Muskoka Madigan MTVS2353SMG-1, Madigan MTVS2353SOK User Manual

MEDIA CONSOLE

Save these instructions | Conserver ces instructions | Guarde estas instrucciones

CONSOLE MÉDIA

CONSOLA DE MEDIOS

MADIGAN

MTVS2353SMG-1 | MTVS2353SOK

Français p. 12

Español p. 22

REV07-02-13

ASSEMBLY TIPS

Before you begin, locate the instructions and hardware. Take out all the parts and compare them to the

diagrams below. Be sure you have all the parts and can identify them. Two people are required to assemble

this product. Assembly time will take approximately 30-90 minutes.

CARE AND MAINTENANCE

1. Dust your fireplace mantel regularly with a soft non-lint producing cloth or household dusting product.

2. You can clean your fireplace insert with a gentle non-abrasive household cleaner. Make sure to dry

your fireplace immediately with a soft cloth or towel.

P

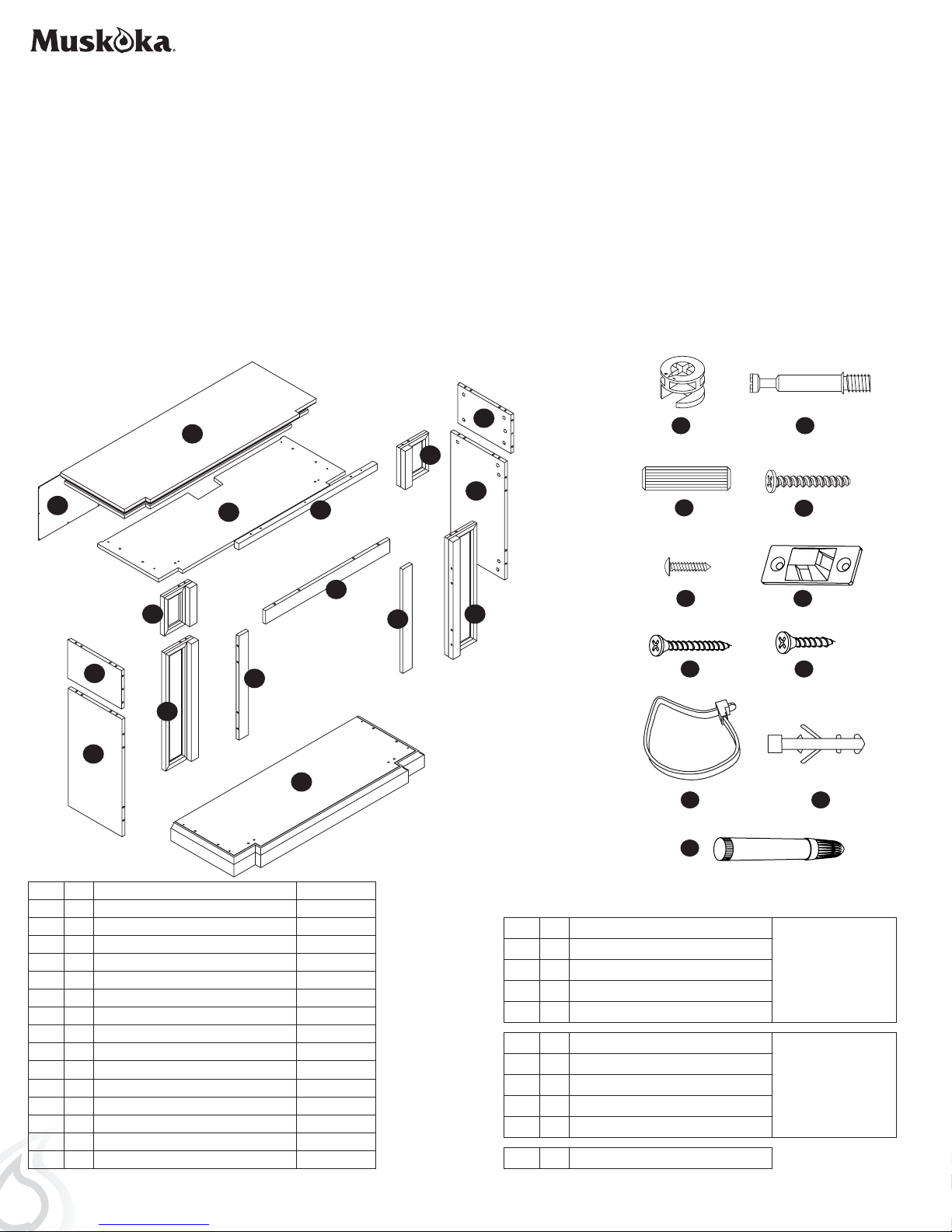

PARTS

E

A

a b

I

G

B

J

M

H

D

N

O

L

c

e

g h

d

f

K

F

C

i

k

J

A 1 TOP ZZ.2353.A

B 1 SHELF ZZ.2353.B

C 1 BASE ZZ.2353.C

D 1 LEFT TOP SIDE PANEL ZZ.2353.D

E 1 RIGHT TOP SIDE PANEL ZZ.2353.E

F 1 LEFT SIDE PANEL ZZ.2353.F

G 1 RIGHT SIDE PANEL ZZ.2353.G

H 1 LEFT TOP FRONT PANEL ZZ.2353.H

I 1 RIGHT TOP FRONT PANEL ZZ.2353.I

J 1 TOP TRIM ZZ.2353.J

K 1 LEFT FRONT PANEL ZZ.2353.K

L 1 RIGHT FRONT PANEL ZZ.2353.L

M 1 TOP OPENING TRIM ZZ.2353.M

N 1 LEFT OPENING TRIM ZZ.2353.N

O 1 RIGHT OPENING TRIM ZZ.2353.O

P 1 BACK PANEL ZZ.2353.P

2

HARDWARE

a 37 CAM LOCK

b 37 CAM LOCK DOWEL

c 42 WOOD DOWEL

d 3 LARGE SCREW

e 16 SMALL SCREW

f 2 MOUNTING BRACKET

g 2 LARGE SCREW

h 2 SMALL SCREW

i 1 NYLON STRAP

J 2 ANCHOR

