Musical Design PA-3-B Owners manual

Musical Concepts

MODIFICATION MANUAL

PA - 3B

FOR HAFLER AMPLIFIERS

Thank you for purchasing the Musical Concepts PA-3BB modification. The PA-3B is the result of many years of

research. The sound quality you are about to enjoy has been achieved through careful engineering and careful

listening evaluation. The PA-3B has the highest quality parts, specifically chosen for their extremely musical qualities.

You will enjoy the state-of-the-art performance that until now was only a hidden promise of your amplifier.

ACKNOWLEDGMENT

Musical Concepts would like to thank Dick Nelson(Qualstar Corporation) for expert assistance with the PA-3B project.

APPLICATION

This modification is designed for the Hafler DH-200/220/500 and XL-280/600 power amplifiers. Dedicated constructors with

considerable experience can use the PA-3B to drive a MOSFET output stage using from 2 to 12 power MOSFETS in complementary

source follower mode. Such projects should be undertaken only by the most self sufficient types, since Musical Concepts will not offer

assistance for custom installations.

DISCLAIMER

Musical Concepts accepts no responsibility for damages, direct or consequential, resulting from this modification. The user solely

determines his or her own ability to properly install this product. Musical Concepts accepts no responsibility for personal injury or death

resulting from electrical shock hazard.

CIRCUIT DESCRIPTION

The PA-3B is a DC coupled amplifier circuit with a low frequency 'corner' of about 0.10 Hz . It is a Single-Ended, Class-A front-end.

The input stage is a Current Sourced Differential Amplifier exhibiting the advantages of symmetry and high input impedance to the

driving device. The following LED biased, Single-Ended Cascoded Stage(SECS) voltage amplifier is operated at high current for

linearity. This stage is collector coupled to the MOSFET output stage. That is correct, there are only three stages, making the PA-3B

an incredibly simple, straightforward design. Of course, the output stage is the tried and proven lateral MOSFETs used in your original

Hafler product. Power MOSFETs have nearly 10 times the bandwidth of bipolar power transistors minimizing the phase and bandwidth

problems of the output stage. In addition, power MOSFETs are known for their ruggedness under adverse drive conditions.

TOROID POWER TRANSFORMERS

Musical Concepts offers the TP-200 toroid power transformer with 7 amp(625 watt) capability to replace the standard 4 amp transformer

of the DH-200/220(cannot be fitted to the XL-280 unless capacitor arrangement is modified as in the dual-mono version). The TP-500

is a pair of transformers, 500 watts each, used to replace the single transformer of the DH-500/XL-600. When used with twin capacitor

power supplies, they are paralleled. They are used separately with the XL-600 or when installed with the DH-500 dual-mono package.

These transformers offer amazing improvements in bass solidity, dynamic range, ambience retrieval and speed. There is a velvet-black

backdrop to the sound revealing subtle imaging clues.

POWER SUPPLY CAPACITORS

The LC-200 package consists of two 25,000 mfd capacitors which replace the standard 10,000 mfd caps used in the Hafler DH-200/

220. The LC-500 is a pair of 39,000 mfd capacitors for the DH-500, replacing the 20,000 mfd originals. The improvements are greatly

improved bass solidity, wider dynamics at any volume level and greater ambience. The sound is more liquid and delicate, yet at the same

time revealing of subtleties. 'LC' capacitors are the same physical size as the original caps which reduces installation difficulty. These

are the same caps used in our dual-mono conversions.

1

DUAL MONO CONVERSIONS

Complete dual-mono versions of these amplifiers are available. In the DH-200/220/280, we use our TP-200 transformer which has

separate secondary windings. Each winding is separately rectified into a pair of the LC-200 filter caps on each channel, i.e.100,000 mfd

of capacitance. In the DH-500/XL-600 amplifier, we use the TP-500 transformer set which consists of two 500 watt transformers stacked

in the space previously occupied by the original transformer. Each transformer feeds a separate rectifier and a pair of 38,000 mfd filter

caps for a total of 152,000 mfd of filter capacitance. The rail fuses are mounted directly on the PA-3B, which makes the dual-mono

conversion easier.

