),

“M” (magenta), “C” (cyan), “K” (black).

♦ Colors for “no ink” are expressed as colors 1 to 4.

Reference:

CON5020Model Name: RJ–4100

CON5020Model Name: RJ–4100

How to Replace Ink Cartridges

How to Replace Ink Cartridges

Step 3

Insert the new cartridge in the slot at the

back of the printer.

Step 4

Check that the display has reverted to its

permanent display.

Reference:

♦ Only specific cartridges can be used. They also have a particular place and

orientation. Be careful not to confuse the location and orientation.

♦ Don’t open the sealed package until you are ready to insert the cartridge in the slot.

If a cartridge is stored for a long period with the seal opened, the printing may be

patchy.

♦ Cartridges should be used within two years of the date printed on the package.

An ink cartridge that has been mounted in the printer for two years should be

replaced.

♦ A cartridge that has been mounted in the printer should be replaced within six months.

Plot OK

Page 21

21

CON5030Model Name: RJ–4100

CON5030Model Name: RJ–4100

How to Replace the Cutter

How to Replace the Cutter

Depending on the type of roll media, paper dust may build up in the cutter groove

and on the cutter blade causing poor cutting. In such cases, the cutter should be

cleaned or replaced or the cutter groove should be cleaned.

The cutter is a consumable item. It it cuts badly, replace it.

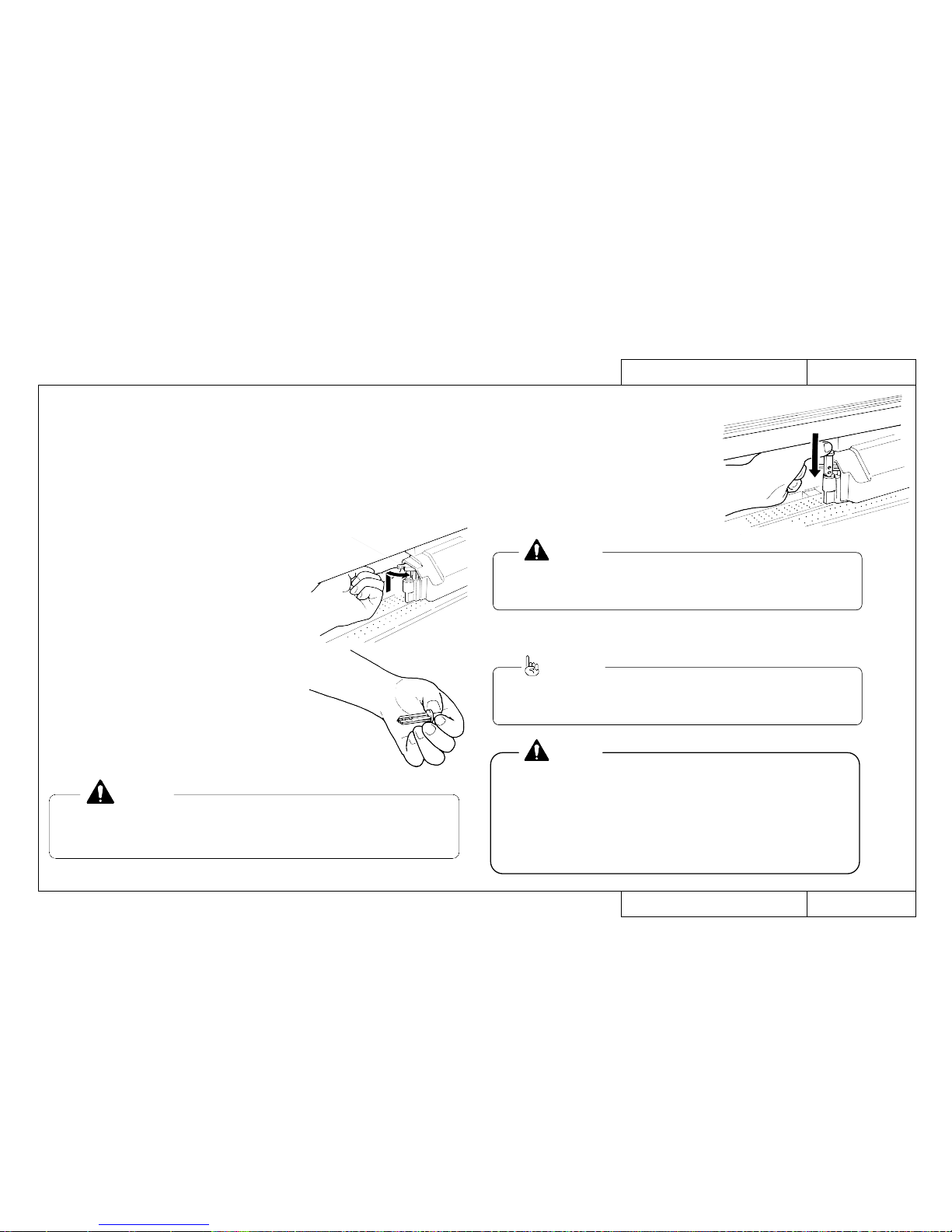

Step 1

Switch off the power and bring the head to the center.

