Page 1

InstructionBook

SnowThrower

Model 620301x4C

Manueld'instructions

Manualdeinstrucciones

Readand keep this book for future reference. This book contains important information on SAFETY,

ASSEMBLY,OPERATION,AND MAINTENANCE.

Lisez et conservez ce manuel pour r_f_rence.Ce manuel contient des informationsimportantes

concernant laSECURITE,LE MONTAGE,L'UTILISATIONET L'ENTRETIEN.

Leay conserve este manual para referenciasfuturas. Estemanual contieneinformaci6n importante

sobreSEGURIDAD, ENSAMBLAJE,FUNCIONAMIENTOY MANTENIMIENTO.

chasse-neige

Quitanieves

module 620301x4C

modelo 620301x4C

F-OO1133M

Page 2

NOTE: This unit is equipped with an internal combustion engine

and must not be used on or near any unimproved

forest-covered, brush-covered or grass-covered land unless

the engine's exhaust system is equipped with a spark arrester

meeting applicable local or state laws (if any). If a spark arrester

is used, it must be maintained in effective working order by the

operator,

In the State of California, the above is required by law (Section

4442 of the California Public Resources Code), Other states

may have similar laws, Federal laws apply on federal lands. See

an Authorized Service Center for a spark arrester for the

muffler.

REMARQUE : cette machine est 6quipee d'un moteur

combustion interne et ne dolt pas etre utilisee sur un terrain

forestier, buissonnant ou herbeux non prepare, a moins que le

dispositif d'echappement soit pourvu d'un pare-etincelles

conforme a la legislation locale ou de 1'etat (le cas 6cheant). Si

un pare-etincelles est utilise, celui-ci dolt etre maintenu en

parfait etat de fonctionnement par I'utilisateur.

Au sein de I'etat de Californie, la ]oi exige la prise en compte

des precautions mentionnees ci_:lessus (clause 4442 du

California Public Resources Code). D'autres 6tats peuvent

presenter des lois similaires. Les lois federales s'appliquent sur

les terres federales. S'adresser 9 un centre de maintenance

agree pour I'achat d'un pare-etincelles pour I'echappement.

Engine Exhaust, some of its constituents, and

certain vehicle components contain or emit

chemicals known to the State of California to

cause cancer and birth defects or other repro-

ductive harm.

Battery posts, terminals and related accesso-

ries contain lead and lead compounds, chemi-

cals known to the State of California to cause

cancer and birth defects or other reproductive

harm. WASH HANDS AFTER HANDLING.

Les gaz d'_chappement du moteur, certains

dl_ments de leur composition, ainsi que

certains organes du vdhicule contiennent ou

dmettent des substances chimiques qui, selon

i'Etat de Californie, peuvent causer le cancer,

des malformations a la naissance, ou

repr_sentent un danger pour la reproduction.

Les bornes et peles de batterie et autres

accessoires de ce type contiennent du plomb et

des compos_s de plomb, substances

chimiques qui, selon rEtat de Californie,

peuvent causer ie cancer, des malformations

ia naissance, ou repr_sentent un danger pour ia

reproduction.

NOTA: Esta unidad est9 equipada con un motor de combustien

intern& per Io que no debe usarse sabre o cerca de terreno

baldio, arbolado, herboso o de matorral a menos que el sistema

de escape del motor dispone de un parachispas que cumpla

con las leyes locales o estatales pertinentes (si las hay). Si hay

un parachispas instalado en el motor, el usuario debe

mantenerlo en buenas condiciones de operacien.

€:ste es un requisito legal para el estado de California (Seccien

4442 del Cedigo de Recursos P_blicos de California), Puede

que arras estados tengan leyes similares, En los terrenos

federales se aplican las leyes Federales. Visite un Centre de

servicio autorizado si desea instalar un parachispas para el

sistema de escape.

Fq)O1133M 2

Las emanaciones de escape producidas por

este motor contienen quimicos reconocidos

por el Estado de California como carcinbgenos,

tambien pueden producir defectos en los reci6n

nacidos o causar otros dahos al sistema

reproductivo.

Los bornes, terminales y accesorios relaciona-

dos con ia bateria contienen plomo y compues-

tos del plomo, ademas de sustancias quimicas

que el Estado de California reconoce como car-

cinbgenas, ademds estas sustancias pueden

producir da_os congenitos a los bebds y da_os

al sistema reproductor humano. DEBE LAVAR-

SE MUY BIEN LAS MANOS DESPUES DE MANi-

PULAR ESTOS COMPONENTES.

Page 3

_2

5

4

3

7

5

4

/

5

F_O1133M

/

3

14

Page 4

Z

2

,/ 8_

f

2

2

3

1

\

1

1

1

2J%

11 12

2

4

}

5

Fq)O1133M 4

Page 5

)111111_

4

13

2

1

5

6

3

14

15

3

4

5

1

17

Fq)O1133M 5

Page 6

CONTENTS

PRODUCT INFORMATION 6

OWNER'S INFORMATION 6

INTERNATIONAL PICTORIALS 7

ASSEMBLY 9

OPERATION 10

MAINTENANCE 12

MAINTENANCE CHART 12

TROUBLE SHOOTING CHART 14

TWO YEAR LIMITED WARRANTY

Murray, Inc. warrants to the original purchaser

that this unit shall be free from defects in

material and workmanship under normal use

and service for a pedod of Two (2) Year from

the date of purchase; however, this warranty

does not cover engines, accessories (such as

electdc starters) and Normal Wear Parts (except

as noted below) as the companies that

manufacture these items furnish their own

warranties and provide service through their

authorized field service facilities. For additional

information, see the warranties covering these

particular parts. If you are uncertain whether

your unit contains or is equipped with one or

more of these pads, consult your dealer prior to

purchase. Subject to the terms and conditions

noted in this Limited WarTanty, we shall, at our

option, repair or replace at no cost to the original

purchaser any part covered by this Limited

Warranty during the applicable warranty period.

Normal Wear Parts are defined as drive belts,

augers, shear pins, tires and headlights. These

parts are warranted to be free from defects in

material and workmanship as delivered with the

product. Any claim for repair or replacement of

Normal Wear Parts must be made within thirty

(30) days of the date of purchase. No claims

involving damage caused from material use,

abuse or misuse will be honored.

This Murray, inc. Two (2) Year Limited

Warranty is your exclusive remedy; however,

this warranty is void or does not apply to any

unit that has been tampered with, altered,

misused, abused or used for rental or other

commercial and/or professional

(non-homeowner) uses. Your warranty does not

cover minor mechanical adjustments which are

not due to any defect in material or

workmanship. For assistance in making such

adjustments, consult your instruction Book.

To make a claim under this Murray, inc. Two (2)

ENGLISH

Year Limited Warranty, return the unit (or if

authorized in advance, the defective part) along

with your proof of purchase to an Authorized

Service Center near you. To locate the nearest

Authorized Service Center, call the Central Parts

Distributor for your area shown in the list

provided with your unit or check the Yellow Page

listings in your local telephone directory. If you

return the entire unit, we will repair the unit. ffwe

authorize the return of the defective part only, we

will either replace or repair the part.This Murray,

Inc. Two (2) Year Limited Warranty gives you

specific legal rights, and you may also have

other rights which vary from state to state. This

Limited Warranty is given in lieu of all other

expressed and implied warranties including

the implied warranty of merchantability and

warranty of fitness for a particular purpose. If

you need additional information on this written

warranty or assistance in obtaining service,

write:

MURRAY, INC.

Outdoor Power Equipment

Customer Service Department

no. Box 268

Brentwood, Tennessee 37027

1-800-251-8007

PRODUCT INFORMATION

The owner must be certain that all the product

information is included with the unit. This

information includes the INSTRUCTION

BOOKS, the REPLACEMENT PARTS and the

WARRANTIES. This information must be

included to make sure state laws and other laws

are followed.

OWNER'S INFORMATION

This instruction book is written for a person with

some mechanical ability. Like most service

books, not all the steps are described. Steps on

how to loosen or tighten fasteners are steps

anyone can follow with some mechanical ability.

Read and follow these instructions before you

use the unit.

Know your product: If you understand the unit

and how the unit operates, you will get the best

performance. As you read this manual, compare

the iIIustrations to the unit. Learn the location

and the function of the controls. To help prevent

an accident, follow the operating instructions

and the safety rules. Keep this manual for future

reference.

IMPORTANT: Many units are not assembled

and are sold in cartons. It is the responsibility of

the owner to make sure the assembly instruc-

tions in this manual are exactly followed. Other

units are purchased in an assembled condition.

On assembled units, it is the responsibility of the

owner to make sure the unit is correctly as-

sembled. The owner must carefully check the

unit according to the instructions in this manual

before it is first used.

WARNING: Look for this symbol to indicate

important safety precautions. This symbol

indicates: "Attention! Become Alert! Your

Safety Is At Risk."

Responsibility Of The Owner

The responsibility of the owner is to

follow the instructions below.

1. Carefully read andfoIIow the rules for safe

operation.

2. Follow all the assembly and preparation

instructions.

3. Inspect the unit.

4. Make sure that the operator of the unit

knows how to correctly use all standard

and accessory equipment.

5. Operate the unit only with guards, shields,

and other safety items in place and working

correctly.