THE FINISHING TOUCH

You can add Gold-plated binding posts to finish the appearance. The finest package includes the Oxygen-Free Copper, Gold-Plated/

Teflon® RCA inputs and Cardas Copper or Gold/Rhodium speaker connectors. These are available in kit or factory installed. All

connectors are available separately.

SOLDERING

We recommend that you have some soldering experience before attempting this modification. We remind the veteran that your solder

should be fresh rosin core type. We provide Kester 63/37 rosin core solder. Some silver solders that we have evaluated will devastate

the sweet delicate sound of the PA-3B. Make sure you are a "solder genius" before substituting for the supplied solder.

TOOLS

25 to 45 watt soldering iron--not gun, fresh 63/37 eutectic rosin core solder--provided

needle nose pliers, diagonal cutting pliers, wire strippers, screwdrivers(philips and flat),

miniature flat blade screwdriver, 1/4 & 3/16 inch nutdrivers (optional),

multimeter with 2 Amp or higher DC Amps scale

INVENTORY

2 - PA-3B circuit boards (stuffed and tested)-- The PA-3B circuit board layout was designed prior to final tweaking, therefore some

parts may be 'missing' from the final board design

Misc. parts: 1- length of solder(10 ft.), 2-33K 1/2W (Or-Or-Or-Gld) resistors, 2-47K 1W (Yel-Pur-Or-Gld) resistors, 4 - 6800 ohm power

resistors (Blue-Gry-Red-Gold), 4 - 2.2 mfd film caps(axial lead), 4 - 0.1 mfd film caps, 2 - 47pf (470J03, 47, etc.) caps, 4 - tie wraps,

3 - 4ft. lengths of 22 ga. wire(3 colors), 2 - 4 ft. lengths of heavy wire (14 GA x 2 colors), 1 - 3 ft. length of 18 Ga. wire, 4 - solder lugs

for #10 screw, 2 - Gold-Plated female RCA jacks with isolating washers(2 flat, 2 shouldered), 1 - 5" length of heavy bus wire(solid and

uninsulated). For DH-200 only: 1 - ground lug tab for #6 screw, NOTE: Some included parts may not be used in all amps; you may

have leftover parts.

INSTALLATION INSTRUCTIONS

We recommend that you read through the instructions before beginning the modification to determine if you will need the assistance

of an experienced friend or professional installation by Musical Concepts. Musical Concepts installations include considerable

performance documentation and a 2 year labor warranty. Kits do not have a labor warranty.

IMPORTANT: Certain instructions may pertain only to specific amplifiers. These instructions will be proceeded by [200], [500/600]

etc. Unlabeled instructions are for all amps.

IMPORTANT: Read each step completely before starting work for that instruction.

1.( ) Turn unit off, remove all connecting cords and disconnect AC plug from wall.

2.( ) Remove all screws holding the top cover in place and remove the top cover. A 1/4" nutdriver is the best tool for this on some amps.

The screws holding the top cover on the DH-200/220 and XL-280 are between the heatsink fins .

3.( ) Unsolder and remove the input wires from eyelets 1 and 2 at the top of DH-200/220, XL-280 PCB. These eyelets are on the rear of

the DH-500/XL-600 PCB.

2

4.( )[200, 220,280] Remove the four screws, between the fins, holding the right channel heatsink to the chassis. Let the heatsink rest

on an old towel to protect the finish.

5.( )[DH-200] Each stock RCA input connector is secured by 2 screws. Remove the connectors and attached wires.

6.( )[DH-200 only] Read the first sentence of step 7 before starting this step. Remove the two screws in the top of the power supply

capacitor, on the left, as you face the front panel. The filter capacitors are held to the bottom by screws in the feet of the capacitor clamps.