k 1 TOUCH UP PAINT

SPARES

INCLUDED

ANTI-TIP DEVICE

2 SETS

INCLUDED

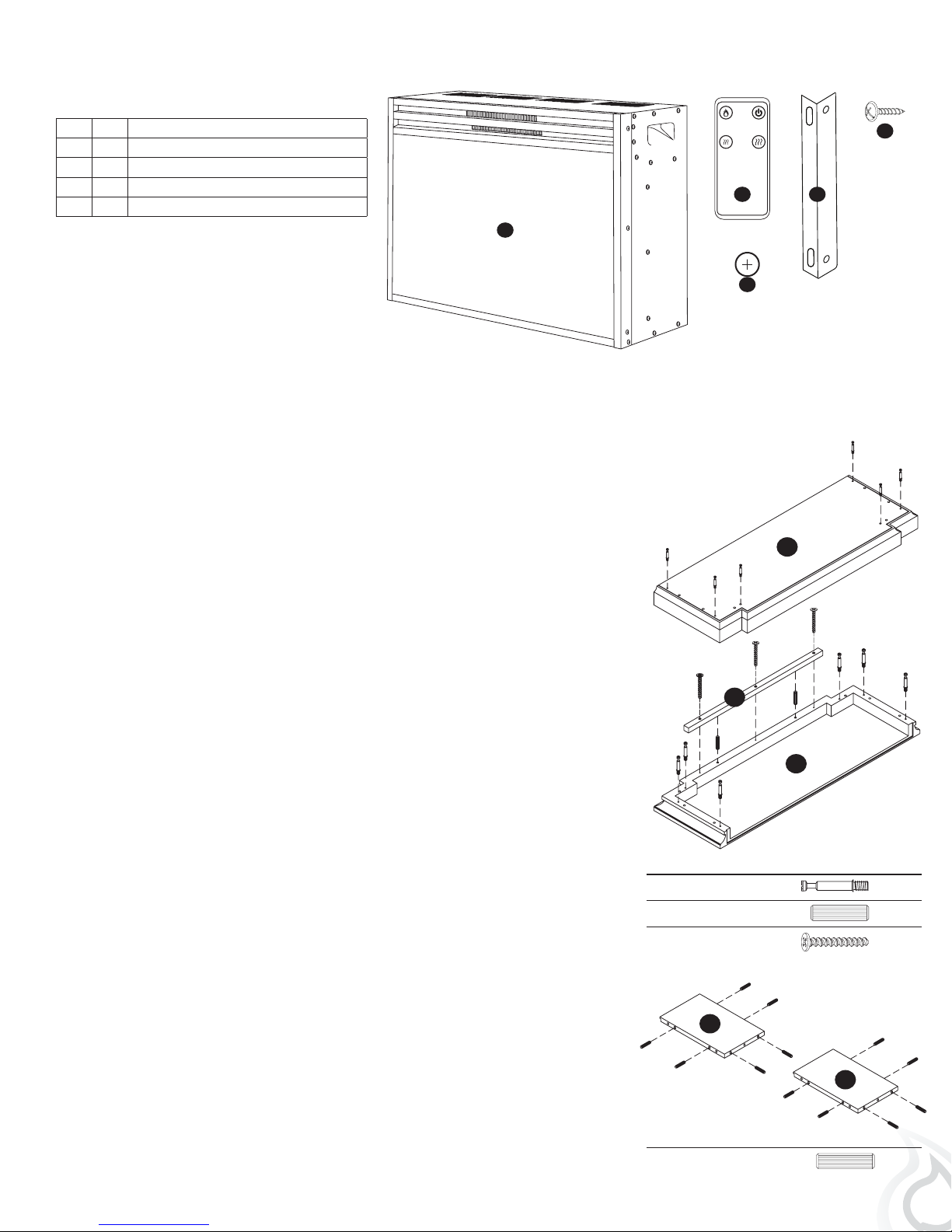

FIREBOX PACKAGE CONTENTS

AAA AAA

Q 1 FIREBOX

R 1 REMOTE

S 2 CR2032 BATTERY

T 3 METAL TRIM

U 7 FIREBOX TRIM SCREW

R

Q

S

T

U

ASSEMBLY

Before assembly, use scissors to unwrap the parts from the packaging. DO NOT use a box cutter or

exacto-knife as you may cut into the mantel pieces inside the box and damage the finish. Check for the

hardware bag which is RED and located inside the packaging, taped to the top box. DO NOT discard

any pieces.

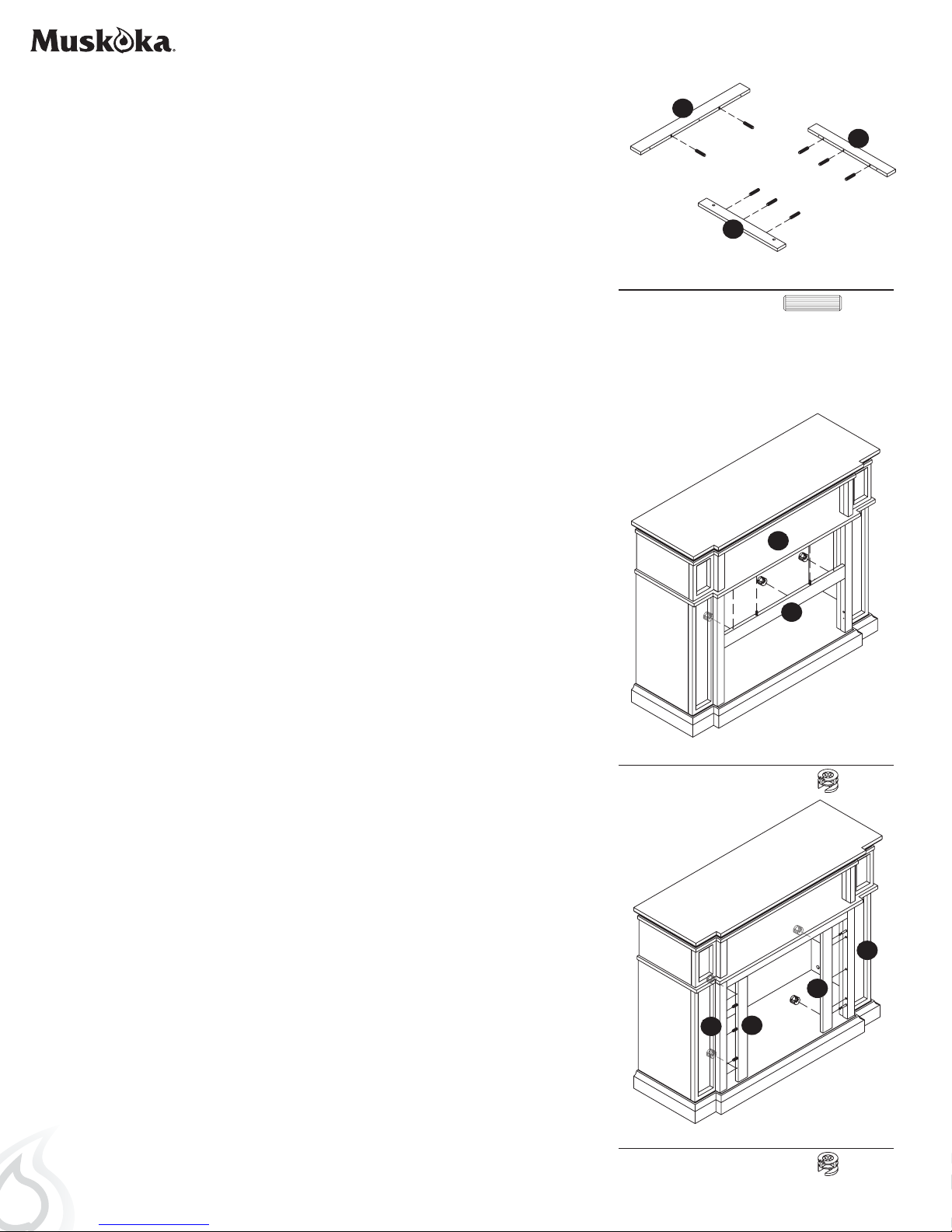

1. Locate the base (C). Insert and tighten 6 cam lock dowels (b) into

the base (C). Make sure the threaded side is down so you can inset

C

and tighten each cam lock dowel (b) into each hole in the base (C).

