Page 1

Shock/Vibration Control Switches

Installation Instructions

Models: VS2, VS2C, VS2EX, VS2EXR, VS2EXRB and VS94

GENERAL INFORMATION

Please read the following instructions before installing. A visual inspection of this product for damage during shipping is recommended before

mounting. It is your responsibility to have a qualified person install the unit, and make sure installation conforms with NEC and local codes.

Model VS2EX

LISTED

*

BEFORE BEGINNING INSTALLATION OF THIS MURPHY PRODUCT

✔✔

Disconnect all electrical power to the machine.

✔✔

Make sure the machine cannot operate during installation.

✔✔

Follow all safety warnings of the machine manufacturer.

✔✔

Read and follow all installation instructions.

VS-7037N

Revised 04-05

Section 20

(00-02-0185)

R

VS-7037N page 1 of 8

Description

The Murphy shock and vibration switches are available in a variety of

models for applications on machinery or equipment where excessive

vibration or shock can damage the equipment or otherwise poses a

threat to safe operation. A set of contacts is held in a latched position

through a mechanical latch and magnet mechanism. As the level of

vibration or shock increases an inertia mass exerts force against the

latch arm and forces it away from the magnetic latch causing the latch

arm to operate the contacts. Sensitivity is obtained by adjusting the

amount of the air gap between the magnet and the latch arm plate.

Applications include all types of rotating or reciprocating machinery

such as cooling fans, engines, pumps, compressors, pump jacks, etc.

Models

VS2: Base mount; non hazardous locations.

VS2C: C-clamp mount; non hazardous locations.

VS2EX: Explosion-proof; Class I, Div. 1,

Groups C and D.

VS2EXR: Explosion-proof with remote reset.

VS2EXRB: Explosion-proof; Class I, Div. 1, Group B; with

remote reset.

VS94: Base mount; non hazardous locations, NEMA 4X/IP66.

Remote Reset Feature (VS2EXR,

VS2EXRB and VS94 only)

Includes built-in electric solenoid which allows reset of tripped unit from a

remote location. Standard on VS2EXR and VS2EXRB. Optional on

VS94 (options listed below).

-R15: Remote reset for 115 VAC

-R24: Remote reset for 24 VDC

Time Delay Option (VS94 only)

Overrides trip operation on start-up. For VS94 series models, the delay

time is field-adjustable from 5 seconds up to 6-1/2 minutes with a 20turn potentiometer (15 seconds per turn approximately). Options listed

below:

-T15: Time delay for 115 VAC

-T24: Time delay for 24 VDC

Space Heater Options (VS94 only)

This optional space heater board prevents moisture from condensing

inside the VS94 Series case. Options listed below:

