Page 1

Instruction Book − Snowthrower Model 621403x61NB

Betriebsanleitung − Schneefräse Modell 621403x61NB

Navodila za uporabo − SneĤna freza Model 621403x61NB

D

GB

1740265

SK

Page 2

2

1740265

2

3

5

8

12

9

4

14

1

22

Page 3

3

1740265

2

1

1

2

3

x

1

4

1

x

5

1

2

Page 4

4

1740265

1

2

2

6

1

7

5

2

1

7

8

9

1

1

1

1

1

2

2

2

2

2

4

3

10

2

3

1

44

5

11

3

4

Page 5

5

1740265

1

2

12

13

1

2

3

4

4

1

3

14

2

4

5

6

15

1

16

1

7

9

8

17

Page 6

6

1740265

1

7

6

18

3

4

4

5

2

2

2

2

8

9

9

10

10

11

19

11

6

20

1

2

Page 7

CONTENTS

HAZARD SYMBOLS AND THE MEANINGS 8. . . . . . . . . .

OPERATING SYMBOLS AND THEIR MEANINGS 8. . . . .

RULES FOR SAFE OPERATION 9. . . . . . . . . . . . . . . . . . . .

ASSEMBLY 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

OPERATION 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MAINTENANCE 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MAINTENANCE CHART 13. . . . . . . . . . . . . . . . . . . . . . . . . . .

TROUBLE SHOOTING CHART 15. . . . . . . . . . . . . . . . . . . . .

LIMITED WARRANTY 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Information

This instruction book is written for a person with some mechanical ability.

Like most service books, not all the steps are described. Steps on how to

loosen or tighten fasteners are steps anyone can follow with some

mechanical ability. Read and follow these instructions before you use the

unit.

Know your product: If you understand the unit and how the unit

operates, you will get the best performance. As you read this manual,

compare the illustrations to the unit. Learn the location and the function of

the controls. To help prevent an accident, follow the operating instructions

and the safety rules. Keep this manual for future reference.

IMPORTANT: Many units are not assembled and are sold in cartons. It is

the responsibility of the owner to make sure the assembly instructions in

this manual are exactly followed. Other units are purchased in an

assembled condition. On assembled units, it is the responsibility of the

owner to make sure the unit is correctly assembled. The owner must

carefully check the unit according to the instructions in this manual before

it is first used.

GB

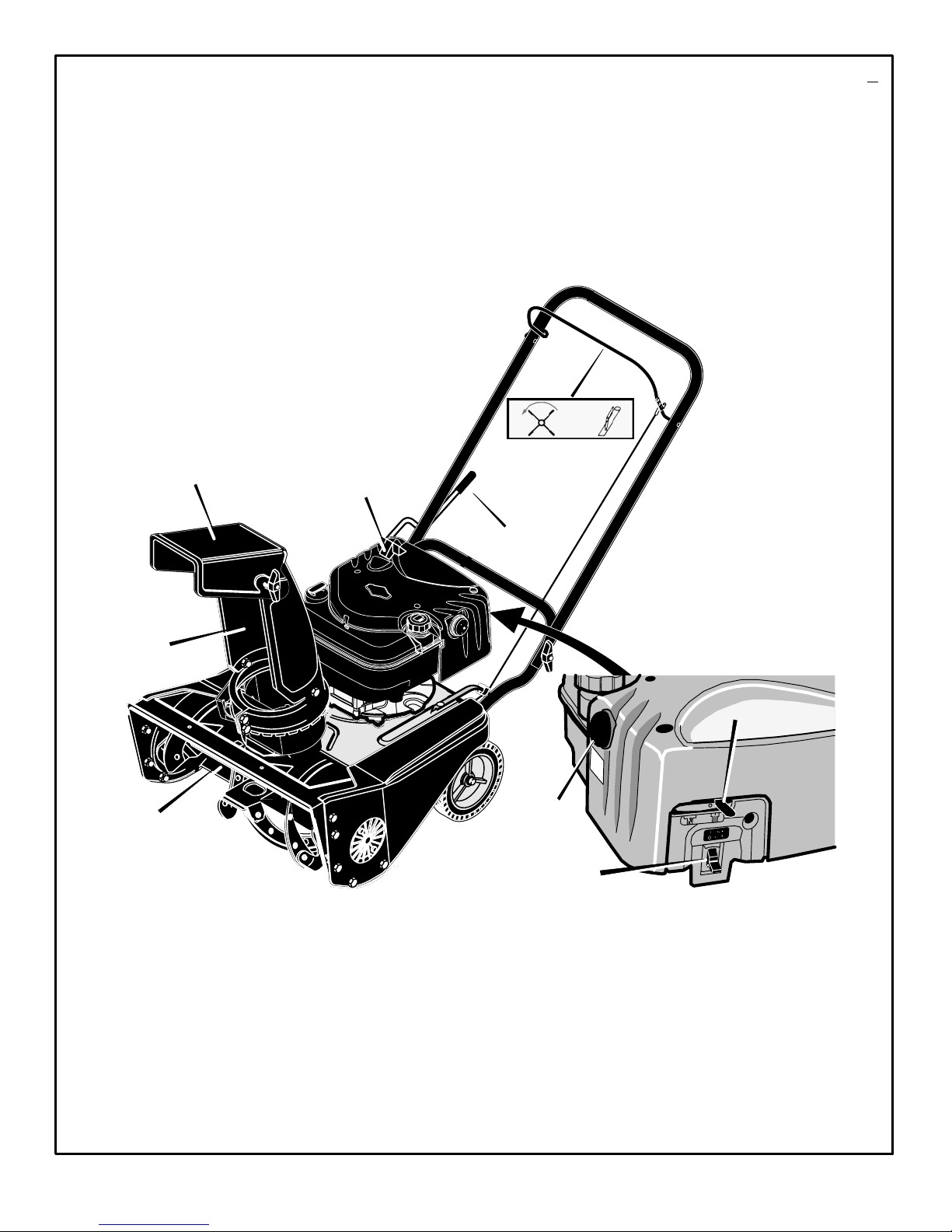

Controls & Equipment Features (see Figure 1)

Crank Assembly (2) − Changes the direction of the discharge chute.

Chute Deflector (3) − Changes the distance the snow is thrown.

Discharge Chute (4) − Changes the direction the snow is thrown.

Auger Drive Lever (5) − Starts and stops the auger (snow gathering and

throwing) which also propels the snowthrower..

Engine Features

Stop Switch (8) − If equipped, move to the ON position to start the

engine.

Primer Button (9) − Injects fuel directly into the carburetor for fast starts

in cold weather.

Recoil Starter Handle (12) − Use to manually start the engine.

Choke Control (14) − Use to start a cold engine.

www.briggsandstratton.com

MODEL NO.: 621403x61NB

SKU No.:

YYYY MM DD:

SERIAL NO.:

3500 min-1

Assembled in Suzhou, China 215218

by Limac for Briggs & Stratton Corporation

30 kg

Declared vibration emission values in accordance with Directive 98/37/EC.

Vibration Emission according to EN 1033;1996: 7,1 m/s2.

Values determined at the handle when the machine was operated stationary on a

concrete surface at 3500 min−1.

Declared airborne noise emissions of LwA 104 dB is in accordance with Directive

2000/14/EC, Annex V.

Sound Pressure Level at operator position 84 dB.

Values determined at ear according to the specifications of EN ISO 11201.

Declared airborne sound

power level of 104 dB(A) is in

accordance with Directive

2000/14/EC.

1740265

7

Page 8

GB

8

1740265

This manual contains safety information to make you

aware of the hazards and risks associated with snow

throwers, and how to avoid them. The snow thrower is designed and

intended for removal of snow, and should not be used for any other

purpose. It is important that you read and understand these

instructions, and anyone operating the equipment read and understand

these instructions.

The engine exhaust from this product contains chemicals known to the

State of California to cause cancer, birth defects, or other reproductive

harm.

WARNING

A signal word (DANGER, WARNING, or CAUTION) is used with the alert

symbol to indicate the likelihood and the potential severity of injury. In

addition, a hazard symbol may be used to represent the type of hazard.

DANGER indicates a hazard which, if not avoided, will result in

death or serious injury.

WARNING indicates a hazard which, if not avoided, could result

in death or serious injury.

CAUTION indicates a hazard which, if not avoided, might result

in minor or moderate injury.

CAUTION, when used without the alert symbol, indicates a

situation that could result in damage to the equipment.

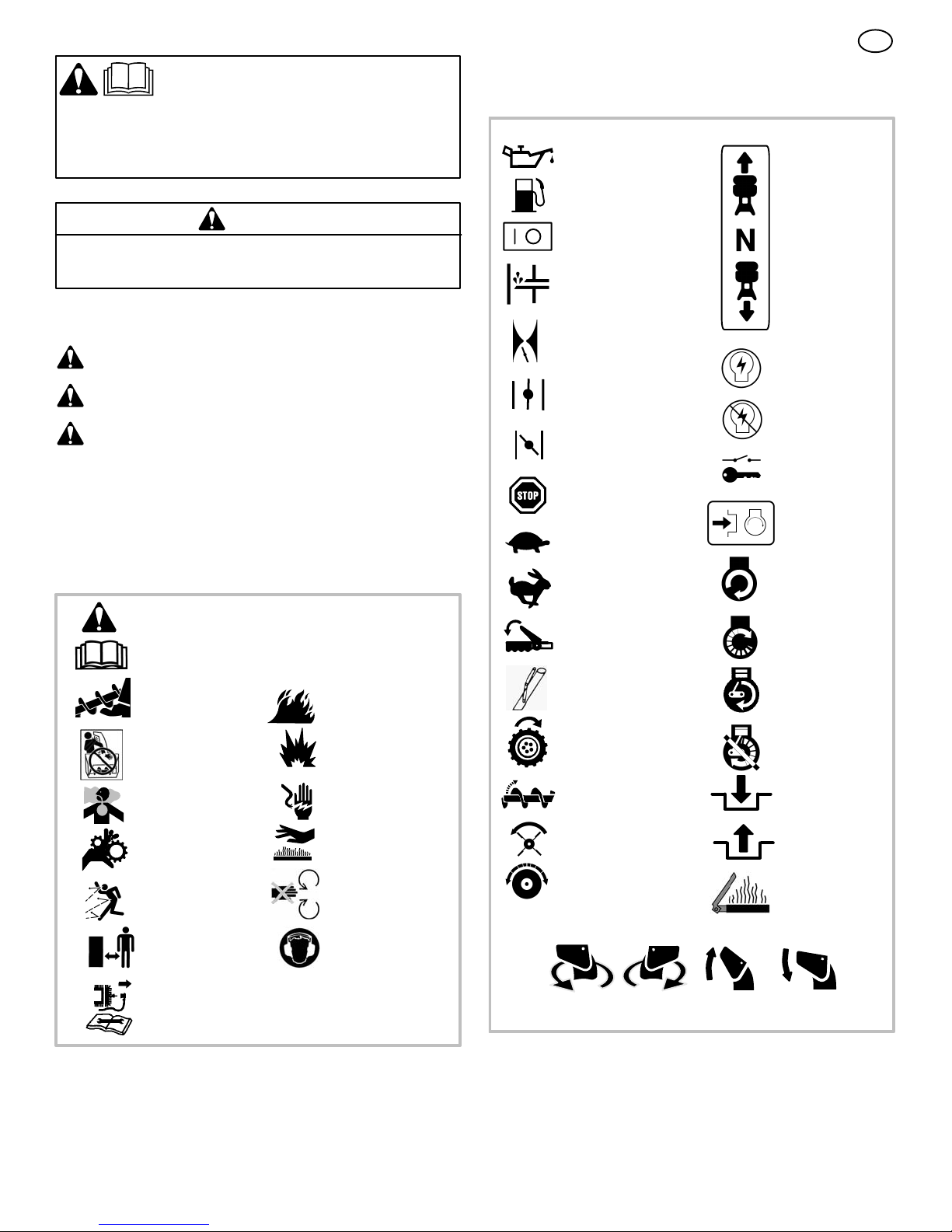

Hazard Symbols and the meanings

These symbols are used on your equipment and defined in your operating

manual. Review and understand the meanings. The use of one of these

symbols combined with a signal word will alert you to potential hazards

and how to avoid them.

