Page 1

Mutoh America

Inc.

Falcon

Outdoor Jr.

Operation Instructions

MUTOH AMERICA INC. PN: MAI-75039

Rev. 1.A – 07/26/05

Page 2

Falcon Outdoor Jr. – Operation Instructions

Page 2

PN: MAI-75039

Rev. 1.A – 07/26/05

Page 3

Falcon Outdoor Jr. – Operation Instructions

Page 3

PN: MAI-75039

Rev. 1.A – 07/26/05

COPYRIGHT NOTICE

COPYRIGHT © 2004 Mutoh Europe N.V. All rights reserved.

This document may not be reproduced by any means, in whole or in part, without written permission of the

copyright owner.

This document is furnished to support the Mutoh Falcon Outdoor Jr. printer Series. In consideration of the

furnishing of the information contained in this document, the party to whom it is given assumes its custody

and control and agrees to the following:

The information herein contained is given in confidence, and any part thereof shall not be copied or

reproduced without written consent of Mutoh Europe N.V.

This document or the contents herein under no circumstances, shall be used in the manufacture or

reproduction of the article shown and the delivery of this document shall not constitute any right or license to

do so.

FCC-WARNING

This equipment complies with the requirements for a Class A computing device in the FCC rules, part 15,

subpart J.

Operation of this device in a residential area may interfere with television reception or operation of utilities.

Printers generate weak radio signals and may interfere with television reception and utilities. If the printer

does interfere with radio or TV reception, try the following:

¾ Change the direction of your radio and TV reception antenna or feeder.

¾ Change the direction of the printer.

¾ Move either the printer or the receiving antenna so there is more distance between them.

¾ Be sure the printer and the receiving antenna are on separate power lines.

Page 4

Falcon Outdoor Jr. – Operation Instructions

Page 4

PN: MAI-75039

Rev. 1.A – 07/26/05

Page 5

Falcon Outdoor Jr. – Operation Instructions

Page 5

PN: MAI-75039

Rev. 1.A – 07/26/05

Dear Customer,

As you know, Mutoh Europe’s core business is outdoor printing and sign m aking.

Developed at Mutoh Europe, the Falcon Outdoor Jr. is specifically targeted at smaller sign shops looking for

an affordable and versatile printer able to produce indoor and outdoor durable graphics on a selected range

of inexpensive uncoated PVC and banner media as well as on coated substrates such as paper, tyvek,

backlit/frontprint film.

Offering a media width of 954 mm (37.55”) and a maximum print width of 934 mm (36.77”), Falcon Outdoor

Jr. incorporates Mutoh’s proven Eco-Solvent Plus ink concept to produce high quality, bright, vivid outdoor

durable images.

Falcon Outdoor Jr. integrates two heating elements, one fixer and one dryer. These heating elements will

promote durability (chemical, abrasion), dot gain as well as drying and will offer a wide media compatibility.

The heating elements are digitally controllable via a separate temperature control LCD.

Please find detailed information on how to handle the Mutoh’s Falcon Outdoor Jr. in this manual.

Happy printing !

Mutoh America Inc.

Page 6

Falcon Outdoor Jr. – Operation Instructions

Page 6

PN: MAI-75039

Rev. 1.A – 07/26/05

Page 7

Falcon Outdoor Jr. – Operation Instructions

Page 7

PN: MAI-75039

Rev. 1.A – 07/26/05

TABLE OF CONTENTS

QUICK START

SEH

PRINTSERVER AND INTERCON NETTOOLS SETUP AND DIAGNOSTIC FEATURE (FILE DOWNLOAD) ...............10

1. SAFETY INSTRUCTIONS..................................................................................................................................... 103

1.1. INTRODUCTION ......................................................................................................................................................13

1.2. WARNINGS, CAUTIONS AND NOTES .......................................................................................................................13

1.3. IMPORTANT SAFETY INSTRUCTIONS ....................................................................................................................... 13

1.4. WARNING LABELS..................................................................................................................................................16

2. PRODUCT OVERVIEW...........................................................................................................................................17

2.1. GETTING TO KNOW THE PRINTER PARTS AND COMPONENTS .................................................................................. 17

2.1.1 Explanation of fixer and dryer........................................................................................................................18

3. SETTING UP THE UNIT......................................................................................................... ................................. 20

3.1. INSTALLATION REQUIREMENTS: SELECTING AN ADEQUATE PLACE FOR SETTING UP YOUR EQUIPMENT .................20

3.2. WHAT’S IN THE BOX?............................................................................................................................................21

3.3. UNPACKING YOUR FALCON OUTDOOR JR. PRINTER ............................................................................................... 22

3.4. PARTS LIST ............................................................................................................................................................24

3.4.1. Contents of the stand box:............................................................................................................................. 24

3.4.2. Contents of the printer box:...........................................................................................................................24

3.4.3. Contents of the accessories box: ...................................................................................................................25

3.5. ASSEMBLING THE PRINTER..................................................................................................................................... 26

3.6. INSTALLATION OF THE WASTE BOTTLE................................................................................................................... 29

4. PREPARING FOR A JOB.........................................................................................................................................31

4.1. CONNECTING THE POWER CABLE ...........................................................................................................................31

4.2. CONNECTING THE INTERFACE CABLE..................................................................................................................... 32

4.2.1. Tips to use high-speed ECP parallel communication.................................................................................... 32

INSTALLATION OF SEH NETWORK INTERFACE BOX..........................................................................................................

D

IAGNOSTIC ASSISTANCE USING ‘FILE Download’ FEATURE OF THE SEH BOX

S

TEP ADJUSTMENT ‘MICRO-BANDING ELIMINATION ON FALCON OUTDOOR’

4.3. LOADING ECO-SOLVENT PLUS INK CASSETTES (FIRST TIME) .................................................................................36

4.4. LOADING MEDIA .................................................................................................................................................... 38

4.4.1. General recommendations with regard to printer media ...............................................................................38

4.4.2. Loading cut sheet media................................................................................................................................38

4.4.3. Loading roll media........................................................................................................................................ 41

4.4.4 Loading media in combination with the Roll Take-Up System.....................................................................46

4.4.5. Eco-Solvent Plus Media List......................................................................................................................... 52

4.5. ADJUSTING HEAD HEIGHT.....................................................................................................................................53

5. HANDLING THE PRINTER....................................................................................................................................55

5.1. GUIDED TOUR AROUND THE OPERATION PANEL ..................................................................................................... 55

5.1.1. Keyboard Concept.........................................................................................................................................59

5.1.2. Menu Structure - overview............................................................................................................................60

5.2. HEATER SYSTEM OPERATION PANEL ......................................................................................................................61

6. DAILY MAINTENANCE & TROUBLESHOOTING............................................................................................63

6.1. CLEANING THE PRINTER ......................................................................................................................................... 63

6.2. REPLACING THE ECO-SOLVENT PLUS INK CASSETTES........................................................................................... 65

6.3. REPLACING THE CUTTING BLADE ...........................................................................................................................66

6.4 CLEANING THE WIPERS...........................................................................................................................................68

6.5. EMPTYING THE WASTE BOTTLE ..............................................................................................................................69

7. APPENDIX..................................................................................................................................................................71

7.1. PRINTER SPECIFICATIONS ......................................................................................................................................71

Page 8

Falcon Outdoor Jr. – Operation Instructions

Page 8

PN: MAI-75039

Rev. 1.A – 07/26/05

Page 9

Falcon Outdoor Jr. – Operation Instructions

Page 9

PN: MAI-75039

Rev. 1.A – 07/26/05

Page 10

Falcon Outdoor Jr. – Operation Instructions

Page 10

PN: MAI-75039

Rev. 1.A – 07/26/05

QUICK START FOR SEH AND FALCON OUTDOOR PRINTERS

SEH PRINTSERVER AND INTERCON NETTOOLS SETUP AND DIAGNOSTIC

FEATURE (FILE DOWNLOAD)

TO INSTALL AN SEH BOX FOR ANY OF THE FALCON OUTDOOR SERIES

PRINTERS FOLLOW THESE STEPS.

1. DO NOT connect the SEH box to the printer at this time.

2. Put the CD in the computer, if ‘autorun’ starts then follow the info to install “English” and choose ‘Intercon

NetTools’ then Go to 9. If ‘autorun’ does not start then proceed.

3. Click – My Computer

4. Right click on the CD icon

5. Select “Explore” from menu

6. Double click on the “NetTool” folder

7. Double click on “Windows” folder

8. Double click “NetTool” Setup

9. Follow prompts to complete installation

• Connect the SEH box ONLY to the network cable, DO NOT attach to the printer at this time. Use a

crossover cable if you are connecting directly to a computer. Use a standard cable if you are connecting

using a ‘switch’, ‘router’ or ‘hub’. Crossover direct connection should not be used for production work.

• After completing 1 – 9 above, launch “InterCon – NetTools” from the desktop icon or find InterConTools

in your Programs folder.

• Double click on the IP address (most likely all zeros). (Loading properties menu should open).

• Select TCP/IP tab on the left.

• Remove the ‘checks’ in the boxes from all items except ARP/Ping. Specifically DHCP.

• ‘Check’ the TCP/IP box and Enter your IP address and submask then click OK. A Gateway is not

required.

CAUTION: The IP address must match all three of the first 3 triads (sets of three numbers) and the only

difference is the last ‘triad’ where the printer is usually ‘1’ number different from the computer. All four triads

of the SUB NET mask must match exactly as well.

• Select ‘rebuild’ on the Intercon NetTools menu. Verify the IP address line changes to your entered

address. The printer icon should show a red X through it.

• Connect the SEH box to the printer LPT port. The red X should come off when the printer is powered

ON. Click the Refresh or Rebuild buttons to make it change if it doesn’t automatically refresh itself.

Notice that the SEH utility now shows the name of the printer.

Print server is now configured for your network and IP address.

• Setup up your RIP software for the IP address of the SEH box.

Page 11

Falcon Outdoor Jr. – Operation Instructions

Page 11

PN: MAI-75039

Rev. 1.A – 07/26/05

DIAGNOSTIC ASSISTANCE USING ‘FILE DOWNLOAD’ FEATURE OF THE SEH BOX.

Both the WEB interface (IP address in browser) or Intercon Nettools have the ability to transfer a file directly

to the IP address. This is important as sometimes the problem in the print is RIP related and if the RIP is

used to create a ‘test’ file then it could have the problem in it.

Mutoh provides a ‘test print’ file for each model of printer. For the Falcon Outdoor or Falcon Outdoor Junior

these files are a low ink density Diagonal nozzle check pattern designed to show whether ‘Step Adjustment’

is correct or not. (ignore the Distance Adjustment feature on the FO series). Once the ‘Step Adjust’ is dialed

in then images printed with the correct profile should be able to be printed.

Each of the SEH options have a ‘Download / file’ section where you will be prompted for a file. Locate the

‘testprint’ file that is appropriate

Please realize that a ‘light band’ can be either missing / misdirected nozzles or that Step Adjust is too high.

Confirm that nozzles are firing and then start this procedure for Micro Banding.

A ‘dark band’ can be from either Step Adjust being too low or it can be from the platen heater not being hot

enough. For this reason it is suggested that if no light band is showing then change the Step adjust higher to

create a light band. Then reduce the number in small steps until either you have no band or a slight dark

band remains. Once you reach this point adding ‘heat’ to the platen should then minimize the banding to an

acceptable amount for solvent printing.

Remember

1. Check nozzles first. Clean as required.

2. Dial out the light and first. Create a light band if necessary.

3. For the bark band that remains after dialing out the light band, start by increasing the platen heat in

small steps.

4. If a small dark band remains after step 3 then Adjust the ‘Step Adjust’ a little lower.

If increasing the platen heat does not remove the dark band then it may be that there is too much ink being

laid down so the RIP profile may need to be adjusted. Call your dealer for assistance with this RIP profile

possibility.