-H15: Space heater for 115 VAC

-H24: Space heater for 24 VDC

Warranty

A limited warranty on materials and workmanship is given with this FW

Murphy product. A copy of the warranty may be viewed or printed by going

to www.fwmurphy.com/support/warranty.htm

WARNING

Page 2

VS-7037N page 2 of 8

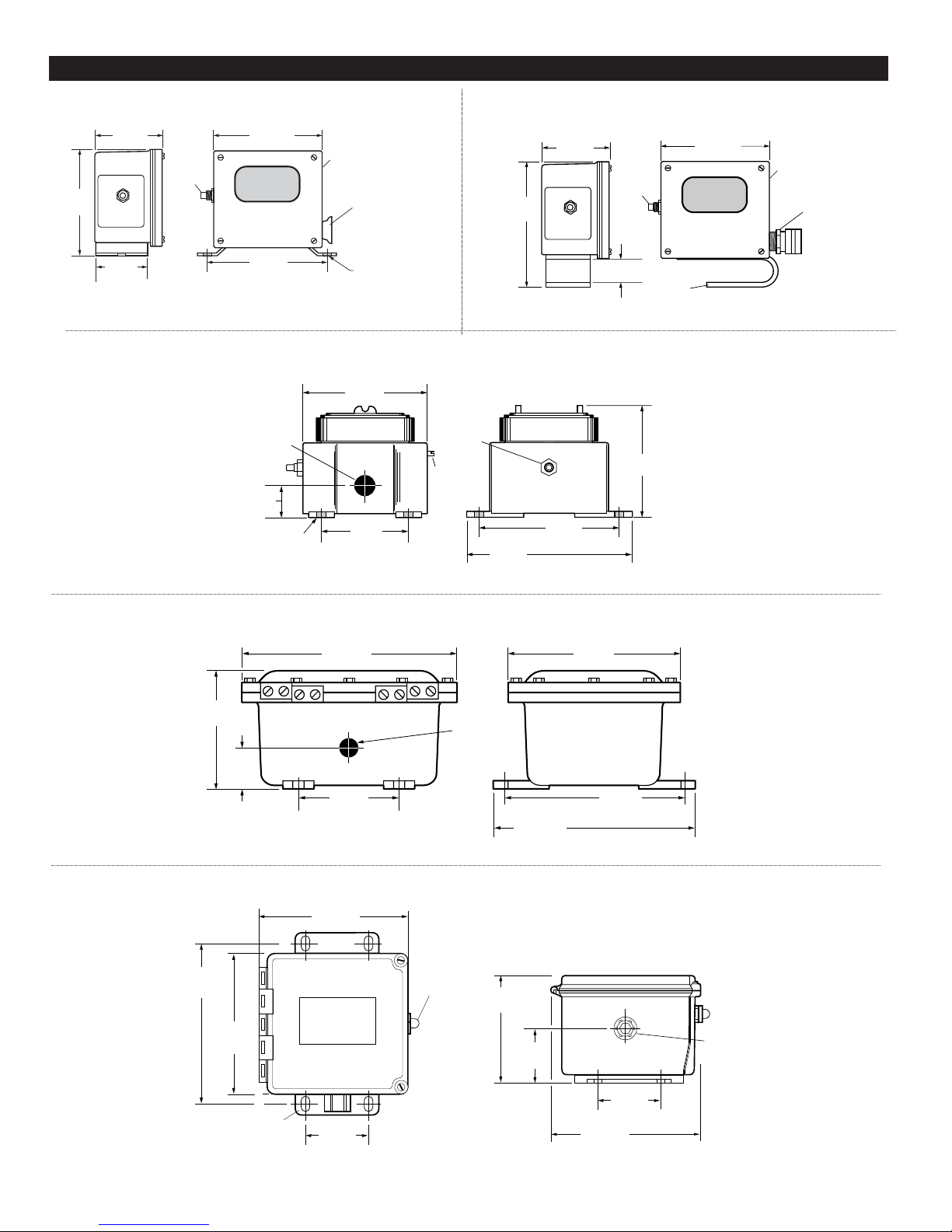

DIMENSIONS

3 in.

(76 mm)

4-3/4 in.

(121 mm)

2-1/4 in.

(57 mm)

5-1/8 in.

(130 mm)

Mounting Holes

Slotted

Sensitivity

Adjustment

Reset

Push

Button

4-19/32 in.

(116 mm)

Plug

1/4 x 1/2 in.

(6 mm x 13 mm)

Slot 2 places

3 in.

(76 mm)

4-3/4 in.

(121 mm)

Slotted

Sensitivity

Adjustment

5-7/16 in.

(138 mm)

Reset

Push

Button

Weatherproof

Strain Relief

Bushing

C-Clamp

27/32 in.

(21 mm)

1/2 NPT

Conduit

5-5/8 in.

(143 mm)

3 in.

(76 mm)

Mounting Holes

Reset

Push

Button

Slotted

Sensitivity

Adjustment

5-1/4 in.

(133 mm)

Mounting Holes

4-7/8 in.

(124 mm)

6-3/8 in.

(162 mm)

3/8 in.

(10 mm)

4 places

1-3/4 in.

(44 mm)

10-5/8 in.

(270 mm)

6 in.

(152 mm)

4-1/2 in.

(114 mm)

Mounting Centers

1/2 NPT

Conduit

9-1/8 in.

(232 mm)

Mounting Centers

10-3/16 in.

(259 mm)

8-5/8 in.

(219 mm)

2-1/2 in.

(64 mm)

VS2

VS2C

VS2EX and VS2EXR

VS2EXRB

7-9/64 in.

