Page 1

DAKOTA MANDOLA KIT

651-439-9120

harpkit.com

Page 2

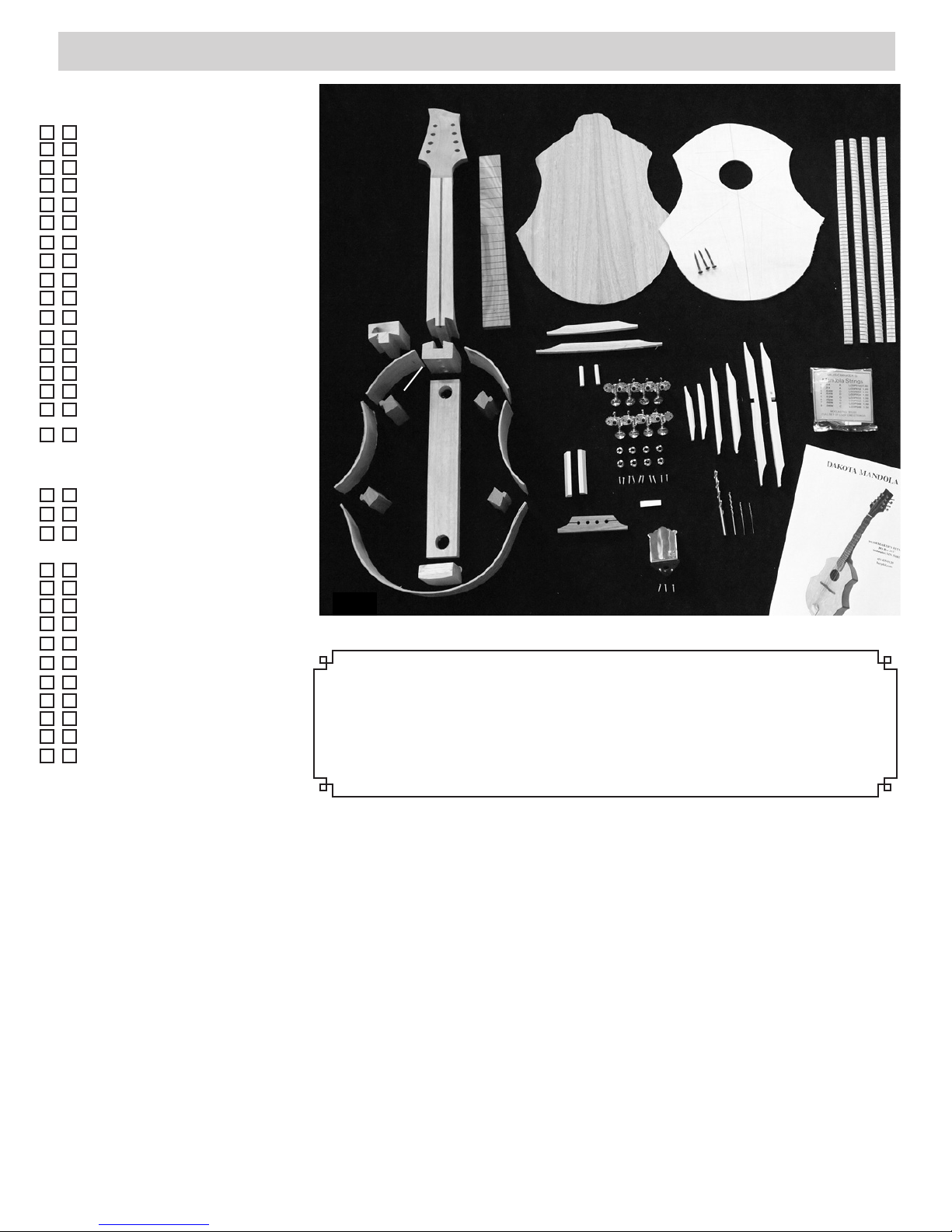

WOOD PARTS:

A - Neck

B - Fingerboard

C - Heel Block

D - Tail Block

E - Clamping Block

F - 2 Short Ribs

G - 4 Corner Blocks

H - 2 Mid-Ribs

I - Long Tail Rib

J - 2 Dowels, 1/4” X 1”

K - 2 Clamping Wedges

L - Back

M - 2 Braces for Back

N - Front (Soundboard)

O - 5 Braces for Front

P - Bridge

Q - Spacer Block (11”)

HARDWARE:

40” Fretwire

1 White Side Marker Rod, 5/64”

8 Gold Geared Tuners

w/bushings & 10 screws

Set of Mandola Strings

Tailpiece w/3 screws

White Nut Material

3 Wood Screws, 1

2 Tiny Nails

Drill Bit, 1/16” for tiny screws

Drill Bit, 5/64” for Marking Dots

Drill Bit, 7/64” for wood screws

Drill Bit, 1/4” for dowels

Medium Donut Ring

Assembly Instructions

-5/8”

DAKOTA MANDOLA KIT

Q

L

M

J

K

P

H

fig 1

A

B

E

F

C

G

Q

G

F

G

H

G

I

D

CUSTOMIZING OPTIONS

If you are an enterprising woodworker who wants to make this project special with

some sort of decorations, here are some ideas for you to think about. You may want

to order decorative materials now so you have them when you need them.

1 Medium Wood Rosette for the Soundhole, with Donut Ring

4 strips of Inlay Banding for trimming the Front and Back

N

O

We recommend assembling this kit with standard woodworker’s glue (such as Elmer’s Carpenters Glue or Titebond Wood

Glue). Don’t use Hotmelt glue, Superglue, 5-minute Epoxy, or the plain white School Glue for assembling the major wood

parts -- they are not strong enough for a high-tension instrument. There is no need to look for any special violin-maker’s adhesive. You may, however, see epoxy or superglue recommended in one or two steps for installing non-wood parts.

Every time you use wood glue on this project, it is wise to have a damp rag handy for cleaning up afterwards. It is always best

to scrub away any excess glue that squeezes out of the joints before it dries, especially on the outside of the instrument. Keep

your hands and workbench as clean as possible too. Glue smudges will show up vividly on the finished instrument.

ASSEMBLY INSTRUCTIONS

_____1. CAUTION: PLEASE DO NOT OPEN THE SEALED PLASTIC BAG CONTAINING THE FRONT

AND BACK PANELS UNTIL YOU REACH STEP #14. These two parts need to be kept very dry until you glue

the braces on them. Check over your kit parts to make sure you have everything (see fig. 1 above). Contact us right

away if you are missing parts so we can rectify the problem without causing too much delay for you. We also recommend checking off each step in the directions as you finish it. You might be skipping forward to another part of the

assembly while waiting for something to dry, and it helps to keep track of where you left off.

A NOTE ABOUT GLUE

2.

Page 3

GLUING THE BODY FRAME

Tools Required for This Stage

Masking Tape Small C -clamps Cordless Hand Drill

Plastic Grocery Bag Spring Clamps Phillips Driver Bit

Wood Glue Damp Rag 7/64” Drill Bit

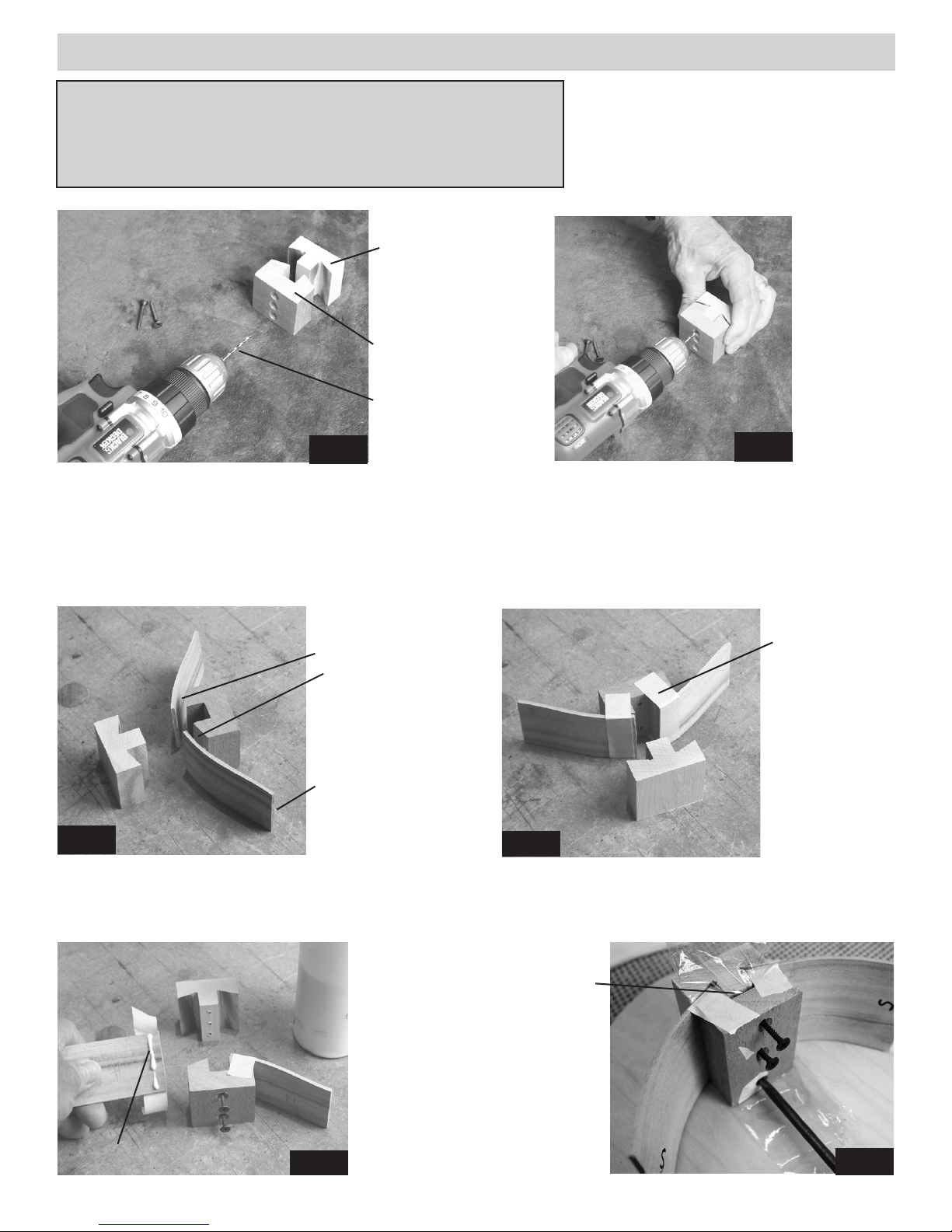

_____2. Begin at the heel where the

body will join the neck. Place the heel

block and the clamping block together

and drill two pilot holes into the clamping block using the 7/64” drill bit provided, as shown in figures 2a and 2b..

clamping block

Hold blocks

carefully on

a flat sur-

face so they

are flush

heel block

with each

other as you

7/64” drill bit

drill pilot

holes.

fig 2a

fig 2b

_____3. Find the two short ribs and look carefully for pencil markings that show “H” at one end. ese are the

ends that get glued to the heel block. Orient these pieces carefully: e end of each piece marked “H” will be

clamped against the heel block with the pencil marks facing the inside of the body (g 3a).

Tape the two short ribs to the heel block WITHOUT GLUE rst, and test the shape against the soundboard (front

piece) of the instrument. It is possible to fasten these pieces backwards and have them ared the wrong way!

short ribs

with “H”

Masking Tape

marks

fig 3a

against

heel block

“S” mark

at free end

fig 3b

Tape the short

ribs in place

WITHOUT

GLUE first.

Test the shape

to make sure it

matches the shape

of the sound-

board.

_____4. When everything checks out, put glue on the end of each short rib and tape them carefully back against heel

block as shown in fig 4a.

CAUTION: Don’t glue the

clamping block to this assembly! Put a thin plastic

barrier between the clamping block and the heel block

so you can remove the

clamping block later.

Wood Glue

fig 4a

Install the screws into the

clamping block to draw parts

firmly together until the glue

dries (fig 4b).

3.