Step 2

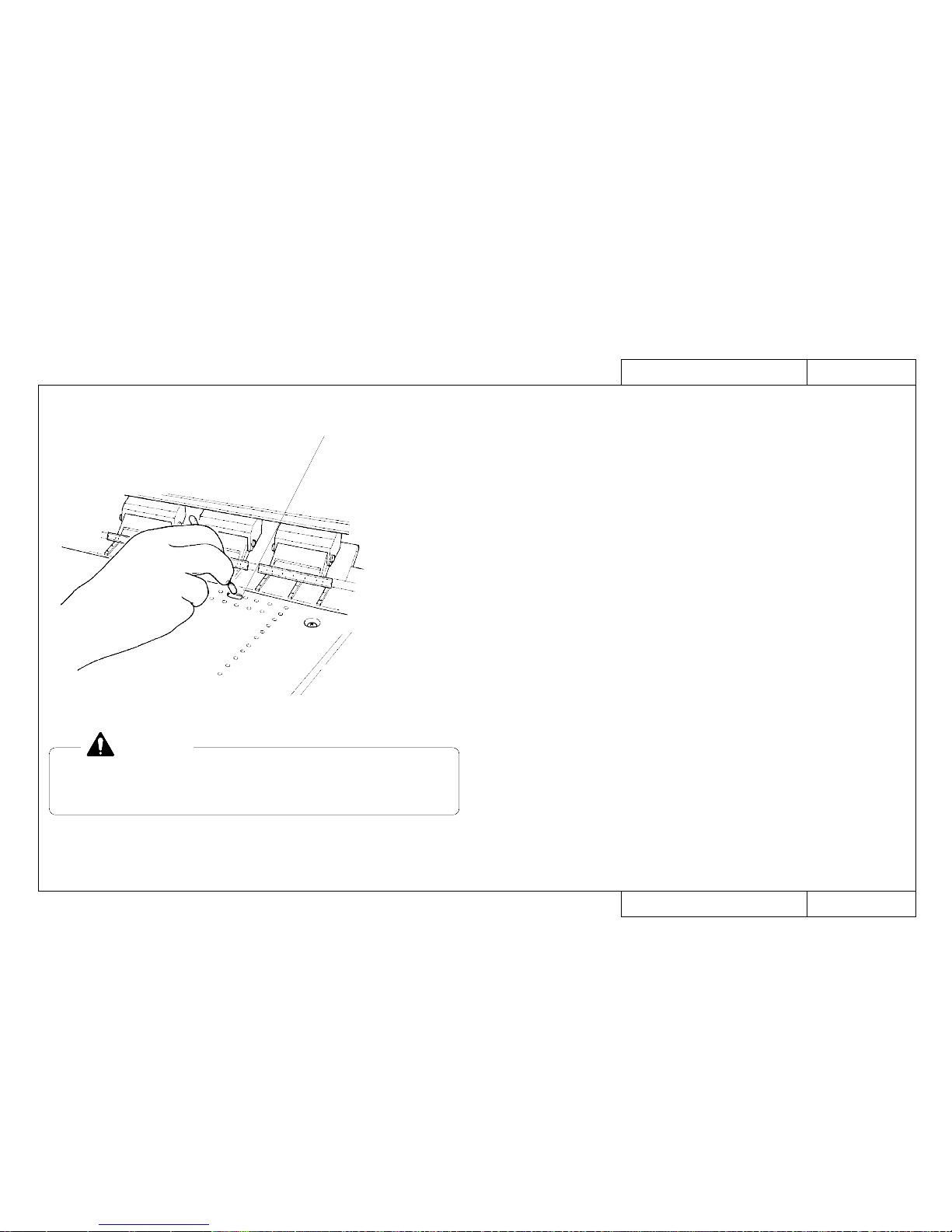

Press the cutter down with your finger and rotate

the arm to the front. Take out the cutter.

Wipe the cutter blade with a dry cloth or replace

the cutter.

Step 3

Insert a new cutter in the hole in the head. As

you push down on the cutter, restore the cutter arm over the cutter. The cutter will only go

in one way.

Cutter Arm

♦ There is a spring in the cutter mounting hole. Be careful not to lose it

when you replace the cutter.

CAUTION:

♦ The cutter blade is very hard and brittle. Be careful not to knock it or

drop it.

Step 4:

Return the head to the right end and switch on the power.

CAUTION:

♦ Since the life of the cutter depends on the type and thickness of the media

and the usage environment, it is recommended that a spare cutter be

procured.

Reference:

The auto-cut function cannot be used with some types of recommended

media.

If these types of media are used, a commercial cutter (such as OLFA 30B)

or scissors must be used for cutting.

The types of recommended media than cannot be cut by auto-cut are:

- Indoor cloth - Yupo tac film

- Fire-resistant cloth - Yupo film

- Outdoor cloth

CAUTION:

Page 22

22

CON5040Model Name: RJ–4100

CON5040Model Name: RJ–4100

How to Replace the Waste Fluid Box

How to Replace the Waste Fluid Box

Waste ink is held in the waste fluid box at the back of the printer. Replace the waste

fluid box when it becomes full.

Step 1

When the printer is stopped and the message, “Chk Waste Ink Tank” appears,

order a waste fluid box to be supplied.

Step 2

When the message, “Waste Fluid Tank

Full” appears, pull out the waste fluid box.

When the waste fluid tank is removed, the

message, “No Waste-Ink Tank” will

appear.

Step 3

Without tipping it up, transfer the waste

fluid box to a plastic bag for disposal.

