Page 1

WS-93002N page 1 of 7

Murphy W-Series Engine Panels

General Installation Instructions

WS-93002N

Revised 04-06

Section 30

(00-02-0191)

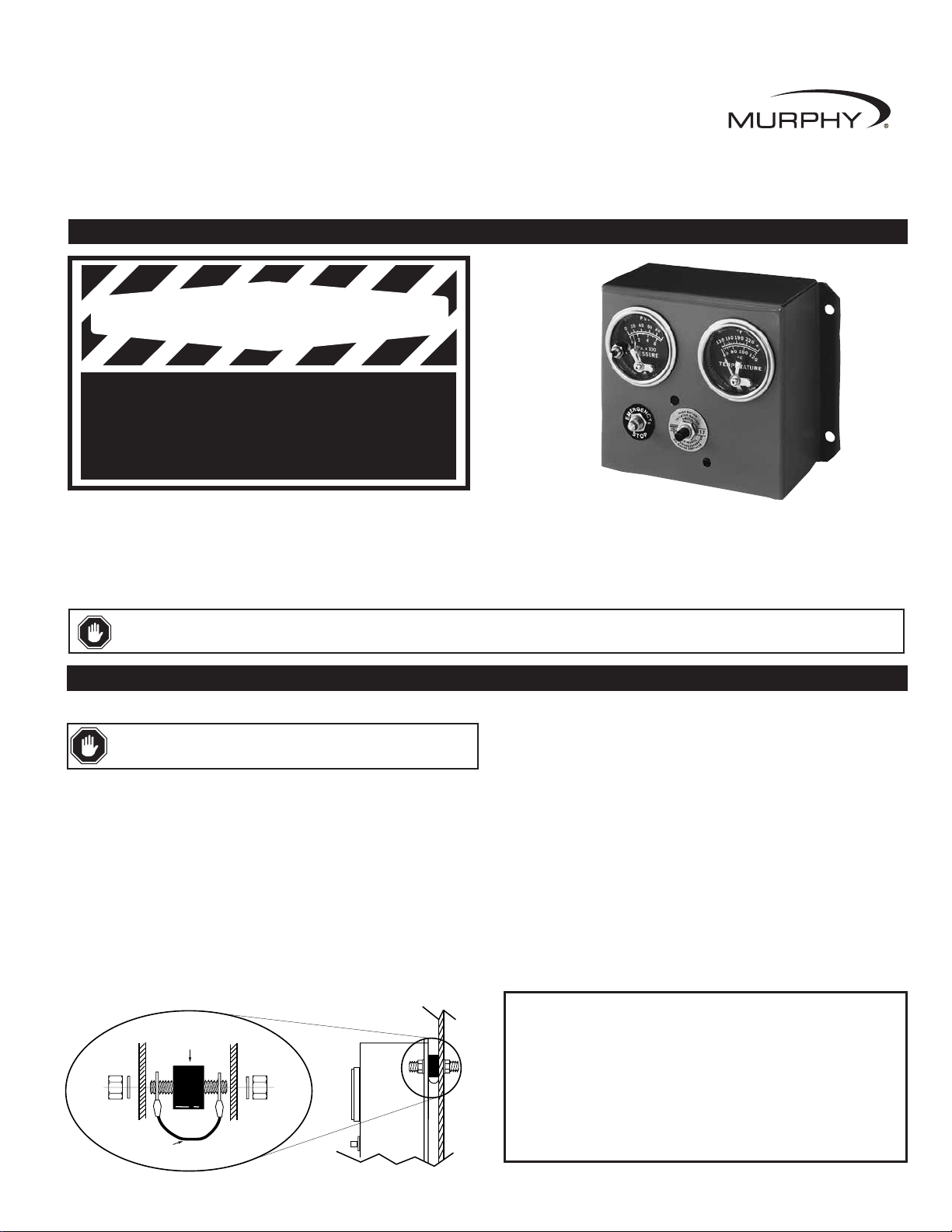

Mounting the Panel

1. Select a suitable mounting location on or near the engine. The location

should provide easy access to the panel and provide unobstructed

viewing of the Swichgage instruments.

2. The mounting location should avoid shock and vibration to the extent

possible. Generally, a location low on the engine is preferred. Avoid

mounting on top of the engine if possible. Shockmounts are

suggested where possible to dampen shock and vibration.

IMPORTANT: Use of improper shockmounts can accelerate the shock

and vibration effects. Consult the factory if you are in doubt.

