Page 1

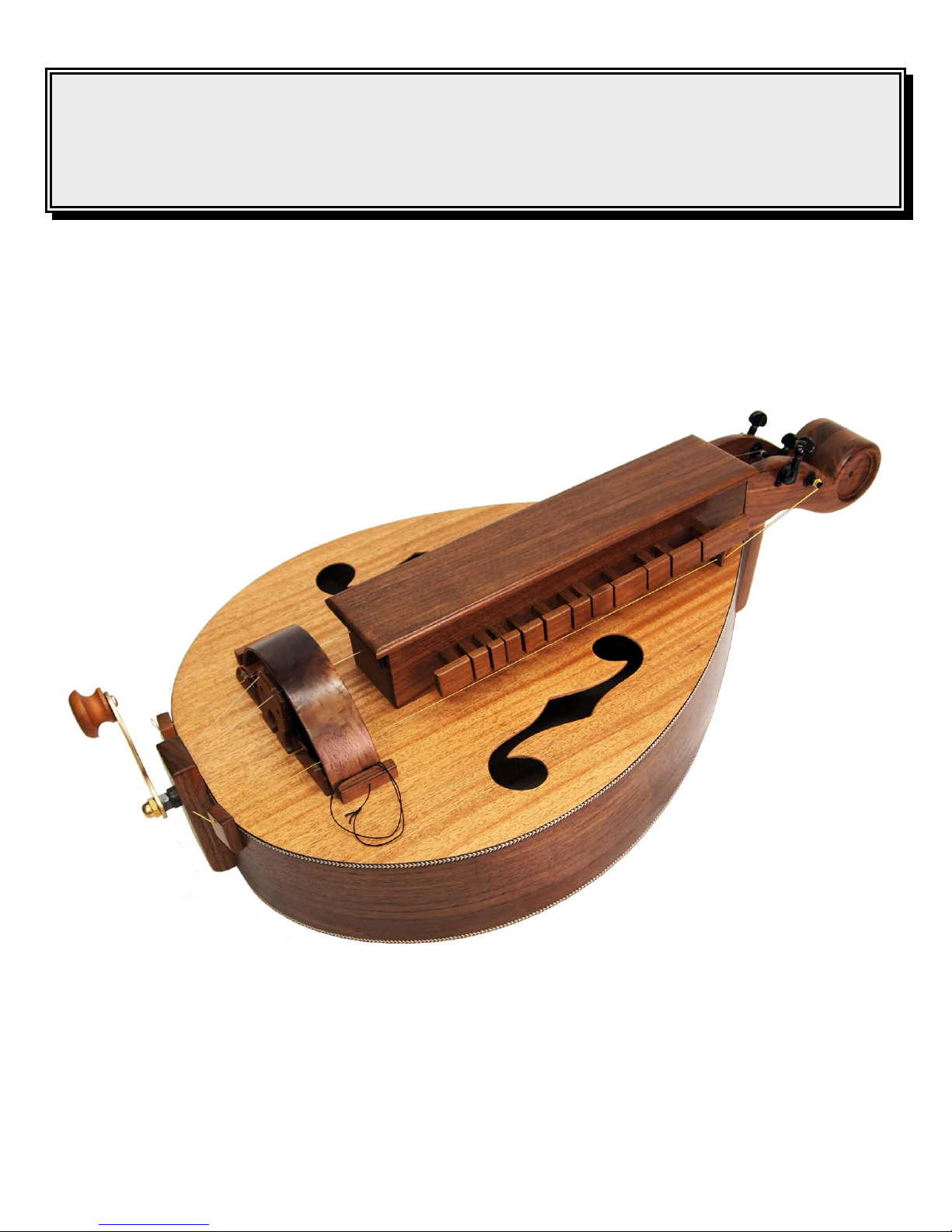

Hurdy Gurdy

Musicmakers

P.O. Box 2117

Stillwater MN 55082

(651) 439-9120

info@harpkit.com

Page 2

HURDY

GURDY

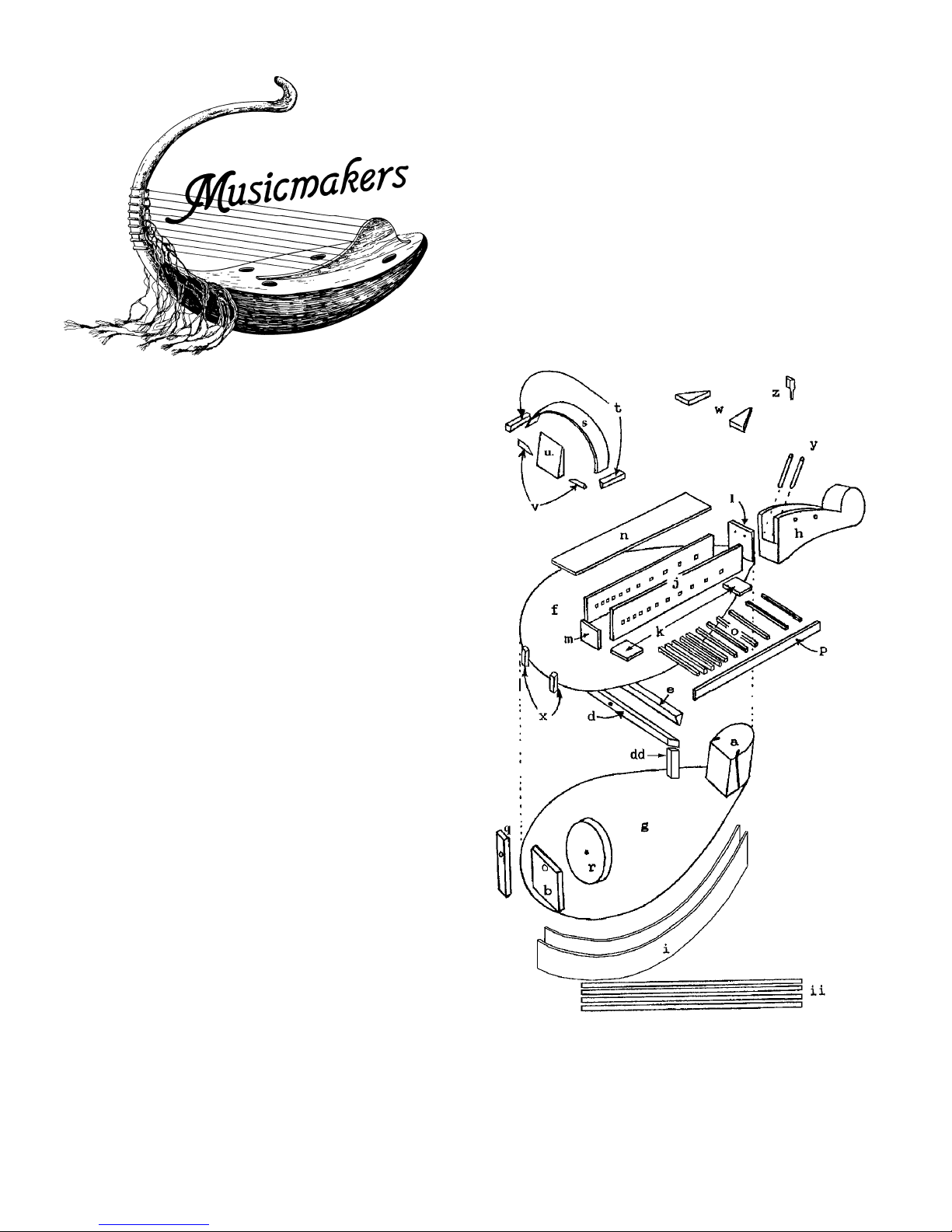

1 set of assembly instructions

WOOD PARTS:

a 1 heel (walnut)

b 1 tail block

d 1 predrilled inner brace

dd 2 support blocks for drilled brace

e 1 triangle inner brace

f 1 soundboard (solid mahogany)

g 1 back (cherry/walnut laminate)

h 1 peg head

i 2 pre-bent sides

ii 4 lining strips (soft wood)

j 2 keychest sides (walnut)

k 2 keychest base pieces (walnut)

l keychest head end (walnut)

m 1 keychest wheel end (walnut)

n 1 keychest lid (walnut)

o 12 keys (walnut)

p 1 button stock (walnut

q 1 tailpiece (walnut)

r 1 wheel (walnut)

s 1 wheel cover (curved walnut)

t 2 wheel cover blocks (walnut)

u 1 melody bridge (walnut)

v 2 drone bridges (walnut)

w 2 drone nuts (walnut)

x 2 drone anchor blocks (walnut)

y 2 dowels, 1/4" dia, 2" long

z 24 key tangents

KIT

2

Page 3

HARDWARE:

1 axle 5/16” X 7”

1 T-nut, 5/16” (in wheel)

1 brass cap nut, 5/16”

1 washer

2 steel hex nuts

1 wood screws, 1-5/8" drywall

1 brass crank, 1/8 x 4 x 1-1/4”

1 crank knob & screw

1 nylon axle bushing, 4” long

4 black tuners/w screws, sleeves,

2 Nylon covers for drone gear posts

1 set strings

2 melody, Viola D

1 drone, Cello G

1 drone, Cello C

2 hinges with screws

1 cake of rosin

1 ball of cotton

1 strip of thin felt, ½” X 12”

2 small rosettes for peg head

washers

BEFORE YOU BEGIN

Please take the time to check over the parts of our kit now, to make sure everything is there.

If you discover a problem, call us right away so we cat rectify it quickly without causing you much

delay in your project. We also suggest skimming through the entire directions before beginning, just

to get an overview of the project. You may decide that you need to gather more tools or purchase a

few optional decorations or accessories to enhance the finished instrument. Now is a good time to

make those plans so you can avoid delays later when you reach those steps of construction.

A NOTE ABOUT GLUE

DO NOT ASSEMBLE THIS PROJECT WITH EPOXY OR SUPERGLUE OR HOT MELT GLUE! Find a

good woodworking glue. Many luthiers (guitar & violin makers) still use the natural hide glues that

have been around for centuries, carrying on a fine old tradition, but that does not mean that you must

do the same. We build this instrument with modern woodworking adhesives (such as Elmer's

Carpenter's Wood Glue or Titebond) because they hold the parts even more securely than the old hide

glues. The few advantages that some people claim with hide glue are more than offset by the

strength, durability, ease of application, and availability of the modern woodworking adhesives.

When gluing parts together, be sure to put enough glue on the joint to wet the entire surfaces

to be joined. A good sign of proper gluing is that a little excess will squeeze out around the joint when

clamping pressure is applied. Too little glue may cause the parts to separate later, whereas too much

glue makes things messy. We always keep a damp rag handy for quick cleanup, as necessary. It is

especially helpful to keep your fingers clean while gluing, because gluey fingerprints have the

embarrassing tendency to appear on the finished product in places you never expected. Most

woodworking adhesives "set" sufficiently after 30 minutes of clamping to allow you to proceed. Check

your dispenser for recommended drying times.

3

Page 4

ASSEMBLY INSTRUCTIONS:

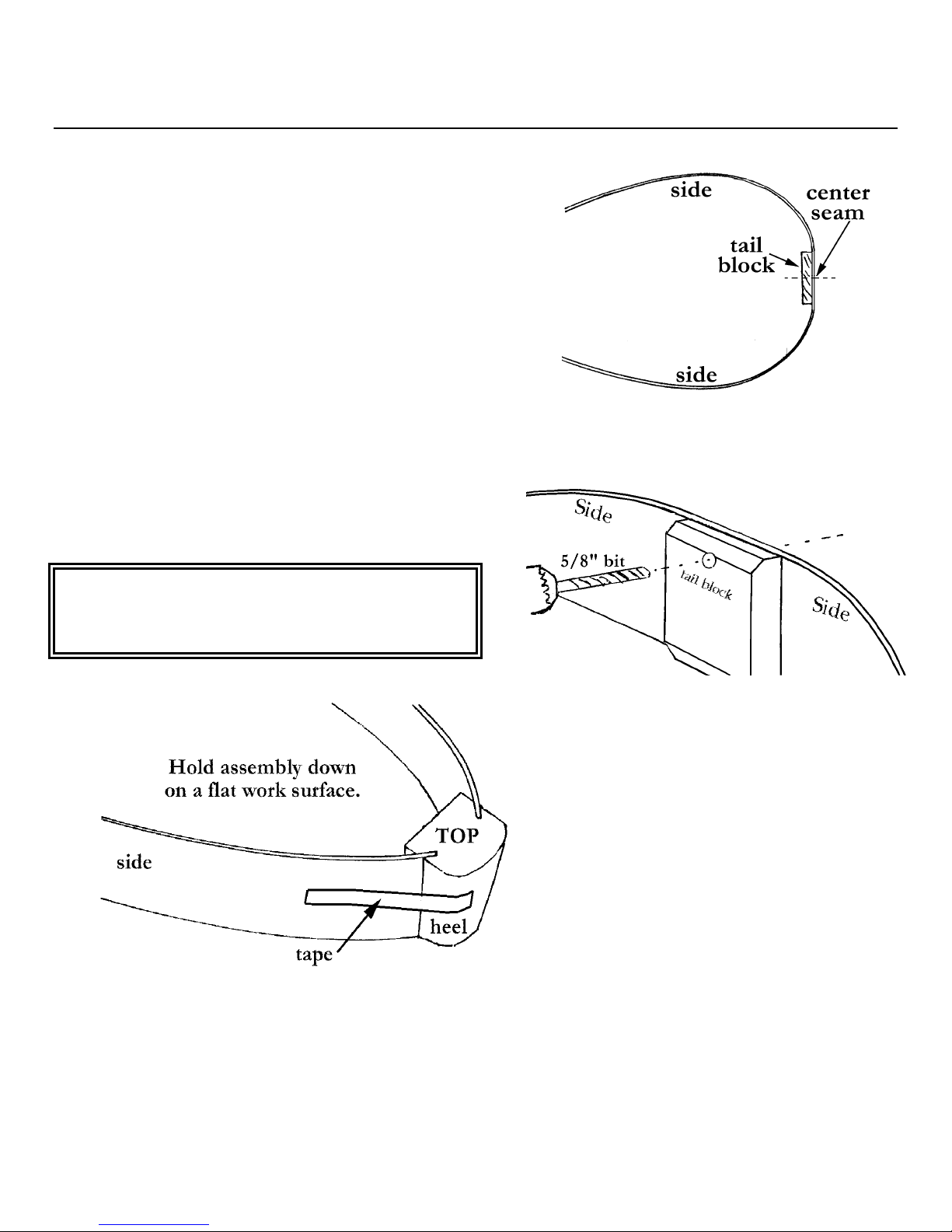

______1. The soundchamber SIDES are pre-bent and

must be joined at the tail end.

Check the fit of each SIDE into the HEEL BLOCK,

sanding the ends as necessary to make them slip into

the slots easily.

______2. Tape the tail end of the SIDES together, on

the outside, and glue the TAIL BLOCK to the inside,

centering it on the seam. Line up the edges carefully.

The hole in the tail block should be centered on the

seam. Use clamps to hold the parts together until dry.

CAUTION: Double check to see that the TAIL BLOCK

does not "drift" out of position under the clamps. You want good alignment of this piece in order to

glue the SOUNDBOARD and BACK successfully.

______3. Use a 5/8" drill bit to open the hole in the

TAIL BLOCK all the way through the SIDE. Take

care to keep this hole clean and straight.

