Page 1

SHD3-97051N 1 of 4

Digital Tach/Hourmeter with Overspeed Trip Point

Installation Instructions for SHD30 and SHD30-45 Models

SHD3-97051N

Revised 05-03

Replaces SHD-96113N

Section 20

(00-02-0288)

Description

The SHD30 and SHD30-45 models are microprocessor-based digital

tachometers with hourmeter and overspeed trip point. The overspeed trip

point can be connected as either a form

“C” relay output or as a normally

open SCR output.

In Class I, Div. 2, hazardous locations the SHD30 form “C” relay contact is

restricted for use with Murphy non-incendive

or intrinsically-safe instruments. In

non-hazardous locations the relay contact may be used to switch resistive loads not

exceeding 0.5 A @ 30 VDC or 125 VAC.

When connected as a normally open SCR, the output is rated 0.5 A, 350 VDC

continuous and can switch up to 3 A @ 350 VDC momentary. The SCR output

may be used to switch designated normally open sensor inputs.

Specifications

Power input:

CD ignition: 90 to 350 VDC. 150 µA typical @ 90 VDC; 300 µA @ 350 VDC.

Magnetic Pickup: 5 to 120 Vrms.

325 µA typical @ 5 Vrms, 100 Hz; 450 µA typical @ 5 Vrms, 1 kHz;

1 mA typical @ 5 Vrms, 5 kHz; 2 mA typical @ 5 Vrms, 10 kHz;

15 mW max. @ 5 Vrms, 10 kHz; 2.8 W max. @ 120 Vrms, 10 kHz.

Backup Battery: 2 replaceable, long life Lithium batteries, Panasonic CR2032

or equivalent, 3 V, 220 mAh power.

Operating Temperature: -4° to 158°F (-20° to 70°C).

Storage Temperature: -40° to 300°F (-40° to 150°C).

Ignition Frequency Range: 3 to 666 Hz.

Magnetic Pickup Frequency Range: 1 to 10 kHz.

Overspeed Output:

Connected to S.C.R. (Silicon Controlled Rectifier) terminals:

0.5 A, 350 VDC continuous.

Connected to Form “C” Relay terminals:

Relay Contact, 0.5 A, 30 VDC, 125 VAC resistive.

Tachometer Accuracy: ±0.5% of the display reading or ±1 RPM

whichever is greater.

Hourmeter Range: 0 to 65535 hrs.

Hourmeter Accuracy: ±15 minutes per year.

Approvals: CSA approved for Cl. I, Div. 2, Grps. C & D hazardous areas.