Chk Waste Ink Tank

No Waste-Ink Tank

Waste-Ink Tank Full

After has appeared, the Waste-Ink Tank Full display

will appear after printing about 20 pages of A1 media (with 20% printing) or cleaning

about 40 times.

Chk Waste Ink Tank

Step 4

Insert a new waste fluid box in the printer.

Step 5

Use the [VALUE +] or [VALUE -] keys on

the purple part of the operating panel to

change the display to “Yes”.

Step 6

Press the [Enter] key on the purple part of

the operating panel.

♦ The waste fluid box can be treated as non-combustible garbage.

♦ Don’t squeeze the absorbent sheet soaked with waste fluid or

the waste fluid may leak.

♦ Since it would be dangerous for children to lick or swallow the absorbent

sheet soaked with waste fluid, it should be disposed of promptly or kept

out of the reach. If the waste fluid is accidentally touched, wash immediately

with soap and water. If waste fluid gets into the eyes, wash with plenty of

water and consult a physician. If it is licked, immediately gargle and wash

with water. If any has been swallowed, as a matter of urgency, drink copious

quantities of water and be sure to consult a physician.

♦ If the waste fluid box has been pulled out by mistake, press the enter key

when “Change Tank?: No” is displayed.

Change Tank? No

Change Tank? Yes

Plot OK

CAUTION:

Page 23

23

CON6000Model Name: RJ–4100

CON6000Model Name: RJ–4100

How to Move the Printer Main Unit

How to Move the Printer Main Unit

This section explains the procedure for moving a printer which is in use to another

floor in the same building or to another building.

How to move on the same floor or by elevator to another floor

A serviceman need not be present but the following procedure should be explained

to the user.

CAUTION:

• Two people are required to move the printer.

• Cleaning is not necessary.

• Cartridges, cutter, waste fluid box may remain installed.

• Be careful to keep the printer level. If it is tilted, waste may spill from the fluid

box.

1. With power off, bring the head to the home position and attach head fastening fittings with wing screws.

2. Remove the power cable and interface cable.

3. Undo castor locks and move the printer by pushing it horizontally.

4. When the move is finished, lock the castors, turn the wing screws and remove

the head fastening fittings.

How to move to a different building by vehicle

A serviceman must bring the following items and follow the procedure set out

below.

• Main unit packing box

• Vinyl bag

• Head fastening plate (DF-40549) and wing bolt (DE-48262)

• Cable keeper (DF-40338) and lever keeper (DF-40337)

• Waste fluid box (Number RJ8-HEB)

• Head cleaning jig

• Packing tape, gum tape, bubble wrap

• PP strapping and stopper (for long distance transportation)

CAUTION:

• For safety, always have two people to dismantle and assemble the printer.

• Always have two people to transport the printer and load and unload it on the

vehicle.

• If the user wishes you to take away the waste fluid box that has been removed

and the packing used for transportation, remove them.

• After the move, carry out the initial filling and wait at least 30 minutes before printing otherwise printing quality can not be assured.

1. Remove the four cartridges.

2. Carry out head cleaning. (Refer to REP1620)

3. With power off, bring the head to the home position and attach the head fastening

plate with the wing bolt.

4. Remove the power cable and interface cable.

5. Remove the waste fluid box and install a new one.

6. Install the cable keeper and lever keeper and fasten them with packaging tape.

7. Attach packaging tape so the front cover will not open and the waste fluid box will

not come out.

8. Remove the main unit from the legs, place it in the packing box and apply gum

tape and PP strapping.

9. Don’t dismantle the legs. Wrap them in bubble wrap.

(Remove the tray assembly and wrap it separately)

(If it needs to be dismantled to fit in the vehicle, dismantle and wrap each piece

separately.)

10. Transport by vehicle and on arrival at the destination, refer to the basic “Printer

Preparation” in the operation manual and make sure it is printing correctly.

How to Move the Printer Main Unit

Page 24

24

TRB0000Model Name: RJ–4100

TRB0000Model Name: RJ–4100

Trouble-Shooting Lists

Trouble-Shooting Lists

Trouble-Shooting Lists

When Message is Displayed

How to Use LEDs to Check CPU System TRB1001

and Mechanical System Faults

Printer Status Messages TRB1000

Data Errors TRB1000

Command Errors TRB1000

CPU System Faults TRB1000

Mechanical System Faults TRB1000

When Message is Not Displayed

Trouble with Initialization TRB2000

Trouble with Printing TRB2000

Trouble with Media Feed TRB2000

Trouble with Media Cutting TRB2001

Problem Involving Noise TRB2001

Online/Function Problems TRB2001

Other TRB2001

Page 25

25

When Message is Displayed

When Message is Displayed

TRB1000Model Name: RJ–4100

TRB1000Model Name: RJ–4100

Trouble-Shooting 1/3 (List of Faults)

Trouble-Shooting 1/3 (List of Faults)

Cases where an error message is displayed on the liquid crystal display of the main printer unit

GO TO ENT No.Minor Faults CPU System/Mechanical System Faults GO TO ENT No.