Plastic

Bag Scrap

fig 4b

Page 4

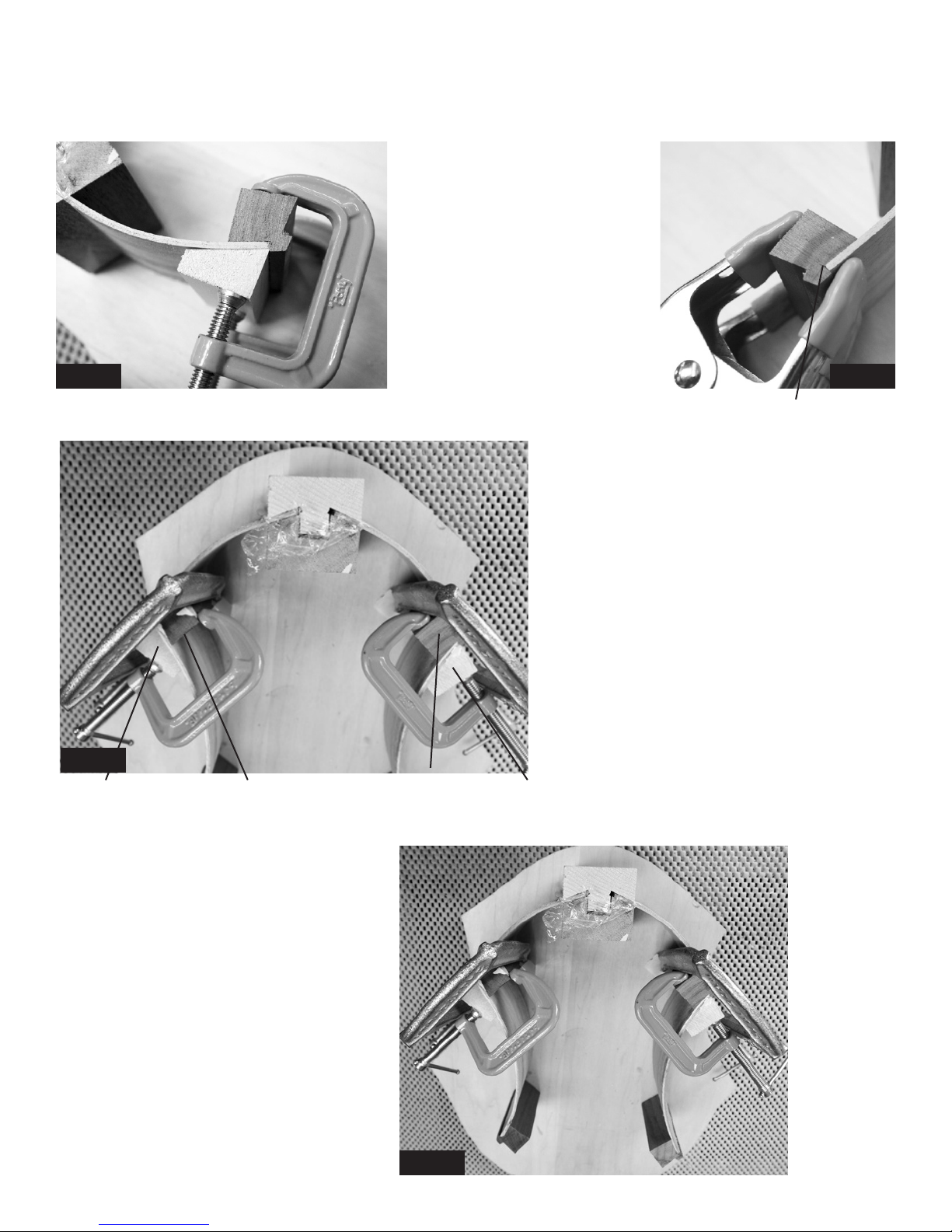

_____5. Find the 4 corner blocks. These are all the same, so they are interchangeable. Test-fit a corner to one of

the short ribs without glue to make sure your clamp will hold it firmly in place (fig 5a). We have included a couple

clamping wedges made of scrap wood in case you need them. When satisfied with the fit, glue and clamp a corner

to each short rib, making sure the rib fits all the way into the corner of the ledge (fig 5b).

Allow at least 30 minutes drying time.

After the corners are dry, you

can remove the clamps. You

can also remove the screws

holding the clamping block to

the heel block.

fig 5a fig 5b

tight fit

_____6. Now you can glue the two mid-ribs

into the corners. These ribs should flare outward, as shown (fig 6). They are symmetrical,

so it does not matter which end you glue to the

first corners. Notice the use of clamping wedges to make it easier to clamp the parts together.

fig 6

corner blockclamping wedge

_____7. Continue by gluing the next two

corner blocks at the open ends of the midribs, as shown (fig 7).

corner block

CAUTION: It’s possible to glue these parts

together crooked! Make sure all the parts are

pushed firmly into the corner blocks, that the

parts remain flush with each other, and that the

entire assembly remains flat. Lift the assembly

up and look carefully at each seam to make sure

it is tightly fit. Also make sure the whole assembly will lay on your flat work surface without rocking.

clamping wedge

fig 7

4.

Page 5

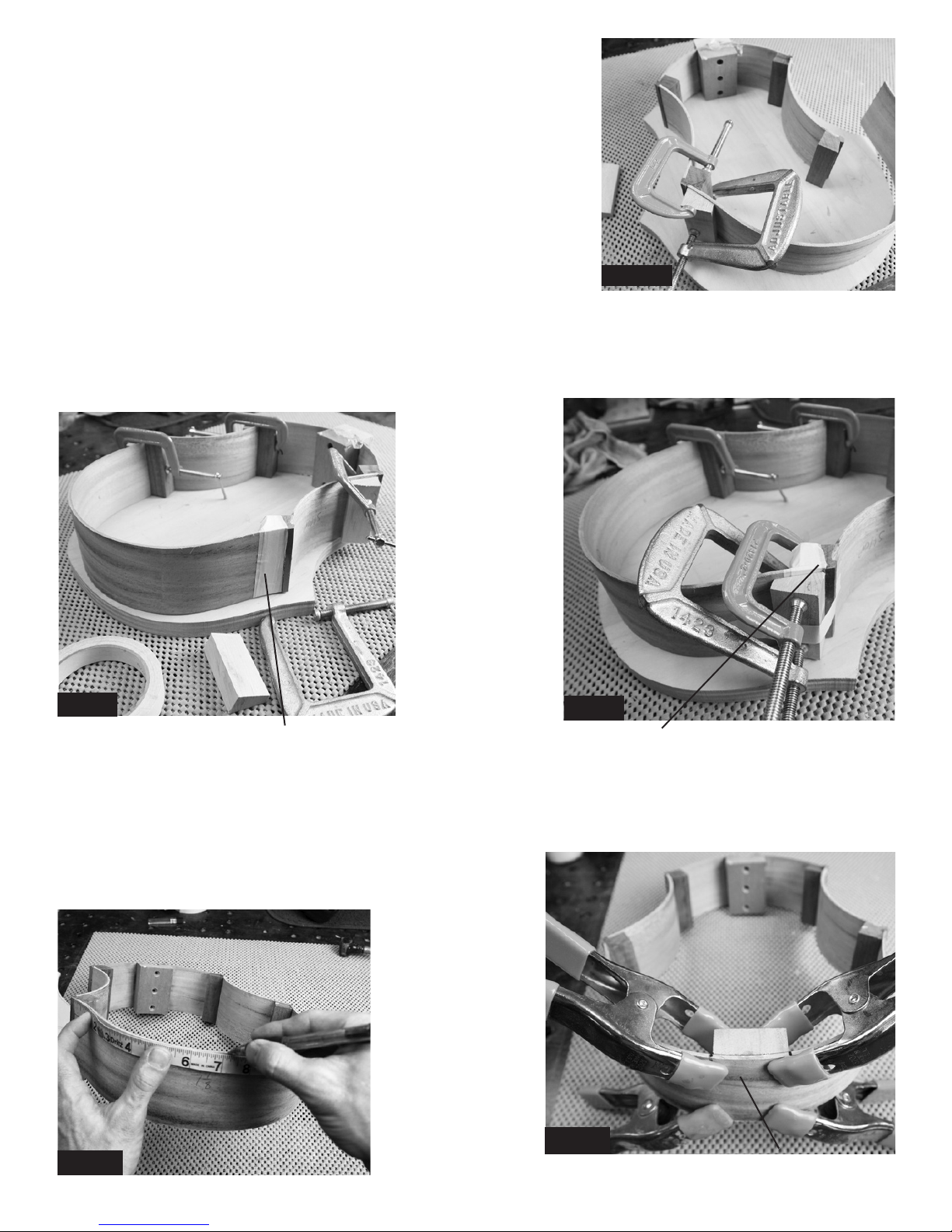

_____8. Glue just one end of the long tail rib to one corner block, as

shown (fig 8). Let the entire assembly dry overnight (or 8 hours) before

proceeding to close the frame. If you proceed too quickly, the glue is

likely to break at one or more of the corners. It takes about 8 hours for

most woodworking glue to harden completely.

While you are waiting for this assembly to dry, you can skip to step #34

(page 15) and begin shaping the neck and peghead.

_____9. When this assembly has fully dried, you can use masking tape to

pull the final corner together roughly (fig 9a). Do this WITHOUT GLUE

first, just to make sure everything works easily for you, and no corner blocks

break free.

fig 8

Tape a clamping wedge to the joint and and then add your clamp, as shown in fig 9b, still without glue.

If the joint comes together correctly, then remove the clamp and tape so you can repeat the process with glue. Allow

this joint to dry another 8 hours (because it is under tension).

While waiting for

this last corner

to dry, go back

to shaping the

neck -- it’s good

to spend time

smoothing it to

fit your hand.

fig 9a

masking tape

fig 9b

nice tight glue joint

_____10. When dry enough to remove the last clamp, measure 7-3/8” from each end of the large curved rib and

mark it for locating the tail block (fig. 10a). Please note that this may not look exactly centered at this point because

the frame may be slightly skewed one way or the other. You’ll straighten it in the next step. Glue and clamp the tail

block in place as shown in fig 10b.

fig 10a

Center the

tail block

between

your

marks.

fig 10b

tail block

5.

Page 6

_____11. Now you need to stretch the frame a little to fit the spacer

block between the heel and tail, as shown in fig 11. DO NOT GLUE

THE SPACER! This is just a temporary piece to hold the instrument

in the proper shape until you glue the soundboard in place. You will

remove it in step #25. Use clamps to hold each end if necessary.

ADDING INNER KERFING

Spacer Block

NO GLUE!

Tools Required for This Stage

Lots of Spring Clothes Pins (or Small Spring Clamps)

Rubber Bands, i f needed

Wood Glue

Damp Rag

Sanding Block, 60-80 grit (see fig 13 below)

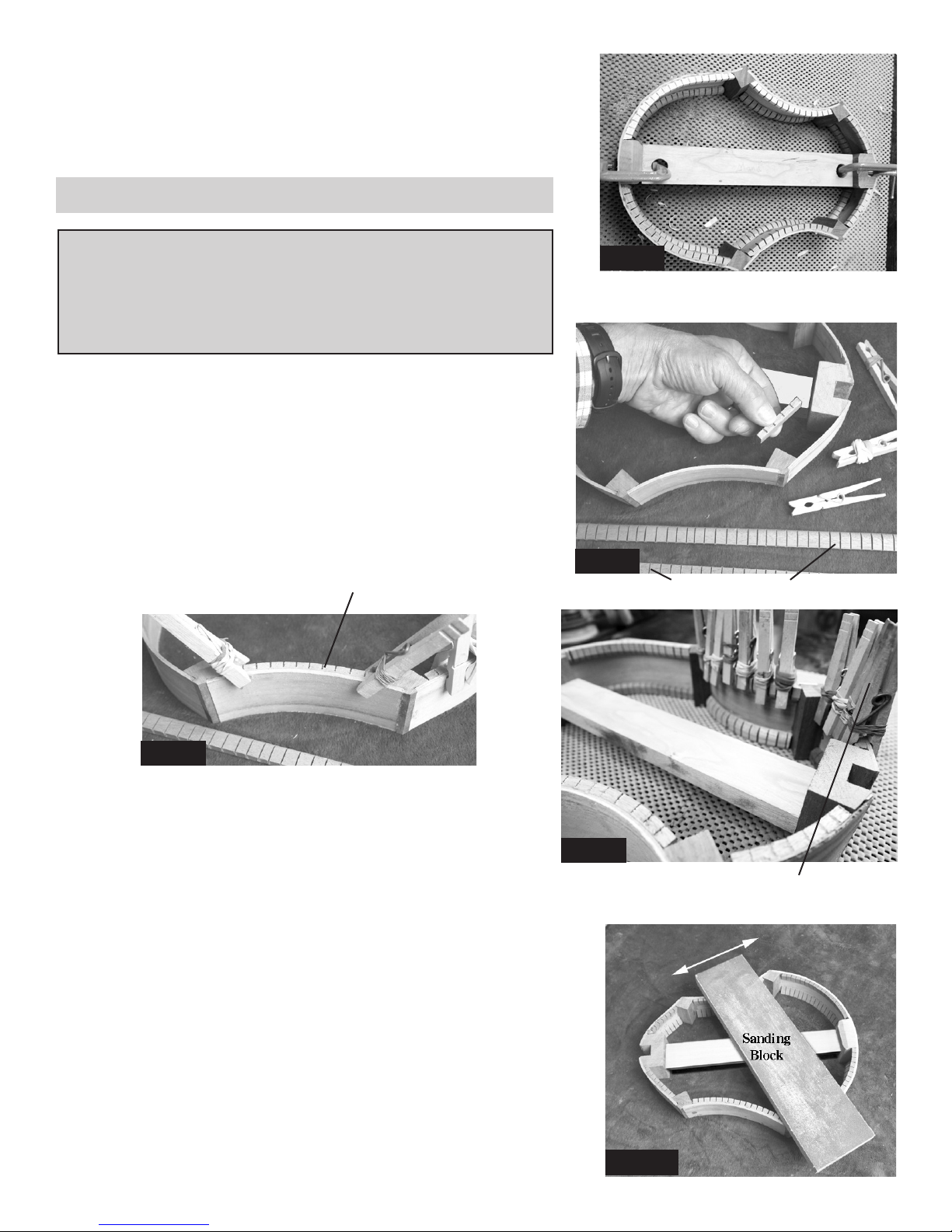

_____12. Add inner kerfing inside the ribs to provide a wider “shelf”

of wood for gluing the front and back panels to the frame. These

wood strips are “kerfed” to make them flexible enough to follow the

curved ribs.

