Page 1

TSM-95129N

®

FRANK W.

MFR.

1-1/2 in. (38 mm)

1/4 in.

(6 mm) dia.

4-places

Mounting Holes

1-1/2 in.

(38 mm)

14 in. (355 mm)

14 in.

(355 mm)

3 in.

(76 mm)

1/4 in.

(6 mm) dia.

4-places

Mounting Holes

25-3/8 in. (645 mm)

14 in.

(355 mm)

3 in.

(76 mm)

1-3/16 in.

(30 mm)

2-1/2 in.

(63 mm)

12-1/4 in.

(311 mm)

1-1/4 in.

(32 mm)

9/32 in.

(7 mm) dia.

6-places

10 in.

(254 mm)

5/8 in.

(16 mm)

4-1/8 in.

(105 mm)

3 in.

(76 mm)

3 in.

(76 mm)

36 in. (914 mm)

1/4 in. (6 mm) dia.

4-places–Mounting Holes

14 in.

(355 mm)

3 in.

(76 mm)

1-3/16 in.

(30 mm)

2-1/2 in.

(63 mm)

14 in.

(355 mm)

3 in.

(76 mm)

1-3/16 in.

(30 mm)

2-1/2 in.

(63 mm)

39-1/2 in. (1 m)

1/4 in. (6 mm) dia.

4-places–Mounting Holes

Revised 01-97

SM Series TANKTENDTMSystems

Section 15

(00-02-2019)

Installation and Operation Instructions

Models: SM1, SM1VR, SM2, SM2VR, SM3, SM3VR, SM4, SM4VR

Please read the following information before installing. A visual inspection of this product for damage during shipping is recommended

before mounting. It is your responsibility to have a qualified person install this unit and make sure it conforms to NEC and local codes.