Locate the top (A) and place it finished side down on a soft clean

surface. Insert and tighten 6 cam lock dowels (b) into the top (A).

Make sure the threaded side is down so you can insert and tighten

each cam lock dowel (b) into each hole in the top (A). Insert 2 wood

dowels (c) into the holes on the underside of the front of the top A.

Line up the holes in the top trim piece J with the wood dowels in the

top A. Push piece J down until flush with the top A. Secure piece J

to top A by inserting 3 long screws (d) into piece J and tightening

until secure.

2. Locate the left and right top side panels (D & E). Insert 6 wood

dowels (c) into the edges of each panel as shown.

J

A

Hardware Used

b Cam Lock Dowel x 12

c Wood Dowel x 2

d Large Screw x 3

D

E

Hardware Used

c Wood Dowel x 12

3

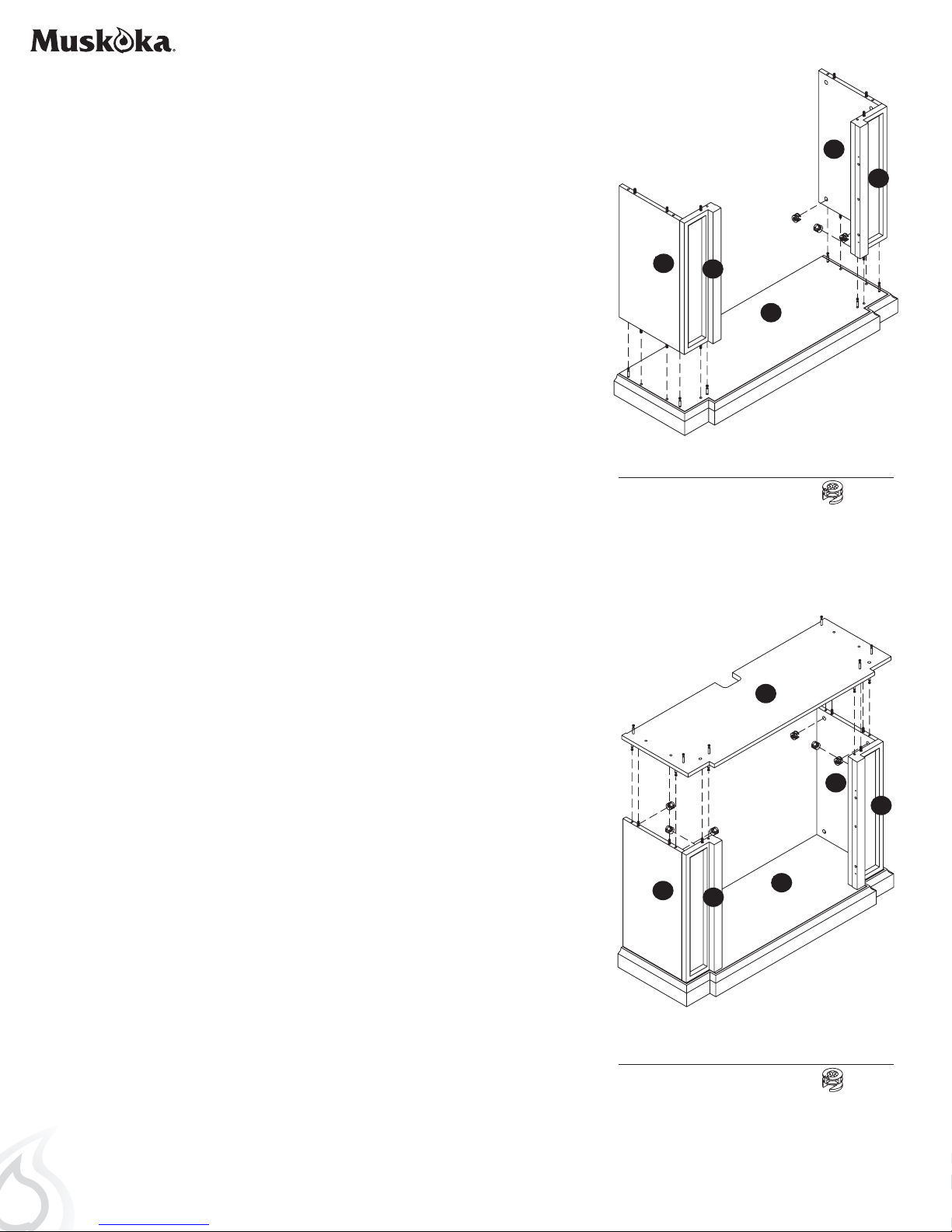

3. Insert 6 cam lock dowels (b) into the holes on the top of shelf B.

Make sure the threaded side is down so you can insert and tighten

each cam lock dowel into the panels.