NOTE: If shockmounts are used, it is suggested that a separate ground

wire be attached to the panel assembly and to the engine. This assures

electrical continuity between the Swichgage contacts and the battery

ground across the shockmounts (see mounting detail below).

Connecting the Pressure Swichgage

1. Pressure tubing is generally not provided. Use of good quality flexible pressure tubing/hose and fittings is strongly suggested. Use at

least

3

/16 in. (5 mm) I.D. tubing. If using copper or rigid

tubing, install at least 12 in. (305 mm) flexible hose from the pressure Swichgage instrument to the rigid tubing. This prevents damaging vibration from reaching the Swichgage instrument.

2. Connect the pressure tubing to the

1

/8-27 NPT pressure port of the

pressure Swichgage instrument. Use of a non-hardening thread sealing compound is recommended although the thread is “dry seal”. Be

sure that thread sealant does not foul the pressure orifice.

NOTE: The orifice can be removed for cleaning.

3. Connect the pressure tubing to the pressure galley of the engine.

Generally this is at the oil filter housing. Use of non-hardening

thread sealant is recommended. Avoid droops or sink traps in

routing of the pressure line.

GENERAL INFORMATION

Installation Accessories

Tools and equipment needed:

●

Thread sealant or Teflon®tape.

●

Straight edge screwdriver (medium).

●

Wire stripping and terminal crimping tools.

●

Electrical wire for use on power connections.

●

Adjustable wrench or open end wrench set.

Read the following information before installing. These installation instructions are typical for a variety of W-Series engine panels and may

not reflect the exact configuration for your panel assembly. It is assumed that the installer is familiar with engine operations and has basic

mechanical and electrical skills. If additional assistance is needed, please call your Murphy dealer or contact one of our offices at the numbers

listed on this instruction sheet. A visual inspection for any damage which may have occurred during shipping is recommended.

WD300-LV

BEFORE BEGINNING INSTALLATION OF THIS MURPHY PRODUCT

✔✔

Disconnect all electrical power to the machine.

✔✔

Make sure the machine cannot operate during installation.

✔✔

Follow all safety warnings of the machine manufacturer.

✔✔

Read and follow all installation instructions.

WARNING: Perform mounting operation with power source OFF.

Disable the engine so it cannot start. Remove the battery ground cable.

INSTALLATION INFORMATION

Description

Generally, pressure and temperature Swichgage®contacts are wired to a

central nerve center called a Magnetic Switch or Tattletale

®

annunciator.

This nerve center is essentially a relay and, when signaled by a

Swichgage contact operation, it either makes or breaks a circuit to operate an alarm or engine shutdown device. Various nerve centers are used

depending upon the operation to be performed, the type of electrical

power available and the type of alarm or shutdown device used.

Typical wiring diagrams for the popular Tattletale annunciators and magnetic switches are included in this instructions. If a drawing of the specific

model number is enclosed, refer to that drawing for specific wiring.

CAUTION: Certain dangers to human safety and to equipment may occur if some equipment is stopped without pre-warning. It is recommended that

monitored functions be limited to alarm only or to alarm before shutdown.