Printer Status Messages

CPU System Faults

• Cover Open

• Lever Up

• Cover and Lever

• Undefined Media

• Media Skew Error

• [User 1] Media End

• Remove Media

• Roll Media End

• Media Cut Error

• Not enough memory SIMM 12 MB

• [KCMY] Ink Low

• [KCMY] No Ink

• [KCMY] No Cartridge

• Capping position not specified

• Not Filled

• No Waste Fluid Box

• Check Waste Fluid Box

• Waste Fluid Box Full

• Ink Type Change

• Wrong Ink Type

ENT1000

ENT1000

ENT1000

ENT1010

ENT1020

ENT1030

ENT1040

ENT1050

ENT1060

ENT1070

ENT1080

ENT1090

ENT1090

ENT1100

ENT1110

ENT1120

ENT1130

ENT1140

ENT1140

ENT1150

ENT1160

• E001 Error DRAM (Standard DRAM error)

• E002 Error Opt.DRAM (Optional DRAM error)

•E016CPUErr[00] (Interrupt exception error)

•E016CPUErr[02] (Command boundary exception error)

•E016CPUErr[03] (Data boundary exception error)

•E016CPUErr[04] (Address error exception)

(Load or command fetch)

•E016CPUErr[05] (Address error exception) (Store)

•E016CPUErr[06] (Bus error exception) (Command fetch)

•E016CPUErr[07] (Bus error exception) (Data load)

•E016CPUErr[08] (System call exception error)

•E016CPUErr[09] (Break point exception error)

•E016CPUErr[10] (Reserved command exception error)

•E016CPUErr[11] (Unable to use coprocessor exception error)

•E016CPUErr[12] (Operation overflow exception error)

•E016CPUErr[13] (Trap exception error)

•E016CPUErr[15] (Floating point exception error)

•E016CPUErr[22] (Watch exception error)

•E016CPUErr[32] (Watchdog timeout exception error)

•E016CPUErr[33] (Abort error)

• Error E237 Transfer memory (Transfer memory error/Transfer memory

access error)

• Error E129 NVRAM

ENT1500

ENT1500

ENT1510

ENT1510

ENT1510

ENT1510

ENT1510

ENT1510

ENT1510

ENT1510

ENT1510

ENT1520

ENT1520

ENT1520

ENT1520

ENT1520

ENT1520

ENT1520

ENT1520

ENT1520

ENT1530

Mechanical System Faults

• E065 Error X Motor

• E069 Error X Encoder

• E071 Error X Timeout

• E073 Error X Overcurrent

• E066 Error Y Motor

• E070 Error Y Encoder

• E072 Error Y Timeout

• E074 Error Y Overcurrent

• E075 Error Sensor Fault

ENT1700

ENT1700

ENT1700

ENT1700

ENT1710

ENT1710

ENT1710

ENT1710

ENT1720

Data Errors

• Network Detection Error

• Network Initialization Error

ENT1230

ENT1230

Command Errors

• MH01 Error (Undefined Command)

• MH02 Error (Parameter Error)

• MH03 Error (Numerical Error)

• MH04 Error (Undefined Character Set)

• MH07 Error (Buffer Overflow)