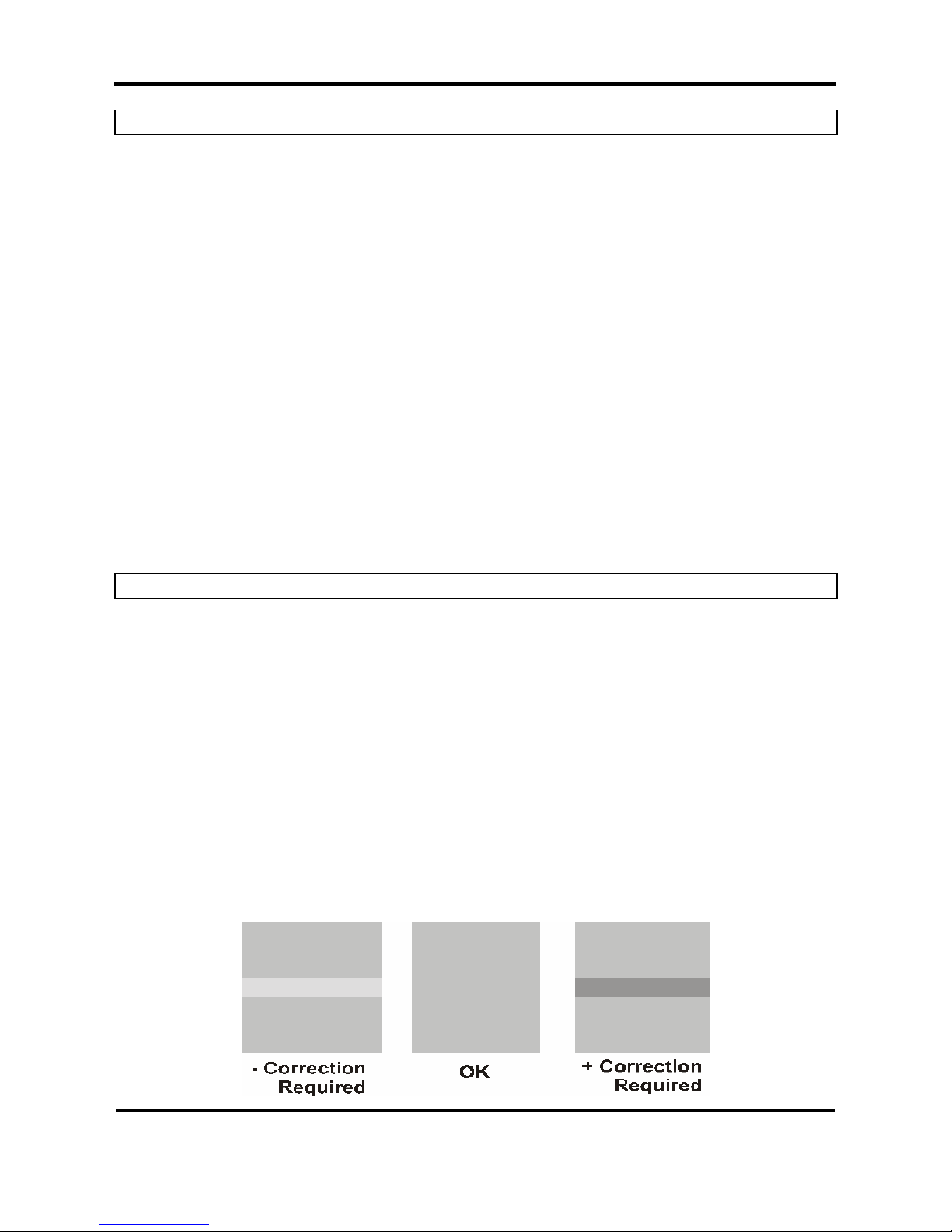

STEP ADJUSTMENT ‘MICRO-BANDING ELIMINATION ON FALCON OUTDOOR’

The nominal paper movement accuracy is ± 0.1 percent, or ±1 mm per meter of moving distance. Different

media types may show different behavior and when the paper movement error exceeds the target

specification, banding can occur. This banding can take the form of either thin dark or light horizontal bands.

If the above happens, these bands will occur in both bi-directional and unidirectional print modes. Thin da rk

bands indicate that the printer firmware is under-compensating and that print swaths are overlapping.

Alternatively, thin light lines indicate that the printer firmware is over-compensating, and that print swaths are

not far apart.

The media feed micro ‘step adjustment’ feature gives the user the ability to set the step compensation

algorithm. To eliminate micro-banding, you can enter a positive or negative percentage of compensation, (±

3.00 percent), in 0.01 percent increments.

A positive value will extend the step and compensate for overlapping print swaths; a negative value will

shorten the step and compensate for non-butting print swaths. Some trial and error testing is typically

required to find the optimum value for any given media type.

Page 12

Falcon Outdoor Jr. – Operation Instructions

Page 12

PN: MAI-75039

Rev. 1.A – 07/26/05

Plot OK

Step 1:

To enter the Menu system, press the [MENU] key.

* Menu * Command >

Step 2:

The key contents change to the yellow section on the outside of the

control panel. Bring up the “Function” menu by pressing the [Menu

up] key or [Menu Down] key.

* Menu * Function >

Step 3:

Press the [ENTER] key to enter the “Function” menu and shift to the

next level.

Step Adjustment : Change

Step 4:

Bring up the “Step Adjustment” item by pressing the [Menu up] key

or [Menu Down] key.

Step Adjustment : Clear

Step 5:

Press the [Value/+] or [Value/-] key to select “Change” or “Clear” and

press ENTER.

Step Adjustment : 0.00%

Step 6:

When pressing “Change”, enter the new value using the [VALUE/+] /

[VALUE/-] keys. Using the [MENU UP] / [MENU DOWN] keys,

you can select which digit you want to change. The value can be

changed in 0.01% increments.

Press [ENTER] to confirm the new value.

Step Adjustment : Change

Step 7:

If no other items are to be changed, press the [BACK] key.

* Menu * Function >

Step 8:

Do not press any other keys for 3 minutes or press [BACK] key

Plot OK

Step 9:

The permanent ONLINE-status display is restored.

Note:

To find the optimum correction value for a certain media, you will need to go through

a series of test cycles. Preferably send to the plotter a small test image such as a

neutral grey square (between 50% and 70% Grey) and check the micro-banding as

described above. Make a note of your correction value for a certain media type, as

the required value will always be the same for this media type.

Note:

Before using this function, always perform a nozzle-check to see if all nozzles are firing

correctly. Nozzles which are not firing or misfiring might mislead you when entering

correction values.

Page 13

Falcon Outdoor Jr. – Operation Instructions

Page 13

PN: MAI-75039

Rev. 1.A – 07/26/05

1. SAFETY INSTRUCTIONS

1.1. INTRODUCTION

This chapter explains the meaning of safety terms for personnel who operate this equipment, important

safety instructions and the positions of the warning labels.

Important :

Be sure to follow all instructions and warnings on this manual when using the

equipment.

1.2. WARNINGS, CAUTIONS AND NOTES

Safety terms in this manual and the contents of warning labels attached to the printer are categorized into

the following three types depending on the degree of risk (or the scale of accident).

Read the following explanations carefully and follow the instructions in this manual.

Safety terms Details

Important Must be followed carefully to avoid death or serious bodily injury

Caution Must be observed to avoid bodily injury (moderately or lightly) or damage to your

equipment

Notes Contains important information and useful tips on the operation of your printer

1.3. IMPORTANT SAFETY INSTRUCTIONS

General safety instructions that must be observed to use the equipment safely are explained below.

¾ Do not place the printer in the following areas. Doing so may result in the printer tipping or falling over

and causing injury.

o Unstable surfaces

o Angled place

o Areas subject to vibration by other equipment

¾ Do not stand on or place heavy objects on your printer. Doing so may result in the printer tipping or

falling over and causing injury.

¾ Do not cover the ventilation hole of your printer with cloth, such as a blanket or table cloth. Doing so

could obstruct ventilation and cause fire.

Page 14

Falcon Outdoor Jr. – Operation Instructions

Page 14

PN: MAI-75039

Rev. 1.A – 07/26/05

¾ Do not place the printer in humid and dusty areas. Doing so may result in electrical shock or fire.

¾ Do not use a damaged power cable. Doing so may result in electrical shock.

¾ Do not attempt to plug in electrical plugs with wet hands. Doing so may result in electrical shock.

¾ Do not connect earth cables in the following areas.

• Gas pipes → Doing so may cause fire or an explosion.

• Earth terminals for telephone line or lightening rod → Doing so may cause a large flow of voltage if

lightening occurs.

• Water pipes or faucets → If there is a plastic part in the pipe, the earth will not work properly.

¾ Do not insert or drop metal or inflammable objects into openings, such as ventilation outlets. Doing so

may result in electrical shock and fire.

¾ Stop using your printer if a liquid is spilled into it. This may cause electrical shock or fire. Turn the

printer off as soon as possible, unplug the power cord, contact your local MUTOH dealer.

¾ Be sure to use the attached cable. Otherwise, electrical shock or fire may occur.

¾ Be sure to use the specified voltage (AC 100 V to 120V, or AC 220V to 240V). Otherwise, electrical

shock or fire may occur.

¾ Use electricity directly from a power outlet (AC 100 V to 120V, or AC 220V to 240V). Do not put many

loads on one electrical output. Otherwise, heat may be generated and cause fire.

¾ Be sure to use an outlet with an earth terminal and use the terminal correctly. Otherwise, electrical

shock or fire may occur.

¾ Follow the instructions below when handling the power cable.

o Do not modify the cable.

o Do not put heavy objects on the cable.

o Do not bend, twist or pull the cable.

o Do not wire the cable near equipment that generates heat.

¾ Follow the instructions below when handling the power plug. Otherwise, fire may occur.

o Wipe away dust and any other residue before inserting the plug.

o Ensure that the plug is firmly inserted as far as it will go.

¾ When handling ink cassettes, be careful that ink does not get in your eyes or on your skin. However, if

this happens, flush immediately with water. Otherwise, your eyes may become congested or inflamed

slightly. If you feel discomfort, consult a doctor immediately.

¾ Do not disassemble ink cassettes. Otherwise, ink may get in your eyes or on your skin.

¾ Be careful not to pinch your fingers when opening and closing the front cover.

¾ Follow the instructions below when connecting the network interface cable. Otherwise, electrical shock

or fire may occur.

o Do not touch the connector.

o Do not connect the network cable connector that is not the same specification to the interface board.

¾ When cutting the roll media, be careful of the following. Incorrect handling can result in injury to the

hands and fingers from the razor blade.

o When holding the media, do not place fingers over the media cut groove.

o Move the razor blade slowly along the media cutting groove.

¾ Do not use thinner, benzene, alcohol or other active agents. Doing so may result in damage or paint

peeling from the casing.

¾ Be careful not to spill water inside the printer. Doing so may result in a short circuit.

¾ Be careful not to touch the heaters during or after operation. Doing so may result in burns.

Page 15

Falcon Outdoor Jr. – Operation Instructions

Page 15

PN: MAI-75039

Rev. 1.A – 07/26/05

¾ Only use Eco-Solvent Plus ink and appropriate Eco-Solvent Plus cleaning liquid. Using other ink (e.g.

dye or pigment) will cause permanent damage to the printer.

¾ Never open the covers fixed with screws. Doing so may result in electrical shock or a malfunctioning in

the printer.

¾ Do not touch the cutter blade. Doing so may result in bodily injury.

¾ Do not cut hard objects or drop the cutter. Doing so may damage or chip the cutter blade.

¾ Do not bend or pull the waste fluid tube. Doing so may cause that the waste fluid will leak out and

malfunction in the product.

¾ Do not touch the cleaning wiper or the head cap unit while cleaning the cleaning wiper. Doing so may

result in poor head cleaning because of oil on your hands.

