Page 1

1695539 Dual Stage Snowthrower, 8.0 Torque Power, 24 Inch

1742237

Revision 00

Rev. Date 7/2008

TP 199-4955-00-LW-R

Page 2

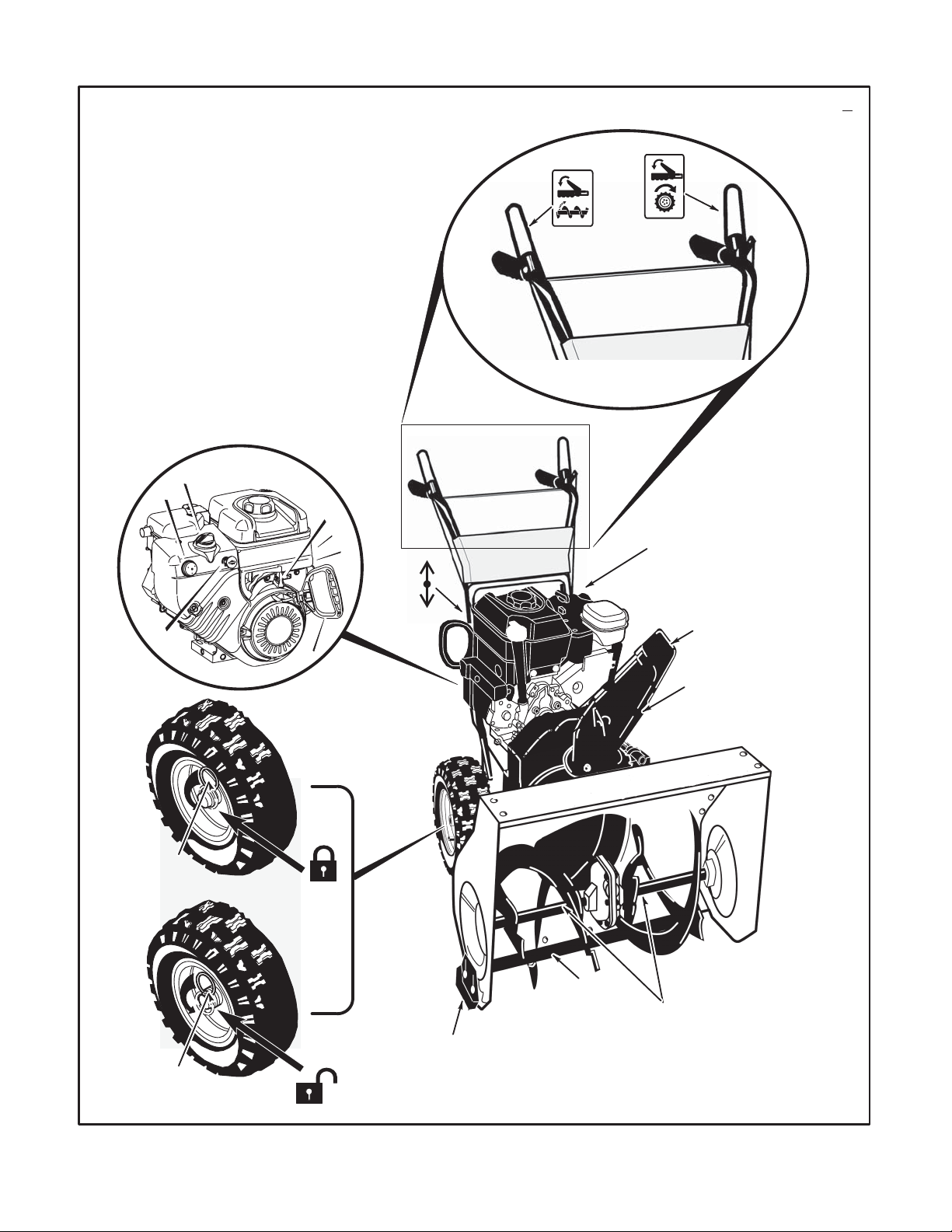

1

1

5

14

9

13

10

11

2

6

8

12

21

15

3

4

19

1742237

7

21

2

Page 3

CONTENTS

HAZARD SYMBOLS AND THEIR MEANINGS 4. . . . . . . . . . . .

OPERATING SYMBOLS AND THEIR MEANINGS 4. . . . . . . . .

ASSEMBLY 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

OPERATION 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MAINTENANCE CHART 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MAINTENANCE 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TROUBLE SHOOTING CHART 15. . . . . . . . . . . . . . . . . . . . . . . . .

LIMITED WARRANTY 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

en

1742237

3

Page 4

en

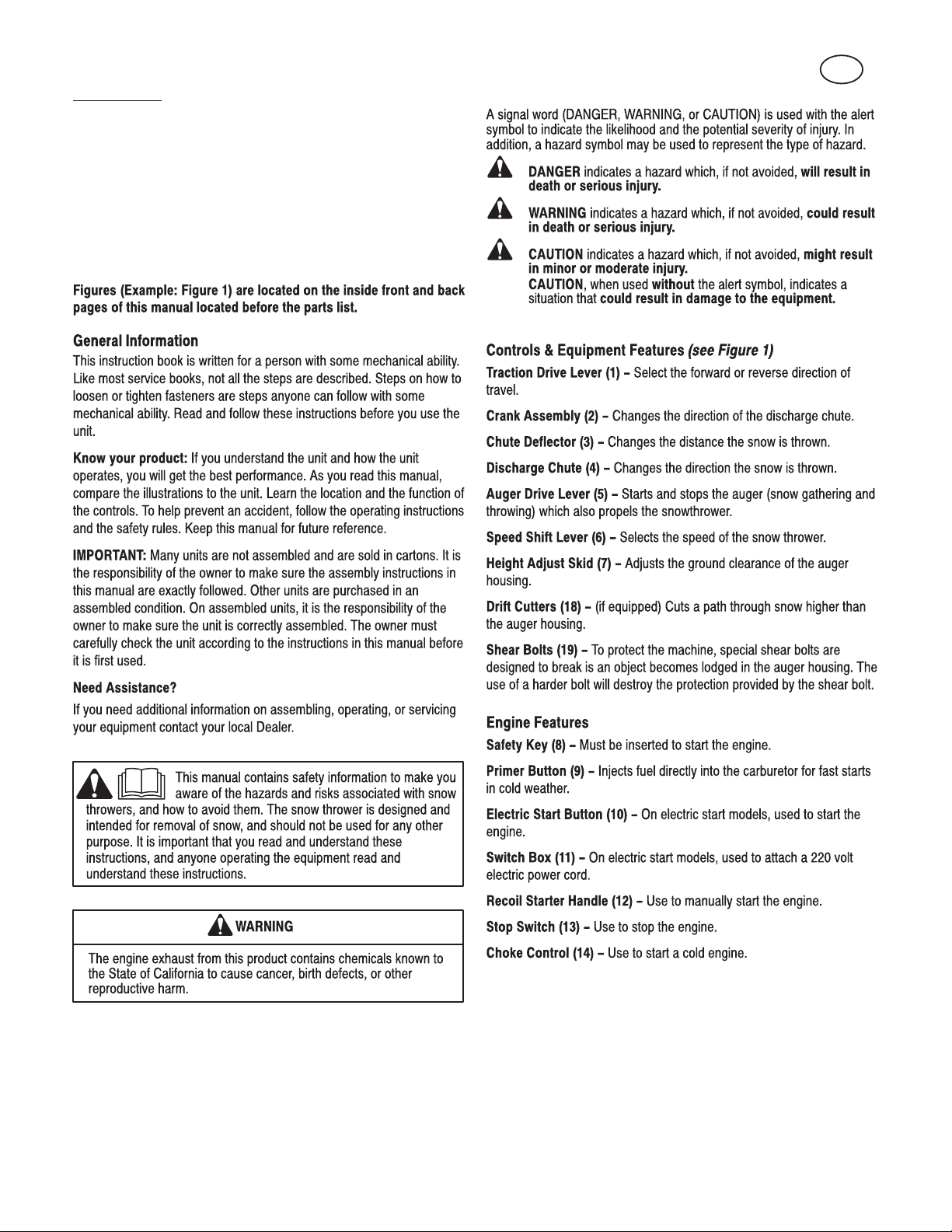

Safety Alert − Identifies safety information about

hazards that can result in personal injury.

Operator’s Manual − Read and understand

before performing any activity or running

equipment.

Rotating auger

Fire

Rotating impeller

Explosion

Toxic fumes

Shock

Rotating gears

Hot Surface

Thrown objects

Keep a safe distance

from the equipment.

Oil

Fuel

On Off

Primer bulb

Throttle

Choke off

Choke on

Stop

Slow

Fast

Engage

Forward

Neutral

Reverse

Ignition On

Ignition Off

Ignition Key

Push to engage

electric start

Electric

Start

Engine

Start

Engine Run

Never reach into

rotating parts.

Shut off engine and

remove spark plug

connector before

performing maintenance

or repair work.

