Page 1

1738207

en

Not for

Reproduction

Operator’s Manual

de

fi

it

no

sv

Bedienungsanleitung

Käyttäjän käsikirja

Manuale dell’Operatore

Brukerhåndbok

Instruktionsbok

Walkbehind Snowthrower

Mfg. No. Description

1695691 Dual Stage Snowthrower, 11.50 TP, 27 Inch (68,6 cm)

1

Revision E

09/2009

Page 2

Not for

Reproduction

2

Page 3

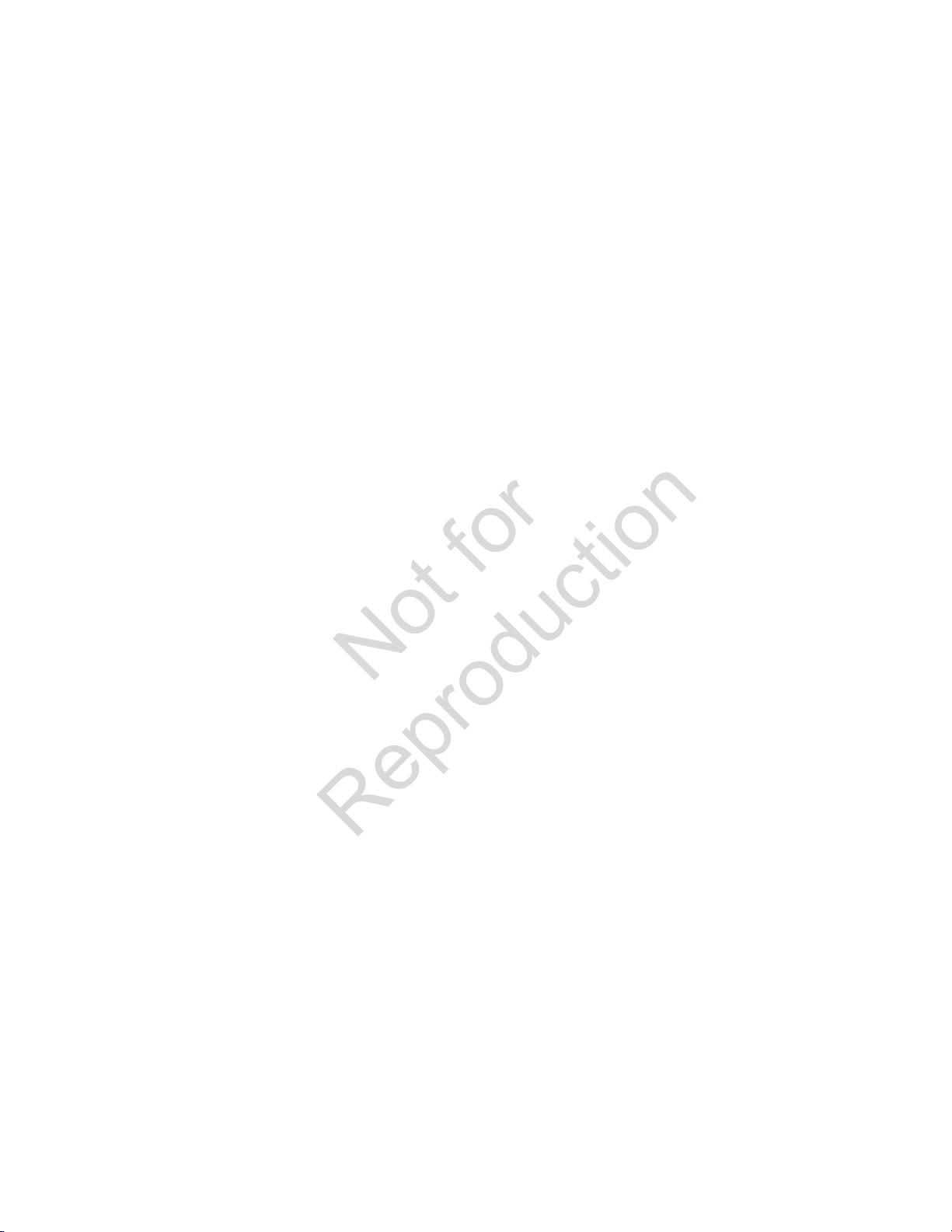

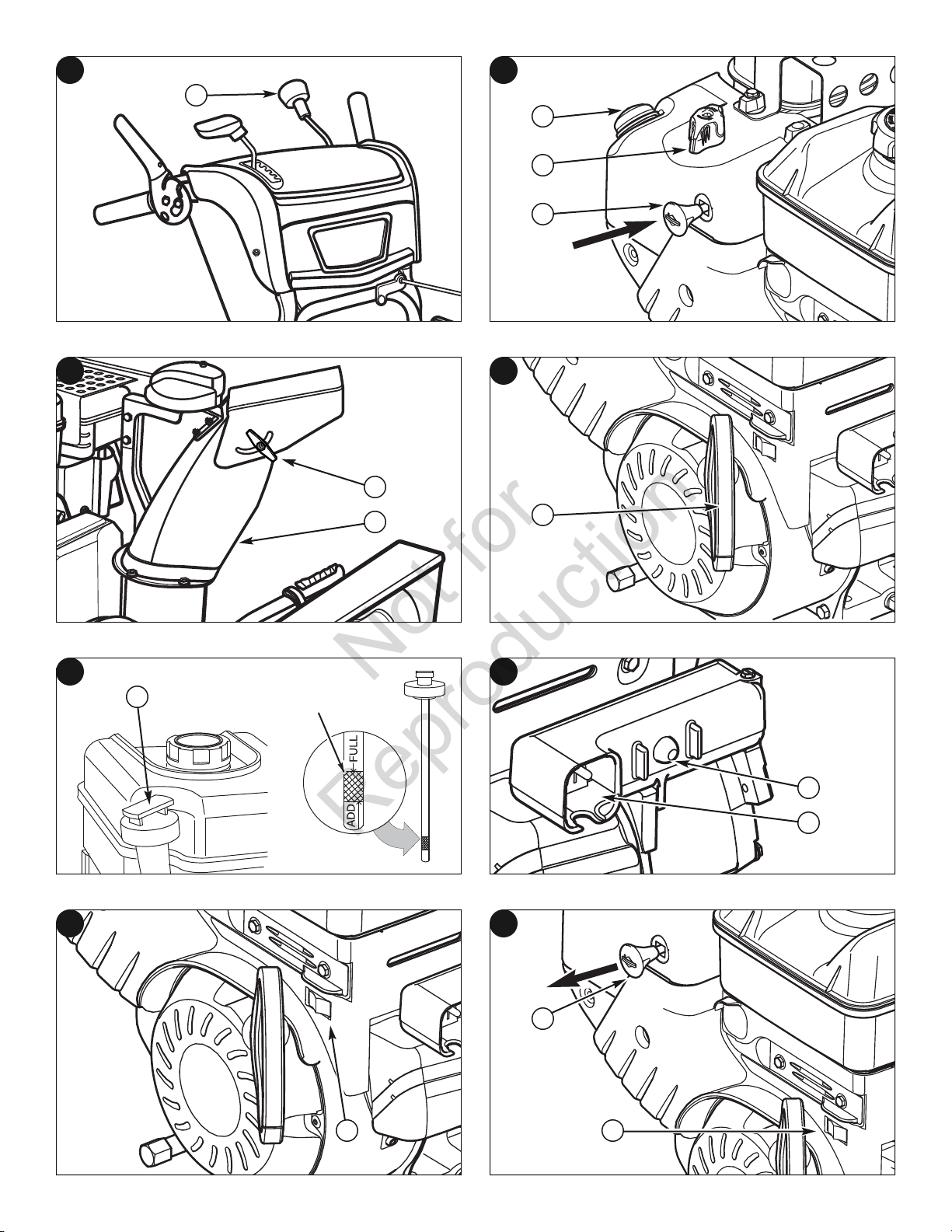

1

Not for

Reproduction

See Page 15.

5

2

3

A B

B

A

B

C

6

C

B

4

E

A

D

C

A

3

Page 4

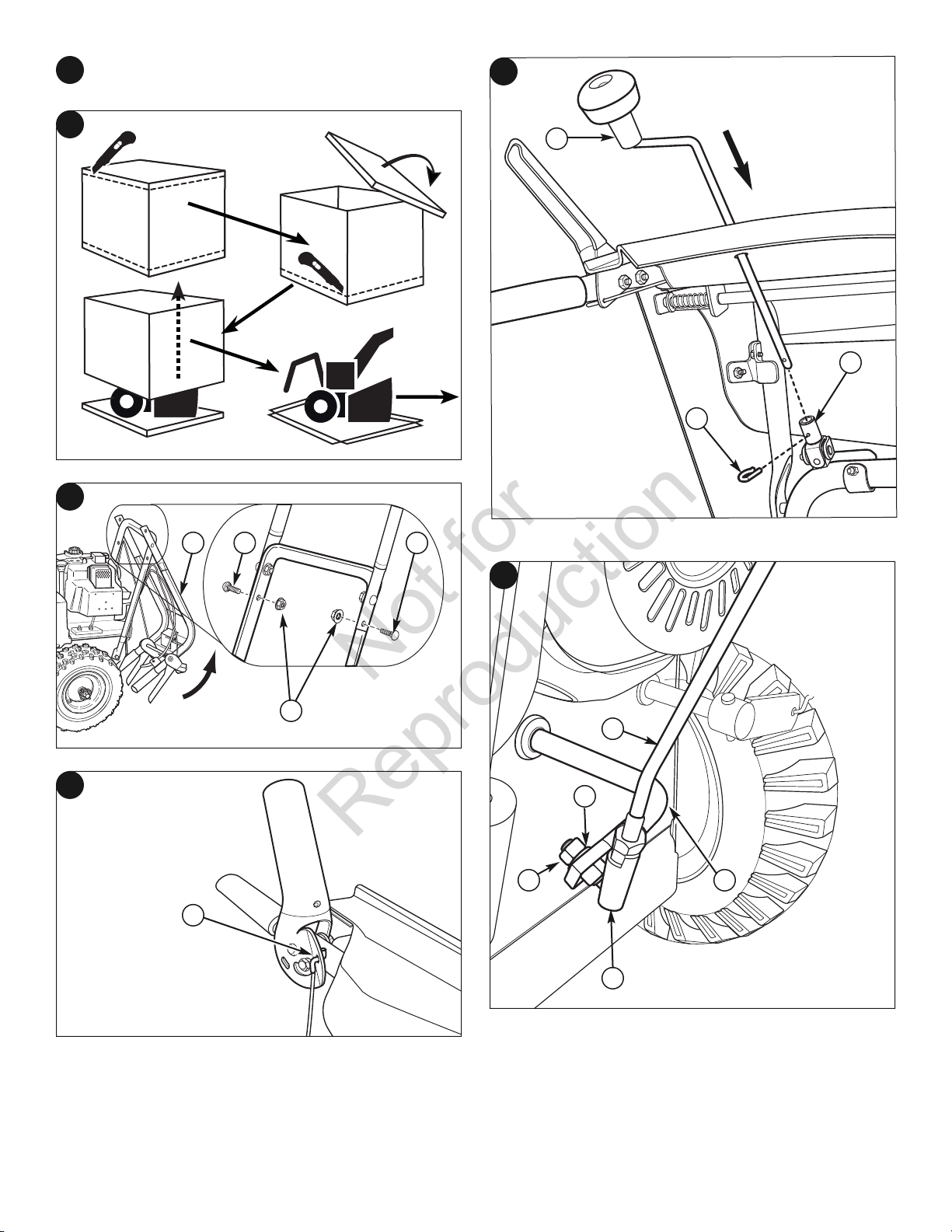

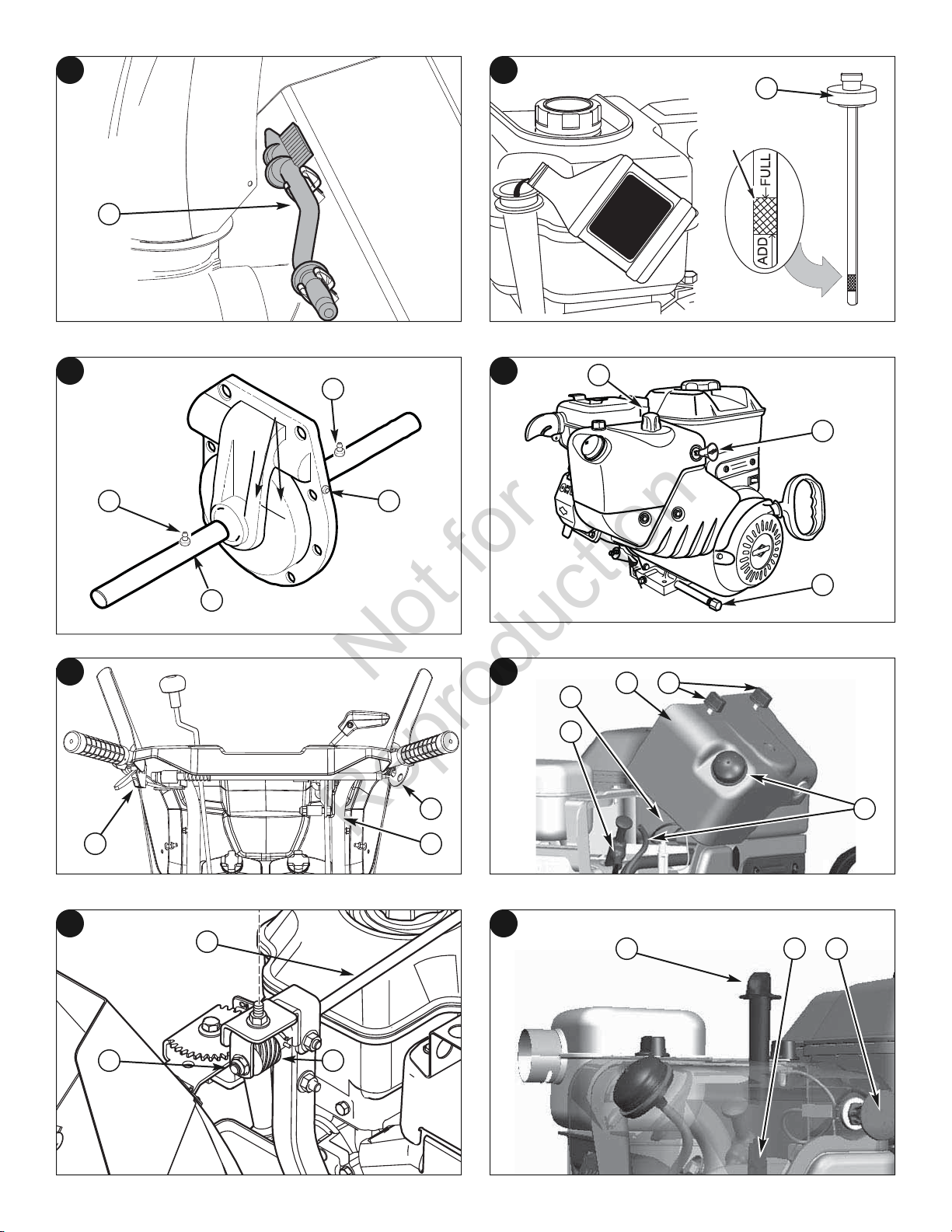

7

Not for

Reproduction

10 11

12

See Pages 18 and 19.