6. Correctly adjust the unit.

7. Service the unit only with authorized or ap-

proved replacement pads.

8. Complete all maintenance on the unit.

Environmental Awareness

• Do not fill the engine's fuel tank completeIy

full.

• Drain fuel for off-season storage.

• Use only unleaded gasoline.

• Service the air cleaner regularly.

• Tune-up the engine regularly.

• Keep equipment in efficient operating

condition.

• Dispose of used engine oil properly.

Fq)O1133M 6

Page 7

INTERNATIONAL PICTORIALS

IMPORTANT: The following pictorials are lo-

cated on your unit or on literature supplied

with the product. Before you operate the

unit, learn and understand the purpose for

each pictorial.

ENGLISH

Safety Warning Symbols

DANGER DANGER

Thrown Objects. Thrown Objects.

Keep Bystanders Away, Keep Bystanders Away. WARNING

DANGER

Stop The Engine

WARNING Before Unclogging

Hot Surface STOP Discharge Chutet

Control And 0perat_ols ) _

Slow Fast Electric Start Engine Start Engine Run Engine Off

IMPORTANT

Read Owner's Manual

Before Operating

This Machine.

DANGER

Avoid Injury From

Rotating Augen Keep

Hands, Feet And

Clothing Awa_

0 I I,I H N

18

Engine Stop On Choke Off Choke On Neutral Forward

Reverse Throttle Primer Button Ignition Key Ignition Off Ignition On

Electric Starter Engage Auger Clutch Auger Collector Discharge DOWN Discharge UP

Discharge LEFT Discharge RIGHT Drive Clutch Fuel

Oil Fuel Oil Mixture

O

Weight Transfer

Lift Handle To Engage

Weight Transfer

Depress Pedal To Disengage

Transmission

Insert To Run, Pull Out To Stop.

Ignition Key

Fq)O1133M 7

Page 8

Safe Operation Practices for Snow Throwers

As Recommended By: American National Standards Institute.

ENGLISH

IMPORTANT: Safety standards require operator

presence controls to minimize the risk of injury.

Your snow thrower is equipped with such con-

trols. Do not attempt to defeat the function of the

operator presence control under any circum-

stances.

Training

1. Read the operating and service instruction

manual carefully. Be thoroughly familiar with

the controls and the proper use of the equip-

ment. Know how to stop the unit and disen-

gage the controls quickly.

2. Never allow children to operate the equip-

ment. Never alow adults to operate the

equipment without proper instruction.

3. Keep the area of operation clear of alI per-

sons, particularly smali chiIdren and pets.

4. Exercise caution to avoid slipping or falling

especially when operating in reverse.

Preparation

1. Thoroughly inspect the area where the equip-

ment is to be used and remove all doormats,

sleds, boards, wires, and other foreign ob-

jects.

2. Disengage all clutches before starting the en-

gine (motor).

3. Do not operate the equipment without wear-

ing adequate winter outer garments. Wear

footwear that will improve footing on slippery

surfaces.

4. Handle fuel with care; it is highly flammable.

a. Use an approved fuel container.

b. Never remove fueI tank cap or add fuel to

a running engine (motor) or hot engine

(motor).

c. Fill fuel tank outdoors with extreme care.

Never fill fuel tank indoors.

d. Reptace fuel cap securely and wipe up

spilled fuel.

e. Never store fuel or snow thrower with fuel

in the tank inside of a building where

fumes may reach an open flame or spark.

Check fuel supply before each use, allow-

ing space for expansion asthe heat of the

engine (motor) and/or sun can cause fuel

to expand.

5. For all units with electric starting motors use

electric starting extension cords certified

CSA/UL Use only with a receptacle that has

been installed in accordance with local in-

spection authorities.

6. Adjust the snow thrower height to dear gravel

or crushed rock surface.

7.

Never attempt to make any adjustments

while the engine (motor) is running (except

when specifically recommended by manufac-

turer).

8.

Let engine (motor) and snow thrower adjust

to outdoor temperatures before starting to

dear snow.

9.

Always wear safety glasses or eye shields

dudng operation or while performing an ad-

justment or repair to protect eyes from foreign

objects that may be thrown from the snow

thrower'.

Operation

1.

Do not operate this machine if you are taking

drugs or other medication which can cause

drowsiness or affect your ability to operate

this machine.

2. Do not use this machine if you are mentally

or physically unable to operate this machine

safely.

3. Do not put hands or feet near or under rotat-

ing parts. Keep clear of the discharge open-

ing at all times.

4. Exercise extreme caution when operating on

or crossing gravel drives, walks or roads.

Stay alert for hidden hazards or traffic.

5.

After striking a foreign object, stop the engine

(motor), remove the wire from the spark plug,

thoroughly inspect snow thrower for any

damage, and repair the damage before re-

starting and operating the snow thrower.

6.

If the unit should start to vibrate abnormally,

stop the engine (motor) and check immedi-

ately for the cause. Vibration is generally a

warning of trouble.

7.

Stop the engine (motor) whenever you leave

the operating position, before unclogging the

auger/impeller housing or discharge chute

and when making any repairs, adjustments,

or inspections.

8.

When cleaning, repairing, or inspecting, make

certain the augedimpeIler and all moving

parts have stopped and all controls are dis-

engaged. Disconnect the spark plug wire and

keep the wire away from the spark plug to

prevent accidental starting.

9.

Take all possible precautions when leaving

the snow thrower unattended. Disengage the

auger/impeller, stop engine (motor), and re-

move key.

10.

Do not run the engine (motor) indoors, except

when starting the engine (motor) and for

transporting the snow thrower in or out of the

building. Open the outside doors; exhaust

fumes are dangerous (containing CARBON

MONOXIDE, an ODORLESS and DEADLY

GAS).

11. Do not clear snow across the face of slopes.

Exercise extreme caution when changing

direction on slopes. Do not attempt to dear

steep slopes.

12. Never operate the snow thrower without

proper guards, plates or other safety protec-

tive devices in place.

13. Never operate the snow thrower near enclos-

ures, automobiles, window wells, drop-offs,

and the like without proper adjustment of the

snow discharge angle. Keep children and

pets away.

14. Do not overload the machine capacity by at-

tempting to clear snow at too fast a rate.

15. Never operate the machine at high transport

speeds on slippery surfaces. Look behind

and use care when backing up.

16. Never direct discharge at bystanders or aliow

anyone in front of the unit.

17. Disengage power to the collector/impeller

when snow thrower is transported or not in

use.

18.

Use only attachments and accessories ap-

proved by the manufacturer of the snow

thrower (such as tire chains, electric start kits,

ect.).

19.

Never operate the snow thrower without good

visibility or light. Always be sure of your foot-

ing and keep a firm hold on the handles.

Walk;never run.

20.

Do not over-reach. Keep proper footing and

balance at all times.

21.

Exercise caution if operating on steep siop-

ing surfaces.

22.

This snow thrower is for use on sidewalks,

driveways and other ground level surfaces.

23.

Do not use the snow thrower on surfaces

above ground level such as roofs of resi-

dences, garages, porches or other such

structures or buiidings.

Maintenance And Storage

1. Check shear"bolts and other bolts at frequent

intervals for proper tightness to be sure the

equipment is in safe working condition.

2. Never store the snow thrower with fuel in the

tank inside a building where ignition sources

are present such as hot water and space

heaters, clothes dryers, and the like. Allow

the engine (motor) to cool before storing in

any enclosure.

3. Always refer to operator's guide instructions

for important details if the snow thrower is to

be stored for an extended period.

4. Maintain or replace safety and instruction Ia-

bels, as necessary.

5. Run the snow thrower a few minutes after

throwing snow to prevent freeze-_p of the

auger/impelIer.

Fq)O1133M 8

Page 9

ASSEMBLY

Read and follow the assembly and adjustment

instructions for your snow thrower. All fasteners

are in the parts bag. Do not discard any parts or

material until the unit is assembled.

assembly or maintenance to the

l_lL WARNING: Before doing any

snow thrower, remove the wire

from the spark plug.

NOTE: In this instruction book, left and right

describe the location of a part from the oper-

ator's position behind the unit.

NOTE: Torque is measured in foot pounds

(metric N.m). This measurement describes

how tight a nut or bolt must be. The torque is

measured with a torque wrench.

NOTE: Illustrations begin on page 3.

Tools Required

1 Knife

1 Pliers

How To Remove The Snow Thrower

From The Carton

1. Locate all parts that are packed separately

and remove from the carton.

2. Remove and discard the packing materiai

from around the snow thrower.

3. Cut down all four corners of the carton and

lay the side panels fiat.

4. Hold onto the lower handle and pull the snow

thrower off the carton.

CAUTION: DO NOT back over cables.

5. Remove the packing material from the han-

dle assembly.

How To Assemble The Handle

1. Remove the packing material from the upper

and lower handles.