Flip shelf B over and insert 9 cam lock dowels (b) into the holes on

the bottom of shelf B. Make sure the threaded side is down so you

can insert and tighten each cam lock dowel into the panels.

4. Locate the top front panel H. Insert 1 cam lock dowel (c) into the

center hole on the back of panel H. Make sure the threaded side is

down so you can insert and tighten each cam lock dowel into the

panels. Insert 2 wood dowels on either end of the top front panel H.

Repeat process for top front panel I.

B

B

Hardware Used

b Cam Lock Dowel x 15

H

Hardware Used

b Cam Lock Dowel x 2

I

5. Locate the left and right front panels (K & L). Insert 1 wood dowel

(d) into each the end of each panel K & L. Insert 2 cam lock dowels

into the back of each panel K & L. Insert 2 cam lock dowels into

the outer edge of each panel K & L. Make sure the threaded side is

down so you can insert and tighten each cam lock dowel into each

panel.

c Wood Dowel x 4

K

L

Hardware Used

b Cam Lock Dowel x 8

c Wood Dowel x 4

4

6. Locate side panels F & G. Insert 6 wood dowels into the edge of

each panel.

7. Line up and insert cam lock dowels and wood dowels on panels

F and K and push together until flush. Insert 2 cam locks into the

holes on panel F. Make sure the arrows on the cam locks are facing

toward panel K. Turn the cam locks to tighten. Do not strip the cam

locks by over tightening.

F

G

Hardware Used

c Wood Dowel x 12

F

G

K

Repeat process for panels G and L.

8. Line up the wood dowels in panel D with the holes in panel H

and the cam lock dowel in panel H with the holes in panel D.

Push together until flush. Insert a cam lock into the center hole at

the bottom of panel D. Make sure the arrows on the cam lock are

facing toward panel H. Turn the cam lock to tighten. Do not strip

the cam lock by over tightening.

Repeat the process for panels E and I.

