Page 1

Instruction Book Snow Thrower Model 624804X31

Manuel d'instructions chasse-neige modèle 624804X31

Read and keep this book for future reference. This book contains important information on

AND MAINTENANCE.

Lisez et conservez ce manuel pour référence. Ce manuel contient des informations importantes

concernant la

SECURITE, LE MONTAGE, L’UTILISATION ET L’ENTRETIEN.

SAFETY, ASSEMBLY, OPERATION,

F–001043J 10/22/99

Page 2

NOTE: This unit is equipped with an internal combustion engine

and must not be used on or near any unimproved

forest–covered, brush–covered or grass–covered land unless

the engine’s exhaust system is equipped with a spark arrester

meeting applicable local or state laws (if any). If a spark arrester

is used, it must be maintained in effective working order by the

operator.

In the State of California, the above is required by law (Section

4442 of the California Public Resources Code). Other states

may have similar laws. Federal laws apply on federal lands. See

an Authorized Service Center for a spark arrester for the

muffler.

REMARQUE : cette machine est équipée d’un moteur à

combustion interne et ne doit pas être utilisée sur un terrain

forestier, buissonnant ou herbeux non préparé, à moins que le

dispositif d’échappement soit pourvu d’un pare–étincelles

conforme à la législation locale ou de l’état (le cas échéant). Si

un pare–étincelles est utilisé, celui–ci doit être maintenu en

parfait état de fonctionnement par l’utilisateur.

Au sein de l’état de Californie, la loi exige la prise en compte

des précautions mentionnées ci–dessus (clause 4442 du

California Public Resources Code). D’autres états peuvent

présenter des lois similaires. Les lois fédérales s’appliquent sur

les terres fédérales. S’adresser à un centre de maintenance

agréé pour l’achat d’un pare–étincelles pour l’échappement.

The engine exhaust from this product

contains chemicals known to the State

of California to cause cancer, birth

defects or other reproductive harm.

Le système d’échappement de cette

unité contient des substances

chimiques, qui selon l’État de

Californie, peut causer le cancer, des

malformations à la naissance, ou un

danger pour la reproduction.

F–001043J

2

Page 3

1

10

9

8

11

5

6

2

1

2

18

2

14

13

1

7

12

16

157

3

2

1

3

9

7 (71037)

1

5 (71071)

4 (6751)

12

15

13

3

4

4

11

10

6 (71060)

17

5

2

1

4

3

7

6

5

14

16

6

F–001043J

3

Page 4

7

8

2

1

1

2

1

2

9 10

6

6

78

3

1

1

3

3

4

1

1

1

2

2

5

11 12

1

6

5

4

1

2

3

7

8

6

F–001043J

4

Page 5

13

14

13

1

2

12

3

15

15

6

5

4

9

10

2

11

1

2

16

8

4

17

2

4

3

5

3

18

5

4

F–001043J

7

5

3”

7.62cm

Page 6

19

5

8

1

6

4

20

9

8

4

21

2

3

4

F–001043J

6

Page 7

22

1– 6751

2– 9524

1– 71060

2– 3943

1– 71071

2 – 73826

1– 71037

1– 6219

F–001043J

7

Page 8

CONTENTS

PRODUCT INFORMATION 8

OWNER’S INFORMATION 8

INTERNATIONAL PICTORIALS 9

ASSEMBLY 11

OPERATION 11

MAINTENANCE 14

MAINTENANCE CHART 14

TROUBLE SHOOTING CHART 17

TWO YEAR LIMITED WARRANTY

Murray, Inc. warrants to the original purchaser

that this unit shall be free from defects in

material and workmanship under normal use

and service for a period of Two (2) Year from

the date of purchase; however, this warranty

does not cover engines, accessories (such as

electric starters) and Normal Wear Parts (except

as noted below) as the companies that

manufacture these items furnish their own

warranties and provide service through their

authorized field service facilities. For additional

information, see the warranties covering these

particular parts. If you are uncertain whether

your unit contains or is equipped with one or

more of these parts, consult your dealer prior to

purchase. Subject to the terms and conditions

noted in this Limited Warranty, we shall, at our

option, repair or replace at no cost to the original

purchaser any part covered by this Limited

Warranty during the applicable warranty period.

Normal Wear Parts are defined as drive belts,

augers, shear pins, tires and headlights. These

parts are warranted to be free from defects in

material and workmanship as delivered with the

product. Any claim for repair or replacement of

Normal Wear Parts must be made within thirty

(30) days of the date of purchase. No claims

involving damage caused from material use,

abuse or misuse will be honored.

This Murray, Inc. Two (2) Year Limited

Warranty is your exclusive remedy; however,

this warranty is void or does not apply to any

unit that has been tampered with, altered,

misused, abused or used for rental or other

commercial and/or professional

(non–homeowner) uses. Your warranty does not

cover minor mechanical adjustments which are

not due to any defect in material or

workmanship. For assistance in making such

adjustments, consult your Instruction Book.

To make a claim under this Murray, Inc. Two (2)

ENGLISH

Year Limited Warranty, return the unit (or if

authorized in advance, the defective part) along

with your proof of purchase to an Authorized

Service Center near you. To locate the nearest

Authorized Service Center, call the Central Parts

Distributor for your area shown in the list

provided with your unit or check the Yellow Page

listings in your local telephone directory. If you

return the entire unit, we will repair the unit. If we

authorize the return of the defective part only, we

will either replace or repair the part.This Murray,

Inc. Two (2) Year Limited Warranty gives you

specific legal rights, and you may also have

other rights which vary from state to state. This

Limited Warranty is given in lieu of all other

expressed and implied warranties including

the implied warranty of merchantability and

warranty of fitness for a particular purpose. If

you need additional information on this written

warranty or assistance in obtaining service,

write:

MURRAY, INC.

Outdoor Power Equipment

Customer Service Department

P.O. Box 268

Brentwood, Tennessee 37027

1–800–251–8007

PRODUCT INFORMATION

The owner must be certain that all the product

information is included with the unit. This

information includes the INSTRUCTION

BOOKS, the REPLACEMENT PARTS and the

WARRANTIES. This information must be

included to make sure state laws and other laws

are followed.

OWNER’S INFORMATION

This instruction book is written for a person with

some mechanical ability. Like most service

books, not all the steps are described. Steps on

how to loosen or tighten fasteners are steps

anyone can follow with some mechanical ability.

Read and follow these instructions before you

use the unit.

Know your product: If you understand the unit

and how the unit operates, you will get the best

performance. As you read this manual, compare

the illustrations to the unit. Learn the location

and the function of the controls. To help prevent

an accident, follow the operating instructions

and the safety rules. Keep this manual for future

reference.

IMPORTANT: Many units are not assembled

and are sold in cartons. It is the responsibility of

the owner to make sure the assembly instructions in this manual are exactly followed. Other

units are purchased in an assembled condition.

On assembled units, it is the responsibility of the

owner to make sure the unit is correctly assembled. The owner must carefully check the

unit according to the instructions in this manual

before it is first used.

WARNING: Look for this symbol to indicate

important safety precautions. This symbol

indicates: “Attention! Become Alert! Your

Safety Is At Risk.”

Responsibility Of The Owner

The responsibility of the owner is to

follow the instructions below.

1. Carefully read and follow the rules for safe

operation.

2. Follow all the assembly and preparation

instructions.

3. Inspect the unit.

4. Make sure that the operator of the unit

knows how to correctly use all standard

and accessory equipment.

5. Operate the unit only with guards, shields,

and other safety items in place and working

correctly.

6. Correctly adjust the unit.

7. Service the unit only with authorized or approved replacement parts.

8. Complete all maintenance on the unit.

Environmental Awareness

Do not fill the engine’s fuel tank completely

full.

Drain fuel for off–season storage.

Use only unleaded gasoline.

Service the air cleaner regularly.

Change oil regularly. Use 5W–30 oil.

Tune–up the engine regularly.

Keep equipment in efficient operating

condition.

Dispose of used engine oil properly.

F–001043J

8

Page 9

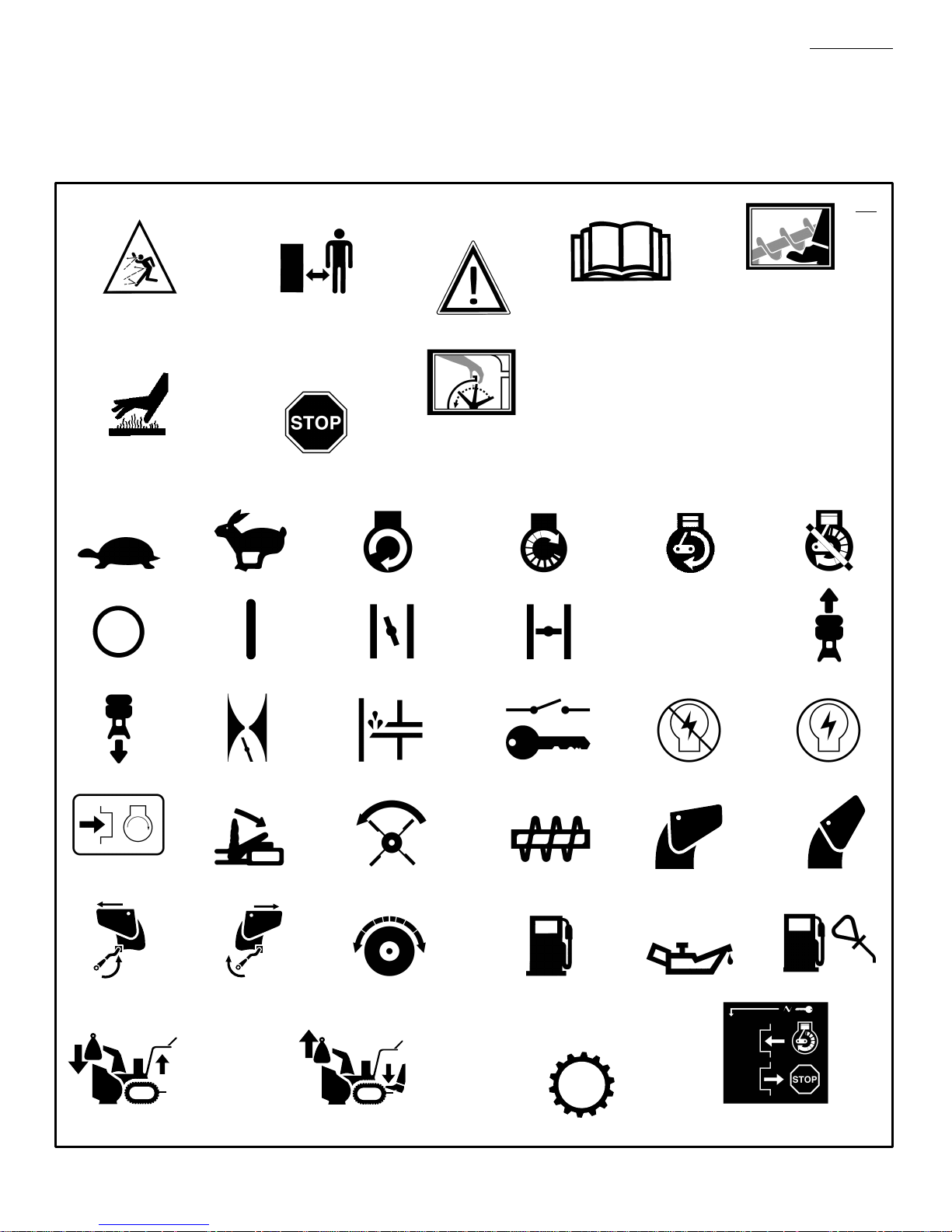

INTERNATIONAL PICTORIALS

IMPORTANT: The following pictorials are located on your unit or on literature supplied

with the product. Before you operate the

unit, learn and understand the purpose for

each pictorial.