NOTE: If you do not have a good 5/8" drill

bit, use a smaller bit and then use a rat-tail

file to carefully enlarge to the same size as

the hole in the TAIL BLOCK.

______4. IMPORTANT: There is a top and

a bottom to these parts. The top of the

TAIL BLOCK is nearest the hole for the

axle, and the top of the HEEL BLOCK has

the narrow slots nearest the square

corners. You'd be smart to mark the top of

the HEEL and TAIL BLOCKS.

______5. Test-fit the SIDES into the HEEL

BLOCK without glue first. If they don't

slide into the slots easily, just sand the

inside surfaces of the SIDES near each

end, as necessary to achieve an easy fit.

______6. When satisfied with the fit, glue the SIDES into the slots, as shown, on a very flat table top

(or floor).

Use masking tape to hold the SIDES in the slots until the glue dries.

4

Page 5

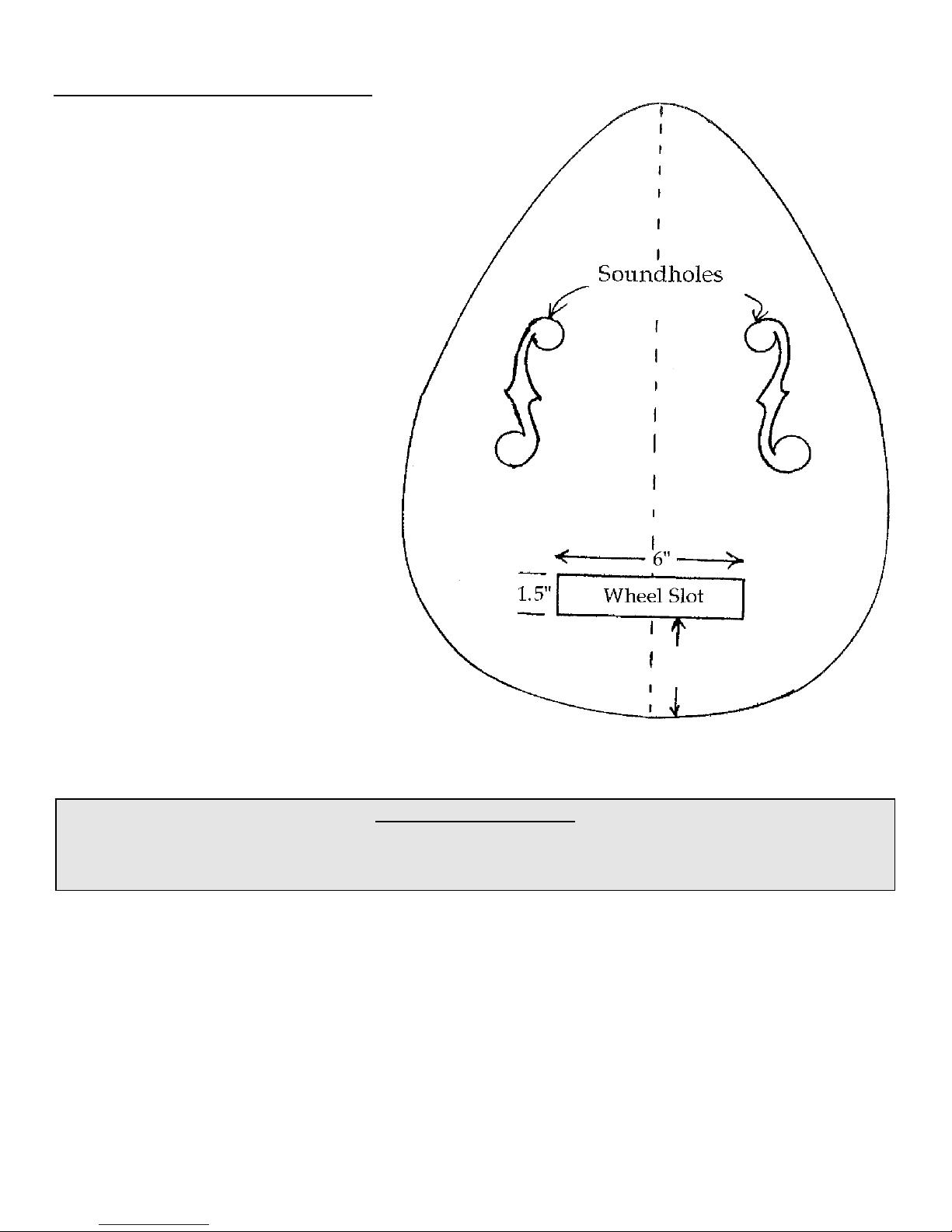

THE SOUNDBOARD

______7. Find the

SOUNDBOARD. We have already

cut out the wheel slot and two “f”

shaped “soundholes” on one face.

Draw a center line down this face

(if it isn’t there already), centering

it on the “f” holes and the wheel

slot.

POINT OF INTEREST

The “soundholes” are a bit of a mis-nomer, as they do not contribute to the volume

or tone of the instrument. There is enough opening around the WHEEL to take care

of that.

______8. Sand the edges of these holes in the SOUNDBOARD now. It will be harder to do

that later on.

3-1/4”

5

Page 6

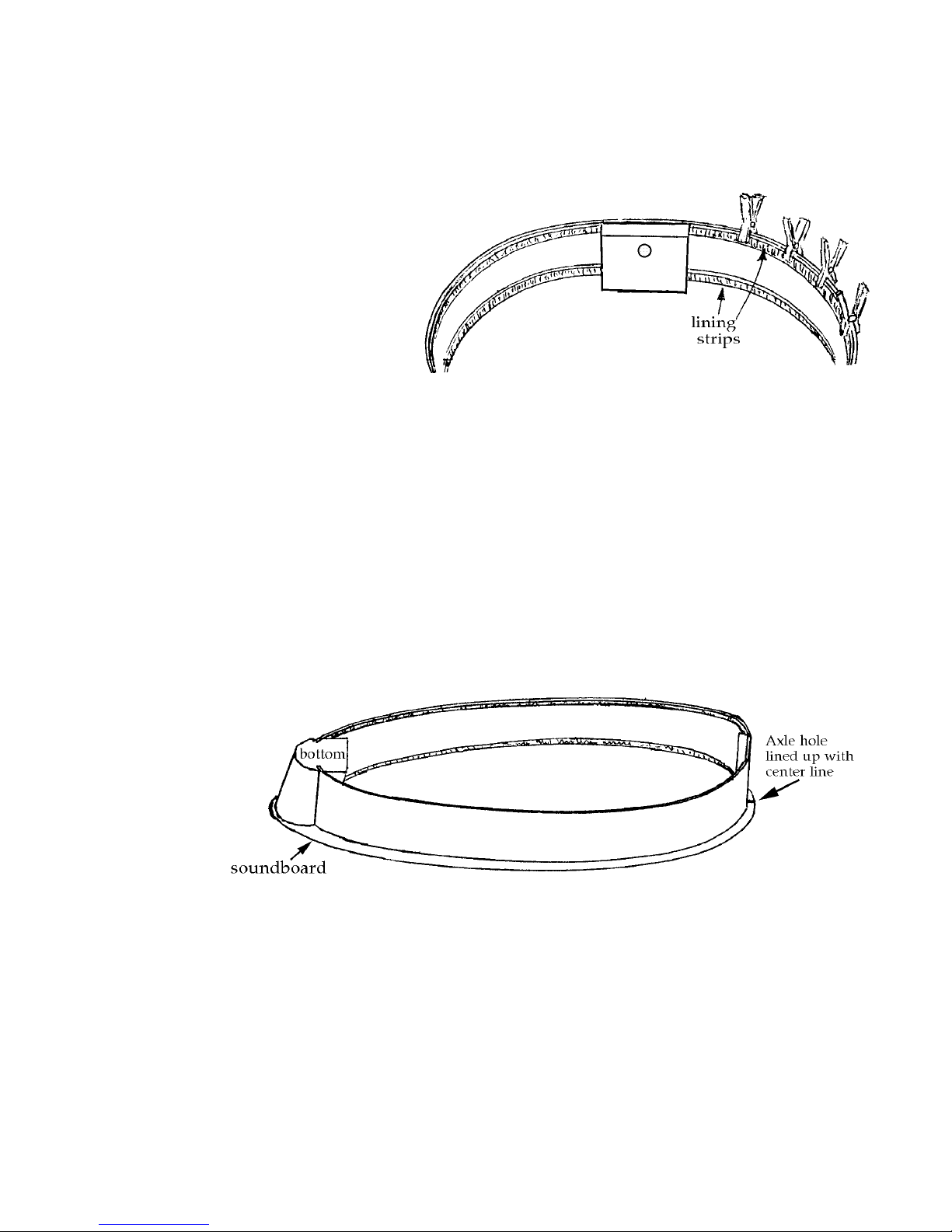

______9. Before proceeding further, you should check the symmetry of the SIDES of the

instrument. To do this, trace around its shape on a large piece of paper, and then flip the

