Murphy SM1, SM1VR, SM2, SM3VR, SM4 User Manual

...

TSM-95129N

®

FRANK W.

MFR.

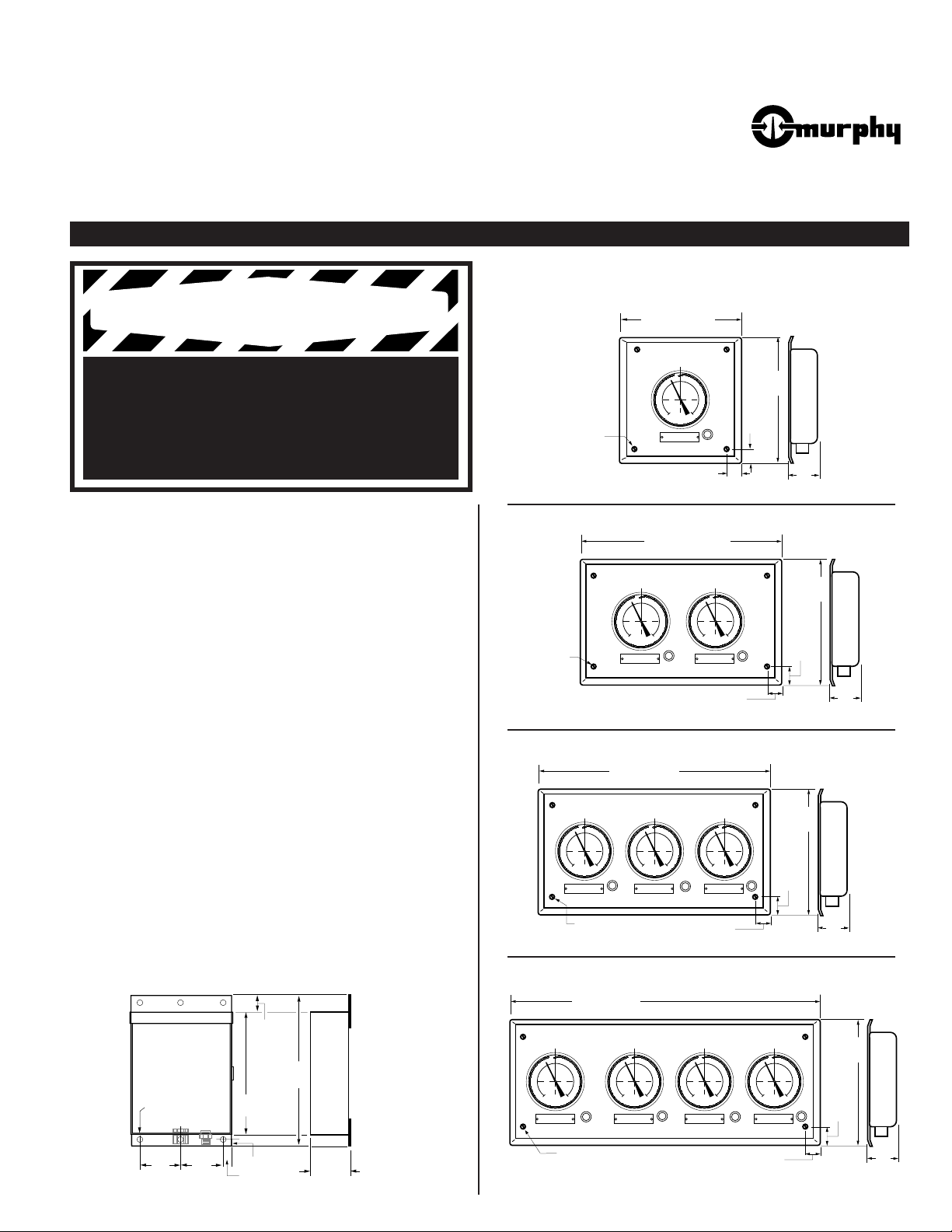

1-1/2 in. (38 mm)

1/4 in.