ENGLISH

Safety Warning Symbols

DANGER

Thrown Objects.

Keep Bystanders Away.

WARNING

Hot Surface

DANGER

Thrown Objects.

Keep Bystanders Away.

STOP

WARNING

DANGER

Stop The Engine

Before Unclogging

Discharge Chute!

IMPORTANT

Read Owner’s Manual

Before Operating

This Machine.

Control And Operating Symbols

Slow Fast Electric Start Engine Start Engine Run

DANGER

Avoid Injury From

Rotating Auger. Keep

Hands, Feet And

Clothing Away.

Engine Off

23

Engine Stop On Choke Off Choke On

Reverse

Push To Engage

Electric Starter

Discharge LEFT Discharge RIGHT

KGS

Throttle Primer Button Ignition Key Ignition Off Ignition On

Engage

Auger Clutch Auger Collector

Drive Clutch

KGS

Fuel Oil Fuel Oil Mixture

N

Neutral

Discharge DOWN Discharge UP

Forward

Weight Transfer

Lift Handle To Engage

F–001043J

Weight Transfer

Depress Pedal To Disengage

Transmission

Insert To Run, Pull Out To Stop.

Ignition Key

9

Page 10

Safe Operation Practices for Snow Throwers

As Recommended By: American National Standards Institute.

ENGLISH

IMPORTANT: Safety standards require operator

presence controls to minimize the risk of injury.

Your snow thrower is equipped with such controls. Do not attempt to defeat the function of the

operator presence control under any circumstances.

Training

1. Read the operating and service ins t ruct ion

manual carefully. Be thoroughly familiar with

the controls and the proper use of the equipment. Know how to stop the unit and disengage the controls quickly.

2. Never allow children to operate the equipment. Never allow adults to operate the

equipment without proper instruc t ion.

3. Keep the area of operation clear of all per sons, particularly small children and pets.

4. Exercise caution to avoid slipping or falling

especially when operating in reverse.

Preparation

1. Thoroughly inspect the area where the equipment is to be used and remove all doorm at s,

sleds, boards, wires, and other foreign objects.

2. Disengage all clutches before start ing the engine (motor).

3. Do not operate the equipment wit hout wear ing adequate winter outer garments. Wear

footwear that will improve foot ing on slippery

surfaces.

4. Handle fuel with care; it is highly flam mable.

a. Use an approved fuel container.

b. Never remove fuel tank cap or add fuel to

a running engine (motor) or hot engine

(motor).

c. Fill fuel tank outdoors with extreme care.

Never fill fuel tank indoors.

d. Replace fuel cap securely and wipe up

spilled fuel.

e. Never store fuel or snow thrower with fuel

in the tank inside of a building where

fumes may reach an open flame or spark.

f. Check fuel supply before each use, allow-

ing space for expansion as the heat of the

engine (motor) and/or sun can cause fuel

to expand.

5. For all units with electric starting motors use

electric starting extension cords certified

CSA/UL. Use only with a receptac le that has

been installed in acc ordanc e with local inspection authorities.

6. Adjust the snow thrower height to clear gravel

or crushed rock surfac e.

7. Never attempt to mak e any adjus tm ents

while the engine (motor) is running (except

when specifically recommended by manuf ac turer).

8. Let engine (motor) and snow thrower adjust

to outdoor temperatures before st art ing to

clear snow.

9. Always wear safety glas s es or eye shields

during operation or while perform ing an adjustment or repair to protect eyes from foreign

objects that may be thrown from the snow

thrower.

Operation

1. Do not operate this machine if you are taking

drugs or other medication which can caus e

drowsiness or affect your ability to operate

this machine.

2. Do not use this machine if you are mentally

or physically unable to operate this mac hine

safely.

3. Do not put hands or feet near or under rotat ing parts. Keep clear of the discharge opening at all times.

4. Exercise extreme caution when operating on

or crossing gravel driv es, walks or roads.

Stay alert for hidden hazards or traffi c.

5. After striking a foreign object, stop the engine

(motor), remove the wire from the spark plug,

thoroughly inspect snow thrower for any

damage, and repair the damage before restarting and operating the snow thrower.

6. If the unit should start to vibrat e abnormally,

stop the engine (motor) and check im mediately for the cause. Vibration is generally a

warning of trouble.

7. Stop the engine (motor) whenever you leave

the operating position, before unclogging the

auger/impeller housing or dis charge chute

and when making any repairs, adjus tm ents ,

or inspections.

8. When cleaning, repairing, or inspecting, make

certain the auger/impeller and all moving

parts have stopped and all cont rols are dis engaged. Disconnect the spark plug wire and

keep the wire away from the spark plug to

prevent accidental start ing.

9. Take all possible precaut ions when leaving

the snow thrower unattended. Dis engage the

auger/ impeller, stop engine (motor), and remove key.

10. Do not run the engine (motor) indoors, except

when starting the engine (motor) and for

transporting the snow thrower in or out of the

building. Open the outside doors; exhaust

fumes are dangerous (containing CARBON

MONOXIDE, an ODORLESS and DEADLY

GAS).

11. Do not clear snow across the face of slopes.

Exercise extreme caution when changing

direction on slopes. Do not attempt to clear

steep slopes.

12. Never operate the snow thrower without

proper guards, plates or other safety protective devices in place.

13. Never operate the snow thrower near enclosures, automobiles, window wells, drop–offs ,

and the like without proper adjust ment of the

snow discharge angle. Keep children and

pets away.

14. Do not overload the machine capacit y by attempting to clear snow at too fas t a rate.

15. Never operate the machine at high trans port

speeds on slippery surfac es. Look behind

and use care when backing up.

16. Never direct discharge at by s tanders or allow

anyone in front of the unit.

17. Disengage power to the collector/impeller

when snow thrower is transport ed or not in

use.

18. Use only attachments and accessories approved by the manufacturer of the snow

thrower (such as tire chains, electric start kits,

ect.).

19. Never operate the snow thrower without good

visibility or light. Always be sure of your foot ing and keep a firm hold on the handles.

Walk;never run.

20. Do not over–reach. Keep proper footing and

balance at all times.

21. Exercise caution if operating on steep sloping surfaces.

22. This snow thrower is for use on sidewalks,

driveways and other ground level surfaces.

23. Do not use the snow thrower on surfaces

above ground level such as roofs of residences, garages, porches or other such

structures or buildings.

Maintenance And Storage

1. Check shear bolts and other bolts at frequent

intervals for proper tightness to be sure the

equipment is in safe working conditi on.

2. Never store the snow thrower with fuel in the

tank inside a building where ignition sources

are present such as hot water and space

heaters, clothes dryers , and the like. Allow

the engine (motor) to cool before st oring in

any enclosure.

3. Always refer to operator’s guide instructions

for important details if the snow thrower is to

be stored for an extended period.

4. Maintain or replace safety and instruc tion la bels, as necessary.

5. Run the snow thrower a few minutes after

throwing snow to prev ent freeze–up of the

auger/impeller.

F–001043J

10

Page 11

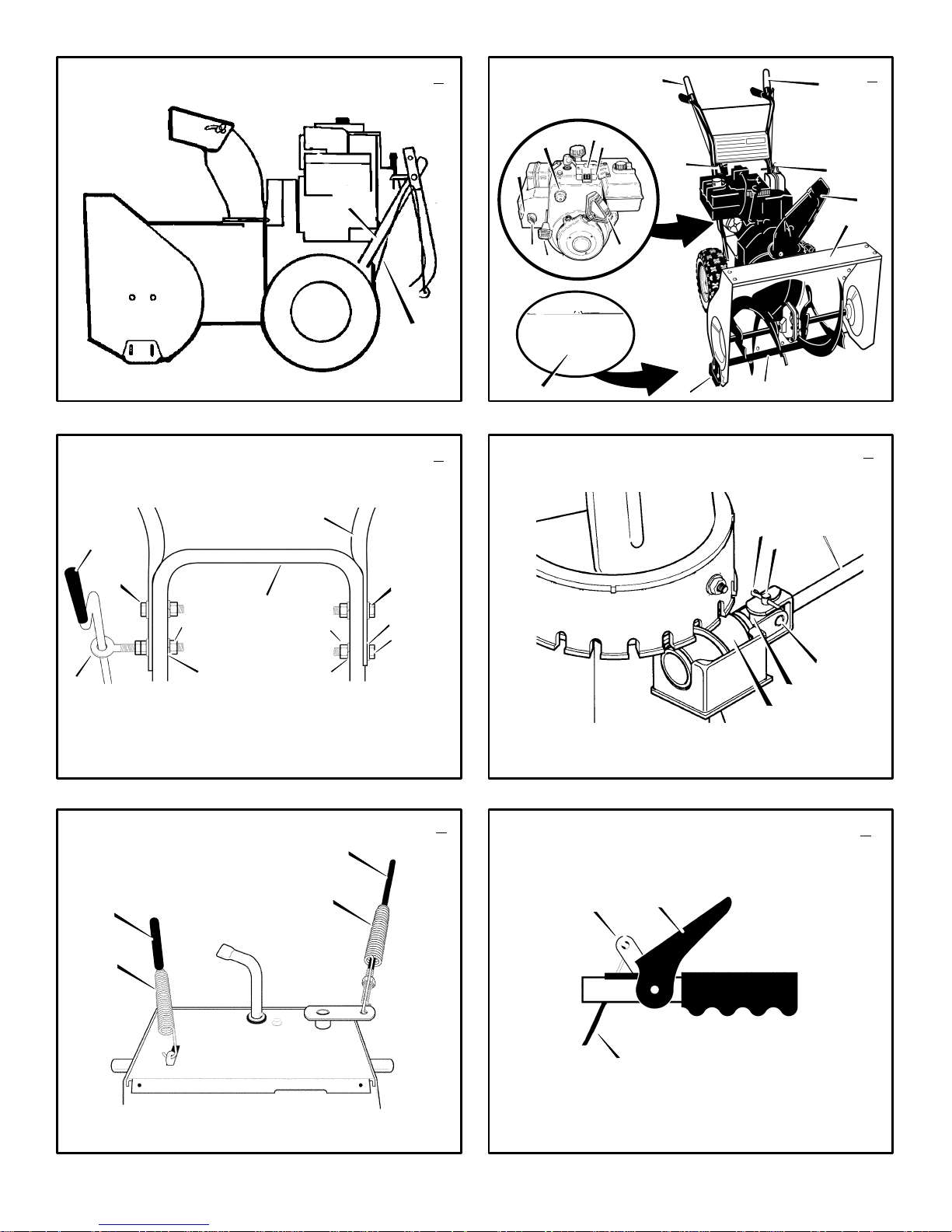

ASSEMBLY

Read and follow the assembly and adjustment

instructions for your snow thrower. All fasteners

are in the parts bag. Do not discard any parts or

material until the unit is assembled.