¾ Do not tilt the printer, stand it against a wall or turn it upside down. Doing so may cause ink to leak

inside the printer. Movement after transport is also not covered by the warranty.

¾ When installing options, do not touch the elements on the circuit board. The elements on the boards

can be very hot and can cause burns.

¾ Have two or more people unpack and assemble the printer.

¾ When lifting the printer out of the packing box, be sure to remove the vinyl cover first, then grab the

holding grips on the sides of the printer. Lifting the printer with the vinyl cover on may cause your

hands to slip and drop or damage the printer.

¾ Have two or more people transport the printer.

¾ Ensure that the plug has been disconnected from the power socket when it is not to be used for a long

time.

¾ Earth wires must be connected to wires or terminals that fulfil the conditions below.

o Earth terminals of power sockets

o Earth wires with copper morsel that is at least 650 mm under the ground

¾ Earth wires must be connected to wires or terminals that fulfil the conditions below.

¾ When setting roll media, place it on top of a desk or other flat surface. Setting roll media with the

scroller standing up may damage them.

¾ Keep the printer horizontal during transportation.

¾ Be sure to do the following before attaching options.

o Turn the printer off.

o Unplug the power cord from the socket.

o Unplug cables connected to the printer. Otherwise, damage to the printer or your computer may

occur.

o Remove electrostatic charge from your clothes and body by touching the metal parts of the printer.

o Electronic components such as the memory may malfunction if exposed to an electrostatic charge.

Page 16

Falcon Outdoor Jr. – Operation Instructions

Page 16

PN: MAI-75039

Rev. 1.A – 07/26/05

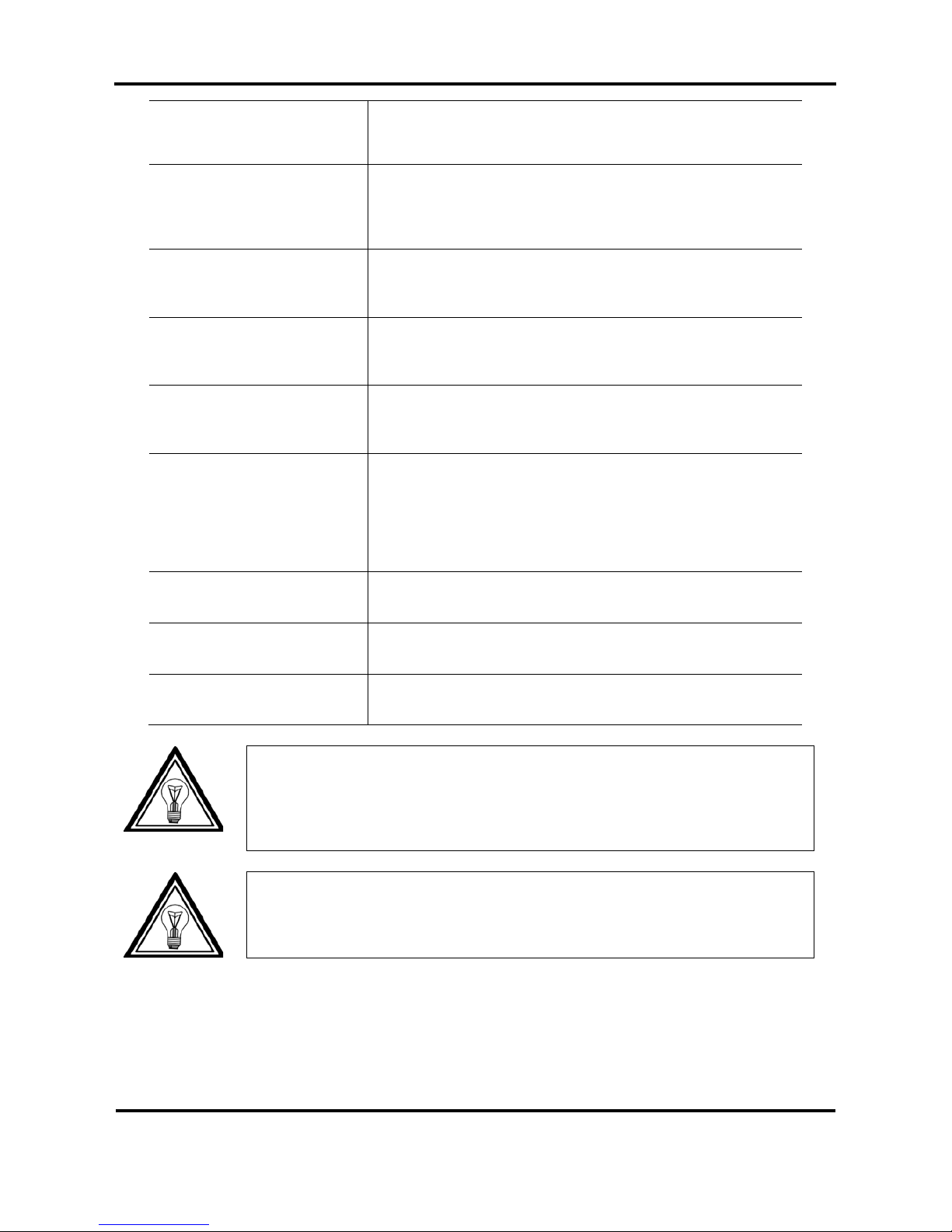

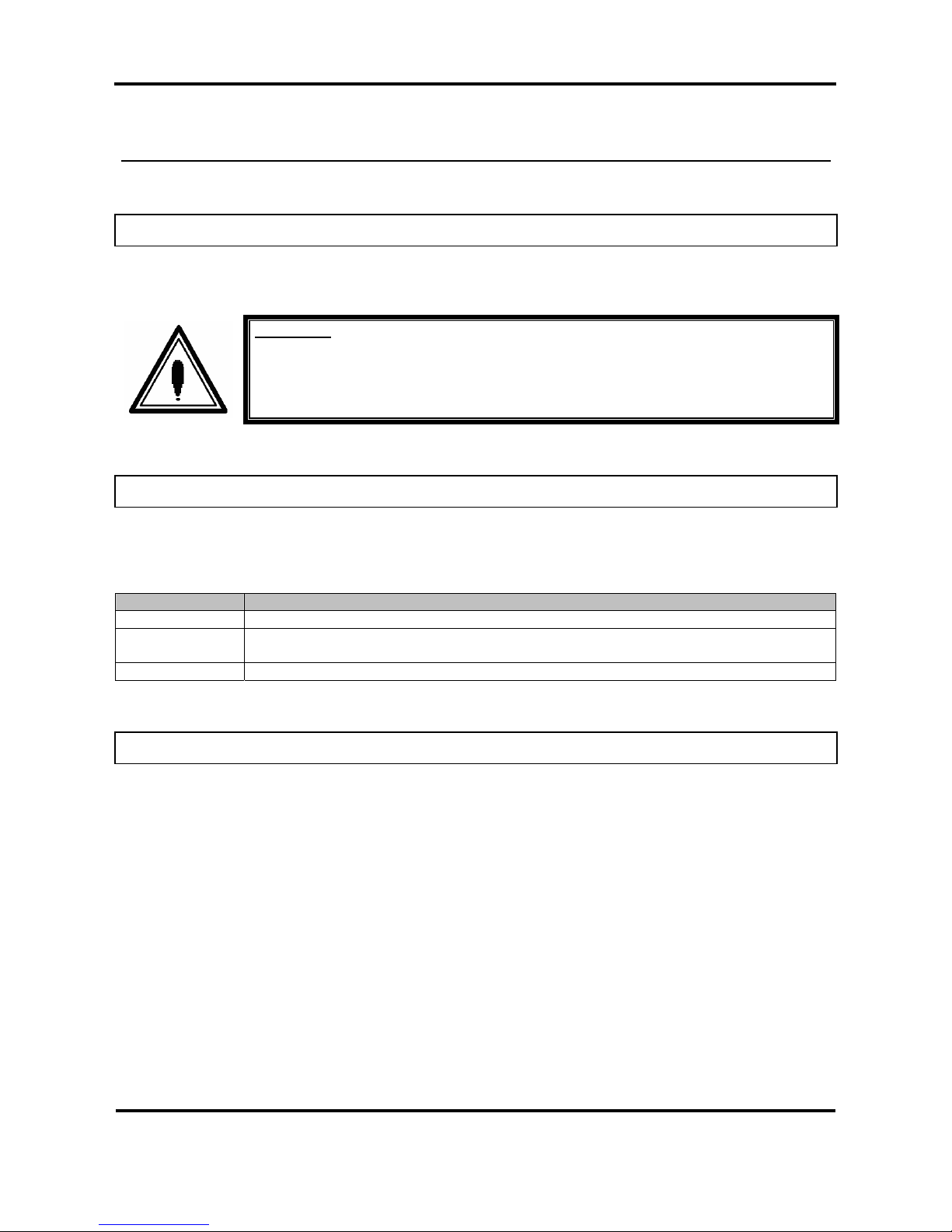

1.4. WARNING LABELS

Be sure to note the following when handling the labels.

Notes :

Make sure that all labels can be recognized. If text or illustrations cannot be seen

clearly, either clean or replace the label.

When cleaning labels, use a cloth with water or neutral detergent. Do not use a solvent

or gasoline.

If a warning label is damaged, lost or cannot be recognized, replace the label. When

replacing warning labels, contact your local MUTOH dealer.

Safety Labels are attached to the internal and external area of the printer to alert you to potentially

hazardous situations or conditions. The following safety labels are used in and on the printer:

Page 17

Falcon Outdoor Jr. – Operation Instructions

Page 17

PN: MAI-75039

Rev. 1.A – 07/26/05

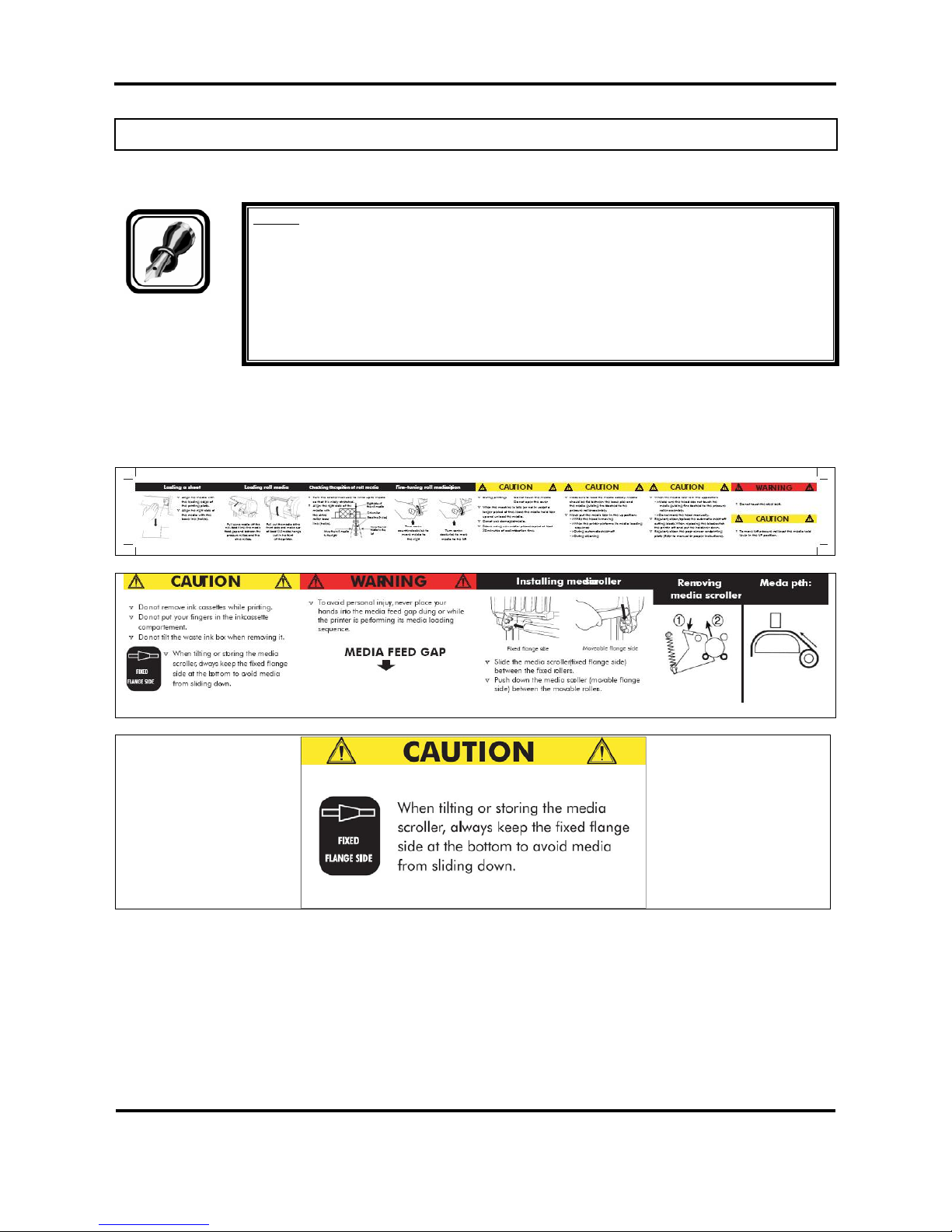

2. PRODUCT OVERVIEW

2.1. GETTING TO KNOW THE PRINTER PARTS AND

COMPONENTS

Page 18

Falcon Outdoor Jr. – Operation Instructions

Page 18

PN: MAI-75039

Rev. 1.A – 07/26/05

N° Part Description

1 Cover

The protective cover protects the action environment. Opening the

cover immediately pauses printing which resumes when the cover is

closed.

2 Operation Panel

Positive touch keyboard with integrated LCD-Display.

3 Media Hold Lever

Lowers / releases pressure rolls to load / unload media.

4 Power switch

ON / OFF Power Switch.

Full shut down takes about 5 seconds.

5 Paper Basket

Media collecting basket prevents finished prints to fall on the floor

when they are sheet-off.

6 Print Plate

The print plate is a firm, flat base which supports the media during

printing.

7 Waste bottle

Collects Eco-Solvent Plus ink flow resulting from: purging, cleaning.

8

9

Paper Guide

The Paper Guide supports the media and incorporates the fixer (8;

heater element below printhead) and dryer (9; heater element)

10 Slip Ring

Prevent that Scroller to slip.

11 Eco-Solvent Plus ink

cassette slots

Hold / detect the Eco-Solvent Plus ink cassettes which are in use.

12 Scroller

Feeds through the roll media core to hold the media.

13 Scroller receiver

Set of 4 wheels which keeps the scroller into place.

Caution:

Do not put anything on the cover.

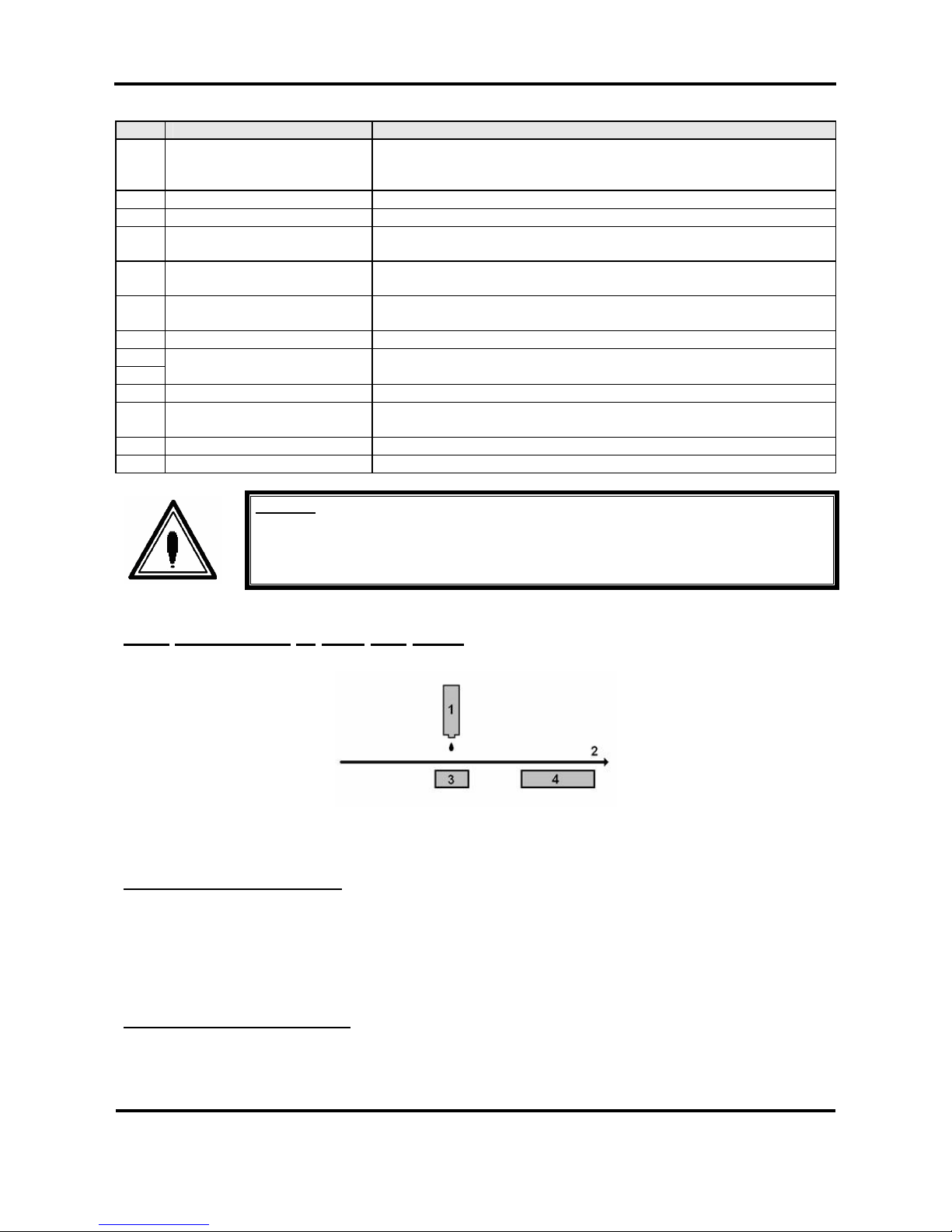

2.1.1

Explanation of fixer and dryer

Print Head

Media Direction

Fixer (Direct Heater)

Post Heater (dryer)

The FIXER will make it possible :

• To overcome the temperature gap between the room and the target printing temperature.

• To establish fast and immediate anchorage of the Eco-Solvent Plus inks onto/into the uncoated

substrate

• To optimize dot gain control on a wide media range

• To limit ink coalescence effect

The DRYER will make it possible

:

• To finalize the fixation process.

• Helps to make the prints touch-dry.

Page 19

Falcon Outdoor Jr. – Operation Instructions

Page 19

PN: MAI-75039

Rev. 1.A – 07/26/05

Page 20

Falcon Outdoor Jr. – Operation Instructions

Page 20

PN: MAI-75039

Rev. 1.A – 07/26/05

3. SETTING UP THE UNIT

3.1. INSTALLATION REQUIREMENTS: SELECTING AN

ADEQUATE PLACE FOR SETTING UP YOUR EQUIPMENT

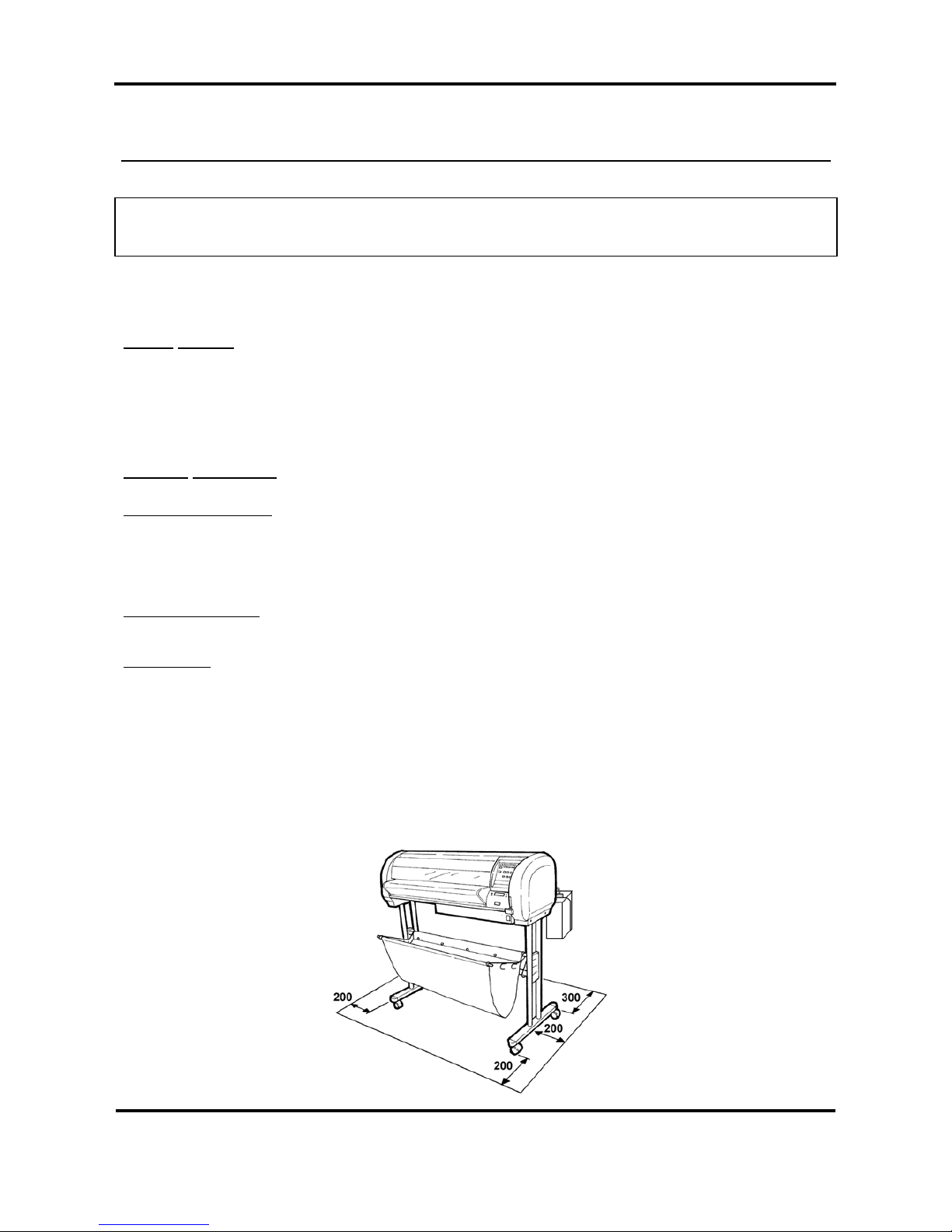

The location where you set up your equipment is very important. Please see to it that it meets following

conditions:

Power supply:

- Voltage: 200 to 240 VAC or 100 to 120 VAC

- Frequency: 50/60 Hz ± 1 Hz

- Current: < 10 A (110 V)

< 5 A (220 V)

Ambient conditions:

Operating environment

- Temperature: 18°C to 35°C

- Humidity: 20% - 60% non-condensing

- Recommended working environment

Temperature: 22-30°C

Humidity: 40-60%

Storage environment

- Temperature: -10°C to 60°C

- Humidity: 20% - 85% non-condensing

Variation rate

- Temperature: 2°C per hour

- Humidity: 5% per hour

¾ Avoid using your Falcon Outdoor Jr. printer near heating system s, such as stoves or heaters.