WARNING

nut and

washer

panel

electrical

ground jumper

DETAIL

shockmount

engine

nut and

washer

panel

engine

frame

Page 2

WS-93002N page 2 of 7

INSTALLATION INFORMATION continued

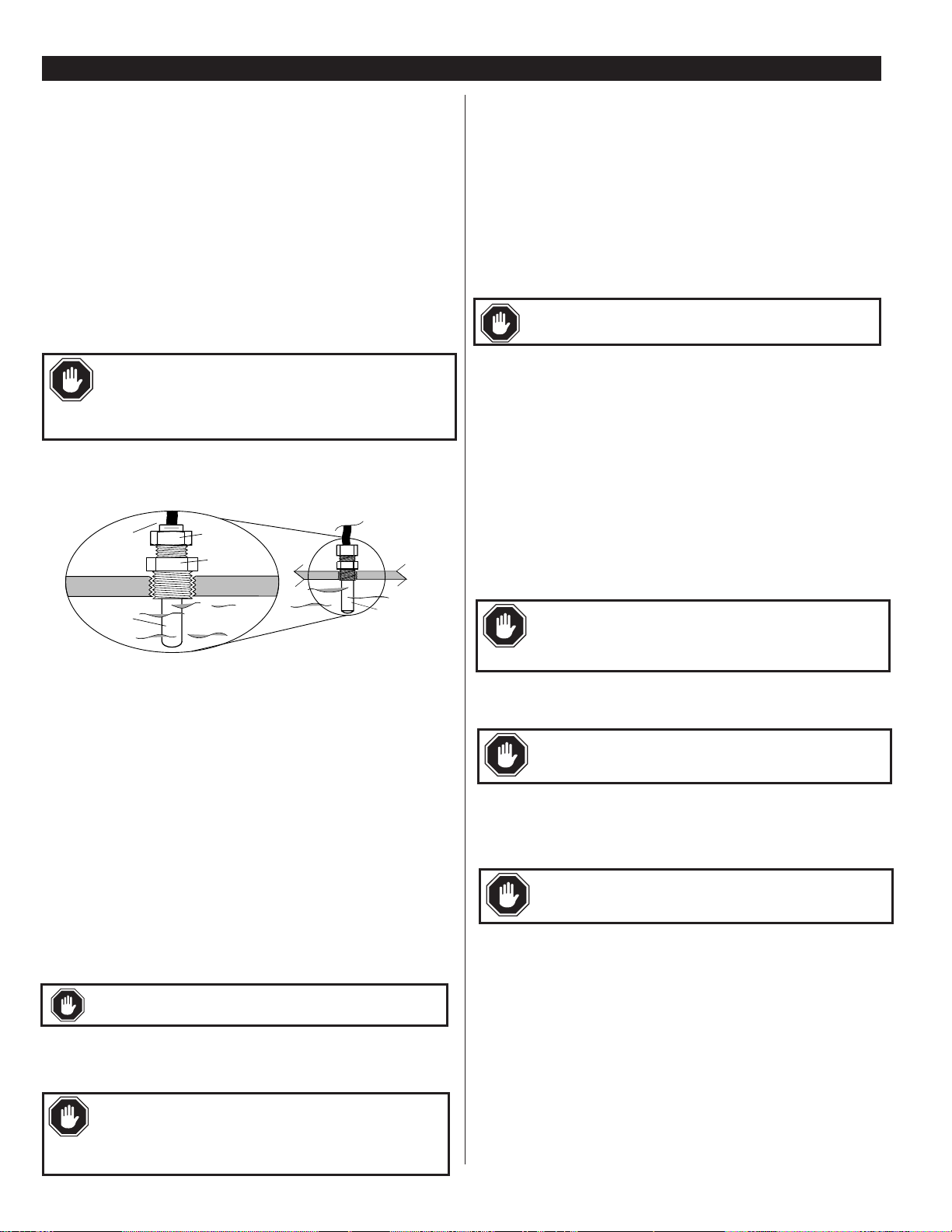

Connecting High Temperatur e

Swichgage instrument

LIQUID COOLED ENGINES:

1. Drain engine coolant to a level below the temperature sensing connection/plug. This connection is on the engine side of the thermostat

generally near the thermostat housing. Consult your engine manual.

2. Remove adapter nut from temperature sensing bulb and union nut.

3. Apply a non-hardening thread sealant to the adapter nut and screw

securely into the water jacket opening on the engine.

4. Route the temperature capillary away from hot surfaces such as

exhaust manifolds.

5. Place the sensing bulb into the adapter nut and observe that the sensing bulb does not “bottom” in the water jacket nor are there other

obstructions in the water jacket opening. Secure sensing bulb into

the adapter nut with the

5

/8-18 union nut. See mounting detail below.

6. Coil excess temperature capillary into a 2 in. (51 mm) diameter

minimum coil. Tie the coil to prevent excessive movement.

Sensing Bulb Mounting Detail

AIR COOLED ENGINES:

Temperature for air cooled engine can be measured in the cylinder head or

in the lubricating oil. Oil temperature will give a more uniform reading

than cylinder head since the oil circulates throughout the engine. Refer to

specific instructions supplied, if any, for your specific application.

1. Oil Temperature

a. The Swichgage sensing probe must be fully immersed in the oil

pan, oil filter housing, oil cooler, etc. depending on engine

model and configuration.

b. Observe all precautions for liquid cooled engines.

2. Cylinder Head Temperature

a. Generally the cylinder head must already have a hole drilled

and tapped for insertion of the temperature sensing probe.

b. If a hole is not provided in the cylinder head and no provision

is made to drill and tap one, it may be possible to install an

external bolt on heat sink such as the Murphy HS7.

c. Coat the temperature sensing probe with a high temperature

grease. A mixture of silicone and graphite flakes is recommended although grease alone can be used.

d. Observe all precautions for liquid cooled engines.