(181 mm)

4 in.

(102 mm)

6-1/2 in.

(165 mm)

6-29/32 in.

(176 mm)

Manual

Reset

Push-button

Mounting slot

5/16 x 9/16 in.

(8 x 14 mm)

4-places.

6-1/2 in.

(165 mm)

4-5/8 in.

(118 mm)

1-5/8 in.

(41 mm)

4 in.

(102 mm)

3/4 NPT

conduit fitting

VS94

Page 3

VS-7037N page 3 of 8

SPECIFICATIONS

VS2 and VS2C

•

Case: Weatherproof (equal to NEMA 3R) suitable for non-hazardous areas.

VS2: Base mount

VS2C: C-clamp mount. Includes 45 feet (13.7 meters), 2-conductor 16

AWG, 30 strands/0.25 mm strand dia. (1.5 mm2) cable, and five cable

hold down clamps.

•

Contacts: SPDT double make leaf contacts, 5A @ 480 VAC.

•

Range adjustment: 0 - 7 G’s; 0 - 100 Hz /0.100 in. displacement.

VS2EX

•

Case: Explosion-proof and weatherproof aluminum alloy housing;

meets NEMA 7/IP50 specifications; Class I, Division 1, Groups C &

D; UL and CSA listed.*

VS2EX: base mount.

•

Snap-switches: 2-SPDT snap-switches; 5A @ 480 VAC;*

2A resistive, 1A inductive, up to 30 VDC.

•

Range adjustment: 0 - 7 G’s; 0 - 100 Hz /0.100 in. displacement.

•

Normal Operating Temperature: -40 to 140°F (-40 to 60°C).

VS2EXR

•

Case: Same as VS2EX.

•

Snap-switch: 1-SPDT snap-switch and reset coil; 5A @ 480 VAC;*2A

resistive, 1A inductive, up to 30 VDC.

•

Remote Reset (optional):

Option Operating Current

-R15: 350 mA @ 115 VAC

-R24: 350 mA @ 24 VDC

•

Range adjustment: 0 - 7 G’s; 0 - 100 Hz /0.100 in. displacement.

•

Normal Operating Temperature: -40 to 140°F (-40 to 60°C).

VS2EXRB

•

Case: Explosion-proof aluminum alloy housing; rated Class I,

Division 1, Group B hazardous areas.

•

Snap-switch: 1-SPDT snap-switch with reset coil (option available for

additional SPDT switch); 5A @ 480 VAC; 2A resistive, 1A inductive,

up to 30 VDC.

•

Remote Reset:

Option Operating Current

-R15: 350 mA @ 115 VAC

-R24: 350 mA @ 24 VDC

•

Range adjustment: 0 - 7 G’s; 0 - 100 Hz /0.100 in. displacement.

VS94

•

Case: Polyester fiberglass reinforced; NEMA type 4 and 4X; IP66; CSA

types 4 and 12.

•

Conduit Fitting: 3/4 NPT conduit fitting connection.

•

Normal Operating Ambient Temperature:

0 to 140°F (-18 to 60°C).

•

Snap-switches: 2-SPDT snap acting switches; 5A @ 480 VAC; 2A

resistive, 1A inductive, up to 30 VDC.

•

Range adjustment: 0 - 7 G’s; 0 - 100 Hz /0.100 in. displacement.

•

Heater (optional):

Option Operating Current

H15 .023 A @ 115 VAC

H24 .12 A @ 24 VDC

•

Remote Reset (optional):

Option Operating Current

R15 .17 A @ 115 VAC

R24 .36 A @ 24 VDC

•

Time Delay (optional):

Option Operating Current Standby Current

T15 .360 A @ 115 VAC .01 A @ 115 VAC

T24 1.15 A @ 24 VDC .01 A @ 24 VDC

•

Time Delay/Remote Reset: Adjustable 20-turn potentiometer from

5 seconds to 6-1/2 minutes (15 seconds per turn approximately).

*CSA and UL listed with 480 VAC rating.

The VS2 and VS94 series shock switches are sensitive to shock and

vibration in all three planes of motion - up/down, front/back and side/side.