Traction

Auger Collector

Auger Clutch

Drive Clutch

Engage

Disengage

Discharge Chute

LEFT UP

RIGHT

Chute Deflector

Engine Off

DOWN

1742237

4

Page 5

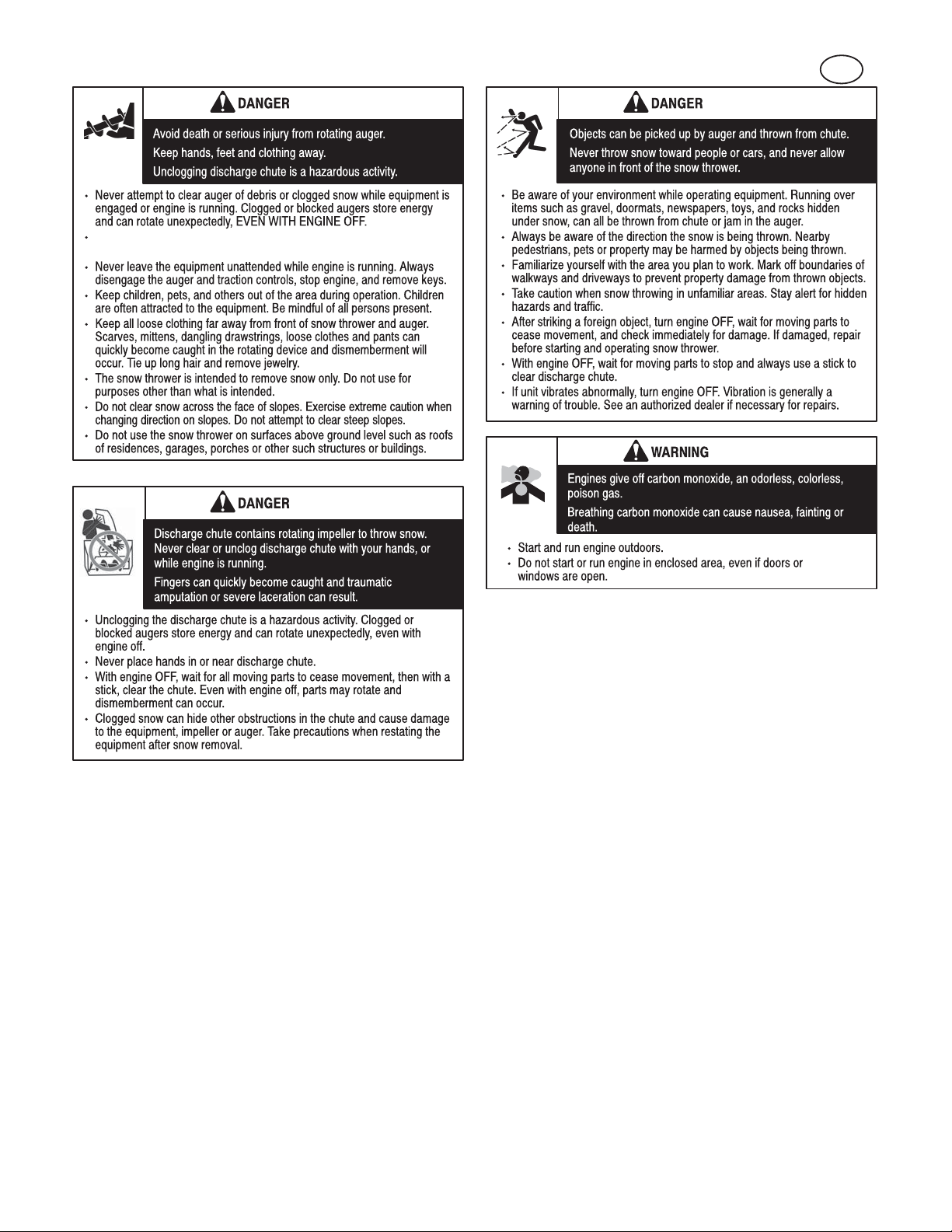

Stop engine and remove keys when performing maintenance on

equipment.

en

1742237

5

Page 6

en

1742237

6

Page 7

RULES FOR SAFE OPERATION

WARNING: This machine is capable of amputating hands and feet and throwing objects. Read these safety

rules and follow them closely. Failure to obey these rules could result in loss of control of unit, severe

personal injury or death to you, or bystanders, or damage to property or equipment. The triangle in text

signifies important cautions or warnings which must be followed.

Safe Operation Practices for Snowthrowers

en

IMPORTANT: Safety standards require operator presence controls

to minimize the risk of injury. Your snowthrower is equipped with

such controls. Do not attempt to defeat the function of the operator

presence control under any circumstances.

Training

1. Read, understand, and follow all instructions on the machine and in the

manuals before operating this unit. Be thoroughly familiar with the

controls and the proper use of the equipment. Know how to stop the unit

and disengage the controls quickly.

2. Never allow children to operate the equipment. Never allow adults to

operate the equipment without proper instruction.

3. Keep the area of operation clear of all persons, particularly small

children and pets.

4. Exercise caution to avoid slipping or falling especially when operating in

reverse.

Preparation

1. Thoroughly inspect the area where the equipment is to be used and

remove all doormats, sleds, boards, wires, and other foreign objects.

2. Disengage all clutches and shift into neutral before starting the engine

(motor).

3. Do not operate the equipment without wearing adequate winter outer

garments. Wear footwear that will improve footing on slippery surfaces.

Avoid loose fitting clothing that can get caught in moving parts.

4. Handle fuel with care; it is highly flammable.

a. Use an approved fuel container.

b. Never add fuel to a running engine or hot engine.

c. Fill fuel tank outdoors with extreme care. Never fill fuel tank

indoors. Replace fuel cap securely and wipe up spilled fuel.

d. Never fill containers inside a vehicle or on a truck or trailer bed with

a plastic liner. Always place containers on the ground, away from

your vehicle, before filling.

e. When practical, remove gas−powered equipment from the truck or

trailer and refuel it on the ground. If this is not possible, then refuel

such on a trailer with a portable container, rather than from a

gasoline dispenser nozzle.

f. Keep nozzle in contact with the rim of the fuel tank or container

opening at all times, until refueling is complete. Do not use a nozzle

lock−open device.

g. Replace gasoline cap securely and wipe up spilled fuel.

h. If fuel is spilled on clothing, change clothing immediately.

5. Use extension cords and receptacles as specified by the manufacturer

for all units with electric drive motors or electric starting motors.

6. Adjust the collector housing height to clear gravel or crushed rock

surfaces.

7. Never attempt to make any adjustments while the engine (motor) is

running (except when specifically recommended by manufacturer).

8. Let engine (motor) and snowthrower adjust to outdoor temperatures

before starting to clear snow.

9. Always wear safety glasses or eye shields during operation or while

performing an adjustment or repair to protect eyes from foreign objects

that may be thrown from the machine.

10.Never operate the snowthrower without proper guards, plates or other

safety protective devices in place.

Operation

1. Do not put hands or feet near or under rotating parts. Keep clear of the

discharge opening at all times.

2. Exercise extreme caution when operating on or crossing gravel drives,

walks or roads. Stay alert for hidden hazards or traffic.

3. After striking a foreign object, stop the engine (motor), disconnect the cord

on electric motors, thoroughly inspect snowthrower for any damage, and

repair the damage before restarting and operating the snowthrower.

4. If the unit should start to vibrate abnormally, stop the engine (motor) and

check immediately for the cause. Vibration is generally a warning of

trouble.

5. Stop the engine (motor) whenever you leave the operating position,

before unclogging the collector/impeller housing or discharge chute and

when making any repairs, adjustments, or inspections.

6. When cleaning, repairing, or inspecting, make certain the

collector/impeller and all moving parts have stopped. Disconnect the

spark plug wire and keep the wire away from the spark plug to prevent

accidental starting.

7. Do not run the engine indoors, except when starting the engine and for

transporting the snowthrower in or out of the building. Open the outside

doors; exhaust fumes are dangerous (containing CARBON

MONOXIDE, an ODORLESS and DEADLY GAS).

8. Exercise extreme caution when operating on slopes. Do not attempt to

clear steep slopes.

9. Never operate the snowthrower without proper guards, plates, or other

safety protective devices in place and working.

10.Never direct the discharge toward people or areas where property

damage can occur. Keep children and others away.

11.Do not overload the machine capacity by attempting to clear snow at too

fast a rate.

12.Never operate the machine at high transport speeds on slippery

surfaces. Look behind and use care when operating in reverse.

13.Disengage power to the collector/impeller when snowthrower is

transported or not in use.

14.Use only attachments and accessories approved by the manufacturer of

the snowthrower (such as cabs, tire chains, etc.).

15.Never operate the snowthrower without good visibility or light. Always be

sure of your footing and keep a firm hold on the handles. Walk, never

run.

16.Never touch a hot engine or muffler.

17.Never operate the snowthrower near glass enclosures, automobiles,

window wells, drop−offs, and the like without proper adjustment of the

snow discharge angle.

1742237

7

Page 8

en

18.Never direct discharge at bystanders or allow anyone in front of the unit.

19.Never leave a running unit unattended. Always disengage the auger and

traction controls, stop engine, and remove keys.

20.Do not operate the unit while under the influence of alcohol or drugs.

21.Keep in mind the operator is responsible for accidents occurring to other

people or property.

22.Data indicates that operators, age 60 years and above, are involved in a

large percentage of power equipment−related injuries. These operators

should evaluate their ability to operate the unit safely enough to protect

themselves and others from injury.

23.DO NOT wear long scarves or loose clothing that could become

entangled in moving parts.

24. Snow can hide obstacles. Make sure to remove all obstacles from the

area to be cleared.

Children

Tragic accidents can occur if the operator is not alert to the presence of

children. Children are often attracted to the unit and the operating activity.

Never assume that children will remain where you last saw them.

1. Keep children out of the area and under the watchful care of another

responsible adult.

2. Be alert and turn off if children enter the area.

3. Never allow children to operate the unit.

4. Use extra care when approaching blind corners, shrubs, trees, or other

objects that may obscure vision.

Clearing A Clogged Discharge Chute

Hand contact with the rotating impeller inside the discharge chute is the

most common cause of injury associated with snowthrowers. Never use

your hand to clean out the discharge chute.

To clear the chute:

1. SHUT OFF THE ENGINE.

2. Wait 10 seconds to be sure the impeller blades have stopped rotating.

3. Always use a clean out tool, not your hands.

2. Never store the machine with fuel in the tank inside a building where

ignition sources are present such as hot water and space heaters, or

clothes dryers. Allow the engine to cool before storing in any enclosure.

3. Always refer to operator’s manual for important details if the

snowthrower is to be stored for an extended period.

4. Maintain or replace safety and instruction labels as necessary.

5. Run the machine a few minutes after throwing snow to prevent

freeze−up of the collector/impeller.

6. If fuel is spilled, do not attempt to start the engine but move the machine

away from the area of spillage and avoid creating any source of ignition

until fuel vapors have dissipated.

7. Always observe safe refueling and fuel handling practices when

refueling the unit after transportation or storage.

8. Always follow the engine’s manual instructions for storage preparations

before storing the unit for both short and long term periods.