Installing the Engine Stop Device or Alarm

Follow instructions provided with the stop device or alarm.

Electric Wiring

1. Disconnect the battery ground cable or otherwise disconnect

electric power from the engine and panel.

2. See the appropriate typical or specific wiring diagram for the nerve

center/magnetic switch in your panel.

3. Generally you will only be required to wire the battery or other electrical power to the nerve center/magnetic switch and the output circuit

from the nerve center/magnetic switch to the alarm or shutdown device.

4. Ammeters should be direct wired according to the wiring included

with this panel. Use minimum 10 AWG cable.

5. Be sure that the connected load(s) does not exceed the voltage and

current ratings of the nerve center/magnetic switch or Swichgage.

Placing Into Operation

1. Refill oil and coolant to proper levels.

2. Reconnect electrical power.

3. Service the engine as required by the engine manufacturer before

attempting to start the engine.

To Start the Engine

1. Fully depress the red or black push button of the nerve center/magnetic switch on the panel face. Hold in the button while cranking the

engine. This overrides the engine shutdown to allow starting. When

the oil pressure pointer moves away from the pointer contact (or

when pressure exceeds the preset low trip point) release the push

button. The engine should be operating. If the push button is red, it

should remain depressed. If the push button is black, it should

return to an extended position.

2. Allow the engine to warm up and the thermostat to open. Slightly

loosen the 5/8-18 union nut on the temperature sensing bulb to allow

trapped air to escape from the cooling system. Retighten the nut.

3. Loosen the oil line fitting slightly at the pressure Swichgage to

allow trapped air to escape from the tubing. Retighten the fitting.

To Stop the Engine

1. Return the engine to idle speed and unload any driven equipment.

2. DISTRIBUTOR IGNITION engine panels may have an

Emergency Stop Button, a start key switch or other power on/off

switch. Operate that switch or button. The nerve center/Magnetic

Switch will trip and open the ignition circuit to stop the engine.

3. DIESEL ENGINES may be equipped with “energized to RUN” or

“energized to STOP” devices. For “energized to RUN” devices such

as Murphy SV series fuel valves or RP-type solenoids, operation is

identical to above for distributor ignition engines. The “energized to

RUN” device is de-energized and the engine stops. For “energized

to STOP” devices the nerve center/magnetic switch applies battery

power to the stop device. Power is removed after a short time delay

depending on the specific nerve center/magnetic switch.

See instructions supplied with the shutdown or alarm device.

For normal stop, pull the manual stop cable.

CAUTION: Do NOT cut or bend the temperature capillary at a

sharp angle. Excess capillary must be carefully coiled and

secured. The temperature sensing bulb must be immersed

directly into the water jacket flow to sense coolant temperature. Do NOT

install into a tee or other fitting. Use only Murphy adapter nuts.

CAUTION: If the pressure Swichgage is equipped with a face mounted

lockout push button, be sure that pressure has been established and

that the lockout mechanism has disengaged. Failure to disengage will

prevent the Swichgage control from operating on low pressure.

WARNING: Perform this operation using appropriate protection.

Trapped air and coolant may cause skin burns.

CAUTION: You should stop the engine in a normal manner.

Turn off the power switch, pull shutoff cable, etc. Do NOT use

the Swichgage control instrument as a normal shutoff.

CAUTION: Never check for voltage by shorting a wire or terminal to

ground. This will ALWAYS damage the electrical components.

CAUTION: Do NOT apply too much grease. If grease is pushed out of

the hole when temperature probe is inserted, remove some grease.

CAUTION: The Swichgage contacts are “pilot duty”. Generally a

nerve center/magnetic switch or relay is required between the

Swichgage contacts and the shutdown or alarm device. Failure to

use a nerve center/magnetic switch will result in contact failure in

the Swichgage and failure of the shutdown or alarm device to operate.

capillary

engine block

sensing

bulb

insertion

union

nut

adapter

nut

coolant

flow

Sensing

bulb

Page 3

WS-93002N page 3 of 7

Setting the SWICHGAGE® contacts

1. Face mounted contacts are set using a 1/16 in. hex wrench.

2. Some models such as 20PE, 20TE, etc. may not have field adjustment. Consult the factory if in doubt.

3. Observe the “normal operating” oil pressure and coolant temperature readings. Set the oil pressure Swichgage contact slightly below

the minimum reading observed or slightly above the minimum

pressure recommended by the engine manufacturer.