Cut or break the kerfing into the approximate size needed for each

space -- it does not need to fit perfectly (fig. 12a). In fact, it is easier

if you cut it slightly shorter than the space so you can easily slide it

into position.

kerfing flush with edge of rib, or slightly higher

fig 11

fig 12a

kerfing strips

fig 12b

CAUTION: FLAT EDGE UP! Pay attention to how you orient the

kerfing strips (fig 12b). Keep the flat edge flush with the edge of

the rib, or a tad higher, and wipe off excess glue with a damp rag.

Try to keep glue off the outside of the ribs, as that will show on the

finished instrument.

Glue and clamp kerfing in place using clothes pins or small spring

clamps (fig 12c). It may be helpful to add rubber bands to your

clamps to increase clamping pressure. Allow at least 30 minutes

for drying before removing clamps.

Glue kerfing around the entire inside frame, on both front and back edges,

as shown in fig 12c.

_____13. When the kerfing is dry, make yourself a long sanding block by

gluing 60 or 80 grit paper to the face of a straight scrap of wood at least

12 inches long and 3 or 4 inches wide.

This type of sanding block will rest across the frame of the body, allowing

you to sand the edges perfectly flat (fig 13). The goal is to remove glue

blobs and to sand any high spots down flush with the ribs.

fig 12c

use plenty of clamps

fig 13

6.

Page 7

PREPARING THE BACK PANEL

Tools Required for This Stage

Pencil Spring Clamps

Wood Glue Chisel or Razor Knife

Damp Rag MaskingTape

_____14. NOW YOU CAN OPEN THE SEALED BAG AND REMOVE

THE BACK PANEL (DARKER MAHOGANY PIECE). IF YOU ARE

WORKING IN A HUMID ENVIRONMENT, PLEASE STORE THE

FRONT PIECE (SOUNDBOARD) IN AN AIR-CONDITIONED (DE-

HUMIDIFIED) PLACE UNTIL YOU GET TO STEP #16.

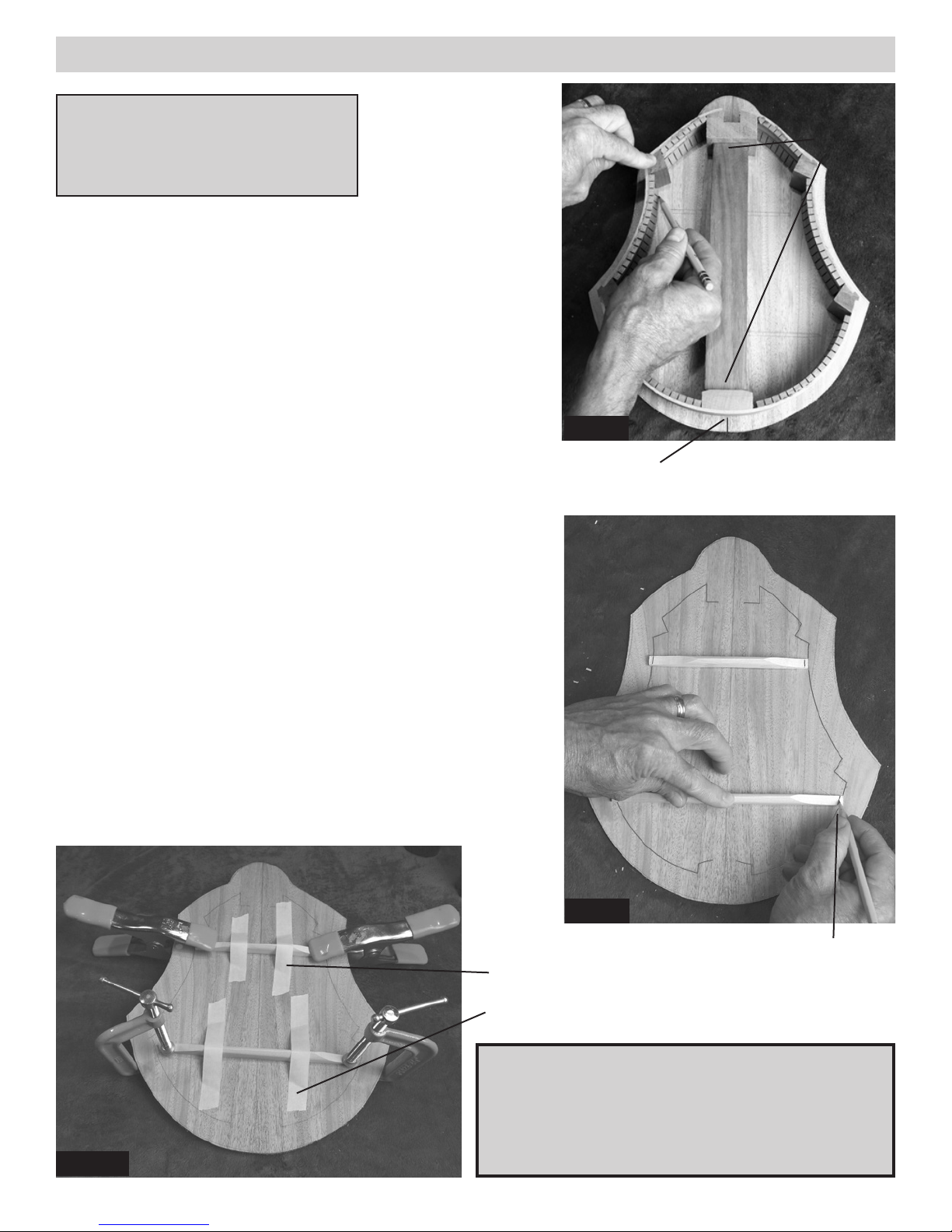

Center the frame of the instrument on the inside face of the back panel

and outline the inside edges onto the back panel with a pencil, as shown

in fig 14a. Note the center lines at each end of this panel, and the two

horizontal lines marking the positions of the inner braces.

Once you have the outline of the instrument on the back panel, you can

position the two back braces over the lines marked and check how they

fit. If they cross your outline, mark where to trim them so they will not

interfere with the kerfing strips inside the frame (fig 14b).

NOTE: The two back braces are arched on the bottom so that when

you clamp them to the back, the back will become arched.

NO GLUE

ON

SPACER

spacer block

fig 14a

center line

Use a sharp chisel or razor knife to trim the braces to length. Note:

Some builders may prefer to cut little “pockets” (notches) in the kerfing

to receive the ends of the braces. That is the more professional method of

fitting, but it is more difficult than trimming the braces shorter.

Then you can glue the braces in place, taking care to keep them from sliding out of position under clamping pressure.

HINT: Use masking tape to hold the braces in place while you put a

clamp at each end (Fig 14c). This will produce an arched back because

of the curve in the braces. Double-check the middle to see if you might

need to add some weight in the center to achieve a firm glue joint along

the entire brace. You can prop the back on a block of wood to support

the middle, and then add weights to the center of the braces, if necessary.

Use tape to keep

braces from

slipping out

of position when

adding clamps.

fig 14b

Mark and cut

braces to length.

fig 14c

CAUTION: Don’t glue the back to the frame yet!

We glue the soundboard in place first (next page).

Store the back panel in an air-conditioned space until

you need it again near the end of the project. That’s

when you will close the box by installing the back.

7.

Page 8

PREPARING THE FRONT (SOUNDBOARD)

Tools Required for This Stage

Pencil Spring Clamps

Wood Glue Chisel or Razor Knife

Damp Rag MaskingTape

Sandpaper (60-80 grit)

Pencil

Outline

fig 16

Notice the Center Lines!

fig 17a

_____15. We highly recommend making

yourself a clamping pad for the body of the

instrument out of 3/4 plywood or particle

Clamping Pad

3/4” thick

board (fig 15). Cut it at least the size of the

soundboard, or a little larger.

fig 15

IMPORTANT NOTE ABOUT SOUNDBOARD

The front panel (soundboard) is the lighter colored piece made of solid Sitka Spruce,

and has a sound hole cut through it. If this panel has been exposed to high humidity

for more than a few hours, you will need to dry it out in an air-conditioned (dehumidified) room for a few days to shrink the grain. This will help prevent cracks

from developing in the future. Hint: Another easy way to dry it out is to place it in

the oven at low heat (200 degrees) for 6-8 hours. Put clean tin foil under it to protect it

from any grease on the rack.

_____16. The inside face has pencil marks showing the placement of the braces.

Place it on your work table with the inside facing up.

Center the frame of the instrument on the soundboard and outline the interior in

pencil (fig 16), just as you did for the back panel. Make certain the frame is centered in relation to the sound hole and the tail end. Slide the frame up toward

the top of the panel to make sure there will be room for the top brace and

the “donut” for the rosette.

_____17. (OPTIONAL)

If you purchased

a decorative rosette for the sound hole, you’ll

need to glue a “donut ring” (fig 17a) inside the

sound hole now to provide a ledge for gluing the

rosette in place. It is easiest to see the correct

position of the donut ring if you look from the

outer face of the sound board (fig 17b). Glue

this ring to the inside of the soundboard now,

before installing the braces.