ENT1250

ENT1250

ENT1250

ENT1250

ENT1250

Page 26

26

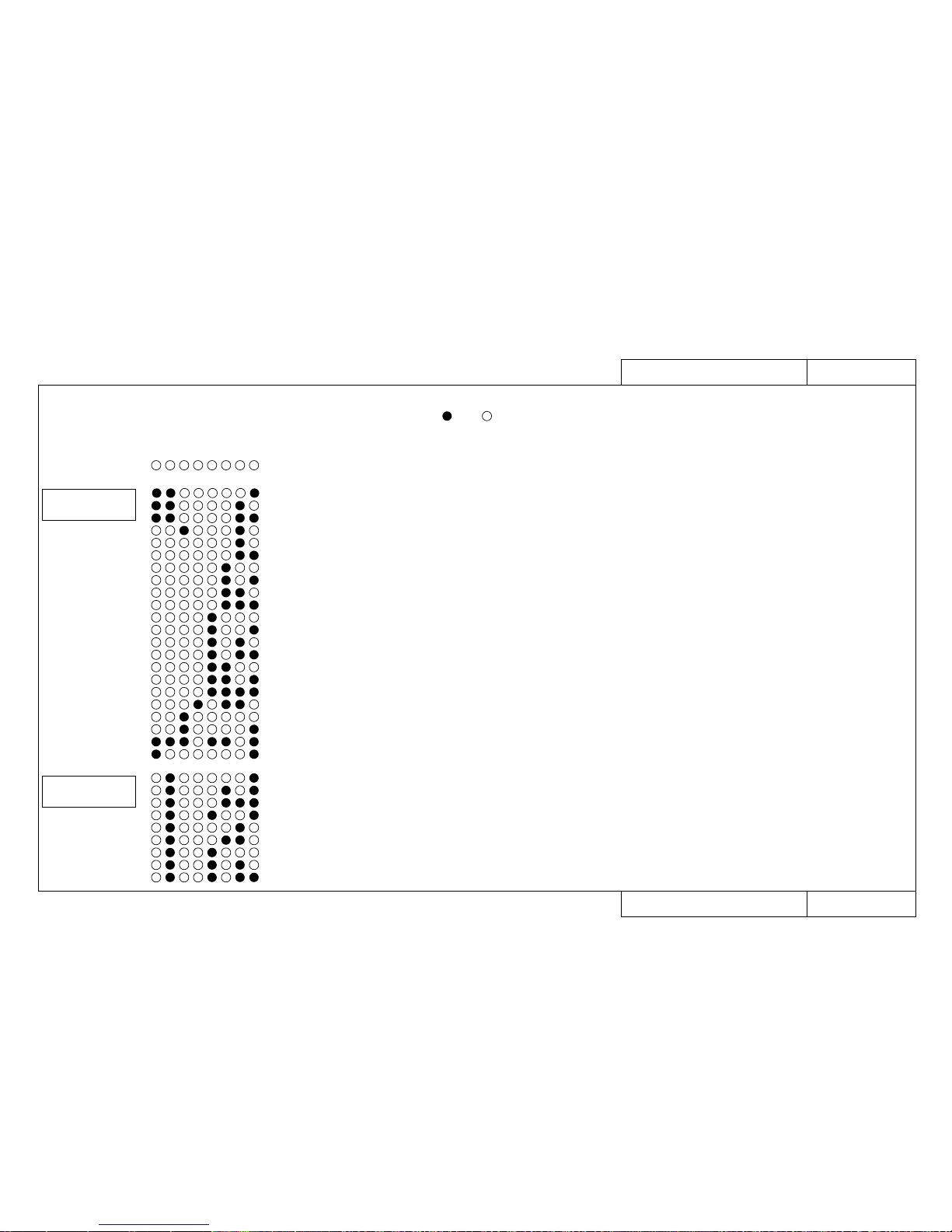

TRB1001Model Name: RJ–4100

TRB1001Model Name: RJ–4100

How to Use LEDs to Check CPU System and Mechanical System Faults

How to Use LEDs to Check CPU System and Mechanical System Faults

• When the printer stops working and nothing appears on the liquid crystal display (LCD),

a fault has probably occurred in the CPU system or the mechanical system.

In that case, open the control box and check the error by the LEDs on the main board. is on, is off.

LED display

12345678

• E001 Error DRAM

CPU System Faults

Details of Error

• E002 Error Opt.DRAM

• E002 Error Opt.DRAM

• E016CPUErr[00]

• E016CPUErr[02]

• E016CPUErr[03]

• E016CPUErr[04]

• E016CPUErr[05]

• E016CPUErr[06]

• E016CPUErr[07]

• E016CPUErr[08]

• E016CPUErr[09]

• E016CPUErr[10]

• E016CPUErr[11]

• E016CPUErr[12]

• E016CPUErr[13]

• E016CPUErr[15]

• E016CPUErr[22]

• E016CPUErr[32]

• E016CPUErr[33]

• E237 Error Transfer memory

• E129 Error NVRAM

(Standard DRAM error)

(Optional DRAM 1 error)

(Optional DRAM 2 error)

(Interrupt exception error)

(Command boundary exception error)

(Data boundary exception error)

(Address error exception) (Load or command fetch)

(Address error exception) (Store)

(Bus error exception) (Command fetch)

(Bus error exception) (Data load)

(System call exception error)

(Break point exception error)

(Reserved command exception error)

(Unable to use coprocessor exception error)

(Operation overflow exception error)

(Trap exception error)

(Floating point exception error)

(Watch exception error)

(Watchdog timeout exception error)

(Abort error)

(Transfer memory error/Transfer memory access error)

ENT1500

Primary Consultation page

ENT1500

ENT1500

ENT1510

ENT1510

ENT1510

ENT1510

ENT1510

ENT1510

ENT1510

ENT1510

ENT1510

ENT1520

ENT1520

ENT1520

ENT1520

ENT1520

ENT1520

ENT1520

ENT1520

ENT1520

ENT1530

• E065 Error X Motor

• E066 Error Y Motor

• E069 Error X Encoder

• E070 Error Y Encoder

• E071 Error X Timeout

• E072 Error Y Timeout

• E073 Error X Overcurrent

• E074 Error Y Overcurrent

• E075 Error Sensor Fault

ENT1700

ENT1700

ENT1700

ENT1700

ENT1710

ENT1710

ENT1710

ENT1710

ENT1720

Mechanical System

Faults

Page 27

27

TRB2000Model Name: RJ–4100

TRB2000Model Name: RJ–4100

Trouble-Shooting 2/3 (List of Faults)

Trouble-Shooting 2/3 (List of Faults)

When Message is Not Displayed

When Message is Not Displayed

GO TO

ENT No.

Cases where no error message is displayed

on the liquid crystal display of the main printer unit

GO TO

ENT No.

Cases where no error message is displayed

on the liquid crystal display of the main printer unit

Trouble with Initialization

Trouble with Printing

• No power

• Faulty liquid crystal display (no display/unstable display)

• Initial filling of inks failed

• Initial filling is completed but no ink comes out

• After power is switched on, nothing works

•

When power is applied, “Initializing” appears and then a reset is executed.

• Media is mounted but the initialization operation is not done

• Printer does not work even with the cover closed

• Printer does not stop even with the cover opened

• Ink cartridges are installed but not recognized

• Can not make entries from the operating panel

• Data is received but not printed

• Media is not suction

ENT2000

ENT2000

ENT2010

ENT2020

ENT2030

ENT2030

ENT2030

ENT2030

ENT2030

ENT2040

ENT2050

ENT2060

ENT2070

ENT3000

ENT3000

ENT3000

ENT3000

ENT3000

ENT3010

ENT3010

• Does not print continuously

• There is an extra feed after printing is finished

• Dots are missing from the printing

• Cleaning does not cure blockage

• Does not print at all

• Does not print a specific color

• The entire surface is printed black

• Printing becomes shaded

• The image contains blurs

• Transverse lines appear to be split

• Black and white lines appear in the printed image

• Edges of printing are blurred

• Many satellites (unwanted dots)