L

Hardware Used

a Cam Lock x 4

D

E

H

I

Hardware Used

a Cam Lock x 2

5

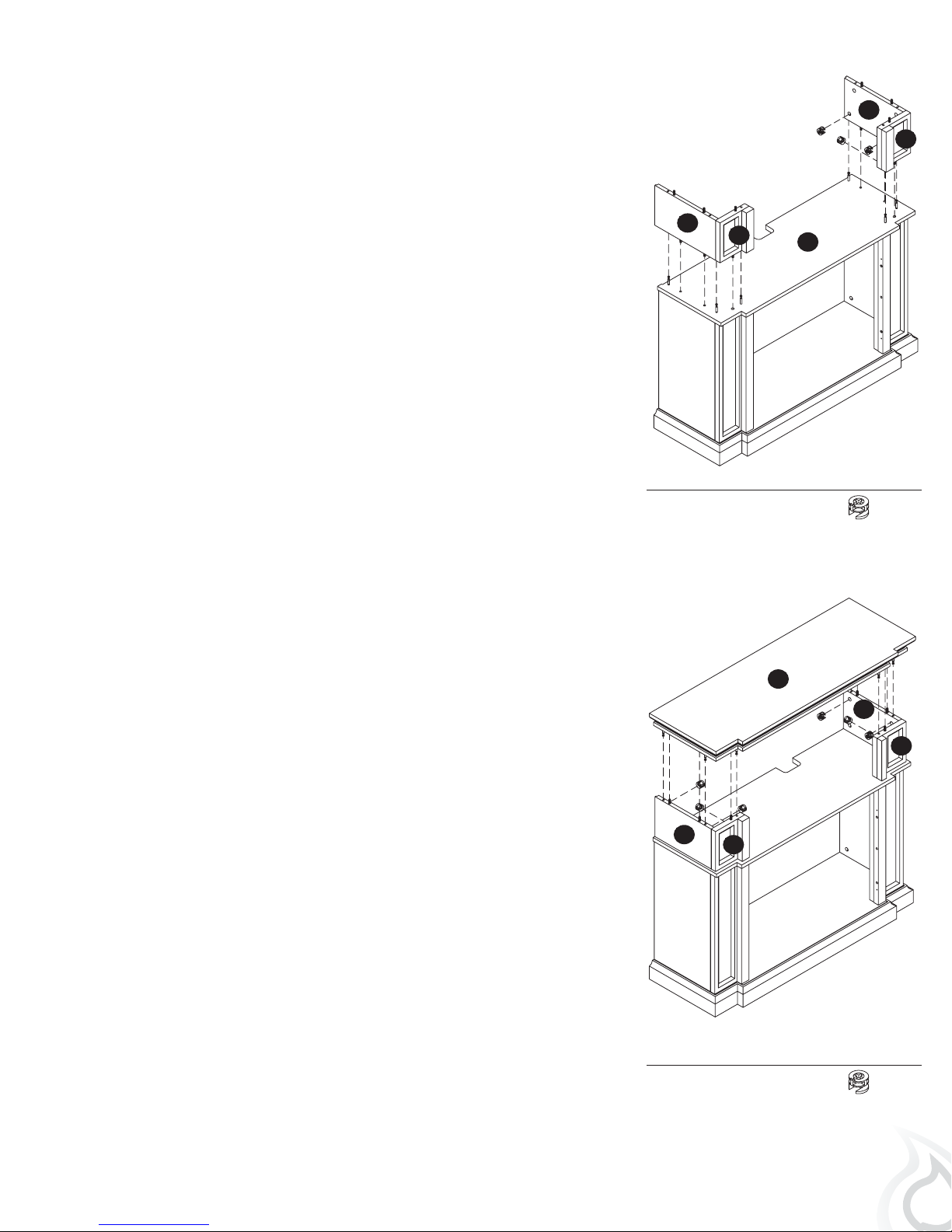

9. Line up the wood dowels in the bottom of panels F & K with the

holes in the base C. Also line up the cam lock dowels in the base

C with the holes in the bottom of panels F & K. Push the assembly

of panels F & K down until flush with the base C. Once flush, insert

cam locks at the bottom of panels F & K making sure the arrows on

the cam locks are facing down toward the base C. Turn the cam

locks to tighten. Do not strip the cam locks by over tightening.

G

L

F

K

Repeat the process for panels G & L.

10. Line up the wood dowels in the top edge of panels F, K, G, & L

with the holes on the bottom of shelf B and the cam lock dowels

in the bottom of shelf B with the holes on the top edge of panels F,

K, G, & L. Push the shelf B down on the mantle assembly until flush.

Insert cam locks into the holes on panels F, K, G, & L. Make sure

the arrows on the cam locks are facing up toward shelf B. Turn the

cam locks to tighten. Do not strip the cam locks by over tightening.

C

Hardware Used

a Cam Lock x 6

B

G

L

6

F

Hardware Used

a Cam Lock x 6

K

C

11. Line up the wood dowels in panels D & H with the holes on the top

of shelf B and the cam lock dowels on shelf B with the holes in the

bottom edge of panels D & H. Push panels D & H down onto shelf

B until flush. Insert 3 cam locks into the bottom holes of panels D &

H. Make sure the arrows on the cam locks are facing down toward

shelf B. Turn the cam locks to tighten. Do not strip the cam locks by

over tightening.

Repeat process for panels E & I.

E

D

Hardware Used

a Cam Lock x 6

H

B

I

12. Note: Top is heavy. It is recommended that 2 people be used at this

point in the assembly.

Line up the wood dowels in the top of the mantel assembly with

the holes in the underside of top A. Also make sure the cam lock

dowels on the underside of top A are lined up with the holes in

the in the top of the mantel assembly. Push top A down until flush.

Insert 6 cam locks into the holes on panels D, H, E, and I. Make

sure the arrows on the cam locks are facing up toward the top A.

Turn the cam locks to tighten. Do not strip the cam locks by over

tightening.

D

Hardware Used

H

A

E

I

a Cam Lock x 6

7

13. Locate panels M, N & O. Insert 8 wood dowels into the edge of

each panel.

14. Place panel M, making sure the finished side is facing out, into the

firebox opening and up against panel J on shelf B. Make sure the

wood dowels in panel M line up with the holes in panel J and the

cam lock dowels in panel J line up with the holes in panel M. Once

panel M is flush with panel J insert 3 cam locks on the back side

of panel M making sure the arrows on the cam locks are facing up

toward the shelf B. Turn the cam locks to tighten. Do not strip the

cam locks by over tightening.

M

N

O

Hardware Used

c Wood Dowel x 8

B

M

15. Place panel N, making sure the finished side is facing out, into

the firebox opening and up against panel K. Make sure the wood

dowels in panel N line up with the holes in panel K and the cam

locks dowels in panel K line up with the holes in panel N. Once

panel N is flush with panel K insert 2 cam locks on the back side

of panel N making sure the arrows on the cam locks are facing

toward panel K. Turn the cam locks to tighten. Do not strip the cam

locks by over tightening.

Repeat process for panels O & L.