A D

C

A

8

A

D

C

B

13

D

A

B

B

9

B

A

4

Page 5

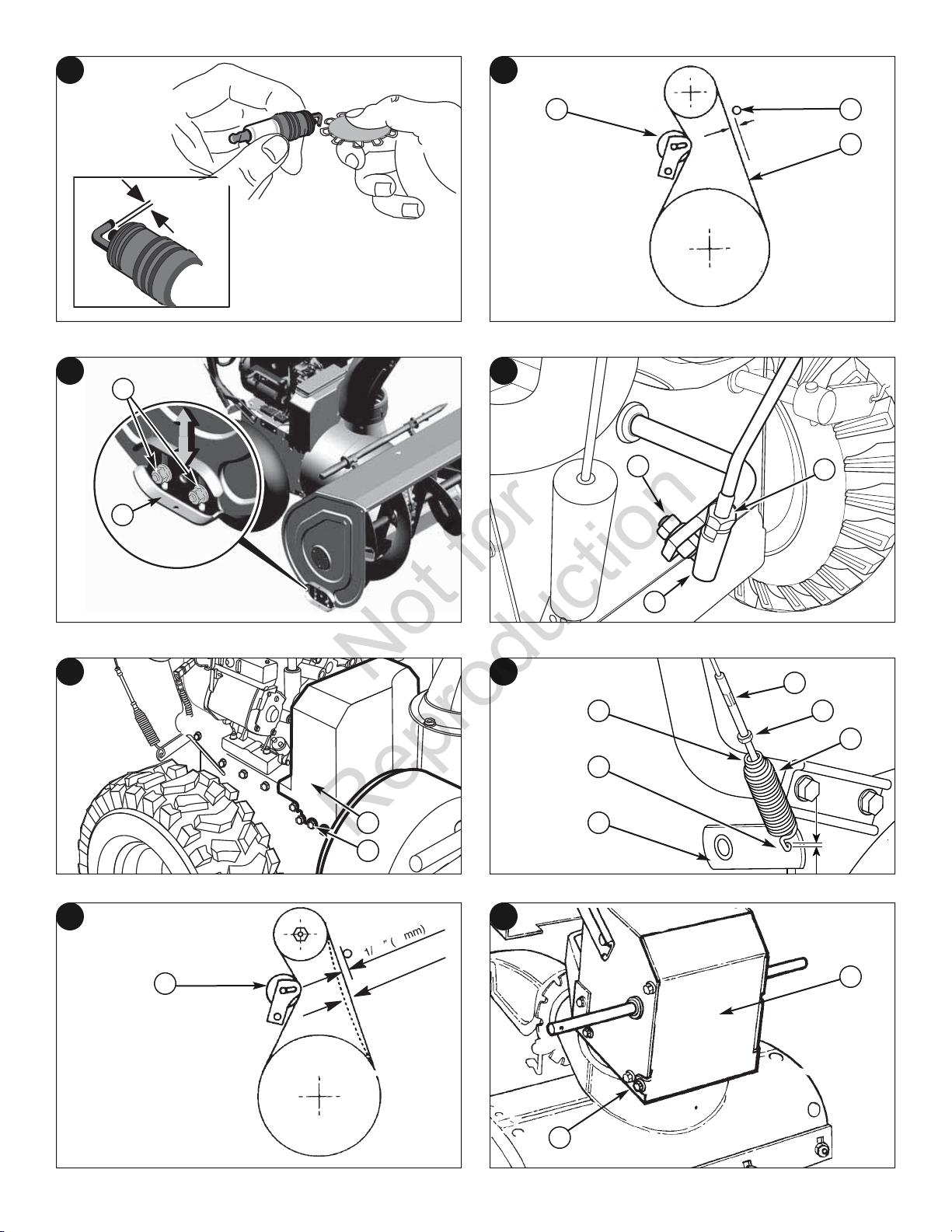

14

FULL

Not for

Reproduction

18

A

C

B

A

15

16

19

A

B

A

A

20

A

B

17

21

B

A

A

5

Page 6

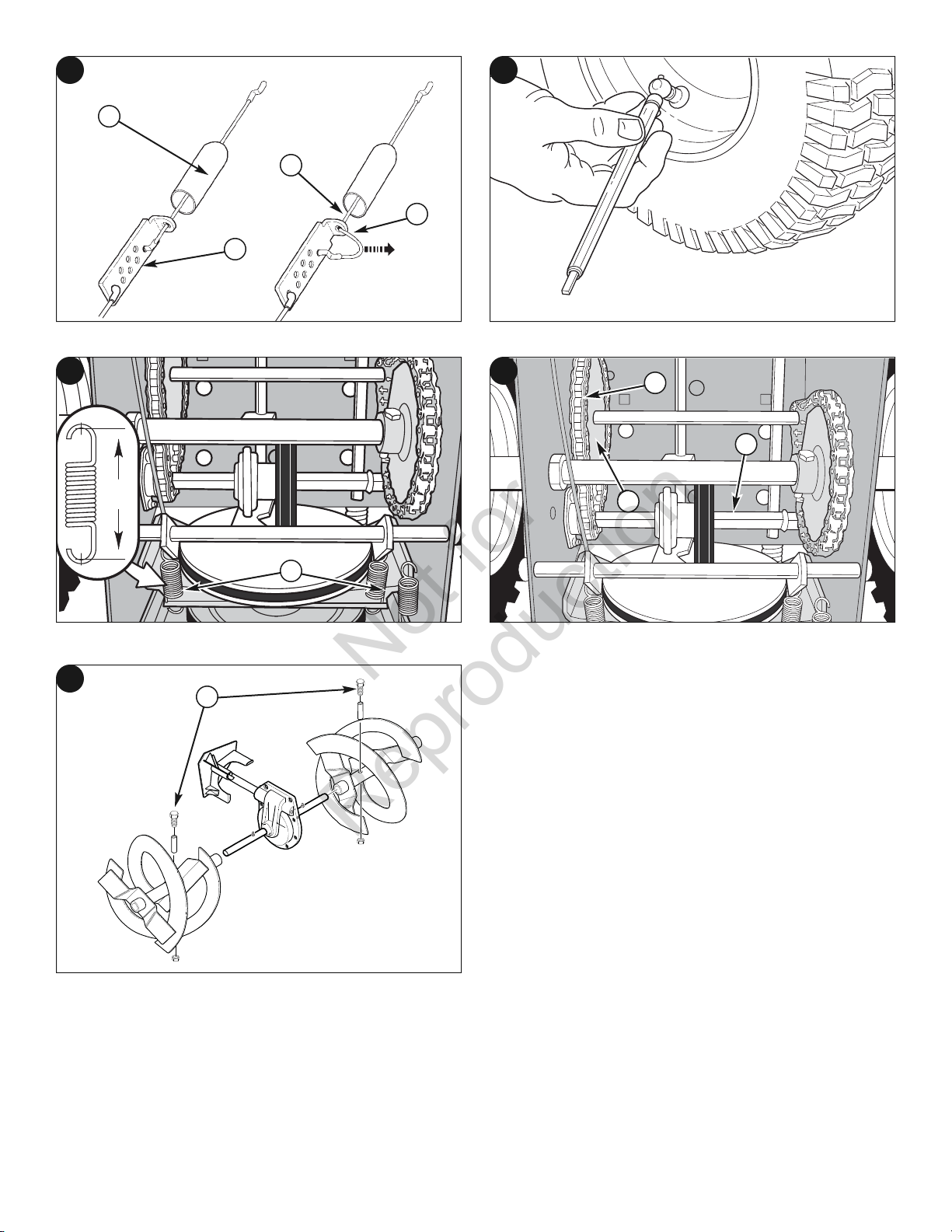

22

E

D

Not for

Reproduction

26

A

Full

A

23

24

27

B

B

C

A

28

C

B

C

A

B

A

C

6

25

A

B

C

A

B

29

A

B C

Page 7

1/2” (12.5mm)

Deflection

8

3

.030 in.

(.76 mm)

30

1/32”

(0.8mm)

Screw

B

C

Not for

Reproduction

34

31

A B

1/8” (3mm)

C

35

A

B

A

32

33

B

A

A

36

37

D

E

A

B

C

F

B

A

7

Page 8

38

“A”

A

B

C

Not for

Reproduction

41

A

C

D

B

39

40

42

A

A

8

Page 9

CONTENTS

Not for

Reproduction

Illustrations ...........................................................................................3

Operator Safety......................................................................................10

Assembly.............................................................................................16

Features and Controls..............................................................................17

Operation.............................................................................................19

Maintenance.........................................................................................23

Storage ...............................................................................................28

Troubleshooting .....................................................................................29

Warranty .............................................................................................31

Specifications .......................................................................................32

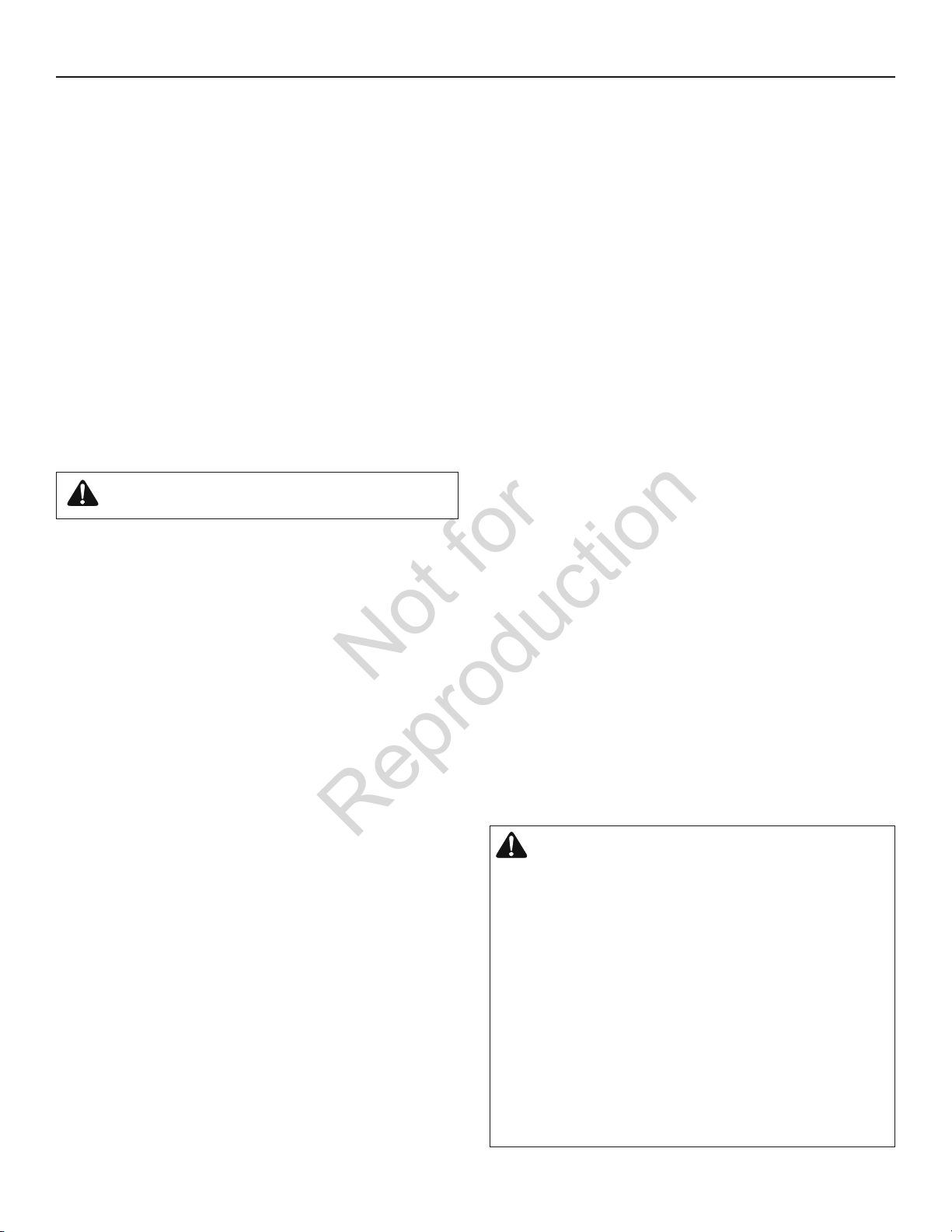

General Information

Thank you for purchasing this quality-built Murray snowthrower. We’re pleased that you’ve placed your confidence in the Murray brand.

When operated and maintained according to the instructions in this manual, your Murray product will provide many years of

dependable service.

This manual contains safety information to make you aware of the hazards and risks associated with snowthrowers and how to avoid

them. This snowthrower is designed and intended only for snow throwing and is not intended for any other purpose. It is important that

you read and understand these instructions throughly before attempting to start or operate this equipment. This snowthrower requires

final assembly before use. Refer to the Assembly section for instructions on final assembly procedures. Follow the instructions

completely. Save these instructions for future reference.

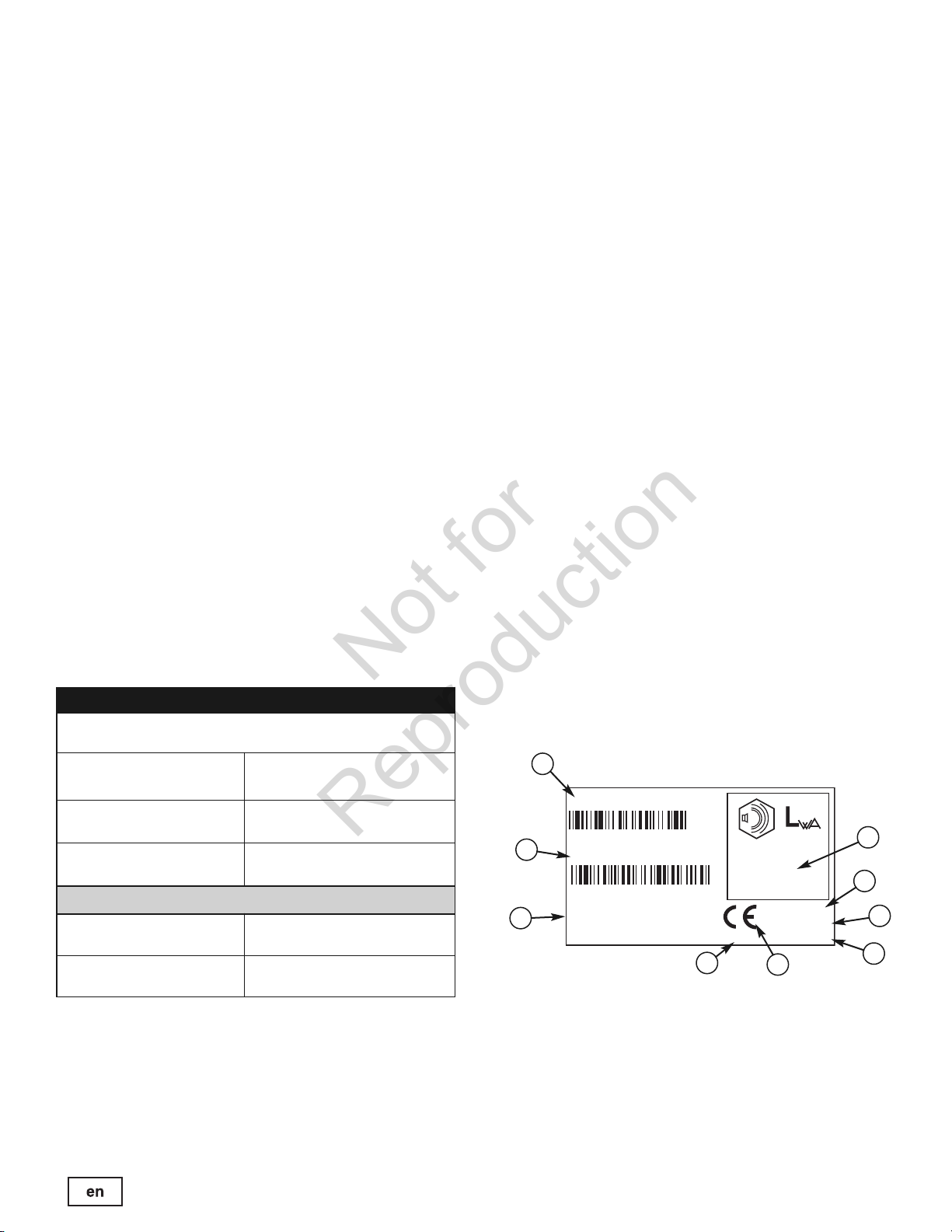

Product Reference Data

Record your model name/number, manufacturer’s identification

numbers, and engine serial numbers in the space provided for

easy access. These numbers can be found in the locations

shown.

When contacting your authorized dealer for replacement

parts, service, or information you MUST have these numbers.

PRODUCT REFERENCE DATA

Model Description Name/Number

Unit MFG Number Unit SERIAL Number

Mower Deck MFG Number Mower Deck SERIAL Number

Dealer Name Date Purchased

ENGINE REFERENCE DATA

Engine Make Engine Model

Engine Type/Spec Engine Code/Serial Number

CE Identification Tag

A. Manufacturer’s Identification Number

B. Manufacturer’s Serial Number

C. Power Rating in Kilowatts

D. Maximum Engine Speed in Rotations per Minute

E. Manufacturer’s Name and Address

F. Year of Manufacture

G. CE Compliance Logo

H. Mass of Unit in Kilograms

I. Guaranteed Sound Power in Decibels

A

Part No. xxxxxxx

B

E

xxxxxxxxxxxxxxx

Serial No. xxxxxxxxxx

xxxxxxxxxxxxxxxxxxxxxxx

xxxxxxxxxxxxxxxxxxxxxxx

xxxxxxxxxxxxxxxxxxxxxxx

xxxxxxxxxxxxxxxxxxxxxxx

xxx dB

20xx

F

kg: xxx

kW: x.xx

xxxx max

G

I

H

C

D

The Illustrated Parts List for this machine can be downloaded from www.simplicitymfg.com. Please provide model and serial number

when ordering replacement parts.

Copyright © 2009 Briggs & Stratton Power Products Group, LLC

Milwaukee, WI, All rights reserved.

SIMPLICITY is a trademark of Briggs & Stratton Power Products

Group, LLC Milwaukee, WI USA.

9

Page 10

OPERATOR SAFETY

Not for

Reproduction

DANGER - Amputation Hazard

The discharge chute contains a rotating

impeller to throw snow. Never clear or unclog

the discharge chute with your hands. Fingers

can quickly become caught and traumatic

amputation or severe laceration will result.

Always use a clean-out tool to clear or unclog

the discharge chute.

DANGER

• Hand contact with the rotating impeller inside the discharge

chute is the most common cause of injury associated with

snow throwers.

• This snow thrower is capable of amputating hands and feet,

and throwing objects. Read and observe all the safety

instructions in this manual. Failure to do so will result in

death or serious injury.