Explosion

Toxic fumes

Shock

Hot Surface

Fire

Operator’s Manual − Read and understand before

performing any activity or running equipment.

Safety Alert − Identifies safety information about

hazards that can result in personal injury.

Rotating auger

Rotating impeller

Rotating gears

Thrown objects

Keep a safe distance

from the equipment.

Shut off engine and remove spark plug connector

before performing maintenance or repair work.

Never reach into

rotating parts.

Recommended ear

protection for extended

use.

Operating Symbols and their meanings

These symbols are used on your equipment and defined in your operating

manual. It is important that you review and understand the meanings.

Failure to understand the symbols might result in harm to you.

Stop

Fuel

Choke off

Oil

Choke on

Slow

Fast

On Off

Ignition Key

Ignition Off

Ignition On

Primer bulb

Throttle

Drive Clutch

Auger Clutch

Engage

RIGHT

Auger Collector

Traction

Discharge Chute

LEFT UP

DOWN

Foward

Neutral

Reverse

Push to engage

electric start

Electric

Start

Engine

Start

Engine Run

Engine Off

Chute Deflector

Engage

Disengage

Heated Grips

Engage

Page 9

GB

9

1740265

WARNING: This machine is capable ofto amputating hands and feet and throwing objects. Read these safety rules

and follow them closely. Failure to obey these rules could result in loss of control of unit, severe personal injury or

death to you, or bystanders, or damage to property or equipment. The triangle in text signifies important cautions or warnings which must be followed.

Safe Operation Practices for Snowthrowers

IMPORTANT: Safety standards require operator presence controls to

minimize the risk of injury. Your snowthrower is equipped with such controls. Do not attempt to defeat the function of the operator presence control under any circumstances.

Training

1. Read, understand, and follow all instructions on the machine and in the

manuals before operating this unit. Be thoroughly familiar with the controls and the proper use of the equipment. Know how to stop the unit

and disengage the controls quickly.

2. Never allow children to operate the equipment. Never allow adults to

operate the equipment without proper instruction.

3. Keep the area of operation clear of all persons, particularly small

children and pets.

4. Exercise caution to avoid slipping or falling especially when operating in

reverse.

Preparation

1. Thoroughly inspect the area where the equipment is to be used and

remove all doormats, sleds, boards, wires, and other foreign objects.

2. Disengage all clutches and shift into neutral before starting the engine

(motor).

3. Do not operate the equipment without wearing adequate winter outer

garments. Wear footwear that will improve footing on slippery surfaces.

Avoid loose fitting clothing that can get caught in moving parts.

4. Handle fuel with care; it is highly flammable.

a. Use an approved fuel container.

b. Never add fuel to a running engine or hot engine.

c. Fill fuel tank outdoors with extreme care. Never fill fuel tank indoors.

Replace fuel cap securely and wipe up spilled fuel.

d. Never fill containers inside a vehicle or on a truck or trailer bed with

a plastic liner. Always place containers on the ground, away from

your vehicle, before filling.

e. When practical, remove gas−powered equipment from the truck or

trailer and refuel it on the ground. If this is not possible, then refuel

such on a trailer with a portable container, rather than from a gasoline dispenser nozzle.

f. Keep nozzle in contact with the rim of the fuel tank or container

opening at all times, until refueling is complete. Do not use a nozzle

lock−open device.

g. Replace gasoline cap securely and wipe up spilled fuel.

h. If fuel is spilled on clothing, change clothing immediately.

5. Use extension cords and receptacles as specified by the manufacturer for all units with electric drive motors or electric starting motors.

6. Adjust the collector housing height to clear gravel or crushed rock

surfaces.

7. Never attempt to make any adjustments while the engine (motor) is

running (except when specifically recommended by manufacturer).

8. Let engine (motor) and snowthrower adjust to outdoor temperatures

before starting to clear snow.

9. Always wear safety glasses or eye shields during operation or while

performing an adjustment or repair to protect eyes from foreign objects

that may be thrown from the machine.

Operation

1. Do not put hands or feet near or under rotating parts. Keep clear of the

discharge opening at all times.

2. Exercise extreme caution when operating on or crossing gravel drives,

walks or roads. Stay alert for hidden hazards or traffic.

3. After striking a foreign object, stop the engine (motor), remove the wire

from the spark plug, disconnect the cord on electric motors, thoroughly

inspect snowthrower for any damage, and repair the damage before

restarting and operating the snowthrower.

4. If the unit should start to vibrate abnormally, stop the engine (motor)

and check immediately for the cause. Vibration is generally a warning

of trouble.

5. Stop the engine (motor) whenever you leave the operating position,

before unclogging the collector/impeller housing or discharge chute and

when making any repairs, adjustments, or inspections.

6. When cleaning, repairing, or inspecting, make certain the collector/impeller and all moving parts have stopped. Disconnect the spark plug

wire and keep the wire away from the spark plug to prevent accidental

starting.

7. Do not run the engine indoors, except when starting the engine and for

transporting the snowthrower in or out of the building. Open the outside

doors; exhaust fumes are dangerous (containing CARBON MONOXIDE, an ODORLESS and DEADLY GAS).

8. Exercise extreme caution when operating on slopes. Do not attempt to

clear steep slopes.

9. Never operate the snowthrower without proper guards, plates, or other

safety protective devices in place and working.

10. Never direct the discharge toward people or areas where property

damage can occur. Keep children and others away.

11. Do not overload the machine capacity by attempting to clear snow at

too fast a rate.

12. Never operate the machine at high transport speeds on slippery surfaces. Look behind and use care when operating in reverse.

13. Disengage power to the collector/impeller when snowthrower is transported or not in use.

14. Use only attachments and accessories approved by the manufacturer

of the snowthrower (such as cabs, tire chains, etc..).

15. Never operate the snowthrower without good visibility or light. Always

be sure of your footing and keep a firm hold on the handles. Walk,

never run.

16. Never touch a hot engine or muffler.

17. Never operate the snowthrower near glass enclosures, automobiles,

window wells, drop−offs, and the like without proper adjustment of the

snow discharge angle.

18. Never direct discharge at bystanders or allow anyone in front of the

unit.

19. Never leave a running unit unattended. Always disengage the auger

and traction controls, stop engine, and remove keys.

20. Do not operate the unit while under the influence of alcohol or drugs.

21. Keep in mind the operator is responsible for accidents occurring to

other people or property.

22. Data indicates that operators, age 60 years and above, are involved

in a large percentage of power equipment−related injuries. These

operators should evaluate their ability to operate the unit safely

enough to protect themselves and others from injury.

23. DO NOT wear long scarves or loose clothing that could become

entangled in moving parts.

24. Snow can hide obstacles. Make sure to remove all obstacles from

the area to be cleared.

Page 10

GB

10

1740265

Children

Tragic accidents can occur if the operator is not alert to the presence of children. Children are often attracted to the unit and the operating activity. Never

assume that children will remain where you last saw them.

1. Keep children out of the area and under the watchful care of another

responsible adult.

2. Be alert and turn off if children enter the area.

3. Never allow children to operate the unit.

4. Use extra care when approaching blind corners, shrubs, trees, or

other objects that may obscure vision.

Clearing A Clogged Discharge Chute

Hand contact with the rotating impeller inside the discharge chute is the

most common cause of injury associated with snowthrowers. Never use

your hand to clean out the discharge chute.

To clear the chute:

1. SHUT OFF THE ENGINE.

2. Wait 10 seconds to be sure the impeller blades have stopped rotating.

3. Always use a clean out tool, not your hands.

Service, Maintenance And Storage

1. Check shear bolts and other bolts at frequent intervals for proper tightness to be sure the equipment is in safe working condition.

2. Never store the machine with fuel in the tank inside a building where

ignition sources are present such as hot water and space heaters, or

clothes dryers. Allow the engine to cool before storing in any enclosure.

3. Always refer to operator’s manual for important details if the snowthrower is to be stored for an extended period.

4. Maintain or replace safety and instruction labels as necessary.

5. Run the machine a few minutes after throwing snow to prevent freeze−

up of the collector/impeller.

6. If fuel is spilled, do not attempt to start the engine but move the machine away from the area of spillage and avoid creating any source of

ignition until fuel vapors have dissipated.

7. Always observe safe refueling and fuel handling practices when refueling the unit after transportation or storage.

8. Always follow the engine’s manual instructions for storage preparations

before storing the unit for both short and long term periods,

9. Always follow the engine manual instructions for proper start-up procedures when returning the unit to service.

10. Maintain or replace safety and instruction labels as necessary.

11. Keep nuts and bolts tight and keep equipment in good condition.

12. Never tamper with safety devices. Check their proper operation regularly and make necessary repairs if they are not functioning properly.

13. Components are subject to wear, damage, and deterioration. Frequently check components and replace with manufacturer’s recommended

parts, when necessary.

14. Check control operation frequently. Adjust and service as required.

15. Use only factory authorized replacement parts when making repairs.

16. Always comply with factory specifications on all settings and adjustments.

17. Only authorized service locations should be utilized for major service

and repair requirements.

18. Never attempt to make major repairs on this unit unless you have been

properly trained. Improper service procedures can result in hazardous

operation, equipment damage and voiding of manufacturer’s warranty.

19. Check shear bolts (pins) and other bolts at frequent intervals for proper

tightness to be sure the equipment is in safe working condition.

Emissions

1. Engine exhaust from this product contains chemicals known, in certain

quantities, to cause cancer, birth defects, or reproductive harm.

2. If available, look for the relevant Emissions Durability Period and Air

Index information on the engine emissions label.

Ignition System

1. This spark ignition system complies with Canadian ICES-002.

Page 11

ASSEMBLY

Read and follow the assembly and adjustment

instructions for your snow thrower. All fasteners

are in the parts bag. Do not discard any parts or

material until the unit is assembled.

WARNING: Before doing any assembly or maintenance to the snow

thrower, remove the wire from the

spark plug.

NOTE: In this instruction book, left and right

describe the location of a part from the operator’s position behind the unit.

NOTE: Torque is measured in foot pounds

(metric N.m). This measurement describes

how tight a nut or bolt must be. The torque is

measured with a torque wrench.

NOTE: Illustrations are located on page 2

and on pages 3 through 6.

Tools Required

1Knife

1 Pliers

How To Remove The Snow Thrower

From The Carton

1. Locate and remove the container of oil.

2. Locate all parts that are packed separately

and remove from the carton.

3. Remove and discard the packing material

from around the snow thrower.

4. Cut down all four corners of the carton and

lay the side panels flat.

5. Hold onto the lower handle and pull the snow

thrower off the carton.

CAUTION: DO NOT back over cables.

6. Remove the packing material from handle

assembly. Remove the lower insert from the

axle.