8

Hardware Used

a Cam Lock x 3

O

N

K

Hardware Used

a Cam Lock x 4

L

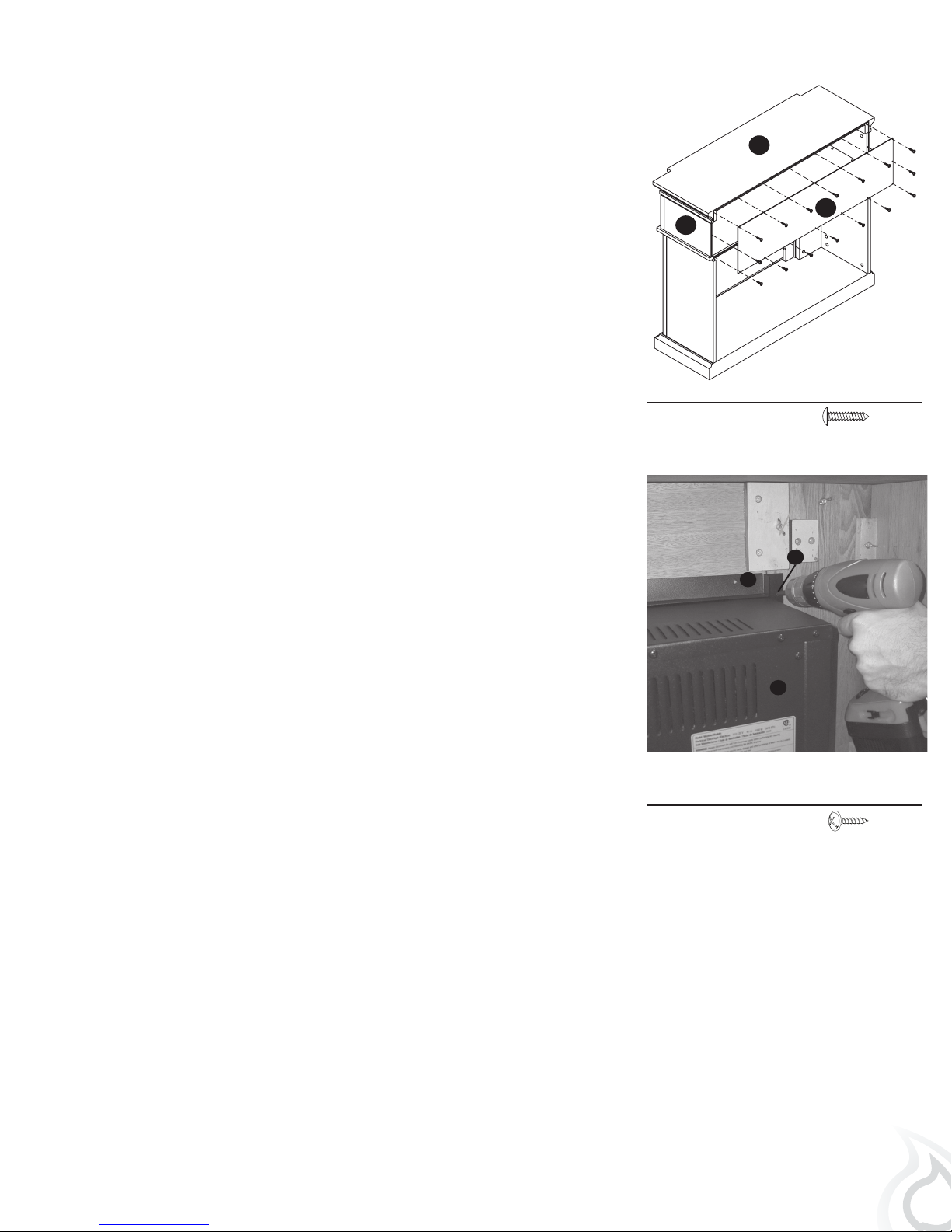

16. Locate back panel P. Making sure the finished side is facing in

toward the mantel, line up the holes in panel P with the holes on

the back of the mantel. Secure panel P to the mantel using 16 small

screws (e). Tighten until secure.

17. Installing your electric firebox

Refer to the manual included in your electric firebox carton. It will provide

you with the step by step instructions to prepare the electric firebox,

maintenance instructions and the firebox functions prior to installation

in the media console.

A

P

E

Hardware Used

e Small Screw x 16

U

T

The firebox comes with 3 metal brackets and 11 black screws (10

required plus 1 spare). These metal brackets must be attached to all 3

sides of the firebox and 2 sides of the mantel to ensure that your firebox

does not move around as you use it.

Insert your firebox from the rear of the mantel and position between the

two opening trims.

The top trim does not attach to the mantel, just the firebox. If you have any

questions about the firebox please reference the installation instructions

that come with the firebox.