¾ Avoid using your printer under strong lighting, such as halogen lamps, light bulbs or direct sun light.

When selecting a place for your printer, leave at least 200 mm in front and at the sides, and 300 mm at the

rear, as shown in the illustration below.

Page 21

Falcon Outdoor Jr. – Operation Instructions

Page 21

PN: MAI-75039

Rev. 1.A – 07/26/05

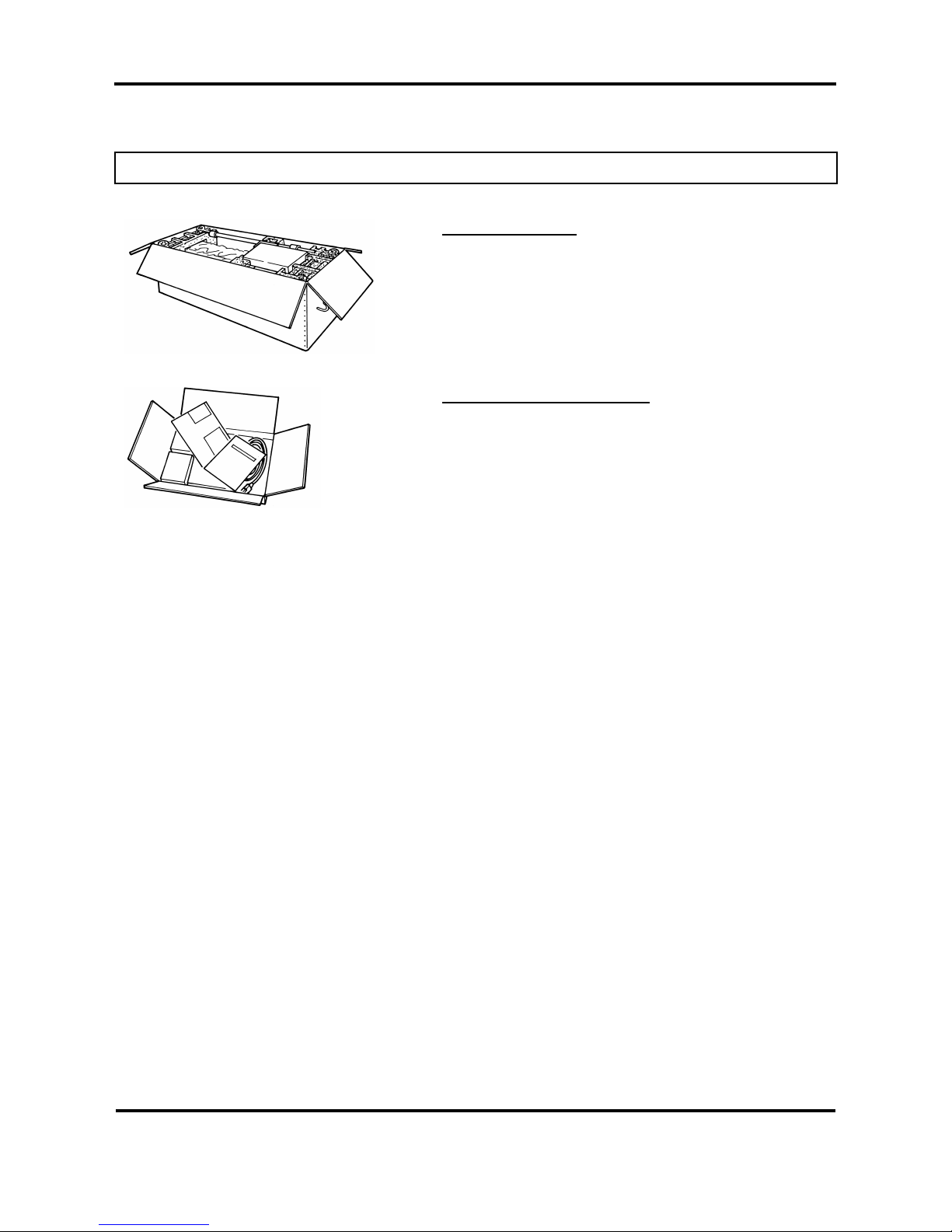

3.2. WHAT’S IN THE BOX?

What’s in the box ?

¾ Falcon Outdoor Jr. printer unit

¾ Printer stand (packed separately)

¾ 1 Paper scroller (3”) including plastic flanges

¾ 1 Sheet-off knife, pre-installed in head

¾ Media Collection Basket

¾ Starter Software Kit

¾ Scroller Slip Ring

Accessories kit consisting of:

¾ Power cable

¾ Set of Eco-Solvent Plus ink cassettes (CMYK)

¾ User’s guide

¾ Waste bottle

¾ Extra Box with Roll Take-Up System (optional)

¾ Cleaning cartridges

Page 22

Falcon Outdoor Jr. – Operation Instructions

Page 22

PN: MAI-75039

Rev. 1.A – 07/26/05

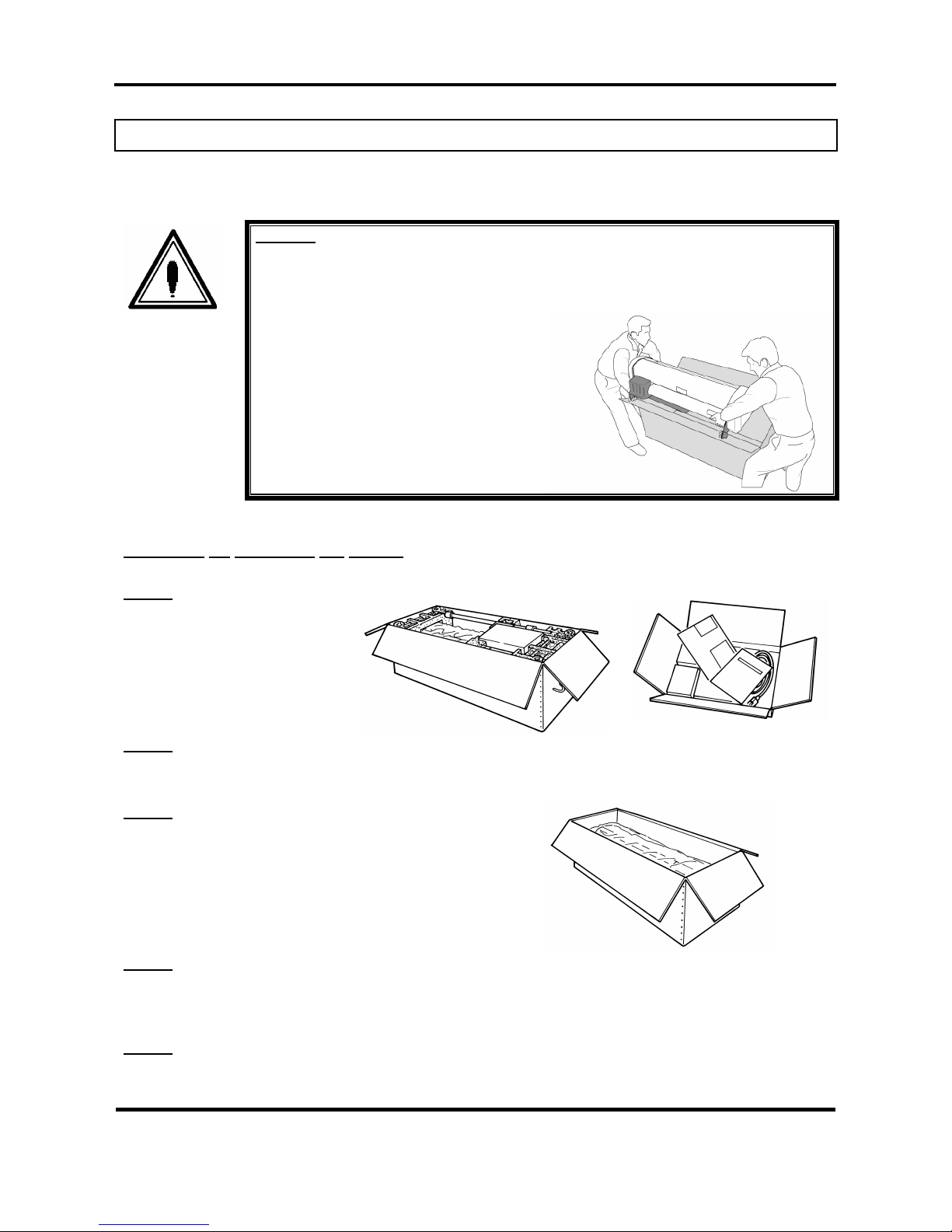

3.3. UNPACKING YOUR FALCON OUTDOOR JR. PRINTER

The printer body and printer stand are packed in two separate boxes. Unpack the printer body first.

Caution:

When unpacking the printer, check whether all parts described in the parts list are

included in the box. Consult your dealer if anything seems to be missing.

Lifting the machine out of the box should

be done by two people.

Protect the printer from shocks.

Do not dismantle the unit.

Procedure for unpacking the printer:

Step 1:

Open the printer body box.

Take out the accessories box and

scroller.

Step 2:

Open the accessories box and take out the User’s guide.

Step 3:

Remove the pieces of foam protecting the printer body during

transportation.

Step 4:

Remove all plastic materials wrapped around the printer.

Step 5:

Open the printer stand box. Check whether all parts described in the parts list are included in the box.

Consult your dealer if anything seems to be missing.

Page 23

Falcon Outdoor Jr. – Operation Instructions

Page 23

PN: MAI-75039

Rev. 1.A – 07/26/05

Page 24

Falcon Outdoor Jr. – Operation Instructions

Page 24

PN: MAI-75039

Rev. 1.A – 07/26/05

3.4. PARTS LIST

3.4.1. Contents of the stand box:

Stand leg (left)

(1 pc)

Stand leg (right)

(1 pc)

Cross bar (2 pcs)

Plastic cover

(2 pcs)

Hexagon wrench

(1 large & 1 small)

Hexagon bolt (long) (4

pcs)

Hexagon bolt (short) (2

pcs)

+ premounted washers

Paper basket

assembly

(1 set)

3.4.2. Contents of the printer box:

Printer unit (1 pc)

3” Scroller (flange on

both sides) (1 set)

Accessories box

Slipring (1 pc)

Page 25

Falcon Outdoor Jr. – Operation Instructions

Page 25

PN: MAI-75039

Rev. 1.A – 07/26/05

3.4.3. Contents of the accessories box:

Cleaning cartridges (4

pc)

Eco-Solvent Plus ink

Cassettes

(C,M,Y,K)

(1 each colour)

Power cable (1 pc)

User’s Guide

Waste bottle + waste

bottle bracket

Page 26

Falcon Outdoor Jr. – Operation Instructions

Page 26

PN: MAI-75039

Rev. 1.A – 07/26/05

3.5. ASSEMBLING THE PRINTER

Caution:

Before lifting the printer body out of the box, make sure to remove all plastic wrapping

materials first, in order to avoid that the machine slips from your hands.

Step 1:

Unpack the stand and assemble it by screwing the left and right stand legs to the cross bars. To do this, use

the 4 long hexagon bolts and the large hex wrench provided. Make sure the leg welding points outwards and

the caster wheels are on the front. After securing the bolts permanently, put on the two plastic side covers.

(See 1 on figure below).

Step 2:

Place the printer onto the stand. The bottom part of the printer body has 4 spherical knobs that exactly fit

into the stand holes. Note that the front side of the stand is the side where the lockable caster wheels are

located. (See 2 on figure below).

Step 3:

Secure the printer body onto the printer stand using the 2 short bolts and the small hexagon wrench

provided. (See 3 on figure below).