• The printing has whiskers

• Printed lines appear blurred (printing is dirty)

• Mixed color lines do not overlap

• Black and color positions are offset

•

Inaccurate line length in the direction of head movement (Main scanning direction)

• Inaccurate straight line in the direction of head movement (straightness)

•

Inaccurate line distance in the direction of media feed (Subsidiary scanning distance)

• Inaccurate straight line in the direction of media feed (joining precision Y)

• Bad right angle precision

ENT4000

ENT4010

ENT4020

ENT4020

ENT4030

ENT4030

ENT4040

ENT4050

ENT4050

ENT4050

ENT4050

ENT4060

ENT4070

ENT4070

ENT4070

ENT4080

ENT4080

ENT4090

ENT4100

ENT4110

ENT4120

ENT4130

Trouble with Media Feed

• The media comes off when it is initialized or during printing

• The media is skewed or meanders when it is initialized or during printing

• The media becomes wrinkled when it is initialized or during printing

• The media jams when it is initialized or during printing

• The media tears when it is initialized or during printing

• The media size is different after media mounting and initialization

• Tracing paper and thin media cannot be detected

Page 28

28

TRB2001Model Name: RJ–4100

TRB2001Model Name: RJ–4100

Trouble-Shooting 3/3 (List of Faults)

Trouble-Shooting 3/3 (List of Faults)

When Message is Not Displayed

When Message is Not Displayed

GO TO

ENT No.

Cases where no error message is displayed

on the liquid crystal display of the main printer unit

GO TO

ENT No.

Cases where no error message is displayed

on the liquid crystal display of the main printer unit

Problem Involving Noise

Online/Function ProblemsOther

• Abnormal noise when media is sucked down

• Abnormal noise when standing by ready to print

• Abnormal noise when head is moving left and right

• Abnormal noise when media is fed

• Abnormal noise when cutting

ENT5000

ENT5010

ENT5020

ENT5030

ENT5040

ENT6000

ENT6010

ENT6020

ENT6020

ENT6030

ENT6040

ENT6050

ENT6050

ENT7000

ENT7000

ENT7020

ENT7020

ENT7020

ENT7020

ENT7030

ENT7040

ENT7050

ENT7060

• The printer hangs up

• Power shutdown during printing

• The ink cartridges will not go in

• Mounting the media is difficult

• Inserting the scroller is difficult

• Ink has overflowed from the waste fluid box

• Ink overflows from flushing box

• Ink is split around the X-rail

• Trouble related to ink (consumable item)

• Trouble related to media (consumable item)

• Trouble related to cutters (consumable item)

• Trouble related to extended memory (optional item)

• Trouble related to the network board (optional item)

• Can not install the printer driver

• Cannot connect normally with Centronics

• Cannot connect normally with Network

• The scale function does not work correctly

• The rotate function does not work correctly

• The mirror function does not work correctly

• Other functions are not working correctly

• Printing position is offset

• Some data are not printed (omitted)

• Text and printing data are garbled (extra lines appear)

• There is an extra feed after printing is finished

ENT8000

ENT8010

ENT8020

ENT8030

ENT8040

ENT8050

ENT8050

ENT8050

ENT8060

ENT8060

ENT8060

ENT8070

ENT8070

ENT8070

Trouble with Media Cutting

• Does not cut normally

• Cutting occurs during printing

• The cutting operation is normal but the media is not cut

• The cutting is bad and the media jams

• The cutting operation is normal but the media does not fall out

• Inaccurate media cutting

• Cutting is delayed for some time after printing has ended

• White paper is cut

Page 29

29

ENT0000Model Name: RJ–4100

ENT0000Model Name: RJ–4100Primary Consultation

Primary Consultation

Primary Consultation

When Message is Displayed

Printer Status Messages ENT1000

Data Errors ENT1200

Command Errors ENT1250

CPU System Faults ENT1500

Mechanical System Faults ENT1700

When Message is Not Displayed

Trouble with Initialization ENT2000

Trouble with Printing ENT4000

Trouble with Media Feed ENT3000

Trouble with Media Cutting ENT6000

Problem Involving Noise ENT5000

Online/Function Problems ENT7000

Other ENT8000

Page 30

ENT1000Model Name: RJ–4100

ENT1000Model Name: RJ–4100

Printer Status Messages

When Message is Displayed

1

2

3

• Cover Open

This message means that the Front

Cover is open

• Lever Up

This message means that the

Pressure Lever is up.

• Cover and Lever

This message means that the Front

Cover and Pressure Lever are up.

1-1

1-2

1-3

1-4

1-5

1-6

• The front cover is open.

→ Please close the front cover securely.

• Is the pressure lever up?

→ Please lower the pressure lever securely.

• Is the Cover Shaft R fastening screw in place?

→ Maintenance by a Serviceman is required.

• Please open and close the front cover several times. Does the beeper sound when the cover is open?

→ If there is no noise when the cover is opened, the main unit has probably developed a fault for some reason.

Maintenance by a Serviceman is required.

• Please raise and lower the pressure lever several times. Does the beeper sound when the lever is raised?

→ If there is no noise when the pressure lever is raised, the main unit has probably developed a fault for some

reason. Maintenance by a Serviceman is required.

• The power supply may be unstable if several devices are connected to one power outlet.

→ Switch off the power temporarily and try again by connecting to a different outlet.