frame over and compare the shape to your outline. Use strong tape pulled across the

instrument to change the curves until you are satisfied with the symmetry. No need for

perfection here, but you don’t want

the instrument to be obviously

misshapen.

______10. Leave your bands of tape

in place while gluing and clamping

the four LINING STRIPS inside the

SIDES, so the edges are flush, as

shown. Clothes pins do a nice job of

clamping these LINING STRIPS.

When dry, the instrument should hold its correct shape pretty well. Carefully sand all four

edges so they are flat and smooth, ready for gluing the SOUNDBOARD and BACK.

Check for symmetry again, stretching tape across the backside if necessary, and then

proceed with the next step.

______11. We cut the SOUNDBOARD a bit oversize, just to make sure it will fit, so you

need to line it up carefully on the soundchamber. Transfer the center-line to the backside

of the SOUNDBOARD and align the soundchamber on it so the center-line matches the

seam at the TAIL and the middle of the HEEL BLOCK. When satisfied, glue the assembly

to the SOUNDBOARD, using weights or clamps to hold the parts firmly together.

Leave roughly

equal overhang

all around.

6

Page 7

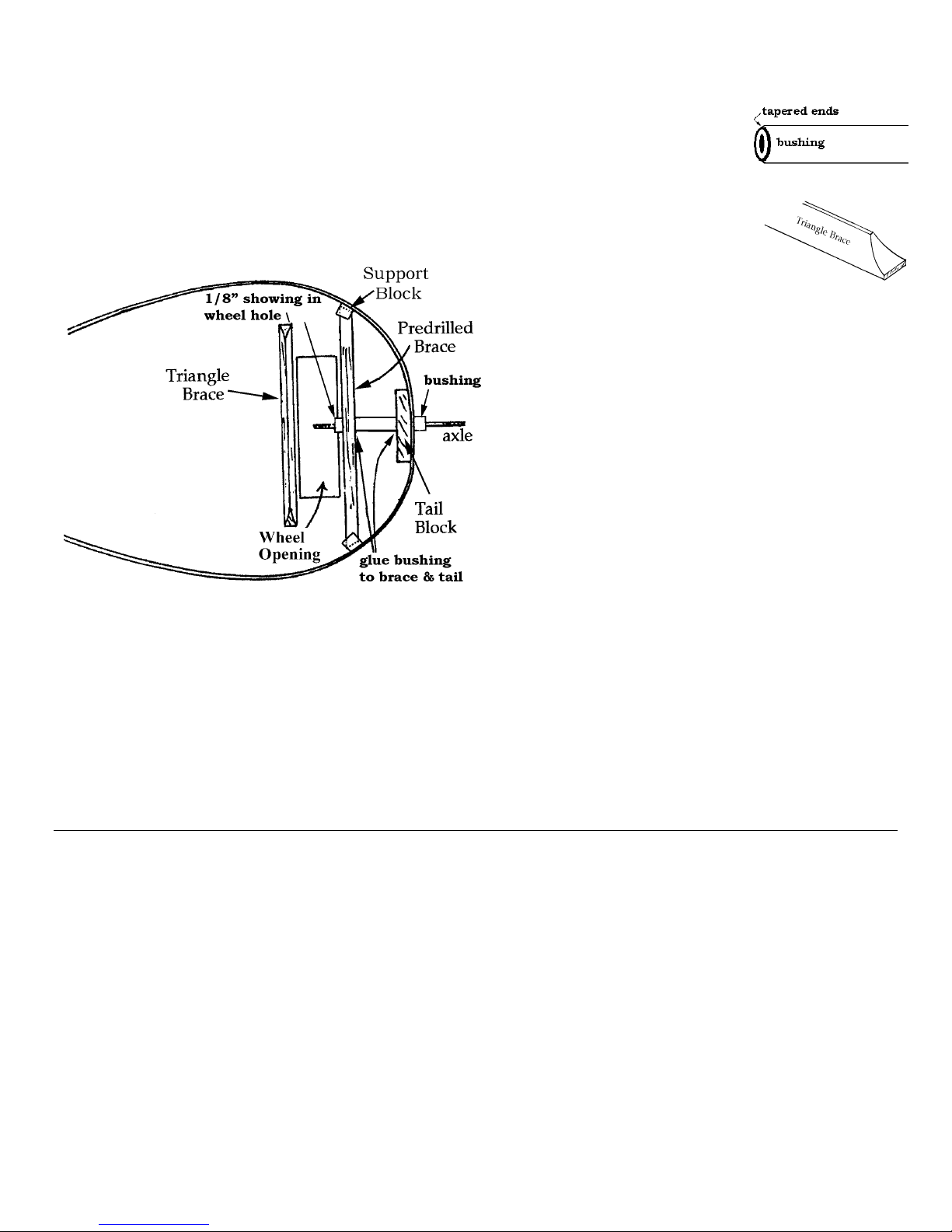

______13. Position the PREDRILLED INNER BRACE inside the SOUNDBOARD, just 1/8" from the

edge of the wheel slot, as shown.

Before gluing, taper the ends of the NYLON BUSHING and insert it

through the TAIL BLOCK and into the INNER BRACE. Then insert the

AXLE into the BUSHING, making sure that you can turn it easily with

your fingers. Glue the INNER BRACE to the SOUNDBOARD, about 1/8”

from the wheel opening, making sure the AXLE remains easy to turn. Use

weights or clamps to hold the brace until the glue dries.

______13a. Glue the

TRIANGLE INNER BRACE

along the other side of the wheel slot, 1/8"

away from the edge of the hole.

______14. This is a good time to secure the

NYLON BUSHING in place so it doesn’t slide

or turn when you play the instrument. Leave

1/8” of the BUSHING showing in the WHEEL

OPENING, as shown. The excess length

should stick out at the tail end. Put some

epoxy glue or Superglue on the BUSHING at

the inside edges of the BRACE and the TAIL

to secure it in this position, keeping the glue

away from the outside of the instrument.

Add the two SUPPORT BLOCKS over the

ends of the PREDRILLED BRACE, gluing them onto the ends of the brace and to the inside of the

SIDES, as shown. This anchors the BRACE securely at the ends and helps reduce unwanted

overtones in the melody strings. Clamp them to the sides until dry.

THE BACK

15. Check the fit of the BACK to the soundchamber. When satisfied, glue the BACK to the

soundchamber, spreading glue all the way around the circumference, including the HEEL and TAIL

blocks. Use weights or clamps to hold the parts firmly together until the glue dries.

16. Now is a good time to trim off the excess SOUNDBOARD and BACK to match the SIDES.

A router with a flush-cutting bit makes short work of this step, but you can also accomplish it by

hand with a rasp or some coarse sandpaper wrapped around a wood block. You may, if you wish,

leave a small lip of wood overhanging the sides.