9. Always follow the engine manual instructions for proper start-up

procedures when returning the unit to service.

10.Keep nuts and bolts tight and keep equipment in good condition.

11.Never tamper with safety devices. Check their proper operation

regularly and make necessary repairs if they are not functioning

properly.

12.Components are subject to wear, damage, and deterioration. Frequently

check components and replace with manufacturer’s recommended

parts, when necessary.

13.Check control operation frequently. Adjust and service as required.

14.Use only factory authorized replacement parts when making repairs.

15.Always comply with factory specifications on all settings and

adjustments.

16.Only authorized service locations should be utilized for major service

and repair requirements.

17.Never attempt to make major repairs on this unit unless you have been

properly trained. Improper service procedures can result in hazardous

operation, equipment damage and voiding of manufacturer’s warranty.

Emissions

1. Engine exhaust from this product contains chemicals known, in certain

quantities, to cause cancer, birth defects, or reproductive harm.

2. If available, look for the relevant Emissions Durability Period and Air

Index information on the engine emissions label.

Service, Maintenance And Storage

1. Check shear bolts (pins) and other bolts at frequent intervals for proper

tightness to be sure the equipment is in safe working condition.

1742237

Ignition System

1. This spark ignition system complies with Canadian ICES-002.

8

Page 9

ASSEMBLY

Read and follow the assembly and adjustment

instructions for your snow thrower. All fasteners

are in the parts bag. Do not discard any parts or

material until the unit is assembled.

WARNING: Before doing any

assembly or maintenance to the

snow thrower, remove the wire

from the spark plug.

NOTE: In this instruction book, left and right

describe the location of a part from the

operator’s position behind the unit.

NOTE: Torque is measured in foot pounds

(metric N.m). This measurement describes

how tight a nut or bolt must be. The torque is

measured with a torque wrench.

NOTE: Fasteners and loose parts are shown

at full size in Figure 2 on page 32.

NOTE: Illustrations are located on page 2

and on pages 33 through 38.

Tools Required

1 Knife

1 Pliers

2 1/2 inch open end wrenches

2 9/16 inch open end wrenches

2 3/4 inch open end wrenches

1 Measuring tape or ruler

1 Screwdriver

1 3/8 inch open end wrench

1 7/16 inch open end wrench

How To Remove The Snow Thrower

From The Carton

1. (Figure 3) The snow thrower is shown in the

shipping position.

2. Remove packing material from wheels,

handle, and auger housing.

3. Locate and remove the parts bag (some

models do not have a parts bag).

4. Cut open the end of the carton next to the

handle.

5. To roll the snowthrower off of the carton, pull

on the handle.

CAUTION: DO NOT back over cables.

6. Remove any packing material that remains

from handle and auger housing.

7. Cut orange plastic shipping ties that may

secure the control cables to the LOWER

HANDLE.

8. If the control cables have become

disconnected from the control levers, then

attach the cable to the levers (see Owner’s

Manual for illustration of cable and lever).

How To Assemble The Handle And

Crank Assembly

1. (Figure 4) Loosen, but do not remove, the

fasteners (1) in the upper holes of the lower

handle.

2. Remove the fasteners and the crank

assembly eyebolt (11) from the lower holes

of the lower handle.

3. (Figure 1) Put the shift lever (6) into first

forward position.

4. (Figure 4) Raise the upper handle (2) to the

operating position.

NOTE: Make sure the cables are not

caught between the upper and lower

handle.

1742237

5. Install the fasteners and the crank assembly

eyebolt (11) that were removed in step 2.

DO NOT tighten until all fasteners are in

place.

6. (Figure 5) Attach the crank rod (15) to the

universal joint assembly (16) with the hair

pin (12).

7. (Figure 4) Tighten nut on eye bolt (11).

Make sure eye bolt (11) is properly aligned

and the crank (18) can freely rotate.

8. Tighten all handle fasteners.

How To Install The Knob(s) (Figure 6)

NOTE: If knob(s) are already installed, go to

the next selection.

1. Attach the knob (3) onto the speed shift

lever (2). On some models, the knob (3)

is attached. To lock in position, tighten the

hex jam nut (1) against the bottom of the

knob (3).

2. Make sure the speed shift lever (2)

functions correctly. Move the speed shift

lever (2) through all speeds.

How To Assemble The Chute Deflector

NOTE: The chute ring assembly (1) comes

installed on the unit from the factory (see

Figure 7).

1. Turn crank assembly (18, Figure 4) until

the arrow on outer ring (2, Figure 7) of

chute ring assembly points forward.

2. Place chute ring (3) onto outer ring (2)

so the slot in the chute ring aligns with

the arrow on the outer ring.

3. Install chute deflector (4) using four screws

(5) and nuts (6) in holes as shown. The chute

deflector must point forward for proper

installation.

4. Tighten screws snugly but be careful not to

over-tighten.

Check The Cables

1. (Figure 8) Check the traction drive cable

(1) and the auger drive cable (2). If the

bottom of the cables have become

disconnected, reinstall the cables.

2. (Figure 10) If the top of the cables (5) have

become disconnected from the drive

levers (6), attach the cables (5) to the “Z”

fitting (7).

How To Set The Skid Height (Figure 1)

The snow thrower is equipped with height

adjustable skids (7) mounted on the outside of

the auger housing (4). To adjust the height of

the skids, see “How To Adjust The Height Of

The Skids” in the Maintenance section.

How To Set The Length Of The Cables

The cables were adjusted at the factory and no

adjustments should be necessary. However,

after the handles are put in the operating

position, the cables can be too tight or too loose.

If an adjustment is necessary, see “How To

Check And Adjust The Cables” in the Service

And Adjustment section.

9

en

How To Assemble The Drift Cutter

(if equipped)

Drift cutters are used to cut a path through snow

deeper than the auger housing.

1. (Figure 11) Loosen the fasteners (2) that

secure the drift cutters (1) to the auger

housing.

2. Raise the drift cutters (1) to the desired

height.

3. Tighten the fasteners (2).

How To Prepare The Engine

NOTE: The engine was shipped from the

factory filled with oil. Check the level of the

oil. Add oil as needed.

WARNING: Follow the engine

manufacturer’s instructions for the

type of fuel and oil to use. Always

use a safety fuel container. Do not smoke

when adding gasoline to the engine. When

inside an enclosure, do not fill with

gasoline. Before you add fuel, stop the

engine. Let the engine cool for several

minutes.

Check the oil. See the engine manufacturer’s

instructions for the type of fuel and oil to use.

Before you use the unit, read the information on

safety, operation, maintenance, and storage.

Important! Before You Start Operating

Check the fasteners. Make sure all

fasteners are tight.

On electric start models, the unit was

shipped with the starter cord plugged

into the engine. Before operating,

unplug the starter cord from the engine.

OPERATION

NOTE: Illustrations are located on page 2

and on pages 33 through 38.

CAUTION: Use only attachments and

accessories approved by the manufacturer

of the snow thrower (such as tire chains,

electric start kits, etc.).

Know Your Snow Thrower (Figure 1)

Read this Instruction Book and safety rules

before operation the snow thrower. Compare the

illustration with your snow thrower to familiarize

yourself with the location of various controls and

adjustments.

How To Control The Discharge Of

The Snow

WARNING: Never direct the

discharge of snow toward

bystanders.

WARNING: Always stop the engine

before unclogging the discharge

chute or the auger housing and

before leaving the snow thrower.

1. (Figure 1) Turn the crank assembly (2) to

change the discharge direction of the snow.

2. (Figure 12) Loosen the wing knob (1) on

the chute deflector (2) and move the chute

deflector (2) to set the distance. Move the

chute deflector (2) UP for more distance,

DOWN for less distance. Then tighten the

wing knob (1).

Page 10

How To Stop The Snow Thrower

(Figure 1)

1. To stop discharging snow, release the auger

drive lever (5).

2. To stop the wheels, release the traction

drive lever (1).

3. To stop the engine, move the stop switch

(13) to the OFF position.

CAUTION: To stop the engine, do not move

the choke control to CHOKE position.

Backfire or engine damage can occur.

How To Go Forward or Backward

(Figure 1)

1. To change the ground speed, first release the

traction drive lever (1) and then move the

speed shift lever (6) to the desired speed.

2. Ground speed is determined by snow

conditions. Select the speed by moving the

speed shift lever (6) into the appropriate

notch on the shift lever plate.

Speed 1, 2 Wet, Heavy

Speed 3 Light

Speed 4 Very Light

Speed 5, 6 Transport only

3. To go forward, engage the traction drive

lever (1). Maintain a firm hold on the handle

as the snow thrower starts to move forward.

Guide the snow thrower by moving the

handle either left or right. Do not attempt to

push the snow thrower.

4. To go backward, release the tractor drive

lever (1).

5. Move the speed shift lever (6) into either

first or second reverse.

6. Engage the traction drive lever (1).

IMPORTANT: Do not move the speed shift

lever (6) while the traction drive lever (1) is

engaged.

How To Throw Snow (Figure 1)

1. Engage the auger drive lever (5).

2. To stop throwing snow, release the auger

drive lever (5).

WARNING: The operation of any

snow thrower can result in foreign

objects being thrown into the eyes,

which can result in severe eye damage.

Always wear safety glasses or eye shields

while operating the snow thrower. We

recommend standard safety glasses or use

a wide vision safety mask over your

glasses.

How To Use The Wheel Lockout Pin

(Figure 13)

1. The right hand wheel is secured to the axle

with a klick pin (1). This unit was shipped

with this klick pin (1) through the wheel hole

in the locked position (2).

2. For ease of maneuverability in light snow

conditions, change the klick pin (1) to an

unlocked position (3).

3. Disconnect the klick pin (1) from the wheel

locked position (2). Push the klick pin (1)

through the unlocked axle hole only. The unit

is now in the single wheel drive unlocked

position (3).

1742237

Before Starting The Engine

1. Before you service or start the engine,

familiarize yourself with the snow thrower. Be

sure you understand the function and

location of all controls.

2. Check the tension of the clutch cable before

starting the engine. See “How To Adjust The

Clutch Cable” in the Maintenance section of

this manual.