WARNING: Before doing any

assembly or maintenance to the

snow thrower, remove the wire

from the spark plug.

NOTE: In this instruction book, left and right

describe the location of a part from the operator’s position behind the unit.

NOTE: Torque is measured in foot pounds

(metric N.m). This measurement describes

how tight a nut or bolt must be. The torque is

measured with a torque wrench.

NOTE: Illustrations begin on page 3.

NOTE: To assemble the following loose

parts, use the fasteners shown at full size in

Figure 22.

Tools Required

1 Knife

1 Pliers

1 1/2 inch adjustable open end wrenches

1 9/16 inch adjustable open end wrenches

1 3/4 inch adjustable open end wrenches

1 Measuring tape or ruler

1 Screwdriver

How To Remove The Snow Thrower

From The Carton

1.

(Figure 1)

shipping position.

2. Locate all parts that are packed separately

and remove from the carton.

3. Cut and discard the plastic ties that secure

the crank assembly to the pallet.

4. Remove and discard the packing material

from around the snow thrower.

5. Cut down all four corners of the carton and

lay the side panels flat.

6. Hold onto the lower handle and pull the snow

thrower off the carton.

CAUTION: DO NOT back over cables.

7. Remove the packing material from the handle assembly.

8. Cut the ties that secure the clutch control

cables (1) to the lower handle (2). Move the

cables away from the motor frame.

How To Assemble The Handle And

Crank Assembly

1.

(Figure 3)

fasteners (1) in the upper holes of the lower

handle.

2.

(Figure 2)

forward position.

3.

(Figure 3)

operating position.

NOTE: Make sure the cables are not

caught between the upper and lower handle.

4. Install the screw (4), flatwasher (5), lockwasher (6), and hex nut (7) into the bottom

hole on the right side of the handles. DO

NOT tighten until all fasteners are in place.

F–001043J

The snow thrower is shown in the

Loosen, but do not remove, the

Put the shift lever (6) into first

Raise the upper handle (2) to the

5. Locate the crank assembly (18) removed

earlier. Remove the locknut (9) and flat-

washer (10) from the eye bolt assembly

(11).

6. Install the eye bolt (11) through the lower

hole on the left side of the handles.

7. Install the flatwasher (10) and the locknut

(9) loosely on the eye bolt (11).

8.

(Figure 4)

clevis pin (13), universal joint pin (14), and

universal joint (16) from the crank rod assembly (15).

9. Mount the universal joint (16) into the end

of the worm gear (17). Make sure the large

holes are aligned.

10.Insert universal joint pin (14). Make sure

opening in universal joint pin (14) is aligned

with small opening in universal joint (16).

11.Mount the yoke end of crank rod (15)

around the universal joint (16). Fasten with

clevis pin (13) and cotter pin (12). Spread

ends of cotter pin (12) to lock in place.

12.

(Figure 3)

Make sure eye bolt (11) is properly aligned

and the crank (18) can freely rotate.

13.Tighten all handle fasteners.

Carefully remove cotter pin (12),

Tighten nut on eye bolt (11).

Check The Cables

1.

(Figure 5)

(1) and the auger drive cable (2). If the bot-

tom of the cables have become disconnected, reinstall the cable springs. Make sure

the long spring (3) is attached to the traction

drive and the short spring (4) is attached to

the auger drive.

2.

(Figure 6)

become disconnected from the drive levers

(6), attach the cables (5) to the “Z” fitting

(7).

How To Set The Skid Height

The snow thrower is equipped with height adjustable skids (7) mounted on the outside of the

auger housing (4). To adjust the height of the

skids, see “How To Adjust The Height Of The

Skids” in the Maintenance section.

Check the traction drive cable

If the top of the cables (5) have

(Figure 2)

How To Prepare The Engine

NOTE: The engine was shipped from the factory filled with oil. Check the level of oil. Add

oil as needed. Engine does not contain GASOLINE.

WARNING: Follow the engine

manufacturer’s instructions for the

type of fuel and oil to use. Always

use a safety fuel container. Do not smoke

when adding gasoline to the engine. When

inside an enclosure, do not fill with gasoline. Before you add fuel, stop the engine.

Let the engine cool for several minutes.

Check the oil. See the engine manufacturer’s

instructions for the type of fuel and oil to use.

Before you use the unit, read the information on

safety, operation, maintenance, and storage.

OPERATION

NOTE: Illustrations begin on page 3.

Know Your Snow Thrower

Read this Instruction Book and safety rules before operation the snow thrower. Compare the

11

(Figure 2)

ENGLISH

illustration with your snow thrower to familiarize

yourself with the location of various controls and

adjustments.

Traction Drive Lever (1) – Select the forward or

reverse direction of travel.

Crank Assembly (2) – Changes the direction of

the discharge chute.

Discharge Chute (3) – Changes the distance the

snow is thrown.

Auger Drive Lever (5) – Starts and stops the auger and impeller (snow gathering and throwing).

Speed Shift Lever (6) – Selects the speed of the

snow thrower.

Height Adjust Skid (7) – Adjusts the ground

clearance of the auger housing.

Ignition Key (8) – Must be inserted to start the engine.

Primer Button (9) – Injects fuel directly into the

carburetor for fast starts in cold weather.

Electric Start Button (10) – On electric start models, used to start the engine.

Switch Box (11) – On electric start models, used

to attach a 120 volt electric power cord.

Recoil Starter Handle (12) – Use to manually

start the engine.

Throttle Control (13) – Controls the speed of the

engine.

Choke Control (14) – Use to start a cold engine.

How To Control

The Discharge Of The Snow

WARNING: Never direct the discharge of snow toward bystanders.

WARNING: Always stop the engine

before unclogging the discharge

chute or the auger housing and be-

fore leaving the snow thrower.

1.

(Figure 2)

change the discharge direction of the snow.

2.

(Figure 7)

chute deflector (2).

3. Move the chute deflector (2) up for more

distance or down for less distance.

4. Tighten the wing knob (1).

How To Stop

The Snow Thrower

1. To stop discharging snow, release the auger

drive lever (5).

2. To stop the wheels, release the traction

drive lever (1).

3. To stop the engine, push the throttle control

lever (13) to off and remove the ignition key

(8).

How To Go Forward or Backward

(Figure 2)

1. To change the ground speed, first release the

traction drive lever (1) and then move the

speed shift lever (6) to the desired speed.

Turn the crank assembly (2) to

Loosen the wing knob (1) on the

(Figure 2)

Page 12

2. Ground speed is determined by snow conditions. Select the speed by moving the speed

shift lever (6) into the appropriate notch on

the shift lever plate.

Speed 1, 2 Wet, Heavy

Speed 3 Light

Speed 4 Very Light

Speed 5, 6 Transport only

3. To go forward, engage the traction drive

lever (1). Maintain a firm hold on the handle

as the snow thrower starts to move forward.

Guide the snow thrower by moving the handle either left or right. Do not attempt to push

the snow thrower.

4. To go backward, release the tractor drive

lever (1).

5. Move the speed shift lever (6) into either

first or second reverse.

6. Engage the traction drive lever (1).

IMPORTANT: Do not move the speed shift

lever (6) while the traction drive lever (1) is

engaged.

How To Throw Snow

1. Engage the auger drive lever (5).

2. To stop throwing snow, release the auger

drive lever (5).

WARNING: The operation of any

snow thrower can result in foreign

objects being thrown into the eyes,

which can result in severe eye damage.

Always wear safety glasses or eye shields

while operating the snow thrower. We recommend standard safety glasses or use a

wide vision safety mask over your glasses.

(Figure 2)

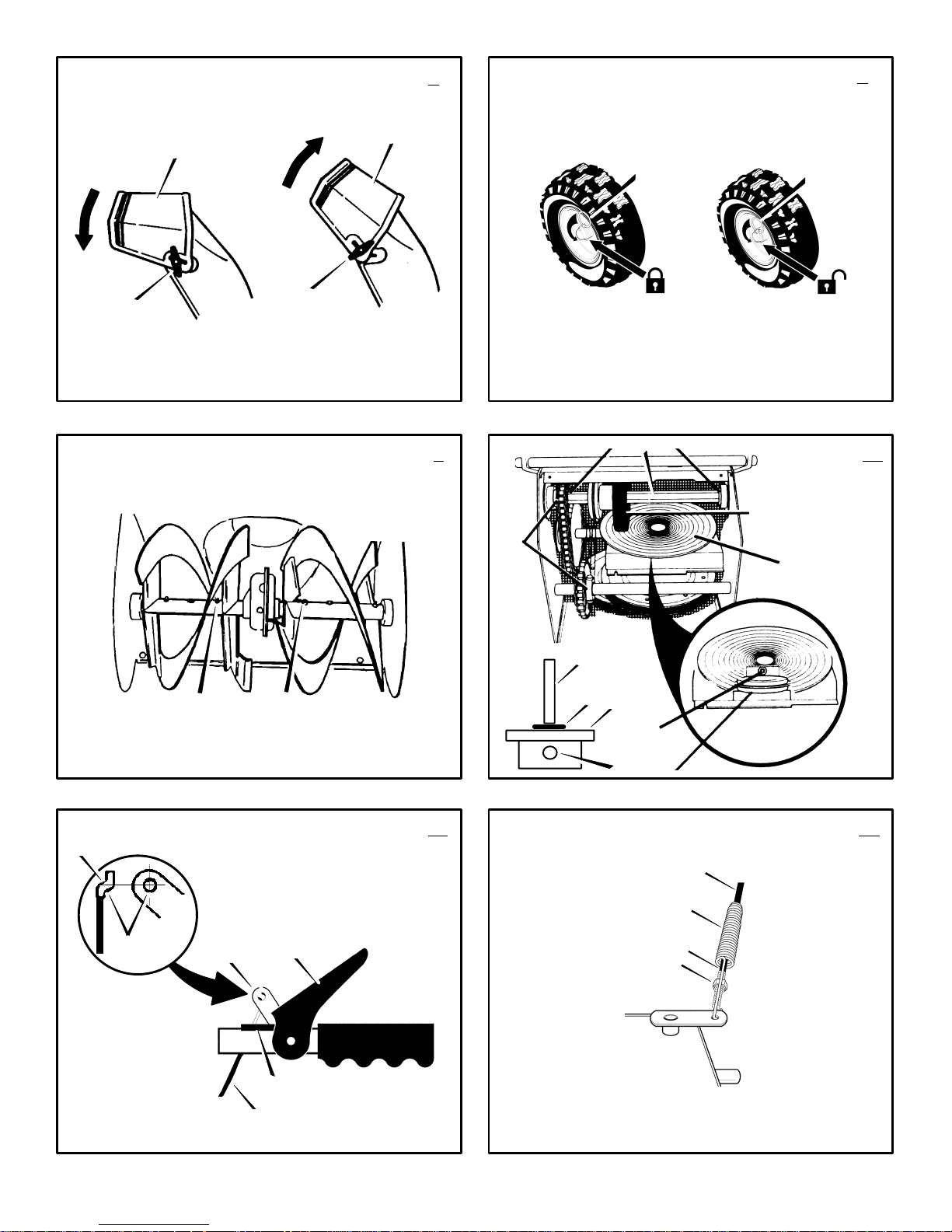

How To Use The Wheel Lockout Pin

(Figure 8)

1. The left hand wheel is secured to the axle

with a klick pin (1). This unit was shipped

with this klick pin (1) through the wheel hole

in the locked position (2).