In either case, it is important to clean off any excess glue that squeezed out along the joints. Glue

blobs, smudges, and drips may be difficult to see now, but they will show up on the finished

instrument like spinach in your teeth, so it is best to take care of these things as you go along. We

like to clean away excess glue before it gets rock-hard, using a sharp chisel or knife to peel it off the

wood.

7

Page 8

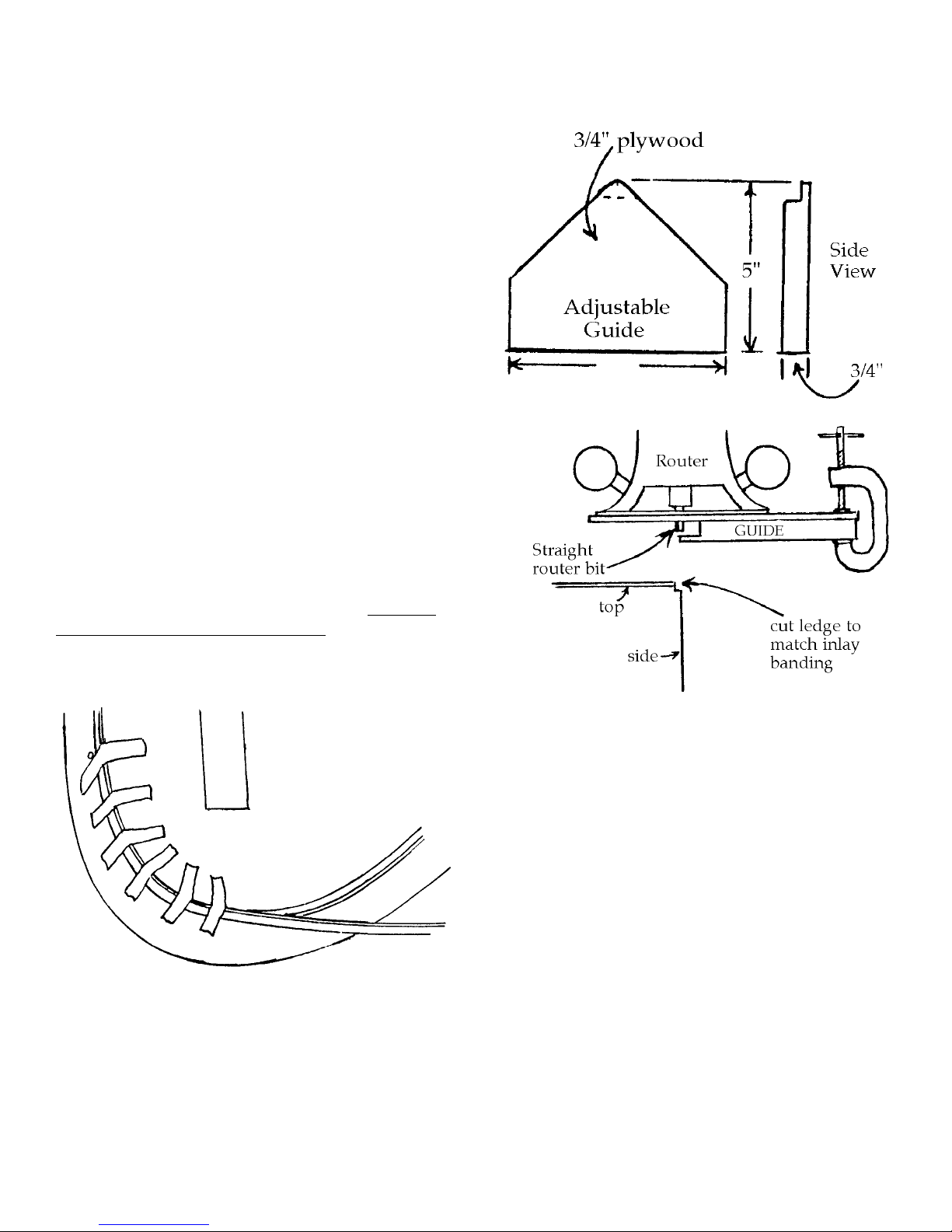

_____17. (OPTIONAL) Another nice option, if

you have a router, is to inlay some decorative

binding around the circumference of the

SOUNDBOARD and BACK. All you need is a

straight bit of any size (good and sharp). Here

is how to set it up:

a) Make a guide board to clamp to the base

of your router or to the top of the router table.

This is simply a triangular shaped scrap of

plywood with one point hanging over the router

bit, as shown.

b) Adjust the depth of the cut by sliding

the guide board over the top of the router bit.

c) Adjust the height of the cut by raising or

lowering the router bit.

d) Make a sample cut in a scrap of wood

and check your inlay banding to see how it fits.

e) When satisfied with the adjustment of

the cut, rout a ledge all the way around the

circumference of the soundchamber, stopping

where the SIDES meet the HEEL (it is hard to

bend the inlay banding around the sharp curve of

the HEEL BLOCK).

f) Glue your INLAY BANDING into the

slot with the appropriate adhesive

(carpenter's glue for wood inlay, or

airplane cement for plastic binding).

Use masking tape to hold the

decorative strips in place until dry.

8

Page 9

THE KEYCHEST

The KEYCHEST consists of two long walnut SIDES with square holes cut in them, a

walnut LID, and four small pieces of walnut that hold the SIDES together at the correct

spacing:

a) The HEAD END is the larger square piece to be located at the end nearest the

PEGHEAD;

b) Two BASE pieces are smaller rectangular pieces that lay flat against the

SOUNDBOARD, forming just a partial bottom to the keychest;

c) And the WHEEL END is identical to the BASE pieces, but stands up at the

end nearest the WHEEL.

_____18 Be very careful to assemble the

keychest correctly. Here are a few

details that must be observed in order

to have a playable instrument.

A) Make sure that both SIDES

are mirror images of each other.

Notice that the square holes are spaced

farther apart near the HEAD END.

B) The ENDS and BASE pieces

must all be oriented so they fit properly

between the SIDES.

C) The keychest parts must be

squared and parallel in order for the

KEYS to slide easily.

When satisfied with the

placement of each part, glue the

keychest together on a flat surface, using clamps, tape, or large rubber bands to hold the

parts firmly until dry.

HINT: When dry, sand and round over the sharp edges of the KEYCHEST so it feels

good to the touch. Rounded corners always look better than sharp corners.

9

Page 10

_____19. Do a little fine sanding on the SOUNDBOARD now, too, while it is easy to work on the

entire surface. We like to use an electric orbital sander (palm sander) with 180 grit sandpaper for a

quick smoothing and cleaning of flat surfaces. Dust carefully afterward.

THE PEGHEAD

Draw a light pencil line on the SOUNDBOARD 1-1/4" from the narrow end, as shown.

The PEGHEAD and KEYCHEST will meet at that point. Test how well they fit together in that

position.

_____20. Sand the PEGHEAD to your

satisfaction and glue that to the soundboard

first, lining it up with the pencil line. Doublecheck to see that the KEYCHEST will also fit

properly, but don't glue that down yet. You need

easy access to the scroll for the next step.

_____21. Reinforce the joint of the PEGHEAD to

the SOUNDCHAMBER by placing two 1/4"

dowels through the PEGHEAD into the HEEL

BLOCK, as shown. Use a 17/64" drill bit to bore

two holes about 1-1/2" deep. Glue the dowels

into the holes and trim off with a sharp chisel

flush with the bottom of the PEGHEAD.

_____ 22. Two small holes (1/16" bit) must be drilled

at an angle through the TALL END of the keychest for

the melody strings. They should be 1” apart and

about 5/8” from the top edge of the TALL END, as

shown. Use an awl to punch-mark the locations

before drilling, so your drill bit does not wander.