3. Make sure that all fasteners are tight.

4. Make sure the height adjust skids are

properly adjusted. See “How To Adjust The

Height Of The Skids” in the Maintenance

section of this manual.

5. Check the air pressure in the tires. The

correct air pressure is 14 PSI (1 BAR) to 17

PSI (1.25 BAR). Do not exceed the

maximum amount of air pressure shown on

the side of the tire.

How To Stop The Engine (Figure 1)

1. Push the stop switch (13) to the OFF

position.

2. Pull out the safety key (8).

CAUTION: To stop the engine, do not move

the choke control to CHOKE position.

Backfire or engine damage can occur.

How To Start The Engine (Figure 1)

Models equipped with an Electric Starter

NOTE: An electric starter kit can be added to

recoil start engines. Electric starter kits are

available from your nearest authorized

service center.

WARNING: The starter is equipped

with a three−wire power cord and

plug and is designed to operate on

A.C. household current. The power cord

must be properly grounded at all times to

avoid the possibility of electrical shock

which can injure the operator. Carefully

follow all instructions in the “How To Start

The Engine” section. Make sure that your

house wiring is a three−wire grounded

system. If you are not sure, ask a licensed

electrician. If your house wire system is not

a three−wire grounded system, do not use

this electric starter under any conditions. If

your system is grounded but a three−hole

grounded receptacle is not available to start

the engine, have a three−hole grounded

receptacle installed by a licensed

electrician. To connect an A.C. power cord,

always connect the power cord to the

switch box (11) on the engine first. Then,

plug the other end into the three−hole

grounded receptacle. When disconnecting

the power cord, always unplug the end from

the three−hole grounded receptacle first.

How To Start A Cold Engine (Figure 1)

1. Check the engine oil.

2. Fill the fuel tank with regular unleaded petrol.

See “How To Prepare The Engine”.

3. Make sure the traction drive lever (1) and

the auger drive lever (5) are in the

disengaged (released) position.

10

en

4. Push the stop switch (13) to the ON

position.

5. Push in the safety key (8).

6. Rotate the choke knob (14) to the CHOKE

position.

7. (Electric Start) Connect the power cord to

the starter motor located on the engine.

8. (Electric Start) Plug the other end of the

power cord into a three−hole, grounded

A.C. receptacle. (See the WARNING in

this section).

9. Push the primer button (9). Every time you

push the primer button (9), wait two

seconds. For the number of times required to

push the primer button (9), see the engine

manufacturer’s instructions.

10.(Electric Start) Push on the electric start

button (10) until the engine starts. Do not

crank for more than 5 seconds at a time.

Wait one minute between starts to allow the

starter to cool.

11. (Recoil Start) Slowly pull the recoil starter

handle (12) until resistance is felt and then

pull rapidly to start the engine. Do not allow

the recoil starter handle (12) to snap back.

Slowly return the recoil starter handle (12).

12.If the engine does not start in 5 or 6 tries,

See the “Trouble Shooting Chart”

Instructions.

13.Allow the engine to warm up for several

minutes. As the engine warms up, adjust the

choke knob (14) toward the RUN position.

Wait until the engine runs smoothly before

each choke adjustment.

14.(Electric Start) First disconnect the power

cord from the three−hole receptacle. Then,

disconnect the power cord from the starter

motor.

NOTE: In temperatures below 0

allow the engine to warm up for several

minutes before blowing snow.

WARNING: Never run the engine

indoors or in enclosed, poorly

ventilated areas. Engine exhaust

contains carbon monoxide, an odorless

and deadly gas. Keep hands, feet, hair and

loose clothing away from any moving parts

located on the engine or the snow thrower.

The temperature of muffler and nearby

areas may exceed 150°F (66° C). Avoid

these areas.

How To Start A Warm Engine (Figure 1)

If an engine has been running and is still warm,

leave the choke control (14) in the off position

and do not push the primer button (9). If the

engine fails to start, follow the instructions “How

To Start A Cold Engine”.

NOTE: Do not use the primer button (9) to

start a warm engine.

How To Start An Engine With A Frozen Electric

Starter (Figure 1)

If the electric starter is frozen and will not turn

the engine, follow the instructions below.

1. Pull as much starter rope as possible out of

the starter.

2. Release the starter handle and let it snap

back against the starter. Repeat until the

engine starts.

F (-18 C),

Page 11

Warm engines will cause condensation in cold

weather. To prevent possible freeze−up of recoil

starter and engine controls, proceed as follows

after each snow removal job.

1. Run the snow thrower a few minutes after

throwing snow to prevent freeze−up of the

auger/impeller.

2. With engine off, allow engine to cool for

several minutes.

3. Pull starter rope very slowly until resistance

is felt, then stop. Allow the starter rope to

recoil. Repeat three times.

4. With the engine not running, wipe all snow

and moisture from the carburetor cover in

area of controls and levers. Also, move the

choke control and starter handle several

times.

How To Remove Snow or Debris From

The Auger Housing

WARNING: Do not attempt to

remove snow or debris that may

become lodged in auger housing

with your hands. Use the clean−out tool or

a pry bar to remove snow or debris.

CUSTOMER RESPONSIBILITIES

(Figure 21) On some models, a clean−out tool

(1) is attached to the top of the auger housing.

Use the clean−out tool (1) to remove snow

from the auger housing.

1. (Figure 1) Release the auger drive lever

(5).

2. Pull out the safety key (8).

3. Do not place your hands in the auger

housing (4) or the discharge chute (3).

4. (Figure 21) Use the clean−out tool (1) or a

pry bar to remove any snow or debris.

Snow Throwing Tips

1. For maximum snow thrower efficiency in

removing snow, adjust ground speed. Go

slower in deep, freezing or wet snow. If the

wheels slips, reduce forward speed.

2. Most efficient snow throwing is accomplished

when the snow is removed immediately after

if falls.

CAUTION: Do not overload the machine

capacity by attempting to clear snow at

too fast a rate.

MAINTENANCE CHART

en

3. For complete snow removal, slightly overlap

each previous path.

4. Whenever possible, discharge the snow

down wind.

5. For normal usage, set the skids so that the

scraper bar is 1/8” (3 mm) above the skids.

For extremely hard−packed snow surfaces,

adjust the skids upward so that the scraper

bar touches the ground.

6. Rocks and gravel must not be picked up and

thrown by the machine. On gravel or crushed

rock surfaces, set the skids at 1−1/4 inch

(32 mm) below the scraper bar. See “How To

Adjust The Height Of The Skids” in the

Maintenance section.

7. After each snow throwing job, allow the

engine to idle for a few minutes. The snow

and accumulated ice will melt off the engine.

8. Clean the snow thrower after each use.

9. Remove ice, snow and debris from the entire

snow thrower. Flush with water to remove all

salt or other chemicals. Wipe snow thrower

dry.

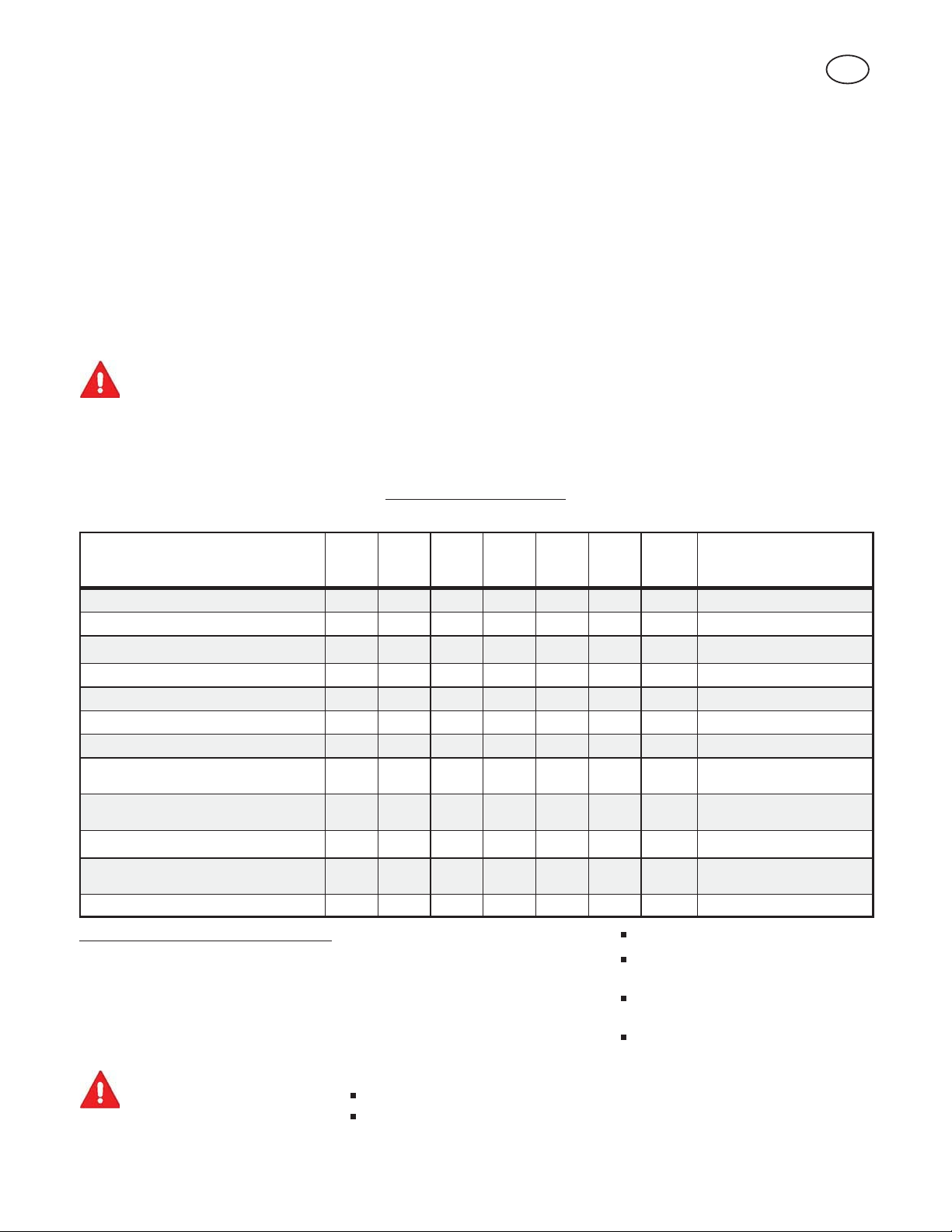

SERVICE RECORDS

Fill in dates as you complete

regular service.