4. Set the temperature Swichgage contact slightly above

the “normal

operating” temperature reading observed or slightly below the maximum temperature recommended by the engine manufacturer.

NOTE: More detailed instructions are contained in Installation Sheet

P-95033N for pressure Swichgage instruments and T-8446N for

Temperature Swichgage instruments.

Testing the SwichgageInstruments

For face mounted contacts (20P, 20T, 20PW7, etc.):

1. With the engine running; use a

1

/16 in. hex wrench to rotate the con-

tact until it touches the gauge pointer. Do NOT force the contact

against the pointer. Engine should shut down and/or alarm should

operate. Reset the contact.

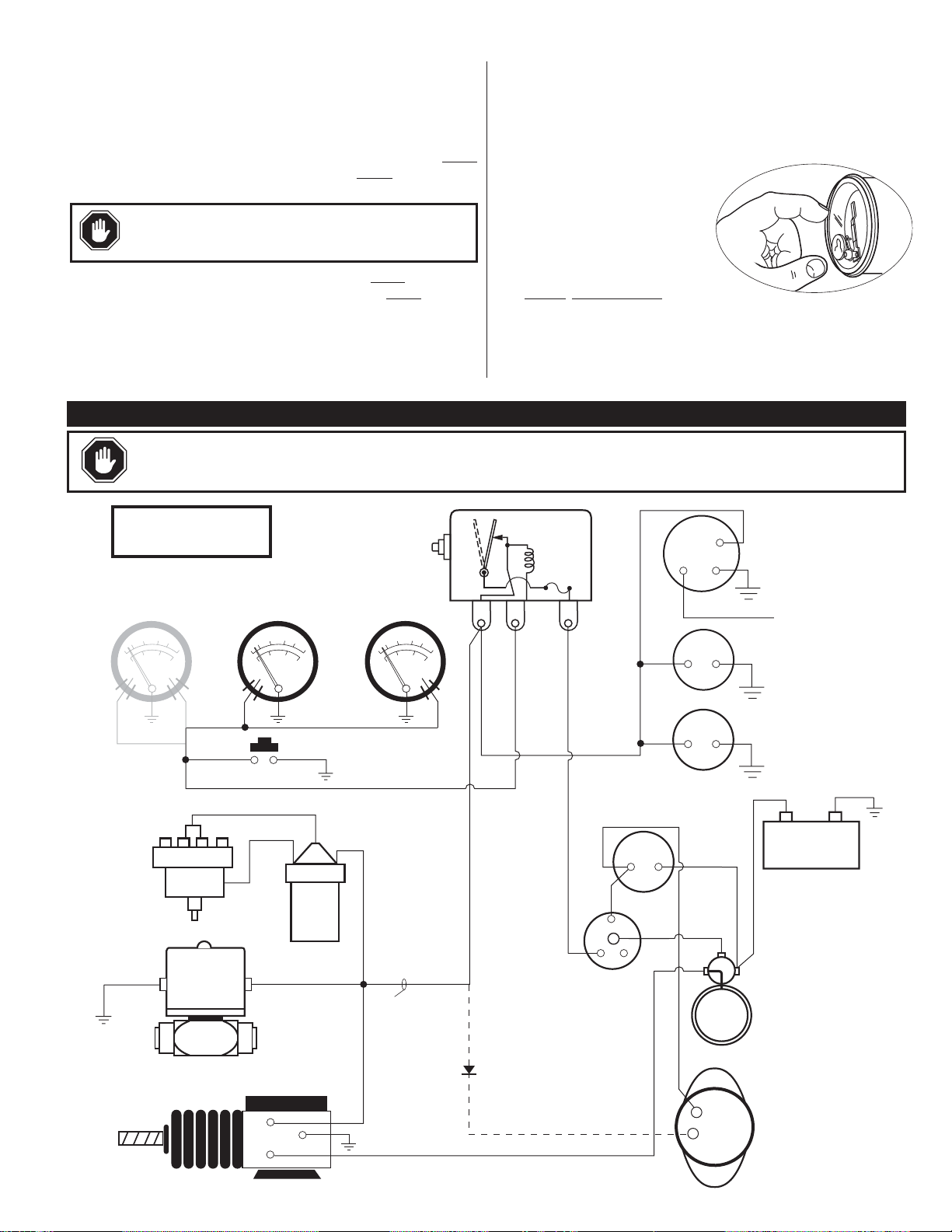

2. An alternative method of testing the

shutdown circuit is to place a coin

or other metal object between the

contact adjustment and the bezel.