Accurate placement of these holes is quite

important.

No, your electric drill cannot fit down into the

keychest -- that’s fine, because these holes should be

drilled at an angle, aiming toward the cavity in the

PEGHEAD.

_____22-b. Now would be a good time to glue the decorative rosettes into the

peghead, though you could wait until after applying the finish, if you want the

inside of the hole to be finished. Some people paint the inside of the hole black for

contrast. When you glue the rosettes to unfinished wood, you can use Elmer’s

Wood Glue, but if you wait until the wood is finished, you’ll need to use Superglue

or epoxy to hold them to the finished surface.

10

Page 11

_____22a. Test-fit the KEYCHEST onto the

SOUNDBOARD, as shown above. Sometimes, if

the soundboard is slightly curved downward in

the center (concave), it is hard to get the

KEYCHEST to make contact with the spruce

along the length of the KEYCHEST. If that

happens with your kit, then you'll need to get

some clamps through the soundholes to hold the

KEYCHEST firmly against the SOUNDBOARD

while gluing (step #23).

Another option, if your soundholes are not large

enough or convenient for clamping, you could cut

openings through the SOUNDBOARD inside the

KEYCHEST for your clamps.

_____23. Now you can glue the KEYCHEST in

place. Glue it to the SOUNDBOARD and to the

PEGHEAD, centered on the center-line, using

weights and/or clamps to hold firmly.

(holes off center on purpose)

_____24. The 12 KEYS may need a little sanding to get them to slide smoothly in the

square holes of the keychest. Fit them with their small holes facing vertically. Check the

square holes to make sure they are cut cleanly too. A triangle file or fingernail file may be

helpful in removing wood fuzz or glue residue from the corners. The KEYS should slide

freely enough that they will fall out when the KEYCHEST is tipped at a 45 degree angle.

11

Page 12

Once the KEYS are fitted, we recommend numbering them so you will replace them in the

same positions later.

_____25. When the KEYS are properly fitted and correctly positioned, you may glue them

to the BUTTON STOCK. This is best done with the KEYS in place in the KEYCHEST.

Glue the BUTTON STOCK to all the KEYS at once, so they will all be interconnected.

You’ll cut them apart later.

CUSTOMER SUGGESTION: One builder recommends slotting the BUTTON STOCK with a

shallow groove on one face to fit the KEYS. Good idea! This would make it easier to glue so

many parts together at once.

Note that the BUTTON STOCK is to be glued on the right side of the KEYCHEST as

you look from the wheel end of the instrument. This is best for right-handed players. You

will turn the crank with your right hand and push the keys with your left. If you wish to

make this a left-hand instrument, simply glue the BUTTON STOCK to the other end of the

KEYS (and fasten the KEYCHEST LID in reverse when you get to that step).

12

Page 13

When dry, pull all the KEYS out of the KEYCHEST with the BUTTON STOCK and

use a bandsaw or jigsaw to slice them apart midway between the KEYS. We hope you

numbered the KEYS so you can easily figure out where to place them again!

This would be a good time to sand and round over all the rough edges and corners of

the BUTTONS, now that they have been cut apart. Handle with care so the BUTTONS

don't break off the KEYS. Set the KEYS aside in a safe place while you work on other parts

of the soundchamber.

BRIDGES & NUTS, ETC.

_____26. Before installing the TAIL PIECE,

drill two 1/16" diameter holes through the

TAIL PIECE in the positions illustrated.

These will be for the MELODY STRINGS.

We also like to round over all sharp corners of

the TAIL PIECE so it looks and feels smooth.

_____27. The TAIL PIECE can now be installed. Apply glue to the mating surfaces and use

one wood screw to pull the TAIL PIECE firmly into place.

13

Page 14

_____28. Sand the two DRONE NUTS to your liking, rounding over the sharp edges and

sanding off the saw marks left by our machines. When satisfied, glue them in place near

the narrow end of the instrument, so they contact the SOUNDBOARD and the KEYCHEST

SIDES, as shown.

_____29. Sand the two WHEEL COVER

BLOCKS in the same way. Glue these

blocks near each end of the wheel slot, in

an upside-down sort of way. Look

carefully at the illustration. Place them 61/2” to 7" apart (centered on the wheel

slot) so the curved WHEEL COVER will

be held securely between them (test-fit

the WHEEL COVER before gluing the

blocks in place).

NOTE: The WHEEL COVER will not be

glued in. You want to be able to

remove it frequently for tuning and

adjusting the strings. That is why the

WHEEL COVER BLOCKS are cut at

angles to hold the cover without glue.

_____30. Cut the MELODY BRIDGE to

the shape outlined here. Sand to remove

rough edges and saw marks.

_____31. Glue the BRIDGE to the SOUNDBOARD so that

the edge near the WHEEL is exactly 16-3/4" from the inside

edge of the HEAD END of the KEYCHEST. That should put

it within about 1" of the wheel slot, as shown. Center the

BRIDGE on the center-line of the SOUNDBOARD.

14

Page 15

_____32. Glue the two DRONE BRIDGES on either side

"

of the MELODY BRIDGE with the pointed ends sloping

down toward the center of the instrument, as shown.

Position them about 1/4" from the main BRIDGE.

_____33. Drill one 1/8" hole near the end of each

DRONE ANCHOR BLOCK and then glue them near the

TAIL of the instrument, as shown. Position these

blocks about 1" from the TAIL PIECE with the tiny hole

above the surface of the SOUNDBOARD.

______34. The KEY TANGENTS come

in two parts which must be glued

together before installing into the

KEYS. Use clothespins or spring clamps to glue the rounded walnut pieces to the

maple parts with tapered posts, as shown.

_____35. You are done with all the

gluing on this kit! Now it is time to

prepare everything for the finish. We recommend sanding

the entire instrument and all remaining wood parts

(except the WHEEL) to remove any glue spots, machining

marks and scratches, and to round over any sharp

corners.

Drill a 5/16" hole near one end of the brass bar and a

3/16" hole near the other end. The holes should about 3"

apart.

_____36. When shaping the BRASS CRANK, you may

want to be a little creative. Brass is soft enough to be

workable on a jigsaw or bandsaw, and it is fun to cut this

piece into a curved shape. If you take the time for fine

sanding and buffing, you can make this a very shiny

accessory on the instrument.

3"

5/16" holes

3

3/16" holes

side view

15

Page 16

APPLYING THE FINISH

Here are some suggestions on finishing (use only one of the following options):

STAIN -- STAINS are coloring agents and should only be used if you dislike the natural color of the

wood. We usually do not apply stains to our projects, especially when they are made with naturally

beautiful hardwoods such as cherry or walnut. These woods look very nice with just a clear finish.

But, if you want to color the wood differently, your staining should be accomplished before applying

a surface finish such as oil, varnish, or lacquer.

OIL -- An oil finish will give your wood a low luster appearance, bringing out the natural color of the

grain, but it tends soak into the wood and appear dry and "thirsty" after awhile. The principal

advantage of an oil finish is that it can be applied and wiped dry immediately, so you can proceed to

installing hardware (and strings) right away. The disadvantages of oil are that it usually does not

give much surface protection or sheen, although there are some brands that include waxes and/or

varnishes to give more surface build-up and luster.

VARNISH -- Any regular varnish will work fine on this project, but we recommend our wipe-on gel

urethane called MUSICMAKER'S INSTRUMENT FINISH. Our complete finishing kit includes

detailed instructions, sandpaper sheets and a half-pint can of satin gel urethane varnish. The

advantages of finish are its simple application, durability, and deep, soft luster. It also works well

for protecting Heat Transfer decorations.