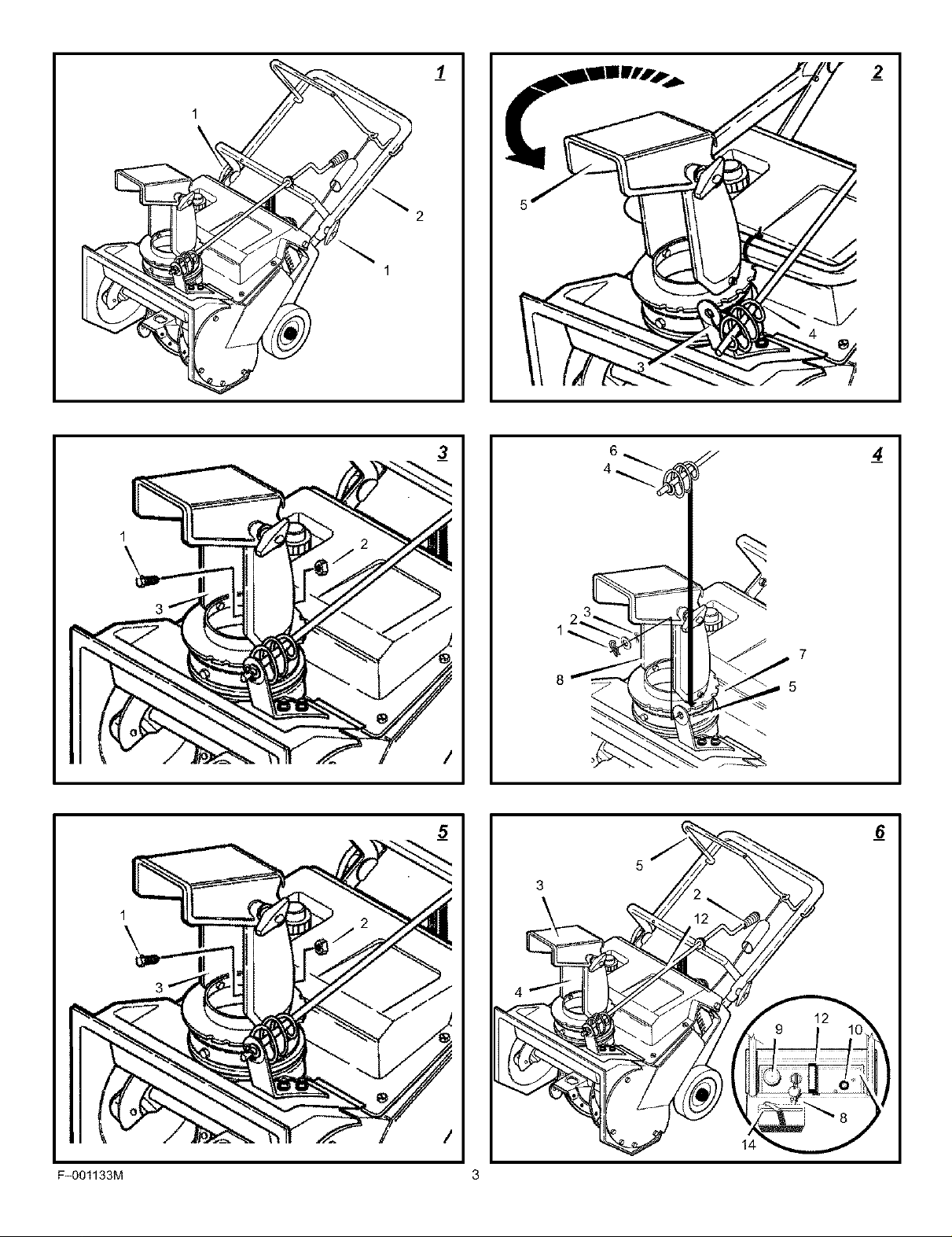

2. (Figure 1) Loosen the knobs (1) on each

side of the handle (2).

3. Raise the upper handle (2) to the operating

position.. Hold the upper handle (2) apart to

prevent scratching the lower handle.

NOTE: Make sure the cables are not

caught between the upper and lower han-

dle.

4. Tighten the knobs (f).

5. (Figure 2) Cut and discard the cable tie (3)

from the lower end of the chute control rod

(4).

6. Turn the chute deflector (5) around toward

the front of the snow thrower.

How To Assemble The Lower Chute

(Figure 3)

For shipping purposes, some models are

shipped with the rear nut and bolt removed from

the lower chute (3). If the lower chute is not at-

tached, assemble as follows.

1. Use the bolt (1) and nut (2) found in the

parts bag to attach the lower chute (3).

2. Tip the lower chute (3) backward until the

hole in the chute ring is aligned with the hole

in the lower chute (3).

3. Attach the lower chute (3) with bolt (f) and

nut (2). Make sure the nut (2) is tight.

How To Assemble

The Chute Control Rod (Figure 4)

1. Remove the cotter pin (1), flat washer (2),

and wave washer (3) from the end of the

chute control rod (4). DO NOT DISCARD.

2. Mount the end of the chute control rod (4)

through the hoIe in the control rod bracket

(5). Make sure the worm gear (6) is aligned

with the notches (7) in the discharge chute

(8).

3. Fasten the chute control rod (4) to the con-

trol rod bracket (5) with cotter pin (1), flat

washer (2), and wave washer (3).

4. Rotate the chute control rod (4) clockwise

and counterclockwise. Make sure the dis-

charge chute (8) rotates freely.

How To Prepare The Engine

_k ARNING: Follow the engine

manufacturer's instructions for the

type of fuel and oil to use. Always

use a safety fuel container. Do not smoke

when adding the fuel mixture to the engine.

When inside an enclosure, do not fill the

fuel tank. Before you add the fuel mixture,

stop the engine. Let the engine cool for

several minutes.

See the engine manufacturer's instructions for

the type of fuel and oil to use. Before you use

the unit, read the information on safety, opera-

tion, maintenance, and storage.

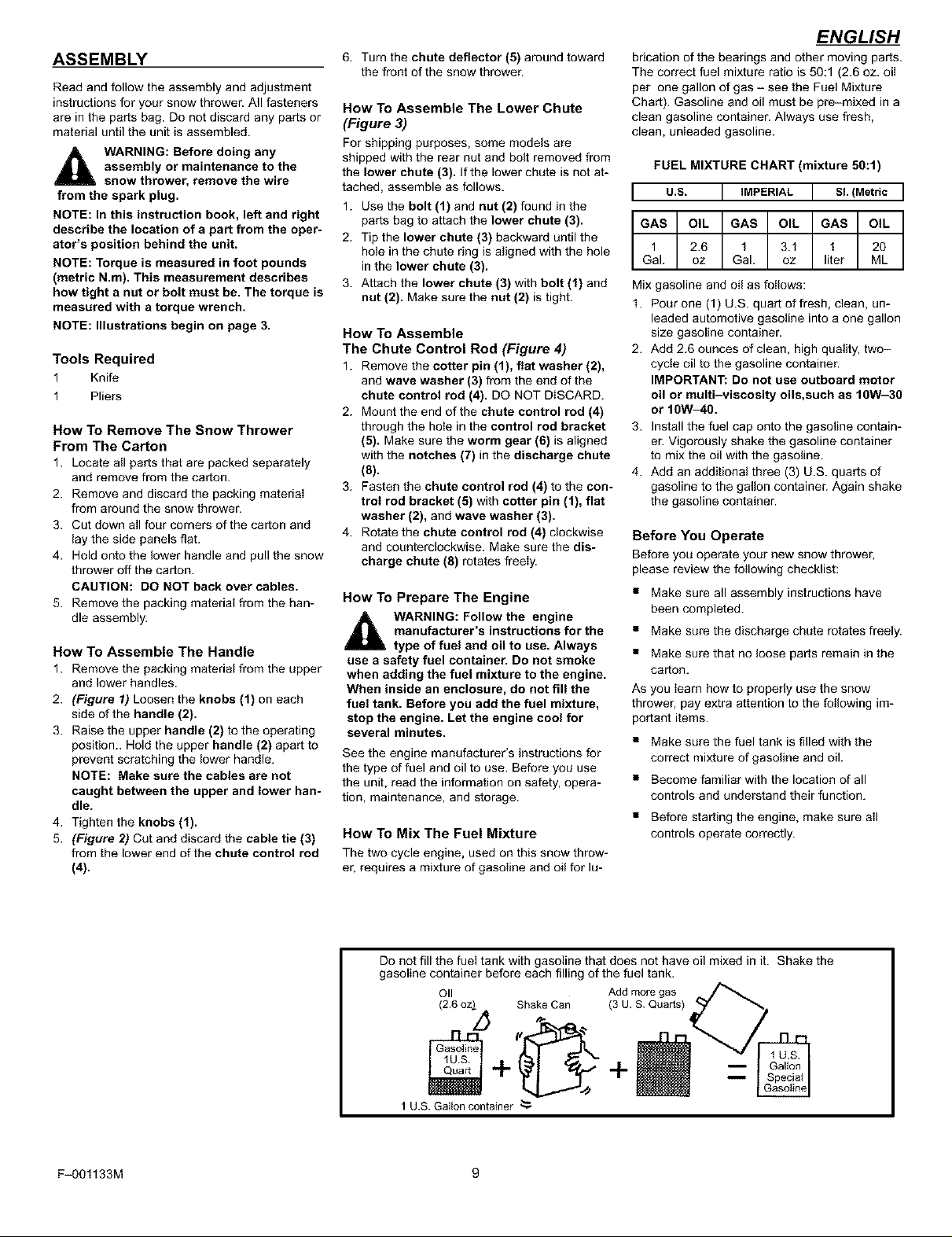

How To Mix The Fuel Mixture

The two cycle engine, used on this snow threw-

er, requires a mixture of gasoline and oil for lu-

ENGLISH

brication of the bearings and other moving parts.