2. For ease of maneuverability in light snow

conditions, change the klick pin (1) to an

unlocked position (3).

3. Disconnect the klick pin (1) from the wheel

locked position (2). Push the klick pin (1)

through the unlocked axle hole only. The unit

is now in the single wheel drive unlocked

position (3).

Before Starting The Engine

1. Before you service or start the engine, familiarize yourself with the snow thrower. Be

sure you understand the function and location of all controls.

2. Check the tension of the clutch cable before

starting the engine. See “How To Adjust The

Clutch Cable” in the Maintenance section of

this manual.

3. Make sure that all fasteners are tight.

4. Make sure the height adjust skids are properly adjusted. See “How To Adjust The Height

Of The Skids” in the Maintenance section of

this manual.

5. Check the air pressure in the tires. The correct air pressure is 14 PSI (1 BAR) to 17 PSI

(1.25 BAR). Do not exceed the maximum

amount of air pressure shown on the side of

the tire.

F–001043J

How To Stop The Engine

To stop the engine, move the throttle control

(3) to the stop position and remove the ignition

key (8). Keep the ignition key (8) in a safe

place. The engine will not start without the ignition key (8).

How To Start The Engine

Models equipped with an Electric Starter

NOTE: An electric starter kit can be added to

recoil start engines. Electric starter kits are

available from your nearest authorized service center.

WARNING: The starter is equipped

with a three–wire power cord and

plug and is designed to operate on

120 volt A.C. household current. The power

cord must be properly grounded at all tim es

to avoid the possibility of electrical shock

which can injure the operator. Carefully follow all instructions in the “How To Start The

Engine” section. Make sure that your house

wiring is a three–wire grounded system . If

you are not sure, ask a li censed el ectri cian.

If your house wire system is not a

three–wire grounded system, do not use

this electric starter under any conditions. If

your system is grounded but a three–hole

grounded receptacle is not available to start

the engine, have a three–hole grounded receptacle installed by a licensed electrician.

To connect a 120 volt A.C. power cord, always connect the power cord to the switch

box (11) on the engine first. Then, plug the

other end into the three–hole grounded re ceptacle. When disconnecting the power

cord, always unplug the end from the

three–hole grounded receptacle first.

How To Start A Cold Engine

1. Check the engine oil.

2. Fill the fuel tank with regular unleaded petrol.

See “How To Prepare The Engine”.

3. Make sure the traction drive lever (1) and

the auger drive lever (5) are in the disengaged (released) position.

4. Move the throttle control (13) to the fast

position.

5. Insert the ignition key (8) into the ignition

slot. Make sure the ignition key (8) snaps

into place. Do not turn the ignition key (8).

Remove the extra ignition key and keep in a

safe place.

6. Move the choke control (14) to the full

choke position.

7.

(Electric Start)

the switch box (11) located on the engine.

8.

(Electric Start)

power cord into a three–hole, grounded 120

VOLT, A.C. receptacle. (See the WARNING

in this section).

9. Push the primer button (9). Every time you

push the primer button (9), wait two seconds. For the number of times required to

push the primer button (9), see the engine

manufacturer’s instructions.

Connect the power cord to

Plug the other end of the

(Figure 2)

(Figure 2)

(Figure 2)

12

ENGLISH

10.

(Electric Start)

button (10) until the engine starts. Do not

crank for more than 10 seconds at a time.

The electric starter is thermally protected. If

the electric starter overheates, it will automatically stop and can only be restarted

when it has cooled to a safe temperature. A

wait of about 5 to 10 minutes is required to

allow the electric starter to cool.

11.

(Recoil Start)

handle (12). Do not allow the recoil starter

handle (12) to snap back. Slowly return the

recoil starter handle (12).

12.If the engine does not start in 5 or 6 tries,

See the “Trouble Shooting Chart” Instructions.

13.

(Electric Start)

lease the electric start button (10) and

move the choke control (14) to 1/2 choke

position. When the engine runs smoothly,

move the choke control (14) to the off position.

14.

(Electric Start)

cord from the three–hole receptacle. Then,

disconnect the power cord from the switch

box (11).

NOTE: In temperatures below 0F, allow

the engine to warm up for several minutes

before blowing snow.

15.When throwing snow, always run the engine

with the throttle control (13) in the fast position.

WARNING: Never run the engine

indoors or in enclosed, poorly ven-

tilated areas. Engine exhaust contains carbon monoxide, an odorless and

deadly gas. Keep hands, feet, hair and

loose clothing away from any moving parts

located on the engine or the snow thrower.

The temperature of muffler and nearby

areas may exceed 150°F. Avoid these

areas.

How To Start A Warm Engine

If an engine has been running and is still warm,

leave the choke control (14) in the off position

and do not push the primer button (9). If the

engine fails to start, follow the instructions “How

To Start A Cold Engine”.

NOTE: Do not use the primer button (9) to

start a warm engine.

How T o Start An Engine W ith A Frozen Electric

Starter

If the electric starter is frozen and will not turn

the engine, follow the instructions below.

1. Pull out the recoil starter handle (12) as far

2. Quickly release the recoil starter handle

If the engine still fails to start, repeat the two previous steps until the engine starts. Then, continue with the directions “How To Start A Cold

Engine”.

To help prevent the possible freeze–up of the

recoil starter and of the engine controls, proceed

as follows after each snow removal job.

1. With the engine running, quickly pull the re-

(Figure 2)

as possible.

(12). Allow the recoil starter handle (12) to

snap back against the recoil starter.

coil starter handle (12) three or four times

with a continuous full arm stroke. This will

produce a loud clattering sound that is not

harmful to the engine or starter.

Push on the electric start

Rapidly pull the recoil starter

When the engine starts, re-

First disconnect the power

(Figure 2)

Page 13

2. Stop the engine. Wipe all snow and moisture

from the carburetor cover, control levers and

cables. Also move the throttle control (13),

choke control (14), and recoil starter handle (12) several times.

How To Remove Snow or Debris From

The Auger Housing

WARNING: Do not attempt to remove snow or debris that may become lodged in auger housing

without taking the following precautions.

1. Release the auger drive lever (5).

2. Move the throttle control (13) to the stop

position.

3. Remove (do not turn) the ignition key (8).

4. Disconnect the spark plug wire.

(Figure 2)

5. Do not place your hands in the auger housing (4) or the discharge chute (3). Use a

pry bar to remove any snow or debris.

Snow Throwing Tips

1. For maximum snow thrower efficiency,

change the ground speed, NEVER change

the engine speed. The engine is designed to

deliver maximum performance at full throttle

and must be run in the fast position at all

times. In deep, freezing, or wet snow, reduce

forward speed. If the wheels slip, also reduce

forward speed.

2. Most efficient snow throwing is accomplished

when the snow is removed immediately after

if falls.

3. For complete snow removal, slightly overlap

each previous path.

4. Whenever possible, discharge the snow

down wind.

ENGLISH

5. For normal usage, set the skids so that the

scraper bar is 1/8” above the skids. For extremely hard–packed snow surfaces, adjust

the skids upward so that the scraper bar

touches the ground.

6. Rocks and gravel must not be picked up and

thrown by the machine. On gravel or crushed

rock surfaces, set the skids at 1–1/4 inch below the scraper bar. See “How To Adjust The

Height Of The Skids” in the Maintenance

section.

7. After each snow throwing job, allow the engine to idle for a few minutes. The snow and

accumulated ice will melt off the engine.

8. Clean the snow thrower after each use.

9. Remove ice, snow and debris from the entire

snow thrower. Flush with water to remove all

salt or other chemicals. Wipe snow thrower

dry.

F–001043J

13

Page 14

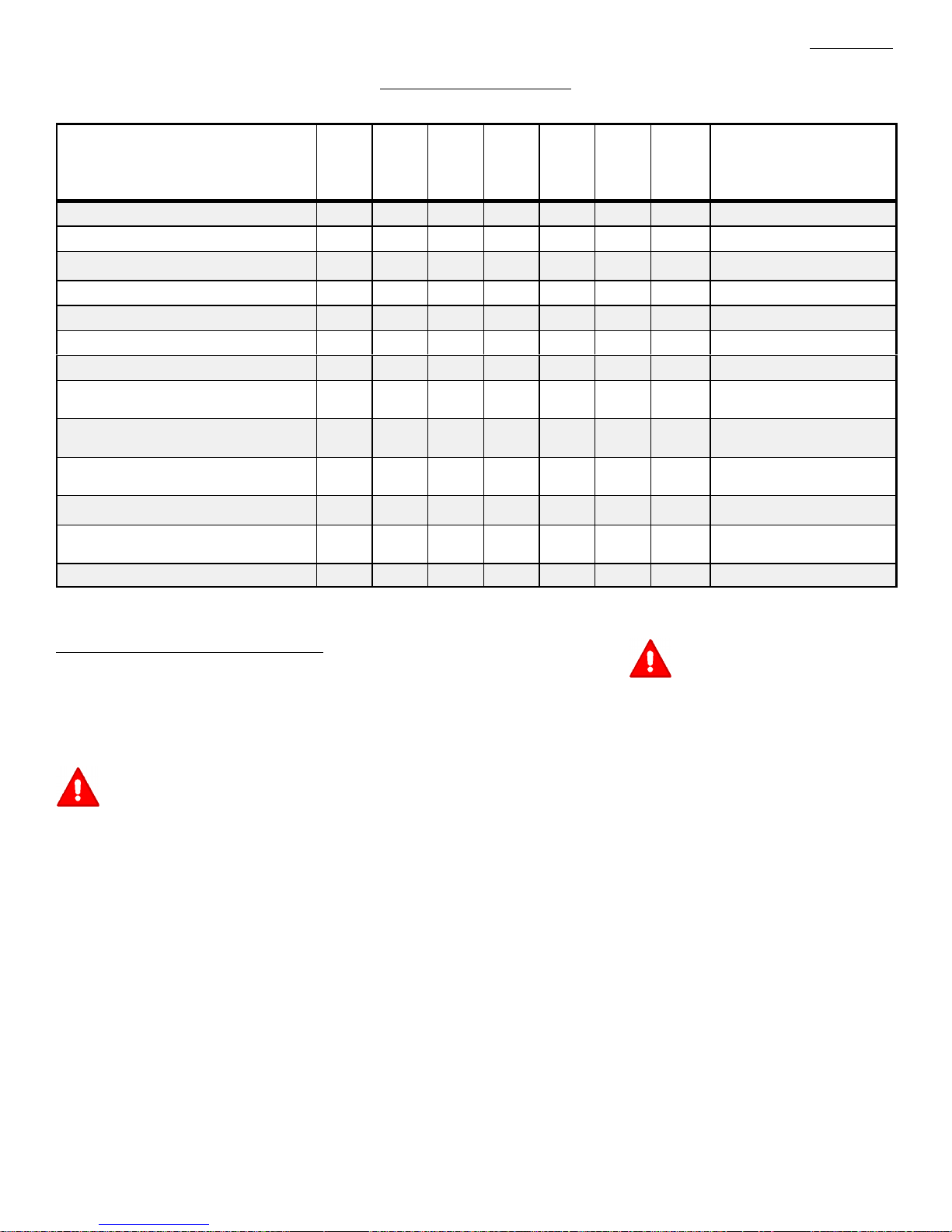

CUSTOMER RESPONSIBILITIES

SERVICE RECORDS

Fill in dates as you

complete regular

service.