fig 17b

THIS

fig 18a

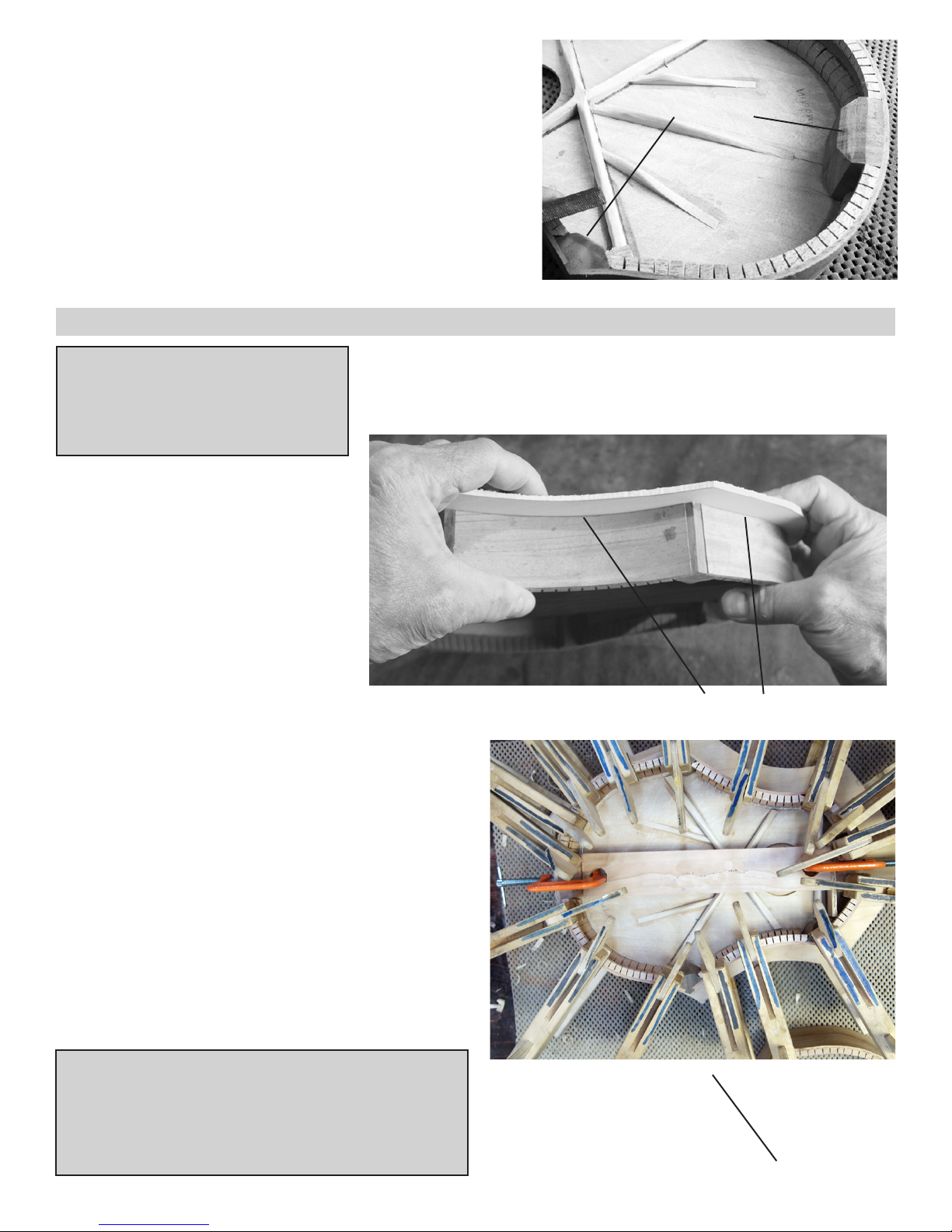

_____19. Position the X braces in place first, without glue,

and then arrange the three shorter ones as shown in fig. 19.

Trim the ends that are too long, just as you did for the back

panel.

When satisfied with the fit, glue and clamp the X braces in

place first, making sure to put glue in the joint where they

cross. Use clamps and/or weights to hold the X braces in

place firmly.

fig 19

When the X braces are dry, go ahead and glue the other

small braces too, as shown in fig 19.

NOT THIS

_____18. Find the two braces that are notched to fit

together forming an “X” (figs. 18a & 18b). These can

be joined two different ways, and we want the longer

legs to be spread as wide as they can go (fig 18a).

This will give you the maximum bracing strength on

the soundboard. Test fit the X to the soundboard, just

to be sure you have it correct.

fig 18b

fig 20a

8.

Page 9

_____20. Now you can taper the edges of the X-braces if you like,

using a chisel, coarse sandpaper or a sharp knife (fig 20a). We recommend leaving the braces full height for stability, but you can bevel the

“shoulders” to lighten them up a little. A lightweight soundboard will

sound the best.

We also like to chamfer (bevel) the inside corners of the corner blocks

and the tail block (but NOT the heel block) to give the soundboard a

little more room to vibrate (fig 20b). Basically, we like to have about

the same amount of glue surface at each corner as there is on the kerfing strips. Us a file or coarse sanding block to do this on both sides

(front and back) of the frame to achieve the best sound.

GLUING FRONT (SOUNDBOARD) TO FRAME

Tools Required for This Stage

Pencil 6 Clamps (minimum)

Wood Glue Damp Rag

Clamping Pad

_____22. Test fit the soundboard to the

frame, looking carefully around the entire

circumference to make sure the soundboard will make good tight contact with

the edges of the ribs all the way around

(fig 22).

NOTE: There is no front or back to the frame until you glue the front to

one edge, so you can choose either edge.

cham fered blocks

fig 20b

If you find a blob of glue or other irregularity or unevenness that prevents a

tight fit, go back to step 12 and use your

coarse sanding block to level off the edg-

fig 22

es of the ribs.

_____23. Continue test-fitting the frame to the soundboard WITHOUT GLUE, carefully lining it up on the

center of the soundboard. Leave the spacer block in place

for this step so the body maintains the proper length and

shape (fig 23).

Take your time here. Darken the center lines on each

part, if necessary, so you can easily see when the frame is

centered on the front panel.

Outline the outside of the frame on the soundboard

in pencil when you have it positioned where you want

it. This will help you re-position quickly when gluing.

Make sure you have enough clamps to do the gluing job

shown in step 24 -- test them to make sure they open far

enough and reach in far enough to press the frame down.

Tight fit when pressed together

DRY FIT

FRAME

TO

SOUND

BOARD

NOTE: We always clamp the frame down against the soundboard, as shown here, rather than placing the soundboard on top

of the frame. This leaves everything open and visible while you

install the clamps so you double-check for proper alignment as

you work. It also ensures that whatever excess glue squeezes out

around the edges will not run down the outside surface of the ribs

and make a big mess to clean up.

fig 23

Line up centerlines

9.

Page 10

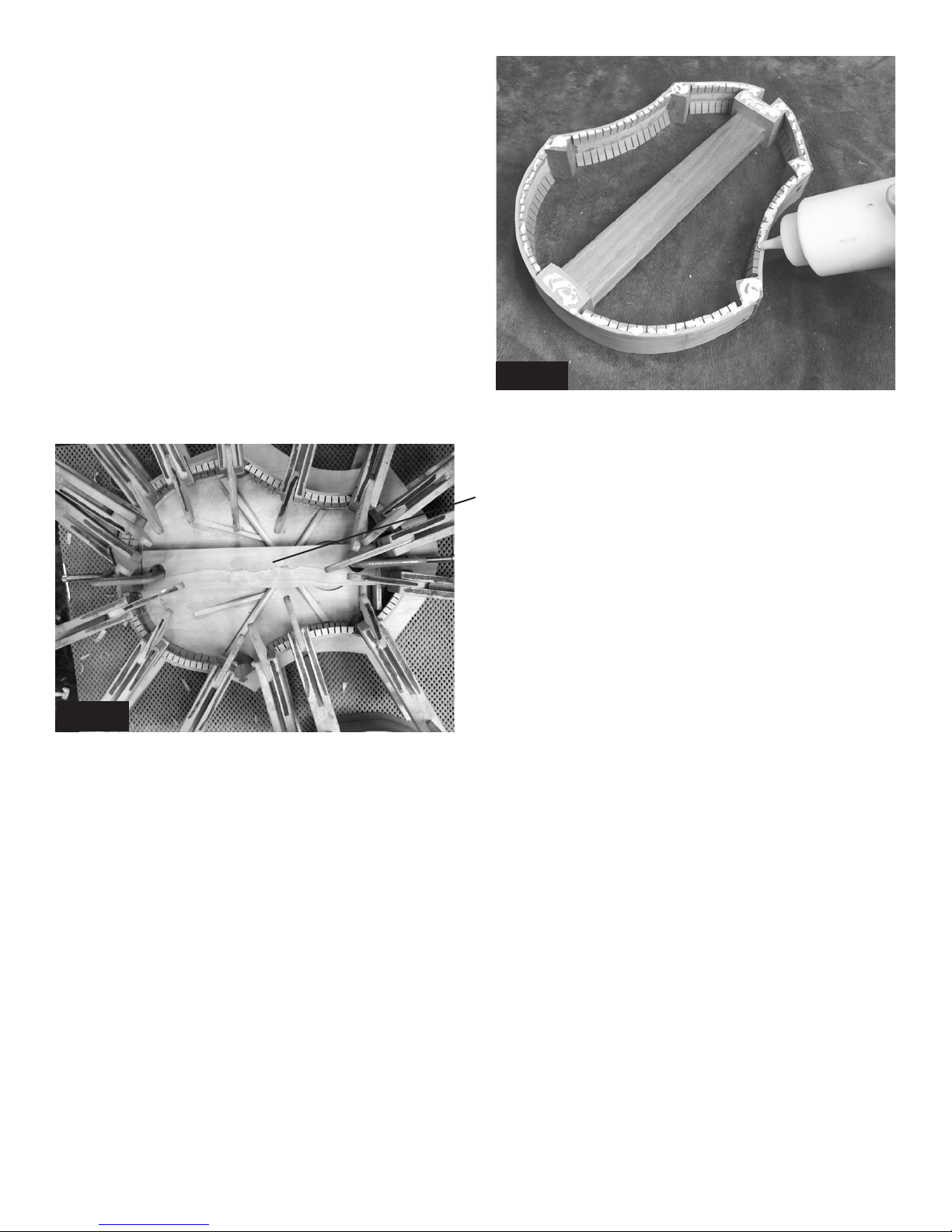

_____24. When you are ready to proceed, squirt a good

bead of glue all the way around the frame, including the

corner blocks, heel block and tail block, as shown in figure

24a. You want enough glue so that a little excess will

squeeze out when the parts are clamped.

Then flip the frame upside down and replace it over the

soundboard within the outline you drew in step 23.

Clamp the heel and tail ends first, making sure the centerlines match up. Then put a clamp on each corner piece,

as a minimum (fig 24b). If you see areas that need more

pressure, add more clamps.

Allow 2 hours for drying before removing clamps.

fig 24a

_____25. When this assembly has dried, remove the

spacer block and save it for later (Step 41).

_____26. Trimming the excess soundboard material flush

with the ribs of the instrument requires some special care.

DO NOT attempt to cut off the overhang with a hand-held

jigsaw or a coarse hand saw. The spruce wood is fragile,

so you must work it carefully.

There are several possible tools for this delicate step, and

we’ll try to give you some guidance for whichever one

you might have available. If you don’t have any of these

fig 24b

tools, this is a great excuse to go out and buy something!

OPTION #1: HAND COPING SAW -- If you are working with just hand tools, a cheap coping saw will cut the

excess soundboard very easily. We recommend trimming a little wide, leaving 1/8” or so overhang that can easily

be sanding down flush.

OPTION #2: BAND SAW -- If you have a bandsaw available, it will do this job very quickly. But be very careful

not to cut into the frame of the instrument. A band saw could ruin the whole project in the blink of an eye!

OPTION #3: BELT SANDER -- If you have a stationary belt sander, you can sand away the excess soundboard

material quite easily. But take care to prevent sanding too deeply -- you could gouge the frame if you are not

watching closely.

OPTION #4: ROUTER (figs 26a & 26b): This is our preferred trimming tool because it is fast, safe and accurate.

Take care, however, to move the router in a clockwise direction around the soundboard (fig 26-b). This is called a

“climb cut” because the router bit is pulling the machine that same direction, “climbing” through the wood. If you

push the router against the spin of the bit, you will likely chip the soft wood and cause damage to the edges. You

don’t need a large router for this step, but you can certainly use a larger one than shown here.

10.

Page 11

Flush-trim bit

Router

fig 26a

fig 26e

Roller bearing follows ribs

fig 26b

Move router clockwise around instrument, as shown.

SANDING BLOCKS

Please note that however you trim the soundboard, you will still

need to do some careful hand sanding to finish the job. Thankfully, spruce is soft, so it sands quickly with a sanding block.

We recommend gluing sandpaper to a flat piece of wood for

sanding the outside curves and taping some sandpaper around a

curved item (like a can) for sanding the inside curves (fig 26e).

Use coarse sandpaper (60-80 grit) for removing excess wood,

and then 100-150 grit for smoothing.

Sand the remaining excess soundboard flush with the sides of the

body, as shown in figs 26f and 26g. Make sure the corner blocks

are flush and smooth with the ribs too.

fig 26f

fig 26g

Sand walnut corner blocks flush

and smooth too.

CAUTION:

ful to keep the heel

square to the top when

you are sanding (fig

26h). This will be very

important when fitting

the neck and fretboard

in place later.

Be care-

11.