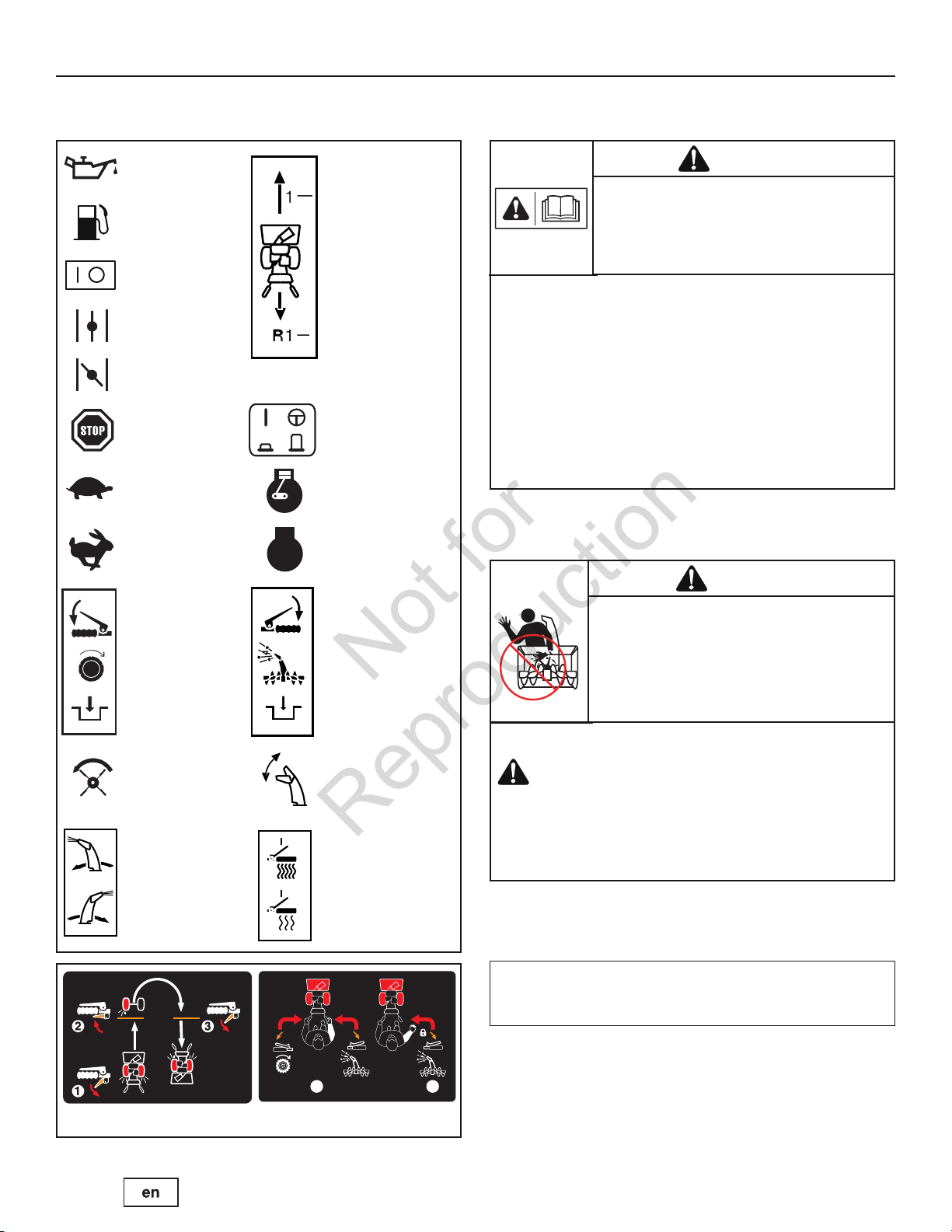

Safety Alert Symbol and Signal Words

The safety alert symbol and signal word (DANGER,

WARNING, CAUTION, or NOTICE) is used to indicate the

likelihood and potential severity of personal injury and/or damage

to the product. In addition, a hazard symbol may be used to

represent the type of hazard.

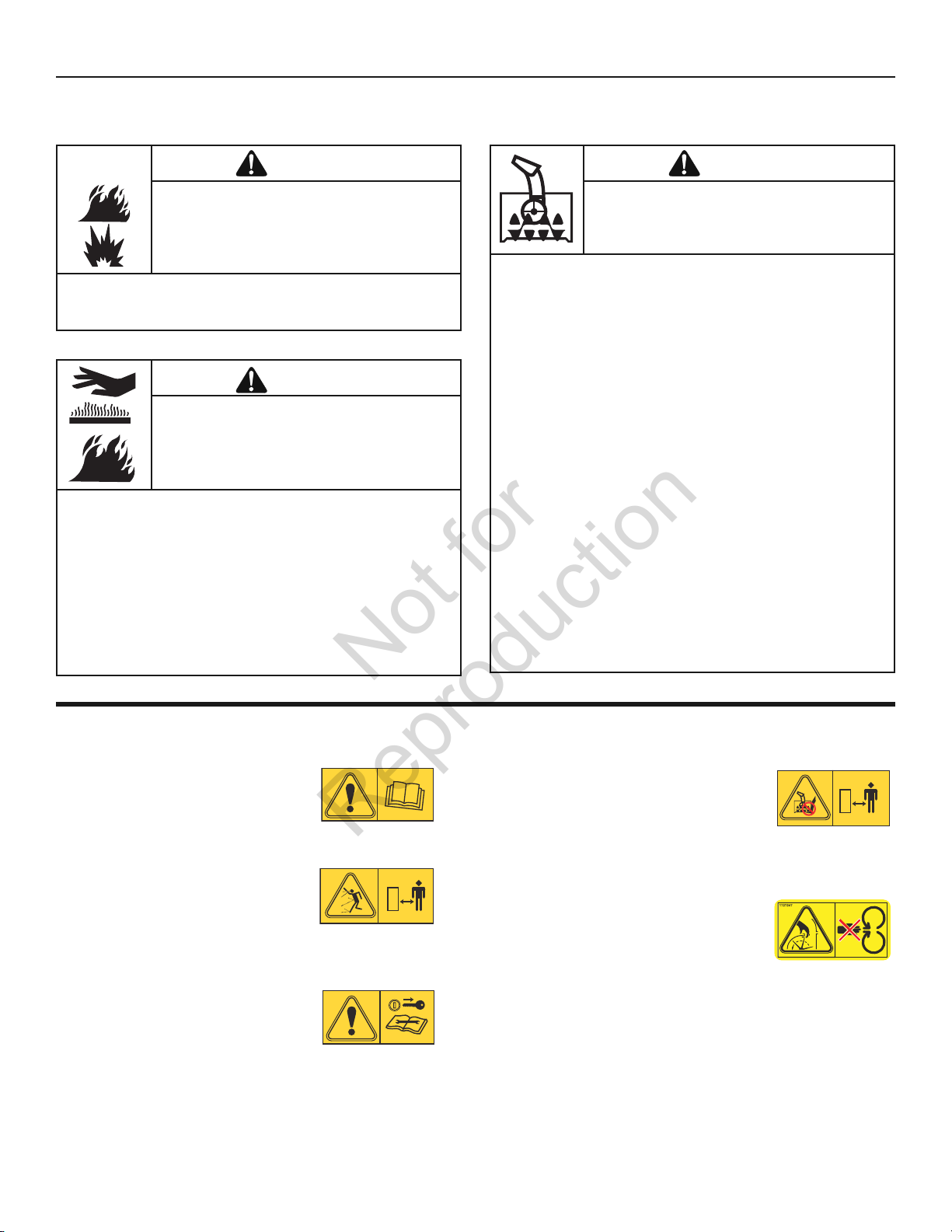

Hazard Symbols and Meanings

Safety Alert – Identifies safety information about

hazards that can result in personal injury.

Operator’s Manual – Read and understand before

performing any activity or running snow thrower.

Rotating Impeller

Rotating Auger Rotating Gears

Never Reach into

Rotating Parts

Fire Explosion

Shock Toxic Fumes

Keep a Safe

Distance from

Snow Thrower

Thrown Objects

DANGER indicates a hazard which, if not avoided, will

result in death or serious injury.

WARNING indicates a hazard which, if not avoided, could

result in death or serious injury.

CAUTION indicates a hazard which, if not avoided, could

result in minor or moderate injury.

NOTICE indicates a situation that could result in damage

to the product.

WARNING

U.S.A. Models: Certain components in this product and its

related accessories contain chemicals known to the state of

California to cause cancer, birth defects, or other

reproductive harm. Wash hands after handling.

Recommended Ear

Hot Surface

Shut off engine and remove spark plug connector

before performing maintenance or repair work.

Protection for

Extended Use

WARNING

U.S.A. Models: The engine exhaust from this product contains

chemicals known to the State of California to cause cancer,

birth defects, or other reproductive harm.

10 www.murray.com

Page 11

1

2

Free-HandTMControlEasy-TurnTMTraction Control

Read, understand, and follow all the instructions on the

snow thrower and in the operator’s manual before operating

this unit.

Failure to observe the safet y instructions in this manual

will result in death or serious injury.

DANGER: Hand contact with the rotating impeller inside the discharge

chute is the most common cause of injury associated with snow

throwers. Never use your hands to clean out the discharge chute.

Discharge chute contains rotating impeller to throw snow.

Never clear or unclog the discharge chute with your hands.

Fingers can quickly become caught in the impeller. Always

use a clean-out tool.

Failure to observe these safety instructions will result in

traumatic amputation or severe laceration.

OPERATOR SAFETY

Not for

Reproduction

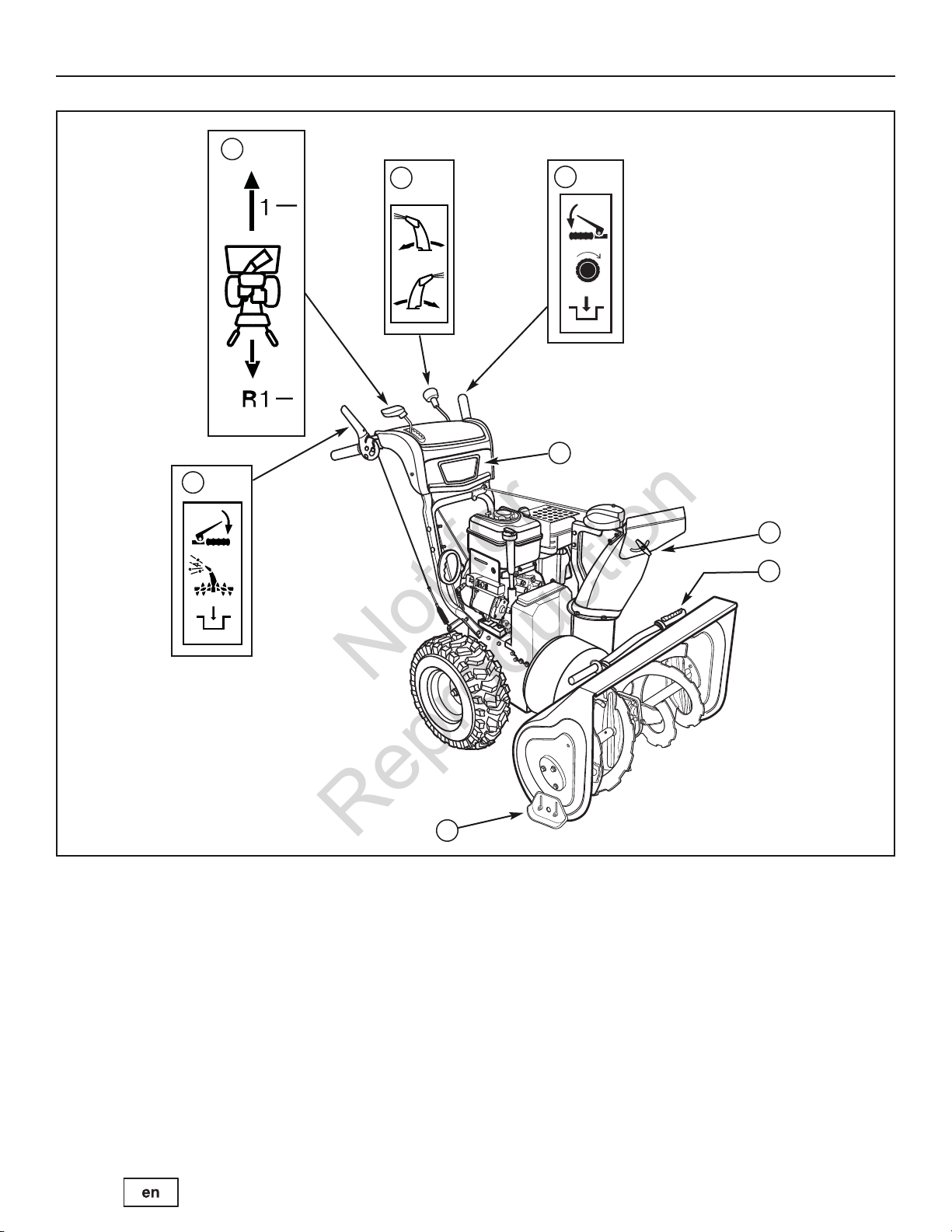

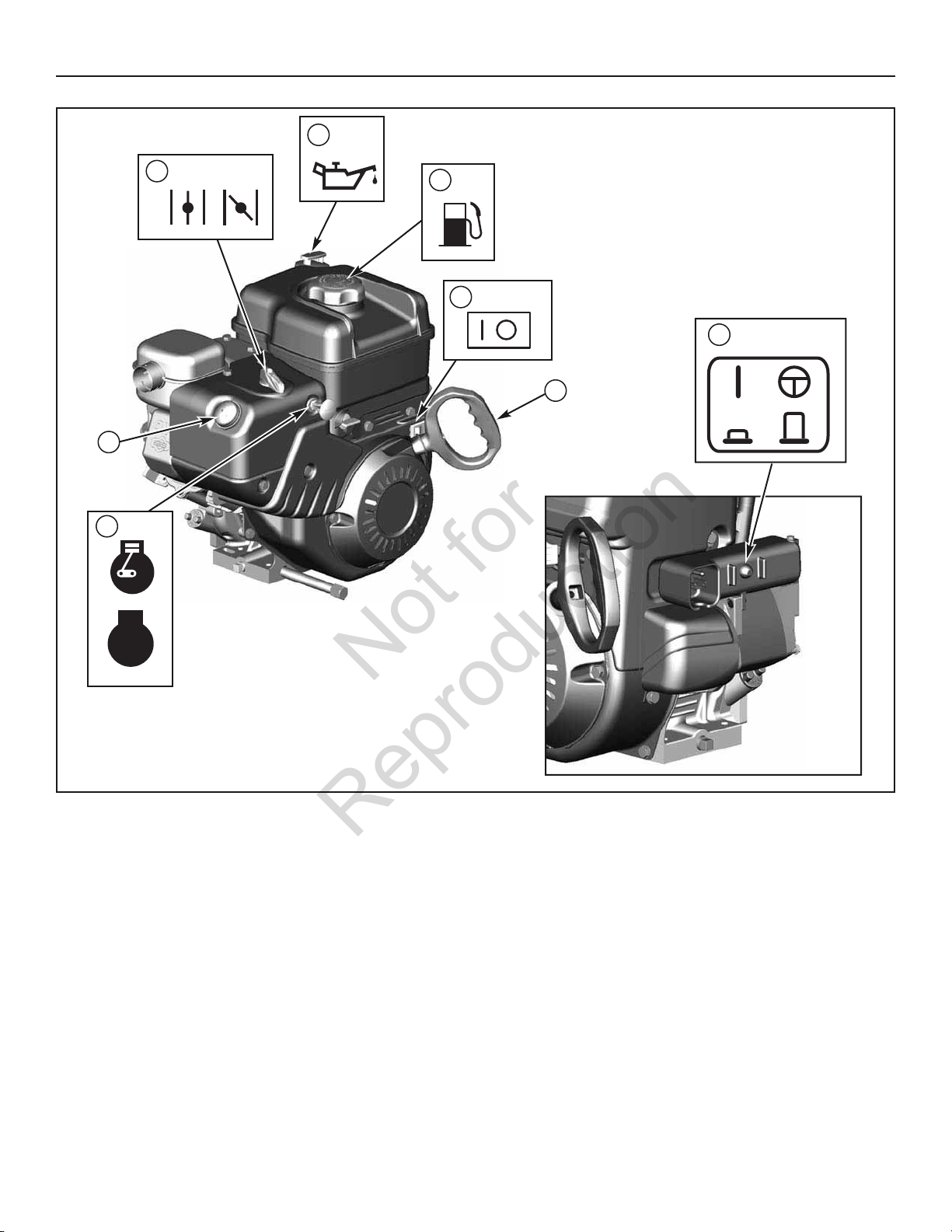

Control Symbols on Equipment

Oil

Fuel Forward

On Off Neutral

Choke Off Reverse

Choke On

Stop

Slow Engine - Run

Fast

STOP

Electric Start Engage (Down) &

Disengage (Up)

Engine - Stop

Read the Manual

DANGER

• Be thoroughly familiar with the controls and the proper use of the snow

thrower.

• Make sure you are properly trained before operating the snow thrower.

• Know how to stop the unit and disengage the controls quickly.

• Never allow anyone to operate the snow thrower without proper instruction.

• Always follow the instructions in the operator’s manual, if the snow thrower

will be stored for an extende d period.

• Maintain or replace safety and instruction labels as necessary.

• Never attempt to make major repairs on the snow thrower unless you have

been properly trained. Improper servicing of the snow thrower can result in

hazardous operation, equipment damage, and voiding of the product

warranty.

Discharge Chute

Traction Control Engage (Down)

Auger Clutch

Discharge Chute

(Left and Right)

Auger Control Engage (Down)

Chute Deflector

(Up and Down)

Heated Hand Grips

(High and Low)

DANGER

TO SAFELY CLEAR A CLOGGED DISCHARGE CHUTE

FOLLOW THESE INSTRUCTIONS:

1. Shut OFF the engine.

2. Wait 10 seconds to be sure the impeller blades have stopped rotating.

3. Always use a clean-out tool, not your hands.

NOTE: Not all control symbols shown on this page will appear

on your snow thrower. See FEATURES AND CONTROLS section

for the applicable symbols.