Front/back is the most sensitive (The reset pushbutton is located on the

“front” of the unit). For maximum sensitivity mount the unit so that the

front faces into the direction of rotation of the machine. (See Dimensions on

page 2 for sensitivity adjustment location).

The VS2 and VS94 Series must be firmly attached/mounted to the machine

so that all mounting surfaces are in rigid contact with the mounting surface

of the machine. For best results, mount the instrument in-line with the

direction of rotating shafts and/or near bearings. In other words, the reset

push button should be mounted pointing into the direction of shaft rotation

(see page 5). It may be necessary to provide a mounting plate or bracket to

attach the VS2 and VS94 Series to the machine. The mounting bracket

should be thick enough to prevent induced acceleration/vibration upon the

VS2 or VS94 Series. Typically 1/2 in. (13mm) thick plate is sufficient. See

illustrations on page 5 for typical mounting locations.

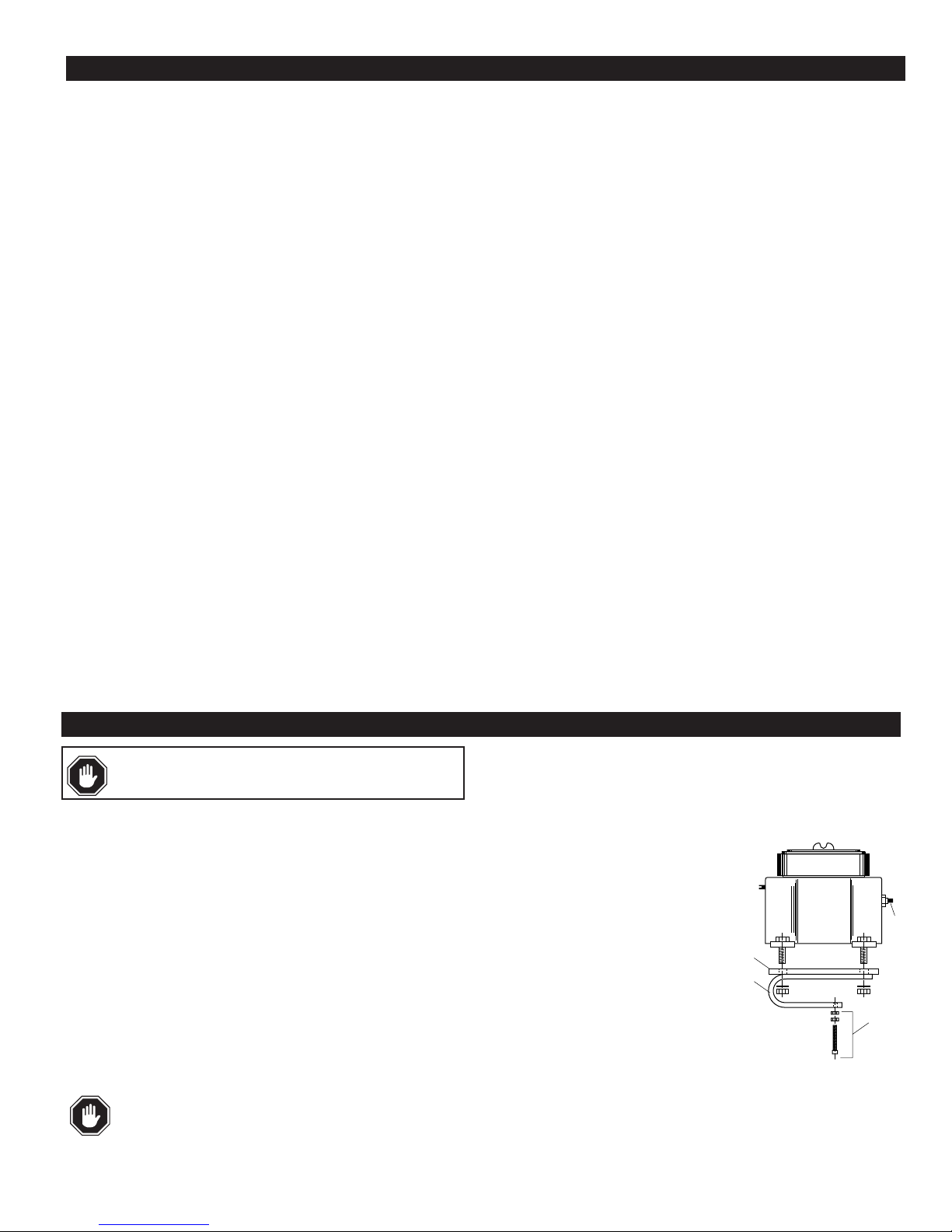

CAUTION:

A dust boot is provided on the reset pushbutton

for all series to prevent moisture or dust intrusion. The sensitivity

adjustment for model VS2EX is not sealed; therefore, mounting

orientation should be on a horizontal plane or with the sensitivity adjustment

pointing down. Sensitivity adjustment for model VS2 is covered by a plug.

The plug must be in place and tight to prevent moisture or dust intrusion.

C-Clamp Installation (VS2C model only)

A C-Clamp is supplied with the VS2C model only.

The C-Clamp is shipped installed on the VS2C

but must be installed on the VS2EX and

VS2EXR switches.

1. The C-Clamp (B) will already be installed on

a 1/4 in. (6 mm) thick steel mounting plate

(A). Bolt the VS2 switch to the mounting

plate as illustrated — with four 5/16 in.

bolts, nuts, and washers.

2. The mounting location should provide

convenient access to the TATTLETALE

®

push button (C).

3. The hardened set screw and nuts (D) are used to

tighten the switch to an I-Beam or cross member such as a

Sampson post of an oilwell pumpjack.

WARNING: STOP THE MACHINE AND DISCONNECT ALL

ELECTRICAL POWER BEFORE BEGINNING INSTALLATION.

INSTALLATION

Continued on next page.

A

B

C

D

Page 4

All Models

1. Firmly secure the unit to the equipment using the base foot mount or

C-Clamp if applicable. See C-Clamp Installation page 3.

For oilwell pumpjacks attach the VS2 and VS94 Series to the Sampson

post or walking beam. See Typical Mounting Locations page 5.

2. Make the necessary electrical connections to the vibration switch. See

Internal Switches, page 6 for electrical terminal locations and page 7 for

typical wiring diagrams. DO NOT EXCEED VOLTAGE OR CURRENT

RATINGS OF THE CONTACTS. Follow appropriate electrical

codes/methods when making electrical connections. Be sure that the run of

electrical cable is secured to the machine and is well insulated from

electrical shorting. Use of conduit is recommended.

NOTE: If the electrical cable crosses a pivot point such as at the pivot of

the walking beam, be sure to allow enough slack in the cable so that no

stress is placed on the cable when the beam moves.

If conduit is not used for the entire length of wiring, conduit should be

used from the electrical supply box to a height above ground level that

prevents damage to the exposed cable from the elements, rodents, etc. or

as otherwise required by applicable electrical codes. If conduit is not

attached directly to the VS2 and VS94 Series switch, use a strain relief

bushing and a weatherproof cap on the exposed end of the conduit. A

“drip loop” should be provided in the cable to prevent moisture from

draining down the cable into the conduit should the weathercap fail.

Sensitivity Adjustment

All models of the VS2 and VS94 Series cover a wide range of sensitivity.

Each model is adjusted to the specific piece of machinery on which it is

installed. After the switch has been installed in a satisfactory location (see

page 5) the sensitivity adjustment will be increased or decreased so that the

switch does not trip during start-up or under normal operating conditions.

This is typically done as follows:

1. REPLACE ALL COVERS, LIDS, AND

ELECTRICAL ENCLOSURES.

2. Press the reset push button to engage the magnetic latch. To be sure the

magnetic latch has engaged, observe latch

through the window on the VS2 and

VS2C (see DETAIL “A”). On the

VS2EX, VS94 series the reset button

will remain depressed meaning the

magnetic latch has engaged.

3. Start the machine.

4. If the instrument trips on start-up,

allow the machine to stop. Turn the sensitivity adjustment 1/4 turn

clockwise, (adjustment for VS94 and VS2EXRB models is located within

the box, see DETAIL “B”).