Check Engine Oil Level

Change Engine Oil

Check And Tighten All Screws and Nuts

Check Spark Plug

Adjust Drive Belt

Check Fuel

Drain Fuel

Check Auger Clutch Cable Adjustment

(See Cable Adjustment)

Check Traction Clutch Cable Adjustment

(See Cable Adjustment)

Lubricate All Pivot Points

Lubricate Auger Shaft

(See Shear Bolt Replacement)

Lubricate Drive Chains and Sprockets

MAINTENANCE

NOTE: Illustrations are located on page 2

and on pages 33 through 38.

Use the following maintenance section to keep

your unit in good operating condition. All the

maintenance information for the engine is in the

engine manufacturer’s instructions. Before you

start the engine, read this book.

WARNING: Before you make an

inspection, adjustment (except

carburetor), or repair, disconnect

the wire from the spark plug.

1742237

Before

Each

Use

First 2

Hours

Every

5

Hours

Every

10

Hours

Every

25

Hours

√ √ √

√ √

√ √

√ √

√ √ √

√

√ √

√ √

√

√ √

√ √

General Recommendations

The warranty on this snow thrower does not

cover items that have been subjected to

operator abuse or negligence. To receive full

value from the warranty, the operator must

maintain the snow thrower as instructed in this

manual.

Some adjustments must be made periodically to

properly maintain the snow thrower.

After Each Use

Check for any loose or damaged parts.

Tighten any loose fasteners.

11

Each

Season

Before

Storage

SERVICE DATES

√

√

Check and maintain the auger.

Check controls to make sure they are

functioning properly.

If any parts are worn or damaged, replace

immediately.

Check all safety and instruction decals and

labels. Replace any decals or labels that are

missing or cannot be clearly read.

All adjustments in the Maintenance section of

this manual should be checked at least once

each season.

Page 12

As Required

The following adjustment should be preformed

more than once each season.

1. Adjust the auger drive belt after the first 2 to

4 hours, again at mid−season, and twice

each season thereafter. See “How To Adjust

The Auger Drive Belt” in the Maintenance

section.

Lubrication

Every 10 Hours (Figure 14)

1. Lubricate the Zerk fittings (1) every ten

hours with a grease gun.

2. Each time a shear bolt is replaced, the auger

shaft must also be greased.

3. Lubricate all pivot points.

Every 25 Hours

Chute Rotation Gear

(Figure 5) Lubricate the chute rotation gear (1)

with automotive type oil.

Chains

1. (Figure 1) Move the speed shift lever (6) to

first gear.

2. Remove the gas from the gas tank. Stand

the snow thrower up on the front end of the

auger housing (4).

WARNING: Drain the gasoline

outdoors, away from fire or flame.

3. (Figure 23) Loosen the bolts (3) on each

side of the bottom panel (2).

4. Remove the bottom panel (2).

5. (Figure 15) Lubricate the chains (5) with a

chain type lubricant.

6. Wipe the hexshaft and sprockets (6) with

5W30 motor oil.

NOTE: If grease or oil come in contact

with the disc drive plate (1) or the friction

wheel (3), damage can result. Clean off

any oil or grease with a alcohol base

solvent.

7. (Figure 23) Install the bottom panel (2).

8. Tighten the bolts (3) on each side of the

bottom panel (2).

Items Not To Lubricate (Figure 15)

1. Do not lubricate the hex shaft and

sprockets (6). All bearings and bushings are

lifetime lubricated. For storage, put a slight

amount of 5W−30 motor oil on a cloth and

wipe the hex shaft and sprockets (6) to

prevent rust.

2. If grease or oil comes in contact with the

disc drive plate (1) or the friction wheel

(3), the friction wheel (3) can be damaged.

Make sure to thoroughly clean the disc drive

plate (1) and the friction wheel (3).

CAUTION: Any greasing or oiling of the

above components can cause

contamination of the friction wheel (3). If

the disc drive plate (1) or the friction

wheel (3) become contaminated with

grease or oil, damage to the friction wheel

will result.

1742237

3. The auger gear case is lubricated at the

factory and does not require additional

lubrication. If for some reason the lubricant

leaks out, have the auger gear case checked

by a factory authorized service center.

How To Adjust The Height Of The Skids

(Figure 1)

This snow thrower is equipped with two height

adjustable skids (7). These skids elevate the

front of the snow thrower. For normal hard

surfaces, such as a paved driveway or walk,

adjust the skids as follows.

1. Put the snow thrower on a level surface.

2. Make sure both tires are equally inflated. The

correct air pressure is 14 PSI (1 BAR) to 17

PSI (1.25 BAR). Do not exceed the

maximum amount of air pressure shown on

the side of the tire.

3. Put the extra shear bolts (found in the parts

bag) under each end of the scraper bar (15)

next to the adjustable skids (7).

4. Loosen the mounting nuts (16) that hold the

adjustable skids (7). To bring the front of the

snow thrower down, raise each adjustable

skids (7). Tighten the mounting nuts (16).

NOTE: For rocky or uneven surfaces, raise

the front of the snow thrower by moving the

adjustable skids (7) down.

WARNING: Be certain to maintain

proper ground clearance for the

area to be cleared. Objects such as

gravel, rocks or other debris, if struck by

the impeller, can be thrown with sufficient

force to cause personal injury, property

damage or damage to the snow thrower.

How To Adjust The Scraper Bar

(Figure 1)

After considerable use, the scraper bar (15) will

become worn. The scraper bar (15), in

conjunction with the skids, must be adjusted to

allow 1/8 inch clearance between the scraper

bar (15) and the sidewalk or area to be cleared.

1. Put the snow thrower on a level surface.

2. Make sure both tires are equally inflated. The

correct air pressure is 14 PSI (1 BAR) to 17

PSI (1.25 BAR). Do not exceed the

maximum amount of air pressure shown on

the side of the tire.

3. Loosen the carriage bolts and nuts that

hold the scraper bar (15) to the auger

housing (4).

4. Adjust the scraper bar (15) to allow 1/8 inch

clearance between the scraper bar (15) and

the sidewalk or area to be cleared.

5. Tighten the carriage bolts and nuts. Make

sure that the scraper bar (15) is parallel with

the sidewalk or area to be cleared.

6. To extended the life of the scraper bar (15),

remove and reverse the mounting of the

scraper bar (15).

12

en

How To Check And Adjust The Cables

The traction drive cable and the auger drive

cable are adjusted at the factory. During normal

use, a cable can become stretched and must be

checked and adjusted as follows.

How To Check The Cables (Figure 16)

1. To check for correct adjustment, disconnect

the “Z” fitting (1) from the drive lever (2).

2. Move the drive lever (2) forward until the

drive lever (2) is contacting the plastic

bumper (3).

3. The control cable is correctly adjusted if the

center of the “Z” fitting (1) is aligned (4)

with the hole in the drive lever (2) and there

in no droop in the cable.

How To Adjust The Auger Drive Cable

1. Remove the gas from the gas tank. Stand

the snow thrower up on the front end of the

auger housing.

WARNING: Drain the gasoline

outdoors, away from fire or flame.

2. (Figure 16) Disconnect the “Z” fitting (1)

from the drive lever (2).

3. (Figure 17) Pull the spring cover up to

expose the spring (5). Push the cable (6)

through the spring (5) to expose the square

end (7) on the cable (6).

4. Hold the square end (7) with pliers and

adjust the locknut (8) in or out until the

excess slack is removed.

5. Pull the cable (6) back through the spring

(5).

6. (Figure 16) Connect the “Z” fitting (1) to the

drive lever (2).

NOTE: When the auger drive belt is adjusted

or replaced, check and adjust the cable.

How To Adjust The Traction Drive Cable

1. Remove the gas from the gas tank. Stand

the snow thrower up on the front end of the

auger housing.

WARNING: Drain the gasoline

outdoors, away from fire or flame.

2. (Figure 23) Loosen the bolts (3) on each

side of the bottom panel (2).

3. Remove the bottom panel (2).

4. (Figure 16) Disconnect the “Z” fitting (1)

from the traction drive lever (2).

5. (Figure 28) Slide the cable boot (3) off the

cable adjustment bracket (4).

6. Push the bottom of the traction control

cable (5) through the cable adjustment

bracket (4) until the “Z” hook (6) can be

removed.

7. Remove the “Z” hook (6) from the cable

adjustment bracket (4). Move the “Z” hook

(6) down to the next adjustment hole.

8. Pull the traction control cable (5) up

through the cable adjustment bracket (4).

9. Put the cable boot (3) over the cable

adjustment bracket (4).

10.(Figure 16) Install the “Z” fitting (1) to the

traction drive lever (2).

Page 13

11. (Figure 15) To check the adjustment,

depress the drive lever and check the length

“A” of the drive spring (7). In correct

adjustment, the length “A” of the drive

spring (7) is as follows:

minimum 3 inches (76 mm)

maximum 3-3/8 inches (85 mm).

12.(Figure 23) Install the bottom panel (2).

13.Tighten the bolts (3) on each side of the

bottom panel (2).

How To Adjust The Belts

The belts will stretch during normal use. If you

need to adjust the belts due to wear or stretch,

proceed as follows.

How To Adjust The Auger Drive Belt

If the snow thrower will not discharge snow,

check the adjustment of the auger drive cable.

See “How To Check And Adjust The Cables” in

the Maintenance section. If the adjustment is

correct, then check the condition of the auger

drive belt. If the auger drive belt is damaged,

replace the auger drive belt. See “How To

Replace The Belts” in the Maintenance section.

If the auger drive belt is loose, adjust as follows.

1. Disconnect the spark plug wire.

2. (Figure 18) Remove screw (2) from belt

cover (1). Remove the belt cover (1).