11

Page 12

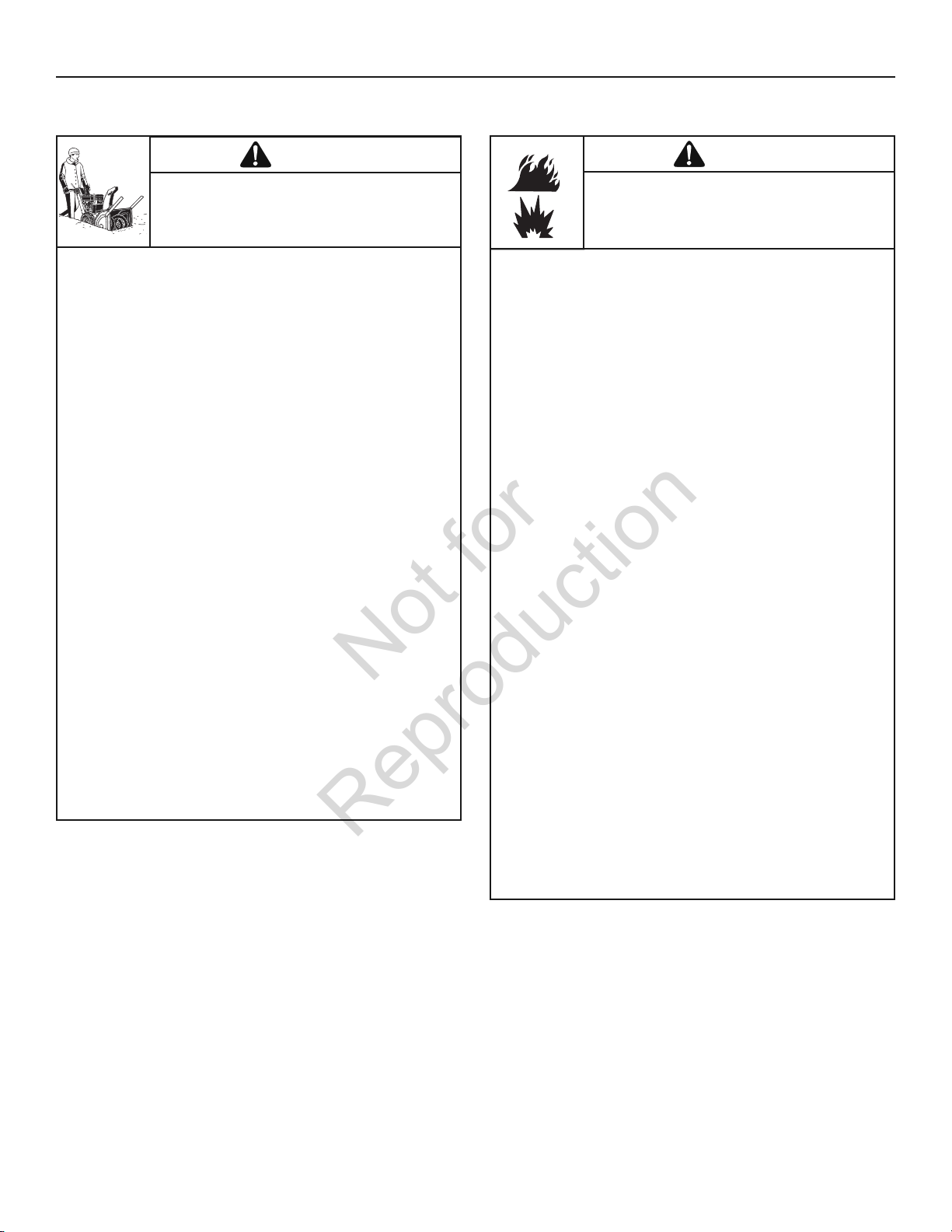

Fuel and its vapors are extremely flammable and explosive.

Always handle fuel with extreme care.

Failure to observe these safety instructions can cause a fire

or explosion which will result in severe burns or death.

This snow thrower is only as safe as the operator. If it is

misused, or not properly maintained, it can be dangerous.

Remember you are responsible for your safety and that of

those around you.

OPERATOR SAFETY

Not for

Reproduction

Operation and Equipment Safety

DANGER

• Keep the area of operation clear of all persons, particularly small children

and pets.

• Thoroughly inspect the area where the snow thrower will be used and remove

all doormats, sleds, boards, wires, and other foreign objects.

• Do not operate the snow thrower without wearing adequate winter clothing.

• Wear footwear that will improve footing on slippery surfaces.

• Use caution to avoid slipping or falling especially when operating the snow

thrower in reverse.

• Never operate the snow thrower without good visibility or light. Always be

sure of your footing, and keep a firm hold on the handles.

• Do not clear snow across the face of slopes. Use extreme caution when

changing direction on slopes. Do not attempt to clear steep slopes.

• Do not overload the machine capacity by attempting to clear snow too

quickly.

• Never operate the snow thrower at high transport speeds on slippery

surfaces. Look behind the snow thrower and use care when operating in

reverse.

• Do not use the snow thrower on surfaces above ground level such as roofs of

residences, garages, porches, or other such structures or buildings.

• Operators should evaluate their ability to operate the snow thrower safely

enough to protect themselves and others from injury.

• The snow thrower is intended to remove snow only. Do not use the snow

thrower for any other purpose.

• Do not carry passengers.

• After striking a foreign object, shut OFF the engine, disconnect the cord on

electric motors, thoroughly inspect the snow thrower for any damage, and

repair the damage before restarting and operating the snow thrower.

• If the snow thrower vibrates abnormally, shut OFF the engine. Vibration is

generally a warning of trouble. See an authorized dealer if necessary for

repairs.

• For models equipped with electric starting motors, disconnect the power cord

after the engine starts.

Fuel Handling

DANGER

WHEN ADDING FUEL

• Turn off engine and let cool at least 2 minutes before removing the fuel cap

and adding fuel.

• Fill fuel tank outdoors or in a well ventilated area.

• Do not overfill the fuel tank. To allow for the expansion of gasoline, do not fill

above the bottom of the fuel tank neck.

• Keep fuel away from sparks, open flames, pilot lights, heat, and other ignition

sources.

• Check fuel lines, cap, and fittings frequently for cracks or leaks. Replace if

necessary.

• Use an approved fuel container.

• If fuel spills, wait until it evaporates before starting engine.

WHEN STARTING ENGINE

• Ensure that spark plug, muffler, fuel cap, and air cleaner (if equipped) are in

place and secured.

• Do not crank the engine with the spark plug removed.

• If fuel is spilled, do not attempt to start the engine, but move the snow

thrower away from the area of the spill, and avoid creating any source of

ignition, until the fuel vapors have dissipated.

• Do not over-prime the engine. Follow the engine starting instructions in this

manual.

• If the engine floods, set choke (if equipped) to OPEN/RUN position, move

throttle (if equipped) to FAST position and crank until engine starts.

WHEN OPERATING EQUIPMENT

• Do not tip the snow thrower at an angle which causes the fuel to spill.

• Do not choke the carburetor to stop the engine.

• Never run the engine with the air cleaner assembly (if equipped) or the air

filter (if equipped) removed.

WHEN CHANGING OIL

• If you drain the oil from the top oil fill tube, the fuel tank must be empty or

fuel can leak out and result in a fire or explosion.

WHEN TRANSPORTING EQUIPMENT

• Transport with fuel tank EMPTY, or with fuel shut-off valve OFF.

WHEN STORING GASOLINE OR EQUIPMENT WITH FUEL IN TANK

• Store away from furnaces, stoves, water heaters, or other appliances that

have pilot light or other ignition source because they can ignite fuel vapors.

12 www.murray.com

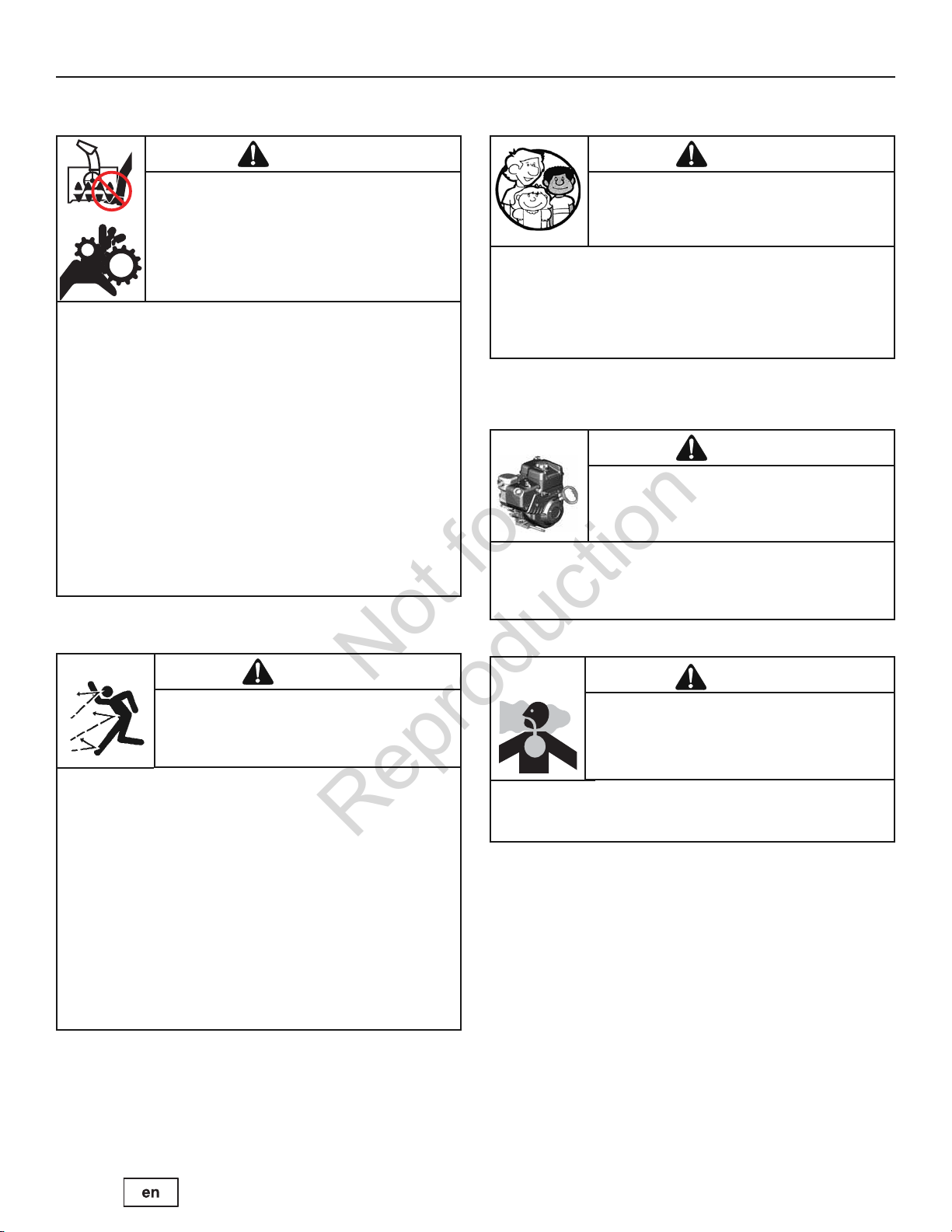

Page 13

Tragic accidents can occur if the operator is not alert to the

presence of children. Children are often attracted to the unit

and the operating activity. Never assume that children will

remain where you last saw them.

Engines give off carbon monoxide, an odorless, colorless,

poison gas.

Breathing carbon monoxide can cause nausea, fainting, or

death.

Safe operation of the snow thrower requires the proper care

and maintenance of the engine. Failure to observe the safety

instructions in this manual will result in death or serious

injury.

Objects can be picked up by auger and thrown from chute.

Never discharge snow toward bystanders or allow anyone in

front of the snow thrower. Failure to observe these safety

instructions will result in death or serious injury.

Keep hands, feet, and clothing away from rotating parts.

Rotating parts can contact or entangle hands, feet, hair,

clothing, or accessories.

Failure to observe these safety instructions will result in

traumatic amputation or severe laceration.

OPERATOR SAFETY

Not for

Reproduction

Moving Parts

DANGER

• Whenever cleaning, repairing, or inspecting the snow thrower, make sure the

engine is OFF, spark plug wire is disconnected, and all moving parts have

stopped.

• Do not put hands or feet near or under rotating parts. Keep clear of the

discharge opening at all times.

• Never operate the snow thrower without proper guards, and other safety

devices in place and working.

• Never leave the snow thrower unattended while engine is running. Always

disengage the auger and traction controls, stop engine, and remove keys.

• Keep all loose clothing away from the front of the snow thrower and auger.

Scarves, mittens, dangling drawstrings, loose clothes, and pants can quickly

become caught in the rotating device and amputation will occur. Tie up long

hair and remove jewelry.

• Run the machine a few minutes after discharging snow to prevent freeze-up

of the collector/impeller.

• Disengage power to the collector/impeller when snow thrower is transported

or not in use.

Thrown Objects

Children

DANGER

• Keep children out of the area during operation. Children are often attracted to

the equipment. Be mindful of all persons present.

• Be alert and turn unit off if children enter the area.

• Never allow children to operate the unit.

• Use extra care when approaching blind corners, shrubs, trees, or other

objects that may obscure vision. Children may be present.

Engine Safety

DANGER

• Disengage all clutches and shift into neutral before starting the engine.

• Let the engine adjust to outdoor temperatures before starting to clear snow.

• Use a grounded three-wire plug-in for all snow throwers equipped with

electric drive motors or electric starting motors.

DANGER

• Always wear safety glasses or eye shields while during operation, and while

performing an adjustment or repair.

• Always be aware of the direction the snow is being thrown. Nearby

pedestrians, pets, or property may be harmed by objects being thrown.

• Be aware of your environment while operating the snow thrower. Running

over items such as, gravel, doormats, newspapers, toys, and rocks hidden

under snow, can all be thrown from the chute or jam in the auger.

• Use extreme caution when operating on or crossing gravel drives, walks, or

roads.

• Adjust the collector housing height to clear gravel or crushed rock surface.

• Never operate the snow thrower near glass enclosures, automobiles, window

wells, drop-offs, and the like without proper adjustment of the discharge

chute angle.

• Familiarize yourself with the area in which you plan to operate the

snowthrower. Mark off boundaries of walkways and driveways.

DANGER

• Start and run engine outdoors.

• Do not run the engine in an enclosed area, even if doors or windows are

open.

13

Page 14

This snow thrower must be properly maintained to ensure

safe operation and performance. Failure to observe the safety

instructions in this manual could result in death or serious

injury.

Starting engine creates sparking.

Sparking can ignite nearby flammable gases.

Explosion and fire could result.

U.S.A. Models:

Running the engine produces heat. Engine parts, especially

muffler, become extremely hot.

Failure to observe these safety instructions could result in

severe thermal burns on contact.

OPERATOR SAFETY

Not for

Reproduction

Engine Safety (Continued)

WARNING

-

• If there is natural or LP gas leakage in area, do not start engine.

• Do not use pressurized starting fluids because vapors are flammable.

WARNING

• Never touch a hot engine or muffler. Allow muffler, engine cylinder, and fins

to cool before touching.

• Remove debris from muffler area and cylinder area.

• Install and maintain in working order a spark arrester before using equipment

on forest-covered, grass-covered, or brush-covered unimproved land.

•U

4442 to use or operate the engine on or near any forest-covered, brushcovered, or grass-covered land unless the exhaust system is equipped with a

spark arrester meeting any applicable local or state laws. Other states or

federal areas may have similar laws.

It is a violation of California Public Resource Code Section

Maintenance and Storage

WARNING

• When performing any maintenance or repairs on the snow thrower, shut OFF

the engine, disconnect spark plug wire, and keep the wire away from the plug

to prevent someone from accidently starting the engine.

• Check shear bolts and other hardware at frequent intervals for proper

tightness to be sure the snow thrower is in safe working condition.

• Keep nuts and bolts tight and keep snow thrower in good condition.

• Never tamper with safety devices. Check their proper operation regularly and

make necessary repairs if they are not functioning properly.

• Components are subject to wear, damage, and deterioration. Frequently

check components and replace with recommended parts, when necessary.

• Check control operation frequently. Adjust and service as required.

• Use only factory authorized replacement parts when making repairs.

• Always comply with factory specifications on all settings and adjustments.

• Only authorized service locations should be utilized for major service and

repair requirements.

• Use only attachments and accessories approved by the factory (such as

wheel weights, counterweights, or cabs).

• Never attempt to make any adjustments while the engine is running (except

when specifically recommended by the factory).

• Do not allow grease or oil to contact the rubber friction wheel or the disc

drive plate. If the disc drive plate or friction wheel come in contact with

grease or oil damage to rubber friction wheel will result.

SAFETY ICONS

DANGER: READ OPERATOR’S

MANUAL.

Read the Operator’s Manual for

operating and safety instructions.

DANGER: THROWN OBJECTS

HAZARD.

Never direct discharge chute

towards persons or property. Keep

bystanders away.

DANGER: REMOVE KEY BEFORE

SERVICING.

Shut off engine and remove key

before performing maintenance or

repair work.

DANGER: AMPUTATION HAZARD.

Contact with auger will cause

serious injury. Keep hands, feet, and

clothing away. Keep bystanders

away.

DANGER: AMPUTATION HAZARD.

Contact with moving parts inside

chute will cause serious injury. Shut

off engine before unclogging

discharge chute. Use clean-out tool,

not hands!