Depress the reset button and restart the machine. Repeat this process until

the unit does not trip on start-up.

5. If the instrument does NOT trip on start-

up, stop the machine. Turn the sensitivity

adjustment 1/4 turn counter-clockwise.

Repeat the start-up/stop process until the

instrument trips on start-up. Turn the

sensitivity adjustment 1/4 turn clockwise

(less sensitive). Restart the machine to

verify that the instrument will not trip on

start-up.

6. Verify that the unit will trip when abnormal shock/vibration exists.

VS94 Time Delay Adjustment

1. Apply power to the time delay circuit. (see

page 7 for time delay circuit). The time delay function will be initiated.

2. Time the length of the delay with a watch. Let time delay expire. After it

expires, the override circuit will de-energize the solenoid, allowing the latch

arm to trip. A clicking noise is heard.

3. TURN THE POWER OFF TO RESET THE TIME DELAY CIRCUIT.

NOTE: Allow 30 seconds bleed-time between turning the

power “OFF” and “ON”.

4. Locate the time adjustment pot (DETAIL “C”).

The time is factory-set at the lowest setting (5

seconds approximately). To increase time,

rotate the 20-turn pot clockwise as needed

(15 seconds per turn approximately).

5. Repeat the above steps as necessary to

obtain desired time delay.

NOTE: An external time delay can be used

with the remote reset feature of the VS2EXR

series to provide a remote reset and override of the trip

operation on start-up. Time delay must automatically disconnect after

equipment start-up.

VS-7037N page 4 of 8

INSTALLATION

Continued

WARNING: STOP THE MACHINE AND DISCONNECT ALL

ELECTRICAL POWER BEFORE BEGINNING INSTALLATION.

DETAIL “A”

Sensitivity

Adjustment

Reset Push button

DETAIL “C”

Turn to

increase

Pot

Turn to

decrease

WARNING: MAKE THE AREA NON-HAZARDOUS BEFORE

OPENING THE EXPLOSION-PROOF (-EX) ENCLOSURES.

WARNING: REMOVE ALL POWER BEFORE OPENING

THE ENCLOSURE. IT IS YOUR RESPONSIBILITY TO HAVE A

QUALIFIED PERSON PERFORM ADJUSTMENTS, AND MAKE

SURE IT CONFORMS WITH NEC AND LOCAL CODES. DO

NOT ADJUST SENSITIVITY WHILE THE MACHINE IS RUNNING. STAND

CLEAR OF THE MACHINE AT ALL TIMES WHEN IT IS OPERATING.

WARNING: REMOVE ALL POWER BEFORE OPENING

ACCESS DOOR. IT IS YOUR RESPONSIBILITY TO HAVE A

QUALIFIED PERSON ADJUST THE UNIT, AND MAKE SURE

IT CONFORMS WITH NEC AND LOCAL CODES.

DETAIL “B”

Less

Sensitive

Sensitivity

adjustment

More Sensitive

Page 5

VS-7037N page 5 of 8

TYPICAL MOUNTING LOCATIONS

Engine Compressor

Turbine Centrifugal

Compressor

Engine

and

Vertical

Shaft

Pump

“Y” Type

Reciprocating

Compressor

Generator

Sets

Cooling Tower Fan or

Heat Exchanger

Pumping Unit

2-Throw Balance-Opposed Compressor

NOTE: If installing on

cylinders, 2 vibration/shock

switches are recommended1 for each cylinder.

Reset

Reset

Reset

Reset

Reset

These are typical mounting locations for best operation. Other mountings are possible.

See

Installation

section on page 3.