NOTE: This method does NOT test

the actual contact pair. It does test the

circuit beyond the contact.

3. VER

Y IMPORT

ANT

Each time you

start the engine, observe that the Swichgage instruments are indicating pressure or temperature, etc. Visual inspection and regular testing should be normal procedure to ensure proper operation and to

achieve maximum results from your Swichgage system.

WARNING: If the pressure Swichgage instrument has a

lockout push button on the face, a contact setting higher than the

factory setting will make the lockout device inoperative.

CAUTION: This wiring is typical for Murphy W-Series small engine panels. Items shown may or may not be included in your panel;

however, the circuit is typical of how the component will be wired if it is included. Refer to installation instructions for the specific

component if included. For off-panel items such as shutdown devices, see specific instructions supplied with the device.

TYPICAL WIRING DIAGRAM WITH 117PH MAGNETIC SWITCH

C

S

B

B

+

GRDSIG

_

+

Ignition coil

Distributor

Fuel Valve

Rack Pull Solenoid

(RP2300 Series shown)

Tachometer

Hourmeter

Voltmeter

117PH

20T

Temperature

20P

Pressure

Ammeter

Battery

_

+

_

+

_

+

ST

ACC

IGN

BAT

Start

Switch

Alternator

To Magnetic Sensor,

Alternator “Tach”

Terminal, or

Signal Generator

B

+

Energized

to Run

Model 117PH

Use for 12 or 24 VDC

PB128S Stop Switch

Other

Swichgage instruments

Starter

S

B

Exciter

Page 4

WS-93002N page 4 of 7

CAUTION: This wiring is typical for Murphy W-Series small engine panels. Items shown may or may not be included in your panel;

however, the circuit is typical of how the component will be wired if it is included. Refer to installation instructions for the specific

component if included. For off-panel items such as shutdown devices, see specific instructions supplied with the device.

TYPICAL WIRING WITH 518PH TATTLETALE CLOSED LOOP

Tachometer

518PH WIRED CLOSED LOOP

MUST specify 12 or 24 VDC

518PH

B

+

GRDSIG

Swichgage instruments

Other

To

Other Normally Closed Contacts

Distributor

20P-F

Pressure

PB128S Stop Switch

Temperature

From

20T-F

R

GNC

SW1 SW2

B

Ammeter

_

+

Hourmeter

_

+

Voltmeter

_

+

To Magnetic Sensor,

Alternator “Tach”

Terminal, or

Signal Generator

+

_

Battery

Fuel Valve

Energized to Run

Rack Pull Solenoid

(RP2300 Series shown)

Ignition coil

Energized

to Run

Start

Switch

ST

IGN

BAT

ACC

Alternator

S

B

Starter

B

+

Exciter

Page 5

WS-93002N page 5 of 7

CAUTION: This wiring is typical for Murphy W-Series small engine panels. Items shown may or may not be included in your panel;

however, the circuit is typical of how the component will be wired if it is included. Refer to installation instructions for the specific

component if included. For off-panel items such as shutdown devices, see specific instructions supplied with the device.

TYPICAL WIRING DIAGRAM WITH 518PH TATTLETALE JUMPERED

518PH WIRED WITH JUMPER

Must specify 12 or 24 VDC

Other

Swichgage instruments

Distributor

20P

Pressure

PB128S Stop Switch

20T

Temperature

518PH

R

GNC

SW1 SW2

Jumper

B

Tachometer

Ammeter

_

+

B

+

GRDSIG

Hourmeter

_

+

Voltmeter

_

+

To Magnetic Sensor,

Alternator “Tach”

Terminal, or

Signal Generator

+

_

Battery

Fuel Valve

Energized to Run

Rack Pull Solenoid

(RP2300 Series shown)

Ignition coil

Energized

to Run

Start

Switch

ST

IGN

BAT

ACC

Alternator

S

B

Starter

B

+

Exciter

Page 6

WS-93002N page 6 of 7

B+

GRDSIG

Hourmeter

Tachometer

To Magnetic Senso

Alternator "Tach"

Terminal, or

Signal Generator

Voltmeter

760A/761APH

20T

Temperature

20P

Pressure

PB128S Stop Switch

_

+

_

+

760A and 761APH

Must specify 12 or 24 VDC.