❈ If the above procedures do not improve the symptoms, the main unit has probably developed a fault for

some reason.

Go to MAP1000

No. Symptom

Sequence

Items to be Confirmed

When Message is Displayed

Printer Status Messages

30

Page 31

ENT1010Model Name: RJ–4100

ENT1010Model Name: RJ–4100

Printer Status Messages

When Message is Displayed

1 • Undefined Media

This message means that when

media was mounted, it was not able

to be recognized.

1-1

1-2

1-3

1-4

1-5

1-6

1-7

1-8

1-9

• Is the type of media that is not being recognized the type of media recommended for the printer?

→ Please change to a recommended media and try again.

• Is a breeze from the airconditioner blowing straight on to the media?

→ Please change the direction of the airstream and try again.

• Is there a scrap of paper or something else covering the paper sensor on the printer?

→ Please refer to "Daily Maintenance" in the Operation Manual and carry out the cleaning.

• Is the media that is not being recognized torn?

→ Replace it with new media.

• Has the media that is mounted already been printed?

→ It is possible that printed media may not be recognised correctly. Replace it with new media.

• Is the pressure lever down properly?

→ Lower the pressure lever securely.

• The media is mounted normally if, during the media detection operation, the media moves forward and backward parallel to

the marker line and the position is the same as before media detection. If the position is different, the mounting of the

media must be repeated.

→ Mount the media again so that the positions before and after media detection are the same.

For details, please refer to “Trouble Shooting” under “Daily Maintenance” in the Operation Manual.

• Is there ink or paper dust, etc. around the printing board and cutter groove?

→ Carry out cleaning with reference to “Trouble Shooting” under “Daily Maintenance” in the Operation Manual.

• Is there strong light falling on the area where the media is mounted?

→ Cover the Y Rail Cover and Front Cover with opaque paper and mount the media again. If the error display disappears,

move the printer to a location away from the strong light and try mounting the media once more.

❈ If the above procedures do not improve the symptoms, the main unit has probably developed a fault for some reason.

Go to MAP1000

No. Symptom

Sequence

Items to be Confirmed

When Message is Displayed

Printer Status Messages

31

Page 32

ENT1020Model Name: RJ–4100

ENT1020Model Name: RJ–4100

Printer Status Messages

When Message is Displayed

1 • Media Skew Error

This message appears when the right

(origin side) edge of the media has

been detected beyond the allowable

range of variation from the standard

position.

1-1

1-2

1-3

1-4

1-5

1-6

• Is recommended media being used?

→ Replace with recommended media and try again.

• Is the pressure lever lowered properly?

→ Lower the lever securely.

• Is there any foreign matter interfering with the media feed, such as paper cuttings sticking to the grid roller?

→ Remove them with a brush, etc.

• In the case of roll paper, is the roll shaft seated properly in both the left and right printer shaft support rollers?

→ Install the shaft properly.

• In the case of roll paper, the media is set correctly if it moves backward and forward parallel to the marker line during media

detection, and it is in the same position as it was prior to detection. However, if the position seems to be offset, it must be

remounted.

→ Mount the media again so that it is in the same position before and after media detection.

• Are you explaining what is meant by skew and meander?

Check this condition in detail during the primary consultation.

Explain that skew up to the figures shown below is within the acceptable limit.

Also, have the repeatability checked and explain that poor repeatability is probably caused by badly mounted media.

No. Symptom

Sequence

Items to be Confirmed

When Message is Displayed

Printer Status Messages

32

Cut sheet

Roll media

Within 1.5 mm

Within 2.5 mm

However, it should be explained that in the case of roll media, if the pressure is left down for a long period with the media

mounted, or in an environment with sudden changes of temperature and humidity, the whole roll may not necessarily feed

properly.

• In a case where the symptoms are not reproduced (no problem up to the fifth sheet then frequent skewing after remounting,

etc.) the method of mounting the media may be at fault and this should be checked with the Operation Manual.

→ Check "Loading the media" under "Installation procedures:" in the Operation Manual.

❈ If the above procedures do not improve the symptoms, the main unit has probably developed a fault for some reason.

Go to MAP1000

1-7

Page 33

ENT1030Model Name: RJ–4100

ENT1030Model Name: RJ–4100

Printer Status Messages

When Message is Displayed

1 • [User 1] Media End

This message is displayed when no

media is mounted or printing in cut

media mode has been completed.

1-1

1-2

• Is the lever down with no media mounted, or has printing in cut media mode been completed?

→ Mount new recommended media.

• When cut media is being mounted, is it placed so that it covers the sensor that detects the trailing edge of the

media?

→ When cut media is being mounted, push it right back until the media suction fan starts to turn and then try

again.

❈ If the above procedures do not improve the symptoms, the main unit has probably developed a fault for

some reason.

Go to MAP1000

No. Symptom

Sequence

Items to be Confirmed

When Message is Displayed

Printer Status Messages

33

Page 34

ENT1040Model Name: RJ–4100

ENT1040Model Name: RJ–4100

Printer Status Messages

When Message is Displayed

1 • Remove Media

This message is displayed, if after

raising the lever during printing and

cutting the media, the lever is lowered

without the media having been

removed.

1-1 • Does the error appear after raising the lever during printing and cutting the media and then removing the

media?

→ Switch on the power again.

❈ If the above procedures do not improve the symptoms, the main unit has probably developed a fault for

some reason.