The correct fuel mixture ratio is 50:1 (2.6 oz. oil

per one gallon of gas - see the Fuel Mixture

Chart). Gasoline and oil must be pre-mixed in a

clean gasoline container'. Always use fresh,

clean, unleaded gasoline.

FUEL MIXTURE CHART (mixture 50:1)

I U.S. I IMPERIAL I St.(Metric I

Mix gasoline and oil as follows:

1. Pour one (1) U.S. quart of fresh, clean, un-

leaded automotive gasoline into a one gallon

size gasoline container.

2. Add 2.6 ounces of clean, high quality, two-

cycle oil to the gasoline container.

IMPORTANT: Do not use outboard motor

oil or multi-viscosity oils,such as 10W-30

or 10W_,0.

3. Install the fuel cap onto the gasoline contain-

er. Vigorously shake the gasoline container

to mix the oil with the gasoline.

4. Add an additional three (3) U.S. quarts of

gasoline to the gallon container. Again shake

the gasoline container.

Before You Operate

Before you operate your new snow thrower,

please review the following checklist:

• Make sure all assembly instructions have

been completed.

• Make sure the discharge chute rotates freely.

• Make sure that no loose parts remain in the

carton.

As you ieam how to propedy use the snow

thrower, pay extra attention to the foilowing im-

portant items.

• Make sure the fuel tank is filled with the

correct mixture o1gasoline and oil.

• Become familiar with the location of all

controls and understand their function.

• Before starting the engine, make sure aii

controls operate correctly.

Do not fill the fuel tank with gasoline that does not have oil mixed in it. Shake the

gasoline container before each filling of the fuel tank.

Oll Add more gas

(2.6oz_. Shake Can (3 U.S. Quarts)

1 U.S. Galton container '_-

Fq)O1133M 9

Page 10

OPERATION

NOTE: Illustrations begin on page 3.

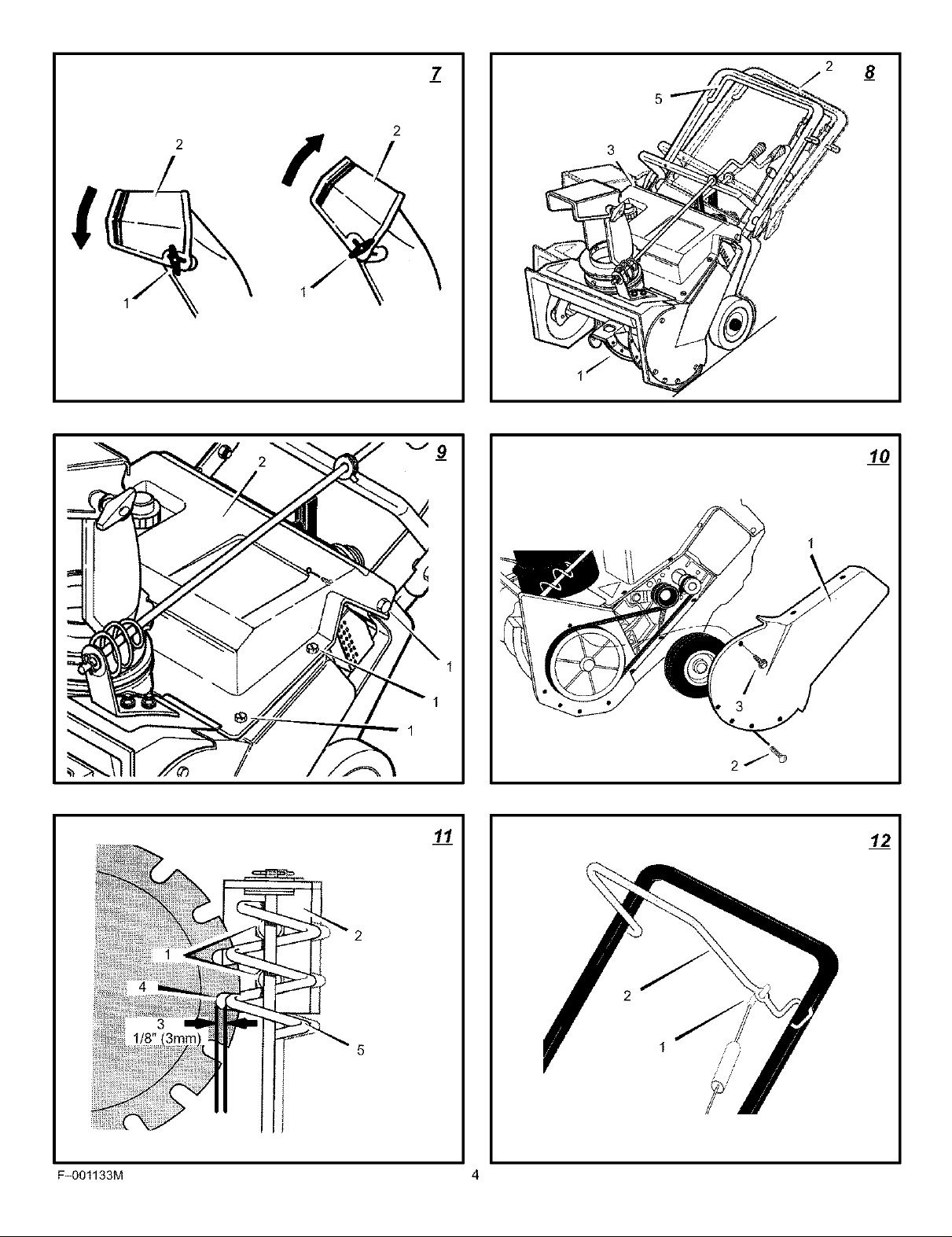

Know Your Snow Thrower (Figure 6)

Read this Instruction Book and safety rules be-

fore operation the snow thrower'. Compare the

illustration with your snow thrower to familiarize

yourself with the location of various controls and

adjustments.

Crank Assembly (2) - Changes the direction of

the discharge chute.

Chute Deflector (3) - Changes the distance the

snow is thrown.

Discharge Chute (4) - Changes the direction the

snow is thrown.

Auger Drive Lever (5) - Starts and stops the au-

ger which propels the snow thrower.

Ignition Key (8) - Must be inserted and turned to

the on position to start the engine.

Primer Button (9) - Injects fuel directly into the

carburetor for fast starts in cold weather.

Electric Start Button (10)-On electric start mod-

els, used to start the engine.

Switch Box (11) - On electric start models, used

to attach a 120 voit electric power cord.

Recoil Starter Handle (12) - Use to manually

start the engine.

Choke Control (14) - Use to start a cold engine.

Spark Plug Access Panel (15) - Remove to ac-

cess the spark plug.

How To Control

The Discharge Of The Snow

,_ WARNING: Never direct the dis-

,_ WARNING: Always stop the engine

1. (Figure 6) Turn the crank assembly (2) to

2. (Figure 7) Loosen the wing knob (1) on the

3. Move the chute deflector (2) up for more

4. Tighten the wing knob (1).

How To Throw Snow (Figure 6)

1. Engage the auger drive lever (5).

2. To stop throwing snow, release the auger

charge of snow toward bystanders.

before unclogging the discharge

chute or the auger housing and be-

fore leaving the snow thrower.

change the discharge direction of the snow.

chute deflector (2).

distance or down for less distance.

drive lever (5).

F_01133M

,_ WARNING: The operation of any

How To Stop Discharging Snow

(Figure 6)

1. To stop discharging snow, release the auger

2. To stop the engine, turn the ignition key (8)

How To Move Forward (Figure 8)

1. Hold the auger drive lever (5) against the

2. To go forward, raise the handle (2) to allow

3. To stop, release the auger drive lever (5).

NOTE: If the auger continues to rotate, see

"How To Adjust The Auger Control Cable" in

the Service and Adjustments section.

Before Starting The Engine

1. Before you service or start the engine, famii-

2. Make sure that all fasteners are tight.

3. Make sure the fuel tank is filled with the cor-

4. Become familiar with the location of all con-

5. Before starting the engine, make sure all

snow thrower can result in foreign

objects being thrown into the eyes,

which can result in severe eye damage.

Always wear safety glasses or eye shields

while operating the snow thrower. We rec-

ommend standard safety glasses or use a

wide vision safety mask over your glasses.

drive lever (5).

to the off position.

handle (2). The auger will begin rotating.

the rubber auger blades (f) to contact the

ground. Maintain a firm hold on the handle

(2) as the snow thrower starts to move for-

ward. Guide the snow thrower by moving the

handle (2) either left or right. Do not attempt

to push the snow thrower.

iarize yourself with the snow thrower. Be

sure you understand the function and loca-

tion of all controls.

rect mixture of gasoline and oil

trois and understand their function.

controls operate correctly.

Add The Fuel Mixture

_k ARNING: Follow the engine

manufacturer's instructions for the

type of fuel and oil to use. Always

use a safety fuel container. Do not smoke

when adding the fuel mixture to the engine.