Page 27

Falcon Outdoor Jr. – Operation Instructions

Page 27

PN: MAI-75039

Rev. 1.A – 07/26/05

Step 4:

Loosen the wing screw which is fixed to the printing table (4) and remove the metal fixing plate (5) protecting

the printer head during transportation. (See 4 & 5 on figure below). Keep the metal fixing plate and wing

screw, since the printing head needs to be blocked during any transportation of your printer.

Caution:

Take care not to drop the wing screw inside the printer body. Should it fall in, do not

boot up your printer until the wing screw has been safely removed.

Remove the white tape that locks the sheet-off mechanism during transportation

(See 6 on figure below).

Step 5:

Remove the cable block between rail and cover (7).

Remove the lever block (8).

Page 28

Falcon Outdoor Jr. – Operation Instructions

Page 28

PN: MAI-75039

Rev. 1.A – 07/26/05

Step 6:

Assemble the paper basket as follows :

Insert the metal bar into the small sleeve of the cloth basket. Then put on the two metal basket supports to

the left and the right side. Next insert the end caps onto the metal bar. (See 9 on the figure below).

Attach the cloth basket around the lower cross bar of the stand by way of the push buttons. (See 10 on the

figure below).

Secure the paper basket to the printer stand. Fix the front hook of the metal basket supports over the upper

cross bar of the stand, then in-between the two cross bars and finally under the lower cross bar. (See 1 1 on

the figure below).

The extra hooks provided on the metal basket supports are meant to stack your paper basket vertically along

the legs of the printer.

Step 7:

After setting up the printer, wheel it to the desired location and lock the caster wheels.

Page 29

Falcon Outdoor Jr. – Operation Instructions

Page 29

PN: MAI-75039

Rev. 1.A – 07/26/05

3.6. INSTALLATION OF THE WASTE BOTTLE

In the accessories box, you will find the Waste Bottle Bracket together with the Waste Bottle.

After unpacking and assembling the Falcon Outdoor Jr. printer, you must install the Waste Bottle Bracket

with the Waste Bottle.

Important :

Do NOT power on the unit before installation of the Waste Bottle.

Please follow the instructions below to install the Waste Bottle.

Step 1 : Screw the Waste Bottle Bracket onto the Scroller System on the left side standing at the rear of

the unit. (2 screws) (Please refer to picture A on the following page.)

Step 2 : Remove the adhesive tape holding the Waste Tubes to the unit.

Step 3 : Push the big Waste Tube in the hole in the middle of the top of the bracket. Check if the tube is

fixed securely. (Please refer to picture A on the following page.)

Step 4 : For the 2 smaller tubes, do as follows :

¾ Slide the upper plastic ring upwards.

¾ Loosen the lowest plastic ring.

¾ Insert the waste tube in one of the two remaining holes.

¾ Fix the tube by sliding the plastic ring back to the tube.

¾ If necessary lower the upper plastic ring.

¾ Check if the tube is locked securely.

¾ Repeat point 1 to 7 for the other small tube.

1 : plastic rings on small tube 3 : Top Waste Bottle Bracket

2 : big waste tube 4 : Top Waste Bottle

(Please refer to picture A mentioned below.)

Step 5 : Connect the connector of the Waste Bottle Sensor. (Please refer to picture A mentioned below.)

Page 30

Falcon Outdoor Jr. – Operation Instructions

Page 30

PN: MAI-75039

Rev. 1.A – 07/26/05

Picture A :

1. Big waste tube

2. 2 thin waste tubes

3. Screws to mount Waste Bottle Bracket

4. Top Waste Bottle Bracket

1 2 3 4

Page 31

Falcon Outdoor Jr. – Operation Instructions

Page 31

PN: MAI-75039

Rev. 1.A – 07/26/05

4. PREPARING FOR A JOB

4.1. CONNECTING THE POWER CABLE

Step 1 : Make sure the printer’s power switch is turned OFF.

Step 2 : Plug the printer-end of the power cable into the connector at the back of the printer.

Step 3 : Plug the other end of the power cable into an electrical outlet of the correct voltage and with a

proper grounding.

Power supply:

• Voltage:

100-120V 200-240V

• Frequency:

50/60 Hz 50/60 Hz

• Current:

6.8A 3.4A

Note:

When you turn off the power, please note that your printer needs about five seconds to

perform its shut down sequence.

To this end, wait for at least five seconds to switch the printer on again.

The disconnect device is the plug on the power supply.

Page 32

Falcon Outdoor Jr. – Operation Instructions

Page 32

PN: MAI-75039

Rev. 1.A – 07/26/05

4.2. CONNECTING THE INTERFACE CABLE

Caution:

When connecting the printer to your computer, make sure that both your printer and

your computer are switched OFF.

Note:

For optimum output, please use a cable recommended by Mutoh.

The printer can use the Centronics interface (IEEE1284 compatible, Nibble, ECP). Connect to the printer as

shown in the following diagram with an interface cable (option) for the connection system you will use.

Connect to the host computer with another interface cable.

Note:

The use of an unnecessary long cable may influence your data transmission. Therefore,

keep your interface cable as short as possible.

An Ethernet board RJ-ETH14TX (for networking) is available as an optional extra.

4.2.1. Tips to use high-speed ECP parallel communication

¾ If the parallel port setting on the printer is set to BI CENTRO (See Menu Mode Operation – Menu

Structure Overview) your printer is ready for high-speed bi-directional communication.

¾ In order to be able to use this high-speed mode without problems please note:

Computer Bios for parallel port should be set to ECP

Only use a shielded and balanced parallel cable, which is IEEE 1284 compliant.

If your RIP software is protected with a hardware lock (dongle), which needs to be placed on the

parallel port, it is best to have available 2 parallel ports.

• One port to connect: hardware lock, scanner, external drive or CD-ROM,…

• One port (ECP) directly connected to the printer.

In case either of the above mentioned topics is not respected you may encounter all kinds of printer artefacts

such as: unexplainable error messages, sheet-off during printing, unexpected media feed during printing,

etc…

If this occurs, switch your system to unidirectional parallel communication.

Set print parallel port to Mode > CENTRO

Set computer parallel port Bios to SPP or EPP

The data transfer will then slow down and the artefacts will disappear. Before switching back to the highspeed bi-directional parallel mode, have your computer system examined closely by a trained computer

technician.

Page 33

Falcon Outdoor Jr. – Operation Instructions

Page 33

PN: MAI-75039

Rev. 1.A – 07/26/05

QUICK START FOR SEH AND FALCON OUTDOOR PRINTERS

SEH PRINTSERVER AND INTERCON NETTOOLS SETUP AND DIAGNOSTIC

FEATURE (FILE DOWNLOAD)

TO INSTALL AN SEH BOX FOR ANY OF THE FALCON OUTDOOR SERIES

PRINTERS FOLLOW THESE STEPS.

10. DO NOT connect the SEH box to the printer at this time.

11. Put the CD in the computer, if ‘autorun’ starts then follow the info to install “English” and choose ‘Intercon

NetTools’ then Go to 9. If ‘autorun’ does not start then proceed.

12. Click – My Computer

13. Right click on the CD icon

14. Select “Explore” from menu

15. Double click on the “NetTool” folder

16. Double click on “Windows” folder

17. Double click “NetTool” Setup

18. Follow prompts to complete installation

• Connect the SEH box ONLY to the network cable, DO NOT attach to the printer at this time. Use a

crossover cable if you are connecting directly to a computer. Use a standard cable if you are connecting

using a ‘switch’, ‘router’ or ‘hub’. Crossover direct connection should not be used for production work.

• After completing 1 – 9 above, launch “InterCon – NetTools” from the desktop icon or find InterConTools

in your Programs folder.

• Double click on the IP address (most likely all zeros). (Loading properties menu should open).

• Select TCP/IP tab on the left.

• Remove the ‘checks’ in the boxes from all items except ARP/Ping. Specifically DHCP.

• ‘Check’ the TCP/IP box and Enter your IP address and submask then click OK. A Gateway is not

required.

CAUTION: The IP address must match all three of the first 3 triads (sets of three numbers) and the only

difference is the last ‘triad’ where the printer is usually ‘1’ number different from the computer. All four triads

of the SUB NET mask must match exactly as well.

• Select ‘rebuild’ on the Intercon NetTools menu. Verify the IP address line changes to your entered

address. The printer icon should show a red X through it.

• Connect the SEH box to the printer LPT port. The red X should come off when the printer is powered

ON. Click the Refresh or Rebuild buttons to make it change if it doesn’t automatically refresh itself.

Notice that the SEH utility now shows the name of the printer.

Print server is now configured for your network and IP address.

• Setup up your RIP software for the IP address of the SEH box.

Page 34

Falcon Outdoor Jr. – Operation Instructions

Page 34

PN: MAI-75039

Rev. 1.A – 07/26/05

DIAGNOSTIC ASSISTANCE USING ‘FILE DOWNLOAD’ FEATURE OF THE SEH BOX.

Both the WEB interface (IP address in browser) or Intercon Nettools have the ability to transfer a file directly

to the IP address. This is important as sometimes the problem in the print is RIP related and if the RIP is

used to create a ‘test’ file then it could have the problem in it.

Mutoh provides a ‘test print’ file for each model of printer. For the Falcon Outdoor or Falcon Outdoor Junior

these files are a low ink density Diagonal nozzle check pattern designed to show whether ‘Step Adjustment’

is correct or not. (ignore the Distance Adjustment feature on the FO series). Once the ‘Step Adjust’ is dialed

in then images printed with the correct profile should be able to be printed.

Each of the SEH options have a ‘Download / file’ section where you will be prompted for a file. Locate the

‘testprint’ file that is appropriate

Please realize that a ‘light band’ can be either missing / misdirected nozzles or that Step Adjust is too high.

Confirm that nozzles are firing and then start this procedure for Micro Banding.

A ‘dark band’ can be from either Step Adjust being too low or it can be from the platen heater not being hot

enough. For this reason it is suggested that if no light band is showing then change the Step adjust higher to

create a light band. Then reduce the number in small steps until either you have no band or a slight dark

band remains. Once you reach this point adding ‘heat’ to the platen should then minimize the banding to an

acceptable amount for solvent printing.

Remember

5. Check nozzles first. Clean as required.

6. Dial out the light and first. Create a light band if necessary.

7. For the bark band that remains after dialing out the light band, start by increasing the platen heat in

small steps.

8. If a small dark band remains after step 3 then Adjust the ‘Step Adjust’ a little lower.

If increasing the platen heat does not remove the dark band then it may be that there is too much ink being

laid down so the RIP profile may need to be adjusted. Call your dealer for assistance with this RIP profile

possibility.

STEP ADJUSTMENT ‘MICRO-BANDING ELIMINATION ON FALCON OUTDOOR’

The nominal paper movement accuracy is ± 0.1 percent, or ±1 mm per meter of moving distance. Different

media types may show different behavior and when the paper movement error exceeds the target

specification, banding can occur. This banding can take the form of either thin dark or light horizontal bands.

If the above happens, these bands will occur in both bi-directional and unidirectional print modes. Thin da rk

bands indicate that the printer firmware is under-compensating and that print swaths are overlapping.

Alternatively, thin light lines indicate that the printer firmware is over-compensating, and that print swaths are

not far apart.

The media feed micro ‘step adjustment’ feature gives the user the ability to set the step compensation

algorithm. To eliminate micro-banding, you can enter a positive or negative percentage of compensation, (±

3.00 percent), in 0.01 percent increments.

A positive value will extend the step and compensate for overlapping print swaths; a negative value will

shorten the step and compensate for non-butting print swaths. Some trial and error testing is typically

required to find the optimum value for any given media type.

Page 35

Falcon Outdoor Jr. – Operation Instructions

Page 35

PN: MAI-75039

Rev. 1.A – 07/26/05

Plot OK

Step 1:

To enter the Menu system, press the [MENU] key.