Square

fig 26h

Page 12

_____ 27. Use a flat file or razor knife to finish cleaning out the notch in the heel block, as shown in figures 27a and

27b. Note how we beveled the edges of the spruce top (fig 27b). This will help make sure the neck seats fully into

the mortise slot.

beveled

edges on

spruce top

fig 27a fig 27b

OPTIONAL DECORATION: INLAY BANDING

Tools Required for This Stage

Pencil Razor Knife or Chisel Wood Glue Masking Tape

Router Inlay Bit Damp Rag Sandpaper (150 grit)

Wire Cutter

_____28. If you wish to decorate the edges of the soundboard all around the top of the

instrument, you will need a router with a small straight bit that can cut a ledge for the inlay strips. A nice inexpensive way to do this is to adapt a 1/2” flush-trim router bit with

a 3/8” diameter roller bearing, so the cutters extend 1/16” beyond the roller, as shown

in figure 28a. We have these router bits and bearings available on our website at www.

harpkit.com/inlays.

When you put this bit into your router, you only want the cutting edge to be as far above

the router base as the width of your inlay banding (fig 28b).

Be sure to test your cut on a piece of scrap wood first! The router bearing should follow

the edge of the wood, and the cutting blades should make a shallow ledge just the right

size for the inlay strip (fig 28c).

Inlay Bit

fig 28a

fig 28b

fig 28c

12.

Page 13

_____29. When satisfied with the depth of your cut, you can rout a

ledge around the circumference of instrument. Make sure to move

the router in a CLOCKWISE direction, just as you did when flush

trimming the spruce soundboard (fig 29).

If your inlay banding is more than 1/8” wide, you will be cutting

into the mahogany ribs too. That’s just fine. There’s plenty of

thickness available, and the inner kerfing strips add extra strength

to these edges also.

fig 29

_____30. Once the ledge is cleanly cut all the way around the perimeter, you can begin to install the inlay strips in

short sections that are mitered at the corner blocks, as shown in figs 30a and 30b).

Use a sharpened pencil to mark where to cut the strip, drawing the line at an angle that approximately bisects the

corner, as shown in fig 30b.

fig 30a fig 30b

_____31. Cut the strip a little beyond your mark (fig 31a), then use a razor knife or sharp chisel to make a more

precise cut on the line (fig 31b). If you need to change the angle a little or shave it a hair shorter, do that on a sanding

block, as shown in fig 31c.

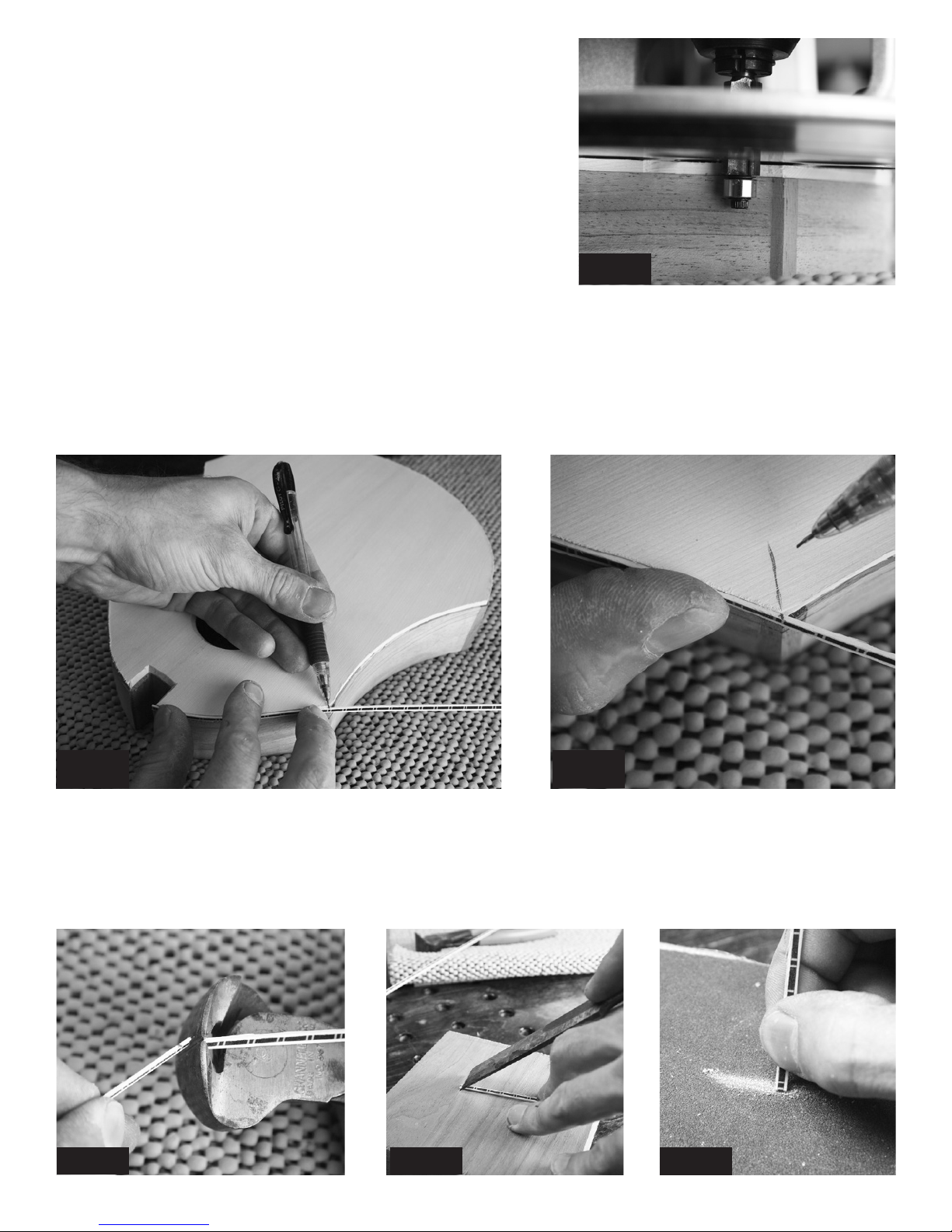

fig 31a fig 31b fig 31c

13.

Page 14

_____32. When you have the first strip ready to install, squirt a thin bead of woodworker’s glue into just that short

section of the ledge where the strip will fit (fig 32a). Use masking tape to hold the strip tightly in place, as shown in

fig 32b.

HINT: Pretend the masking tape is elastic -- pull the tape both ways as you press it down against the wood.

This will pull the inlay strip all the way into the ledge.

fig 32a

fig 32b

_____33. Now you can fit the next piece of inlay in place, as shown in fig 33a. Notice the pattern of your inlay band-

ing -- your inlays will look the most professional if you trim the end of the second strip to continue the pattern of the

first strip (fig 33b). You can make this decoration appear to be seemless if you are careful and patient.

Continue around the instrument in this way, leaving

the tape in place for 8 hours before removing. Note

that the neck and fingerboard will cover the ends at

the heel block, so the strips can stop slightly short of

the mortise slot (fig 33c).

Once dry, you’ll want to remove the tape and sand

the edges clean and smooth, making sure to remove

all excess glue that squeezed out around the inlay

strips. Don’t worry about sanding the inlay strips

themselves. The colors go all the way through, so

you can clean them up and smooth the surface without removing the pattern. Just don’t sand too aggressively on the inlay strips -- they are less than

fig 33a

1/16” thick!

fig 33b

fig 33c

14.

Page 15

PREPARING THE FINGERBOARD

A NOTE ABOUT FRET MARKING DOTS

This kit comes with side markers that you will install along one edge of the fingerboard later (step 58),

but we also offer mother-of-pearl dots in our catalog (the 5 mm size is best for a mandolin). If you want to

inlay fret-marking dots on the front of the fingerboard, you should do that now, before installing the frets.

_____34. We like cutting the wide end of the fingerboard to make it more interesting, but you can leave it square.

Figure 34 shows some other options that are common for mandolin fingerboards. The simplest option is to cut a 3”

diameter arc, as shown at left, to mirror the shape of the soundhole. You can use a soup can as a pattern for that.

Make the cuts with a bandsaw and

then smooth out the edges with

sandpaper.

NOTE: Before installing frets, take

time to make sure the face of the

fretboard is nice and smooth. Sand

with progressively finer sandpaper,

starting with about 180 or 220 grit.

We go all the way to 600 grit to polish the rosewood nicely. You won’t

be applying finish to the playing surface, so this is your chance to shine

it up nicely.

fig 34

_____35. Trim your fretwire a little longer than necessary to reach across

the fingerboard (fig 35a). Then use a light hammer to tap the fret into the

slot (figs 35b & 35c).

HINT: It helps to place the fingerboard on a very solid surface, such as an

anvil or a cement floor. That way the frets will drive in more easily and uniformly. Don’t pound too hard, or you will likely distort the fretwire and/or

dent the fingerboard.

It is is important to seat the frets fully into the slots so the underside of the

fret rests on the wood. Use the curve in the wire to your advantage, tapping

the middle of the fret home after the ends are in place. That way the arch

helps prevent the ends from bending back up out of the slot.

If you over-work a fret, just remove it and use a pair of pliers to restore the

shape before making a second attempt.

fig 35a

fig 35c fig 35b

15.

Page 16

_____36. Clip the frets as close to the wood as you can (fig 36a), and then

sand the sharp metal ends down flush with the wood. Fretwire is quite soft

metal, so you can sand it or file it quite easily. We hold the fingerboard up

against a belt sander for this operation, but you can do the job by hand with

a flat file (fig 36b) or coarse sanding block (80 - 100 grit). HINT: Clothbacked sandpaper is stronger than paper-backed types for sanding metal.

fig 36b

_____37. Put a bevel on the ends of the frets by tilting your file to a 45 de-

gree angle, as shown in fig 37. Run your hand along the edges to check for

smoothness. It is important to remove all sharp metal ends and make the

edges flush and smooth.

fig 36a

fig 37

GLUING THE FINGERBOARD TO THE NECK

Tools Required for This Stage

Pencil Wood Glue Sanding Block (150 grit)

Lots of Clamps Clamping Blocks Hammer

Damp Rag Putty Knife Wire Cutter

NUT

fig 38

_____38. Once the fingerboard is done, you can

glue it to the neck (we wait on shaping the neck

until the fingerboard is attached).

The narrow end of the fingerboard should end

about 1/8” before the angle of the peghead, giving

just enough flat surface on which to place the nut

(fig 38). Hold the parts in place and draw a pencil

line on the neck to mark the end of the fingerboard.

_____39. Tap 2 tiny nails partway into the neck,

leaving most of the nail standing above the wood,

as shown in fig 39a. These will help keep the fingerboard aligned when you glue it to the neck. The

exact placement is not critical for these nails.

Then clip off most of the exposed nails, leaving

just a short stub poking above the surface of the

neck (fig 39b).

Pencil Line

fig 39a

fig 39b

16.

Page 17

_____40. Carefully align the fingerboard on the neck, checking that the narrow end matches the pencil line by the

peghead, and the sides are aligned with the neck as closely and evenly as possible. Yes, the fingerboard is standing on

those two tiny nails! Now press (or tap) the fingerboard over those two nails so the tiny nails punch a depression in

the underside of the fingerboard (fig 40a). This will enable you to re-position the fingerboard in exactly the same place

after applying glue. The nails will keep the fingerboard from slipping out of place as you apply clamping pressure.

fig 40a fig 40b

Make sure there is still room for the nut at the end of the fingerboard (fig 40b). It should stand on a little flat shelf

next to where the peghead slopes down.

_____41. Gather a bunch of clamps and scraps of wood to use as clamping blocks before doing any gluing. You

want to be well prepared for this step so you don’t end up with gaps between the neck and fingerboard. In fact, it

would be smart to experiment with your clamping system before applying any glue. You may have different types of

clamps than we use, so make sure your system will work well, and have the clamps open to approximately the right

size to save time.

Rehearse installing

plenty of clamps by

dry-fitting the fingerboard with clamping

blocks (fig 41a).

Notice how we use

long narrow scraps

of wood on each side

of the fingerboard to

make sure we can press

both edges of the fin-

fig 41a

gerboard firmly against

the neck (fig 41b).

fig 41b

_____42. When satisfied with your clamping set-up, apply glue to the neck, as shown in fig 42a. Then clamp the

fingerboard again and check for any open gaps along the sides. Wrap a damp rag around a putty knife to clean excess

glue from the each end of the fingerboard for the nut and the heel joint (fig 42b). Allow 8 hours for drying.

fig 42a fig 42b

1 7.

Page 18

SHAPING THE ASSEMBLED NECK

Tools Required for

This Stage

Curved File

Flat file

Sanding Block (150 grit)

Drum Sander (optional)

Razor Knife

fig 43a

_____43. We have done basic shaping on the neck for you, but there is some hand-

work to be done to create the profile you like and for smoothing everything out nicely.