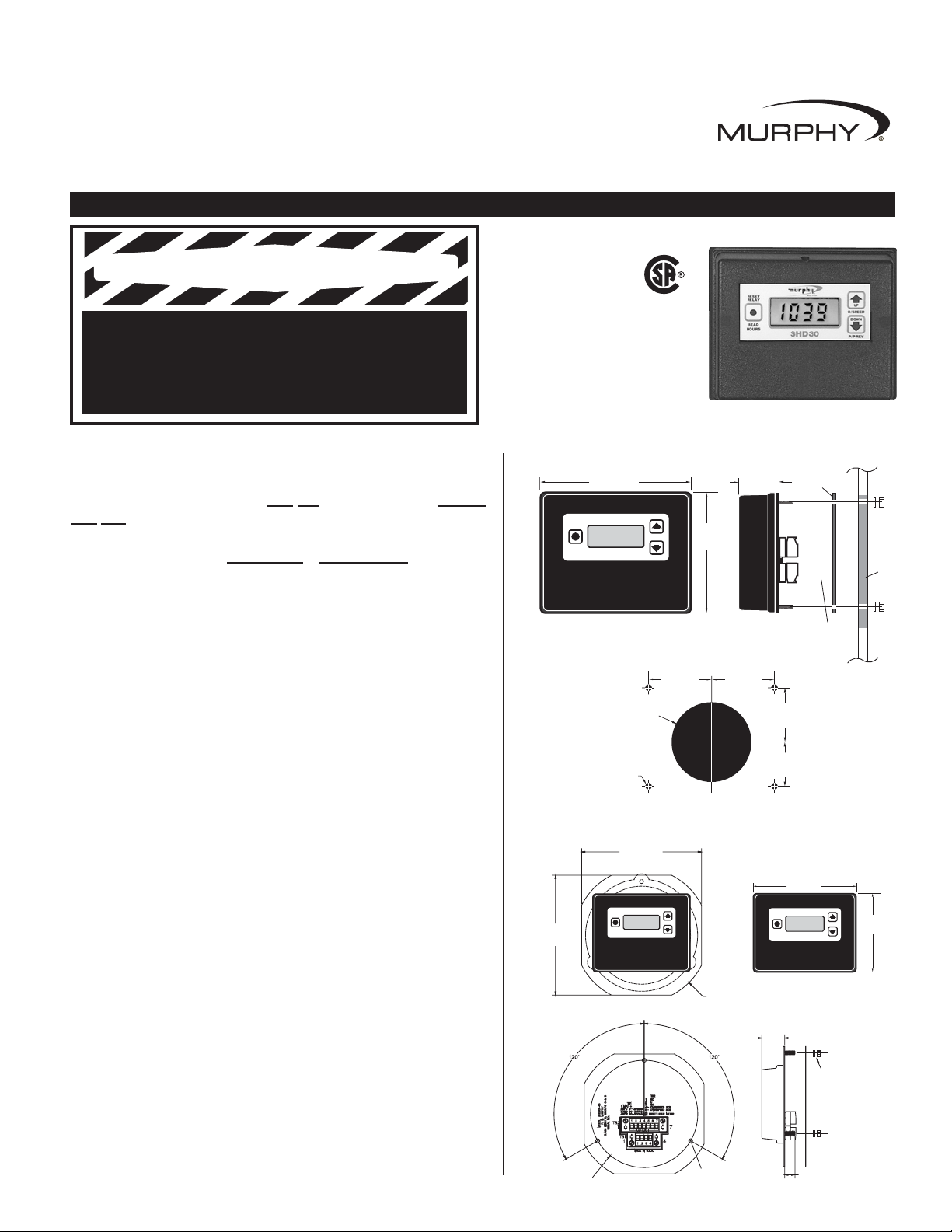

Mounting

The SHD30 is designed for installation in panels from 0.032 to 0.125 in. (1 to

3 mm) thick. A round hole, 3-1/8 in. (79 mm) in diameter is needed for

mounting. Install the unit within a weatherproof enclosure to protect it from

the elements. Keep the unit away from ignition coils and coil leads; a minimum of 12 in. (305 mm) is recommended.

Please read the following information before installing. A visual inspection for any damage which may have occurred during shipping is

recommended. It is your responsibility to have a qualified person install the unit, and make sure it conforms with NEC and local codes.

GENERAL INFORMATION

panel

gasket

Terminal

Blocks

4-1/4 in.

(108 mm)

5-1/16 in.

(129 mm)

1-9/32 in.

(33 mm)

2 in.

(51 mm)

2 in.

(51 mm)

1-1/2 in.

(38 mm)

2 in.

(51 mm)

3/16 in

(5 mm)

diameter,

4 places

3-1/8 in.

(79 mm)

diameter

BEFORE BEGINNING INSTALLATION OF THIS MURPHY PRODUCT

✔ Disconnect all electrical power to the machine.

✔ Make sure the machine cannot operate during installation.

✔ Follow all safety warnings of the machine manufacturer.

✔ Read and follow all installation instructions.

SHD30 Dimensions

SHD30-45 Dimensions/Mounting

Mounting Hole

Approved for Class I, Division 2,

Groups C & D Hazardous Areas

When installed per Murphy

Drawing 20-08-0258

C US

A,

Vd

Vd

YP:

A

@

Vd

@

Vd

PU

Va

YP

A

A@

Va

X

AX

@

Va

A

@

Va

A

EL

AY

Vd

Vd

WARNING

5-13/16 in.

(148 mm )

5-13/16 in.

(148 mm )

Front View

Ø5-13/64 in.

Rear View

Ø6-1/2 in.

c 1kHz;

c

c, 10kHz

5Va

c

300Vd

120Va

@

300Vd

SCR = 0.5A,

c; 600uA @

@ 5Vac,10kHz;

c res

@ 5Vac,100Hz; 450uA@

90Vd

@

c, 125Vd

: 325uA

c,5kHz; 2mA

@ 5Vac,10kHz; 2.8W MAX

150uA

5Va

@

c TYP:

= 0.5A, 30Vd

INSTALLE CONFORMEMENT MURPHY 20-08-0258

MUST BE INSTALLED PER MURPHY DWG. 20-08-0258

1mA

15mw MAX

AY

c-120Vac TYP

5Va

MPU

OUTPUT REL

CD IGN 90-300Vd

1/4 in. (6 mm ) dia. holes

(3 places)

1-5/16 in.