* Menu * Command >

Step 2:

The key contents change to the yellow section on the outside of the

control panel. Bring up the “Function” menu by pressing the [Menu

up] key or [Menu Down] key.

* Menu * Function >

Step 3:

Press the [ENTER] key to enter the “Function” menu and shift to the

next level.

Step Adjustment : Change

Step 4:

Bring up the “Step Adjustment” item by pressing the [Menu up] key

or [Menu Down] key.

Step Adjustment : Clear

Step 5:

Press the [Value/+] or [Value/-] key to select “Change” or “Clear” and

press ENTER.

Step Adjustment : 0.00%

Step 6:

When pressing “Change”, enter the new value using the [VALUE/+] /

[VALUE/-] keys. Using the [MENU UP] / [MENU DOWN] keys,

you can select which digit you want to change. The value can be

changed in 0.01% increments.

Press [ENTER] to confirm the new value.

Step Adjustment : Change

Step 7:

If no other items are to be changed, press the [BACK] key.

* Menu * Function >

Step 8:

Do not press any other keys for 3 minutes or press [BACK] key

Plot OK

Step 9:

The permanent ONLINE-status display is restored.

Note:

To find the optimum correction value for a certain media, you will need to go through

a series of test cycles. Preferably send to the plotter a small test image such as a

neutral grey square (between 50% and 70% Grey) and check the micro-banding as

described above. Make a note of your correction value for a certain media type, as

the required value will always be the same for this media type.

Note:

Before using this function, always perform a nozzle-check to see if all nozzles are firing

correctly. Nozzles which are not firing or misfiring might mislead you when entering

correction values.

Page 36

Falcon Outdoor Jr. – Operation Instructions

Page 36

PN: MAI-75039

Rev. 1.A – 07/26/05

4.3. LOADING ECO-SOLVENT PLUS INK CASSETTES (FIRST

TIME)

Important :

Before installing Eco-Solvent Plus ink cassettes in your new Falcon Outdoor Jr.

printer, it is necessary to clean the Falcon Outdoor Jr. with special Eco-Solvent

Plus Cleaning Liquid.

Before transportation (e.g. service) it is necessary to clean the Falcon Outdoor

Jr. (which used Eco-Solvent Plus ink) with special Eco-Solvent Plus Cleaning

Liquid.

When the machine returns or is installed at another place, perform again a

cleaning with the special Eco-Solvent Plus Cleaning Liquid.

Please only use the Eco-Solvent Plus Cleaning liquid. Using other cleaning

cassettes will result in clogging of ink in the machine. As a result all internal

ink-passages must be replaced.

Note :

When loading Eco-Solvent Plus ink for the first time, please make sure to have four

Eco-Solvent Plus Cleaning liquid cassettes.

Before installing Eco-Solvent Plus ink cassettes in your new Falcon Outdoor Jr. printer, it is necessary to

clean the Falcon Outdoor Jr. with special Eco-Solvent Plus Clean ing Liquid.

To do so, please follow the instructions mentioned below.

Step 1:

Power ON the unit.

Step 2:

Slide the four Eco-Solvent Plus Cleaning liquid cassettes into their cassette

position. Automatic detection of cleaning cassettes occurs due to label

recognition.

Step 3:

Press the [VALUE +] key or [VALUE -] key to select “Yes” and pre ss

ENTER.

Note :

Please note that the Falcon Outdoor Jr. printer has two print heads (K, CMY). A head

wash cycle is done per print head. This means that the first head wash cycle is

performed for the K print head only, and then a head wash cycle is performed for the

CMY print head.

[YMCK] discharge

Wash: Black&Colour

Page 37

Falcon Outdoor Jr. – Operation Instructions

Page 37

PN: MAI-75039

Rev. 1.A – 07/26/05

Step 4:

The unit is cleaning the K print head.

.

Step 5:

Remove the Black (K) Eco-Solvent Plus Cleaning Liquid cassette.

Note :

Only remove the Black (K) Eco-Solvent Plus cleaning liquid cassette (Not all four Eco-

Solvent Plus cleaning liquid cassettes). Removing all Eco-Solvent Plus cleaning liquid

cassettes could cause the printer to lock-up. If this is the case, please re-insert the

Eco-Solvent Plus cleaning liquid cassettes into the CMY cassette slots to recover the

ink load procedure.

Step 6:

The unit is cleaning the CMY print heads.

Step 7:

Remove the Eco-Solvent Plus Cleaning Liquid cassette from the CMY

slots.

Step 8:

The rest of the cleaning fluid in the printer unit is discharged when cleaning

cassette is removed.

Step 9:

Empty the waste ink box from the printer.

Step 10:

Insert the four Eco-Solvent Plus ink cassettes one by one in the correct

slot.

Step 11:

Eco-Solvent Plus ink is being loaded into the ink supply system (tubing +

heads).

Note :

Please wait after loading Eco-Solvent Plus Ink for about 1 hour before start printing.

The printer is now ready to print.

Head Wash

Remove Bk Wash Cart

Head Wash

Remove Co Wash Cart

Head Wash

Change Waste ink

[CMYK] discharge

Ink refill 4M

Page 38

Falcon Outdoor Jr. – Operation Instructions

Page 38

PN: MAI-75039

Rev. 1.A – 07/26/05

4.4. LOADING MEDIA

4.4.1. General recommendations with regard to printer media

¾ For best quality output and printing results on your Mutoh Falcon Outdoor Jr. Eco-Solvent Plus printer, it

is recommended to use MUTOH media.

¾ For printing onto uncoated media, the temperature that can be reached on top of the media is important

to obtain the right output quality and ink fixation. Note that the temperature reached on top of the media

depends on the heater settings, the heat capacity of the media which is used and the exposure time (=

time the media is exposed to heat), which is influenced by the output mode, printing width and ink setup.

¾ Lower cost self-adhesive PVC media are produced with a normal clay coated paper backing. This

backing paper tends to dry out because of the heating and may start to cockle. This phenomenon can

be overcome by reducing the heating temperature or by selecting a media with a PE-coated backing

paper.

¾ It is strongly recommended to acclimatize your media before printing on it. Ideally, bring the media rolls

in the neighbourhood of the printer 24 hours on beforehand. Bringing in cold media and printing on it

usually results in inferior output quality because of the big temperature gap that needs to be overcome.

We recommend a working environment with a temperature between 22° C and 30° C and a humidity

between 40% - 60% (without condensation).

¾ We recommend you to wear cotton gloves to avoid fingerprints on the media.

¾ Always make sure that you are printing on the correct side (printable side) of the media.

4.4.2. Loading cut sheet media

Step 1:

Open the cover and verify that the hold lever is in the UP position.

Step 2: Selecting the media

Press the Media-key to select media loading sequence with roll

take-up system (Both LEDs ON).

By pressing the key you will see the LEDs alternate between three

choices (sheet, roll and take-up). Now select roll take-up loadi ng

sequence (both LEDs ON).

Now select sheet

Note:

When making the wrong media selection choice by selecting roll when a cut-sheet is

being loaded, the printer will give the roll media end warning when the end of the cutsheet is reached, and printing will not be finished normally.

Step 3: Installing the media

Insert the media, which has already been acclimatized, between the pressure roller system and the drive

Page 39

Falcon Outdoor Jr. – Operation Instructions

Page 39

PN: MAI-75039

Rev. 1.A – 07/26/05

roller.

Step 4:

Align the right side of the media with the base line (holes), as shown in the figures.

Align the media with the leading edge of the printing plate.

Align the right side of the media with the baseline holes. You are

allowed about 5 mm of play to the right and left of the centre of

the base line holes.

Please examine the position of the left side of the media and compare it with the illustrations below.

There is not enough clearance between the media edge and the

pressure roll (less than 5 mm), which may cause a media jam or

damage if the media slightly shifts during printing.

Media is set correctly, it is held down completely by the pressure

roll. Even slight shifting will not cause media damage or a

media jam.

Media is set correctly. There is at least 5 mm clearance

between the pressure roller and the media edge.

Important:

The base line is just a guideline. You are allowed about 5 mm of play to the left

and right of the centre of the base line holes. This play allows you to correctly

load the media as described under step 4.

Page 40

Falcon Outdoor Jr. – Operation Instructions

Page 40

PN: MAI-75039

Rev. 1.A – 07/26/05

Step 5:

Lower the media hold lever by tilting it down(wards).

Notes:

Always remove the roll media and scroller from the scroller receiver before loading a cut

sheet.

Install your media straight. If you do not do this, the printer might misread the actual

media size, resulting in abnormal printing.

When the roll media indicator is ON while a cutsheet is loaded, this indicates a media

selection error

and printing will not be finished normally.

You can install a cut sheet both in the horizontal and in the vertical direction, except for

A0 size cut sheets. This size can only be installed in the vertical direction.

The media has a printing side and a non-printing side.

If you print on the non-printing side, this may influence the quality.

The printable side is normally whiter.

Step 6:

Close the cover. The head starts moving automatically to detect the media size.

Step 7:

When media is loaded correctly and the printer is ready to receive data, the display shows the message:

Step 8:

Removing the media

Open the cover, tilt the media hold lever UP, and remove the media.

Note:

During plotting, media detection, cutting and cleaning always keep the media hold lever

down.

If the print head is not situated at the maintenance position, the media hold lever cannot

be lifted UP.

Do not move the print head while the hold lever is UP.

Roll Media End

Media Initialization

Plot OK

Page 41

Falcon Outdoor Jr. – Operation Instructions

Page 41

PN: MAI-75039

Rev. 1.A – 07/26/05

4.4.3. Loading roll media

Step 1 : Open the cover, check that the head is in a position where it will not touch the media keeper

blade and put the hold lever up.

Step 2 : Selecting the media

Press the Media-key to select media loading sequence with roll

take-up system (Both LEDs ON).

By pressing the key you will see the LEDs alternate between three

choices (sheet, roll and take-up). Now select roll take-up loadi ng

sequence (both LEDs ON).

Now select roll

Note :

When making the wrong choice by selecting cut-sheet when a roll is loaded, the printer

will pull off the maximum cut-sheet length, searching the back edge. Finally the printer

will report a media search error.

Step 3 : Take your roll of media.

Step 4 : Remove the movable flange from the scroller by

pulling it off.

Step 5 : Load the media over the scroller

Turn the roll media as shown in the diagram and pass it over the scroller until the media tube fits

firmly over the fixed flange. Replace the movable flange on the scroller and fit it firmly into the

media tube.

Page 42

Falcon Outdoor Jr. – Operation Instructions

Page 42

PN: MAI-75039

Rev. 1.A – 07/26/05

Note:

Do not drop the media roll over the scroller as this might damage the scroller end caps.

All Mutoh recommended roll media are rolled up with the printable side facing the

outside, so that you can load the roll media easily.

When the cut sheet indicator light is ON when loading a roll, the printer will display a

media search error after feeding the media for about 3m.

Step 6 : Installing the scroller slip ring

Install the scroller slip ring onto the scroller. Slide the scroller slip ring on the left side of the

scroller (side with fixed flange).

Step 7 : Installing the scroller

Install the scroller as follows:

Stand at the back side of the printer, holding the scroller with the fixed flange side in your left

hand. Slide the scroller (left side) into the scroller receiver, as shown in the illustration. Push the

scroller (Right side - movable flange side) down into the right scroller receiver. You will noti ce it

dropping nicely into place.

Step 8 : Locking the scroller slip ring

Lock the scroller by sliding the scroller slip ring onto the scroller rollers. The scroller slip ring will

prevent unwinding of the roll media from the scroller when roll media is still not loaded in the

machine.

Page 43

Falcon Outdoor Jr. – Operation Instructions

Page 43

PN: MAI-75039

Rev. 1.A – 07/26/05

Step 9 : Loading roll media

Pull some media off the roll, feed it into the media feed gap and

between the pressure rollers and the drive roller.