(6 mm) dia.

4-places

Mounting Holes

1-1/2 in.

(38 mm)

14 in. (355 mm)

14 in.

(355 mm)

3 in.

(76 mm)

1/4 in.

(6 mm) dia.

4-places

Mounting Holes

25-3/8 in. (645 mm)

14 in.

(355 mm)

3 in.

(76 mm)

1-3/16 in.

(30 mm)

2-1/2 in.

(63 mm)

12-1/4 in.

(311 mm)

1-1/4 in.

(32 mm)

9/32 in.

(7 mm) dia.

6-places

10 in.

(254 mm)

5/8 in.

(16 mm)

4-1/8 in.

(105 mm)

3 in.

(76 mm)

3 in.

(76 mm)

36 in. (914 mm)

1/4 in. (6 mm) dia.

4-places–Mounting Holes

14 in.

(355 mm)

3 in.

(76 mm)

1-3/16 in.

(30 mm)

2-1/2 in.

(63 mm)

14 in.

(355 mm)

3 in.

(76 mm)

1-3/16 in.

(30 mm)

2-1/2 in.

(63 mm)

39-1/2 in. (1 m)

1/4 in. (6 mm) dia.

4-places–Mounting Holes

Revised 01-97

SM Series TANKTENDTMSystems

Section 15

(00-02-2019)

Installation and Operation Instructions

Models: SM1, SM1VR, SM2, SM2VR, SM3, SM3VR, SM4, SM4VR

Please read the following information before installing. A visual inspection of this product for damage during shipping is recommended

before mounting. It is your responsibility to have a qualified person install this unit and make sure it conforms to NEC and local codes.

GENERAL INFORMATION

Mounting Dimensions

SM1 / SM1VR (1-Tank Monitoring Systems)

WARNING

BEFORE BEGINNING INSTALLATION OF THIS MURPHY PRODUCT

✔ Disconnect all electrical power to the machine.

✔ Make sure the machine cannot operate during installation.

✔ Follow all safety warnings of the machine manufacturer.

✔ Read and follow all installation instructions.

The SM Series System

can monitor above or below ground,

single or multi-tank systems (4 tanks maximum). The SM Series

includes BGT1 gage (s) in a wall mounting panel. The SMVR series

includes a vapor recovery option that compensates for gas blankets or

head pressure caused by vapor recovery storage systems.

The SM includes a push-button actuated electrical pump assembly, that

supplies the air to clear sensing lines for current readings. Pump operating voltages available are 120 or 230 VAC (see below).

SM Series Specifications

Panel: Hollow wall mount, cold rolled steel, painted.

Shipping Weight (P100 Pump included):

SM1: 27 lb. (12.25 kg) approximately.

SM2: 44 lb. (20 kg) approx.

SM3: 54 lb. (24.5 kg) approx.

SM4: 65 lb. (29.5 kg) approx.

Shipping Dimensions for All Models (P100 Pump included):

40 x 9 x 15-3/4 in. (1016 x 229 x 400 mm).

SMPA and SMPA230 Pump Assemblies

Operating Voltage: 120 VAC (SMPA); 230 VAC (SMPA230).

2

Power Cable: Insulated, 16 AWG (1.5 mm

) x 8 ft. (2.4 m).

Case: Weatherproof enclosure; painted.

Shipping Weight: 10 lbs. (4.53 kg).

Shipping Dimensions: 12 x 12 x 10 in. (305 x 305 x 254 mm).

SM2 / SM2VR

SM3 / SM3VR

(2-Tank Monitoring Systems)

(3-Tank Monitoring Systems)

*

*

SMPA and SMPA230 Mounting Dimensions

SM4 / SM4VR

(4-Tank Monitoring Systems)

*

* Mounting dimensions also apply for vertical mounting configurations.