3. (Figure 19) Loosen the nut (2) on the idler

pulley (3) Move the idler pulley (3) 1/8 inch

(3 mm) toward the auger drive belt (4).

4. Tighten the nut (2).

5. (Figure 22) Depress the auger drive lever.

Check the tension on the auger drive belt

(4). In correct adjustment, the auger drive

belt (4) will deflect 1/2 inch (12.5 mm) (5)

with moderate pressure. If the adjustment is

not correct, repeat the adjustment.

6. (Figure 18) Install the belt cover (1). Tighten

screw (2).

7. Check the adjustment of the auger drive

cable. See “How To Check And Adjust The

Cables” in the Maintenance section.

8. Attach the spark plug wire.

Traction Drive Belt

The traction drive belt has constant spring

pressure and does not require an adjustment. If

the traction drive belt is slipping, replace the

belt. See “How To Replace The Belts” in the

Maintenance section.

How To Replace The Belts

The drive belts are of special construction and

must be replaced with original factory

replacement belts available from your nearest

authorized service center.

Some steps require the assistance of a second

person.

How To Remove the Auger Drive Belt

If the auger drive belt is damaged, the snow

thrower will not discharge snow. Replace the

damaged belt as follows.

1. Disconnect the spark plug wire.

2. (Figure 23) Loosen the bolts (3) on each

side of the bottom panel (2).

1742237

3. Remove the bottom panel (2).

4. (Figure 18) Remove screw (2) from belt

cover (1). Remove the belt cover (1).

5. (Figure 19) Loosen the belt guide (9). Pull

the belt guide (9) away from the auger

drive pulley (10).

6. Pull the idler pulley (3) away from the auger

drive belt (4) and slip the auger drive belt

(4) off of the idler pulley (3).

7. Remove the auger drive belt (4) from the

engine pulley (11). To remove the auger

drive belt (4), the engine pulley (11) may

have to be partially rotated.

8. (Figure 20) Remove the top four bolts (21)

that hold together the auger housing (22)

and the motor box (23). Loosen the bottom

two bolts (24). The auger housing (22) and

the motor box

removal of the belt.

9. (Figure 19) Remove the old auger drive

belt (4) from the auger drive pulley (10).

Replace the auger drive belt (4) with an

original factory replacement belt available

from an authorized service center.

10.Install the new auger drive belt (4) onto the

auger drive pulley (10).

11.Assemble the auger housing (22) to the

motor box (23) with the four bolts (21) that

were removed in step 8. Tighten the bottom

two bolts (24).

12.Install the auger drive belt (4) onto the

engine pulley (11).

13.Slip the auger drive belt (4) under the idler

pulley (3).

14.Adjust the auger drive belt (4). See “How To

Adjust The Auger Drive Belt” in the

Maintenance section.

15.Adjust the belt guide (9). See “How To

Adjust The Belt Guide” in the Maintenance

section.

16.(Figure 18) Install the belt cover (1). Tighten

screw (2).

17.Check the adjustment of the cables. See

“How To Check And Adjust The Cables” in

the Maintenance section.

18.Connect the spark plug wire.

How To Remove the Traction Drive Belt

If the snow thrower will not move forward, check

the traction drive belt for wear or damage. If the

traction drive belt is worn or damaged, replace

the belt as follows.

1. Disconnect the spark plug wire.

2. Remove the auger drive belt. See “How To

Remove The Auger Drive Belt” in the

Maintenance section.

3. (Figure 19) Remove the e−ring (17) from

one end of the swing plate axle rod (18).

Remove the swing plate axle rod (18) to

allow the the swing plate to pivot forward.

4. Remove the traction drive spring (16).

5. Remove the old traction drive belt (13) from

the traction drive pulley (14) and from the

engine pulley (15). Replace the traction

drive belt (13) with an original factory

replacement belt available from an

authorized service center.

6. Install the new traction drive belt (13) onto

the traction drive pulley (14) and onto

engine pulley (15).

(23) can now be split apart for

13

en

7. Make sure the traction drive idler pulley

(12) is properly aligned with the traction

drive belt (13).

8. Attach the traction drive spring (16).

9. Install the swing plate axle rod (18) and

secure with the e−ring (17) removed earlier.

10.(Figure 31)

(20) must be positioned between the

alignment tabs (19). Make sure the swing

plate (20) is properly secured.

NOTE: If the drive will not engage after

the traction drive belt has been replaced,

then check to make sure that the swing

plate is positioned between the alignment

tabs (19).

11. (Figure 19) Install and adjust the auger

drive belt (4). See “How To Remove The

Auger Drive Belt” in the Maintenance section.

12.Adjust the belt guide (9). See “How To

Adjust The Belt Guide” in the Maintenance

section.

13.(Figure 23) Install the bottom panel (2).

14.Tighten the bolts (3) on each side of the

bottom panel (2).

15.(Figure 18) Install the belt cover (1). Tighten

screw (2).

16.Check the adjustment of the cables. See

“How To Check And Adjust The Cables” in

the Maintenance section.

17.Connect the spark plug wire.

How To Adjust The Belt Guide

1. Disconnect spark plug wire.

2. (Figure 18) Remove screw (2). Remove the

belt cover (1).

3. (Figure 1) Engage the auger drive lever (5).

4. (Figure 24) Measure the distance between

the belt guide (2) and auger drive belt (3).

The correct distance (4) is 1/8 inch (3 mm).

5. If an adjustment is necessary, loosen the

mounting bolt for the belt guide (2). Move

the belt guide (2) to the correct position

(4). Tighten the mounting bolt for the belt

guide (2).

6. (Figure 18) Install the belt cover (1). Tighten

screw (2).

7. Connect the spark plug wire.

How To Adjust Or Replace The Friction

Wheel

How To Check The Friction Wheel

If the snow thrower will not move forward, check

the traction drive belt, the traction drive cable or

the friction wheel. If the friction wheel is worn or

damaged, it must be replaced. See “How To

Replace the Friction Wheel” in this section. If the

friction wheel is not worn or damaged, check as

follows.

1. (Figure 1) Remove the gas from the gas

tank. Stand the snow thrower up on the front

end of the auger housing (4).

2. Disconnect the spark plug wire.

3. (Figure 23) Loosen the bolts (3) on each

side of the bottom panel (2).

4. Remove the bottom panel (2).

5. (Figure 1) Position the shift speed lever (6)

in the lowest forward speed.

The bottom of the

WARNING: Drain the gasoline

outdoors, away from fire or flame.

swing plate

Page 14

6. (Figure 25) Note the position of the friction

wheel (4). The correct distance “A” from the

right side of the friction wheel (4) to the

outside of the motorbox is as follows:

Tire Size Distance “A”

12 and 13 inch 4-1/8” (10.5 cm)

16 inch 4-5/16” (10.95 cm)

If the friction wheel (4) is not in the correct

position, adjust as follows.

How To Adjust The Friction Wheel

1. (Figure 1) Position the shift speed lever (6)

in the lowest forward speed.

2. (Figure 9) Loosen the bolts (1) on the

speed control rod (8).

3. (Figure 25) Move the friction wheel (4) to

the correct position.

4. (Figure 9) Tighten the bolts (1) on the

speed control rod (8).

5. (Figure 23) Install the bottom panel (2).

6. Tighten the bolts (3) on each side of the

bottom panel (2).

How To Replace The Friction Wheel

If the friction wheel is worn or damaged, the

snow thrower will not move forward. The friction

wheel must be replaced as follows.

1. (Figure 1) Remove the gas from the gas

tank. Stand the snow thrower up on the front

end of the auger housing (4).

WARNING: Drain the gasoline

outdoors, away from fire or flame.

2. Disconnect the spark plug wire.

3. (Figure 29) Remove the fasteners that

secure the left wheel (10). Remove the left

wheel (10) from the axle (11).

4. Loosen the bolts (3) on each side of the

bottom panel (2).

5. Remove the bottom panel (2).

6. (Figure 30) Remove the fasteners that

secure the drive sprocket (12) to the axle

(11).

7. Remove the right wheel, axle (11), and drive

sprocket (12).

8. (Figure 31) Remove the four bolts (16) that

hold the bearings (7) on each side of the

hex shaft (8).

9. (Figure 32) Remove the hex shaft (8) and

bearings (7).

NOTE: Take special note of the position of

the washers (17).

10.(Figure 27) Remove the three fasteners (4)

that hold the friction wheel (5) to the hub

(6).

11. (Figure 27) Remove the friction wheel (5)

from the hub (6). Slip the friction wheel (5)

off the hex shaft (8).

12.Assemble the new friction wheel (5) onto

hub (6) with the fasteners removed earlier.

13.(Figure 32) Install the hex shaft (8) and

bearings (7) with the four bolts removed

earlier.

Make sure the washers (17) are properly

installed in the original position. Also,

make sure the two washers (13) are

properly aligned with the actuator arms

(14).

14.Make sure the hex shaft (8) turns freely.

15.(Figure 30) Install the right wheel, axle (11),

and drive sprocket (12) with the fasteners

removed earlier. Install the chain (15) onto

the drive sprocket (12).

16.Check the adjustment of the friction wheel.

See “How To Adjust The Friction Wheel” in

this section.

17.Make sure the friction wheel and the disc

drive plate are free from grease or oil.

18.(Figure 23) Install the bottom panel (2).

19.Tighten the bolts (3) on each side of the

bottom panel (2).

20.Install the left wheel (10) to the axle (11)

with the fasteners removed earlier.

21.Connect the spark plug wire.

How To Replace the Auger Shear Bolt

The augers are secured to the auger shaft with

special shear bolts. These shear bolts are

designed to break and protect the machine if an

object becomes lodged in the auger housing. Do

not use a harder bolt as the protection provided

by the shear bolt will be lost.

WARNING: For safety and to

protect the machine, use only

original equipment shear bolts.

To replace a broken shear bolt, proceed as

follows. Extra shear bolts were provided in the

assembly parts bag.

1. (Figure 1) Move the stop switch (13) to the

stop position. Disengage all controls.

2. Disconnect the spark plug wire. Make sure

all moving parts have stopped.