GENERAL INFORMATION

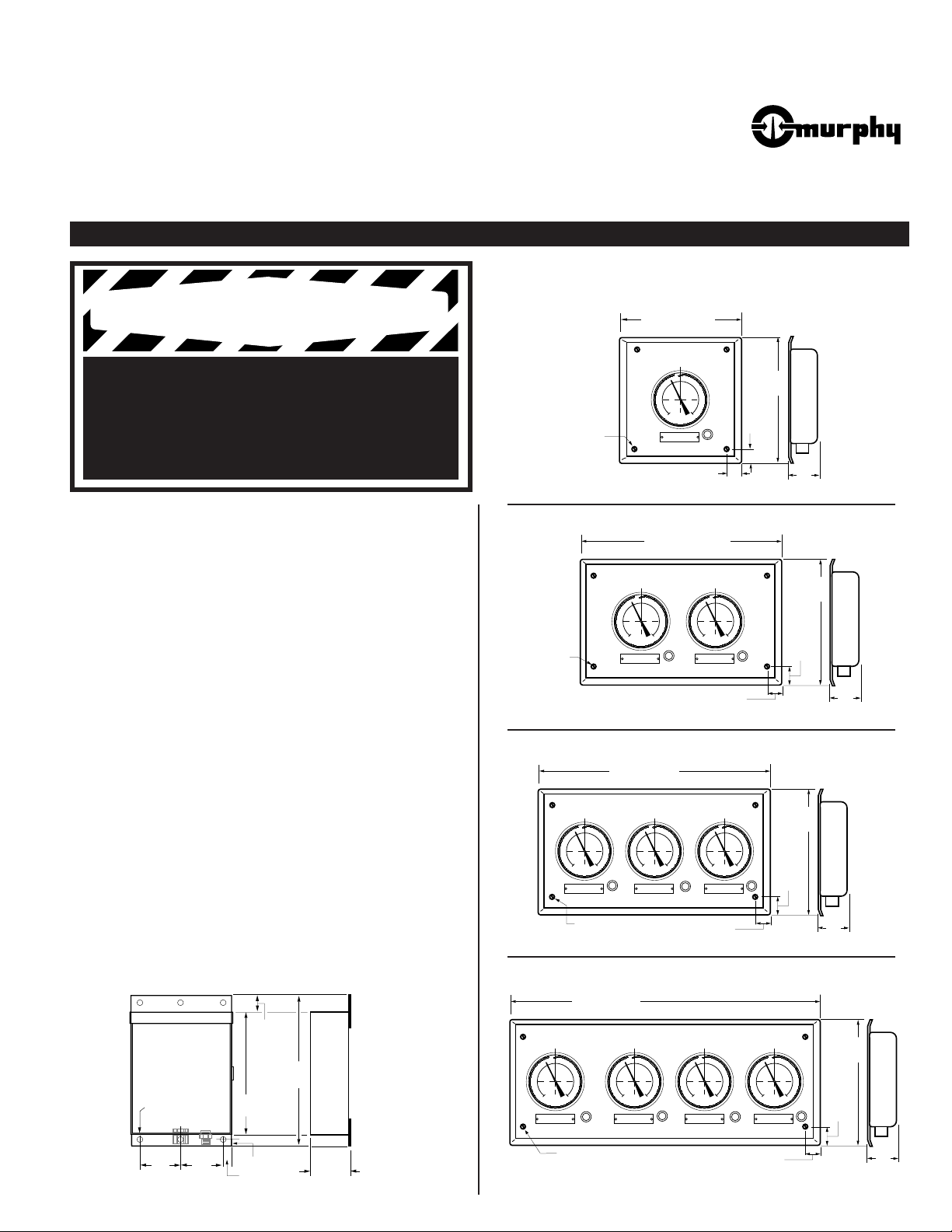

Mounting Dimensions

SM1 / SM1VR (1-Tank Monitoring Systems)

WARNING

BEFORE BEGINNING INSTALLATION OF THIS MURPHY PRODUCT

✔ Disconnect all electrical power to the machine.

✔ Make sure the machine cannot operate during installation.

✔ Follow all safety warnings of the machine manufacturer.

✔ Read and follow all installation instructions.

The SM Series System

can monitor above or below ground,

single or multi-tank systems (4 tanks maximum). The SM Series

includes BGT1 gage (s) in a wall mounting panel. The SMVR series

includes a vapor recovery option that compensates for gas blankets or

head pressure caused by vapor recovery storage systems.

The SM includes a push-button actuated electrical pump assembly, that

supplies the air to clear sensing lines for current readings. Pump operating voltages available are 120 or 230 VAC (see below).

SM Series Specifications

Panel: Hollow wall mount, cold rolled steel, painted.

Shipping Weight (P100 Pump included):

SM1: 27 lb. (12.25 kg) approximately.

SM2: 44 lb. (20 kg) approx.

SM3: 54 lb. (24.5 kg) approx.

SM4: 65 lb. (29.5 kg) approx.

Shipping Dimensions for All Models (P100 Pump included):

40 x 9 x 15-3/4 in. (1016 x 229 x 400 mm).

SMPA and SMPA230 Pump Assemblies

Operating Voltage: 120 VAC (SMPA); 230 VAC (SMPA230).

2

Power Cable: Insulated, 16 AWG (1.5 mm

) x 8 ft. (2.4 m).

Case: Weatherproof enclosure; painted.

Shipping Weight: 10 lbs. (4.53 kg).

Shipping Dimensions: 12 x 12 x 10 in. (305 x 305 x 254 mm).

SM2 / SM2VR

SM3 / SM3VR

(2-Tank Monitoring Systems)

(3-Tank Monitoring Systems)

*

*

SMPA and SMPA230 Mounting Dimensions

SM4 / SM4VR

(4-Tank Monitoring Systems)

*

* Mounting dimensions also apply for vertical mounting configurations.