Pull out the media at the front side and make sure at least 0.5

meters hangs out in front of the printer.

Caution:

When you load roll media from the back, be careful not to hurt yourself by touching the

pressure roll system.

Step 10 : Checking the position of roll media

Turn the scroller by hand and wind up several turns of roll media. As you wind up the media, check the

relative positions of the drive roller on the right and the right hand edge of the roll media. It is normal if with

the roll media pulled tight, the portion that is being wound and the portion that was unwound are straight and

the right hand side edge of the media is on the guide line. If this is not the case, adjust the position of the roll

media in accordance with step 9.

Guide line (holes) can be seen Guide line (holes) is hidden

Step 11 : Fine-tuning the roll media position

If the guide line (holes) can be seen, the roll media must be moved to the right.

If the guide line (holes) is hidden, the roll media must be moved to the left.

Turn the scroller receiver screw counter -clockwise to move

the roll media to the right (when standing in front of the

printer).

Page 44

Falcon Outdoor Jr. – Operation Instructions

Page 44

PN: MAI-75039

Rev. 1.A – 07/26/05

Turn the scroller receiver screw clockwise to move the roll

media to the left (when standing in front of the printer).

Important:

The guide line (holes) is a guide.

There is a possibility of a jam if the pressure roller is not holding the left edge of

the media and the pressure roller is near the right edge. Either hold the left edge

of the media completely with the pressure roller or slide it so that the pressure

roller is about 5 mm away from the right edge of the media and the right edge of

the media within 5 mm to the left or right of the guide line (holes).

Step 12 : Check if the roll media has been installed correctly.

Lower the media hold lever and close the cover.

The head moves automatically and detects the media size.

The display will show the following message during loading:

After performing its media loading sequence (± 30 seconds) the printer displays the following message:

Important:

If the roll media has not been fed straight or incorrectly, messages such as,

“media error” or “media jam error” are shown on the display. If this is the case,

reload the media following the instructions above.

ConfirmPaperKind

Plot OK

Page 45

Falcon Outdoor Jr. – Operation Instructions

Page 45

PN: MAI-75039

Rev. 1.A – 07/26/05

Step 13 : During the media detection sequence, check if the media runs straight. After media detection,

check the position of the right side of the roll media. If the position is almost on the same line as

it was before closing the cover, media loading was performed successfully. If after the media

detection sequence, the roll media position is not on the same position as it was before closin g

the cover, repeat the instructions from steps 8 and 9 for installing the media.

Note:

Removing roll media

Step 1:

After printing, open the cover, tilt the media hold lever UP and wind up the roll media.

Step 2:

Stand behind the printer. Unlock the scroller receiver

by pressing the lock lever down. You can now lift the

right side of the scroller and remove it from the printer.

Step 3:

Remove the roll media by gently pushing the roll media off the scroller via the moveable

flange side.

At no times drop the scroller end-caps on the floor as this might damage the scroller

end-caps and reduce media tracking or loading problems.

Important:

• Please make sure not to load media that is wider than 954 mm (37,55”).

The maximum width that you can load is indicated with a sticker on left

most side of the printing table.

• Loading wider media may cause the head carriage to bump against the left

end plate and cause an error. In this case you will need to power cycle the

printer before you can continue.

Page 46

Falcon Outdoor Jr. – Operation Instructions

Page 46

PN: MAI-75039

Rev. 1.A – 07/26/05

4.4.4 Loading media in combination with the Roll Take-Up System.

Step 1 : Open the cover and put the hold lever in the UP position by tilting it up(wards).

Step 2 : Selecting roll take-up system

Press the Media-key to select media loading sequence with roll

take-up system (Both LEDs ON).

By pressing the key you will see the LEDs alternate between

three choices (sheet, roll and take-up). Now select roll take-up

loading sequence (both LEDs ON).

Step 3 : Take an empty cardboard core. Slide the empty cardboard roll over the scroller of the roll take-

up system.

Note :

Notice that one flange is fixed. A warning sticker is attached near the flange. Do not

remove this flange.

Step 4 : Take your roll of media.

Step 5 : Remove the moveable flange from the

scroller by pulling it off.

Movable Flange

Step 6 : Load the media onto the scroller.

Feed the scroller through the media core.

Gently but firmly press the roll media over the fixed flange.

Slide the moveable flange over the scroller and firmly press the flange inside the roll media core.

Page 47

Falcon Outdoor Jr. – Operation Instructions

Page 47

PN: MAI-75039

Rev. 1.A – 07/26/05

1 = Fixed flange

2 = Media winding direction

Note :

Do not drop the media roll over the scroller as this might damage the scroller end caps.

Damaged end caps may cause media tracking problems.

All Mutoh recommended roll media are rolled up with the printable side facing the

outside, so that you can load the roll media easily.

Step 7 : Installing the scroller slip ring

Install the scroller slip ring onto the scroller. Slide the scroller slip ring on the left side of the

scroller (side with fixed flange).

Step 8 : Installation of the scroller.

Install the scroller as follows :

¾ Stand at the back side of the printer, holding the scroller with the fixed flange side in your left hand.

¾ Slide the scroller (left side) into the scroller receiver, as shown in the illustration.

¾ Push the scroller (Right side – movable flange side) down into the right scroller receiver. You will

notice it dropping nicely into place.

Step 9 : Locking the scroller slip ring

Lock the scroller by sliding the scroller slip ring onto the scroller rollers. The scroller slip ring will prevent

unwinding of the roll media from the scroller when roll media is still not loaded in the machine.

Page 48

Falcon Outdoor Jr. – Operation Instructions

Page 48

PN: MAI-75039

Rev. 1.A – 07/26/05

Page 49

Falcon Outdoor Jr. – Operation Instructions

Page 49

PN: MAI-75039

Rev. 1.A – 07/26/05

Step 10 : Loading roll media.

Pull some media off the roll, feed it into the media feed gap and between

the pressure rollers and the drive roller.

Pull out the media at the front side and make sure at least 0.5 meters

hangs out in front of the printer.

Caution :

When you load roll media from the back, be careful not to hurt yourself by touching the

pressure roller system.

Step 11 : Checking the position of roll media.

Turn the scroller by hand and wind up several turns of roll media. As you wind up the media, check the

relative positions of the drive roller on the right and the right hand edge of the roll media. It is normal if with

the roll media pulled tight, the portion that is being wound and the portion that was unwound are straight and

the right hand side edge of the media is on the guide line. If this is not the case, adjust the position of the roll

media in accordance with step 9.

Guide line (holes) can be seen Guide line (holes) is hidden

Step 12 : Fine-tuning the roll media position.

If the guide line (holes) can be seen, the roll media must be moved to the right.

If the guide line (holes) is hidden, the roll media must be moved to the left.

Turn the scroller receiver screw counter -clockwise to move

the roll media to the right (when standing in front of the

printer).

Page 50

Falcon Outdoor Jr. – Operation Instructions

Page 50

PN: MAI-75039

Rev. 1.A – 07/26/05

Turn the scroller receiver screw clockwise to move the roll

media to the left (when standing in front of the printer).

Important:

The guide line (holes) is a guide.

There is a possibility of a jam if the pressure roller is not holding the left edge of

the media and the pressure roller is near the right edge. Either hold the left edge

of the media completely with the pressure roller or slide it so that the pressure

roller is about 5 mm away from the right edge of the media and the right edge of

the media within 5 mm to the left or right of the guide line (holes).

Step 13 : Before lowering the media hold lever, hold the media on the front side and turn the media feeding

scroller slightly backward, making sure that there is an even tension across the f ull media width.

Lower the media hold lever and close the cover. The head moves automatically and will search

for the left and right edge of the media being loaded.

Important :

If the roll media has not been fed straight or incorrectly, messages such as “Stuck

Media error” or “Take out paper” are shown on the display. If this is the case,

reload the media following the instructions mentioned above.

Step 14 : In the MENU “Function” of your printer, set media cut to OFF.

Page 51

Falcon Outdoor Jr. – Operation Instructions

Page 51

PN: MAI-75039

Rev. 1.A – 07/26/05

Step 15 : Feed the media forward by pressing the SHIFT &

ADVANCE keys simultaneously until the media

reaches the cardboard core on the take-up system.

Step 16 : Fix the media on the cardboard core by means of self-adhesive tape strips in the middle and on

the left and right side.

Note :

First attach the middle of the media on the cardboard core to avoid slipping of the media.

Step 17 : Feed the media slightly forward (using SHIFT & ADVANCE) and wind it up on the take-up

system.

Now you are ready to start printing.

Once the printer has printed as much as shown on the figure below, the senso r s will be activated and the

take-up system will start winding up the media.

Once your print is finished and dry you can wind up your print via a manual feed button.

If you want to sheet off the print push the cancel button for 2 seconds and confirm the sheet-off request.

If you want to wind up or wind off your print you can do this via the forward / reverse button.

Page 52

Falcon Outdoor Jr. – Operation Instructions

Page 52

PN: MAI-75039

Rev. 1.A – 07/26/05

4.4.5. Eco-Solvent Plus Media List

Mutoh offers media specially targeted for outdoor applications, media aimed for indoor applications where

long-term indoor lifetime of the output is required and media specially engineered for makin g colourful

banners.

Together with your Falcon Outdoor Jr. series printer, you will receive a sample roll of one of the Mutoh EcoSolvent or Eco-Solvent Plus media and a CD-ROM containing pre-ripped data, allowing you to test the EcoSolvent and Eco-Solvent Plus media.

On the CD-rom you will find more information on how to correctly use the Eco-Solvent media or Eco-Solvent

Plus media.

More media information, media specification sheets and free of charge media profiles for Mutoh’s in-the-bo x

software are at all times accessible via Mutoh’s website under

http://www.mutoh.be

For pricing and availability details, please contact your Mutoh reseller.

Page 53

Falcon Outdoor Jr. – Operation Instructions

Page 53

PN: MAI-75039

Rev. 1.A – 07/26/05

4.5. ADJUSTING HEAD HEIGHT.

Depending on the media type and media thickness used, it is possible to adjust the printer’s printhead height

accordingly 1.5 mm to 2.0 mm (± 0.15 mm).

The head height can be adjusted using the lever on the left side of the head (please refer to the picture

mentioned above).

When the lever is put in horizontal position (turn counter clockwise) the head is in his highe st positio n : 2.0

mm

When the lever is turned clockwise, the head is in his lowest position : 1.5 mm.

The lever can only be put in two positions, there are no intermediates.

Typical use :

LOW HIGH

Photo quality output on photo paper type media

(Mutoh Photo Great Piezo Media, Paper, Vinyl,

Synthetic paper,…)

Thick media or media with fibres (Fabrics) which may

touch the printhead during printing.

(Canvas, Art Paper, Cardboard,…)

Page 54

Falcon Outdoor Jr. – Operation Instructions

Page 54

PN: MAI-75039

Rev. 1.A – 07/26/05

Page 55

Falcon Outdoor Jr. – Operation Instructions

Page 55

PN: MAI-75039

Rev. 1.A – 07/26/05

5. HANDLING THE PRINTER

5.1. GUIDED TOUR AROUND THE OPERATION PANEL

Your printer is equipped with a direct access operation panel, meaning that all frequently use d functions can

be addressed directly from the keyboard.

Nr. Key Description

1. Data LED :

The DATA LED monitors DATA status :

¾ LED ON

indicates data is being received.

¾ LED FLASHING

means data is being processed.

2. Error LED :

The ERROR LED is ON

after an ERROR has occurred, to indicate

a possible hazardous situation. The LED will go out if the error is

corrected or after pressing the [CANCEL] key.

3. Cancel Key :

The [CANCEL] key is a special key, controlling both the CANCEL

FUNCTION as well as the ROLL MEDIA sheet-off function.

Printer Condition

Result by pressing CANCEL