14 www.murray.com

Page 15

OPERATOR SAFETY

Not for

Reproduction

Look for this symbol to indicate important safety

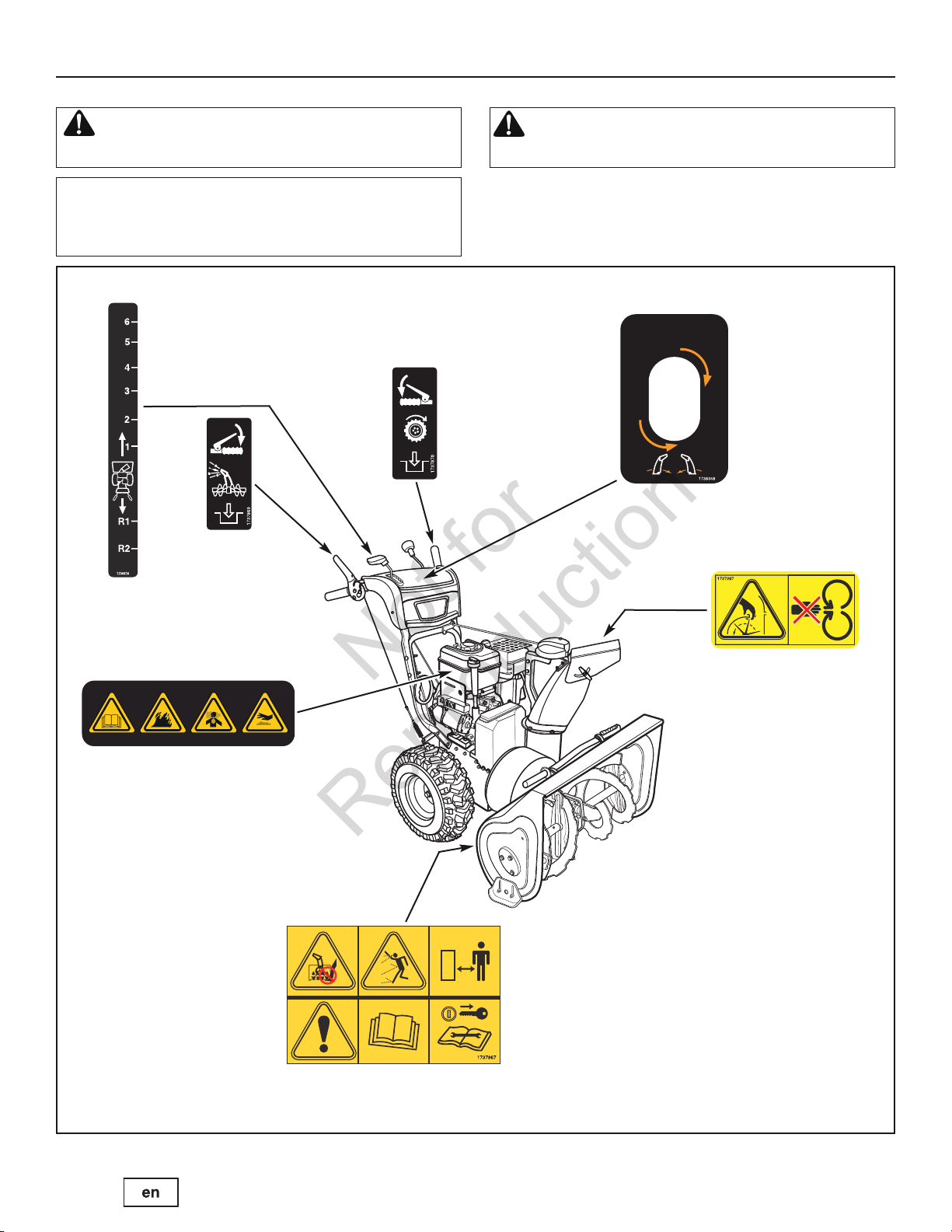

precautions. This symbol indicates: “Attention!

Become Alert! Your Safety Is At Risk.”

Before operating your snow thrower, read the safety decals as

shown on your snow thrower. The cautions and warnings are

for your safety. To avoid a personal injury or damage to your

snow thrower, understand and follow all the safety decals.

Part No. 1736616

Shift Decal

Part No. 1737869

Auger Control Decal

Part No. 1737870

Traction Control Decal

WARNING: If any safety decals become worn or

damaged and cannot be read, order replacement decals

from your local dealer.

Part No. 1738348

Main Dash Decal

Engine Warning Icons

Part No. 276925

Product ID Number &

Serial Number Decal

(Rear of Motor Box)

Part No. 1737867

Auger Control Icons

Part No. 1727207

Chute Control Icons

Safety Decals Figure 1

15

Page 16

ASSEMBLY

B

B

B

Not for

Reproduction

TOOLS REQUIRED FOR ASSEMBLY

1 – Knife

2 – 1/2" Wrenches (or adjustable wrenches)

1 – 7/16” Wrenches (or adjustable wrenches)

1 – Wrench (or adjustable wrench)

1 – Pair pliers or screw driver (to spread cotter pin)

1 – Hammer

1 – Pry Bar

PARTS BAG CONTENTS

1 – Shear Bolt Kit, 1/4-20 x 1-3/4 in.

1 – Bag of Shear Bolts

1 – Screw, 1/4-20 x 1-3/4 in.

1 – Spacer, Sleeve, 1/4 in.

1 – Hex Locknut, 1/4-20

1 – Fresh Fuel Packet

NOTE: “Right” and “Left” are from the Operating Position.

WARNING: Always wear safety glasses or eye shields

when assembling the snow thrower.

UNPACK THE SNOW THROWER

1. Using knife, cut along the dotted lines around the top of the carton.

Then remove top of carton as shown in Figure 2.

2. Using knife, cut along the dotted lines around the bottom of the

carton.

3. Push snow thrower off the bottom of the carton to proceed with

assembly.

ASSEMBLE THE HANDLES

1. Raise the upper handle (AA, Figure 3) to the operating position.

2. Guide speed control rod over wheel.

3. Remove blue shipping tape from cables and cut orange zip ties that

secure control cables to handle assembly and chute rotation parts.

INSTALL THE SPEED CONTROL ROD

Attach the ball joint (AA, Figure 6), located on the bottom end of the speed

control rod (B

and 5/16" nut (EE).

), to the shift yoke assembly (CC) with 5/16" lock washer (DD)

CHECK CABLE CONNECTION AND ADJUSTMENT

The traction control cable (AA, Figure 7) and auger control cable (BB) are

adjusted at the factory and no adjustment should be necessary.

If the cables become stretched, unattached or begin to sag, adjustment

will be necessary. See MAINTENANCE section of this manual.

INSTALL THE DISCHARGE CHUTE

1. Place discharge chute (AA, Figure 8) over tabs on chute ring (BB) as

shown.

2. Secure discharge chute with three carriage bolts (CC) and nuts (DD).

3. Tighten hardware to 66 in-lbs (7.6 Nm).

NOTE: Check all bolts and nuts in flange for tightness. Do not

over-tighten.

NOTE: If the chute rotation is slow or binding, loosen the

chute rotation screw 1/4 turn.

INSTALL THE DRIFT CUTTER

Drift cutters are used to cut a path through snow deeper than the auger

housing.

1. Loosen the wing nuts (AA, Figure 9) that secures the drift cutters (BB) to

the auger housing.

2. Raise the drift cutters to the desired height.

3. Tighten the wing nuts.

CHECK THE TIRES

Check tires for damage. Check the air pressure in the tires with an

accurate gauge. See the sidewall of the tire for the proper inflation.

NOTE: Make sure the “Z bend ends of the control lever cables

are secured in the holes on the control levers (A, Figure 4).

Be careful not to cut or damage the control cables. Make sure

the cables are not caught between the upper and lower

handle.

4. Slide two carriage bolts (B

two 5/16" lock nuts (CC). Tighten all four carriage bolts and nuts with a

1/2" wrench or deep socket.

, Figure 3) into lower holes and fasten with

INSTALL THE CHUTE ROTATION CRANK

1. Insert chute rotator crank rod (AA, Figure 5) through hole in dash and

subdash.

2. Align small holes before inserting end of rod into universal bushing

(B

3. Push straight side of hair pin (CC) through both small holes until it

clicks into place.

16 www.murray.com

).

CAUTION: Avoid Injury! Explosive separation of tire

and rim parts is possible when they are serviced

incorrectly.

• Do not attempt to mount a tire without the proper

equipment and experience to perform the job.

• Do not inflate the tires above the recommended

pressure.

• Do not weld or heat a wheel and tire assembly. Heat can

cause an increase in air pressure resulting in an

explosion. Welding can structurally weaken or deform

the wheel.

• Do not stand in front or over the tire assembly when

inflating. Use appropriate tool that allows you to stand

to one side.

NOTICE: Check side of tire for maximum tire pressure. DO

NOT exceed maximum.

Page 17

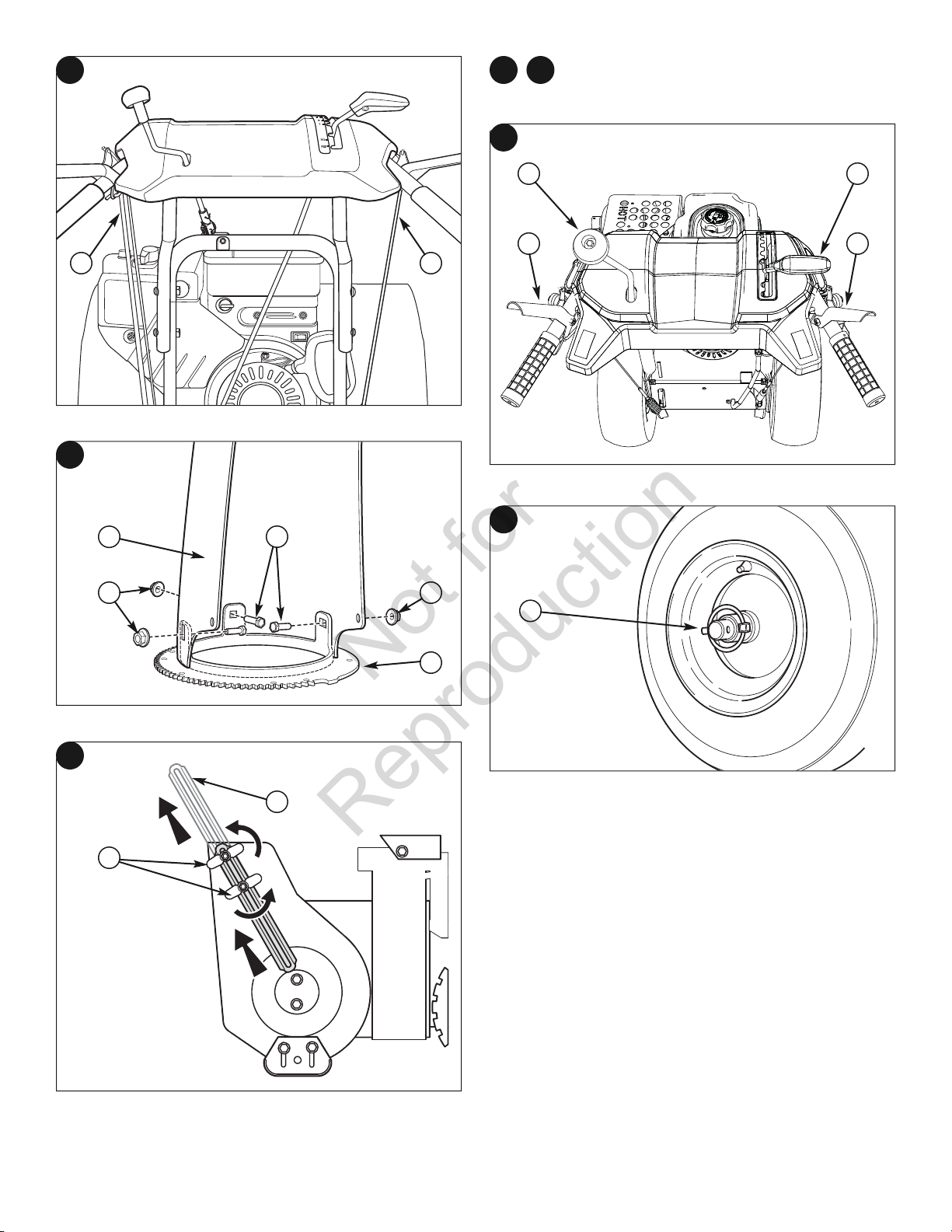

FEATURES AND CONTROLS

B

A

C

E

F

G

D

H

Not for

Reproduction

Snow Thrower Controls Figure 10

SNOW THROWER AND ENGINE CONTROLS

SNOW THROWER CONTROLS

A. Speed Select Lever — Allows the operator to use one of six (6)

forward and two (2) reverse speeds (see Figure 10). To shift, move

speed select lever to desired position.

NOTICE: Do not move speed select lever while Traction

Drive Clutch is engaged. This may result in severe damage

to drive system.

B. Auger Control Lever — Used to engage and disengage the auger

and impeller. To engage push down, to disengage release.

C. Chute Rotation Crank — Used to rotate the discharge chute to the

left or right.

D. Chute Deflector Wing Nut — Used to control the angle of the

chute deflector (up or down).

E. Traction Control Lever — Used to propel snow thrower forward or

reverse. Push down to engage, release to disengage.

F. Skid Shoe — Used to adjust ground clearance of auger housing.

G. Clean-Out Tool — Used to remove snow and debris from the

discharge chute and the auger housing.

H. Headlight — Used to operate the snow thrower in poor lighting

conditions.

17

Page 18

FEATURES AND CONTROLS

C

H

A

F

E

B

G

D

Not for

Reproduction

STOP

Engine Controls Figure 11

ENGINE CONTROLS

A. Choke Control Knob — Used to start a cold engine (see

Figure 11).

B. Electric Start Button — Used to start the engine using the electric

starter.

C. Primer Button — Used to inject fuel directly into the carburetor

manifold to ensure fast starts in cool weather.

D. Safety Key — Must be inserted to start engine. Pull out to stop. Do

not turn safety key.

E. Starter Cord Handle — Used to start the engine manually.

F. ON/OFF Switch — Used to start and stop the engine.

G. Fuel Tank and Cap — Fill the fuel tank to approximately 1-1/2 in.

(38 mm) below the top of the neck to allow for fuel expansion.

H. Oil Fill Cap (Extended Dipstick)

18 www.murray.com

Page 19

A

OPERATION

■

■

C

B,

A

A

Not for

Reproduction

BEFORE OPERATING SNOW THROWER

Check the fasteners. Make sure all fasteners are tight.

Read this OPERATOR’S MANUAL and OPERATOR SAFETY before

operating your snow thrower. Compare the illustrations with

your SNOW THROWER to familiarize yourself with the location of

various controls and adjustments. Save this manual for future

reference.

WARNING: The operation of any snow thrower can result in foreign objects being thrown into the eyes, which can result

in severe eye damage. Always wear safety glasses or eye shields before beginning snow thrower operation. We

recommend standard safety glasses or Wide Vision Safety Mask over spectacles.

OPERATE THE SNOW THROWER

CAUTION: Operation with a Snow Cab. Wind may blow

exhaust gasses back towards the operator. If you notice

the smell of exhaust, change direction of operation.

NOTICE: Do not throw snow toward a building as hidden

objects could be thrown with sufficient force to cause damage.

1. Start the engine. See “Start the Engine” in this section.

2. Turn the chute rotation crank (A

right) of the discharge chute. See “Discharge Chute and Deflector” in

this section.

3. Loosen the wing nut (A

to set angle (up or down) the snow is thrown. See “Discharge Chute

and Deflector” in this section.

, Figure 12) to set the direction (left or

, Figure 15) on the side of the discharge chute

NOTE: This snow thrower was shipped WITH OIL in the engine.

See “Before Starting Engine” instructions in the OPERATION

section of this manual before starting engine.

6. Use the speed select lever (DD) to select the forward drive speed. Set

the speed select lever to one of the following positions as determined

by snow conditions:

1-2 Wet, Heavy, Slushy, Extra Deep

3 Moderate

4-5 Very Light

6 Transport

NOTE: When clearing wet, heavy, snow, it is recommended

that the ground speed of the unit be reduced, maintained full

throttle and do not attempt to clear the full width of the unit.

7. To stop moving forward, release the traction control lever (C

8. To move the snow thrower backwards, move the speed select lever

into either first or second reverse position and engage the traction

control lever.

).

CAUTION: Before operating, make sure the area in

front of the snow thrower is clear of bystanders or

obstacles.

4. Fully press and hold the auger control lever (B

the auger rotation. Releasing the auger control lever will disengage

the auger.

5. Fully press and hold the traction control lever (CC) to engage the

traction drive and begin moving the snow thrower. To disengage the

traction drive, completely release the lever.

NOTE: Always release the traction control lever before moving

the speed select lever.

Figure 12) to engage

STOP THE SNOW THROWER

1. Release the auger control lever (BB,Figure 12).

2. Release the traction control lever (CC).

3. Push the ON/OFF switch (A

out the safety key (BB).

WARNING: Never run engine indoors or in an enclosed,

poor ventilated area. Engine exhaust contains CARBON

MONOXIDE, an ODORLESS and DEADLY GAS.

• Keep hands, feet, hair, and loose clothing away

from any moving parts on engine and snow

thrower.

• Temperature of muffler and nearby areas can

exceed 150°F (66°C). Avoid these areas.

• DO NOT allow children or young teenagers to

operate or be near snow thrower while it is

operating.

, Figure 21) to the OFF position and pull

19

Page 20

OPERATION

Not for

Reproduction

WARNING: Read Operator’s Manual before operating

machine. This machine can be dangerous if used

carelessly.

• Never operate the snow thrower without all

guards, covers, shields in place.

• Never direct discharge towards windows or allow

bystanders near machine while engine is

running.

• Stop the engine whenever leaving the operating

position.

• Disconnect spark plug before unclogging the

impeller housing or the discharge chute and

before making repairs or adjustments.

• When leaving the machine, remove the safety key.

To reduce the risk of fire, keep the machine clean

and free from spilled gas, oil, and debris.

TRACTION LOCK PINS

The right traction wheel can be completely released using the locking pin

(AA, Figure 13). This allows the unit to be easily moved with the engine off.

DISCHARGE CHUTE AND DEFLECTOR

CHECK THE OIL (BEFORE STARTING ENGINE)

NOTE: The engine was shipped from the factory filled with oil.

Check the level of the oil. Add oil as needed.

1. Make sure the unit is level. Use a high quality detergent oil classified

“For Service SF, SH, SJ, SL, or higher”.

2. Remove the oil fill cap/dipstick (AA, Figure 16) and wipe with a clean cloth.

3. Insert the oil fill cap/dipstick and turn clockwise to tighten.

4. Remove the oil fill cap/dipstick and check the oil.

NOTE: Do not check the level of the oil while the engine runs.

5. If necessary, add oil until the oil reaches the FULL mark on the oil fill

cap/dipstick. Do not add too much oil.