Check Engine Oil Level

Change Engine Oil

Check And Tighten All Screws and Nuts

Check Spark Plug

Adjust Drive Belt

Check Fuel

Drain Fuel

Check Auger Clutch Cable Adjustment

(See Cable Adjustment)

Check Traction Clutch Cable Adjustment

(See Cable Adjustment)

Lubricate Disc Drive Plate Zerk

(See Maintenance)

Lubricate All Pivot Points

Lubricate Auger Shaft

(See Shear Bolt Replacement)

Lubricate Drive Chains and Sprockets

MAINTENANCE CHART

Before

Each

Use

First

2

Hours

Every

5

Hours

Every

10

Hours

Every

25

Hours

√ √ √

√ √

√ √ √

√

√ √

√ √

√

√ √

√ √

√ √

√ √

Each

Season

Before

Storage

√

√

√

ENGLISH

SERVICE DATES

MAINTENANCE

NOTE: Illustrations begin on page 3.

Use the following maintenance section to keep

your unit in good operating condition. All the

maintenance information for the engine is in the

engine manufacturer’s instructions. Before you

start the engine, read this book.

WARNING: Before you make an inspection, adjustment (except

carburettor), or repair, disconnect

the wire from the spark plug.

General Recommendations

The warranty on this snow thrower does not cover items that have been subjected to operator

abuse or negligence. To receive full value from

the warranty, the operator must maintain the

snow thrower as instructed in this manual.

Some adjustments must be made periodically to

properly maintain the snow thrower.

After Each Use

Check for any loose or damaged parts.

Tighten any loose fasteners.

Check and maintain the auger.

Check controls to make sure they are

functioning properly.

If any parts are worn or damaged, replace

immediately.

F–001043J

All adjustments in the Maintenance section of

this manual should be checked at least once

each season.

As Required

The following adjustment should be preformed

more than once each season.

1. Adjust the auger drive belt after the first 2 to

4 hours, again at mid–season, and twice

each season thereafter. See “How To Adjust

The Auger Drive Belt” in the Maintenance

section.

Lubrication

Every 10 Hours

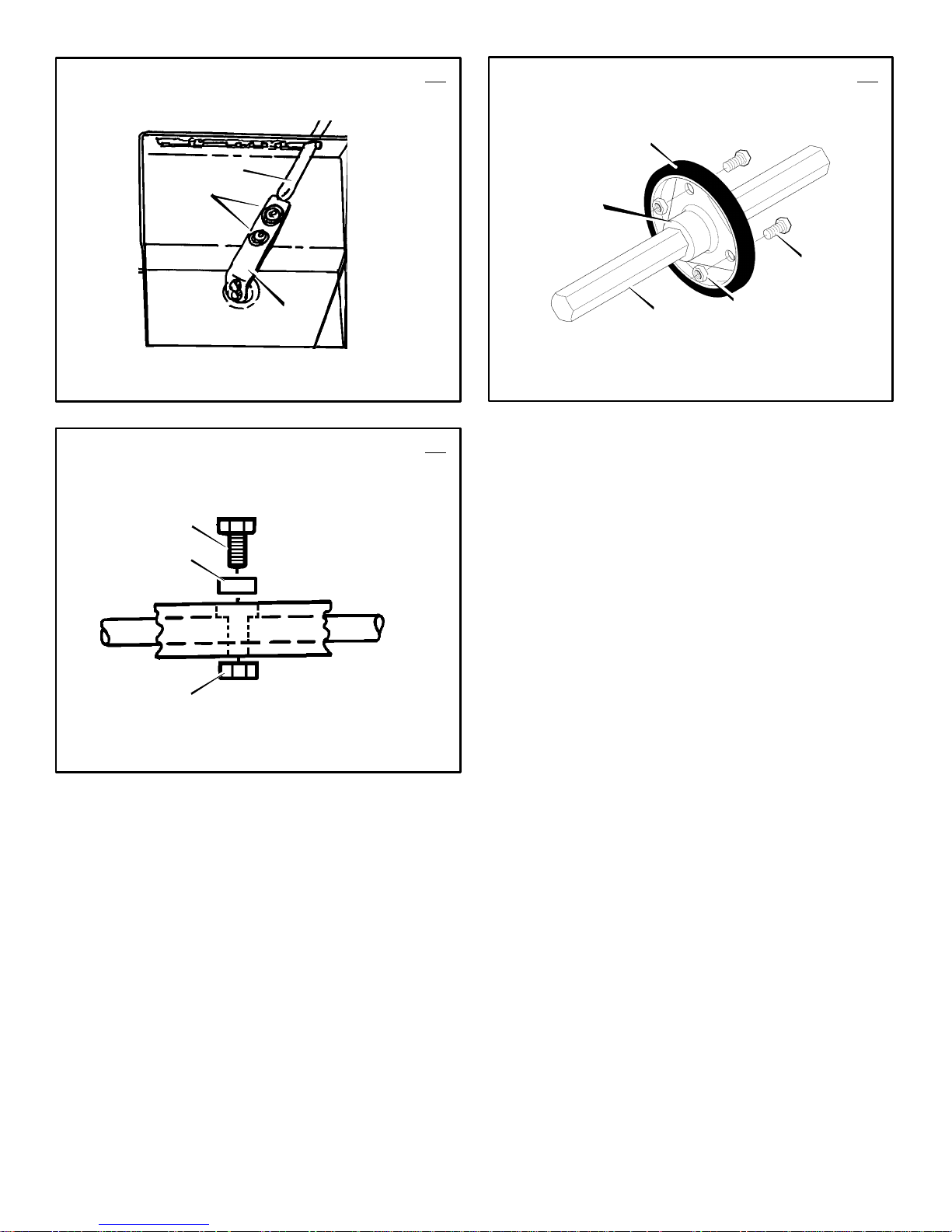

1. Lubricate the Zerk fittings (1) every ten

hours with a grease gun.

2. Each time a shear bolt is replaced, the auger

shaft must also be greased.

3. Lubricate all pivot points.

Every 25 Hours

Lubricate the disc drive plate (1) every 25

hours, at the end of the season and before storage.

1.

(Figure 2)

first gear.

2. Remove the gas from the gas tank. Stand

the snow thrower up on the front end of the

auger housing (4).

(Figure 9)

(Figure 10)

Move the speed shift lever (6) to

14

WARNING: Drain the gasoline outdoors, away from fire or flame.

3.

(Figure 16)

side of the bottom panel (2).

4. Loosen the bolts (3) on each side of the bot-

tom panel (2).

5. Remove the bottom panel (2).

6.

(Figure 10)

clockwise by hand until the Zerk fitting (2) is

visible.

7. To prevent the rubber friction wheel (3) from

contacting the drive disc plate (1), put a

coin (4) (or a shim of equal thickness) between the rubber friction wheel (3) and the

disc drive plate (1).

8. Lubricate the Zerk fitting (2) with a grease

gun. Use a high temperature EP Moly

grease. Fill the Zerk fitting (2) only until

grease becomes visible below the bearing

assembly (5) located under the Zerk fitting

(2). DO NOT over fill. Clean all excess

grease from the friction disc hub.

CAUTION: Do not allow grease to come

in contract with the disc drive plate (1) or

the friction wheel (3) or damage will result.

9. Remove coin (4) used in step 7. Make sure

that a gap exists between the friction wheel

(3) and the disc drive plate (1).

10.

(Figure 16)

11.Tighten the bolts (3) on each side of the bot-

tom panel (2).

12. Install the bolts (1) on each side of the bottom panel (2).

Remove the bolts (1) on each

Turn the disc drive plate (1)

Install the bottom panel (2).

Page 15

Items Not To Lubricate

1. Do not lubricate the hex shaft and sprockets (6). All bearings and bushings are life-

time lubricated. For storage, put a slight

amount of 5W–30 motor oil on a cloth and

wipe the hex shaft and sprockets (6) to

prevent rust.

2. If grease or oil comes in contact with the

disc drive plate (1) or the friction wheel

(3), the friction wheel (3) can be damaged.

Make sure to thoroughly clean the disc drive

plate (1) and the friction wheel (3).

CAUTION: Any greasing or oiling of the

above components can cause contamination of the friction wheel (3). If the disc

drive plate (1) or the friction wheel (3) become contaminated with grease or oil,

damage to the friction wheel will result.

3. The auger gear case is lubricated at the factory and does not require additional lubrication. If for some reason the lubricant leaks

out, have the auger gear case checked by a

factory authorized service center.

(Figure 10)

How To Adjust The Height Of The Skids

(Figure 2)

This snow thrower is equipped with two height

adjustable skids (7). These skids elevate the

front of the snow thrower. For normal hard surfaces, such as a paved driveway or walk, adjust

the skids as follows.

1. Put the snow thrower on a level surface.

2. Make sure both tires are equally inflated.

The correct air pressure is 14 PSI (1 BAR) to

17 PSI (1.25 BAR). Do not exceed the maximum amount of air pressure shown on the

side of the tire.

3. Put the extra shear bolts (found in the parts

bag) under each end of the scraper bar (15)

next to the adjustable skids (7).

4. Loosen the mounting nuts (16) that hold the

adjustable skids (7). To bring the front of the

snow thrower down, raise each adjustable

skids (7) . Tighten the mounting nuts (16).

NOTE: For rocky or uneven surfaces, raise

the front of the snow thrower by moving the

adjustable skids (7) down.

WARNING: Be certain to maintain

proper ground clearance for the

area to be cleared. Objects such

as gravel, rocks or other debris, if struck

by the impeller, can be thrown with sufficient force to cause personal injury, property damage or damage to the snow thrower.

How To Adjust

The Scraper Bar

After considerable use, the scraper bar (15) will

become worn. The scraper bar (15), in conjunction with the skids, must be adjusted to allow

1/8 inch clearance between the scraper bar

(15) and the sidewalk or area to be cleared.