When inside an enclosure, do not fill the

fuel tank. Before you add the fuel mixture,

stop the engine. Let the engine cool for

several minutes.

(Figure 8) Fill the fuel tank (3) to the full posi-

tion with a fresh, clean fuel mixture. See "How

To Mix The Fuel Mixture" in the Assembty sec-

tion.

How To Stop The Engine (Figure 6)

To stop the engine, turn the ignition key (8) to

the off position. Keep the ignition key (8) in a

safe place. The engine will not start without the

ignition key (8).

10

ENGLISH

How To Start The Engine (Figure 6)

Models equipped with an Electric Starter

NOTE: An electric starter kit can be added to

recoil start engines. Electric starter kite are

available from your nearest authorized ser-

vice center.

_1 ARNING: The starter is equipped

How To Start A Cold Engine (Figure 6)

1. FilI the fuel tank with a fresh, clean fuel mis-

2. Move the choke control to FULL position.

3. Make sure the auger drive lever (5) is in the

4. Insert the ignition key (8) and turn to the on

5. Move the choke control (14) to the full

6. (Electric Start) Connect the power cord to

7. (Electric Start) Plug the other end of the

8. Push the primer button (9). Every time you

9. (Electric Start) Push on the electric start

10. (Recoil Start) Rapidly pull the recoil starter

11. If the engine does not start in 5 or 6 tries,

12. (Electric Start) When the engine starts, re-

with a three-wire power cord and

plug and is designed to operate on

120 volt A.C. household current. The power

cord must be properly grounded at all times

to avoid the possibility of electrical shock

which can injure the operator. Carefully fol-

low all instructions in the "How To Start The

Engine" section. Make sure that your house

wiring is a three-wire grounded system. If

you are not sure, ask a licensed electrician.

If your house wire system is not a

three-wire grounded system, do not use

this electric starter under any conditions. If

your system is grounded but a three-hole

grounded receptacle is not available to start

the engine, have a three-hole grounded re-

ceptacle installed by a licensed electrician.

To connect a 120 volt A.C. power cord, al-

ways connect the power cord to the switch

box (11) on the engine first. Then, plug the

other end into the three-hole grounded re-

ceptacle. When disconnecting the power

cord, always unplug the end from the

three-hole grounded receptacle first.

ture. See "How To Mix The Fuel Mixture" in

the Assembly section.

disengaged (released) position.

position.

choke position.

the switch box (11) located on the engine.

power cord into a three-hole, grounded 120

VOLT, A.C. receptacle. (See the WARNING

in this section).

push the primer button (9), wait two sec-

onds. For the number of times required to

push the primer button (9), see the engine

manufacturer's instructions.

button (10) until the engine starts. Do not

crank for more than 10 seconds at a time.

The electric starter is thermally protected. If

the electric starter overheates, it will auto-

matically stop and can only be restarted

when it has cooied to a safe temperature. A

wait of about 5 to 10 minutes is required to

allow the electric starter to cool.

handle (12). Do not allow the recoil starter

handle (12) to snap back. Slowly return the

recoil starter handle (12).

See the "Trouble Shooting Chart" Instruc-

tions.

lease the electric start button (10) and

move the choke control (14) to 1/2 choke

position. When the engine runs smoothly,

move the choke control (14) to the off posi-

tion.

Page 11

13.(Electric Start) First disconnect the power

cord from the three-hole receptacle. Then,

disconnect the power cord from the switch

box (11).

NOTE: In temperatures below 8°F, allow

the engine to warm up for several minutes

before blowing snow.

indoors or in enclosed, poorly ven-

m_l= ARNING: Never run the engine

tilated areas. Engine exhaust con-

tains carbon monoxide, an odorless and

deadly gas. Keep hands, feet, hair and

loose clothing away from any moving parts

located on the engine or the snow thrower.

The temperature of muffler and nearby

areas may exceed 150°F. Avoid these

areas.

How To Start A Warm Engine (Figure 6)

If an engine has been running and is still warm,

leave the choke control (14) in the off position

and do not push the primer button (9). If the

engine fails to start, follow the instructions "How

To Start A Cold Engine".

NOTE: Do not use the primer button (9) to

start a warm engine.

How To Start An Engine With A Frozen Electric

Starter (Figure 6)

If the electric starter is frozen and will not turn

the engine, follow the instructions below.

1. Pull out the recoil starter handle (12) as far

as possible.

2. Quickly release the recoil starter handle

(12). Allow the recoil starter handle (12) to

snap back against the recoil starter.

If the engine still fails to start, repeat the two pre-

vious steps until the engine starts. Then, contin-

ue with the directions "How To Start A Cold

Engine".

To help prevent the possible freeze-up of the

recoil starter and of the engine controls, proceed

as follows after each snow removal job.

1. With the engine running, quickly pull the re-

coil starter handle (12) three or four times

with a continuous full arm stroke. This will

produce a loud clattering sound that is not

harmful to the engine or starter.

2. Stop the engine. Wipe all snow and moisture

from the carburetor cover', control levers and

cables. Also move the choke control (14)

and recoil starter handle (12) several times.

How To Remove Snow or Debris From

The Auger Housing (Figure 6)

_k ARNING: Do not attempt to re-

1. Release the auger drive lever (5).

2. Remove the ignition key (8).

3. Disconnect the spark plug wire.

4. Do not place your hands in the auger hous-

Snow Throwing Tips

1. This snow thrower will propel itself forward

2. Most efficient snowthrowing is accomplished

3. For complete snow removal, slightly overlap

4. Whenever possible, discharge the snow

5. The distance the snow will be discharged

6. In windy conditions, lower thechute deflector

move snow or debris that may be-

come lodged in auger housing

without taking the following precautions.

ing (4) orthe discharge chute (3). Use a

pry bar to remove any snow or debris.

when the handle is raised enough to cause

the auger blades to contact the ground. The

auger should stop when auger control bar is

released. If it does not stop, see "How To Ad-

just The Auger Control Cable" in the adjust-

ment section.

when the snow is removed immediately after

if falls.

each previous path.

down wind.

can be adjusted by moving the discharge

chute deflector. Raise the deflector for more

distance or lower the deflector for less dis-

tance.

to direct the discharged snow close to the

ground where it is less likely to blow into un-

wanted areas.

ENGLISH

7. For safety and to prevent damage to the

snow thrower, keep the area to be cleated

free of stones, toys and other foreign objects.

8. Do not use the auger propelling feature when

clearing gravel or crushed rock driveways.

Move the handle down to slightly raise the

auger.

9. The forward speed of the snow thrower is

dependent on the depth and weight of the

snow. Experience will establish the most ef-

fective method of using the snow thrower un-

der different conditions.

10.After each snow throwing job, allow the en-

gine to run for a few minutes. The snow and

accumulated ice will melt off the engine.

11. Clean the snow thrower after each use.

12. Remove ice, snow and debris from the entire

snow thrower. Flush with water to remove all

salt or other chemicals. Wipe snow thrower

dry.

Dry And Average Snow

1. Snow up to eight inches deep can be re-

moved rapidly and easily by walking at a

moderate rate. For snow or drifts of a greater

depth,slow your pace to allow the discharge

chute to dispose of the snow as rapidly as

the auger receives the snow.

2. Plan to have the snow discharged in the di-

rection the wind is blowing.

W_ Packed Snow

Move slowly into wet, packed snow. If the wet,

packed snow causes the auger to slow down or

the discharge chute begins to clog, back off and

begin a series of short back and forth jabs into

the snow. These short back and forth jabs, four

to six inches, will "belch" the snow from the

chute.

Snow Banks And Drifts

In snow of greater depth than the unit, use the

same "jabbing" technique described above. Turn

the discharge chute away from the snow bank.

More time will be requited to remove snow of

this type than level snow.

Fq)01133M 11

Page 12

MAINTENANCE CHART

CUSTOMER RESPONSIBILITIES

SERVICE RECORDS

Fill in dates as you Before First Every Every Every

complete regular Each 2 5 10 25 Each Before

service. Use Hours Hours Hours Hours Season Storage

Check And Tighten All Screws and Nuts ' N/

Check Spark Plug

Check Fuel

Drain Fuel ....... N/

Lubricate Chute Control Flange

• . . ..

ENGLISH

SERVICE DATES

MAINTENANCE

NOTE: Illustrations begin on page 3.

Use the following maintenance section to keep

your unit in good operating condition. All the

maintenance information for the engine is in the

engine manufacturer's instructions. Before you

start the engine, read this book.

,_ WARNING: Before you make an in-

General Recommendations

The warranty on this snow thrower does not cov-

er items that have been subjected to operator

abuse or negIigence. To receive full value from

the warranty, the operator must maintain the

snow thrower as instructed in this manual.

Some adjustments must be made periodically to

propedy maintain the snow thrower.

After Each Use

• Check for any loose or damaged parts.

• Tighten any Ioose fasteners.

• Check and maintain the auger.

• Check controls to make sure they are

• If any parts are worn or damaged, replace

All adjustments in the Maintenance section of

this manual should be checked at least once

each season.