INSTALLATION

A

B

C

D

E

F

G

Steel Tube Located

3 in. (76 mm) Off

Bottom (typical)

A. Manwell

B. Driveway Surface

C. UTKN Tank Plug

D. Coupling

E. Stand-Pipe

F. Tank Plug Opening

G. 1/4 in. (6 mm) dia. Steel Tube

Product

SM1 Model

Below ground

tank (vented)

Tubing

To Pump

Assembly

FEET

MURPHY

LEVELGAGE

A

B

C

D

E

F

G

H

Steel Tube Located

3 in. (76 mm) Off

Bottom (typical)

A. Manwell

B. Driveway Surface

C. UTKN Tank Plug

D. Coupling

E. Stand-Pipe

F. Tank Plug Opening

G. 1/4 in. (6 mm) dia. Steel Tube

H. Vapor Recovery Line

Product

Below ground

tank (vented)

Keep tip of

line above

product level

Vapor Recovery

Tubing

Tubing

SM1 Model

To Pump

Assembly

FEET

MURPHY

LEVELGAGE

UTKN Tank Plug

or tank top

1/2 in. (13 mm)

Ferrule

Tubing

Tubing Fitting

(2 included)

Compression

Nut

Hole Plug

1/4 in. (6 mm) dia.

304 Stainless Steel

tubing (probe);

12 ft. (3.6 m) long

Compression

Nut

Ferrule

Hole Plug

Sensor Fitting

UTKN

Tank Plug

Vapor Recovery

connection (plugged)

Tubing

Connection

1/4 x 12 ft. (3.6 m)

Steel Tubing

WARNING: Installation of the SM and SMVR Series MUST BE made by qualified installer. Hazardous conditions exist with flam-

mable and corrosive products. Extinguish all smoking materials. Risk of explosion, fire and burning can cause serious or fatal injury.

Installing a Tank Plug Kit (all models)

The tank plug kit includes 12 ft. (3.6 m) x 1/4 in.

(6 mm) dia. stainless steel tube and fittings.

Tank plug is available in 2 NPT or 4 NPT.

1.

Locate tank(s) service cover and install

a UTKN tank plug kit for each tank.

Necessary hardware is available from

Murphy, refer to “Service Parts and

Accessories” section, on page 4.

2.

Route a tubing line (1/4 in. [6 mm] outside dimension) from the tank top to the

panel location. If applicable, cut a channel in the

driveway surface to route the tubing. The use of rigid conduit is recommended especially when routing the tubing line under a driveway surface.

Refer to Fig. 1, at right.

3.

Before inserting the 1/4 in. (6 mm) dia.

stainless steel tubing (probe) through tank

plug fitting, make sure tubing can reach

bottom and also will allow extra tubing for adjustments. Now lower the

tubing until it touches the bottom

of the tank, do this as follows

(refer to Detail A, at right):

A. First, loosen ferrule and ferrule

fitting nut.

B. Insert the tubing through the

ferrule nut and fitting.

C. Mark tubing at top of fitting–raise tub-

ing exactly 3 in. (76 mm) off bottom and

finger tighten ferrule and compression nut.

Tank Plug

Detail A

Fig. 1

Fig. 2

SM Series Typical Installation

SMVR Series (Vapor Recovery Systems)

typical Installation

D. Cut excess stainless steel tubing allowing 1/2 in. (13 mm) extension

4.

Connect tubing line to tank probe as shown

(refer to Detail B, at right).

5.

Now connect other end of tubing line

to the SM/SMVR gage panel fitting. Tubing should be continuous

length without splices.

6.

For SMVR models, connect a

second line from the tank top (if

using UTKN kit, remove Hole

Plug and install second sensor fitting and line) to the SMVR gage 1/8

NPTF fitting line. Second sensing line

is to be installed through the tank top and

into the tank, but keep the tip of the line above

product level (refer to Fig. 2, at right and Fig. 3, next page).

7.

Securely tighten all fittings; all connections must be air tight.

2

prohibit re-adjustment if necessary.

above the compression nut.

CAUTION:

Excessive tightening of ferrule fittings will

Detail B

Loading...

Loading...