Go to MAP1000

No. Symptom

Sequence

Items to be Confirmed

When Message is Displayed

Printer Status Messages

34

Page 35

ENT1050Model Name: RJ–4100

ENT1050Model Name: RJ–4100

Printer Status Messages

When Message is Displayed

1 • Roll Media End

This message is displayed when roll

media is being used and the trailing

edge of the media is detected. It will

be cancelled by raising the lever.

1-1 • Is the roll media finished?

→ Replace the roll.

• Have cut media been mounted while roll media is selected?

→ Mount roll media.

• Is the roll media floating?

→ Mount the media again.

• Does "Roll Media End" appear when the pressure lever is up?

→ If this is displayed, maintenance by a Serviceman is required.

❈ If the above procedures do not improve the symptoms, the main unit has probably developed a fault for

some reason.

Go to MAP1000

No. Symptom

Sequence

Items to be Confirmed

When Message is Displayed

Printer Status Messages

35

Page 36

ENT1060Model Name: RJ–4100

ENT1060Model Name: RJ–4100

Printer Status Messages

When Message is Displayed

1 • Media Cut Error

This message is displayed when the

media is not cut and does not fall out

despite the cutting operation having

been performed.

1-1

1-2

1-3

1-4

1-5

1-6

1-7

• Is the type of media that is not being cut the type of media recommended for the printer?

→ Since the message is cancelled when the lever is raised, please change to a recommended media and try

again.

• Is there paper dust or other matter in the cutter groove?

→ Please refer to "Daily Maintenance" in the Operation Manual and carry out the cleaning.

• Is the cutter and cutter spring mounted in the head mount?

→ Mount the cutter.

• Is the cutter cap fitted properly over the cutter blade?

→ Please refer to "Daily Maintenance" in the Operation Manual and refit it then try again.

• Does the usage environment conform to the recommended working environment?

→ Please refer to "Specifications" in the Operation Manual.

• Is dew condensed on the printer?

→ Wait until the printer has adjusted to the environment and the dew has disappeared and then try again.

• Had the tip of the cutter blade become blunt?

→ The cutter is a consumable item. Replace it with a new one and try again.

No. Symptom

Sequence

Items to be Confirmed

When Message is Displayed

Printer Status Messages

36

The auto-cut function cannot be used with some types of recommended

media.

If these types of media are used, a commercial cutter (such as OLFA 30B)

or scissors must be used for cutting.

The types of recommended media than cannot be cut by auto-cut are:

- Indoor cloth - Yupo tac film

- Fire-resistant cloth - Yupo film

- Outdoor cloth

CAUTION:

❈ If the above procedures do not improve the symptoms, the main unit has probably

developed a fault for some reason.

Go to MAP1000

Page 37

ENT1070Model Name: RJ–4100

ENT1070Model Name: RJ–4100

Printer Status Messages

When Message is Displayed

1 • Not enough memory SIMM✼✼MB

(Intermediate code buffer overflow)

When this printer has insufficient

memory for the amount of data sent

by the personal computer, this message indicates the required memory

size.

1-1

1-2

2-1

2-2

Check: Which of the following applies to the error?

No extended memory Go to Step 2-1

Extended memory fitted Go to Step 1-2

Check: In the memory capacity that is printed on the list of setting details, is it only the extended memory that is

increased?

Not increased → The printer will not be aware of extended memory if it is inserted in the

wrong slot.

Please check whether the extended memory is in the proper slot.

Increased Go to Step 2-2

Reference: For details on how to mount extended memory, please refer to "Installing Options" in

the Applications Operating Manual.

Treatment: When the printer was developed, printing data transmitted from HOST was sometimes too great to

be accommodated in memory.

Since the display shows the memory required to plot the data on the screen, advise the user to pro-

cure at least this amount of memory.

Reference: For details on how to mount extended memory, please refer to "Installing Options" in

the Applications Operating Manual.

Treatment: The extended memory that has been procured may be faulty.

❈ If the above procedures do not improve the symptoms, the main unit has probably developed a fault for

some reason.

Go to MAP1000

No. Symptom

Sequence

Items to be Confirmed

When Message is Displayed

Printer Status Messages

37

Page 38

ENT1090Model Name: RJ–4100

ENT1090Model Name: RJ–4100

Printer Status Messages

When Message is Displayed

12• [KCMY] Ink Low

This message is displayed when the

amount of ink shown on the operating

panel is low.

Printing can continue.

(Refer to GID2010 for details)

• [KCMY] No Ink

This message is displayed when the

ink shown on the operating panel has

been used up.

If this message appears while an

image is being printed, stop printing

immediately.

(Refer to GID2010 for details)

1-1

2-1

2-2

• This indicates that the amount of ink shown on the operating panel is low.

→ Advise the operator to complete the current printing output after “Ink Low” has appeared and then replace

the ink cartridge.

❈ If the above procedures do not improve the symptoms, the main unit has probably developed a fault for

some reason.

Go to MAP1000

• This indicates that the ink shown on the operating panel has been used up.

→ For example, if "[KY] No Ink" is displayed, insert new K (Black) and Y (Yellow) ink cartridges.

• Is "[KY] No Ink" displayed on the operating panel despite new ink cartridges having been inserted?

→ If this is displayed, maintenance by a Serviceman is required.

❈ If the above procedures do not improve the symptoms, the main unit has probably developed a fault for

some reason.

Go to MAP1000

No. Symptom