6. Tighten the oil fill cap/dipstick securely each time you check the oil

level.

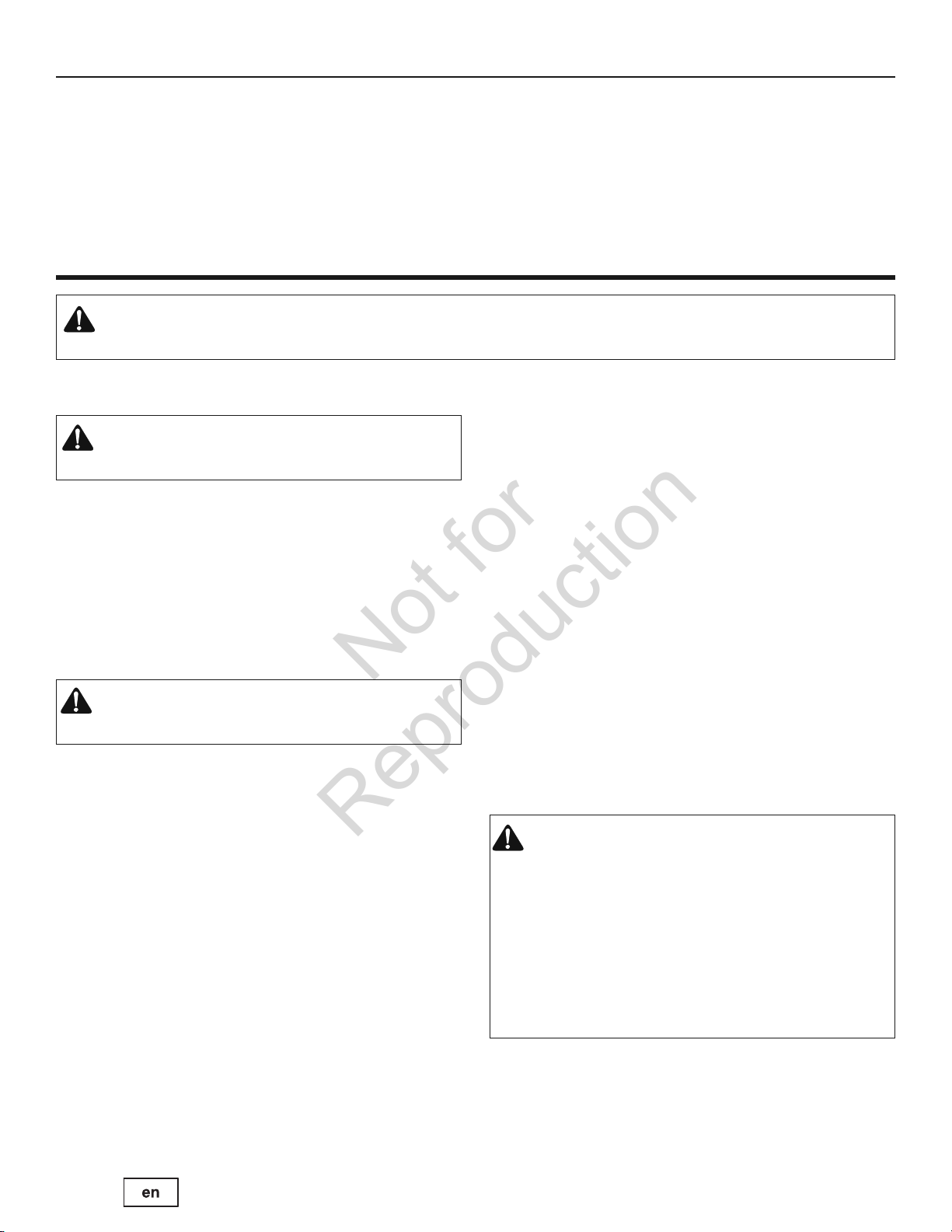

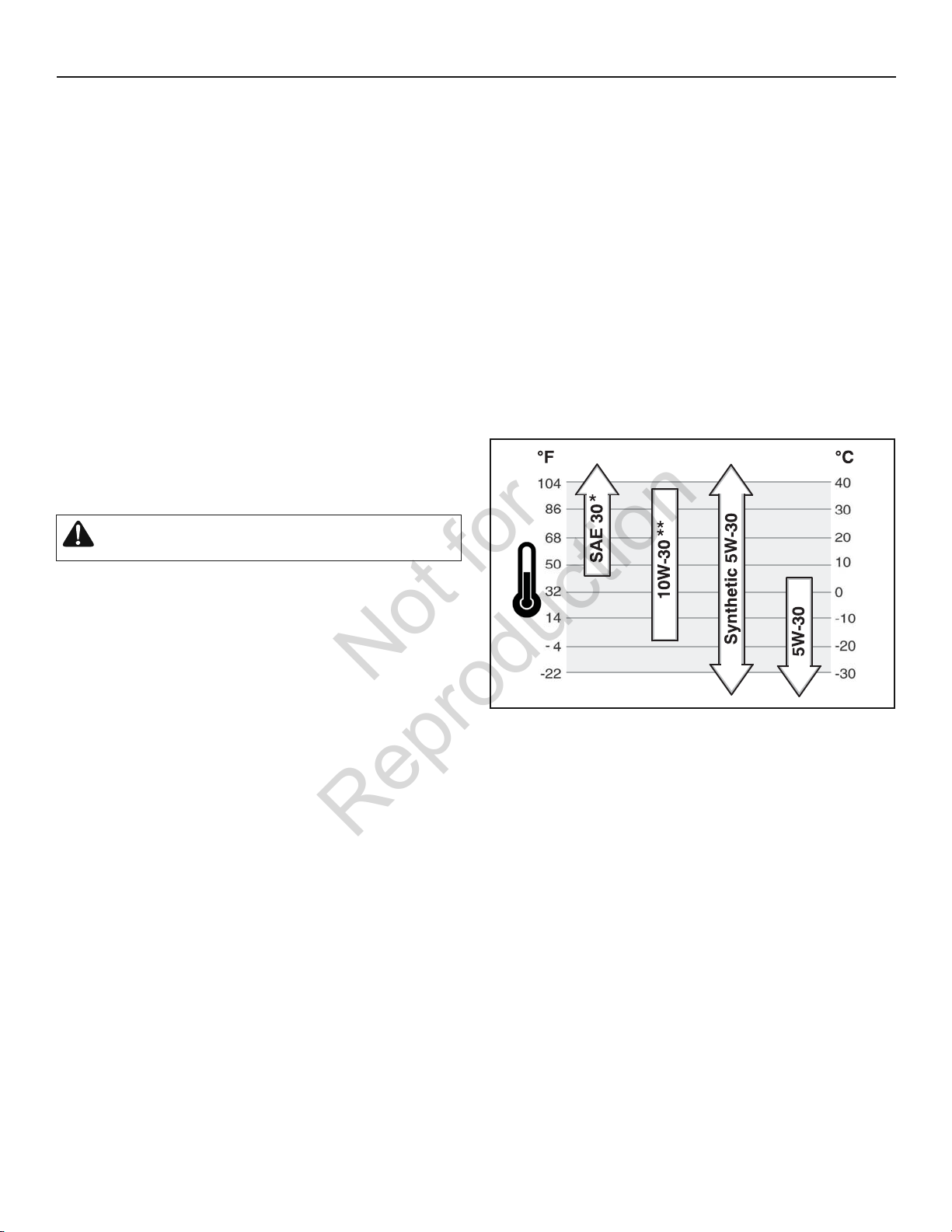

NOTE: Synthetic 5W30 motor oil is acceptable for all

temperatures. DO NOT mix oil with gasoline. See Chart for oil

recommendations.

Discharge Chute Rotation (Left/Right)

1. Turn the chute rotation crank (AA, Figure 14) clockwise to rotate the

chute to the right (see Figure 15).

2. Turn crank counterclockwise to rotate the chute to the left.

3. After the desired position is obtained, release the crank.

Chute Deflector (Up/ Down)

1. Loosen the wing nut (AA, Figure 15) on the side of the discharge chute

(BB).

2. Raise the deflector to provide a higher stream and greater distance. Or,

lower the deflector to provide a lower stream and less distance.

3. After the desired angle is obtained, tighten the wing nut.

* Below 40°F (4°C) the use of SAE 30 will result in hard starting.

** Above 80°F (27°C) the use of 10W-30 may cause increased oil consumption. Check oil

level more frequently.

20 www.murray.com

Page 21

A

C

OPERATION

DO NOT

Not for

Reproduction

FILL THE FUEL TANK

This engine is certified to operate on gasoline. Exhaust Emission Control

System: EM (Engine Modifications).

Fill the fuel tank with fresh, clean, unleaded regular, unleaded premium, or

reformulated automotive gasoline with a minimum of 85 octane along with

a fuel stabilizer (follow instructions on fuel stabilizer package). D

use leaded gasoline. We recommend that fuel stabilizer be added to the

fuel each time that gasoline is added to the fuel tank.

NOTE: Winter grade gasoline has higher volatility to improve

starting. Be certain container is clean and free from rust or

other foreign particles. Never use gasoline that may be stale

from long periods of storage in the container.

CAUTION: DO NOT use gasoline containing any

amount of alcohol as it can cause serious damage to

the engine or significantly reduce the performance.

WARNING: Gasoline is flammable. Always use

caution when handling or storing gasoline. Turn

engine off and let engine cool at least two minutes before

removing the gas cap. Do not add gasoline to the fuel tank

while snow thrower is running, hot, or when snow thrower

is in an enclosed area. Keep away from open flame,

electrical sparks and DO NOT SMOKE while filling the fuel

tank. Never fill the fuel tank completely; but fill the fuel tank

to within 1-1/2 inches (3.8 mm) from the top to provide

space for the expansion of the fuel. Always fill fuel tank

outdoors and use a funnel or spout to prevent spilling. Make

sure to wipe up any spilled fuel before starting the engine.

Store gasoline in a clean, approved container, and keep the

cap in place on the container. Keep gasoline in a cool well

ventilated place; never in the house. Never buy more than a

30 day supply of gasoline to assure volatility. Gasoline is

intended to be used as a fuel for internal combustion

engines; therefore, do not use gasoline for any other

purpose. Since many children like the smell of gasoline,

keep it out of their reach because the fumes are dangerous

to inhale, as well as being explosive.

START THE ENGINE

Be sure that engine oil is at FULL mark on the oil fill cap/dipstick. The

snow thrower engine is equipped with an A.C. electric starter and recoil

starter. Before starting the engine, be certain that you have read the

following information.

If engine floods, set the choke to the OPEN/RUN position and crank until

the engine starts.

WARNING: The electric starter is equipped with a

three−wire power cord and plug designed to operate

on AC house hold current. The power cord must be

properly grounded at all times to avoid the possibility of

electric shock which can cause injury to the operator.

Follow all instructions carefully as set forth:

Make sure your house has a three−wire grounded system.

If you are not sure, ask a licensed electrician. If your house

does not have a three−wire grounded system, do not use

this electric starter under any condition.

If your house has a three−wire grounded system but a

three-hole receptacle is not available to connect the

electric starter, have a three−hole receptacle installed by a

licensed electrician.

WARNING: To connect power cord, always connect the

power cord first to the switch box located on the

engine and then plug the other end into a three−hole

grounded receptacle.

WARNING: To disconnect the power cord, always

unplug the end connected to the three−hole grounded

receptacle first.

Start the engine as follows:

1. Check the oil level. See the “Check/Add Oil” section in the ENGINE

MANUAL.

2. Make sure equipment drive controls are disengaged.

3. Push the ON /OFF switch (A

4. Insert the safety key (AA, Figure 18) into the safety key slot and push

fully in to the RUN position.

5. Turn the choke knob (BB) fully clockwise if engine is cold.

NOTE: Do not use the choke to start a warm engine.

6. Push the primer button (C

NOTE: Do not use the primer to start a warm engine.

NOTE: Ensure that electric extension cord is removed from the

power receptacle.

, Figure 17) to the ON position.

) two times.

21

Page 22

OPERATION

A

• SHUT OFF THE ENGINE!

• Wait 10 seconds to be sure that the impeller blades have stopped

rotating.

• Always use a clean-out tool, not your hands.

Not for

Reproduction

7. Rewind Start: Firmly hold the starter cord handle (AA, Figure 19).

Pull the starter cord handle slowly until resistance is felt, then pull

rapidly.

WARNING: Rapid retraction of the starter cord (kickback)

will pull your hand and arm toward the engine faster

than you can let go. Broken bones, fractures, bruises, or

sprains could result. When starting engine, pull the

starter cord slowly until resistance is felt and then pull

rapidly to avoid kickback.

NOTE: If the engine does not start after three attempts, see the

Engine Manual Troubleshooting section.

8. Electric Start: First connect the extension cord to the power cord

receptacle and then into a wall receptacle. If additional extension

cord is required, make sure it is three-wire.

WARNING: If the extension cord is damaged, it must be

replaced by the manufacturer (or its service agent) or a

similarly qualified person to avoid a hazard.

9. Electric Start: Depress the starter push button (AA, Figure 20). After

you start the engine, first disconnect the extension cord from the wall

receptacle and then from the power cord receptacle (BB).

IMPORTANT: To extend the life of the starter, use short

starting cycles (five seconds maximum). Wait one minute

between starting cycles.

NOTE: If the engine does not start after three attempts, see the

Engine Manual Troubleshooting section.

STOP THE ENGINE

Before stopping the engine, allow it to run for a few minutes to help dry

off any moisture on the engine.

WARNING: Gasoline and vapors are extremely

flammable and explosive. Fire or explosion can

cause severe burns or death. DO NOT choke the

carburetor to stop the engine.

1. Push the ON/OFF switch (A

2. Remove the safety key (BB). Keep the safety key out of the reach of

children.

, Figure 21) to the OFF position.

CLEAR A CLOGGED DISCHARGE CHUTE

DANGER: Hand contact with the rotating impeller inside

the discharge chute is the most common cause of injury

associated with snow throwers. Never clear or unclog

discharge chute with your hands, or while engine is

running. Fingers can quickly become caught and

traumatic amputation or severe laceration can result.

A clean-out tool (AA, Figure 22) is attached to either the handle or the top

of the auger housing. Use the clean-out tool to remove snow from the

auger housing.

OPERATING TIPS

1. Most efficient snowthrowing is accomplished when snow is removed

immediately after it falls.

2. For complete snow removal, slightly overlap each swath previously

taken.

3. Snow should be discharged downwind whenever possible.

4. For normal usage, set the skids 1/8 inch (3 mm) below the scraper

bar. For extremely hard-packed snow surfaces, the skids may be

adjusted upward to ensure cleaning efficiency.

5. On gravel or crushed rock surfaces, the skids should be set at

1-1/4 inch (32 mm) below the scraper bar (see “Adjust Skid Height”

in the MAINTENANCE section of this manual). Rocks and gravel

must not be picked up and thrown by the machine.

6. After the snowthrowing job has been completed, allow the engine to

idle for a few minutes, to melt snow and ice accumulated on the

engine.

7. Clean the snow thrower thoroughly after each use.

8. Remove ice and snow accumulation and all debris from the entire

snow thrower, and flush with water (if possible) to remove all salt or

other chemicals. Wipe snow thrower dry.

9. Before starting snow thrower, always inspect augers and impeller for

ice accumulation and/or debris, which could result in snow thrower

damage.

10. Check oil level before every start. Make sure the oil is at the FULL

mark on the oil fill cap/dipstick.

NOTE: Do not lose the safety key. Keep the safety key in a safe

place. The engine will not start without the safety/ignition key.