1. Put the snow thrower on a level surface.

2. Make sure both tires are equally inflated.

The correct air pressure is 14 PSI (1 BAR) to

17 PSI (1.25 BAR). Do not exceed the maximum amount of air pressure shown on the

side of the tire.

3. Loosen the carriage bolts and nuts that hold

the scraper bar (15) to the auger housing

(4).

F–001043J

(Figure 2)

4. Adjust the scraper bar (15) to allow 1/8 inch

clearance between the scraper bar (15) and

the sidewalk or area to be cleared.

5. Tighten the carriage bolts and nuts. Make

sure that the scraper bar (15) is parallel with

the sidewalk or area to be cleared.

6. To extended the life of the scraper bar (15),

remove and reverse the mounting of the

scraper bar (15).

How To Check And Adjust The Cables

The traction drive cable and the auger drive

cable are adjusted at the factory. During normal

use, a cable can become stretched and must be

checked and adjusted as follows.

How To Check The Cables

1. To check for correct adjustment, disconnect

the “Z” fitting (1) from the drive lever (2).

2. Move the drive lever (2) forward until the

drive lever (2) is contacting the plastic

bumper (3).

3. The control cable is correctly adjusted if the

center of the “Z” fitting (1) is aligned (4)

with the hole in the drive lever (2) and there

in no droop in the cable.

How To Adjust The Cables

1. Remove the gas from the gas tank. Stand

the snow thrower up on the front end of the

auger housing.

WARNING: Drain the gasoline outdoors, away from fire or flame.

2.

(Figure 11)

from the drive lever (2).

3.

(Figure 12)

pose the spring (5). Push the cable (6)

through the spring (5) to expose the square

end (7) on the cable (6).

4. Hold the square end (7) with pliers and adjust the locknut (8) in or out until the excess

slack is removed.

5. Pull the cable (6) back through the spring

(5).

6.

(Figure 11)

drive lever (2).

NOTE: When the traction drive belt or the

auger drive belt is adjusted or replaced,

check and adjust the cable.

Disconnect the “Z” fitting (1)

Pull the spring cover up to ex-

Connect the “Z” fitting (1) to the

(Figure 11)

How To Adjust The Belts

The belts will stretch during normal use. If you

need to adjust the belts due to wear or stretch,

proceed as follows.

How To Adjust The Auger Drive Belt

If the snow thrower will not discharge snow,

check the adjustment of the auger drive cable.

See “How To Check And Adjust The Cables” in

the Maintenance section. If the adjustment is

correct, then check the condition of the auger

drive belt. If the auger drive belt is damaged,

replace the auger drive belt. See “How To Replace The Belts” in the Maintenance section. If

the auger drive belt is loose, adjust as follows.

1. Disconnect the spark plug wire.

2.

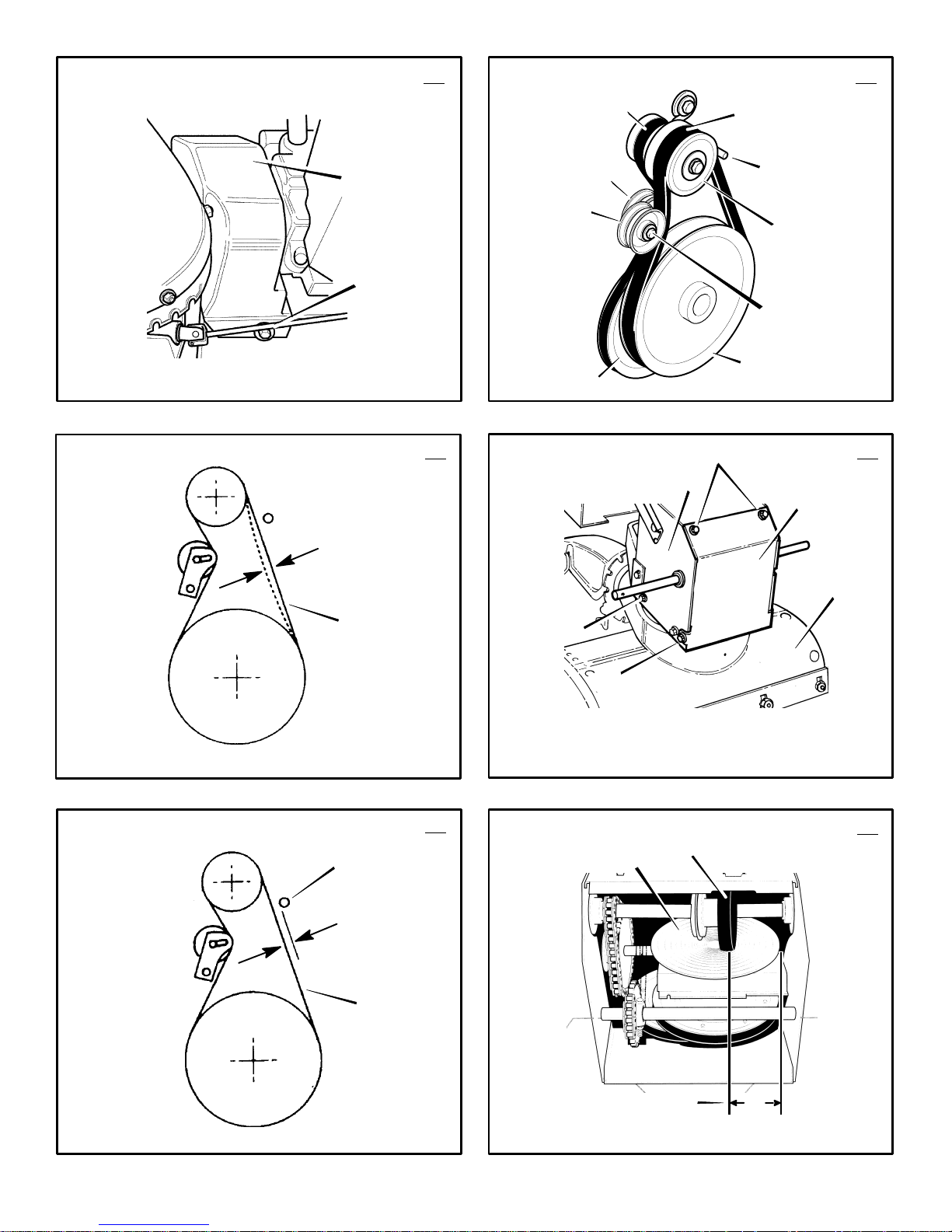

(Figure 13)

cover (1). Remove the belt cover (1).

Remove screw (2) from belt

15

ENGLISH

3.

(Figure 14)

pulley (3) Move the idler pulley (3) 1/8 inch

toward the auger drive belt (4).

4. Tighten the nut (2).

5.

(Figure 15)

Check the tension on the auger drive belt

(4). In correct adjustment, the auger drive

belt (4) will deflect 1/2 inch (5) with moder-

ate pressure. If the adjustment is not correct,

repeat the adjustment.

6.

(Figure 13)

screw (2).

7. Check the adjustment of the auger drive

cable. See “How To Check And Adjust The

Cables” in the Maintenance section.

8. Attach the spark plug wire.

Traction Drive Belt

The traction drive belt has constant spring pressure and does not require an adjustment. If the

traction drive belt is slipping, replace the belt.

See “How To Replace The Belts” in the Maintenance section.

How To Replace The Belts

The drive belts are of special construction and

must be replaced with original factory replacement belts available from your nearest authorized service center.

Some steps require the assistance of a second

person.

How To Remove the Auger Drive Belt

If the auger drive belt is damaged, the snow

thrower will not discharge snow. Replace the

damaged belt as follows.

1.

(Figure 2)

tank. Stand the snow thrower up on the front

end of the auger housing (4).

2. Disconnect the spark plug wire.

3.

(Figure 13)

cover (1). Remove the belt cover (1).

4.

(Figure 16)

side of the motor mount frame (6).

5. Loosen the bolts (3) on each side of the mo-

tor mount frame (6). The auger housing

(8) and the motor mount frame (6) will sep-

arate, hinged by bolts (3).

6.

(Figure 14)

the belt guide (9) away from the auger

drive pulley (10).

7. Loosen the nut (2) on the idler pulley (3).

Pull the idler pulley (3) away from the auger

drive belt (4).

8. Remove the old auger drive belt (4) from

the auger drive pulley (10) and from pulley

(11). Replace the auger drive belt (4) with

an original factory replacement belt available

from an authorized service center.

9. Install the new auger drive belt (4) onto the

auger drive pulley (10) and onto pulley

(11).

10.Adjust the auger drive belt (4). See “How To

Adjust The Auger Drive Belt” in the Maintenance section.

11.Adjust the belt guide (9). See “How To Adjust The Belt Guide” in the Maintenance section.

Loosen the nut (2) on the idler

Depress the auger drive lever.

Install the belt cover (1). Tighten

Remove the gas from the gas

WARNING: Drain the gasoline outdoors, away from fire or flame.

Remove screw (2) from belt

Remove the bolts (5) on each

Loosen the belt guide (9). Pull

Page 16

12.

(Figure 16)

of the motor mount frame (6).

13.Tighten the bolts (3) on each side of the mo-

tor mount frame (6).

14.

(Figure 13)

screw (2).

15.Check the adjustment of the cables. See

“How To Check And Adjust The Cables” in

the Maintenance section.

16.Connect the spark plug wire.

How To Remove the Traction Drive Belt

If the snow thrower will not move forward, check

the traction drive belt for wear or damage. If the

traction drive belt is worn or damaged, replace

the belt as follows.

1.

(Figure 2)

tank. Stand the snow thrower up on the front

end of the auger housing (4).

2. Disconnect the spark plug wire.

3. Remove the auger drive belt. See “How To

Remove The Auger Drive Belt” in the Maintenance section.

4.

(Figure 14)

pulley (12) away from the traction drive

belt (13).

5. Remove the old traction drive belt (13) from

the traction drive pulley (14) and from the

engine pulley (15). Replace the traction

drive belt (13) with an original factory re-

placement belt available from an authorized

service center.

6. Install the new traction drive belt (13) onto

the traction drive pulley (14) and onto en-

gine pulley (15).

7. Make sure the traction drive idler pulley

(12) is properly aligned with the traction

drive belt (13).

8. Install and adjust the auger drive belt (4).

See “How To Remove The Auger Drive Belt”

in the Maintenance section.

9. Adjust the belt guide (9). See “How To Adjust The Belt Guide” in the Maintenance section.

10.

(Figure 16)

of the motor mount frame (6).

11.Tighten the bolts (3) on each side of the mo-

tor mount frame (6).

12.

(Figure 13)

screw (2).

13.Check the adjustment of the cables. See

“How To Check And Adjust The Cables” in

the Maintenance section.

14.Connect the spark plug wire.

Install the bolts (5) on each side

Install the belt cover (1). Tighten

Remove the gas from the gas

WARNING: Drain the gasoline outdoors, away from fire or flame.

Pull the traction drive idler

Install the bolts (5) on each side

Install the belt cover (1). Tighten

How To Adjust The Belt Guide

1. Disconnect spark plug wire.

2.