How To Remove The Top Cover

(Figure 9)

1. Remove the five screws (1) from the top

2. Remove the top cover (2).

3. To install the top cover (4), reverse the

Lubrication

Before Storage (Figure 9)

1. Lubricate the clute control flange (7). Apply

spection, adjustment (except

carburettor), or repair, disconnect

the wire from the spark plug.

functioning properly.

immediately.

cover (2).

above steps.

a clinging type of grease such as Lubriplate.

Fq)O1133M

How To Adjust The Chute Crank

If the chute crank will not rotate fully to the left or"

right, adjust as folIows.

1. (Figure 11) Loosen nuts (1).

2. Move the crank adjusting bracket (2) to

allow 1/8 inch (3ram) clearance (3) between

the notch in the flange (4) and the outer di-

ameter of the worm gear (5).

3. Tighten the nuts (1).

How To Adjust The Auger Control Cable

The auger control cable is adjusted at the facto-

ry. During normal use, the auger control cabie

can become stretched and the auger drive lever

wiII not properly engage or disengage the auger.

1. (Figure 12) Remove the "Z" hook (f) from

the auger drive lever (2).

2. (Figure 13) Slide the cable boot (3) offthe

cable adjustment bracket (4).

3. Push the bottom of the auger control cable

(5) through the cable adjustment bracket

(4) until the "Z" hook (6) can be removed.

4. Remove the "Z" hook (6) from the cable

adjustment bracket (4). Move the "Z" hook

(6) down to the next adjustment hole.

5. Pull the auger control cable (5) up through

the cable adjustment bracket (4).

6. Put the cable boot (3) over the cable ad-

justment bracket (4).

7. (Figure 12) Install the "Z" hook (1) to the

auger drive lever (2).

8. To check the adjustment, start the snow

thrower. Make sure the auger does not rotate

when the auger drive lever is released.

How To Remove The Belt Cover

(Figure 10)

1. The belt cover (1) is fastened with ten

screws (2). Remove all ten screws.

2. There are five screws on the front of the belt

cover (1). Three screws on the bottom of the

belt cover (1). Two screws on the top of the

belt cover (1).

3. Remove the belt cover (1).

4. To install the belt cover (1), reverse the

above steps.

NOTE: One screw (3) is shorter than the oth-

er screws• Make sure to install screw (3) in

the correct location•

12

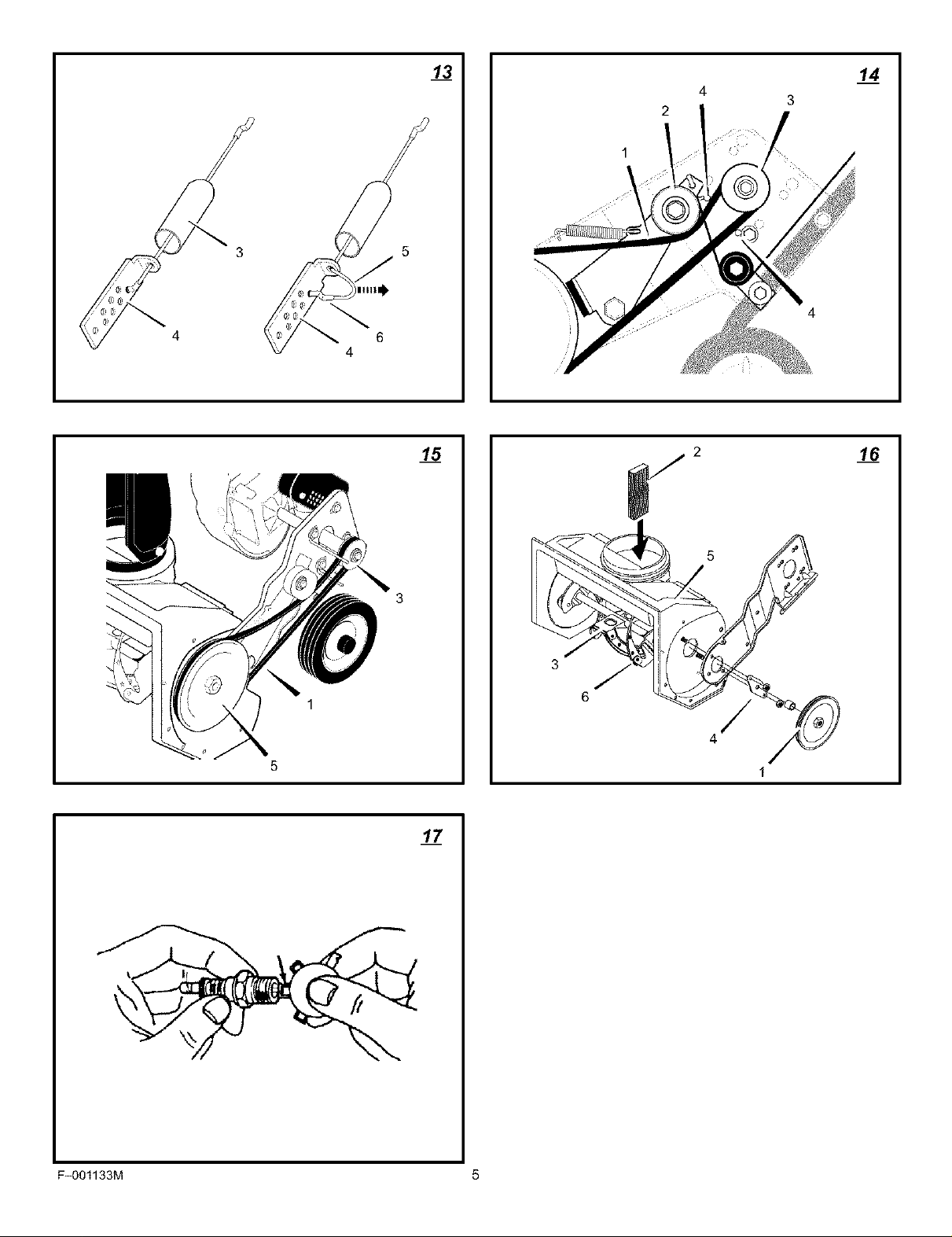

How To Replace The Drive Belt

The drive belt is of special construction and

must be replaced with odginaI factory replace-

ment belt available from your nearest authorized

service center.

1.

Remove the belt cover. See "How To Re-

move The Belt Cover".

2.

(Figure 14) Remove the drive belt (1) from

the idler pulley (2).

3.

Remove the drive belt (1) from the engine

pulley (3). Be careful, not to bend the belt

guides (4).

4. (Figure 15) Remove the drive belt (1) from

the auger pulley (5).

5. Remove the old drive belt (1).

6. To install the new drive belt (f), reverse the

above steps.

7. Make sure the drive belt (1) is seated prop-

erly on the pulleys.

NOTE: When the auger control lever is

engaged, the belt guides (4) must be 1/16"

from the drive belt (1).

8. Install belt cover. See "How To Remove The

Belt Cover".

How To Replace The Auger (Figure 16)

1. Remove the belt cover. See "How To Re-

move The Belt Cover".

2. Remove the drive belt. See "How To Replace

The Drive Belt".

3. Remove the auger pulley (1) from the auger

shaft (threads are left hand; turn clockwise to

remove).

4. To keep the auger (6) from rotating, set a

2"x4" piece of wood (2) on the center

paddle (3) to secure auger (6).

5. Remove the fasteners from the bearing as-

sembly (4). Remove the bearing assembly

(4) from the auger housing (5).

6. Slide the auger (6) out of the bearing assem-

bly on the right side of the snow thrower.

7. Tip the auger (6) enough to allow the auger

(6) to slide out of the auger housing (5).

8. To install auger (6), reverse the above steps.

Page 13

How To Replace The Spark Plug

NOTE: This spark ignition system meets all

requirements of the Canadian Interference-

Causing Equipment Regulations.

NOTE: This engine complies with all current

Australian and New Zealand limitations elec-

tromagnetic interference.

The spark plug is housed in the engine compart-

ment under the top cover and cannot be seen

under normal conditions.

1. Remove the top cover. See "How To Remove

The Top Cover".

2. The spark plug and wire are now visible.

3. Remove the spark piug wire.

4. Clean the area around the spark plug base to

prevent dirt from entering the engine when the

spark plug is removed.

5. Remove the spark plug.

6. Check the spark plug. If the spark plug is

cracked, fouIed or dirty, it must be replaced.

7. (Figure 17) Set the gap between the elec-

trodes of the new spark plug at .030 inch. Next,

install the spark plug in the cylinder head and

firmIy tighten. Recommended torque is 18 to

20 foot pounds.

How To Prepare The Snow Thrower For

Storage

_lk ARNING: Do not remove gasoline

while inside a building, near a fire,

or while you smoke. Gasoline

fumes can cause an explosion or a fire.

1. Drain the fuel tank.

2. Let the engine run until it is out of gasoIine.

3. Remove the spark plug from the cylinder.

Pour one ounce of oil into the cylinder. Slow-

ly pull the recoil-stad grip so that the oil will

protect the cylinder. Install a new spark plug

in the cylinder.

4. Thoroughly ciean the snow thrower.

5. Lubricate all lubrication points. See the Main-

tenance section.

6. Be sure that all nuts, bolts and screws are

secureiy fastened. Inspect all visible moving

parts for damage, breakage and wear. Re-

place if necessary.