22 www.murray.com

www.murray.com

Page 23

SAFETY

Not for

Reproduction

PROCEDURE

Check to Make Sure

Auger Blade Stops Within

5 Seconds After Right

Control Lever is Released

Lubricate Control Levers

and Linkages

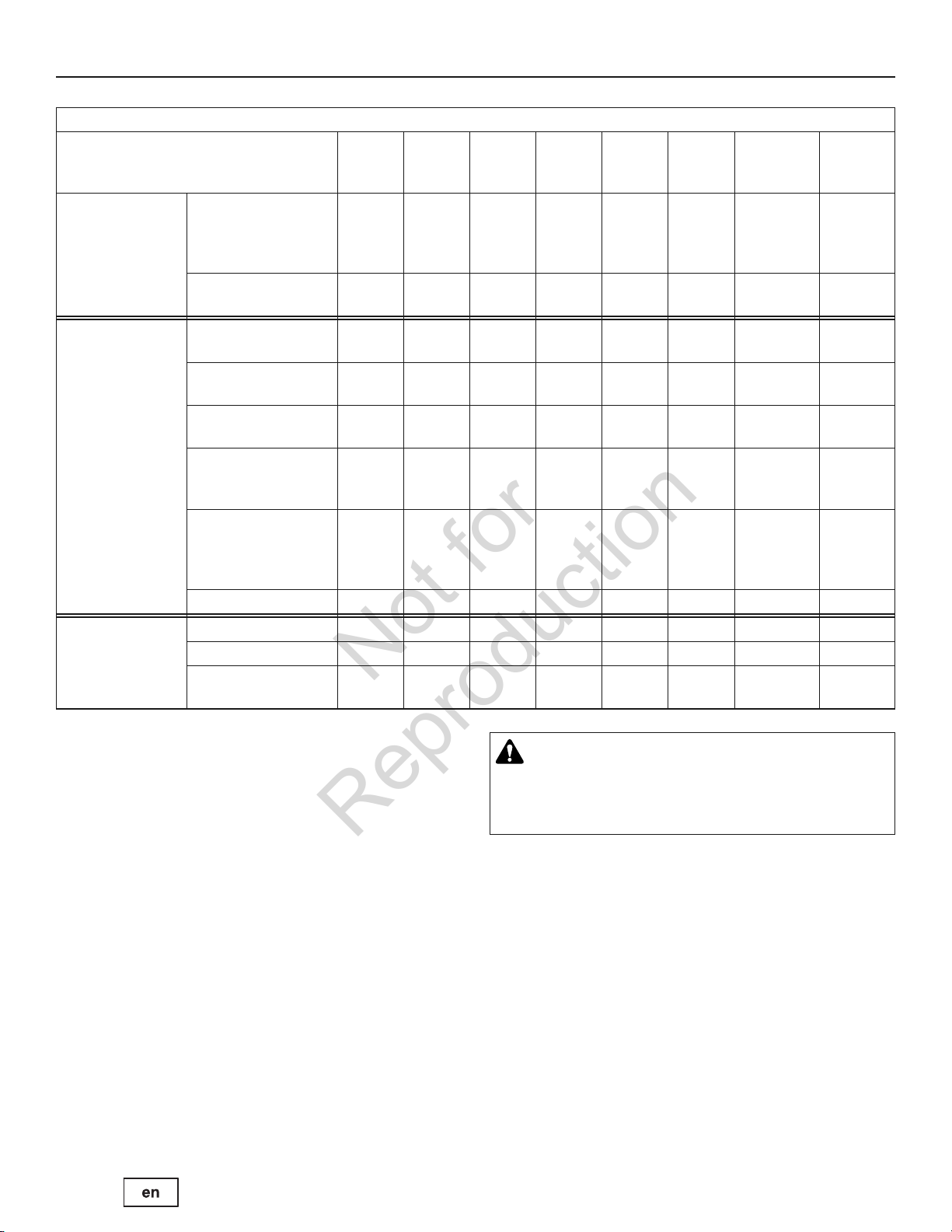

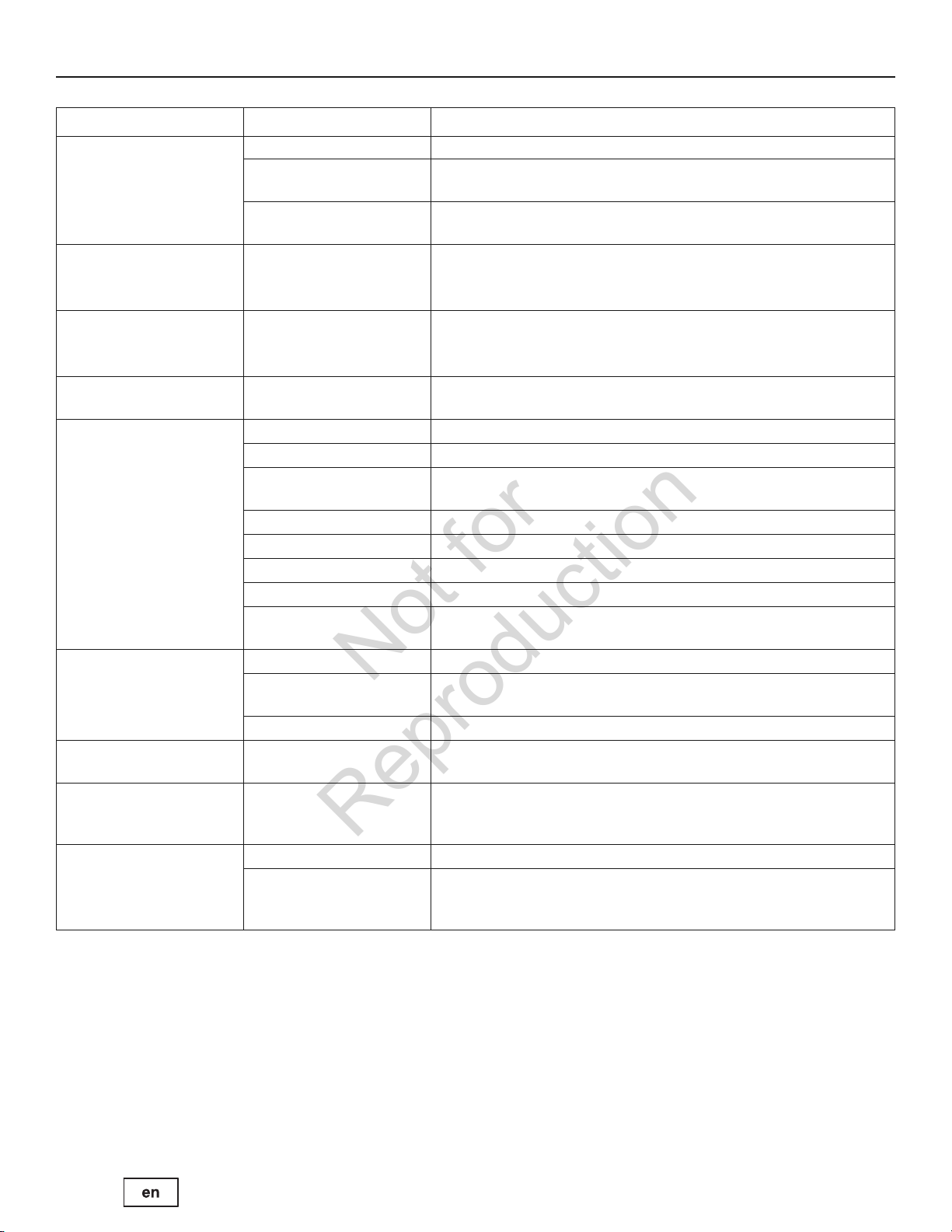

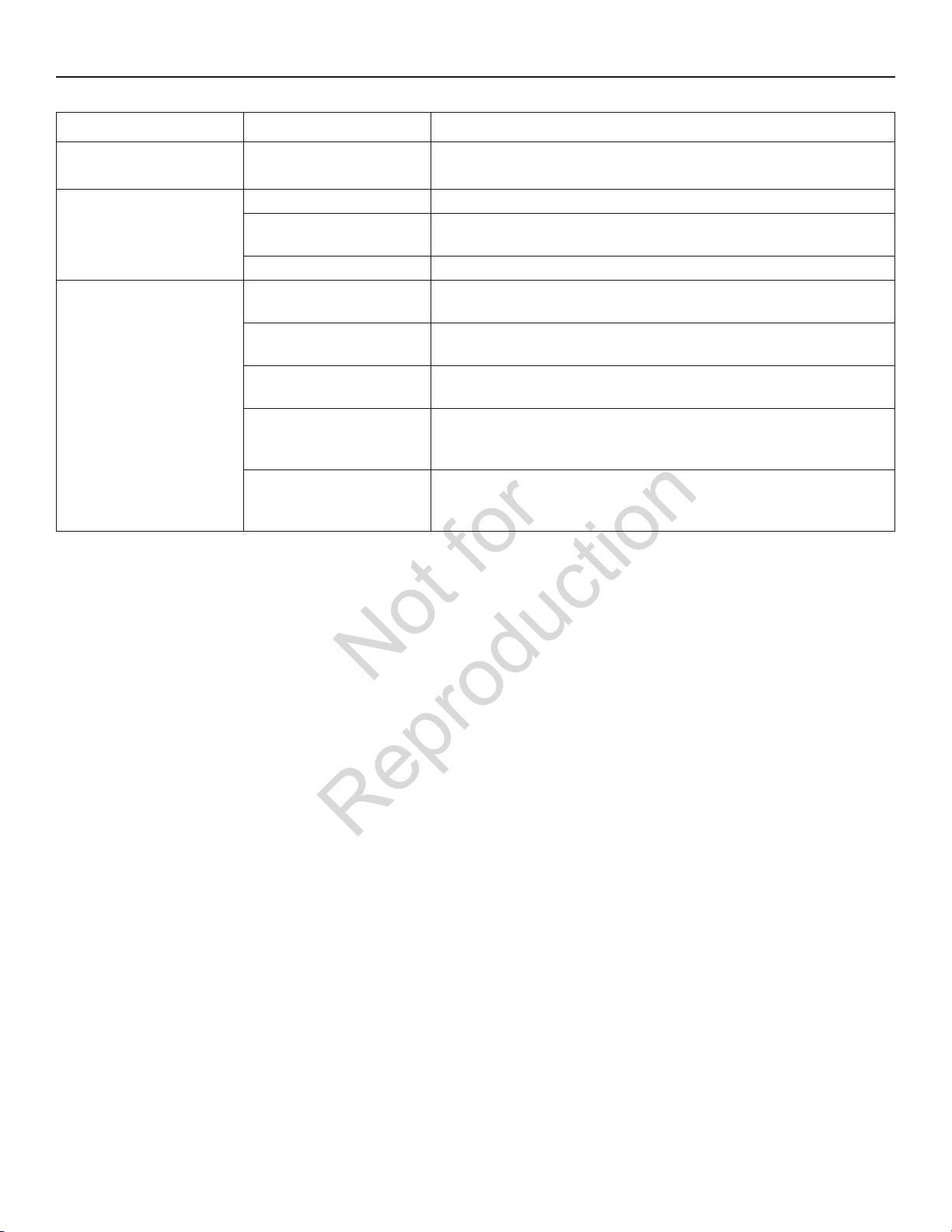

SERVICE RECOMMENDATIONS

FIRST

HOURS

✓ ✓ ✓

BEFORE

5

EACH

USE

✓

AFTER

EACH

USE

EVERY

5

HOURS

EVERY

10

HOURS

EVERY

25

HOURS

MAINTENANCE

BEGINNING

EACH

SEASON

BEFORE

STORAGE

Check Snow Thrower for

Loose Hardware

Lubricate Hex Shaft and

Chains

Lubricate Auger Shaft

Fittings

SNOW THROWER

ENGINE

NOTE: The warranty on this snow thrower does not cover items

that have been subjected to operator abuse or negligence. To

receive full value from the warranty, operator must maintain

snow thrower as instructed in this manual.

The above Service Recom mendations are supplied to assist the

operator to properly maintain the snow thrower.

Lubricate Chute Rotation

Gear and Deflector

Mechanism

Remove All Snow and

Slush off Snow Thrower

to Prevent Freezing of

Auger or Controls

Check Tire Pressure

Oil, Check

Oil, Change

Check and Replace Spark

Plug

✓ ✓ ✓

✓ ✓

✓ ✓

✓ ✓

✓ ✓

✓

✓

✓

✓ ✓

CAUTION: Do not allow grease or oil to contact the

rubber friction wheel or the disc drive plate. If the disc

drive plate or friction wheel come in contact with

grease or oil damage to rubber friction wheel will

result.

NOTICE: If grease or oil comes into contact with the disc drive

plate or friction wheel, make sure to clean plate and wheel

thoroughly with an alcohol base solvent.

23

Page 24

A

C

MAINTENANCE

C

B

A

A

A

Not for

Reproduction

LUBRICATE AUGER GEAR BOX

The auger gear box is lubricated at the factory and should not require

additional lubrication. If for some reason the lubricant should leak out, or

if the auger gear box has been serviced, add Lubriplate GR132 Grease or

equivalent. Maximum 3- 1/4 ounces, (92 grams) should be used.

Remove filler plug (A

add. If grease is not visible, use a piece of fine wire, like a dipstick to

check if there is grease in the gear box. Mobilux EP1 and Shell Alvania

EP1 are suitable equivalents.

, Figure 23), once a year. If grease is visible, do not

LUBRICATE AUGER SHAFT FITTINGS

1. Using a hand grease gun, lubricate the auger shaft fittings (BB, Figure

23) every ten (10) operating hours. Each time a shear pin is replaced,

the auger shaft (C

Replacement” section.)

2. For storage or when replacing shear pins, remove shear pins and

lubricate auger shaft fittings (B

shaft and reinstall the shear pins.

) MUST be greased. (See “Auger Shear Pin

). Rotate augers several times on the

LUBRICATE CONTROL LEVER LINKAGE

The controls should function as described in the OPERATION section.

WARNING: It is critical for the safe operation of the unit

that the controls disengage when released.

ENGINE MAINTENANCE

Check Crankcase Oil Level - Before starting engine and after each 8

hours of continuous use. Add the recommended motor oil as required.

NOTE: Over filling the engine can affect performance. Tighten

the oil fill cap securely to prevent leakage.

Change Oil - Every 50 hours of operation or at least once a year, even if

the snow thrower is not used for fifty hours. Use a clean, high quality

detergent oil. Fill the crankcase to FULL line on dipstick (A

sure original container is marked: A.P.I. service “SF” or higher. Do not use

SAE10W40 oil (as it may not provide proper lubrication). See Chart for

oil recommendations.

Drain Oil – Position snow thrower so that the oil drain plug (A

27) is lowest point on engine. When the engine is warm, remove oil drain

plug and oil fill cap and drain oil into a suitable container.

Replace oil drain plug and tighten securely. Refill crankcase with the

recommended motor oil.

, Figure 26). Be

, Figure

Lubricate the linkage for the traction control (A

control (BB), and auger control (CC) every ten (10) operating hours, or as

necessary to ensure safe operation.

NOTICE: Under no circumstances should the unit be used if the

controls do not function properly.

, Figure 24), speed select

LUBRICATE CHUTE ROTATION GEAR

Lubricate the chute rotation gear (AA, Figure 25) and shaft (BB) with

automotive type oil every twenty-five (25) operating hours.

ADJUST THE DRAG ON THE CHUTE ROTATION

NOTE: After repeated use, the chute rotation gear may loosen,

causing the chute to move back to the center position.

Adjust the drag by tightening the nut (C

will limit the chute from moving without the operator turning the chute

rotation crank.

, Figure 25). Tightening the nut

* Below 40°F (4°C) the use of SAE 30 will result in hard starting.

** Above 80°F (27°C) the use of 10W-30 may cause increased oil consumption. Check oil

level more frequently.

24 www.murray.com

Page 25

A

A

A

C

MAINTENANCE

Not for

Reproduction

CHANGE THE SPARK PLUG

Remove the Snow Hood

1. Remove the choke control knob (AA, Figure 27).

2. Remove the safety key (BB).

3. Remove the mounting screws (A

4. Slowly remove the snow hood (BB) Make sure that the primer button

hose (CC) and the ignition wire (DD) are not disconnected.

5. The spark plug (EE) can now be accessed.

6. To install the snow hood, first make sure that the primer button hose

and the ignition wire are connected.

7. Mount the snow hood to the engine and secure with the mounting

screws.

8. Connect the choke control knob (A

on the carburetor (BB). Make sure the choke control knob is properly

installed. If the choke control knob is not installed correctly, the

choke will not operate.

9. Install the safety key (C

).

, Figure 28).

, Figure 29) with the choke shaft

Check and Replace Spark Plug

Check the spark plug every twenty-five (25) hours. Replace the spark plug

(Figure 30) if the electrodes are pitted or burned or if the porcelain is

cracked.

1. Remove snow hood (see “Remove the Snow Hood” section).

2. Clean spark plug and reset gap periodically.

3. Clean area around spark plug base before removal, to prevent dirt

from entering engine.

4. Replace spark plug if electrodes are pitted or burned or if porcelain is

cracked.

5. Clean spark plug by carefully scraping electrodes (do not sandblast

or use wire brush).

6. Be sure spark plug is clean and free of foreign material. Check

electrodes gap with a wire feeler gauge and reset gap to 0.030"

(0.76 mm) if necessary.

7. Before installing spark plug, coat threads lightly with graphite grease

to insure easy removal.

8. Tighten plug firmly into engine. If torque wrench is available, tighten

plug to 18-23 ft-lbs (24.4-31.2 Nm).

WARNING: Always turn unit off, remove ignition key,

and disconnect the spark plug wire before making any

repairs or adjustments.

ADJUST SKID HEIGHT

This snow thrower is equipped with two height adjust skids, secured to

the outside of the auger housing. These elevate the front of the snow

thrower.

When removing snow from a hard surface area such as a paved driveway

or walk, adjust the skids up to bring the front of the snow thrower down.

When removing snow from rock or uneven construction, raise the front of

the snow thrower by moving the skids down. This will help to prevent

rocks and other debris from being picked up and thrown by the augers.

To adjust skids, proceed as follows:

1. Place a block (equal to height from ground desired) under scraper

bar near but not under skid.

2. Loosen skid mounting nuts (A

(BB) until it touches the ground. Retighten mounting nuts.

3. Set skid on other side at same height.

NOTE: Make sure that snow thrower is set at same height on

both sides.

WARNING: Be certain to maintain proper ground

clearance for your particular area to be cleared.

Objects such as gravel, rocks, or other debris, if

struck by the impeller, may be thrown with sufficient

force to cause personal injury, property damage, or

damage to the snow thrower.

, Figure 31) and push the skid down

25

Page 26

A

A

A

The auger must stop within 5

seconds.

MAINTENANCE

C

The auger must stop within

5 seconds.

B

Not for

Reproduction

BELT ADJUSTMENT

Traction Drive Belt

The traction drive belt has constant spring pressure and does not require

an adjustment. If the traction drive belt is slipping, replace the belt. See

authorized dealer.

Auger Drive Belt

If your snow thrower will not discharge snow, check the control cable

adjustment. If it is correct, then check the condition of the auger drive belt. If it

is damaged or loose, replace it (see authorized dealer).

1. Disconnect spark plug wire.

2. Remove screw (A

3. Loosen nut on idler pulley (AA, Figure 33) and move idler pulley

towards belt about 1/8 inch (3 mm).

WARNING: Do not over-tighten, as this may lift the lever

and cause the auger drive to be engaged without

depressing the auger control lever.

4. Tighten nut.

5. With the aid of an assistant, engage the auger drive clutch. Check

tension on belt which is opposite idler pulley (A

should deflect about 1/2 inch (12.5 mm) with moderate pressure.

You may have to move idler pulley more than once to obtain the

correct tension.

6. Release the auger control lever. T

7. If auger does not operate properly, stop engine and recheck drive

linkage adjustments.