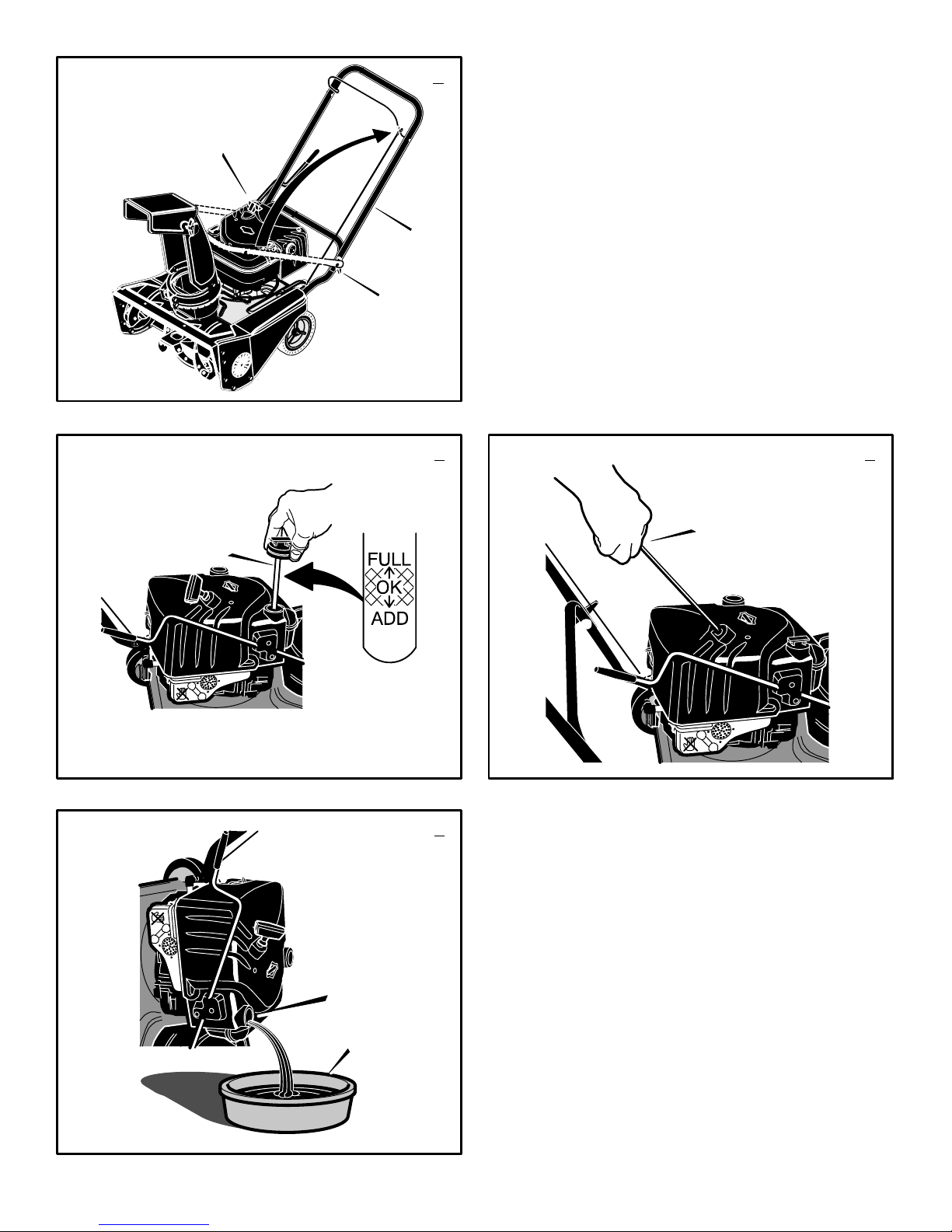

How To Assemble The Handle

1. Remove the packing material from the upper

and lower handles.

2. (Figure 2) Loosen the knobs (1) on each

side of the handle (2).

3. Raise the upper handle (2) to the operating

position. Hold the upper handle (2) apart to

prevent scratching the lower handle.

NOTE: Make sure the auger drive cable is

not caught between the upper and lower

handle.

4. Tighten the knobs (1).

How To Prepare The Engine

WARNING: Follow the engine

manufacturer’s instructions for the

type of fuel and oil to use. Always

use a safety fuel container. Do not smoke

when adding fuel to the fuel tank. When

inside an enclosure, do not fill the fuel

tank. Before you add the fuel, stop the engine. Let the engine cool for several minutes.

See the engine manufacturer’s instructions for

the type of fuel and oil to use. Before you use

the unit, read the information on safety, operation, maintenance, and storage.

1740265

NOTE: Engine horsepower ratings may vary

by engine adjustments, manufacturing variances, altitude, atmospheric conditions, fuel

and maintenance.

Add Oil To The Engine (Figure 3)

NOTE: Engine may already contain some

residual oil. Check frequently when filling

the crankcase. DO NOT overfill.

The snow thrower was shipped with a container

of 5W30 motor oil. This oil must be added to the

engine before operating.

1. Make sure the unit is level.

2. Remove the oil fill cap/dipstick (1) and fill

the crankcase to “FULL” line on dipstick. DO

NOT overfill.

3. Tighten the oil fill cap/dipstick (1) securely

each time you check the oil level.

NOTE: Synthetic oil can assist with starting

in extreme cold temperatures. Synthetic

5W30 is acceptable for all temperatures. DO

NOT mix oil with petrol.

Add Petrol To The Engine

This engine is certified to operate on petrol. Exhaust Emission Control System: EM (Engine

Modifications).

WARNING: Alcohol blended fuels

(called gasohol or those using

ethanol or methanol) can attract

moisture which leads to separation and

formation of acids during storage. Acidic

gas can damage the fuel system of an engine while in storage.

NOTE: To avoid engine problems, the fuel

system must be emptied before storage for

30 days or longer. Start the engine and let it

run until the fuel lines and carburetor are

empty. Use fresh fuel next season. See the

Storage section in this manual for additional

information.

Fill the fuel tank only with a fresh, clean, unleaded regular, unleaded premium, or reformulated automotive petrol with a minimum of 85

octane. DO NOT use leaded petrol. Make sure

that the container you pour the petrol from is

clean and free from rust or other foreign particles. Never use petrol that may be stale from

long periods of storage in the container.

Before You Operate

Before you operate your new snow thrower,

please review the following checklist:

G Make sure all assembly instructions have

been completed.

G Make sure the discharge chute rotates freely.

G Make sure that no loose parts remain in the

carton.

As you learn how to properly use the snow

thrower, pay extra attention to the following important items.

G Make sure the engine oil is at the proper

level. For the type engine oil to use, see the

Engine Manufacturer’s manual.

11

GB

G Make sure gas tank is filled properly with

clean, fresh, unleaded petrol with a minimum

of 85 octane.

G Become familiar with the location of all

controls and understand their function.

G Before starting the engine, make sure all

controls operate correctly.

OPERATION

NOTE: Illustrations are located on page 2

and on pages 3 through 6.

CAUTION: Use only attachments and accessories approved by the manufacturer of the

snow thrower (such as tire chains, electric

start kits, etc.).

Know Your Snow Thrower (Figure 1)

Read this Instruction Book and safety rules before operation the snow thrower. Compare the

illustration with your snow thrower to familiarize

yourself with the location of various controls and

adjustments.

How To Control

The Discharge Of The Snow

WARNING: Never direct the discharge of snow toward bystanders.

WARNING: Always stop the engine

before unclogging the discharge

chute or the auger housing and be-

fore leaving the snow thrower.

1. (Figure 1) Turn the crank assembly (2) to

change the discharge direction of the snow.

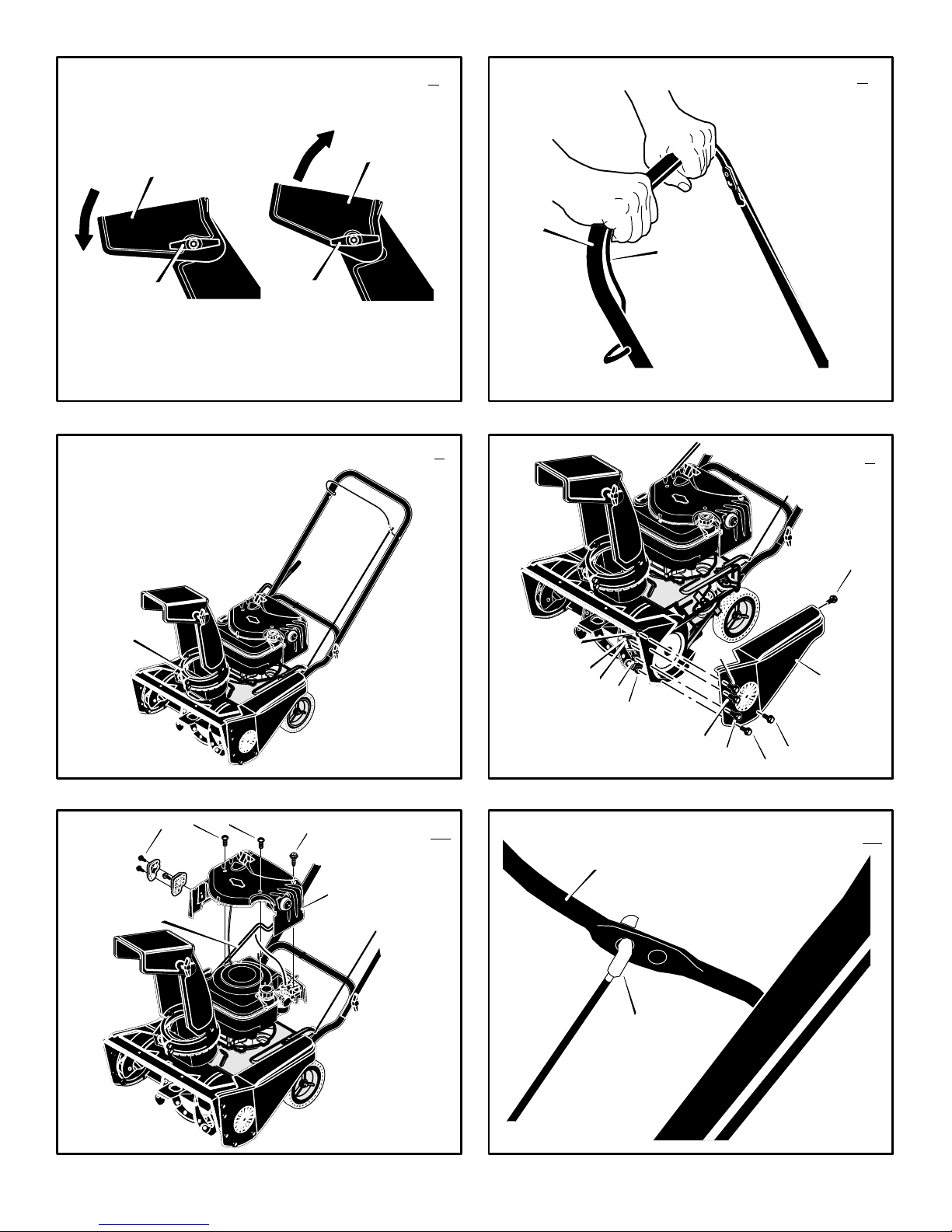

2. (Figure 6) Loosen the wing knob (1) on the

chute deflector (2).

3. Move the chute deflector (2) up for more

distance or down for less distance.

4. Tighten the wing knob (1).

How To Throw Snow (Figure 1)

1. Engage the auger drive lever (5).

2. To stop throwing snow, release the auger

drive lever (5).

WARNING: The operation of any

snow thrower can result in foreign

objects being thrown into the eyes,

which can result in severe eye damage.

Always wear safety glasses or eye shields

while operating the snow thrower. We recommend standard safety glasses or use a

wide vision safety mask over your glasses.

How To Stop Discharging Snow

(Figure 1)

1. To stop discharging snow, release the auger

drive lever (5).

NOTE: If the snow thrower continues to

slowly move forward, see “How To Adjust

The Auger Control Cable” in the Maintenance Section.

2. To stop the engine, push the stop switch (8)

to the off position.

CAUTION: To stop the engine, do not move

the choke control to CHOKE position. Backfire or engine damage can occur.

Page 12

GB

12

1740265

2. To go forward, raise the handle (2) to allow

the rubber auger blades to contact the

ground. Maintain a firm hold on the handle

(2) as the snow thrower starts to move forward. Guide the snow thrower by moving the

handle (2) either left or right. Do not attempt

to push the snow thrower.

3. To stop, release the auger drive lever (5).

NOTE: If the auger continues to rotate, see

“How To Adjust The Auger Control Cable” in

the Maintenance section.

Before Starting The Engine

1. Before you service or start the engine, familiarize yourself with the snow thrower. Be

sure you understand the function and location of all controls.