3. (Figure 14)

fitting (1), if equipped, with a grease gun.

4. (Figure 26) Align the hole in the auger with

the hole in the auger shaft. Install the new

shear bolt (2), spacer (3), and locknut (4).

5. Connect the spark plug wire.

Lubricate the auger shaft Zerk

How To Prepare The Snow Thrower For

Storage

WARNING: Do not remove gasoline

while inside a building, near a fire,

or while you smoke. Gasoline

fumes can cause an explosion or a fire.

If the snow thrower is to be stored for an

extended period, refer to the engine

manufacturer’s operating manual (included with

some models) for important maintenance or

storage details.

en

1. Drain the fuel tank.

2. Let the engine run until it is out of gasoline.

3. Never store the snow thrower with fuel in the

tank inside a building where ignition sources

are present such as hot water and space

heaters, clothes dryers, and the like. Allow the

engine (motor) to cool before storing in any

enclosure.

4. Drain the oil from the warm engine. Fill the

engine crankcase with new oil.

5. Thoroughly clean the snow thrower.

6. Lubricate all lubrication points. See the

Maintenance section.

7. Be sure that all nuts, bolts and screws are

securely fastened. Inspect all visible moving

parts for damage, breakage and wear.

Replace if necessary.

8. Cover the bare metal parts of the blower

housing, auger, and the impeller with spray

rust preventative lubricant.

9. Put the unit in a building that has good

ventilation. Store in a clean and dry area, but

NOT near a stove, furnace or water heater

which uses a pilot light or any device that can

create a spark.

10. If the machine must be stored outdoors,

block up the snow thrower to be sure the

entire machine is off the ground.

11.Cover the snow thrower with a suitable

protective cover that does not retain

moisture. Do not use plastic.

How To Order Replacement Parts

The replacement parts are shown either on the

back pages of this Instruction Book or in a

separate Parts List Book.

Use only manufacturer’s authorized or approved

replacement parts. Do not use attachments or

accessories not specifically recommended for

this unit. In order to obtain proper replacement

parts you must supply the model number (see

nameplate).

To obtain replacement parts, contact your local

Dealer.

Replacement parts for the engine, transaxle, or

transmission, are available from the

manufacturer’s authorized service centre found

in the yellow pages of the telephone directory.

Also, see the individual engine or transmission

warranties to order replacement parts.

When ordering the following information is

required:

(1) The Model Number

(2) Serial Number

(3) Part Number

(4) Quantity

1742237

14

Page 15

TROUBLE SHOOTING CHART

TROUBLE CAUSE CORRECTION

Difficult starting Defective spark plug. Replace spark plug.

en

Water or dirt in fuel system. Use carburetor bowl drain to flush and refill with

Engine runs erratic Blocked fuel line, empty gas tank, or stale

Engine stalls Unit running on CHOKE. Set choke lever to RUN position.

Engine runs erratic;

Loss of power

Excessive vibration Loose parts: damaged impeller. Stop engine immediately and disconnect spark

Unit fails to propel itself Drive belt loose or damaged. Replace drive belt.

Unit fails to discharge snow Auger drive belt loose or damaged. Adjust auger drive belt; replace if damaged.

gasoline.

Water or dirt in fuel system. Use carburetor bowl drain to flush and refill with

Incorrect adjustment of traction drive cable. Adjust traction drive cable.

Worn or damaged friction wheel. Replace friction wheel.

Auger control cable not adjusted correctly. Adjust auger control cable.

Shear bolt broken. Replace shear bolt.

Discharge chute clogged. Stop engine immediately and disconnect spark

Foreign object lodged in auger. Stop engine immediately and disconnect spark

fresh fuel.

Clean fuel line; check fuel supply; add fresh

gasoline.

fresh fuel.

plug wire. Tighten all bolts and make all

necessary repairs. If vibration continues, have

the unit serviced by a competent repairman.

plug wire. Clean discharge chute and inside of

auger housing.

plug wire. Remove object from auger.

1742237

15

Page 16

en

BRIGGS AND STRATTON POWER PRODUCTS GROUP, L.L.C. OWNER WARRANTY POLICY

Effective January 1, 2008 replaces all undated Warranties and all Warranties dated before January 1, 2008

Briggs & Stratton Power Products Group, LLC will repair or replace, free of charge, any part(s) of the product that is defective in material or workmanship or

both. Transportation charges on product submitted for repair or replacement under this warranty must be borne by purchaser. This warranty is effective for

the time periods and subject to the conditions stated below. For warranty service, find the nearest Authorized Service Dealer in our dealer locator map at

www.murray. com.

THERE IS NO OTHER EXPRESS WARRANTY, IMPLIED WARRANTIES, INCLUDING THOSE OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, ARE LIMITED TO ONE YEAR FROM PURCHASE, OR TO THE EXTENT PERMITTED BY LAW. ANY AND ALL IMPLIED WARRANTIES

ARE EXCLUDED. LIABILITY FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES ARE EXCLUDED TO THE EXTENT EXCLUSION IS PERMITTED BY

LAW. Some states or countries do not allow limitations on how long an implied warranty lasts, and some states or countries do not allow the exclusion or

limitation of incidental or consequential damages, so the above limitation and exclusion may not apply to you. This warranty gives you specific legal rights

and you may also have other rights which vary from state to state or country to country.

Consumer Commercial

Brand / Unit Use Use

Dual Stage Snowthrower . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 years . . . . . . . . . . . . . . . . . . . . . . . . 90 Days

The warranty period begins on the date of purchase by the first retail consumer or commercial end user, and continues for the period of time stated above.

“Consumer use” means personal residential household use by a retail consumer. “Commercial use” means all other uses, including use for commercial, income producing or rental purposes. Once product has experienced commercial use, it shall thereafter be considered as commercial use for purposes of

this warranty.

No warranty registration is necessary to obtain warranty on Murray branded products. Save your proof of purchase receipt. If you do not provide

proof of the initial purchase date at the time warranty service is requested, the manufacturing date of the product will be used to determine the warranty.

We welcome warranty repair and apologize to you for being inconvenienced. Any Authorized Service Dealer may perform warranty repairs. Most warranty

repairs are handled routinely, but sometimes requests for warranty service may not be appropriate. For example, warranty service would not apply to the

product if damage occurred because of misuse, lack of routine maintenance, shipping, handling, warehousing or improper installation. Similarly, the warranty is void if the serial number on the product has been removed or the product has been altered or modified.

LIMITED WARRANTY

W

ARRANTY TERMS

A

BOUT YOUR WARRANTY

This warranty covers product related defective material and/or workmanship only. To avoid misunderstanding which might occur between the customer and

the Dealer, listed below are some of the causes of product failure that the warranty does not cover.

•N

ormal Wear: Small Engine Powered Equipment, like all mechanical devices, needs periodic parts and service to perform well. Warranty does not

cover repair when normal use has exhausted the life of the product or part.

•I

nstallation: This warranty does not apply to product that has been subjected to improper or unauthorized installation, alteration or modification. Nor

installations that prevent starting cause unsatisfactory engine performance.

•Improper Maintenance: The life of this product depends upon the conditions under which it operates, and the care it receives. Recommended maintenance and adjustment intervals are stated in the Operator’s Manual. Often product, such as tillers, edgers, rotary mowers, are used in dusty or dirty

conditions, which can cause what appears to be premature wear. Such wear, when caused by dirt, dust, or other abrasive material entering the product because of improper maintenance is not covered by warranty. The warranty will not cover repairs due to problems caused by replacement parts

that are not original manufactured part(s).

•I

ncorrect and/or Insufficient Fuel or Lubrication: This warranty does not cover damage caused by the use of stale fuel, or altered gasoline. Damage to

engine or engine components i.e., combustion chamber, valves, valve seats, valve guides, burned starter motor windings caused by use of alternate

fuels such as liquefied petroleum, natural gas, are not covered unless engine is certified for this operation. Parts which are scored or broken because

product was operated with insufficient, contaminated or incorrect grade of lubricating oil as well as product components damaged due to lack of lubrication are not covered.

•O

perational Misuse: Proper operation of the product is stated in the Operator’s Manual. Product damaged by overspeeding, overheating, or operation

in a confined area without sufficient ventilation. Product broken by excessive vibration caused by a loose engine mounting, loose or unbalanced

blades, impellers, overspeeding, or bent crankshaft due to striking of solid object. Damage or malfunctions resulting from accidents, abuse, or improper servicing or freezing or chemical deterioration, as well as operating in excess of recommended capacities as outlined in the Operator’s Manual

are not covered.

•R

outine Tune-Up, Wear Items, or Adjustments: This warranty excludes wear items such as oil, belts, blades, o-rings, filters, etc.

•O

ther Exclusions: Repair or adjustments for part(s) that are not manufactured by Briggs & Stratton Corporation, are not covered, see warranty for respective manufacturers. This warranty excludes failures due to acts of God and other major forceful events beyond the manufacturer’s control.

Also excluded are used, reconditioned, and demonstration products.

Warranty service is available only through Authorized Service Dealers. Locate your nearest dealer in our locator map at www.murray.com.

1742237

16

Page 17

TABLE DES MATIÈRES

SYMBOLES DE DANGERS ET LEURS

SIGNIFICATIONS 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SYMBOLES DE DANGERS ET LEURS

SIGNIFICATIONS 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MONTAGE 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FONCTIONNEMENT 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TABLEAU DE MAINTENANCE 26. . . . . . . . . . . . . . . . . . . . . . . . .

MAINTENANCE 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TABLEAU DE DEPANNAGE 30. . . . . . . . . . . . . . . . . . . . . . . . . . .