LACQUER -- Many professional instrument makers still use lacquer for their finish. The most

readily available lacquer is called Deft Clear Wood Finish. It is best to purchase a can of liquid to

brush on as a sealer coat first, and then use an aerosol can of the same product to spray on the

final coats. The advantage of this finish is its quick drying time, but the disadvantage is the strong

odor of the toxic lacquer fumes. CAUTION: Lacquer finish will not work over Heat Transfer

decorations -- it dissolves the toner.

Apply the finish of your choice to all wood parts except the WHEEL. Don’t forget to coat the

BRASS CRANK and the wooden CRANK KNOB too.

HINT: For finishing the KEY TANGENTS, we drill a bunch of small holes in a scrap of wood to

hold these tiny parts.

Now you are ready to tackle the WHEEL. This is the most important part of the Hurdy

Gurdy, so take your time in truing it up.

TRUING THE WHEEL

_____37. You want the BUSHING to protrude a little beyond the TAIL PIECE to act as a

bearing surface for the CRANK. The exact amount is not critical, as long as you can fit all

the parts on the AXLE.

a) Insert the AXLE into the BUSHING.

16

Page 17

b) Pound the T-NUT into the

WHEEL, on the side where the

center hole has been enlarged.

c) Turn the WHEEL onto the axle,

with the T-NUT facing toward the

TAIL END. The AXLE should

protrude beyond the WHEEL.

Add the washer and the HEX NUT

and use a wrench to tighten the

HEX NUT up against the WHEEL.

The WHEEL must be securely

pinched between the T-NUT and

the HEX NUT.

_____38. Now to true the wheel,

you must have an electric hand

drill and a SHARP chisel. We have

not found another system to be

sufficient to the task, so dust off

the old grindstone and sharpen a

chisel -- it will be worth the effort.

You may want to ask a friend to

help with this step, as it is a bit

challenging to hold the chisel

steadily while the wheel turns.

Lay a small scrap of wood

across the wheel slot and hold the chisel very firmly on the scrap so the sharp edge just

contacts the WHEEL. Turn a HEX NUT onto the axle and then fasten the chuck of your

electric drill onto the end of the axle. Rotate the wheel toward the chisel by spinning the

axle with the electric drill. Hold the chisel as steadily as you can, letting the blade scrape

against the turning wood. If it only contacts the wheel at one point in the circle, that's fine.

Let the chisel remove that "high" point of wood. Pretty soon the blade will make continuous

contact with the rotating wheel. Then you will know that the wheel is true. Inspect it

carefully for signs of the sanding scratches left by our machines. Continue truing the

wheel until all those machining marks are smoothed off.

HINT: You will have an easier time with initial truing if you use just one corner of

the chisel for cutting against the wheel. Move the chisel across the face of the

WHEEL in order to eliminate the major “bumps”. Then you can switch to using the

full width of the chisel blade against the wheel so as to remove the gouges left by the

corner cuts.

17

Page 18

If the wheel has some side-to-side wobble, turn your chisel diagonally against the edges of

the wheel and scrape the corners.

Take your time on this because an uneven wheel will create music with a "wow-wow" effect as

it pushes on the strings up and down. (You want your friends to say "Wow!", but you definitely do

not want the hurdy gurdy to go "wow-wow".)

Follow after the chisel with medium (120 grit) sandpaper and then a fine (180 grit) sandpaper to

make sure the WHEEL has no rough spots on the surface that will contact the strings. Just hold

the sandpaper against the WHEEL as you spin the axle with the electric drill.

_____39. Now you can install the BRASS CRANK. Start by attaching the WOOD KNOB to one end

of the BRASS CRANK (end with the smaller hole). You may need to cut the mounting screw shorter

with a hack-saw. One customer also recommends placing a scrap of felt as a washer between the

brass and the knob to make the knob turn more smoothly and quietly. I like to put a drop of epoxy

glue on the threads of the knob and leave the screw just slightly loose, so the knob can turn without

coming unscrewed.

______40. Install the other HEX NUT onto the AXLE and turn it down to the BUSHING by hand in

order to take up the play in the AXLE. Place the brass CRANK on the axle, and then screw the

brass CAP NUT against the CRANK. Make sure the axle turns freely, but has very little play in it.

Tighten both nuts to hold the CRANK securely.

BE CAREFUL HERE! Your goal is to tighten the HEX NUT against the CAP NUT, not against

the tail of the instrument. You should end up with a little gap between the instrument and

the HEX NUT.

______41. Install the KEYCHEST LID, using the

HINGES provided. Place the hinges on the "up-

hill" side of the keychest, opposite where the key

buttons will be. The lid will generally remain

closed while playing, making a nice platform on

which to rest your left hand. You will open it for

purposes of installing new strings or adjusting the

intonation of the keys. We recommend cutting a

shallow mortise in the keychest side for the

hinges, as shown.

CAUTION: The tiny screws that come with the

hinges may be a bit too long. To avoid having

them poke through the top surface of the

KEYCHEST LID, sand off the points to shorten

them a bit.

______42. Insert all 12 KEYS into their proper

holes in the KEYCHEST.

______43. Carefully fit all the KEY TANGENTS into the predrilled holes of the KEYS. Note that the

stems of the TANGENTS are tapered, so they become tighter as you push them in.

You want them

to go down far enough so they will not touch the LID when it is closed. Sand the stems of

the TANGENTS if necessary to get them to fit down far enough into the KEYS.

18

Page 19

______44. The KEYS will rattle a bit as

you play. One way to reduce this

extra noise is to put some FELT

PADDING inside the keychest, as

shown. Use a few drops of glue to

hold the FELT in place on the inside

of the KEYCHEST.

______45. Install the four black GEARED TUNERS into the

PEGHEAD, as shown. Notice that the two furthest from the

keychest (closest to the end of the head) must be installed

from the inside of the PEGHEAD, aiming outward for the

drone strings. The other two are installed on the outside of

the PEGHEAD, aiming inward. Yes, it is a bit challenging to

insert the tiny “keeper” screw in the inside. If you cannot

manage that, just tighten the sleeve to hold the GEARED

TUNER from moving.

______46. Use a 1/8” bit to drill a small hole near the point of

each DRONE NUT so the drone strings can be threaded

through the holes.Drill from an angle, as shown, to make sure

the string cannot buzz inside the hole.

The easiest way to figure the correct position for the notch in

the DRONE BRIDGE is to hold a straight-edge against the

WHEEL and the DRONE NUT. File a notch in the DRONE

BRIDGE where the straight-edge crosses it. This will hold the

DRONE string lightly against the WHEEL.

We like to file another notch to the outside of the "playing"

notch on each DRONE BRIDGE, so the string can also be held

away from the WHEEL in the "off" position.

______47. Install the two drone strings (Cello C and G) by

threading them through the holes in the DRONE ANCHOR

BLOCKS and pulling through until the brass ring stops against

the wood. Note these are two different diameter strings. We

like to put the heavier one © on the right side.

19

Page 20

Slide the two nylon bushings over the posts of the tuning gears that show outside of the

PEGHEAD (see photo on step 45), and line up the string holes Thread the drone strings through

the holes drilled in the DRONE NUTS and the GEARED TUNERS on the outside of the PEGHEAD,

as shown. Wind the strings up tightly by turning the GEARED TUNERS. The bushings help ease

the tight winding of these thick strings. You’ll need to cut off a fair amount of string length so you

don’t accumulate too many wraps areound the bushings.

Check to see that the drone strings rest in

the notches of the bridges.

______48. Hold the cake of ROSIN against the

WHEEL and turn the CRANK several revolutions to

apply some rosin to the wheel. The drone strings

should begin to make noise--I mean, music! You

can listen to one at a time if you pull one string

away from the wheel while turning the crank. Tune

these drone strings to the D notes in the bass clef.

This will give you the key of D major (Note: we use

two different size strings here to allow tuning the

th

drones a 4

the key you want).

, 5th or an octave apart, depending on

______49. The strings need some padding to protect them

from wearing thin and to give the rosin a little something

more to bite into as the wheel turns. We provide 100%

cotton balls that work well for that purpose.