Page 2

INSTALLATION

A

B

C

D

E

F

G

Steel Tube Located

3 in. (76 mm) Off

Bottom (typical)

A. Manwell

B. Driveway Surface

C. UTKN Tank Plug

D. Coupling

E. Stand-Pipe

F. Tank Plug Opening

G. 1/4 in. (6 mm) dia. Steel Tube

Product

SM1 Model

Below ground

tank (vented)

Tubing

To Pump

Assembly

FEET

MURPHY

LEVELGAGE

A

B

C

D

E

F

G

H

Steel Tube Located

3 in. (76 mm) Off

Bottom (typical)

A. Manwell

B. Driveway Surface

C. UTKN Tank Plug

D. Coupling

E. Stand-Pipe

F. Tank Plug Opening

G. 1/4 in. (6 mm) dia. Steel Tube

H. Vapor Recovery Line

Product

Below ground

tank (vented)

Keep tip of

line above

product level

Vapor Recovery

Tubing

Tubing

SM1 Model

To Pump

Assembly

FEET

MURPHY

LEVELGAGE

UTKN Tank Plug

or tank top

1/2 in. (13 mm)

Ferrule

Tubing

Tubing Fitting

(2 included)

Compression

Nut

Hole Plug

1/4 in. (6 mm) dia.

304 Stainless Steel

tubing (probe);

12 ft. (3.6 m) long

Compression

Nut

Ferrule

Hole Plug

Sensor Fitting

UTKN

Tank Plug

Vapor Recovery

connection (plugged)

Tubing

Connection

1/4 x 12 ft. (3.6 m)

Steel Tubing

WARNING: Installation of the SM and SMVR Series MUST BE made by qualified installer. Hazardous conditions exist with flam-

mable and corrosive products. Extinguish all smoking materials. Risk of explosion, fire and burning can cause serious or fatal injury.

Installing a Tank Plug Kit (all models)

The tank plug kit includes 12 ft. (3.6 m) x 1/4 in.

(6 mm) dia. stainless steel tube and fittings.

Tank plug is available in 2 NPT or 4 NPT.

1.

Locate tank(s) service cover and install

a UTKN tank plug kit for each tank.

Necessary hardware is available from

Murphy, refer to “Service Parts and

Accessories” section, on page 4.

2.

Route a tubing line (1/4 in. [6 mm] outside dimension) from the tank top to the

panel location. If applicable, cut a channel in the

driveway surface to route the tubing. The use of rigid conduit is recommended especially when routing the tubing line under a driveway surface.

Refer to Fig. 1, at right.

3.

Before inserting the 1/4 in. (6 mm) dia.

stainless steel tubing (probe) through tank

plug fitting, make sure tubing can reach

bottom and also will allow extra tubing for adjustments. Now lower the

tubing until it touches the bottom

of the tank, do this as follows

(refer to Detail A, at right):

A. First, loosen ferrule and ferrule

fitting nut.

B. Insert the tubing through the

ferrule nut and fitting.

C. Mark tubing at top of fitting–raise tub-

ing exactly 3 in. (76 mm) off bottom and

finger tighten ferrule and compression nut.

Tank Plug

Detail A

Fig. 1

Fig. 2

SM Series Typical Installation

SMVR Series (Vapor Recovery Systems)

typical Installation

D. Cut excess stainless steel tubing allowing 1/2 in. (13 mm) extension

4.

Connect tubing line to tank probe as shown

(refer to Detail B, at right).

5.

Now connect other end of tubing line

to the SM/SMVR gage panel fitting. Tubing should be continuous

length without splices.

6.

For SMVR models, connect a

second line from the tank top (if

using UTKN kit, remove Hole

Plug and install second sensor fitting and line) to the SMVR gage 1/8

NPTF fitting line. Second sensing line

is to be installed through the tank top and

into the tank, but keep the tip of the line above

product level (refer to Fig. 2, at right and Fig. 3, next page).

7.

Securely tighten all fittings; all connections must be air tight.

2

prohibit re-adjustment if necessary.

above the compression nut.