Remove the screw nearest to the center of the amp on the same capacitor's foot. Loosen the other screw slightly. 'Twist' the capacitor

out of the way and sand off the paint around the hole where you have removed the 'foot' screw. Select the #6 solder lug(ground lug). This

is installed where you removed the 'foot' screw, by sandwiching it between the bottom cover and the foot of the clamp. Orient it toward

the rear of the amp so it will be convenient to solder wire to it in the following steps. Retighten both of the 'foot' screws securely so

that you will have a rock solid ground point. Reinstall the two screws in the top of the capacitor, tighten them securely.

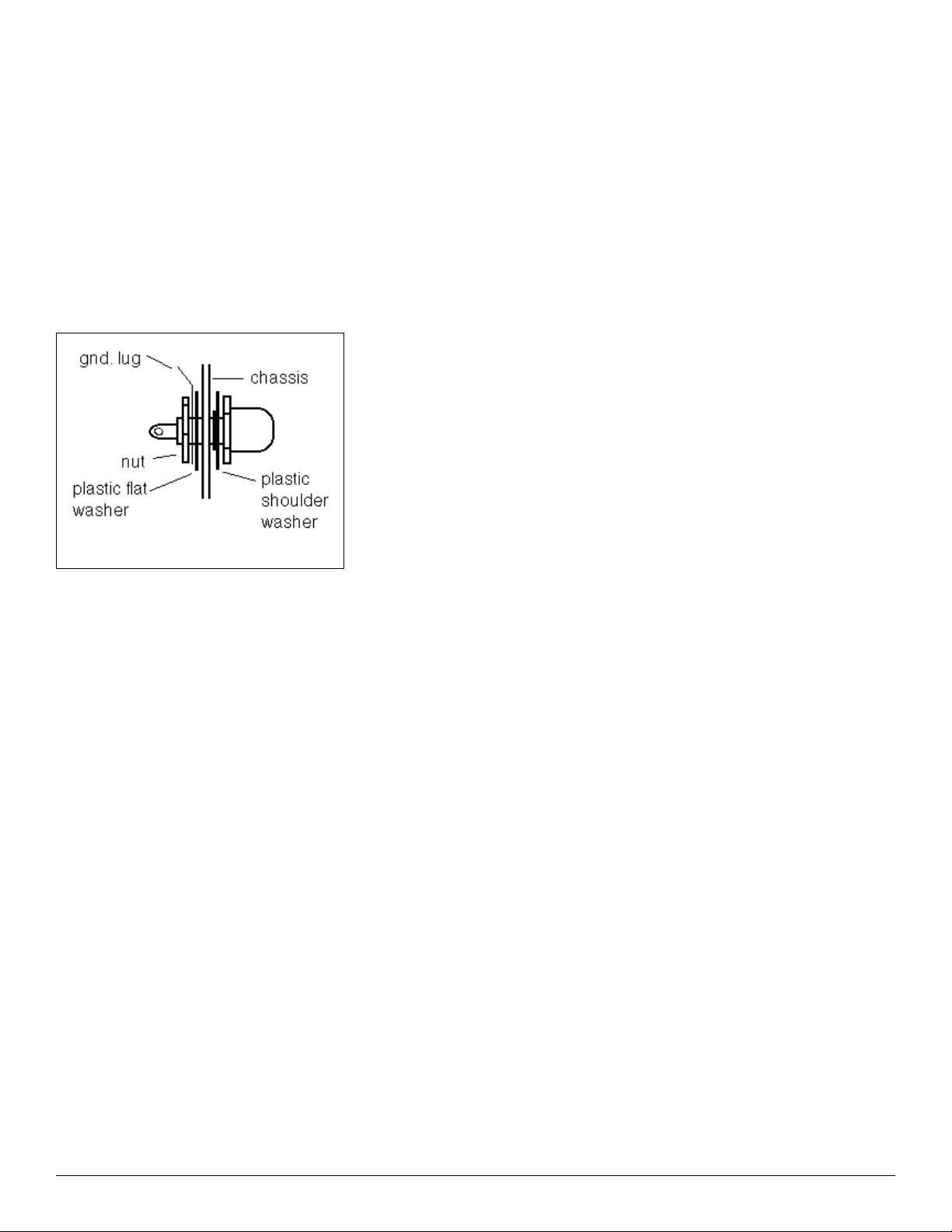

7.( )[DH-200 only]You may find this step easier if you temporarily remove the power

supply caps. Select the new Gold-Plated, Teflon® insulated RCA jacks and isolating

washers (one shouldered, one flat per connector). Presolder the wires to the RCA jacks

before they are physically installed into the chassis. The required wire lengths are as

follows.: [10" white, 10" and 8" gray for L. Ch., 10" blue, 10" and 8" gray for R. Ch].