2. Make sure that all fasteners are tight.

3. Make sure the fuel tank is filled with the correct mixture of gasoline and oil.

4. Become familiar with the location of all controls and understand their function.

5. Before starting the engine, make sure all

controls operate corrently.

How To Stop The Engine (Figure 1)

To stop the engine, push the stop switch (8) to

the off position.

CAUTION: To stop the engine, do not move

the choke control to CHOKE position. Backfire or engine damage can occur.

How To Start The Engine (Figure 1)

Make sure that the engine oil is at FULL mark on

dipstick. The engine is equipped with a recoil

starter. Before starting the engine, make certain

that you have read the following information.

If engine floods, set the choke to the OPEN/

RUN position and crank until the engine starts.

WARNING: Rapid retraction of the

starter cord (kickback) will pull

your hand or arm toward the engine faster than you can let go of the starter cord.

S When starting the engine, slowly pull

the starter cord until resistance is felt.

Then, rapidly pull the starter cord.

S Make sure components; such as impel-

lors, pulleys or sprockets, are securely

attached.

How To Start A Cold Engine (Figure 1)

1. (Figure 1) Push the stop switch (8) to the

ON position.

2. When starting the engine, do not engage the

auger drive lever.

3. Move the choke control (14) to the FULL

choke position.

4. Push the primer button (9) as specified below. Remove finger from the primer button

(9) between primes.

S Push two times if temperature is 15° F

(−9° C) or higher.

S Push four times if temperature is below

15° F (−9° C).

5. (Figure 4) Slowly pull the recoil starter han-

dle (1) until resistance is felt and then pull

rapidly to start the engine. Do not allow the

recoil starter handle (1) to snap back. Slowly return the recoil starter handle (1).

NOTE: In temperatures below 0F, allow

the engine to warm up for several minutes

before blowing snow.

WARNING: Never run the engine

indoors or in enclosed, poorly ven-

tilated areas. Engine exhaust contains carbon monoxide, an odorless and

deadly gas. Keep hands, feet, hair and

loose clothing away from any moving parts

located on the engine or the snow thrower.

The temperature of muffler and nearby

areas may exceed 150°F. Avoid these

areas.

How To Start A Warm Engine (Figure 1)

If an engine has been running and is still warm,

leave the choke control (14) in the off position

and do not push the primer button (9). If the

engine fails to start, follow the instructions “How

To Start A Cold Engine”.

NOTE: Do not use the primer button (9) to

start a warm engine.

How To Start An Engine With A Frozen Electric

Starter (Figure 1)

If the starter is frozen and will not turn the engine, follow the instructions below.

1. Pull out the recoil starter handle (12) as far

as possible.

2. Quickly release the recoil starter handle

(12). Allow the recoil starter handle (12) to

snap back against the recoil starter.

If the engine still fails to start, repeat the two previous steps until the engine starts. Then, continue with the directions “How To Start A Cold

Engine”.

To help prevent the possible freeze−up of the

recoil starter and of the engine controls, proceed

as follows after each snow removal job.

1. Before storing, run the snow thrower a few

minutes to prevent freeze−up of the auger/

impeller.

2. With engine off, allow engine to cool for several minutes.

3. Pull starter rope very slowly until resistance

is felt, then stop. Allow the starter rope to recoil. Repeat three times.

4. With the engine not running, wipe all snow

and moisture from the carburetor cover in

area of controls and levers. Also, move the

choke control and starter handle several

times.

How To Remove Snow or Debris From

The Auger Housing

(Figure 1)

WARNING: Do not attempt to remove snow or debris that may become lodged in auger housing

without taking the following precautions.

1. Release the auger drive lever (5).

2. To stop the engine, move the stop switch

(8) to the stop position.

3. Disconnect the spark plug wire.

4. Do not place your hands in the auger hous-

ing (22) or the discharge chute (4). Use a

pry bar to remove any snow or debris.

Snow Throwing Tips

1. This snow thrower will propel itself forward

when the handle is raised enough to cause

the auger blades to contact the ground. The

auger should stop when auger control bar is

released. If it does not stop, see “How To Adjust The Auger Control Cable” in the adjustment section.

2. Most efficient snow throwing is accomplished

when the snow is removed immediately after

if falls.

CAUTION: Do not overload the machine capacity by attempting to clear snow at too fast

a rate.

3. For complete snow removal, slightly overlap

each previous path.

4. Whenever possible, discharge the snow

down wind.

5. The distance the snow will be discharged

can be adjusted by moving the discharge

chute deflector. Raise the deflector for more

distance or lower the deflector for less distance.

6. In windy conditions, lower the chute deflector

to direct the discharged snow close to the

ground where it is less likely to blow into unwanted areas.

7. For safety and to prevent damage to the

snow thrower, keep the area to be cleared

free of stones, toys and other foreign objects.

8. Do not use the auger propelling feature when

clearing gravel or crushed rock driveways.

Move the handle down to slightly raise the

auger.

9. The forward speed of the snow thrower is

dependent on the depth and weight of the

snow. Experience will establish the most effective method of using the snow thrower under different conditions.

10.After each snow throwing job, allow the engine to run for a few minutes. The snow and

accumulated ice will melt off the engine.

11.Clean the snow thrower after each use.

12.Remove ice, snow and debris from the entire

snow thrower. Flush with water to remove all

salt or other chemicals. Wipe snow thrower

dry.

Dry And Average Snow

1. Snow up to eight inches deep can be removed rapidly and easily by walking at a

moderate rate. For snow or drifts of a greater

depth,slow your pace to allow the discharge

chute to dispose of the snow as rapidly as

the auger receives the snow.

2. Plan to have the snow discharged in the direction the wind is blowing.

Wet Packed Snow

Move slowly into wet, packed snow. If the wet,

packed snow causes the auger to slow down or

the discharge chute begins to clog, back off and

begin a series of short back and forth jabs into

the snow. These short back and forth jabs, four

to six inches, will “belch” the snow from the

chute.

Snow Banks And Drifts

In snow of greater depth than the unit, use the

same “jabbing” technique described above. Turn

the discharge chute away from the snow bank.

More time will be required to remove snow of

this type than level snow.

Page 13

GB

13

1740265

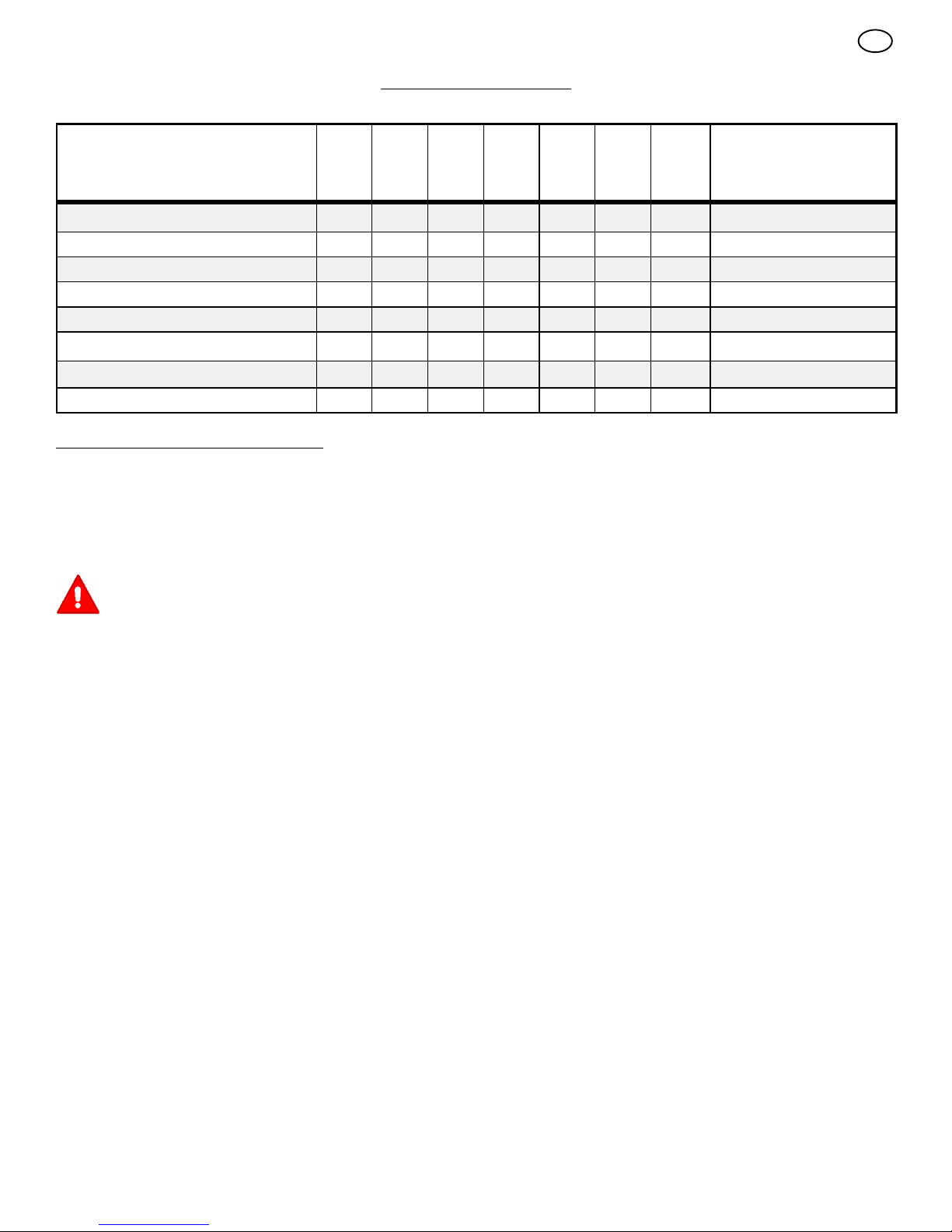

MAINTENANCE CHART

CUSTOMER RESPONSIBILITIES

SERVICE RECORDS

Fill in dates as you

complete regular

service.

Before

Each

Use

First

2

Hours

Every

5

Hours

Every

10

Hours

Every

25

Hours

Each

Season

Before

Storage

SERVICE DATES

Check And Tighten All Screws and Nuts

√ √

Check Spark Plug

√ √

Check Drive Belt

√

Check Fuel

√

Drain Fuel

√

Lubricate Chute Control Flange

√

Check Adjustment of Auger Control Cable

√

Auger Drive Belt

√

MAINTENANCE

NOTE: Illustrations are located on page 2

and on pages 3 through 6.

Use the following maintenance section to keep

your unit in good operating condition. All the

maintenance information for the engine is in the

engine manufacturer’s instructions. Before you

start the engine, read this book.

WARNING: Before you make an inspection, adjustment (except

carburettor), or repair, disconnect

the wire from the spark plug.

General Recommendations

The warranty on this snow thrower does not cover items that have been subjected to operator

abuse or negligence. To receive full value from

the warranty, the operator must maintain the

snow thrower as instructed in this manual.

Some adjustments must be made periodically to

properly maintain the snow thrower.

After Each Use

G Check for any loose or damaged parts.

G Tighten any loose fasteners.

G Check and maintain the auger.

G Check controls to make sure they are

functioning properly.

G If any parts are worn or damaged, replace

immediately.

G Check all safety and instruction decals and

labels. Replace any decals or labels that are

missing or cannot be clearly read.

All adjustments in the Maintenance section of

this manual should be checked at least once

each season.