7. Cover the bare metal parts ofthe blower

housing and auger with spray rust preventa-

tive lubricant.

8. Put the unit in a building that has good ven-

tilation.

9. If the machine must be stored outdoors,

block up the snow thrower to be sure the en-

tire machine is off the ground.

10.Cover the snow thrower with a suitable pro-

tective cover that does not retain moisture.

Do not use plastic.

How To Order Replacement Parts

The replacement parts are shown either on the

back pages of this Instruction Book or in a

separate Parts List Book.

Use only manufacturer's authorized or approved

replacement pads. The letter placed on the end

of the part number denotes the type of finish for

ENGLISH

the part, C for chrome, Z for zinc, a PAfor

purchased assembly, it is important that you

include this when ordering a part. Do not use

attachments or accessories not specifically

recommended for this unit. In order to obtain

proper replacement parts you must supply the

model number (see namepIate).

Replacement pads, except for the engine,

transmission, transaxle or differential, are

available from the store where the product was

purchased, a service shop recommended by the

store or from a "Murray, Inc. Central Parts

Distributor" listed on the back page of this

Instruction Book.

If you are unable to obtain parts or service in the

manner outlined above, then contact:

MURRAY, INC.

Outdoor Power Equipment

Customer Service Department

RO. Box 268

Brentwood, Tennessee 37027

1-800-251-8007 Collect telephone calls will not

be accepted.

Replacement parts for the engine, transaxle, or

transmission, are available from the

manufacturer's authorized service center found

in the yellow pages of the telephone directory.

Also, see the individual engine or transmission

warranties to order replacement pads.

When ordering the following information is

required:

(1) The Model Number

(2) Serial Number

(3) Part Number

(4) Quantity

Fq)O1133M 13

Page 14

TROUBLE SHOOTING CHART

ENGLISH

TROUBLE

Difficult starting

Engine runs erratic Blocked fuel line, empty gas tank, or stale Clean fuel line; check fuel supply; add fresh

Engine stalls Unit running on CHOKE. Set choke lever to RUN position.

Engine runs erratic; Water or dirt in fuel system. Use carburetor bowl drain to flush and refill with

Loss of power fresh fuel.

Excessive vibration Loose parts: damaged impeller Stop engine immediately and disconnect spark

Unit fails to propel itself Replace drive belt.

Unit fails to discharge snow Adjust auger drive belt; replace if damaged.

CAUSE

Defective spark plug.

Water or dirt in fuel system.

gasoline gasoline

Drive belt loose or damaged.

Auger drive belt loose or damaged.

Auger control cable not adjusted correctly.

Discharge chute clogged.

Foreign object lodged in auger Stop engine immediately and disconnect spark

CORRECTION

Replace spark plug.

Use carburetor bowl drain to flush and refill with

fresh fuel.

plug wire. Tighten all bolts and make all

necessary repairs. If vibration continues, have

the unit serviced by a competent repairman.

Adjust auger control cable.

Stop engine immediately and disconnect spark

plug wire. Clean discharge chute and inside of

auger housing.

plug wire. Remove object from auger.

Fq)01133M 14

Page 15

PartsList-Model 620301x4C

Listedepi_ces-ModUle620301x4C

Listadepartes-Modelo620301x4C

F_O1133M 33

Page 16

MODEL 620301x4C REPAIR PARTS

ENGINE ASSEMBLY

10

12

11

Fq)O1133M

42

Key No.

10

11

12

14

28

28

33

4O

41

42

48

46

47

7O

71

72

73

78

14

33

Description

(SEE ENGINE MANUAL)

SCREW, 5/16-18 X.75

WASHER

WASHER, FLAT

GUIDE, BELT

SCREW

SPRING, IDLER BRAKE

ASSY, iDLER ARM

BOLT

NUT, 5/16-18

PULLEY, IDLER

BOLT, CARRIAGE

NUT

PULLEY, ENGINE

WASHER

SCREW, 5/16-24X.75

WASHER

BELT

OPERATOR'S MANUAL

14

41

11

12

25

28

40

7O 71

72

73

47

75

45

342519E

Part No.

ENGINE

180077

120638

71071

313440

710312

165x146

1501013

333594

71391

48924

45892

590

338849

25840

181595

120638

760928

Fq)O1133M

34

Page 17

MODEL 620301x4C REPAIR PARTS

FRAME COMPONENTS ASSEMBLY

11

92

I

112

10

14

113 114

9O

92

91

Fq)01133M

Key No.

8o

81

9o

01

02

lOO

lol

lO2

11o

111

112

113

114

Description

FRAME SIDE SUPPORT RH

FRAME SIDE SUPPORT LH

ROD, SUPPORT

WASHER, HVSPTLK

NUT, 3/8-16 REGHEX

BRACKET, GAS TANK

SCREW, 1/4-20X.75

NUT, 1/4-20 REGHEXCTRLK

TANK, FUEL

SCREW, 1/4-14X.88 WAHHTAP

CAP, GAS-RED

TUBING 11.50 IN.

CLAMP, FUEL LINE

35

342516

Part No.

760272-853

760271-853

760169

71063

71044

578093-583

180020

782585

55381

313681

1257

327290

48672

Page 18

MODEL 620301x4C REPAIR PARTS

TOP COVER ASSEMBLY

172

152

151

157

170

®

®

141 143

145

127

Fq)O1133M 36

153-

313937

Page 19

MODEL 620301x4C

REPAIR PARTS

TOP COVER ASSEMBLY

Key No.

12o

121

122

124

126

127

128

13o

131

14o

141

142

143

145

146

Description Part No.

COVER, BOTTOM 302265

SCREW, 1/4-20Xl .25 313674

WASHER, FLAT .281X.63X.065 71067

NUT, 1/4-20 REGHEXCTRLK 782585

COVER, CARB 326212

SCREW, 1/4-14X.75 313685

NUT, 1/4-10 SPEED J TYPE 578109

GROMMET & WASHER, ROPE GUIDE 57587

KNOB, STAND TEE 333643

SWITCH, IGNITION 56992

WSHER, REGINTLK 313683

NUT, 5/8-32 ACC 300193

2 KEYS & RING 49643

PRIMER, ENGINE 54601

HOSE, PRIMER 1259

147

18o

181

182

183

184

185

187

188

189

17o

171

172

173

174

175

NUT, 1/4-20 REGHEXKEPS 271172

COVER, BELT 57036

SCREW, 10-24X.50 WAHHMA 12342

NUT, #10-24 REGHEXCTRLK 312300

SCREW, 1/4-20X.50 313686

WASHER, FLAT .281X.63X.065 71067

NUT, 1/#-20 TINN 578107

SCREW, 1/4-14X.75 SLWATAP 313685

WASHER, FLAT .281X.63X.065 71067

NUT, 1/4-20 SPEED J TYPE 578109

COVER, TOP 331099

SCREW, 1/4-14X.75 SLWATAP 313685

WASHER, FLAT .281X.63X.065 71067

NUT, 1/4-10 SPEED J TYPE 578109

SEAL, STRIP AUG HSING FOAM 55379

SEAL, STRIP CHUTE & GAS SEAL 55380

Fq)O1133M 37

Page 20

MODEL 620301x4C REPAIR PARTS

AUGERHOUSING

511

512

510

488

520-2

531

534

541

520-8

520

342517

F_O1133M 38

Page 21

MODEL 620301x4C

REPAIR PARTS

AUGERHOUSING

Key No.

48o

481

482

483

486

487

488

489

490

491

492

493

51o

Description

HOUSING, ASSY

SCREW, 1/4-20X.75

WASHER, FLAT .281X.63X.065

NUT, 1/4-20 REGHEXCTRLK

SCREW, 1/4-20X.63

BRACKET, STOP

WASHER, FLAT .333X.87X.119

NUT, 1/4-20 HEX NYLOCK

BLADE, SCRAPER

RIVET, OVSET .250DIAX.61LG

SCREW, 1/4-20X.75

NUT, CNTRLK 1/4-20

BEARING, FLANGE

Part No.

330312

302628

71067

73826

11871

331126

331211

780029

334031

577707

302628

302635

577023

511

512

513

52o

520-2

520-6

520-8

520-10

530

531

532

533

534

541

SCREW, 1/4-20X1.00

WASHER, FLAT .281X.63X.065

NUT, CNTRLK 1/4-20

AUGER, ASSY

BLADE, AUGER

RIVET

BLADE, CENTER

AUGER & BLADE SUPPORT

BEARING & PLATE ASSY

PLATE, RETAINER

SCREW, 1/4-20X.63

WASHER, FLAT .281X.63X.065

NUT, 1/4-20 REGHEXCTRLK

PULLEY V3L 6.00 O.D.

710263

71067

302635

302783

302565

49838

335992

302552

583459

334287

579052

71067

73826

338965

Fq)O1133M 39

Page 22

MODEL 620301x4C

591

\

\

\

X

\

X

591

592

REPAIR PARTS

DISCHARGECHUTE

/603

605

/

/

/

604

.......... 590

/606

/

Fq)01133M

Key No.