CAUTION:

Excessive tightening of ferrule fittings will

Detail B

Page 3

INSTALLATION

To Tank 1 Plug

Sensor Fitting

To Tank 2 Plug

Sensor Fitting

SM Panel (SM2 Model Shown)

To Tank 1 Plug

Vapor Recovery

Fitting

To Tank 2 Plug

Vapor Recovery

Fitting

To Pump

Assembly

FEET

MURPHY

LEVELGAGE

FEET

MURPHY

LEVELGAGE

120 VAC or 230 VAC

Tubing to SM Panel

Pressure SWICHGAGE

®

kPa

PRESSURE

0

100

20

40

60

0

300

80

600

PSI

M

U

R

P

H

Y

S

W

I

C

H

G

A

G

E

®

Low trip point

adjustment

High trip point

adjustment

Tubing

Power

Cable

Compression

Nut

Ferrule

Sensor Fitting

Pump

Panel

Turn to Lower

the Pointer

Turn to Raise

the Pointer

Tubing

Check

Valve

Valve

Flat

1/4 NPTM

straight

fitting

1/4 NPTM

straight fitting

Ferrule

Ferrule nut

1/2 NPTM to

1/4 NPTF

Reducer

UTKN Tank Plug

or tank top

Hole Plug

T

A

N

K

Continued

Installing the CKBO Check Valve

The optional CKBO check valve is designed

to prevent product from backing up into the

Detail C

Fig. 3

gage(s). We recommend installing the

CKBO valve at top of the tank plug as

follows (refer to Detail C):

1.

Determine a location for the valve.

Use of sealant on all fitting

threads is strongly suggested.

2.

Attach CKBO to the tank plug

using wrench on valve flats.

See markings on the valve body

for positioning.

3.

Attach tubing to CKBO as shown.

Securely tighten all fittings.

All connections must be air tight.

Installing the SMPA /SMPA230 Pump Assembly

The pump assembly should be installed near the SM or SMVR panel.

Connect the pump as follows (refer to Fig. 3 and 4 also see Detail D):

1.

Before connecting the tubing from the SM or

SMVR panel to the pump assembly, make sure

the tubing reaches the pump assembly

sensor fitting.

2.

Connect the end of the tubing to the sen-

sor fitting as shown at right (Detail D).

Tubing should be continuous length

without splices.

3.

The pump assembly includes a power

cable, 16 AWG (1.5 mm2), 8 ft. (2.4 m)

long. Connect the cable to 120 VAC or

230 VAC power source.

The pump assembly has a pressure SWICHGAGE

with low and high pressure set points. When the gage pointer reaches the

low pressure set point, the pump starts to built up purge pressure. When the

pointer reaches the high set point, sufficient volume is reached stopping the

pump. The set points are factory pre-set for your convenience.

Detail D

Fig. 4

®

SM Panel Tubing Configuration

(SM2 Model shown)

Pump Assembly

Resetting the Pointer

After the SM/SMVR complete system has been connected, reset the pointer

for proper level indication, proceed as follows

(see Fig. 5 and Detail E):

1.

2.

3.

4.

5.

CAUTION:

SM and SMVR models are precalibrated in feet of

static pressure above gage connection. Pointer MUST be reset to zero.

Detail E

Determine actual product level by any reliable

means and record this value.

Very carefully remove the retaining ring

guarding against its spring-action, it can

cause injuries. Remove the lens also.

Carefully hold the pointer, as shown at

right, making sure not to bend it.

With a small screwdriver, turn the setting

screw to corresponding stick reading value

recorded in step 1.

Clockwise to raise the pointer — counter clockwise to lower the pointer.

Replace the lens and snap ring.

Fig. 5

SM Panel (SM2 Model Shown)

Snap Ring

Pointer

FEET

MURPHY

LEVELGAGE

Read Button

UNLEADED UNLEADED

FEET

MURPHY

LEVELGAGE

3

Page 4

INSTALLATION

®

FRANK W.

MFR.

Continued

Operation Sequence

IMPORTANT:

installed and operative. Check that all connections are air tight.

1.

Make sure that the pump assembly is connected to a power source,

either 120 VAC or 230 VAC according to the pump model used.

2.