How To Remove The Top Cover

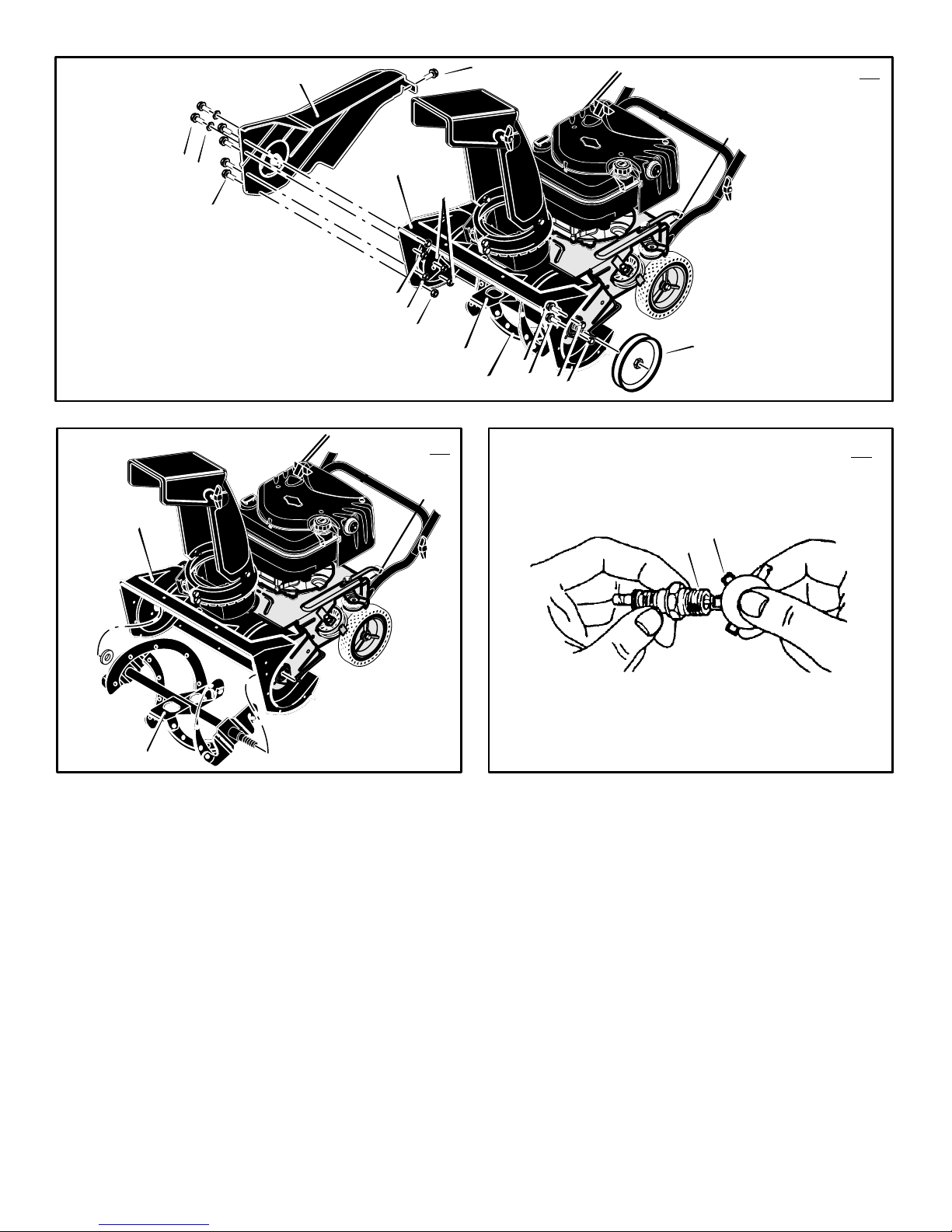

(Figure 8)

1. Remove the five screws (1) from the top

cover (2).

2. Remove the top cover (2).

3. To install the top cover (4), reverse the

above steps.

Lubrication

Before Storage (Figure 8)

1. Lubricate the clute control flange (7). Apply

a clinging type of grease such as Lubriplate.

How To Adjust The Auger Control Cable

The auger control cable is adjusted at the factory. During normal use, the auger control cable

can become stretched and the auger drive lever

will not properly engage or disengage the auger.

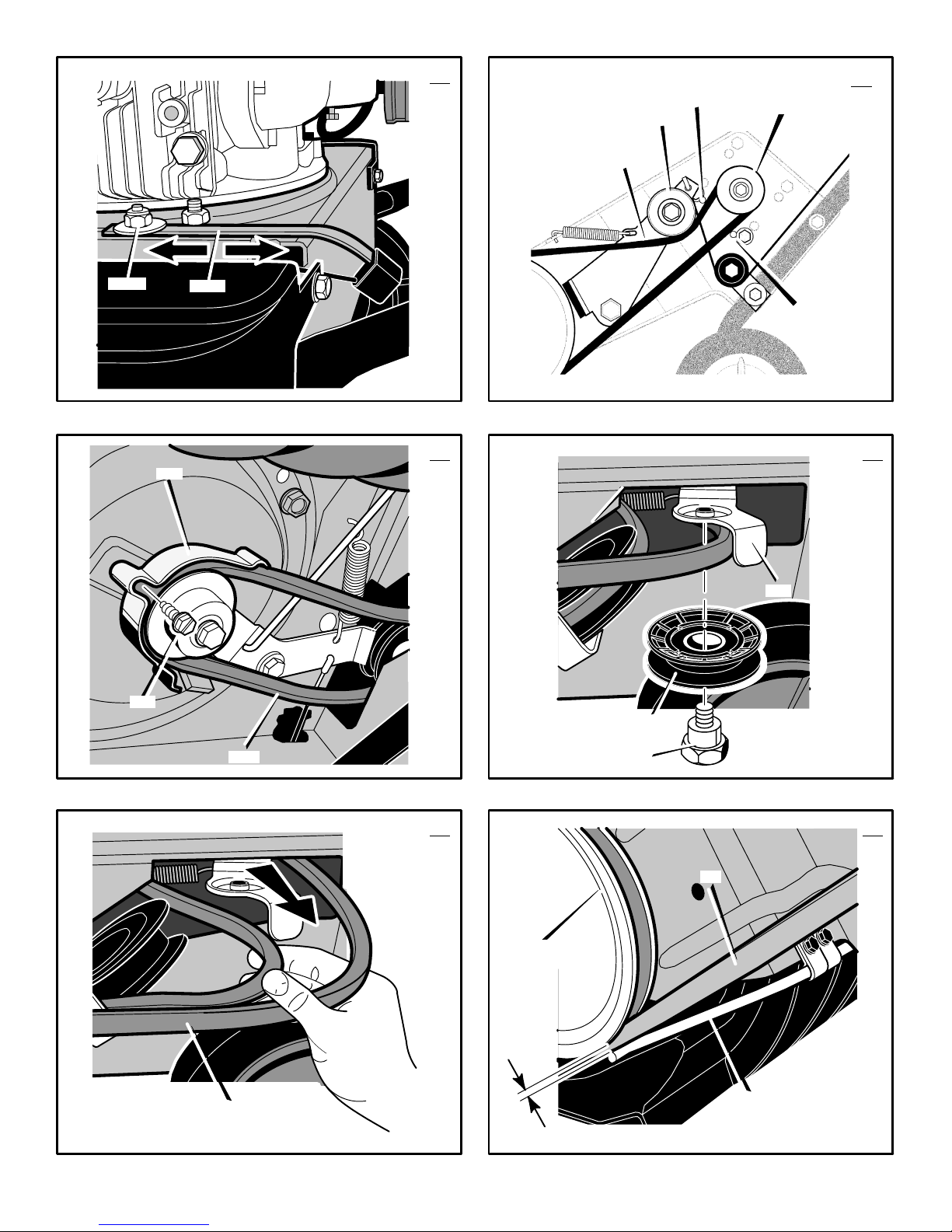

1. (Figure 12) Loosen the nut (1) that holds the

cable tension spring (2).

2. Slide the cable tension spring (2) toward

the rear of the unit until all cable slack is removed.

NOTE: The auger control cable is properly

adjusted when the free cable slack is removed and there is no tension on the

idler arm.

3. Tighten the nut (1) that holds the cable ten-

sion spring (2).

If belt stretch has occured, move the end the

auger control cable to the outside hole as follows:

1. (Figure 12) Loosen the nut (1) that holds the

cable tension spring (2).

2. Move the cable tension spring (2) toward

the front of the unit to achieve maximum

cable slack.

3. (Figure 11) Remove the upper end of the

auger control cable (3) from the auger

drive lever (4).

4. Install the auger control cable (3) in the

hole shown in Figure 11.

5. (Figure 12) Slide the cable tension spring

(2) toward the rear of the unit until all cable

slack is removed.

NOTE: The auger control cable (3) is

properly adjusted when the free cable

slack is removed and there is no tension

on the idler arm.

6. Tighten the nut (1) that holds the cable ten-

sion spring (2).

7. To check the adjustment, start the snow

thrower. Make sure the auger does not rotate

when the auger drive lever is released.

How To Remove The Top Cover

(Figure 10)

There are no adjustments under the top cover

(1). To clean the engine cooling system, follow

the steps below to remove the top cover (1).

1. Remove screws (2) that attach the rod support clamp the the top cover (1). Pivot the

crank assembly rod (3) up and lay on unit.

2. Remove screws (4).

3. Remove attachment screws (5).

4. Remove the top cover (1).

5. To install the top cover (1), reverse the

above steps.

How To Remove The Belt Cover

(Figure 9)

1. Remove the screws (1) and nuts (2) from

the belt cover (3).

2. Remove attachment screw (4) from the rear

of the belt cover (3).

3. Remove the belt cover (3) from the unit.

4. To install the belt cover (3), reverse the

above steps.

NOTE: The belt cover (3) has belt guides

moulded onto the inside of the belt cover (3).

When you install the belt cover (3), engage

the auger drive lever to tighten the belt

against the pulley. This will provide adequate

clearance for the belt guides when installing

the belt cover (3).

How To Replace The Auger Drive Belt

The drive belt is of special construction and

must be replaced with an original factory replacement belt available from your nearest authorized service center.

If the auger drive belt is damaged, the snowthrower will not discharge snow and will not

move forward. Replace the damaged belt as

follows:

1. Disconnect the spark plug wire.

Page 14

GB

14

1740265

2. Remove the belt cover. See “How To Remove The Belt Cover”.

3. Note the path of the auger drive belt (1). For

assistance, a diagram decal is provided.

4. (Figure 14) Remove the belt guide screw

(2) and the belt guide (3). To remove the

belt guide (3), rotate the belt guide (3)

down.

5. (Figure 15) Remove the idler screw (4) and

idler pulley (5) from the idler arm (6).

6. (Figure 16) Remove the auger drive belt (1)

from the engine pulley and pull through side

of motor box.

7. (Figure 17) To remove the auger drive belt

(1) from the impeller pulley (7), move the

idler arm to the engaged position. This will

provide clearance (8) between the impeller

pulley (7) and the brake arm (9) to remove

the auger drive belt.

8. To install a new auger drive belt (1), reverse

the above steps.

9. Check the adjustment of the auger drive

cable. See “Adjust Auger Control Cable”.

How To Remove The Auger

1. Remove the belt cover. See “How To Remove The Belt Cover”.

2. Remove the auger drive belt. See “How To

Replace The Auger Drive Belt”.

3. (Figure 18) Remove the auger pulley (1)

from the auger shaft (threads are left hand;

turn clockwise to remove).

4. To keep the auger (6) from rotating, set a

2”x4” piece of wood on the center paddle

(3) to secure auger (6).

5. Remove bolts (4), washer (5), and nuts (2)

from front of right cover (7).

6. Remove screw (8) from back of right cover

(7).

7. Remove bolts (9) and nuts (10).

8. (Figure 19) Slide the auger (6) out of the

right side of the auger housing (11).

9. Slide the auger (6) out of the bearing on the

left side of the auger housing (11).

10.To install auger (6), reverse the above steps.

Lubrication

How To Check The Engine Oil (Figure 3)

Check the oil level before starting the engine

and after each eight (8) hours of continuous use.

1. Make sure the unit is level.

2. Remove the oil fill cap/dipstick (1) and fill

the crankcase to “FULL” line on dipstick. DO

NOT overfill.

3. Tighten the oil fill cap/dipstick (1) securely

each time you check the oil level.

NOTE: Synthetic oil can assist with starting

in extreme cold temperatures. Synthetic

5W30 is acceptable for all temperatures. DO

NOT mix oil with petrol.