NOTE:

Reset

Reset

Reset

Reset

Page 6

VS-7037N page 6 of 8

INTERNAL SWITCHES

VS2 and VS2C VS2EXR

NO1 NC COM NO2

SPDT Switch Terminals

Sensitivity

Adjustment

Remote Reset

Terminal

Sensitivity

Adjustment

NC NO COM

Ground

Terminal

SPDT Snap-Switch

VS2EX

SPDT Snap-Switch

SPDT Snap-Switch

NC NO COM

NC NO COM

Sensitivity

Adjustment

Ground

Terminal

SPDT

Snap-Switch

VS94

VS2EXB and VS2EXRB

NC NO COM

SPDT

Snap-Switch

Time Delay and/or

Remote Reset

Terminal (Optional)

NC NO COM

Remote Reset

Terminal

Sensitivity

Adjustment

Ground

Terminal

Optional SPDT

Snap-Switch

(VS2EXRB only)

SPDT

Snap-Switch

NC NO COM

NC NO COM

Ground

Terminal

Sensitivity

Adjustment

Heater Board

Terminal (Optional)

Page 7

VS-7037N page 7 of 8

WARNING: REMOVE POWER BEFORE OPENING THE UNIT (ACCESS DOOR). STOP THE MACHINE AND DISCONNECT ALL

ELECTRICAL POWER BEFORE BEGINNING THE WIRING OPERATION. IT IS YOUR RESPONSIBILITY TO HAVE A QUALIFIED

PERSON INSTALL AND WIRE THE UNIT, AND MAKE SURE IT CONFORMS WITH NEC AND APPLICABLE CODES.

ELECTRICAL

Typical Wiring Diagram for Single or Dual CD Ignition

VS2 and VS2C

Resistor

SPDT Switch

COM

To good

engine ground

CD Ignition

2

Contacts shown in the RESET position.

(100 Ω, 3 Watt)

CD Ignition

1

VS2EXR and VS2EXRB

Typical Wiring Diagram for Single or Dual CD Ignitions

SPDT Switch

(Optional 2-SPDT [DPDT])

Contacts shown in the

RESET position

N.C.N.O.

N.C.N.O.

Momentary

Push Button

115 VAC or

Voltage

24 VDC (

is specified

when ordered).

Remote Reset

Typical Wiring Diagram for Single or Dual CD Ignitions

VS2EX

SPDT Switch

(Optional 2-SPDT [DPDT])

Contacts shown in the

RESET position

NO2NCNO1

CD Ignition

2

CD Ignition

1

Resistor

(100 Ω, 3 Watt)

N.C.N.O.

N.C.N.O.

†

COM

COM

To good

engine ground

To good

engine

ground

VS94

Typical Wiring Diagram for Single or Dual CD Ignitions

2-SPDT

Switches (DPDT)

Contacts shown in the

RESET position

N.C.N.O.

N.C.N.O.

COM

COM

To good

engine

ground

COM

COM

†

To good

engine

ground

†

Additional

Switch

Optional

on VS2EXRB

only

Momentary

Contact for

Remote

Reset only

Maintained

Contact for

Time Delay

115 VAC or

24 VDC

Time Delay or

Remote Reset

(Optional)

115 VAC or 24 VDC

Time

Delay

*

*

CD Ignition

2

CD Ignition

Resistor

(100 Ω, 3 Watt)

1

VS2, VS2C, VS2EX, VS2EXR, VS2EXRB and VS94

Typical Wiring Diagram for Electric Motors

NOTE: Terminal N.O. is

terminal NO1 on models

VS2 and VS2C.

L1 L2 L3

MOTOR

Switch Terminals

N.O.

(see Note)

Push-button

Station

HC

N.C.

Hand Off

Automatic

Selector

HC

To good

engine ground

Contacts shown

in the RESET position

COM

A

H

1

Heater Board

(Optional)

Resistor

(100 Ω, 3 Watt)

To good

engine ground

*

Voltage is specified

when ordered.

CD Ignition

VS2, VS2C, VS2EX, VS2EXR, VS2EXRB and VS94

Typical Wiring Diagram for Distributor Ignition or Diesel

NOTE: Terminal N.O. is

terminal NO1 on models

VS2 and VS2C.

Diesel Fuel

Shutoff Valve

Ignition Coil

Switch Terminals

N.O.

(see Note)

Distributor

N.C.