Depress the read button, located next to the gage(s) and hold until the

gage pointer stops traveling across the scale. See Fig. 6, at right.

3.

When pointer stops release the read button to allow pointer to settle.

4.

The value observed in the dial of the gage, is the level of the tank.

5.

Perform this operation as necessary for each tank to be checked.

Make sure SM Series system is completely

Service Parts and Accessories

UTKN2:

UTKN2LT:

UTKN4:

UTKN4LT:

UTKN4VR:

UTKN4VRLT:

SMPA:

SMPA230:

05090051:

CKBO:

85-01-0405:

85-01-0402:

85-01-0403:

86-03-0405:

85-03-0407:

2 NPTM tank plug kit (includes 12 ft. [3.66 m] of stainless steel tubing/probe and fittings).

2 NPTM tank plug less tubing (includes fittings).

4 NPTM tank plug kit (includes 12 ft. [3.66 m] of stainless steel tubing/probe and fittings).

4 NPTM tank plug less tubing (includes fittings).

4 NPTM tank kit for vapor recovery (tubing and fittings included).

4 NPTM tank plug for vapor recovery– less tubing (includes fittings).

Pump assembly for 120 VAC.

Pump assembly for 230 VAC.

Pressure SWICHGAGE®instrument with low and high pressure limit contacts, 15 psi scale.

Check Valve assembly–prevents product from backing up into gage.

1/2 NPTM x 1/4 NPTF reducing bushing–for CKBO valve mounting.

1/4 in. (6 mm) dia. 316 stainless steel tubing/ft. (probe).

1/4 in. (6 mm) dia. poly tubing/ft. (sensing line).

1/4 x 1/4 male hex nipple kit–for connecting tubing line to tank top.

1/4 x 1/4 male hex fitting kit–for connecting tubing or probe line to the tank top.

Fig. 6

SM Panel (SM2 Model Shown)

Snap Ring

Pointer

FEET

MURPHY

LEVELGAGE

Read Button

UNLEADED UNLEADED

FEET

MURPHY

LEVELGAGE

Warranty

A two year limited warranty on materials and workmanship is provided with this Murphy product.

Details are available on request and are packed with each unit.

In order to consistently bring you the highest quality, full featured products, we reserve the right to change our specifications and designs at any time.

■ Murphy de México, S.A. de C.V.

Blvd. Antonio Rocha Cordero 300, Fracción del Aguaje

San Luis Potosí, S.L.P.; México 78384

tel. +52-48-206264 fax +52-48-206336

e-mail murmexsl@sanluis.podernet.com.mx

■ Murphy Switch of California

P.O. Box 900788; Palmdale, California 93590; USA

tel. (805) 272-4700 fax (805) 947-7570

e-mail sales@murphyswitch.com

■ Frank W. Murphy France

tel. +33 1 30 762626 fax +33 1 30 763989

Since 1939

■ Frank W. Murphy Manufacturer

P.O. Box 470248; Tulsa, Oklahoma 74147; USA

tel. (918) 627-3550 fax (918) 664-6146

e-mail fwmurphy@ionet.net

■ Frank W. Murphy Southern Division

P.O. Box 1819; Rosenberg, Texas 77471; USA

tel. (281) 342-0297 fax (281) 341-6006

e-mail murphysd@intertex.net

Printed in U.S.A.

4

■ Frank W. Murphy, Ltd.

Church Rd.; Laverstock, Salisbury SP1 1QZ; U.K.

tel. +44 1722 410055 fax +44 1722 410088 tlx 477088

e-mail sales@fwmurphy.co.uk

■ Frank W. Murphy Pte., Ltd.

26 Siglap Drive; Republic of Singapore 456153

tel. +65 241-3166 fax +65 241-8382

e-mail fwmsales@fwmurphy.com.sg

■ Murphek Pty., Ltd.

1620 Hume Highway; Campbellfield, Vic 3061; Australia

tel. +61 3 9358-5555 fax +61 3 9358-5558

Loading...

Loading...