How To Change The Engine Oil

Change the engine oil every fifty (50) hours or at

least once a year if the snow thrower is not used

for fifty (50) hours.

To change the engine oil, the engine must be

tilted forward and the oil drained from the oil fill

tube. Change oil when the engine is warm.

1. (Figure 5) Lift the rear of the snowthrower

and tilt the unit forward. In the correct position, the snowthrower will be setting on the

front of the auger housing.

2. Put an oil drain pan (1) under the oil fill

tube (2).

3. Carefully remove the oil fill cap/dipstick. Oil

will begin to flow into the oil drain pan (2).

4. After all the oil has drained from the engine,

set the snowthrower in the upright operating

position.

5. (Figure 3) Fill the engine with S.A.E. 5W30

oil. Make sure the oil reaches the FULL mark

on the oil fill cap/dipstick. DO NOT OVERFILL.

NOTE: Synthetic oil can assist with starting

in extreme cold temperatures. Synthetic

5W30 is acceptable for all temperatures. DO

NOT mix oil with petrol.

How To Replace The Spark Plug

(Figure 20)

NOTE: This spark ignition system meets all

requirements of the Canadian Interference−

Causing Equipment Regulations.

NOTE: This engine complies with all current

Australian and New Zealand limitations electromagnetic interference.

Check the spark plug (1) every twenty-five (25)

hours. Replace the spark plug (1) if the electrodes are pitted or burned, if the porcelain is

cracked, or every 100 hours of use.

1. Make sure the spark plug (1) is clean. Clean

the spark plug (1) by carefully scraping the

electrodes (do not sand blast or use a wire

brush).

2. Check the spark plug (1) gap with a feeler

gauge (2) and reset gap to 0.030” if necessary..

3. Before installing the spark plug (1), coat the

threads lightly with oil for easy removal.

Tighten the spark plug (1) to a torque of 15

foot-pounds.

How To Prepare The Snow Thrower For

Storage

WARNING: Do not remove petrol

while inside a building, near a fire,

or while you smoke. Petrol fumes

can cause an explosion or a fire.

If the snow thrower is to be stored for an extended period, refer to the engine manufacturer’s operating manual (included with some

models) for important maintenance or storage

details.

1. Drain the fuel tank.

2. Let the engine run until it is out of gasoline.

3. Never store the snow thrower with fuel in the

tank inside a building where ignition sources

are present such as hot water and space

heaters, clothes dryers, and the like. Allow

the engine (motor) to cool before storing in

any enclosure.

4. Drain the oil from the warm engine. Fill the

engine crankcase with new oil.

5. Remove the spark plug from the cylinder.

Pour one ounce of oil into the cylinder. Slowly pull the recoil−start grip so that the oil will

protect the cylinder. Install a new spark plug

in the cylinder.

6. Thoroughly clean the snow thrower.

7. Lubricate all lubrication points. See the Main-

tenance section.

8. Be sure that all nuts, bolts and screws are

securely fastened. Inspect all visible moving

parts for damage, breakage and wear. Replace if necessary.

9. Cover the bare metal parts of the blower

housing and auger with spray rust preventative lubricant.

10.Put the unit in a building that has good ven-

tilation.

11.If the machine must be stored outdoors,

block up the snow thrower to be sure the entire machine is off the ground.

12.Cover the snow thrower with a suitable pro-

tective cover that does not retain moisture.

Do not use plastic.

How To Order Replacement Parts

The replacement parts are shown either on the

back pages of this Instruction Book or in a

separate Parts List Book.

Use only manufacturer’s authorized or approved

replacement parts. The letter placed on the end

of the part number denotes the type of finish for

the part, C for chrome, Z for zinc, a PA for

purchased assembly. It is important that you

include this when ordering a part. Do not use

attachments or accessories not specifically

recommended for this unit. In order to obtain

proper replacement parts you must supply the

model number (see nameplate).

Replacement parts, except for the engine, transmission, transaxle or differential, are available

from the store where the mower was purchased

or a service shop recommended by the store.

Warranty service is available only through Authorized Service Dealers. Locate your nearest dealer

in our locator map at www.murray.com.

Replacement parts for the engine, transaxle, or

transmission, are available from the

manufacturer’s authorized service center found

in the yellow pages of the telephone directory.

Also, see the individual engine or transmission

warranties to order replacement parts.

When ordering the following information is

required:

(1) The Model Number

(2) Serial Number

(3) Part Number

(4) Quantity

Page 15

GB

15

1740265

TROUBLE SHOOTING CHART

TROUBLE CAUSE CORRECTION

Difficult starting Defective spark plug. Replace spark plug.

Water or dirt in fuel system. Use carburetor bowl drain to flush and refill with

fresh fuel.

Engine runs erratic Blocked fuel line, empty gas tank, or stale

gasoline

Clean fuel line; check fuel supply; add fresh

gasoline

Engine stalls Unit running on CHOKE. Set choke lever to RUN position.

Engine runs erratic;

Loss of power

Water or dirt in fuel system. Use carburetor bowl drain to flush and refill with

fresh fuel.

Excessive vibration Loose parts: damaged impeller Stop engine immediately and disconnect spark

plug wire. Tighten all bolts and make all

necessary repairs. If vibration continues, have

the unit serviced by a competent repairman.

Unit fails to propel itself Drive belt loose or damaged. Replace drive belt.

Unit fails to discharge snow Auger drive belt loose or damaged. Adjust auger drive belt; replace if damaged.

Auger control cable not adjusted correctly. Adjust auger control cable.

Discharge chute clogged. Stop engine immediately and disconnect spark

plug wire. Clean discharge chute and inside of

auger housing.

Foreign object lodged in auger Stop engine immediately and disconnect spark

plug wire. Remove object from auger.

Page 16

GB

BRIGGS & STRATTON CORPORATION OWNER WARRANTY POLICY

Effective January 1, 2006 replaces all undated Warranties and all Warranties dated before January 1, 2006

LIMITED WARRANTY

Briggs & Stratton Corporation will repair or replace, free of charge, any part(s) of the product that is defective in material or workmanship or both.

Transportation charges on product submitted for repair or replacement under this warranty must be borne by purchaser. This warranty is effective

for the time periods and subject to the conditions stated below. For warranty service, find the nearest Authorized Service Dealer in your area. For

warranty service, find the nearest Authorized Service Dealer in our dealer locator map at www.murray.com.

THERE IS NO OTHER EXPRESS WARRANTY. IMPLIED WARRANTIES, INCLUDING THOSE OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, ARE LIMITED TO ONE YEAR FROM PURCHASE, OR TO THE EXTENT PERMITTED BY LAW ANY AND ALL

IMPLIED WARRANTIES ARE EXCLUDED. LIABILITY FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES ARE EXCLUDED TO THE

EXTENT EXCLUSION IS PERMITTED BY LAW. Some states or countries do not allow limitations on how long an implied warranty lasts, and

some states or countries do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation and exclusion

may not apply to you. This warranty gives you specific legal rights and you may also have other rights which vary from state to state or country to

country.

WARRANTY TERMS

Brand / Unit Use Use Warranty Term

Single Stage Snowthrower 1 year 90 days. . . . . . . . . . . . . . . . . . . . . .

Dual Stage Snowthrower 2 year 90 days. . . . . . . . . . . . . . . . . . . . . . .

The warranty period begins on the date of purchase by the first retail consumer or commercial end user, and continues for the period of

time stated in the table above. “Consumer use” means personal residential household use by a retail consumer. “Commercial use” means

all other uses, including use for commercial, income producing or rental purposes. Once product has experienced commercial use, it shall

thereafter be considered as commercial use for purposes of this warranty.

No warranty registration is necessary to obtain warranty on Murray branded products. Save your proof of purchase receipt. If you do not

provide proof of the initial purchase date at the time warranty service is requested, the manufacturing date of the product will be used to

determine the warranty.

Consumer Commercial Condition of

ABOUT YOUR WARRANTY

We welcome warranty repair and apologize to you for being inconvenienced. Any Authorized Service Dealer may perform warranty

repairs. Most warranty repairs are handled routinely, but sometimes requests for warranty service may not be appropriate. For example,

warranty service would not apply to the product if damage occurred because of misuse, lack of routine maintenance, shipping, handling,

warehousing or improper installation. Similarly, the warranty is void if the serial number on the product has been removed or the product

has been altered or modified.

This warranty covers product related defective material and/or workmanship only. To avoid misunderstanding which might occur between the customer and the Dealer, listed below are some of the causes of product failure that the warranty does not cover.

• Normal Wear: Small Engine Powered Equipment, like all mechanical devices, needs periodic parts and service to perform well. Warranty does not

cover repair when normal use has exhausted the life of the product or part.

• Installation: This warranty does not apply to product that has been subjected to improper or unauthorized installation, alteration or modification. Nor

installations that prevent starting, cause unsatisfactory engine performance.

• Improper Maintenance: The life of this product depends upon the conditions under which it operates, and the care it receives. Recommended

maintenance and adjustment intervals are stated in the Operator’s Manual. Often product, such as tillers, edgers, rotary mowers, are used in dusty

or dirty conditions, which can cause what appears to be premature wear. Such wear, when caused by dirt, dust, or other abrasive material entering

the product because of improper maintenance is not covered by warranty. The warranty will not cover repairs due to problems caused by replacement parts that are not original manufactured part(s).

• Incorrect and/or insufficient fuel or lubrication: This warranty does not cover damage caused by the use of stale fuel, or altered gasolines. Dam-

age to engine or engine components ie, combustion chamber, valves, valve seats, valve guides, burned starter motor windings caused by use of

alternate fuels such as liquified petroleum, natural gas, are not covered unless engine is certified for this operation. Parts which are scored or broken because product was operated with insufficient, contaminated or incorrect grade of lubricating oil as well as product components damaged due

to lack of lubrication are not covered.

• Operational Misuse: Proper operation of the product is stated in the Operator’s Manual. Product damaged by overspeeding, overheating, or opera-

tion in a confined area without sufficient ventilation. Product broken by excessive vibration caused by a loose engine mounting, loose or unbalanced

blades, impellers, overspeeding, or bent crankshaft due to striking of solid object. Damage or malfunctions resulting from accidents, abuse, or improper servicing or freezing or chemical deterioration, as well as operating in excess of recommended capacities as outlined in the Operator’s

Manual are not covered.

• Routine tune-up, wear items or adjustments: This warranty excludes wear items such as oil, belts, blades, o-rings, filters, etc.

• Other exclusions: Repair or adjustments for part(s) that are not manufactured by Briggs & Stratton Corporation, are not covered, see warranty for

respective manufacturers. This warranty excludes failures due to acts of God and other force majeure events beyond the manufacturers control. Also excluded are used, reconditioned, and demonstration products.

Warranty service is available only through Authorized Service Dealers. Locate your nearest dealer in our locator map at www.murray.com.

1740265

16

Page 17

INHALT

GEFAHRENSYMBOLE UND IHRE BEDEUTUNGEN 18. .

BETRIEBSSYMBOLE UND IHRE BEDEUTUNGEN 18. . .

REGELN FÜR DEN SICHEREN BETRIEB 19. . . . . . . . . . .

ZUSAMMENBAU 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BEDIENUNG 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

WARTUNG 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

WARTUNGSTABELLE 24. . . . . . . . . . . . . . . . . . . . . . . . . . . .

FEHLERSUCHE 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

EINGESCHRÄNKTE GEWÄHRLEISTUNG 27. . . . . . . . . . .

Allgemeines

Bei dieser Bedienungsanleitung werden einige handwerkliche

Grundkenntnisse vorausgesetzt. Wie in den meisten

Wartungshandbüchern werden nicht alle Schritte beschrieben. Das

Lösen und Anziehen von Schrauben kann jeder ohne große

handwerkliche Fähigkeiten bewältigen. Lesen und befolgen Sie diese

Anweisungen, bevor Sie das Gerät benutzen.