(33 mm )

Side View

5-1/16 in.

(129 mm)

1/2 in.

(12 mm )

KEPS Nuts

(3 Supplied)

4-1/4 in.

(108 mm)

Page 2

SHD3-97051N 2 of 4

TYPICAL WIRING

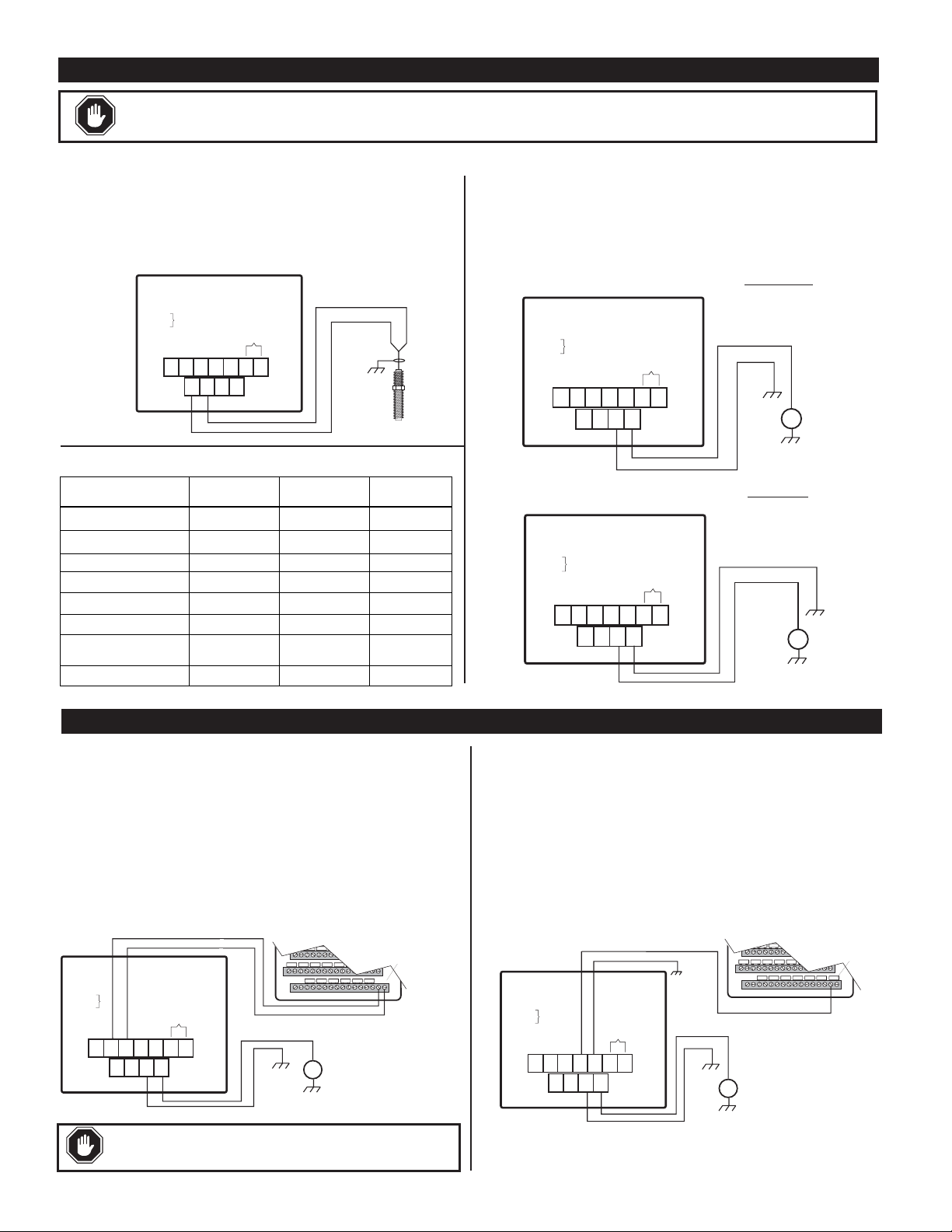

Connecting the Magnetic Pickup

Connect the magnetic pickup cable conductors to the 4-connector terminal strip as shown in Figure 2. Use a two conductor shielded cable

between the SHD30 models and the magnetic pickup.