We recommend taking your time with this step, checking how the neck feels in your

hand for playing. If you have a similar finished instrument available to look at, you

can try to copy the same shape on this kit, or you can customize this kit to fit your grip

more comfortably.

Some people with large fingers prefer to keep the fingerboard full width, but you can

trim it narrower if you like by removing equal amounts of wood from each side.

fig 43c

fig 44

fig 43b

We use a combination of tools for this process. A 3” drum

sander will remove a lot of material quickly (fig 43a), but

you’ll want to be careful to avoid creating bumps and dips

in the wood.

You can do all the shaping without power by using files (fig

43b), sanding blocks, sharp chisels, and/or razor knives (fig

43c).

Razor Knife

_____44. When the major shaping is done, switch to hand

sanding, with the grain, beginning with 80 grit paper and

then 150 grit to remove your tool scratches (fig 44).

POINT OF INTEREST

People sometimes ask if this instrument has an adjustable truss

rod. We build the neck with two

well-cured pieces of mahogany

for stability, and then we inlay a

carbon ber reinforcement bar

down the centerline for added

stability. We think this makes a

stronger neck than one having a

long open slot for an adjustable

truss rod.

18.

Page 19

FITTING THE NECK TO THE BODY

Tools Required for This Stage

Electric Drill 7/64” Drill Bit Masking Tape

Screw Driver Sanding Block (150 grit) Ruler

Pencil Chisel or Razor Knife Square

Wood Glue 2 Clamps Clamping Pad

_____45. Test-fit the neck to the body (fig 45). The goal is to have no visible

gaps where the neck meets the ribs, and the fingerboard should lay flat on top

of the soundboard without bending.

Take note that the back is not yet installed, so it is still possible to flex the ribs a little, if necessary, to achieve a good

fit here. So before you make drastic adjustments, we recommend installing one wood screw to hold the parts together

while you check the alignment of the neck to the body.

_____46. Use the 7/64”

drill bit to drill one pilot

hole into the neck from

inside the body (fig 46a).

We put masking tape on

the drill bit to mark the

length of the screw so we

don’t drill too deeply!

fig 45

fig 46a fig 46b

Then use a hand screw driver to install two 1-5/8” wood screws provided. NOTE: We call for a hand screw driver

here because you don’t want too much power on this screw -- you might strip out the pilot hole in the neck (fig 46b).

If you cannot draw the parts together firmly, however, use a power drill very carefully!

_____47. Now flip the instrument over and hold a straight-edge or ruler along

each side of the fingerboard so you can trace the path of those edges onto the

soundboard with a pencil (fig 47a). Compare those lines with the sound hole

and the centerline to see how straight the neck is with the body (fig 47b). The

centerline should be centered between the two outer lines.

fig 47a

fig 47b

_____48. If you need to tilt the neck one di-

rection or the other to get it aligned with the

centerline of the soundboard, mark which

side of the heel joint needs sanding. Then

remove the neck from the body and sand

the surface of that particular rib, using a flat

sanding block (fig 48a), and checking to

Square

make sure you keep the surface square with

the soundboard (fig 48b). Test fit the neck

again to see how your efforts paid off. A

little trial and error like this should bring the

neck into alignment.

fig 48a

fig 48b

19.

Page 20

Notice that the neck contacts the body more firmly on the outer edges of the

joint than in the center (fig 48c). We design the joint this way on purpose,

so it will be easier for you to achieve a nice fit on the outside.

Check carefully along the heel joint to see if there are any gaps showing on

the outside (fig 48d), and make pencil marks where you want to remove a

little wood so the entire seam closes up nicely. Then use a flat sanding block

or file to make very slight adjustments to the outer edge of the heel (fig 50c)

until you like the way the parts fit. Be careful not to overwork this. It should

only require very light sanding.

Slight

Gap

Sand the areas where the fit is

tight in order to close gaps in

other areas.

Check how the fretboard rests

on the front too.

Tight

fig 48d

Fit

Gaps

Tight

Fit

fig 48c

Sanding

Block

fig 48e

_____49. When satisfied with the fit, you can install the neck perma-

nently with wood glue. Squirt glue on all the contact surfaces: tenon,

shoulders of heel, and fingerboard (fig 49a). Install the neck using the

same screws (fig 49b).

Glue

fig 49a

fig 50a

fig 49b

Then add a couple clamps to hold the fingerboard

down fully against the soundboard (fig 49c).

Notice the scrap of wood used for preventing

the clamps from damaging the fingerboard.

Clamping Pad

Clean up

fig 49c

glue before

it hardens!

_____50. Now is a good time to “level” the tops of all the frets. Use a large flat mill file, resting on the FRETS, to

wear down any that are too high (fig 50a). Check your progress frequently to see which frets are being cut and which

ones are not. As soon as each fret has been scratched lightly with the file, you may consider them all level.

fig 50b

After leveling the tops with a file, you can do a decent job of dressing the

frets by wrapping sandpaper around your fingers, as shown in fig 50b.

Start with about 180 grit paper, sanding back and forth along the length of

the fingerboard. This will help round over the frets again, reducing the flat

areas on the frets.

Change to progressively finer sandpaper (say, 300 grit, 400 grit, and then

600 grit) to smooth and polish the frets nicely.

20.

Page 21

REINFORCING THE HEEL JOINT

fig 51a

Begin by finding the center of the seams on each

side of the tenon, and marking them with a pencil

(fig 51a).

Tools Required for This Stage

Electric Drill 1/4” Drill Bit Masking Tape

Pencil Awl Wood Glue

Chisel or Razor Knife Long Sanding Block

_____51. Once the glue is dry, remove the screw. It

is no longer needed in the joint. We’ll show you how

to reinforce the joint more permanently here.

fig 51c

Put masking tape on the 1/4” drill bit to mark the

depth of hole you want to drill for the dowels provided (fig 51c). It is best to drill a little deeper than

the length of the dowel, just to make it easy to push

the dowels in fully.

fig 51e

fig 51b

Use an awl or nail to punch-mark the center of each

seam to guide your drilling (fig 51b).

fig 51d

Drill 1/4” diameter holes for the dowels straight into

each seam to the depth of your masking tape (51d).

Make sure to get all the sawdust out of the holes.

Then squirt some glue into each hole (fig 51e).

21.

Page 22

fig 51f

fig 51g

Push a dowel fully into each hole until it is flush with

the surface of the heel (fig 51f). Use a damp rag to

clean up excess glue.

_____52. Use your long flat sanding block to

level the entire back frame of the instrument (fig

52). This will ensure a good fit when you glue

the back panel in place.

We use 80 grit sandpaper for this work. Finer

sandpaper won’t cut well enough to accomplish

the task. You need to remove any glue blobs and

high points in the kerfing that stand above the

edge of the ribs. You may also find that the heel

needs sanding down to meet the level of the ribs.

Take your time on this because any gaps between the ribs and back will show on the finished

product, unless you plan to install inlay banding

around the back.

If there is a little bit of the dowel sticking up above the

surrounding wood, use a sharp chisel or razor knife to

carve it down flush (fig 51g).

80 grit

sanding block

fig 52

Tools Required for This Stage

Wood Glue Clamps (at least 8) Clamping Pads

Router (optional) Flush Trim Bit (optional) Coping Saw or Bandsaw

Pencil or Pen Chisel or Razor Knife Sanding Blocks

_____53. We always recommend identifying the builder inside the in-

strument where you can see the inscription through the soundhole (fig

53). You could make a nice label on your computer and print it out

on parchment paper, or you can simply write your signature and date

directly on the wood with a pen. Practice on a scrap piece of the same

wood to make sure your writing will show up nicely.

INSTALLING THE BACK

fig 53

22.

Page 23

_____54. Be sure to test-fit the back without glue first, just to make sure you can pull the panel down tightly to the

ribs all the way around. Check your centerlines on these parts too! You may need to trim the ends of a brace or

something in order to align the back perfectly.

fig 54a

fig 54b

When satisfied with the fit, squirt a bead of glue all the way around the perimeter of the frame, as shown in figure 54a.

Then use lots of clamps to hold the back to the frame (fig 54b). Be sure to lift the assembly up and look carefully at

the seams so make sure the back is making full contact with the ribs all the way around the frame. Allow 8 hours’

drying time.

Coping Saw

Bandsaw

fig 55a

_____55. When the back is dry, you can trim off the ex-

fig 55b

cess overhanging material. DO NOT USE A HANDHELD POWER JIG SAW for this work. A coping saw

works fine if you don’t mind working by hand. (fig 55a).

A band saw works more quickly (fig 55b), but be

careful to avoid cutting into the frame. We like to

cut a little wide of the frame and then work the rest

down by hand, or with a router with a flush trim bit

(fig 55c).

fig 55c

Flush

Trim

Bit

HINT: You may need to use a sharp chisel or razor knife to clean up around the heel block where the

neck meets the body.

23.

Page 24

OPTIONAL DECORATIONS

_____56. (OPTIONAL) If you wish to add inlay banding around

the back, now is the time to do it. Inlay banding not only decorates

the instrument, but it also covers up gaps you might have overlooked when clamping the back to the frame. You’ll need a router

and the same inlay bit that you used for the soundboard banding.

PLEASE REFER BACK TO STEPS #28-33 for detailed instructions on installing the inlay banding. The only difference when routing the back is that you will need to stop short of the heel -- don’t

rout the ledge around the heel (fig 56). You won’t be able to bend

the inlay banding around the tight curve of the heel. Use a chisel or

razor knife to finish cutting the ledge into the corner by hand.

_____57. (OPTIONAL) If you purchased a rosette for decorating the soundhole, this is a good time to install it. If it does not fit easily into the hole, you may

need to sand the outer edge of the rosette a little until it fits.

PLEASE NOTE: If you think you might want to install a pickup inside the instrument in the future, then figure out some way to make the rosette removeable.

Tacky glue or double-stick tape might work well for temporary installation.

Put glue on the exposed ledge of the donut ring, NOT ON THE SOUNDBOARD

or the rosette. This will help you keep from making a mess. Take care to orient

the rosette pattern so it looks straight on the instrument (fig 57).

fig 56

Stop inlay

at heel

Heel

fig 57

_____58. (OPTIONAL) This kit includes a short white plastic rod that can be inlaid along one edge of the finger-

board for marking certain fret positions to guide your playing. This is a good time install those markers.

These marks should be placed on the edge that faces you as you hold the instrument. Right-handed players will put

them along the left edge, as shown in figure 58a. If you expect to play in a left-handed orientation, then just flip the

instrument over and count the spaces from the narrow end of the fingerboard (near the peghead).

fig 58a

We recommend marking at least 4 spaces (#5, 7, 10 & 12),

but you can go further up the scale as shown in fig 58. Notice that we put two dots on the 12th space, as that marks the

octave position.

Punch-mark each position first, and then drill carefully with a

5/64” drill bit to a depth of about 1/8” (Fig 58b).

fig 58b

Then you can push the white plastic rod into the hole, clip of

the excess, and move on to the next hole. Use a razor knife to

trim the plastic flush with the surrounding wood. No need for

glue on these markers.

24.