Informieren Sie sich über Ihr Produkt: Sie erzielen die beste Leistung,

wenn Sie das Gerät und dessen Funktionen verstehen. Beim Lesen

dieser Bedienungsanleitung vergleichen Sie die Abbildungen mit dem

Gerät. Machen Sie sich mit der Anordnung und Funktion der

Bedienelemente vertraut. Befolgen Sie die Anweisungen zum Betrieb

und die Sicherheitshinweise, um einen Unfall zu verhindern. Bewahren

Sie diese Bedienungsanleitung auf, um später darauf zurückgreifen zu

können.

WICHTIG: Viele Geräte sind nicht vollständig zusammengebaut und

werden in Kartons verpackt verkauft. Der Eigentümer muss die

D

Montageanweisungen in dieser Bedienungsanleitung genau befolgen.

Andere Geräte werden im vor−montierten Zustand verkauft. Bei

montierten Geräten ist der Eigentümer dafür verantwortlich zu prüfen, ob

das Gerät korrekt montiert ist. Der Eigentümer muss das Gerät vor dem

ersten Gebrauch entsprechend der Anweisungen in dieser

Bedienungsanleitung sorgfältig prüfen.

Bedienelement & Gerätefunktionen (siehe Abbildung 1)

Auswurfkurbel (2) − Ändert die Richtung des Aeuswurfkamins.

Auswurfumlenkvorrichtung (3) − Ändert den Abstand, in dem der

Schnee ausgeworfen wird.

Auswurfkamin (4) − Ändert die Richtung, in die der Schnee

ausgeworfen wird.

Räumwerkhebel (5) − Startet und hält die Frässchnecke und die

Wurfeinrichtung an (Sammeln und Auswerfen des Schnees).

Motorfunktionen

Stoppschalter (8) − Muss in die Position AN geschoben werden, um

Motor zu starten.

Initialzündungsknopf (9) − Spritzt Benzin direkt in den Vergaser ein,

damit Motor bei kaltem Wetter schnell anspringt.

Rückstarterhebel (12) − Zum manuellen Anlassen des Motors.

Choke (14) − Zum Anlassen eines kalten Motors.

www.briggsandstratton.com

MODEL NO.: 621403x61NB

SKU No.:

YYYY MM DD:

SERIAL NO.:

3500 min-1

Assembled in Suzhou, China 215218

by Limac for Briggs & Stratton Corporation

30 kg

Angegebene Vibrationsemissionswerte gemäß Richtlinie 98/37/EC.

Vibrationsemission gemäß EN 1033;1996: 7,1 m/s2.

Werte ermittelt am Griff während Gerät stationär auf einer Betonfläche mit 3500

min−1 betrieben wurde.

Angegebene Geräuschemissionen von LwA 104 dB erfüllen Richtlinie 2000/14/EC,

Anhang V.

Schalldruckpegel an Bedienerposition: 84 dB.

Werte am Ohr gemäß den Spezifikationen in EN ISO 11201 ermittelt.

Angegebener

Geräuschemissions−Schalld

ruckpegel von 104 dB(A)

erfüllt Richtlinie 2000/14/EC.

1740265

17

Page 18

D

18

1740265

Dieses Handbuch beinhaltet

Sicherheitsinformationen, um Ihnen die Gefahren

und Risiken im Zusammenhang mit Schneefräsen

bewusst zu machen, und Ihnen zu vermitteln, wie man sie

vermeidet. Die Schneefräse wurde zur Räumung von Schnee

entwickelt und sollte zu keinem anderen Zweck verwendet werden.

Es ist wichtig, dass Sie sich diese Anleitung gut durchlesen und sie

verstehen, und ebenso sollte jeder, der mit dem Gerät arbeitet,

diese Anleitung lesen und verstehen.

Die Motorabgase dieses Produkts enthalten Chemikalien, von denen im

Staat Kalifornien bekannt ist, dass sie Krebs, Geburtsfehler hervorraufen

und andere negative Auswirkungen auf die Fortpflanzung haben können.

WARNUNG

Ein Signalwort (GEFAHR, WARNUNG oder VORSICHT) wird zusammen mit

dem Warnsymbol verwendet, um die Wahrscheinlichkeit und die potentielle

Schwere von Verletzungen anzuzeigen. Außerdem kann ein Gefahrensymbol

verwendet werden, um den Gefahrentyp darzustellen

GEFAHR weist auf eine Gefährdung hin, deren

Nichtbeachtungzum Tod oder zu schweren Verletzungen

führen kann.

WARNUNG weist auf eine Gefährdung hin, deren

Nichtbeachtung zum Tod oder zu schweren Verletzungen

führen könnte.

VORSICHT weist auf eine Gefährdung hin, deren

Nichtbeachtung zum Tod oder zu leichten bis mittelschweren

Verletzungen führen könnte.

Wird VORSICHT ohne das Warnsymbol verwendet, weist dies

auf eine Situation hin, die zu Schäden am Gerät führen

könnte.

Gefahrensymbole und ihre Bedeutungen

Diese Symbole werden an Ihrem Gerät verwendet und sind in Ihrer

Bedienungsanleitung definiert. Lesen Sie zu ihren Bedeutungen nach und

merken Sie sich diese. Die Verwendung dieser Symbole in Verbindung mit

einem Signalwort wird Sie auf potentielle Gefahren und deren Vermeidung

hinweisen.

Explosion

Toxische Gase

Schock

Heiße

Oberfläche

Feuer

Bedienungsanleitung – Lesen Sie diese bevor Sie

jegliche Aktivitäten durchführen oder das Gerät

betreiben.

Sicherheitswarnung – identifiziert

Sicherheitsinformationen zu Gefahren, die zu

Verletzungen an Personen führen können.

Rotierende

Schnecke

Rotierendes

Gebläserad

Rotierende

Getriebe

Hochfliegende

Objekte

Sicherheitsabstand

zum Gerät einhalten.

Schalten Die den Motor ab und entfernen Sie den

Zündkerzenstecker, bevor Sie Wartungs− oder

Reparaturarbeiten durchführen.

Nicht in rotierende

Teile greifen.

Empfohlener

Gehörschutz für die

längere Verwendung.

Betriebssymbole und ihre Bedeutungen

Diese Symbole werden an Ihrem Gerät verwendet und sind in Ihrer

Bedienungsanleitung definiert. Es ist wichtig, dass Sie die Bedeutungen lesen

und verstehen. Ein Nichtverstehen der Symbole kann zu Verletzungen führen.

Stop

Kraftstoff

Choke auf

Öl

Choke ein

Langsam

Schnell

Ein Aus

Zündschlüssel

Zündung aus

Zündung ein

Primerkopf

Gashebel

Antriebskupplung

Schneckenkupplung

Einkuppeln

RECHTS

Schneckensammler

Antrieb

Auswurfkanal

LINKS HINAUF

HERUNTER

Vorwärts

Neutral

Rückwärts

Drücken, um den

elektrischen Start

einzukuppeln

Elektrischer

Start

Motorstart

Betrieb des

Motors

Motor aus

Kanalleitblech

Einkuppeln

Auskuppeln

Beheizte Griffe

Einkuppeln

Page 19

D

19

1740265

WARNUNG: Diese Maschine kann Hände und Füße abschneiden und Objekte schleudern. Lesen Sie sich

diese Regeln durch und befolgen Sie sie strikt. Eine Nichteinhaltung dieser Regeln kann dazu führen, dass

Sie die Kontrolle über das Gerät verlieren, was zu schweren Verletzungen an Ihrer Person und anderen

Personen oder zum Tod führen kann und Sachschäden verursachen kann. Das Dreieck im Text stellt

wichtige Warnungen dar, die unbedingt befolgt werden müssen.

REGELN FÜR DEN SICHEREN BETRIEB

Sichere Betriebspraktiken für Schneefräsen

WICHTIG: Die Sicherheitsstandards erfordern

Bediener−Anwesenheitskontrollen, um das Verletzungsrisiko zu

minimieren. Ihre Schneefräse ist mit solchen Kontrollen ausgestattet.

Versuchen Sie unter keinen Umständen die Funktion der

Bediener−Anwesenheitskontrolle zu unterdrücken.

Übung

1. Lesen, verstehen und befolgen Sie alle Anweisungen an der Maschine

und in den Handbüchern, bevor Sie dieses Gerät betreiben. Seien Sie

sehr sorgfältig mit den Kontrollen und der ordnungsgemäßen

Verwendung des Gerätes. Sie müssen wissen wie Sie die Einheit

schnell stoppen und die Kontrollen schnell auskuppeln können.

2. Lassen Sie das Gerät nie von Kindern betreiben. Lassen Sie nie

Erwachsene dieses Gerät betreiben, ohne sie ordnungsgemäß

einzuweisen.

3. Halten Sie den Betriebsbereich frei von Personen, insbesondere von

kleinen Kindern und Haustieren.

4. Gehen Sie vorsichtig vor, um ein Ausrutschen oder Fallen zu

vermeiden, wenn Sie das Gerät im Rückwärtsgang betreiben.

Vorbereitung

1. Untersuchen Sie den Bereich, in dem das Gerät verwendet werden soll,

sorgfältig und entfernen Sie alle Fußabtreter, Schlitten, Bretter, Drähte

und andere Fremdkörper.

2. Kuppeln Sie alle Kupplungen aus und schalten Sie auf Neutral, bevor

Sie den Motor starten.

3. Betreiben Sie das Gerät nicht ohne geeignete Winterkleidung. Tragen

Sie Schuhwerk, das die Trittfestigkeit auf glatten Oberflächen erhöht.

Vermeiden Sie lockere Kleidung, die zwischen die sich bewegenden

Teile geraten könnten.

4. Gehen Sie sorgfältig mit dem Kraftstoff um, er ist hochentzündlich.

a. Verwenden Sie einen zulässigen Kraftstoffbehälter.

b. Füllen Sie niemals Kraftstoff in einen laufenden oder heißen Motor

nach.

c. Befüllen Sie den Kraftstofftank sehr vorsichtig. Befüllen Sie den

Kraftstofftank nie im Haus. Schrauben Sie den Tankdeckel wieder fest

und wischen Sie verschütteten Kraftstoff ab.

d. Befüllen Sie Behälter nie innerhalb eines Fahrzeugs oder auf einem

LKW oder Anhänger mit Kunststoffdichtung. Stellen Sie den Behälter

immer auf den Boden, von Ihrem Fahrzeug entfernt, bevor Sie ihn

befüllen.

e. Wenn praktikabel, entfernen Sie gasgetriebene Geräte vom LKW

oder Anhänger und betanken Sie diese auf dem Boden. Falls das

nicht möglich ist, tanken Sie es lieber auf einem Anhänger auf als von

einer Kraftstoffdispenserdüse.

f. Achten Sie darauf, dass die Düse bis zum Ende des Auftankens

immer mit dem Rand des Kraftstofftank oder Behälters im Kontakt

bleibt. Verwenden Sie kein Gerät mit Düsenverriegelung.

g. Schrauben Sie den Tankdeckel wieder fest und wischen Sie

verschütteten Kraftstoff ab.

h. Falls Kraftstoff auf Ihre Kleidung gelangt, wechseln Sie diese bitte

sofort.

5. Verwenden Sie Verlängerungskabel und Anschlüsse wie vom

Hersteller angegeben für alle Einheiten mit Antriebsmotoren oder

elektrischen Startmotoren.

6. Stellen Sie die Höhe des Sammler−Gehäuses auf Schotter oder

Kiesoberflächen ein.

7. Versuchen Sie nie irgendwelche Einstellungen bei laufendem Motor

vorzunehmen (es sei denn dies wird speziell durch den Hersteller

empfohlen).

8. Warten Sie, bis sich Motor und Schneefräse an die Außentemperaturen

angepasst haben, bevor Sie mit dem Schneeräumen beginnen.

9. Tragen Sie beim Betrieb der Schneefräse sowie bei Einstellungen und

Reparaturen immer eine Sicherheitsbrille oder einen Augenschutz, um

Ihre Augen vor Fremdkörpern zu schützen, welche die Maschine

schleudert.