Connecting to CD Ignition

Before wiring the SHD30 models, determine the output voltage and

ground polarity of the ignition. Table 1 (below, left) lists the Peak

Output Voltage and Ground Polarity of some common ignitions.

Connect the SHD30 models to a positive or a negative ground CD

ignition as shown in Figures 3 or 4.

Figure 2:

SHD30 models to magnetic pickup typical wiring

Figure 3:

SHD30

models

typical wiring for NEGATIVE ground ignition

Figure 4:

SHD30

models

typical wiring for POSITIVE ground ignition

Table 1:

Output Voltage & Polarity of Common CD Ignitions

WARNING

:

PERFORM THE WIRING INSTALLATION WITH THE POWER SOURCE OFF.

NEVER ROUTE THE SHD30 MODELS OVERSPEED OUTPUT LEADS WITH PRIMARY IGNITION WIRING.

OVERSPEED OUTPUT WIRING

Connecting the Overspeed Output

A 7-connector terminal strip, on the back of the SHD30 models, is provided for connection of the overspeed output. Terminals C., and N.C. are

used for connecting the output as a normally closed relay contact.

Terminals (+) and (–) are used for connecting the output as a normally

open SCR. Shown in Figure 5 is a typical wiring installation of the

SHD30 models

normally closed relay output

connected to a Murphy

MARK III digital annunciator. Figure 6 shows a typical wiring of the

SHD30 models

normally open SCR output

connected to a Murphy

MARK III digital fault annunciator.

Figure 7 displays a typical wiring of

the SHD30

models

normally open SCR output to a Murphy MARK IV

annunciator. Figure 8 displays a typical wiring of the SHD30 models normally closed relay output to a Murphy LCDT-NC annunciator. Figure 9

displays a typical wiring of the SHD30

models

normally open SCR output

to a Murphy LCDT-NO annunciator.

Figure 5:

SHD30

models

Normally Closed Relay output to MARK III

SHD30 To be

installed in accordance with NEC

code for Class I,

Div. 2 Grps. C &

D hazardous

locations.

SHD30 models To be installed in accordance with NEC code for Class I,

Div. 2 Grps. C & D hazardous locations.

Figure 6:

SHD30

models

Normally Open SCR output to MARK III

WARNING: Overspeed relay contact for use with FWMurphy nonincendive or intrinsically safe products only.

MFG & Series

Altronic I & V Negative 120 3

Altronic III Negative 225 3

Altronic II Positive 350 4

Bendix S-1800, BLAR Negative 250 3

Bendix Side-winder Positive 300 4

Fairbanks Morse SCSA Positive 180 4

Fairbanks Morse

3000 & 9000

American Bosch Magtronic

SHD30

5-120Vrms

Shield

ground

Magnetic Pickup

5 - 120Vrms

TB1

1 MPU +

5-120Vrms

2 MPU –

3 NEG 90-300vdc

4 POS 90-300vdc

N.O.

TB2

1234

TB1

+

C.

N.C.

1234

+

–

TB2

1 NO

2 C

3 NC

4 +Overspeed SCR

5 –Overspeed SCR

6

Reset Hourmeter

7

–

567

Ignition

Ground

Polarity

Peak Output

Voltage

Use Figure

Negative 225 3

Negative 165

3

TB1

1 MPU +

5-120Vrms

2 MPU –

3 NEG 90-300vdc

4 POS 90-300vdc

N.O.

TB2

1234

TB1

TB1

1 MPU +

5-120Vrms

2 MPU –

3 NEG 90-300vdc

4 POS 90-300vdc

N.O.

TB2

1234

TB1

TB2

1 NO

2 C

3 NC

4 +Overspeed SCR

5 –Overspeed SCR

6

7

+

C.

N.C.

567

1234

+

C.

N.C.