Contacts shown

in the RESET position

COM

Ignition

Switch

Ammeter

Battery

CD Ignition

2

Page 8

VS-7037N page 8 of 8

SERVICE PARTS

PART NO. DESCRIPTION

VS2

20000030 Movement assembly

20000031 Glass and gasket assembly

20000032 Reset push button assembly

VS2C

20000030 Movement assembly

20000031 Glass and gasket assembly

20000032 Reset push button assembly

20050021 Mounting clamp

20000185 VS2C 5-clamp hardware package assembly.

20050465 2-Conductor electrical cable, 45 feet (13.7 meters)

VS2EX

20010091 Movement assembly

20050087 Cover

00000309 Cover gasket

20010090 Snap-switch and insulator kit (1 switch per kit)

prior to September 1, 1995.*

20000288 Snap-switch and insulator kit (1 switch per kit) for models

manufactured on September 1, 1995 or later.*

20000289 C-clamp conversion mounting kit

VS2EXR

20000262 Movement assembly

20050087 Cover

00000309 Cover gasket

20010090 Snap-switch and insulator kit (1 switch per kit)

prior to September 1, 1995.*

20000288 Snap-switch and insulator kit (1 switch per kit) for models

manufactured on September 1, 1995 or later.*

20000049 Reset solenoid assembly (115 VAC)

20000234 Reset solenoid assembly (24 VDC)

20000289 C-clamp conversion mounting kit

PART NO. DESCRIPTION

VS2EXRB

20010090 Snap-switch and insulator kit (1 switch per kit)

prior to September 1, 1995.*

20000288 Snap-switch and insulator kit (1 switch per kit) for models

manufactured on September 1, 1995 or later.*

20000057 Inside snap-switch and insulator kit (1 switch per kit) for

model VS2EXRB-D prior to September 1, 1995.*

20000058 Outside snap-switch and insulator kit (1 switch per kit) for

model VS2EXRB-D prior to September 1, 1995.*

20000287 Outside snap-switch and insulator kit (1 switch per kit) for model

VS2EXRB-D manufactured on September 1, 1995 or later.*

20000290 Inside snap-switch and insulator kit (1 switch per kit) for model

VS2EXRB-D manufactured on September 1, 1995 or later.*

20050077 Adjustment shaft

20000262 Movement assembly

20000049 Reset solenoid assembly (115 VAC)

20000234 Reset solenoid assembly (24 VDC)

VS94 Series

25050506 Dust boot

00000232 Conduit fitting

20010090 Snap-switch and insulator kit (1 switch per assembly)

prior to September 1, 1995.**

20000288 Snap-switch and insulator kit (1 switch per assembly)

for models manufactured on September 1, 1995 or later.***

* If no date code is found, refer to the old switch. Models with date 0895 and before use old switch.

Dated 0995 after, use straight snap-switch arm, no rollers.

** Models dated Q1 thru Q8 (formed snap-switch arm and rollers).

***Models date coded Q9 thru Q12 and R1 thru R12 (straight snap-switch arm, no rollers).

CONTROL SYSTEMS & SERVICES DIVISION

P.O. Box 1819; Rosenberg, Texas 77471; USA

+1 281 633 4500 fax +1 281 633 4588

e-mail sales@fwmurphy.com

INDUSTRIAL PANEL DIVISION

P.O. Box 470248

Tulsa, Oklahoma 74147 USA

+1 918 317 4100 fax +1 918 317 4266

e-mail sales@fwmurphy.com

FRANK W. MURPHY, LTD.

Church Rd.; Laverstock, Salisbury SP1 1QZ; U.K.

+44 1722 410055 fax +44 1722 410088

e-mail sales@fwmurphy.co.uk

www.fwmurphy.co.uk

MURPHY DE MEXICO, S.A. DE C.V.

Blvd. Antonio Rocha Cordero 300, Fracción del Aguaje

San Luis Potosí, S.L.P.; México 78384

+52 444 8206264 fax +52 444 8206336

Villahermosa Office +52 993 3162117

e-mail ventas@murphymex.com.mx

www.murphymex.com.mx

In order to consistently bring you the highest quality, full featured products, we reserve the right to change our specifications and designs at any time.

FW Murphy

P.O. Box 470248

Tulsa, Oklahoma 74147 USA

+1 918 317 4100 fax +1 918 317 4266

e-mail sales@fwmurphy.com

www.fwmurphy.com

Printed in U.S.A. 078792

Loading...

Loading...