Betrieb

1. Halten Sie Hände und Füße von rotierenden Teilen fern. Halten Sie sich

immer von der Entladeöffnung fern.

2. Gehen Sie äußerst vorsichtig vor, wenn Sie auf Schotterwegen oder

Schotterstraßen arbeiten oder diese überqueren. Achten Sie auf

verborgene Gefahren und Verkehr.

3. Stoppen Sie den Motor, wenn Sie einen Fremdkörper berührt haben,

schalten Sie den Motor ab, ziehen Sie Zündkabel ab, entfernen Sie das

Kabel an Elektromotoren, untersuchen Sie die Schneefräse auf jegliche

Schäden, und reparieren Sie den Schaden, bevor Sie die Schneefräse

erneut starten und betreiben.

4. Falls die Einheit beim Start abnormal vibriert, stoppen Sie den Motor

und suchen Sie sofort nach der Ursache. Vibration ist in der Regel ein

Warnhinweis für Probleme.

5. Stoppen Sie den Motor, wann immer Sie die Betriebsposition verlassen,

bevor Sie den Sammler/das Gebläserad−Gehäuse oder den

Auswurfkanal von der Verstopfung befreien und wenn Sie irgendwelche

Reparaturen, Einstellungen oder Untersuchungen vornehmen.

6. Stellen Sie beim Reinigen, Reparieren oder Untersuchen sicher, dass

der Sammler/das Gebläserad und alle beweglichen Teile gestoppt

haben. Ziehen Sie das Zündkabel ab und halten Sie das Kabel von der

Zündkerze fern, um ein zufälliges Starten zu vermeiden.

7. Lassen Sie den Motor nicht im Haus laufen, außer beim Start des

Motors und zum Transport der Schneefräse in das Gebäude hinein

oder aus dem Gebäude heraus. Öffnen Sie die Außentüren; Abgase

sind gefährlich (sie enthalten KOHLENMONOXID, ein GERUCHLOSES

und TÖDLICHES GAS).

8. Gehen Sie besonders vorsichtig vor, wenn Sie an Abhängen arbeiten.

Versuchen Sie nicht, Schnee an steilen Abhängen zu beräumen.

9. Betreiben Sie die Schneefräse nie ohne geeignete Schutzgitter, Platten

oder andere Sicherheitsvorrichtungen am Gerät.

10. Richten Sie den Auswurfkanal niemals auf Menschen oder Bereichewo

Sachschäden entstehen können. Halten Sie Kinder un andere

Personen fern.

11. Überlasten Sie die Maschinenkapazität nicht, indem Sie versuchen den

Schnee zu schnell zu beräumen.

12. Betreiben Sie die Maschine nie bei hohen Transportgeschwindigkeiten

auf glatten Oberflächen. Sehen Sie nach hinten und gehen Sie

vorsichtig vor, wenn Sie im Rückwärtsgang arbeiten.

13. Schalten Sie die Stromzufuhr zum Sammler/Gebläserad aus, wenn die

Schneefräse transportiert oder nicht betrieben wird.

14. Verwenden Sie nur vom Hersteller der Schneefräse zugelassenes

Zubehör und Ersatzteile (wie Kabinen, Radketten etc.).

Page 20

D

20

1740265

15. Betreiben Sie die Schneefräse nie ohne gute Sichtbarkeit oder Licht.

Stellen Sie immer sicher, dass Sie trittfestes Schuhwerk anhaben und

die Griffe richtig festhalten. Gehen Sie, nicht rennen.

16. Berühren Sie niemals einen heißen Motor oder Schalldämpfer.

17. Betreiben Sie die Schneefräse nie in der Nähe von Glaswänden,

Fahrzeugen, Fensterschutzvorrichtungen, Abfalltonnen usw. ohne den

Schneewurfwinkel entsprechend einzustellen.

18. Richten Sie den Schneewurf nie auf Zuschauende und erlauben Sie

niemandem sich vor der Einheit aufzuhalten.

19. Belassen Sie eine laufende Einheit nie ohne Aufsicht. Kuppeln Sie

immer die Schnecke und die Zugsteuerungen aus, schalten Sie den

Motor ab und entfernen Sie die Schlüssel.

20. Betreiben Sie die Einheit nie unter Einfluss von Alkohol oder Drogen.

21. Denken Sie immer daran, dass die Bedienperson für alle Unfälle an

Personen und Sachwerten verantwortlich ist.

22. Daten weisen darauf hin, dass an einem großen Anteil aller

Stromgerät−bezogenen Verletzungen Personen ab einem alter von 60

Jahren beteiligt sind. Diese Bedienpersonen sollten ihre Fähigkeit die

Einheit sicher genug zu bedienen, um sich und andere vor

Verletzungen zu schützen, einschätzen, bevor sie das Gerät betreiben.

23. TRAGEN SIE KEINE langen Schals oder lockere Kleidung, die sich in

den beweglichen Teilen verfangen könnte.

24. Schnee kann Hindernisse verbergen. Stellen sie sicher, dass Sie alle

Hindernisse aus dem zu beräumenden Bereich entfernen.

Kinder

Tragische Unfälle können die Folge sein, wenn die Bedienperson nicht auf die

Anwesenheit von Kindern achtet. Kinder werden oft durch die Einheit und ihren Betrieb

angezogen. Nehmen Sie nie an, dass Kinder dort bleiben, wo Sie sie zuletzt gesehen

haben.

1. Halten Sie Kinder außerhalb des Bereiches und unter der sorgfältigen

Obhut eines anderen verantwortlichen Erwachsenen.

2. Seien Sie gewarnt und schalten Sie die Einheit ab, wenn Kinder den zu

beräumenden Bereich betreten.

3. Lassen Sie das Gerät nie von Kindern betreiben.

4. Seien Sie besonders vorsichtig, wenn Sie sich blinden Ecken, Büschen,

Bäumen oder anderen Objekten nähern, die den Blick behindern.

Freiräumen eines verstopften Auswurfkanal

Handkontakt mit dem rotierenden Gebläserad im Inneren des Auswurfkanal ist

die häufigste Ursache von Verletzungen im Zusammenhang mit Schneefräsen.

Reinigen Sie den Auswurfkanal niemals mit der Hand.

Um den Kanal zu reinigen:

1. SCHALTEN SIE DEN MOTOR AB.

2. Warten Sie 10 Sekunden, um sicher zu gehen, dass die Gebläseblätter

zu rotieren aufgehört haben.

3. Verwenden Sie immer ein Reinigungswerkzeug, nicht die Hände.

Service, Wartung und Lagerung

1. Überprüfen Sie die Schneidebolzen in häufigen Intervallen auf

Festigkeit, um sicher zu stellen, dass das Gerät in einem sicheren

Arbeitszustand ist.

2. Lagern Sie die Maschine niemals innerhalb eines Gebäudes, in dem

sich Zündquellen wie heißes Wasser und Heizkörper oder

Bekleidungstrockner befinden, wenn sich Kraftstoff im Tank befindet.

Lassen Sie den Motor abkühlen, bevor Sie das Gerät in irgendeiner

Einfriedung lagern.

3. Lesen Sie wichtige Details immer in der Bedienungsanleitung nach,

wenn die Schneefräse über einen längeren Zeitraum gelagert werden

soll.

4. Belassen Sie Sicherheits− und Anleitungsetiketten an ihrem Platz oder

ersetzen Sie sie falls erforderlich.

5. Lassen Sie die Maschine nach der Schneeräumung einige Minuten

laufen, um ein Einfrieren des Sammlers/Gebläserades zu verhindern.

6. Falls Kraftstoff verschüttet wird, versuchen Sie nicht den Motor zu

starten, sondern bringen Sie die Maschine aus dem Bereich weg, in

dem der Kraftstoff verschüttet wurde, und vermeiden Sie die Schaffung

jeder Art von Zündquelle zu vermeiden, bis die Kraftstoffdämpfe sich

verzogen haben.

7. Verwenden Sie immer sichere Praktiken beim Auftanken und bei der

Handhabung von Kraftstoff , wenn Sie die Einheit nach Transport oder

Lagerung auftanken.

8. Befolgen Sie immer die Bedienungsanleitung, um das Gerät auf die

Lagerung sowohl für kurze als auch für längere Zeiträume

vorzubereiten.

9. Befolgen Sie immer die Anweisungen im Motor−Handbuch für

ordnungsgemäße Start-verfahren, wenn Sie die Einheit erneut

einsetzen.

10. Belassen Sie Sicherheits− und Anleitungsetiketten an ihrem Platz oder

ersetzen Sie sie falls erforderlich.

11. Halten Sie Muttern und Schrauben fest angezogen und achten Sie

darauf, dass die Einheit im guten Zustand bleibt.

12. Manipulieren Sie nie an den Sicherheitsvorrichtungen herum.

Überprüfen Sie deren ordnungsgemäßen Betrieb regelmäßig und

nehmen Sie die nötigen Reparaturen vor, wenn sie nicht

ordnungsgemäß funktionieren.

13. Die Komponenten unterliegen Abnutzung, Schäden und Alterung.

Überprüfen Sie die Komponenten häufig und ersetzen Sie sie wenn

nötig durch vom Hersteller empfohlene Teile.

14. Überprüfen Sie den Kontrollbetrieb häufig. Nehmen Sie Einstellungen

und Wartungsarbeiten wie erforderlich vor.

15. Verwenden Sie nur vom Hersteller genehmigte Ersatzteile, wenn Sie

Reparaturen vornehmen.

16. Halten Sie sich bei allen Einstellungen und Korrekturen immer an die

Herstellerspezifikation.

17. Nur autorisierte Wartungsdienste sollten für größere Wartungsarbeiten

und Reparaturen genutzt werden.

18. Versuchen Sie nie größere Reparaturen an dieser Einheit

vorzunehmen, es sei denn Sie wurden entsprechend ausgebildet.

Unsachgemäße Wartungsprozeduren können zu gefährlichem Betrieb,

Schäden an der Einheit und zum Erlöschen der Herstellergarantie

führen.

19. Überprüfen Sie die Schneidebolzen in häufigen Intervallen auf

Festigkeit, um sicher zu stellen, dass das Gerät in einem sicheren

Arbeitszustand ist.

Abgase

1. Die Motorenabgase von diesem Produkt enthalten Chemikalien, von

denen bekannt ist, dass sie in bestimmter Menge Krebs, Geburtsfehler

oder negative Auswirkung auf die Fortpflanzung haben können.

2. Falls verfügbar, suchen Sie nach den relevanten Informationen zu

Emissionsgrenzwerten auf dem Motorenetikett.

Zündsystem

1. Dieses Zündkerzensystem entspricht der kanadischen Richtlinie

ICES-002.

Page 21

D

21

1740265

ZUSAMMENBAU

Lesen und befolgen Sie die Anweisungen zum

Zusammenbau und zur Einstellung für Ihre

Schneefräse. Alle Befestigungselemente

befinden sich in dem Teilebeutel. Werfen Sie

keine Teile oder Materialien fort, bis die

Maschine zusammengebaut ist.

WARNUNG: Entfernen Sie das

Kabel von der Zündkerze, bevor Sie

die Schneefräse zusammenbauen

oder Wartungsarbeiten daran vornehmen.

Hinweis: In dieser Anleitung beschreiben die

Begriffe „links“ und „rechts“ den Lageort

eines Teils aus der Sicht des Bedieners, der

hinter der Maschine steht.

Hinweis: Drehmomente werden in Nm

gemessen. Dieser Messwert beschreibt, wie

fest eine Mutter oder Schraube angezogen

werden muss. Das Drehmoment wird mit

einem Drehmomentschlüssel gemessen.

Hinweis: Abbildungen sind auf Seite 2 und

auf den Seiten 3 bis 6 enthalten.

Erforderliche Werkzeuge

1 Messer

1 Zange

Herausnehmen der Schneefräse aus

dem Karton