GARANTIE LIMITÉE 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

fr

1742237

17

Page 18

Contact

activé

Contact

désactivé

Clé de

contact

Appuyer pour

engager le

démarreur

électrique

fr

Engager

Traction

Collecteur de la

fraise

Embrayage

de la fraise

Embrayage de traction

Engager

Désengager

Déversoir

Démarreur

électrique

Démarrage

du moteur

Moteur en

marche

Moteur à

l’arrêt

Déflecteur

1742237

18

GAUCHE

DROIT

HAUT

BAS

Page 19

fr

1742237

19

Page 20

fr

1742237

20

Page 21

RÈGLES D’UTILISATION DANS DES CONDITIONS DE SÉCURITÉ

AVERTISSEMENT : La machine est capable d’amputer des mains ou des pieds et de rejeter des objets. Lisez

ces consignes de sécurité et suivez−les à la lettre. Un manquement à ces consignes pourrait entraîner une

perte de contrôle de la machine, de sérieuses blessures ou même la mort, ou causer des dégâts matériels.

Le triangle situé dans le texte indique un danger ou une mise en garde qui doit être respecté.

Conditions d’utilisation en toute sécurité d’une souffleuse à neige

IMPORTANT : Les normes de sécurité impliquent la présence de

l’opérateur aux commandes afin de minimiser les risques de

blessure. Votre souffleuse à neige est équipée de ces

commandes. En aucun cas, vous ne devez essayer de contourner

la présence de l’opérateur aux commandes.

Formation

1. Lisez, comprenez, et suivez toutes les consignes sur la machine et

dans le manuel avant d’utiliser cette machine. Familiarisez−vous

complètement avec les commandes et l’utilisation appropriée de cet

équipement. Sachez comment débrayer les commandes et arrêter la

machine rapidement.

2. Ne laissez jamais les enfants utiliser la machine. Ne laissez jamais les

adultes utiliser la machine sans rappeler les consignes de sécurité.

3. Tenez les personnes, et en particulier les petits enfants et les animaux

à l’écart de la zone de traitement.

4. Agissez avec prudence afin d’éviter de glisser ou de tomber en

particulier lorsque vous reculez.

Préparation

1. Inspectez complètement la zone de traitement et enlevez les

paillassons, les luges, les planches, les câbles et tous les autres objets

étrangers à l’équipement.

2. Débrayez tous les embrayages et mettez au point mort avant de

démarrer la machine (moteur).

3. N’utilisez jamais l’équipement sans porter une tenue d’hiver

appropriée. Portez des bottes qui résistent aux surfaces glissantes.

Evitez de porter des vêtements larges qui pourraient se prendre dans

des pièces mobiles.

4. Manipulez l’essence avec précaution, elle est hautement inflammable.

a. Utilisez un récipient à essence homologué.

b. N’ajoutez jamais d’essence dans un moteur chaud ou en marche.

c. Remplissez le réservoir d’essence avec une extrême précaution à

l’extérieur. Ne remplissez jamais le réservoir d’essence à

l’intérieur. Revissez le bouchon du réservoir à fond et essuyez

l’essence répandue.

d. Ne remplissez jamais des récipients à l’intérieur d’un véhicule,

d’un camion ou d’une remorque avec une bâche en plastique.

Placez toujours les récipients sur le sol, loin des véhicules, avant

de les remplir.

e. Si cela est plus pratique, enlevez les appareils fonctionnant à

l’essence du camion ou de la remorque et remplissez−les à même

le sol. Si ce n’est pas possible, alors remplissez avec un récipient

portable plutôt qu’à partir du gicleur du distributeur de carburant.

f. Maintenez le gicleur en contact avec le bord du réservoir de

carburant ou l’ouverture du récipient jusqu’à ce que le remplissage

soit complet. N’utilisez pas un outil de fermeture/ouverture de

gicleur.

g. Revissez le bouchon du réservoir à fond et essuyez l’essence

répandue.

h. Si de l’essence s’est répandue sur les vêtements, changez−les

immédiatement.

5. Utilisez des rallonges et des récipients tel qu’indiqué par le fabricant

pour toutes les machines ayant des moteurs à fonctionnement ou à

propulsion électrique.

6. Règlez la hauteur du carter du collecteur pour enlever les graviers ou

les surfaces pierreuses accidentées.

7. N’essayez jamais de faire des réglages pendant que le moteur marche

(sauf si cela est recommandé par le fabricant).

8. Réglez le moteur et la souffleuse selon la température extérieure avant

de commencer à enlever la neige.

9. Portez toujours des lunettes de sécurité ou un masque de protection

pendant la manoeuvre de la machine ou pendant son réglage ou sa

réparation afin de protéger les yeux contre des objets étrangers qui

pourraient être rejetés par la machine.

10.N’utilisez jamais la souffleuse sans plaques de protection ou sans

autres appareils de sécurité appropriés.

Fonctionnement

1. Ne mettez pas les mains ou les pieds sous les pièces mobiles de la

machine. Maintenez toujours la chute propre.

2. Agissez avec une extrême prudence lorsque vous utilisez la machine

ou que vous traversez des routes ou des chemins recouverts de

graviers. Restez vigilant à l’égard du trafic et des dangers cachés.

3. Si vous rencontrez un objet étranger, arrêtez le moteur, retirez le cordon

relié aux moteurs électriques, inspectez complètement la souffleuse

pour vérifier qu’il n’y a pas de dommages et réparez les dommages

avant de redémarrer et de manoeuvrer la souffleuse.

4. Si la machine vibre anormalement, arrêtez le moteur et cherchez−en

immédiatement la cause. Les vibrations sont généralement

l’expression d’un problème.

5. Arrêtez le moteur lorsque vous quittez votre poste avant de

désencrasser le collecteur/rotor ou la chute, et lorsque vous effectuez

des réparations.

6. Lorsque vous nettoyez, réparez ou inspectez, assurez−vous que le

collecteur/rotor et toutes les autres pièces mobiles sont arrêtés.

Débranchez le câble de la bougie d’allumage et tenez−le à l’écart de la

bougie d’allumage afin d’empêcher un démarrage accidentel.

7. N’utilisez pas la machine à l’intérieur d’un bâtiment sauf pour la

démarrer et pour la rentrer ou la sortir. Ouvrez les portes extérieures;

les émanations des gaz de combustion sont dangereuses (contiennent

du MONOXYDE DE CARBONE, un gaz INODORE et MORTEL).

8. Agissez avec une extrême précaution lorsque vous traitez les talus.

N’essayez pas de nettoyer les talus abrupts.

9. N’utilisez jamais la souffleuse sans plaques de protection ou sans

autres appareils de sécurité appropriés.

10.N’orientez jamais la chute en direction des personnes ou des zones où

des biens matériels pourraient être endommagés. Maintenez les

enfants à l’écart.

11.Ne dépassez pas les capacités de la machine en essayant d’enlever la

neige trop rapidement.

12.Ne manoeuvrez jamais la machine à des vitesses élevées sur des

surfaces glissantes. Regardez derrière vous et faites attention lorsque

vous reculez.

13.Débranchez l’alimentation du collecteur/rotor lorsque la souffleuse est

transportée ou non utilisée.

14.N’utilisez que les appareils et les accessoires recommandés par le

fabricant de la souffleuse (tels que cabine, chaînes à pneus, etc.).

15.N’utilisez jamais

éclairage. Faites toujours attention où vous mettez les pieds et tenez

fermement les poignées de commande. Marchez, mais ne courez

jamais.

fr

la souffleuse sans avoir une bonne visibilité ou un bon

1742237

21

Page 22

16.Ne touchez jamais à un moteur chaud ou à un silencieux.

17.N’utilisez jamais la souffleuse près de portes−vitrées, d’automobiles, de

fenêtres, de précipices et sans un réglage approprié de l’angle de

décharge de la chute de la neige.

18.N’orientez jamais la chute vers des personnes présentes ou ne laissez

jamais personne se mettre devant la machine.

19.Ne laissez jamais une machine en marche sans surveillance. Débrayez

toujours les commandes de traction et de vis transporteuse, arrêtez le

moteur et enlevez les clés.

20.N’utilisez pas la machine sous l’emprise de l’alcool ou de la drogue.

21.N’oubliez pas que vous êtes responsable des accidents qui

surviennent à d’autres personnes ou à des biens matériels.

22.Les statistiques indiquent que les utilisateurs agés de 60 ans et plus

sont impliqués pour une large part dans les accidents d’équipements

électriques. Ces utilisateurs doivent évaluer leur capacité à utiliser

cette machine en toute sécurité afin de se protéger eux−mêmes ainsi

que les autres contre d’éventuelles blessures.

23.NE portez PAS de longues écharpes ou de vêtements larges qui

pourraient être pris dans des pièces mobiles.

24. La neige peut cacher des obstacles. Assurez−vous que vous avez bien

enlevé tous les obstacles de la zone de traitement.

Enfants

Des accidents tragiques peuvent survenir si l’utilisateur n’est pas alerté par

la présence d’enfants. Les enfants sont souvent attirés par la souffleuse et

l’activité de soufflage de la neige. N’oubliez pas que les enfants restent là

où vous les avez vu en dernier.

1. Maintenez les enfants en dehors de la zone de traitement et sous la

surveillance d’un autre adulte responsable.

2. Soyez vigilant et éteignez la machine si des enfants entrent dans la

zone de traitement.

3. Ne laissez jamais les enfants utiliser la machine.

4. Soyez extrêmement vigilant lorsque vous vous approchez de coins

invisibles, d’arbustes, d’arbres ou d’autres objets qui pourraient vous

obscurcir la vue.

Nettoyage d’une chute encrassée

fr

2. Ne rangez jamais la machine avec de l’essence dans le réservoir dans

un bâtiment où il existe des sources d’inflammation tels que les

chaudières et les chauffe−eau, ou les sèche−linges. Laissez la

machine refroidir avant de la ranger dans un endroit clos.

3. Référez−vous toujours au manuel utilisateur pour les détails importants

si la souffleuse doit être stockée dans un endroit clos pendant une plus

longue période.

4. Conservez ou remplacez les étiquettes des consignes de sécurité si

nécessaire.

5. Laissez la machine tourner pendant quelques minutes après le

soufflage de la neige afin d’empêcher que le collecteur/rotor ne gèle.

6. Si de l’essence s’est répandue, n’essayez pas de démarrer la machine

mais déplacez−la de la zone et éviter de créer une source

d’inflammation jusqu’à ce que les vapeurs d’essence se soient

dissipées.

7. Respectez toujours les règles de sécurité pour le remplissage et la