8. Reinstall belt cover (BB, Figure 32). Tighten screw (AA).

9. Whenever belts are adjusted or replaced, the cables will need to be

adjusted (see “Check and Adjust the Cables” section).

10. Attach the spark plug wire.

, Figure 32) from belt cover (BB). Remove belt cover.

, Figure 33). Belt

BELT GUIDE ADJUSTMENT

1. Remove spark plug wire.

2. Have someone engage the auger drive. This will engage auger idler

pulley (A

3. Measure the distance between the belt guide (BB) and belt (CC). The

distance should be about 1/8 inch (3 mm).

4. If adjustment is necessary, loosen belt guide mounting bolt. Move

belt guide to the correct position. Tighten mounting bolt.

5. Install belt cover.

6. Connect spark plug wire.

, Figure 34).

SPEED CONTROL ROD ADJUSTMENT

If the speed control rod requires adjustment, loosen jam nut (AA, Figure

35), remove nut (B

out to change neutral.

) from universal joint, and turn universal joint (CC) in or

CHECK AND ADJUST THE CABLES

The cables are adjusted at the factory and no adjustment should be

necessary. If the cables have become stretched or are sagging adjustment

will be necessary.

Whenever belts are adjusted or replaced, the cables will need to be

adjusted.

Auger Control Cable Adjustment

WARNING: Do not over-tighten, as this may lift the

lever and cause the auger drive to be engaged without depressing the auger control lever.

1. With the auger control lever released, the hook (AA, Figure 36) should

barely touch the lever (BB) without raising it. There can be a maximum

of 1/32" (0.8 mm) clearance.

2. To adjust, loosen the nut (C

turning the nut. Then, turn the adjusting flats and hold the

adjustment screw (EE). The adjustment screw is a phillips screw and

the head can be held or turned by inserting a screwdriver through the

spring (FF).

3. Hold the adjusting flats and tighten the nut.

4. Start the engine and check the auger. The auger must not be engaged

unless the auger control lever is depressed.

5. With the engine running, fully depress the auger control lever. The

auger should engage and run normally.

6. Release the auger control lever. T

7. If the auger does not operate properly, stop the engine and recheck

the auger control cable adjustment.

8. If the drive linkage is properly adjusted, the tension of the auger

drive belt may require an adjustment (see “Belt Adjustment” section).

) by holding the adjusting flats (DD) and

26 www.murray.com

Page 27

A

MAINTENANCE

A

C

A

B

Not for

Reproduction

Traction Control Cable Adjustment

1. Remove the gas from the gas tank. Stand the snow thrower up on the

front end of the auger housing.

WARNING: Drain the gasoline outdoors, away from fire

or flame.

2. Loosen the bolts (A

3. Remove the bottom panel.

4. Slide the cable boot (AA, Figure 38) off the cable adjustment bracket

(BB).

5. Push the bottom of the traction control cable (C

adjustment bracket until the “Z” hook (DD) can be removed.

6. Remove the “Z” hook from the cable adjustment bracket. Move the

“Z” hook down to the next adjustment hole.

7. Pull the traction control cable up through the cable adjustment

bracket.

8. Put the cable boot over the cable adjustment bracket.

9. To check the adjustment, depress the control lever and check the

length of the drive spring (A

length of the drive spring is a minimum 3 inches (76 mm) and a

maximum 3-3/8 inches (85 mm).

10. Install the bottom panel (B

11. Tighten the bolts (AA) on each side of the bottom panel.

, Figure 37) on each side of the bottom panel (BB).

) through the cable

, Figure 39). In correct adjustment, the

, Figure 37).

CHECK THE TIRES

Check tires for damage. Check the air pressure in the tires with an accurate

gauge (see Figure 41).

CAUTION: Avoid Injury! Explosive separation of tire and

rim parts is possible when they are serviced

incorrectly.

• Do not attempt to mount a tire without the proper

equipment and experience to perform the job.

• Do not inflate the tires above the recommended

pressure.

• Do not weld or heat a wheel and tire assembly. Heat can

cause an increase in air pressure resulting in an

explosion. Welding can structurally weaken or deform

the wheel.

• Do not stand in front or over the tire assembly when

inflating. Use appropriate tool that allows you to stand to

one side.

NOTICE: Check side of tire for maximum tire pressure. DO

NOT exceed maximum.

AUGER SHEAR PIN REPLACEMENT

The augers are secured to the auger shaft with special shear pins that are

designed to break if an object becomes lodged in the auger housing. Use

of a harder grade shear pin will reduce the protection provided by the

shear pin.

WARNING: Do not go near the discharge chute or auger

when the engine is running. Do not run the engine if any

cover or guard is removed.

Under most circumstances, if the auger strikes an object which could

cause damage to the unit, the shear pin will break. This protects the gear

box and other parts from damage.

The shear pins (A

broken shear pin as follows.

1. Tap out the broken shear pin with a pin punch.

2. Install a new shear pin and cotter pin. Bend the ends of the cotter pin

down.

IMPORTANT: Do not replace shear pins with anything other

than the correct grade replacement shear pin. Use of bolts,

screws, or harder grade shear pins can result in equipment

damage.

, Figure 40) are located on the auger shaft. Replace a

27

Page 28

STORAGE

D

A

Not for

Reproduction

OFF SEASON STORAGE

WARNING: Never store the engine, with fuel in the tank,

indoors or in a poor ventilated enclosure where fuel

fumes could reach an open flame, spark or pilot light as

on a furnace, water heater, clothes dryer, etc.

Handle gasoline carefully. It is highly flammable and

careless use could result in serious fire damage to your

person and/or property.

Drain fuel into approved containers outdoors, away from

open flame.

If the snow thrower will be stored for thirty (30) days or more at the end of

the snow season, the following steps are recommended to prepare your

snowthrower for storage.

NOTE: Gasoline must be removed or treated to prevent gum

deposits from forming in the tank, filter, hose, and carburetor

during storage.

1. Remove gasoline, by running engine until tank is empty and engine

stops. If you do not want to remove the gasoline, add fuel stabilizer

to any gasoline left in the tank to minimize gum deposits and acids.

If the tank is almost empty, mix stabilizer with fresh gasoline in a

separate container and add some of the mixture to the tank. ALWAYS

FOLLOW INSTRUCTIONS ON STABILIZER CONTAINER. THEN RUN

ENGINE AT LEAST 10 MINUTES AFTER STABILIZER IS ADDED TO

ALLOW MIXTURE TO REACH CARBURETOR. STORE SNOW

THROWER IN SAFE PLACE.

2. You can help keep your engine (4-cycles only) in good operating

condition by changing oil before storage.

3. Lubricate the piston/cylinder area. This can be done by first

removing the spark plug and squirting clean engine oil into the spark

plug hole. Then cover the spark plug hole with a rag to absorb oil

spray. Next, rotate the engine by pulling the starter two or three

times. Finally, reinstall spark plug and attach spark plug wire.

4. Thoroughly clean the snow thrower.

5. Lubricate all lubrication points (see “Lubrication” topics in the

MAINTENANCE section).

6. Make sure all nuts, bolts, and screws are securely fastened. Inspect

all visible moving parts for damage, breakage, and wear. Replace if

necessary.

7. Touch up all rusted or chipped paint surfaces; sand lightly before

painting.

8. Cover the bare metal parts of the snow thrower housing auger, and

the impeller with rust preventative.

9. If possible, store your snow thrower indoors and cover it to give

protection from dust and dirt.

10. On models with folding handles, disconnect the shifter and chute

crank, and loosen the knobs that secure the upper handle. Rotate the

upper handle back.

11. If the machine must be stored outdoors, block up the snow thrower

and ensure the entire machine is off the ground. Cover the snow

thrower with a heavy tarpaulin.

LUBRICATE HEX SHAFT AND CHAINS

CAUTION: Do not allow grease or oil to contact the

rubber friction wheel or the disc drive plate. If the disc

drive plate or friction wheel come in contact with

grease or oil damage to rubber friction wheel will

result.

NOTICE: If grease or oil comes into contact with the disc drive

plate or friction wheel, make sure to clean plate and wheel

thoroughly with an alcohol base solvent.

1. Position speed select lever (D

2. Drain fuel to an approved container.

3. Stand the snow thrower up on the auger housing end.

NOTE: When the crankcase is filled with oil, do not leave

the snow thrower standing up on the auger housing for an

extended period of time.

4. Remove the bottom panel.

5. Lubricate the chains (A

before storage or at the beginning of each season, using a clean rag

dipped in motor oil. Do NOT use grease.

NOTE: Use a clean rag to wipe away any excess oil from

the chains, sprockets, and hex shaft.

6. Install the bottom panel.

, Figure 13) in first forward gear.

, Figure 42), sprocket (BB), and hex shaft (CC)

REMOVE FROM STORAGE

1. Put the upper handle in the operating position, tighten the knobs that

secure the upper handle, and connect the shifter and chute crank.

2. Fill the fuel tank with a fresh fuel.

3. Check the spark plug. Make sure the gap is correct. If the spark plug

is worn or damaged, replace before using.

4. Make sure all fasteners are tight.

5. Make sure all guards, shields, and covers are in place.

6. Make sure all adjustments are correct.

28 www.murray.com

Page 29

PROBLEM LOOK FOR REMEDY

Not for

Reproduction

Auger does not stop within

5 seconds after right

control lever is released.

Discharge chute or

deflector does not work

(electric).

Discharge chute or

deflector does not work

(remote-manual).

Drive fails to move snow

thrower at slow speeds.

Engine fails to start.

Engine starts hard or runs

poorly.

Excessive vibration.

Snow thrower does not stop

when traction control lever

is released.

Snow thrower veers to one

side.

TROUBLESHOOTING

Free-HandTMcontrol is ACTIVE. Release both auger control and traction/Free-HandTMcontrol levers to stop auger.

Auger drive belt out of

adjustment.

Auger belt guide out of

adjustment.

Electrical failure. See authorized dealer.

Discharge chute or deflector out

of adjustment or needs

lubrication.

Traction control out of

adjustment.

Key is off. Push key in to the ON position.

Failure to prime a cold engine. Press primer button twice and restart.

Fuel shut-off valve is in

CLOSED position.

Out of fuel. Fill fuel tank.

Choke OFF - cold engine. Turn choke ON, set throttle to FAST.

Engine flooded. Turn choke to OFF; try starting.

No spark. Check gap. Gap spark plug, clean electrode, or replace plug as necessary.

Water in fuel, or old fuel. Drain tank. (Dispose of fuel at an authorized hazardous waste facility.) Fill with

Fuel mixture too rich. Move choke to OFF position.

Spark plug faulty, fouled, or

gapped improperly.

Fuel cap vent is blocked. Clear vent.

Loose parts or damaged

impeller/auger.

Traction control out of

adjustment.

Tire pressure not equal. Check tire pressure.

One wheel is set in free-

wheeling mode. (Traction lock

pin is in the OUTER hole.)

Adjust auger belt.

Adjust auger belt guide.

Adjust and/or lubricate control linkage.

Readjust drive, or select speed lever setting one speed faster.

Turn valve to OPEN position.

fresh fuel.

Clean and gap spark plug, or replace.

Stop engine immediately. Tighten all hardware. If vibration continues, have the unit

serviced by an authorized dealer.

Adjust traction control linkage.

Make sure the left traction lock pin is in the INNER holes (to engage the traction

drive).

29

Page 30

TROUBLESHOOTING

Not for

Reproduction

PROBLEM LOOK FOR REMEDY

Scraper bar does not clean

hard surface.

Unit fails to propel itself.

Unit fails to discharge

snow.

Skid shoes improperly adjusted. Raise or lower skid shoes.

Drive belt loose or damaged. Replace drive belt. See authorized dealer.

Incorrect adjustment of traction

drive cable.

Worn or damaged friction disc. Replace friction disc. See authorized dealer.

Auger drive belt loose or

damaged.

Auger control cable not adjusted

correctly.

Broken shear pin. Replace shear pin. Refer to “Auger Shear Pin Replacement” in the MAINTENANCE

Discharge chute clogged. Stop engine immediately. Always use the clean-out tool to clear a clogged

Foreign object lodged in auger. Stop engine immediately. Always use the clean-out tool to clear a clogged chute,

Adjust traction control cable. Refer to “Check and Adjust the Cables” in the

MAINTENANCE section of this manual.

Replace or adjust auger drive belt. Refer to “Belt Adjustment” in the

MAINTENANCE section of this manual, or see authorized dealer.

Adjust auger control cable. Refer to “Check and Adjust the Cables” in the

MAINTENANCE section of this manual.

section of this manual.

discharge chute, not your hands. Clean discharge chute and inside of auger

housing. Refer to WARNINGS in OPERATOR SAFETY section.

not your hands. Remove object from auger. Refer to WARNINGS in OPERATOR

SAFETY section.

30 www.murray.com

Page 31

WARRANTY

Not for

Reproduction

31

Page 32

SPECIFICATIONS

Not for

Reproduction

ENGINE:

Brand Briggs & Stratton

Model Series Snow Series

Gross Torque* 11.5 T.P. @ 3060 rpm

Type 4-Cycle - OHV

Displacement 15.2 cu in. (249 cc)

Starting System 230V Electric, Recoil

Alternator 60W AC Only

Oil Capacity 20 oz (0,59 liter)

Engine Oil Synthetic 5W30

Fuel Tank Volume 3.0 qts (2,8 liters)

Spark Plug Gap 0.030 in. (0,76 mm)

Resistor Spark Plug 491055

Long Life Platinium Spark Plug 5066

Ignition System This spark plug ignition system complies with Canadian standard ICES-002.

AUGER/IMPELLER:

Clearing Width 27 in. (68,6 cm)

Intake Height 21 in. (53,3 cm)

Auger/Impeller Diameter 12 in. (30,5 cm)

Number of Impeller Blades 3

CHUTE:

Chute Deflector Manual

Chute Rotation Remote - Dash Mounted Crank 190° (3.5 Turn)

DRIVE SYSTEM:

Drive Type Friction Disc - Traction Lock Pin

Drive Speeds 6 Forward Speeds, 2 Reverse

Tire Size 16 x 4.8 in. (40,6 x 12,2 cm)

Tire Inflation See the sidewall of the tire for the proper inflation.

Engine Power Rating Information

*The gross power rating for individual gas engine models is labeled in accordance with SAE (Society of Automotive Engineers) code

J1940 (Small Engine Power & Torque Rating Procedure), and rating performance has been obtained and corrected in accordance with

SAE J1995 (Revision 2002-05). Torque values are derived at 3060 RPM; horsepower values are derived at 3600 RPM. Actual gross

engine power will be lower and is affected by, among other things, ambient operating conditions and engine-to-engine variability. Given

both the wide array of products on which engines are placed and the variety of environmental issues applicable to operating the

equipment, the gas engine will not develop the rated gross power when used in a given piece of power equipment (actual

net power). This difference is due to a variety of factors including, but not limited to, accessories (air cleaner, exhaust, charging,

cooling, carburetor, fuel pump, etc.), application limitations, ambient operating conditions (temperature, humidity, altitude), and engineto-engine variability. Due to manufacturing and capacity limitations, Briggs & Stratton may substitute an engine of higher rated power

for this Series engine.

“

on-site” or

32 www.murray.com

Page 33

INHALT

Not for

Reproduction

Abbildungen...........................................................................................3

Arbeitsschutz ........................................................................................10

Montage ..............................................................................................16

Funktionen und Steuerungen .....................................................................17

Bedienung............................................................................................19

Wartung ..............................................................................................23

Lagerung .............................................................................................28

Fehlersuche und -behebung ......................................................................29

Garantie ..............................................................................................31

Technische Daten ...................................................................................32

Allgemeine Informationen

Vielen Dank, dass Sie sich für den Kauf dieser qualitativ hochwertigen Schneefräse von Murray entschieden haben und Ihr Vertrauen

auf unsere Marke gesetzt haben. Bedienen und warten Sie das Produkt gemäß den Angaben dieser Bedienungsanleitung, damit ein

zuverlässiger und jahrelanger Betrieb gewährleistet ist.

Dieses Handbuch beinhaltet Sicherheitsinformationen, um Ihnen die Gefahren und Risiken im Zusammenhang mit Schneefräsen

bewusst zu machen, und Ihnen zu vermitteln, wie man sie vermeidet. Diese Schneefräse wurde zur Räumung von Schnee entwickelt

und sollte zu keinem anderen Zweck verwendet werden. Es ist wichtig, dass Sie sich diese Bedienungsanleitung durchlesen und sie

verstehen, bevor Sie die Maschine in Betrieb nehmen oder nutzen. Dieser Schneefräsen muss vor der Verwendung fertig montiert

werden. Weitere Informationen entnehmen Sie aus dem Kapitel Montage unter dem Punkt „Durchführung der Endmontage“. Befolgen

Sie vollständig die Anweisungen. Bewahren Sie diese Anleitungen für späteres Nachschlagen auf.

Produktdaten CE Identifikationsetikett

Geben Sie den Namen und die Nummer des Modells, die

Identifikationsnummern des Herstellers und die Seriennummern

des Motors in den entsprechenden Feldern an. Diese Nummern

stehen auf den jeweiligen abgebildeten Teilen.

Sie MÜSSEN über diese Angaben verfügen, um Ersatzteile,

Serviceleistungen oder Informationen vom zugelassenen

Fachhändler zu erhalten.

PRODUKTDATEN

Modellbezeichnung, Name/Nummer

Nummer der Baueinheit Seriennummer

Baugruppennummer der

Schneidwerkabdeckung

Händlername Kaufdatum

MOTORANGABEN

Motorbezeichnung Motormodell

Motortyp/Spezif. Motorkennzeichen/Seriennummer

Seriennummer der Schneidwerkabdeckung

A. Indentifikationsnummer des Herstellers

B. Seriennummer des Herstellers

C. Nutzleistung in Kilowatt

D. Maximale Motorendrehzahl in Umdrehung pro Minute