580

581

582

590

591

592

6o0

6Ol

6o2

6o3

6o4

6o5

6o6

6o7

6o8

JJ HOUSING

Description

RING, CHUTE

SCREW, #10X.50 HHTAPPST

GUIDE, CHUTE

CHUTE, LOWER

SCREW 1/4-20X.50

NUT, CNTRLK 1/4-2

CHUTE, UPPER

WIRE, HINGE

BOLT, 5/16-18X1.25 CARR.

WASHER, FLAT .349X.69X.066

KNOB, T

NUT, 5/16-18 REGHEX

SCREW, 5/16-18X.75

WASHER, FLAT .349X.69X.066

NUT, 5/16-18 REGHEXCTRLK

4O

......REF. ITEM

Part No.

314239

711752

577021

334234

313686

302635

325847

308931

302843

71071

57171

71037

578088

71071

71391

\

\

\

592

313939

Page 23

MODEL 620301x4C REPAIR PARTS

WHEELS

650

651

660

661

334309

Fq)O1133M

Key No.

65o

651

66o

661

662

Description

AXLE SHAFT

WASHER, FLAT .391X1.OOX1.25

TIRE & RIM

WASHER, FLAT .391X1.OOX.125

RING, RET E

41

Part No.

313678

583409

760713

583409

577598

Page 24

MODEL 620301x4C REPAIR PARTS

HANDLE ASSEMBLY

764

763

752

753

753

762 753

750

752

752

751

759

755

5HP OPTION

3HP OPTION

Fq)O1133M 42

342532

Page 25

MODEL 620301x4C REPAIR PARTS

HANDLE ASSEMBLY

Key No.

740

741

742

743

744

78o

781

782

783

785

786

787

Description

CABLE, UPPER

BRACKET, CABLE ADJ

CABLE, LOWER CONTROL

BOOT, CLUTCH SPRING

SPRING, EXTENSION

HANDLE, LOWER

SCREW, 1/4-20Xl .25

WASHER, FLAT

NUT, 1/4_20

BRACKET, CABLE

BOLT

PULLEY

Part No.

760774

313441

760773

308146

165x146

313487-853

313674

71067

782585

761486-853

712234

39298

789

760

761

762

763

764

765

NUT, 1/4_20

UPPER HANDLE

BAIL, CONTROL

BOLT

WASHER, FORM

KNOB, T 3.00 WD

NUT, 5/16-18

782585

313489-853

313308-853

337584

311936

57171

71037

Fq)01133M 43

Page 26

MODEL 620301x4C

REPAIR PARTS

CHUTE ROD ASSEMBLY

as?

874_ ...... _<_

853

851 i

\

860

"857

855

870

REF. ITEM

LOWER HANDLE

/............ 863

F_O1133M

Key No.

85o

851

852

853

855

856

857

86o

861

863

864

87o

871

872

873

874

864

313942

Description Part No.

ROD, ASSY UPPER CHUTE CONTROL 314996

WASHER, FLAT .406X.81X.066 71072

PIN, COTTER .094 DIAX1.09LG 71082

WASHER, CURVED SPRING 313431

WASHER, FLAT .406X.81X.066 71072

KNOB, SLEEVE 57082

NUT, PUSH 331532

BOLT, EYE 3/8-16X2.00 313712

GROMMET, EYE BOLT 148

WASHER, MDSPTLK 71062

NUT, 3/8-16 HEXJAM 71045

BRACKET, CHUTE ROTATE 333946-853

BOLT, 5/16-18X.75 CARR. 340720

WASHER, FLAT .349X.69X.066 71071

WASHER, HVSPTLK .328X.60X.09 71060

NUT, 5/16-18 REGHEX 71037

44

Page 27

Fq)O1133M 45

Page 28

Fq)O1133M 46

Page 29

F_O1133M 47

Page 30

MURRAY,INC.CENTRALPARTSDISTRIBUTORS

DISTRIBUTEURSREGIONAUXDE PIECESMURRAY,INC.

DISTRIBUIDORESCENTRALESDEPIEZASDE MURRAY,INC.

BEBCO, INC.

22212nd.Ave.South

Birmingham,AL 35233

(205)251-4600 1-800-828-8094

Alabama,Florida,Georgia,PuertoRico

BILLIOU'S, INC.

1343SouthMainSt.

Porterville,CA. 93257

(559)784-4102 1-877-245-5468

FAX 1-800-226-7337

Arizona,California, Hawaii,Nevada

BROWN &WISER, INC.

9991S.W.AveryStreet

P.O.Box1109

Tualatin,OR. 97062

(503)692-0330 1-800-882-4782

Alaska, Idaho (countiesAda,Adams,

Benewah,Boise,Bonnet,Boundry,Canyon,

Clearwater,Elmore,Gem,Idaho,Kooten,

Latah,Lewis,NezPerce,Owyee,Payette,

Ravalli,Shoshone,Valley,Washington),

Montana(countiesFlathead,Lake,Uncoln,

Mineral,Missoulo,Ravalli,Sanders),Oregon,

Washington

CPT CANADAPOWER

TECHNOLOGY LIMITED

161WatlineAvenue

Mississauga,Ontario

L4Z-1P2

(905)890-6900

101-10411-178Street

Edmon_n,Alberta

T5S1R5

(780)453-5791 1-800-861-9559

234MigneronStreet

VilleSt-Laurent,Quebec

H4T1Y7

(514)731-3559 1-800-861-9559

Canada

1-800-861-9559

CHILTONAIR COOLED ENGINE

3194th.Ave.South

P.O.Box150806

Nashville,TN. 37215

(615)254-1637 1-800-621-6934

www.chiltoncompanies.com

Arkansas (countiesClay,Craighead,

Crittendan,Cross,Greene,Jackson,

Lawrence,Lee,Mississippi,Monroe,Phillips,

Poinsett,Randolph,St.Francis,Woodruft),

Mississippi(countiesDesota,Panola,

Quitman,Tate,Tunica),Missouri(counties

Dunkin,NewMadrid,Pemiscot),Tennessee,

Virginia (countiesBland,Buchanan,

Dickenson,Lee,Russell,Scott,Smyth,

Tazewell,Washington,Wise)

ENGINES SOUTHWEST

1255NorthHearne

Shreveport,LA. 71107

POBox67

Shreveport,LA. 71161

(318)222-3871 1-800-388-6995

www.enginessw.com

Arkansas (exceptthesecounties:Clay,

Craighead,Crittendan,Cross,Greene,

Hempstead,Howard,Jackson,Lafayette,

Lawrence,Lee,UttleRiver,Miller,Mississippi,

Monroe,Nevada,Phillips,Pike,Poinsett,

Randolph,Sevier,St. Francis,Woodruft)

Louisiana, Mississippi(exceptthese

counties:Desota,Panola,QuitmanTate,

Tunic&)

FRANK EDWARDS CO.

3626ParkwayBlvd.

WestValley,UT 84120

(801)736-8060 1-800-318-0201FAX

1-800-570-0491

Colorado,Idaho (countiesBannockBearlake,

Bingham,Blaine,Booneville,Butte,Camas,

Caribou,Cassia,Custer,Franklin,Fremont,

Gooding,Jefferson,Jerome,Lemhi,Uncoln,

Madison,Minidoka,Oneida,Power,Teton,

TwinFalls)Montana(allcountiesexcept

Flathead,Lake,Lincoln,Mineral,Missoulo,

Ravalli,andSanders),Utah,Wyoming

GARDNER,INC.

1150ChesapeakeAve.

Columbus,OH. 43212

(614)488-7951 1-800-848-8946

Indiana,Kentucky,Michigan(exceptupper

Peninsula),Ohio, WesternPennsylvania

withzipcodesuptoandincluding16999,

WestVirginia

GULF COASTENGINE,INC.

4202RussellDr.

P.O.Box9724

CorpusChristi,TX. 78408

(316)888-6999 1-800-825-6999

Arkansas(countiesHempstead,Howard,

Lafayette,LittleRiver,Miller,Nevada,Pike,

Sevier)NewMexico,Oklahoma,Texas,

Mexico

OSCARWILSON ENGINE& PARTS

826 LoneStarDr.

O'Fallon,MO. 63366

(314)978-1313 1-800-873-6722

Illinois (S.of Hwy.80),Iowa,Kansas,

Missouri(allcountiesexceptDunkin,

NewMadrid,Pemiscet)Nebraska

R.B.I.CORPORATION

P.O.Box9318

Richmond,VA. 23227

(804)550-2210 1-800-888-7149

FAX1-800-947-1335

Connecticut, Delaware,Districtof

Columbia,Maine,Maryland,Massachusetts,

NewHampshire,NewJersey,New York,N.

&S. Carolina,Pennsylvaniazips17000&up,

RhodeIsland,Vermont, Virginia(allcounties

exceptBland,Buchanan,Dickenson,Lee,

Russell,Scott,Smyth,Tazewell,Washington,

Wise)

WISCONSIN MAGNETO

4727N.TeutoniaAve.

P.O.Box9218

Milwaukee,Wt. 53209

(414)445-2800 1-800-733-7388

Illinois (N.ofHwy.80),Michigan(upper

Peninsula),Wisconsin

800McKinleySt.

Anoka,MN. 55303

(612)323-7477 1-800-248-4016

Minnesota,North&SouthDakota

F-OO1133M 48

Loading...

Loading...