Page 25

FINAL SANDING

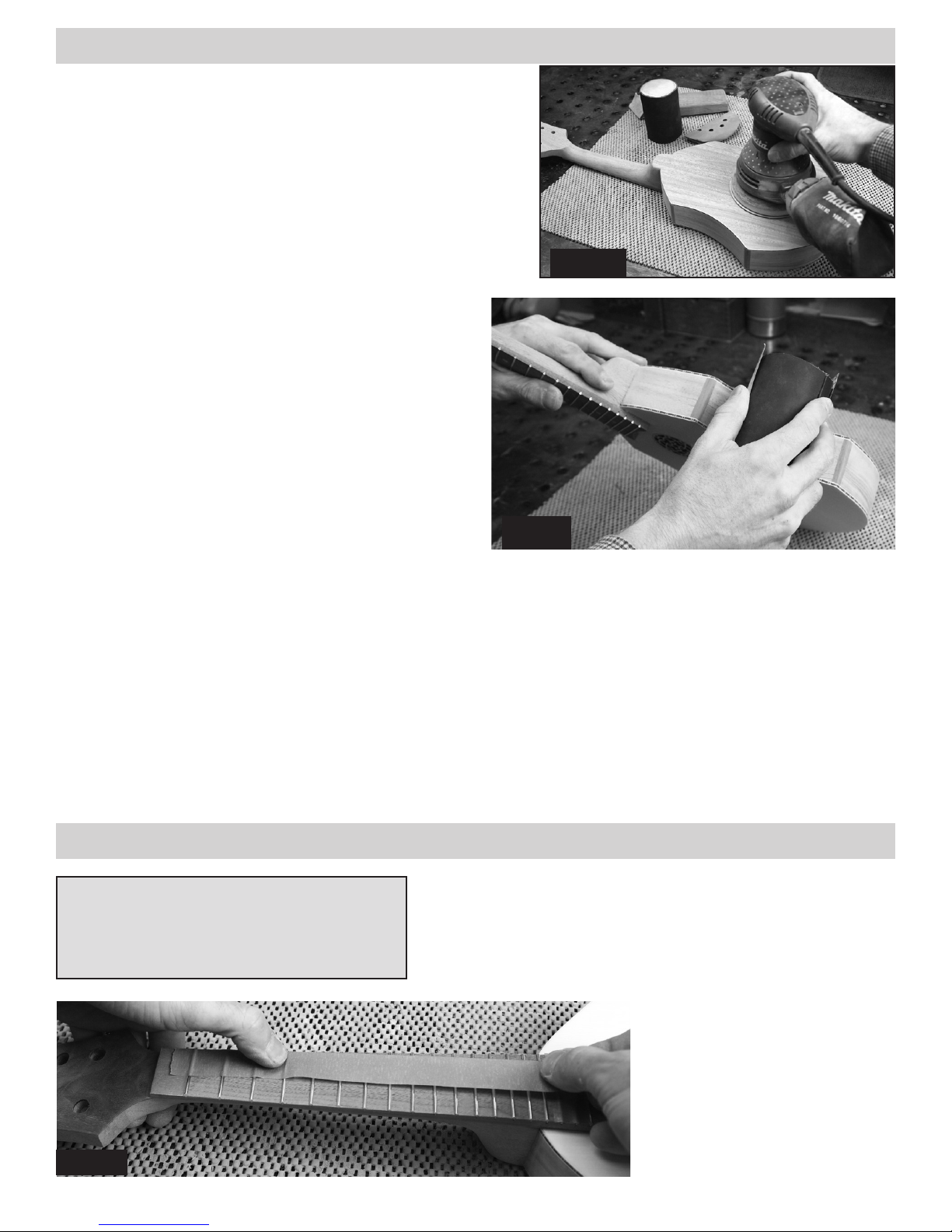

_____59. There may be some large areas of the instrument,

such as the soundboard and back, that need a quick sanding

with a power tool. We use an orbital hand sander with 220-grit

sandpaper for a once-over lightly to take care of major scratches and bumps (fig 59a). BEWARE: These power sanders can

dig major divots in this soft wood if you are not careful. We

just use them very sparingly on a project like this....

Now it is time to go over the entire instrument BY HAND

WITH SANDPAPER to clean up all glue spots, machine

marks, and other signs of amateur construction. Take your

time with this. It helps to have good lighting so you can

look carefully for rough spots and glue smudges.

Hand-sanding is often the least favorite part of a woodworking project, so plan a way to make it relaxing and enjoyable. Sit in a comfortable chair by the fireplace with an

old towel over your lap to catch the dust. A glass of beer

or wine, and some good music will help too.

fig 59a

DO THIS HANDWORK WITH GOOD LIGHTING!

Begin with 150-180 grit sandpaper, looking for glue blobs,

fingerprints, scratches, and machine marks. If you start with sandpaper that is too fine, you’ll work and work without

making any progress.

Sand with the grain direction whenever possible. This will give smoother results. The goal is to remove the offensive

marks with medium paper, and then switch to finer grit for making everything nice and smooth.

One more thing: A good woodworker knows that a slightly rounded corner always looks and feels better than a very

sharp corner. Yes, you can even round the edges of the inlay banding a little bit. It just takes a little sanding at an angle

with fine (220-320 grit) sandpaper to make a big difference in how it feels in your hands. NOTE: We don’t find it

necessary to use finer sandpaper than 320 until we are sanding between coats of finish.

OK, that’s our little pep talk. Now sit down and do some quality handwork. You’ll be glad you did.

fig 59b

APPLYING THE FINISH

Tools Required for This Stage

Masking Tape Razor Knife

Finish of Your Choice Applicator (brush or rag)

Mineral Spirits Paper Towels or Rags

_____60. Before applying finish to the instrument, it is best to

cover the playing surface of the fingerboard with masking tape.

Rosewood fretboards are usually not finished, except along the

edges where you might like seeing the same sheen as you put on

the neck. This wood has natural resins for protection from moisture, so additional finish is not necessary and sometimes causes

problems by becoming sticky under your fingers as you play.

fig 60a

Apply the tape carefully to cover

the entire top of the fingerboard,

frets and all (fig 60a). Use a razor knife to trim off any tape that

hangs over the edges or ends of the

fretboard.

25.

Page 26

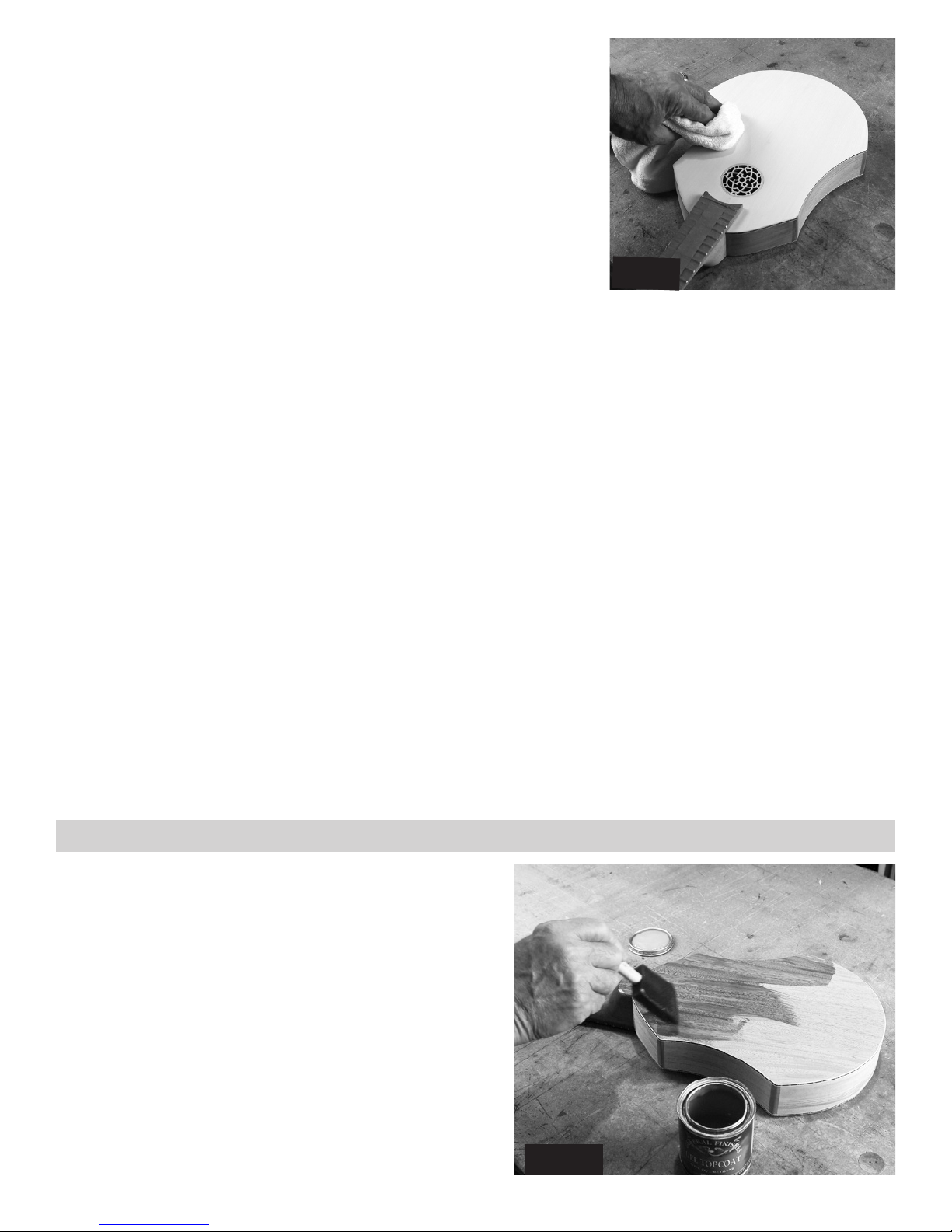

Use a clean cloth to wipe off any sanding dust from the wood (fig 60b).

Some people buy tack cloth for this purpose, but we just use a clean rag.

Another option is to wet the rag with denatured alcohol (from the hardware store) for cleaning the wood more fully. Alcohol does not raise the

grain like water does, and it evaporates quickly, leaving no spots. But this

trick is not a necessary step -- just kind of fun to do. The alcohol will give

you a preview of the beautiful depth and color of the wood.

Now you are ready to apply the nish. Here are some recommendations:

STAIN -- STAINS are coloring agents and should only be used if you dislike the natural color of the wood. We generally discourage people from

trying to stain this project because the natural wood grain is so beautiful

with a simple clear nish. It is dicult to mask o the soundboard, for instance, and just stain the sides and back

of the body because the stain tends to “bleed” under the masking tape. If you are a novice at nishing, or facing a

deadline for completion, we especially recommend avoiding stain.

OIL -- An oil nish (such as Watco Danish Oil) will give your wood a low luster appearance, bringing out the

natural color of the grain, but it tends soak into the wood and appear dry and “thirsty” aer awhile. e principal

advantage of an oil nish is that it can be applied and wiped dry immediately, allowing you to proceed to installing

hardware (and strings) right away. e disadvantage of oil is that it usually does not give much surface protection

or sheen, unless you know how to polish out many coats of gun stock oil.

POLY URETHANE -- Any polyurethane will work ne on this project, but we like the solvent-based ones better

than water-borne versions. Our all-time favorite is wipe-on Gel Topcoat polyurethane that comes with our Instrument Finishing Kit. It is the product featured below. e advantages of this nish are its simple application (no

drips or runs), durability, and deep, so luster.

LACQUER -- Many professional instrument makers still use nitro-cellulose lacquer for their nish. e most

readily available lacquer is called De Clear Wood Finish. If you choose this product, it is best to purchase a can of

liquid to brush on as a sealer coat rst, and then use an aerosol can of the same product to spray the nal coats. e

advantage of this nish is its quick drying time, but the disadvantage is the strong odor and toxic lacquer fumes.

CAUTION: Lacquer nish may smear some painted decorations or blister some types of decorative decals. If you

plan to add paints or decals to your instrument, it would be better to nish with polyurethane instead of lacquer.

fig 60b

So choose your weapon and proceed with nishing all the wood parts. Plan on applying at least three coats of nish. If you don’t use our Gel Topcoat, be sure to follow the directions on the can.

APPLYING GEL TOPCOAT

_____61. We use a cheap foam applicator to apply the

first coat of gel (fig 61a) because the first coat will just

soak into the wood anyway. The goal is to get finish into

all the nooks and crannies so everything gets covered. No

need to worry about brush strokes for this because, if you

read below, you’ll see that all excess finish must be wiped

off.

DO NOT APPLY A THICK COAT:

YOU’LL JUST WASTE PRODUCT!

NOTE: The temptation is to create a deep “pool” of finish on the wood right away. Please resist this urge, as it

will produce bad results and take forever to dry. The best

finishes are applied in very thin coats.

fig 61a

26.

Page 27

As soon as you have coated the instrument, use

paper towels or cloth rags to wipe off all excess

finish, right down to the wood (fig 61b). Make

sure to wipe the corners too.

Wipe off excess gel from your hands too. Then

it won’t hurt anything to handle the freshly finished instrument. No need to worry about fingerprints on this first coat.

When satisfied that all the wood has been wetted

and wiped, hang the instrument on a nail to dry

for at least 8 hours.

fig 61b

_____62. After 8 hours, check to see if the finish is completely

dry. If your fingers slide across the surface without “dragging”

on damp areas, it should be ready for fine sanding and another

coat.

Try sanding lightly with 600 grit paper (fig 62). If the sandpaper loads up with gunk as you sand, then the finish is not dry!

Give it more time. (If it takes 3 days to dry, then you either live

in a rain forest, or your first coat of finish was too thick....)

Your goal in sanding is to just smooth out the finish -- not sand

down to bare wood. So a quick and light sanding should suffice. The 600 grit sandpaper will make the instrument feel very

smooth. You will sand this way between coats every time you

decide to add another coat of finish.