Q

Hardware Used

U Firebox Trim Screw x 10

9

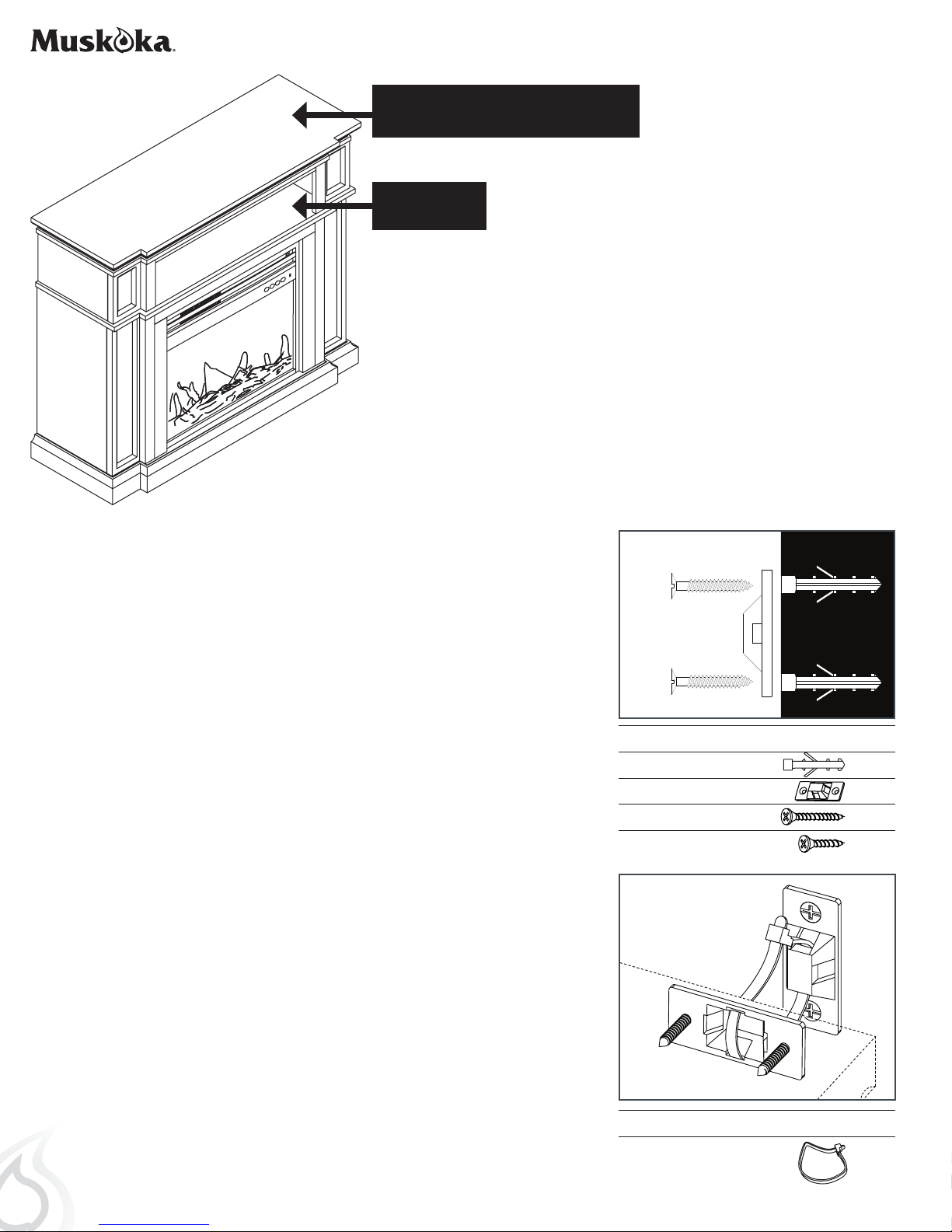

FIT UP TO 47" PLASMA/LCD/LED TELEVISIONS

MAXIMUM LOAD 55 lb. (25 kg)

MAXIMUM LOAD

30 lb. (13.6kg)

CAUTION: This unit is intended for use only with the products

and maximum weights indicated. Use with other products or

products heavier than the maximum weights indicated may

result in instability causing possible injury.

Note: Flat Panel TVs with base support should be placed

squarely in the center of the stand with no overhang on any side.

ANTI-TIPPING DEVICE (instructions included with hardware)

1. Attach one of the mounting brackets (f) securely to the back edge

of the furniture. Use the small screws (h).

2. Determine where furniture is to be placed and mark location on

the wall for the other mounting bracket (f) screw holes. You may

need to use 2 anchors (j) if you are attaching to drywall or plaster.

3. Position the bracket over the holes and use the large screws (g) to

securely attach the bracket to wall.

4. Place the furniture so the mounting bracket (f) on the back edge is

in line with the mounting bracket (f) on the wall.

5. Place an end of the nylon restraint strap (i) down through each

bracket (f). Bring both ends together and slide the end of the

nylon strap (i) through the slot in the other end until snug. Pull

down on the end until it snap locks into the slot.

6. Check to make sure the strap (i) is securely laced and locked to

the mounting brackets (f).

Young children may be injured by tipping furniture. The use of a

tipping restraint is highly recommended. This hardware, when

properly installed, could provide protection against the unexpected

tipping of furniture due to improper use.

WALL

Hardware Used

j

Anchor x 2

f

Mounting Bracket x 2

g

Large Screw x 2

h Small Screw x 2

WARNING: This product is only a deterrent. It is not a substitute for

proper adult supervision.

10

Hardware Used

i Nylon Strap x 1

Loading...

Loading...