(Figure 13)

belt cover (1).

3.

(Figure 2)

4.

(Figure 17)

the belt guide (2) and auger drive belt (3).

The correct distance (4) is 1/8 inch (3.175

mm).

5. If an adjustment is necessary, loosen the

mounting bolt for the belt guide (2). Move

the belt guide (2) to the correct position

(4). Tighten the mounting bolt for the belt

guide (2).

F–001043J

Remove screw (2). Remove the

Engage the auger drive lever (5).

Measure the distance between

6.

(Figure 13)

screw (2).

7. Connect the spark plug wire.

Install the belt cover (1). Tighten

How To Adjust Or Replace The Friction

Wheel

How To Check The Friction Wheel

If the snow thrower will not move forward, check

the traction drive belt, the traction drive cable or

the friction wheel. If the friction wheel is worn or

damaged, it must be replaced. See “How To

Replace the Friction Wheel” in this section. If the

friction wheel is not worn or damaged, check as

follows.

1.

(Figure 2)

tank. Stand the snow thrower up on the front

end of the auger housing (4).

2. Disconnect the spark plug wire.

3.

(Figure 16)

side of the bottom panel (2).

4. Loosen the bolts (3) on each side of the bot-

tom panel (2).

5. Remove the bottom panel (2).

6.

(Figure 2)

in the first forward gear.

7.

(Figure 18)

wheel (4) on the disc drive plate (5). In the

correct position (7), the right outer side of

the disc drive plate (5) must be three inches

(7.62cm.) from the center of the friction

wheel (4). If the friction wheel (4) is not in

the correct position (7), adjust as follows.

How To Adjust The Friction Wheel

1.

(Figure 19)

speed control rod (8).

2.

(Figure 18)

the correct position (7).

3.

(Figure 19)

speed control rod (8).

4.

(Figure 16)

5. Tighten the bolts (3) on each side of the bot-

tom panel (2).

6. Install the bolts (1) on each side of the bottom panel (2).

How To Replace The Friction Wheel

If the friction wheel is worn or damaged, the

snow thrower will not move forward. The friction

wheel must be replaced as follows.

1.

(Figure 2)

tank. Stand the snow thrower up on the front

end of the auger housing (4).

2. Disconnect the spark plug wire.

3.

(Figure 16)

side of the bottom panel (2).

4. Loosen the bolts (3) on each side of the bot-

tom panel (2).

5. Remove the bottom panel (2).

6.

(Figure 19)

(8) from the spring lever (9).

Remove the gas from the gas

WARNING: Drain the gasoline outdoors, away from fire or flame.

Remove the bolts (1) on each

Position the shift speed lever (6)

Note the position of the friction

Loosen the bolts (1) on the

Move the friction wheel (4) to

Tighten the bolts (1) on the

Install the bottom panel (2).

Remove the gas from the gas

WARNING: Drain the gasoline outdoors, away from fire or flame.

Remove the bolts (1) on each

Remove the speed control rod

16

ENGLISH

7.

(Figure 20)

that hold the friction wheel (5) to the hub

(6).

8.

(Figure 10)

the bearing plates (7) on each side of the

hex shaft (8).

NOTE: Take special note of the position of

the washers and retaining ring on the hex

shaft (8) and the sprocket assembly.

9. Remove the bearing plate (7) from the right

side. Do not remove the hex shaft (8). Leave

the hex shaft (8) in position. Carefully raise

hex shaft (8) just enough to allow the fric-

tion wheel (3) to be removed.

10.

(Figure 20)

from the hub (6). Slip the friction wheel (5)

toward the right off the hex shaft (8).

11.Assemble the new friction wheel (5) onto

hub (6) with the fasteners removed earlier.

12.

(Figure 10)

the right side. Make sure the hex shaft (8) is

engaged with both bearing plates (7) and

that the washers and retaining ring are

installed in the original position.

13.Fasten the bearing plates (7) using the four

bolts removed earlier.

14.Make sure the hex shaft (8) turns freely.

15.

(Figure 19)

(8) to the spring lever (9).

16.Check the adjustment of the friction wheel.

See “How To Adjust The Friction Wheel” in

this section.

17.Make sure the friction wheel and the disc

drive plate are free from grease or oil.

18.

(Figure 16)

19.Tighten the bolts (3) on each side of the bot-

tom panel (2).

20. Install the bolts (1) on each side of the bottom panel (2).

21.Connect the spark plug wire.

How To Replace the Auger Shear Bolt

The augers are secured to the auger shaft with

special shear bolts. These shear bolts are designed to break and protect the machine if an

object becomes lodged in the auger housing.

Do not use a harder bolt as the protection provided by the shear bolt will be lost.

To replace a broken shear bolt, proceed as follows. Extra shear bolts were provided in the assembly parts bag.

1.

(Figure 2)

the stop position. Disengage all controls.

2. Disconnect the spark plug wire. Make sure

all moving parts have stopped.

3.

(Figure 9)

fitting (1) with a grease gun.

4.

(Figure 21)

the hole in the auger shaft. Install the new

shear bolt (2), spacer (3) and locknut (4).

5. Connect the spark plug wire.

How To Prepare The Snow Thrower For

Storage

fumes can cause an explosion or a fire.

1. Drain the fuel tank.

Remove the three fasteners (4)

Remove the four bolts that hold

Remove the friction wheel (5)

Install the bearing plate (7) onto

Attach the speed control rod

Install the bottom panel (2).

WARNING: For safety and to protect the machine, use only original

equipment shear bolts.

Move the throttle control (13) to

Lubricate the auger shaft Zerk

Align the hole in the auger with

WARNING: Do not remove gasoline

while inside a building, near a fire,

or while you smoke. Gasoline

Page 17

2. Let the engine run until it is out of gasoline.

3. Drain the oil from the warm engine. Fill the

engine crankcase with new oil.

4. Remove the spark plug from the cylinder.

Pour one ounce of oil into the cylinder. Slowly pull the recoil–start grip so that the oil will

protect the cylinder. Install a new spark plug

in the cylinder.

5. Thoroughly clean the snow thrower.

6. Lubricate all lubrication points. See the Maintenance section.

7. Be sure that all nuts, bolts and screws are

securely fastened. Inspect all visible moving

parts for damage, breakage and wear. Replace if necessary.

8. Cover the bare metal parts of the blower

housing, auger, and the impeller with spray

rust preventative lubricant.

9. Put the unit in a building that has good ventilation.

10.If the machine must be stored outdoors,

block up the snow thrower to be sure the entire machine is off the ground.

11.Cover the snow thrower with a suitable protective cover that does not retain moisture.

Do not use plastic.

How To Order Replacement Parts

The replacement parts are shown either on the

back pages of this Instruction Book or in a

separate Parts List Book.

Use only manufacturer’s authorized or approved

replacement parts. The letter placed on the end

of the part number denotes the type of finish for

the part, C for chrome, Z for zinc, a PA for

purchased assembly. It is important that you

include this when ordering a part. Do not use

attachments or accessories not specifically

recommended for this unit. In order to obtain

proper replacement parts you must supply the

model number (see nameplate).

Replacement parts, except for the engine,

transmission, transaxle or differential, are

available from the store where the product was

purchased, a service shop recommended by the

store or from a “Murray, Inc. Central Parts

ENGLISH

Distributor” listed on the back page of this

Instruction Book.

If you are unable to obtain parts or service in the

manner outlined above, then contact:

MURRAY, INC.

Outdoor Power Equipment

Customer Service Department

P.O. Box 268

Brentwood, Tennessee 37027

1–800–251–8007 Collect telephone calls will not

be accepted.

Replacement parts for the engine, transaxle, or

transmission, are available from the

manufacturer’s authorized service center found

in the yellow pages of the telephone directory.

Also, see the individual engine or transmission

warranties to order replacement parts.

When ordering the following information is

required:

(1) The Model Number

(2) Serial Number

(3) Part Number

(4) Quantity

TROUBLE SHOOTING CHART

TROUBLE CAUSE CORRECTION

Difficult starting Defective spark plug. Replace spark plug.

Water or dirt in fuel system. Use carburetor bowl drain to flush and refill with

Engine runs erratic Blocked fuel line, empty gas tank, or stale

Engine stalls Unit running on CHOKE. Set choke lever to RUN position.

Engine runs erratic;

Loss of power

Excessive vibration Loose parts: damaged impeller Stop engine immediately and disconnect spark

Unit fails to propel itself Drive belt loose or damaged. Replace drive belt.

Unit fails to discharge snow Auger drive belt loose or damaged. Adjust auger drive belt; replace if damaged.

gasoline

Water or dirt in fuel system. Use carburetor bowl drain to flush and refill with

Incorrect adjustment of traction drive cable Adjust traction drive cable.

Worn or damaged friction wheel. Replace friction wheel.

Auger control cable not adjusted correctly. Adjust auger control cable.

fresh fuel.

Clean fuel line; check fuel supply; add fresh

gasoline

fresh fuel.

plug wire. Tighten all bolts and make all

necessary repairs. If vibration continues, have

the unit serviced by a competent repairman.

F–001043J

Shear bolt broken Replace shear bolt

Discharge chute clogged. Stop engine immediately and disconnect spark

plug wire. Clean discharge chute and inside of

auger housing.

Foreign object lodged in auger Stop engine immediately and disconnect spark

plug wire. Remove object from auger.

17

Page 18

SOMMAIRE

INFORMATIONS SUR LE PRODUIT 18

INFORMATIONS DESTINEES AU

PROPRIETAIRE 18

PICTOGRAMMES INTERNATIONAUX 19

MONTAGE 21

FONCTIONNEMENT 21

MAINTENANCE 24

TABLEAU DE MAINTENANCE 24

TABLEAU DE DEPANNAGE 28

GARANTIE LIMITEE DE DEUX ANS

Murray, Inc. garantie auprès de l’acheteur initial

que cette machine est dépourvue de défauts

matériels et de construction sous utilisation et

entretien normaux pendant une durée de deux

(2) ans à partir de la date d’acquisition ; cette

garantie cependant ne couvre pas les moteurs,

accessoires (tels que moteurs électriques) et

pièces d’usure normale (exceptées les pièces

mentionnées ci–dessous) étant donné que les

sociétés fabriquant ces articles offrent leurs

propres garanties et fournissent des réparations

par le biais de leurs centres de maintenance

spécialisés agréés. Pour plus d’informations, se

reporter aux garanties couvrant ces pièces

particulières. Si vous ne savez pas si votre

machine contient ou est équipée d’une ou

plusieurs de ces pièces, adressez vous à votre

revendeur avant l’acquisition. Sous réserve des

modalités et conditions de cette garantie limitée,

nous nous engageons à réparer ou remplacer, à

notre discrétion et gratuitement auprès de

l’acheteur initial, toute pièce couverte par cette

garantie limitée jusqu’à l’expiration de la garantie

applicable.