Specify positive or

negative ground.

30 second time delay

standard.

GNONC BS

TD

Other

Swichgage instruments

NOTE 1

NOTE 1: With terminal “G” grounded, the time delay operates only on start; after the initial time delay,

the shut-down circuit is operated immediately when Swichgage contact operates.

With terminal “G” not grounded, the time delay operates both on start and stop.

Ignition coil

Distributor

Fuel Valve

(Murphy's SV Series)

Energized to Run Rack Pull Solenoid

(Murphy's RP2300 Series shown)

Energized

to Run

_

+

Ammeter

Battery

_

+

ST

ACC

IGN

BAT

Start

Switch

Alternator

B

+

Starter

S

B

Exciter

CAUTION: This wiring is typical for Murphy W-Series small engine panels. Items shown may or may not be included in your panel;

however, the circuit is typical of how the component will be wired if it is included. Refer to installation instructions for the specific

component if included. For off-panel items such as shutdown devices, see specific instructions supplied with the device.

TYPICAL WIRING DIAGRAM WITH 760A AND 761APH

Page 7

WS-93002N page 7 of 7

TROUBLESHOOTING TIPS

SYMPTOM PROBABLE CAUSE CORRECTIVE ACTION

Engine will not start.

Pointer burned in two.

False shutdown.

SWICHGAGE®contact closes

but does not trip the magnetic

switch to stop the engine.

Inaccurate readings.

Engine does not stop

immediately.

Magnetic Switch trips but

engine does not stop.

1. Blown fuse at magnetic switch.

2. Accidental ground to (S) or (C) terminals.

3. Overload circuit due to accessories.

4. Open circuit in 518PH wiring.

Overload of pointer contact due to exces

sive load or short circuit.

1. Wire from Swichgage instrument is

grounded or shorted to contact.

2. Closed Loop circuit has intermittent

open or short.

3. Excessive shock or vibration causes

magnetic switch to trip.

4. Lack of coolant around temperature sensing

bulb causes “hot spot”.

5. Temperature capillary routed too close to

exhaust manifold.

Incomplete circuit.

1. Pressure orifice plugged with thread sealant.

2. Temperature capillary rerouted too close to

exhaust manifold.

3. Broken or crushed temperature capillary.

Fuel shutoff valve used on diesel engine.

Feedback from alternator.

1. Replace fuse.

2. Check for ground and correct.

3. Re-route accessory circuits.

4. Repair circuit.

Remove or reduce load; remove short circuit and replace

Swichgage instrument.

1. Remove ground or short.

2. Check all wiring and repair.

3. Isolate panel from shock/vibration.

4. Check coolant level; loosen the union nut to allow trapped

air to escape.

5. Reroute temperature capillary.

Locate open circuit and repair; turn the contact adjustment

against the pointer causing them to “wipe” against each

other. Be sure magneto is providing power to primary

terminal post. CD type magnetic switch used with magneto.

1. Remove and clean pressure orifice.

2. Reroute capillary.

3. Replace Swichgage instrument.

Be sure all fittings are air tight; use check valve in bypass

line; use rack puller in place fuel valve.

Install diode in excitation circuit.

These instructions will assist in the correction of most problems which you may encounter with the panel. Before checking the list, first refer

to the wiring connections and operation procedures and make sure the panel is properly installed. If problems persist after making the

following checks, consult any Murphy facility.

Make sure the voltage and current requirements are within the W-Series ratings.

Determine the polarity for

the application. Use appropriate wire size for voltage and current.

Warranty

A limited warranty on materials and workmanship is given with this FW Murphy product.

A copy of the warranty may be viewed or printed by going to www.fwmurphy.com/support/warranty.htm

In order to consistently bring you the highest quality, full featured products, we reserve the right to change our specifications and designs at any time.

In order to consistently bring you the highest quality, full featured products, we reserve the right to change our

specifications and designs at any time. MURPHY, the Murphy logo, and Swichgage

®

are registered and/or common

law trademarks of Murphy Industries, Inc. This document, including textual matter and illustrations, is copyright

protected by Murphy Industries, Inc., with all rights reserved. (c) 2006 Murphy Industries, Inc.

www.fwmurphy.com

918.317.4100 Email: sales@fwmurphy.com

Loading...

Loading...