Solder the small gauge white wire to the center lug of the jack for L.Ch. [blue for R.

Ch.], and the 2 small gauge gray wires to the separate ground tabs. Next install the

shoulder washers onto the RCA jack, as shown. From the outside, install the jack

assembly thru the original jack hole with the shouldered insulator against the back

panel. On the inside, install the flat insulator, gnd. lug and nut in that order. Tighten

securely(Hardware is 12 MM)! Both channels are done the same way. The shoulder

washer must fit inside of the hole to be electrically isolated. Once installed, twist the

each pair of 10" wires at least 2 turns per inch. These will be wired to eyelets 1 and

2 of the PA-3B in a later step. Take the remaining gray wires from each RCA jack and

connect to the ground lug installed in step 6. Route these against the bottom of the

chassis. They will be soldered in step 9.

8.( )[All amps except XL-280] Find the center tap of the power transformer secondary. It is one of the wires connected to the existing

'star ground' bus wire between the large filter caps and it goes inside the power transformer housing. Remove it from the star ground and

leave the other wires connected. This may take some serious heat, so clip it if you prefer. Select the 5 in. heavy bus wire. Now install

this wire to the power supply caps just like the original 'star ground'. Make a slight 'V' shape pointing toward the power transformer(DH200/220). Point the 'V'(s) toward the front panel in the DH-500/XL-600. This is illustrated in Fig. B. The XL-600 requires that this be

done with both pair of filter caps - use the #10 lugs. After the wire is formed and crimped around the lugs on each filter cap, solder securely.

Faster heating of the solder joint can be accomplished by temporarily loosening the screws connecting the 'star ground' to the large filter

caps. This wire is the primary 'star ground'. Now solder the power transformer secondary center tap, which you have just removed, to

the center of this new 'primary star ground'. This is the only wire connected on this new bus wire. This removes the charging current

gradients from the sensitive secondary star ground, reducing power supply noise.

9.( )[DH-200 only] Cut a piece of heavy wire about 4.5 inches long. Strip both ends. Solder one end into the ground lug(2 wires are

already there), installed in step 6. Crimp the other end around the rear wire linking the two large power supply caps, i.e. the secondary

star ground. Solder securely near the center of the secondary star ground wire. All wires on the secondary star ground should be as close

as possible to the center. See Fig. B.

It is time for DH-500 and XL-600 owners, to make a choice. Now is the time to decide if you want to remove the power module

during the modification. If you have an original DH-500 with PC-10 circuit boards it will probably be necessary to remove the module.

Why? Because you will find it impossible to replace the old RCA jacks with the module in place. Also there must be a wire from the

'secondary star ground' to the ground lug between the RCA input jacks(marked "A" in Fig. B). Some later amps and PC-19 amps will

already have this wire, earlier amps will not. If you have a DH-500 and you know this ground wire is already in place and you are satisfied

with your present RCA jacks, then you can elect to leave the module in the amp. The same can be said for the XL-600.

10.( )[500, 600] If you would prefer to perform the modification without removing the module, then skip the remainder of this step.

There are several wires routed beneath the module, to the fan switch and thermal breakers. Carefully desolder(Keep records for

reconnection!) at the terminal strip end(PC-43 end in XL-600). This will allow you to remove the complete power module from the amp.

11.( )[500,600] Remove the screws holding the original circuit boards to the module, save the hardware, and 'fold back' the boards.

This will help you determine which wires can be removed from the original PCB and marked for later installation into the PA-3B. Several

wires are still hooked to both circuit boards. NOW, carefully inspect the Figures A, B and C to decide how much labeling you want to

3

Loading...

Loading...