After sanding, be sure to wipe the surface to remove sanding

dust before applying more finish.

_____63. Use a clean cotton cloth (old t-shirt) to apply each

successive coat of finish (fig 63). No need for a brush or foam

applicator from here on! Now your goal is to apply a very even

thin coat to the entire surface. This is not difficult or time-consuming, but you’ll need good lighting to see the results as you

work. Once you have wetted an area, go back over it with long

strokes to smooth the fresh gel.

Here again, you must resist the urge to apply too much finish.

Just a thin film is all you want. It may not look like you are accomplishing much, but it will look nicer with each successive

coat. Thick coats tend to become uneven, and to take a long

time to dry.

fig 62

fig 63

These wiped-on applications will dry more quickly than the first coat because the wood pores are already sealed. If

you are working in a warm dry environment, it might be ready for fine sanding again in 3-4 hours. Test it by touch,

as mentioned above.

THAT’S IT! This is all there is to our simple finishing system. You just repeat step 62 until you like the results.

We recommend a minimum of 3 coats of finish to give a good protective seal on the instrument. After that, it’s all

cosmetics. NOTE: If you wish to add other decorations to the instrument (decals, paints, etc.), it is smart to do that

work between layers of gel finish. This will seal the decorations permanently to the instrument.

2 7.

Page 28

INSTALLING THE HARDWARE

Tools Required for This Stage

Masking Tape Pencil

Electric Drill 1/16” drill bit

#1 Phillips Screwdriver Masking Tape

CA Glue or Epoxy Ruler

180 grit Sandpaper Chisel

Small Triangle File

_____64. You are finally ready for the

final phase! We’ll begin by shaping and

installing the nut at the end of the fingerboard.

The nut is a little longer than necessary,

so if you stand it in place, you can trace

the shape of the neck underneath each

end with a sharp pencil (fig 64a). It looks most professional to trim the nut to

match the curve of the wood below it.

180 grit

Sand

paper

Nut

fig 64b

fig 64c

Nut

fig 64a

fig 64d

We like to tape a sheet of 180 grit sandpaper to the work table (fig 64b) so you can sand the ends of the nut to your

pencil lines, and then round over the top edge that faces the peghead (figs 64c and 64d).

When you have it shaped to your liking,

use CA glue or 5-minute epoxy to glue

it in place at the end of the fingerboard

(fig 64e). We like CA glue because we

can just hold the nut in place until it

dries (a minute or so).

After the glue hardens, you can use

a chisel to chip off any excess that

squeezed out onto the peghead (Fig

chisel

64f). Glue does not adhere well to a

finished surface, so it should be easy to

fig 64e

chip off.

fig 64f

If you goof up on placing the nut, you can just tap it loose,

clean off the original glue residue, and try again.

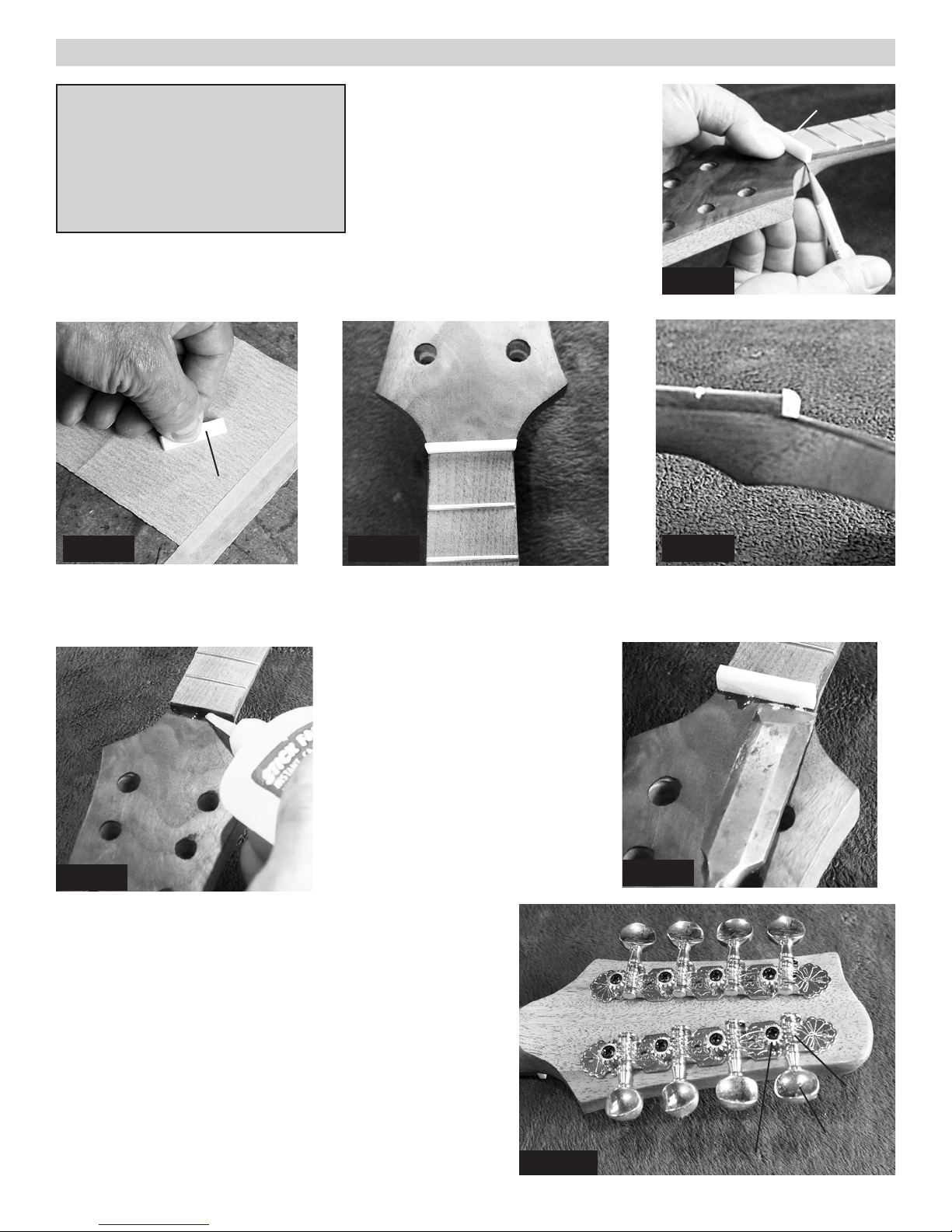

_____65. Find the geared tuners and push them into the back

of the peghead, being careful to orient them on the proper

sides (fig 65a).

Notice that the buttons with the worm gears are situated closer to the end of the instrument than the posts with ring gears.

This is important for longevity and smooth operation of the

tuners because we want the string tension to pull the gears

together instead of apart over time, keeping them operating

smoothly.

28.

fig 65a

Worm

Gear

Button

Ring Gear

Page 29

Push the bushings into the holes around the posts on the front side

(fig 65b). These fit rather tightly, so you may need to use a small

tool to push them in fully.

Use the 1/16” drill bit to make pilot holes for the tiny screws that

hold the gear plate firmly to the back side of the peghead. Be

careful to drill only as deep as the length of the screws. We like

to put tape around the drill bit to mark the maximum depth (fig

65c).

Then install the screws, using a #1 size Phillips screwdriver (fig

65d).

fig 65c fig 65d

_____66. The easiest way to line up the tail piece with the finger-

board is to hold a straight-edge against each side of the fingerboard

and mark its position on a piece of masking tape at the tail end of

the soundboard (fig 66a).

This gives you the outside parameters. If you center the tailpiece

between those marks, the strings will be nicely centered on the fingerboard (66b).

fig 65b

Use the same 1/16” drill bit to make pilot holes for the screws that

hold the tailpiece in place (fig 66c).

fig 66b fig 66c

fig 66a

29.

Page 30

_____67. The Nut and Bridge need to be notched

to hold the strings in the proper positions (fig

67a). It is best to use a metric ruler for marking

these small measurements, as shown in fig 67b.

fig 67b

fig 67a

Use a small triangle file for this notching (unless you have nut

files to match the string gauges). We bought an inexpensive set

of needle files at the hardware, and it includes a nice triangle file

for this purpose (fig 67c & 67d). Note that the bass string pairs

are separated a little further apart than the treble string pairs because the bass strings are the fatter wound strings.

Nut

Bridge

fig 67c fig 67d

HINT: File the notches only about 1 mm deep at first. Once the strings are in place, you may need to file deeper

notches to lower the strings, as instructed toward the end of the next step.

_____68. Now you are ready to install the strings! Begin by sliding the smooth metal cover off the back of the

tailpiece (fig 68a).

We like to begin with one of the fattest bass C strings and one of the lightest treble A strings, and installing them in

the outermost positions on each side of the instrument. These two strings can hold the bridge centered on the instrument, making it a little easier to install the remaining strings, in order.

NOTE: Your string set has two optional

strings included to provide octave tuning at the low C and G positions. It you

want to use this option, we suggest placing the plain C and G strings to the left

Low C

High A

of the wound ones in fig 68b.

fig 68a

Hook the looped end of the string over

the proper hook in the tailpiece, as illustrated in fig 68b. Notice that there are

some extra hooks aiming sideways on

the tailpiece. You can disregard those

and just use the eight vertical hooks for

your complete string set, as shown.

30.

fig 68b

Page 31

fig 68c

The strings are longer than they need to be, so you can pull most of the slack

through the hole in the tuning post before starting to turn the tuning button.

Leave enough slack string across the instrument so that there will be 3-4 wraps

of string around the post before the string becomes taut (fig 68)c.

CAUTION: The correct way to turn the buttons is to make the string fall

to the inside of the peghead, as shown in figure 68d. If you don’t turn them

properly, the strings will rub against neighboring posts and be difficult to tune.

Once the strings are installed, you will likely have some detail work yet ahead

to make the instrument easy to play. You want the strings to hang approximately the heights shown in figure 68e. This is called “setting up” the instrument.

BRIDGE PLACEMENT: This is a “free-floating” bridge, held in place by

the strings. Position it 17-1/4” from the Nut and let the first strings hold it

there. You can make fine adjustments to the intonation of the instrument after

tuning (see back page).

fig 68d

Nut

fig 68e

1st Fret

NOTE: Setting up a new instrument can take several hours,

so put on some relaxing music and take your time!

12th Fret

Start by filing the notches in the nut to get the clearance over the first fret at about 1/32”. That means you should just

be able to slide a credit card between the string and the first fret. Do this for each string individually.

If you file too deeply, the string will buzz against the first fret. In that case, you’ll need to loosen the strings, tap the

nut off the instrument and re-glue it with CA glue. Generally, the new glue is enough to raise the nut enough to stop

the buzz.

Once you have the proper gap at the first fret, work on filing notches in the bridge to lower the strings at the 12th

fret. The 12th fret is the midpoint of the vibrating length, so filing a notch 1/16” deeper in the bridge will lower the

string 1/32” (half as much) at the midpoint. If you need more than that much adjustment, it would be easier to sand

the bottom of the bridge to lower the overall height of all the strings at once.

Conversely, if all the strings are too low to begin with, the easiest solution is to glue a shim under the bridge to raise

all the strings at the same time.

CONGRATULATIONS! We hope you have enjoyed building this kit and that you have many years of pleasure from

playing it. Please let us know if you have suggestions for improving this project. We often get our best ideas from

the customers who build our kits.

31.

Page 32

MUSICMAKERS

PO BOX 2117

Stillwater, MN 55082

651-439-9120

www.harpkit.com

FINE ADJUSTMENTS

You may find the 17-1/4” bridge

location to be slightly off for

good intonation in the highest frets. This is caused by the

amount of stretching required

of the strings when they are

pushed down against the frets.

You can correct for this as follows, using an electronic tuner

for checking accurate pitches:

Check the pitch of each string at

the 12th fret to make sure they

sound exactly one octave above

the open string.

If the fretted pitch is slightly

higher than an octave, slide

the bridge back toward the tail

piece a little bit.

If the 12th fret pitch is slightly

lower than a perfect octave,

then slide the bridge up a little

bit toward the soundhole.

If you’d like to install a strap on the instrument, we

have straps and mounting buttons available at Musicmakers. The mounting buttons can be positioned

as shown in figure 69, with one button replacing the

bottom screw on the tailpiece, and the other resting

on the curved heel of the neck.

fig 69

Loading...

Loading...