Pull a very small amount of cotton from the ball

and hold it near the string as you turn the crank. The

WHEEL should "grab" the fibers and start winding them

around the string as it turns. You want a thin layer of

cotton to cover each string where it contacts the wheel.

Re-tune both drone strings, if necessary, to the proper

notes.

______50. Use a triangle file to put two notches in the

treble bridge, 1" apart. Use a straight-edge (or string)

from the holes at the opposite end of the keychest to your

notches, making sure the strings will pass at least 1/8”

away from the key tangents inside the box (3/16” will be safer). Make these notches deep enough so

the melody strings will just barely contact the wheel. BE CAREFUL NOT TO FILE THESE

NOTCHES TOO DEEPLY, AS IT WILL BE DIFFICULT TO FILL THEM IN LATER IF YOU WISH TO

RAISE THE STRINGS. File a shallower notch to the left of each melody string to be used for the

"off" position.

20

Page 21

______51. Install the Viola melody strings by threading them through the small holes in the TAIL

PIECE, and pulling all the way to the brass rings. Enlarge the holes if necessary to accommodate

the wrapping thread near the ends.

IMPORTANT: THE MELODY STRINGS PASS THROUGH THE MIDDLE OF THE

KEYCHEST. YOU NEED TO TILT THE HURDY GURDY AT AN ANGLE SO THAT THE KEYS

ALL SLIDE AGAINST THE FELT BEFORE INSTALLING THE STRINGS. THAT WILL PUT THE

TANGENTS IN THE PROPER PLAYING POSITION.

Put them into the GEARED TUNERS with the holes on the inside of the PEGHEAD and wind

them up until taut. They should barely touch the wheel, giving a “shisper of sound as you turn the

crank. Too much pressure against the wheel will make them sound harsh.

Tune the two melody strings as shown, for starters. This will give you the key of G major or

E minor (other tunings will give you different major, minor and modal keys -- see chart on page 24).

You can lift off the strings that you don't want to hear by hooking them in the "off" position, as

shown. That way you can tune one string at a time.

Feed a small amount of cotton onto these melody strings too. That will protect them and

make them sound a little louder and sweeter. It will take awhile for the strings to settle in and stay

at the proper pitch. The knots at the tail piece may need to be tied around a scrap of heavy string

or to prevent the knot from pulling into the hole in the wood.

The volume of the strings can be increased in two ways: 1) rub more rosin onto the wheel;

and 2) lower the strings more firmly against the wheel. The second method is easily done by filing

the notches in the bridges in such a way as to hold the strings closer to the WHEEL. Be careful

with the melody strings though. Too much pressure against the wheel causes the higher notes to

sound rough and scratchy.

______52. When the four strings are all playing clearly and in tune, check out the sound of the

KEYS. Pushing a KEY into the KEYCHEST causes the TANGENTS to make contact with both

melody strings at the same time. This shortens the "vibrating length" of the strings, making them

vibrate at a higher frequency (pitch).

The major scale starts on the THIRD KEY, which should make the melody strings sound

exactly an octave above the drone strings when engaged. That is "do" of the scale. Now walk your

fingers up the scale as you move from one key to the next, turning the CRANK all the while. Hold

the instrument at an angle on your lap so the KEYS fall back against the FELT PADDING when you

let them go.

21

Page 22

If any notes sound out of tune, you can correct the pitch by turning the TANGENTS inside

of tailpiece, so it does not interfere with crank

the KEYCHEST. Turning them toward the WHEEL will raise the pitch, and vice versa. Make sure

to adjust both TANGENTS on a key identically, so they make the two melody strings sound the

same pitch.

The notes that are most fussy are those nearest the wheel. A slight change in the

TANGENTS will make quite a difference in pitch.

NOTE: Sometimes, even after very careful construction, we find the upper melody notes wavering a

little in pitch as the wheel is turned. Consult the CARE AND FEEDING suggestions at the end of

these instructions for more help.

FURTHER HINT: Customers have occasionally thought that the key placement must be off

because all the notes are considerably out of tune. This is usually caused by having too much

cotton on the strings. A bulky wad of cotton somehow hampers the vibration of the string,

causing inaccurate tuning, so keep the cotton to a minimum.

______53. When satisfied with the sound, install the WHEEL COVER by wedging it between the

two WHEEL COVER BLOCKS. It should be held firmly in place without need for glue, but

sometimes we add felt to the inside edge of each COVER BLOCK to achieve a more secure grip.

One manufacturer also adds a string to tie the COVER to one of the COVER BLOCKS so you don’t

lose the thing or inadvertently leave it behind somewhere.

DIFFERENT TUNINGS:

Key Tuning Heavy Drone Light Drone Melody Pair Position Of "Do"

F major CFC Low C F below middle C middle C 3rd Key

D major DDA Low D Low D A below middle C 3rd Key

A major EAE Low E A below middle C E above middle C 3rd Key

D Aeolian (minor) DAC Low D A below middle C middle C 1st Key

G Dorian DGC Low D G below middle C middle C 4th Key

CONGRATULATIONS! You have assembled one of our more complex musical instruments.

This instrument is easier to play if you

add a strap or belt to help hold it on

your lap. Attach the ends to the HEEL

and TAIL of the Hurdy Gurdy, making

sure that the strap does not interfere

with the operation of the crank. We

offer an adjustable strap with two

mounting buttons:

STRAP-2 Strap with 2 buttons

Install strap button 3/4" off the edge

3/4"

22

Page 23

CARE AND FEEDING OF YOUR HURDY GURDY

You should know that this can be a cranky instrument (pun intended).

Don't be surprised if it requires a bit of tuning and adjustment every time

you play it. Here are some hints to help you work out the excessive squeaks

and squawks:

GENERAL THEORY OF ROSIN APPLICATION: Too little rosin makes a weak

sound, too much rosin causes chatters and squawks. We just hold the cake

of rosin against the wheel while turning the crank about a dozen

revolutions, and that usually suffices for initial application. After

applying the rosin, hold a smooth block of wood against the wheel while

turning the crank. This burnishes the rosin and polishes the surface of

the wheel. A highly polished wheel makes the sweetest sound.

COTTON-PATCH COROLLARY: We find it best to be minimalistic with cotton

-- just enough to pad the string where it contacts the wheel. It is also

good to check the cotton occasionally for clumps of rosin that cause the

string to jump and chatter against the wheel. In other words, change your

cotton frequently and often, especially after adding rosin to the wheel.

STICKY KEY SYNDROME: Remember, you must hold the instrument at an

angle while playing so the keys will fall away from the strings after being

played. Make sure the keys slide freely enough to fall away when you let

go after playing a note. If the key tangents hang up close to the string,

they will interfere with the vibration, causing high-pitched harmonics

instead of the notes you want to hear.

STRING ACTION AXIOM: The big question is how deep to cut the notches

in the bridges to obtain the proper pressure of strings against the wheel.

The drone strings are not so fussy -- we like fairly good pressure on

those. But the melody strings can be tricky. The highest notes won’t play

well if the strings press too firmly against the wheel. If you need to

raise a melody string, glue a sliver of wood in the notch under it.

CHILD'S-PLAY POSTULATION: The more the kids abuse this thing, the

better it starts to sound! Honestly, we find that our display model

instrument that gets cranked by every child who walks into the store is the

one that sounds the best. But it takes awhile to get "broken in." Our

best suggestion is to hire a youngster to sit out behind the barn and

serenade the cows for a few days.

Thanks again for your patronage, your patience, and your sense of humor.

With your help we can re-populate the street corners of the world with

hurdy-gurdy players! Heaven help us....

23

Page 24

Musicmakers

PO Box 2117

Stillwater, MN 55082

www.harpkit.com

24

Loading...

Loading...