Les pièces d’usure normale comprennent les

courroies d’entraînement, les fraises

hélicoïdales, les goupilles de cisaillement, les

pneumatiques, et les phares. Ces pièces sont

garanties sans défaut matériel ou de

construction dans l’état où elles ont été livrées

avec le produit. Toute réclamation concernant la

réparation ou le remplacement d’une pièce

d’usure normale doit être effectuée dans les

trente (30) jours suivant la date d’acquisition.

Aucune réclamation ne sera honorée

concernant des dommages provenant de la

simple utilisation, d’un usage abusif, ou d’une

mauvaise utilisation.

Cette garantie Murray, Inc. de deux (2) ans

constitue votre recours exclusif ; cependant,

cette garantie est nulle ou ne s’applique pas aux

machines ayant été modifiées, endommagées,

fait l’objet d’une utilisation abusive, ou utilisées

lors d’une location ou à des fins commerciales

et/ ou professionnelles (autre que domestiques).

Votre garantie ne couvre pas les réglages

mécaniques mineurs non dus à des défauts

matériels de fabrication. Consultez votre manuel

d’utilisation pour obtenir une assistance

concernant ces réglages.

Pour effectuer une réclamation sous la garantie

limitée de deux (2) ans Murray, Inc., retourner

FRANÇAIS

la machine, (ou, suivant notre autorisation

préalable, la pièce défectueuse) accompagnée

de votre preuve d’achat, auprès du Centre de

maintenance agréé le plus proche de chez vous.

Pour localiser le centre de maintenance le plus

proche, contactez le Distributeur de pièces

régional de votre région figurant sur la liste

fournie avec votre machine, ou consultez les

pages jaunes de votre annuaire téléphonique

local. Si vous nous retournez la machine

complète, nous réparerons celle–ci. Si nous

autorisons seulement le retour de la pièce

défectueuse, nous effectuerons soit la réparation

de celle–ci, soit son remplacement. Cette

garantie limitée Murray, Inc. de deux (2) ans

vous octroie des droits légaux spécifiques, et

vous pouvez également vous prévaloir d’autres

droits dont le contenu varie selon l’Etat où ils

s’appliquent. Cette garantie limitée est

délivrée en lieu et place de toute garantie

stipulée ou tacite, ceci incluant la garantie

tacite de commerciabilité et la garantie de

fonctionnalité pour une tâche définie. Si

vous souhaitez recevoir des informations

supplémentaires concernant cette garantie

écrite ou une assistance quant à l’obtention de

services de réparation, adressez–vous à :

MURRAY, INC.

Outdoor Power Equipment

Customer Service Department

P.O. Box 268

Brentwood, Tennessee 37027

1–800–251–8007

INFORMATIONS SUR LE

PRODUIT

Le propriétaire doit être certain que tous les

renseignements sur le produit sont inclus avec

la tondeuse. Ces renseignements comprennent

les MANUELS D’INSTRUCTION, les PIECES

DE RECHANGE, et les GARANTIES. Ces

renseignements doivent être inclus pour

s’assurer que les lois d’Etat et les autres lois

sont observés.

INFORMATIONS DESTINEES AU

PROPRIETAIRE

Ce manuel se dirige aux personnes familiarisées

avec ce genre de manipulations mécaniques. La

plupart des ouvrages de maintenance ne mentionnent pas toutes les étapes, et cet ouvrage ne

fait pas exception. Serrer ou desserrer des attaches sont des manipulations que tout le monde

peut effectuer avec une certaine pratique. Lisez

et suivez ces instructions avant d’utiliser la tondeuse.

Apprenez à maîtriser l’appareil : si vous comprenez le fonctionnement de ce modèle, vous en

obtiendrez les meilleures performances. Au fur

et à mesure que vous lisez le manuel, reportez–

vous aux illustrations. Sachez repérer l’emplacement des commandes et leur fonction. Afin de

prévenir tout risque d’accident, observez les instructions de fonctionnement et les règles de sé-

F–001043J

curité. Conservez ce manuel pour future

référence.

IMPORTANT : De nombreux appareils ne sont

pas assemblés et sont vendus démontés dans

leur carton d’emballage. Il est alors de la responsabilité du propriétaire de veiller à ce que les

instructions de montage présentes dans le manuel soient suivies en toute exactitude. D’autres

appareils sont vendus entièrement montés. En

ce qui concerne les machines déjà montées, il

est de la responsabilité du propriétaire de veiller

à ce que la machine soit correctement assemblée. Le propriétaire doit vérifier attentivement la

machine en fonction des instructions présentes

dans le manuel avant de commencer à utiliser

celle–ci.

DANGER : repérez ce symbole qui vous

indiquera les précautions de sécurité importantes. Ce symbole signifie : “Attention!

Soyez prudent! Vous encourrez des risques.”

Responsabilité de l’utilisateur

La responsabilité de l’utilisateur est de

suivre les instructions ci–dessous.

1. Lire soigneusement ce manuel et suivre les

règles indiquées pour un usage de la tondeuse en toute sécurité.

18

2. Suivre les instructions de montage et de

préparation.

3. Inspecter la tondeuse.

4. S’assurer que l’utilisateur de la tondeuse

sait bien utiliser les équipements standards

et les accessoires.

5. N’utiliser la tondeuse qu’avec les équipements de protection, les écrans et autres

dispositifs de sécurité bien en place et en

bon état de marche.

6. Procéder aux réglages nécessaires.

7. Entretenir la tondeuse avec les pièces de

rechange autorisées ou agréées.

8. Veiller à ce qu’un entretien complet soit effectué sur la tondeuse.

Prise de conscience environnementale

Ne pas remplir le réservoir d’essence du

moteur au ras–bord.

Vider l’essence pendant le remisage hors

saison.

N’utiliser que de l’essence sans plomb.

Entretenir régulièrement le filtre à air.

Changer l’huile régulièrement. Utiliser de

l’huile de grade 5W–30.

Effectuer un réglage du moteur régulière-

ment.

Conserver le matériel en bon état de mar-

che.

Eliminer l’huile de vidange de façon écolo-

gique.

Page 19

PICTOGRAMMES INTERNATIONAUX

IMPORTANT : les pictogrammes suivants

sont situés sur votre appareil ou dans la documentation ci–jointe. Avant de vous servir

de la tondeuse, apprenez à reconnaître chaque pictogramme.

FRANÇAIS

Symboles de signalisation de danger

DANGER

Projection d’objets.

Eloigner tout spectateur.

DANGER

surface brûlante

DANGER

Projection d’objets.

Eloigner tout spectateur.

STOP

DANGER

Arrêter le moteur avant de

DANGER

déboucher le déversoir!

IMPORTANT

Lire le manuel de l’utilisa-

teur avant de faire fonc-

tionner cette machine

Symboles de commandes et de conduite

Lent Rapide Démarrage électrique Démarrage moteur Moteur en marche

24

Prévenir les blessures dues

rotation. Ecarter vos mains,

DANGER

à la fraise hélicoïdale en

pieds, et vêtements.

Moteur à l’arrêt

Arrêt moteur Marche Arrêt starter Marche starter

Marche arrière

Appuyer pour en-

gager le starter

électrique

Décharge gauche Décharge droite

KGS

Accélérateur Bouton d’amorçage Clé du démarreur

Embrayage

Embrayage de la fraise Collecteur de la fraise

Embrayage des roues

KGS

Carburant huile

N

Point mort

Démarreur

hors tension

Déversoir ABAISSE Déversoir LEVE

Marche avant

Démarreur

sous tension

Mélange essence/huile

Transfert de poids

Lever la manette pour embrayer

F–001043J

Abaisser la manette pour débrayer

Transfert de poids

19

Transmission

Clé du démarreur

Insérer pour mettre en marche,

retirer pour arrêter.

Page 20

REGLES DE SECURITE A SUIVRE POUR L’UTILISATION DES CHASSE–NEIGE

SELON LES RECOMMANDATIONS DE L’AMERICAN NATIONAL STANDARDS INSTITUTE

IMPORTANT : les normes de sécurité requiè-

rent des contrôles de la présence du conducteur

pour limiter les risques de blessures. Votre chasse–neige est équipé de ces contrôles. Ne pas

tenter de rendre la fonction de contrôle de la

présence du conducteur inopérante quelles que

soient les circonstances.

Conseils préliminaires

1. Lisez soigneusement le manuel de fonctionnement et les consignes. Familiarisez–vous

avec les commandes ainsi qu’avec les modes appropriés d’utilisation de la machine.

2. N’autorisez jamais un enfant ou une personne ignorant ces consignes de sécurité à se

servir de la tondeuse.

3. Assurez–vous que toute personne, les enfants en particulier, sont à l’écart du lieu

d’utilisation de la tondeuse.

4. User de précautions pour éviter de glisser ou

de tomber, surtout lors de la conduite en marche arrière.

Préparation

1. Inspectez à fond le lieu où le matériel doit

être utilisé. Enlevez tous paillassons, patins,

planches, fils, et autres corps étrangers.

2. Débrayer toutes les comm andes av ant de

démarrer le moteur.

3. Ne pas faire fonctionner la machine sans porter de vêtements d’extérieur appropriés pour

l’hiver. Chausser des chaussures permettant

d’améliorer l’adhérence sur surfaces glis san tes.

4. Manipuler le carburant avec prudence ; celui–

ci est hautement inflammable.

a. Utiliser un bidon d’essence approprié.

b. Ne jamais retirer le bouchon du réservoir

d’essence ou ajouter de l’essence dans

un moteur en marche ou un moteur

chaud.

c. Remplir le réservoir en plein air en usant

d’extrêmes précautions. Ne jamais faire

le plein à l’intérieur d’un bâtiment.

d. Revisser le bouchon soigneusement et

essuyer l’essence renversée.

e. Ne remisez jamais de l’essence ou le

chasse–neige lorsqu’il y de l’essence

dans le réservoir, dans un endroit clos où

les émanations pourraient entrer en

contact avec une flamme ou une étincelle.

f. Vérifier le niveau d’essence avant chaque

utilisation, tout en prévoyant de l’espace

pour l’expansion de l’essence due au fait

que la chaleur du moteur et/ou du soleil

peut provoquer l’expansion de l’essence.

5. Pour toutes les machines équipées de mo teur à démarrage électrique, utiliser des rallonges de démarrage certifiées CSA / UL.

N’utiliser qu’avec une prise de courant ayant

été installée conformément aux aut orit és

chargées de l’inspection locale.

6. Régler le chasse–neige de façon à éviter les

graviers et les surfaces couv ert es de gravats .

F–001043J

7. Ne tentez jamais de faire de quelconques

réglages lorsque le moteur est en marche

(sauf si spécifiquement indiqué par le fabricant).

8. Laisser le moteur et le chas s e–neige s’adap ter à la température ext érieure avant de com mencer à déneiger.

9. Portez toujours des lunettes de sécurité ou

un écran pour les yeux lorsque que vous

employez le chasse–neige ou lors de réglages ou de réparations, afin de protéger vos

yeux de corps étrangers pouvant être projetés par le chasse–neige.

Fonctionnement

1. Ne pas se servir de cet te mac hine lors de la

prise de drogues ou d’autres médicaments

pouvant causer la somnolence ou diminuer

vos capacités à conduire la mac hine.