1234

SHD30

Reset Hourmeter

–

CD Ignition

90-350VDC

+

IGN

—

TB2

1 NO

2 C

3 NC

4 +Overspeed SCR

5 –Overspeed SCR

6

Reset Hourmeter

7

–

567

SHD30

CD Ignition

90-350VDC

—

IGN

+

TB1

1 MPU +

5-120Vrms

2 MPU –

3 NEG 90-300vdc

4 POS 90-300vdc

C

N O

TB2

1234

TB1

TB2

1 NO

2 C

3 NC

4 +Overspeed SCR

5 –Overspeed SCR

6

Reset Hourmeter

7

+

NC

–

567

1234

Back of MARK

III

17

IGN

+

CD Ignition

90-350VDC

—

Remove

Jumper

32

16

TB1

1 MPU +

2 MPU –

3 NEG 90-300vdc

4 POS 90-300vdc

TB2

5-120Vrms

C

NO

NC

1234

1234

TB1

+

–

567

TB2

1 NO

2 C

3 NC

4 +Overspeed SCR

5 –Overspeed SCR

6

Reset Hourmeter

7

IGN

17

+

CD Ignition

90-350VDC

—

Back of MARK

III

16

Leave Jumper

in place

32

Page 3

SHD3-97051N 3 of 4

WARNING

:

PERFORM THE WIRING INSTALLATION WITH THE POWER SOURCE OFF.

NEVER ROUTE THE SHD30 MODELS OVERSPEED OUTPUT LEADS WITH PRIMARY IGNITION WIRING.

OVERSPEED OUTPUT WIRING

continued

Figure 8:

SHD30 models Normally Closed Relay output to LCDT-NC

Figure 7:

SHD30 models Normally Open SCR output to MARK IV

Figure 9:

SHD30 models Normally Open S.C.R. output to LCDT-NO

SHD30 models to be installed in accordance with NEC code for

Cl. I, Div. 2 Grps. C & D hazardous locations.

SHD30 to be installed in

accordance with NEC code

for Cl. I, Div. 2 Grps. C & D

hazardous locations.

SHD30 models to be installed in accordance with NEC code for

Cl. I, Div. 2 Grps. C & D hazardous locations.

Figure 10:

SHD30 models with Normally Open S.C.R. output typical

wiring for negative ground ignition systems.

Figure 11:

SHD30 models with Normally Open S.C.R. output typical

wiring for positive ground ignition systems.

Shown below is the SHD30 models with SCR output connected to TATTLETALE®magnetic switches and SWICHGAGE®instruments using an

adapter package. Figure 10 shows a typical wiring for negative ground

ignition. Figure 11 shows a typical wiring for positive ground ignition.

TYPICAL WIRING FOR CONTROL PANEL

SHD30 models to be installed in accordance with NEC code

for Class I, Div. 2 Grps. C & D hazardous locations.

SHD30 models to be installed in accordance with NEC code

for Class I, Div. 2 Grps. C & D hazardous locations.

WARNING: Overspeed relay contact for use with Frank W.

Murphy Mfr. non-incendive or intrinsically safe products only.

SHD30

TB2

LCDT

Terminal Block

TB1

1 MPU +

5-120Vrms

2 MPU –

3 NEG 90-300vdc

4 POS 90-300vdc

N.O.

TB2

1234

TB1

+

NC

C

1234

TB2

1 NO

2 C

3 NC

4 +Overspeed SCR

5 –Overspeed SCR

6

Reset Hourmeter

7

–

567

+

CD Ignition

IGN

90-350VDC

—

44

45

46

47

48

49

50

44

45

46

47

48

49

50

TB1

1 MPU +

5-120Vrms

2 MPU –

3 NEG 90-300vdc

4 POS 90-300vdc

C

NO

TB2

1234

1234

TB1

TB1

1 MPU +

5-120Vrms

2 MPU –

3 NEG 90-300vdc

4 POS 90-300vdc

C

NO

TB2

1234

1234

TB1

1 NO

2 C

3 NC

4 +Overspeed SCR

5 –Overspeed SCR

6

Reset Hourmeter

7

+

–

NC

567

+

CD Ignition

90-350VDC

IGN

—

LCDT

Terminal Block

46

48

50

NC

+

–

567

TB2

1 NO

2 C

3 NC

4 +Overspeed SCR

5 –Overspeed SCR

6

Reset Hourmeter

7

RESET

–

Back of MARK

45

47

49

+

CD Ignition

90-350VDC

IGN

—

IV

46

SHD30

TB1

1 MPU +

5-120Vrms

2 MPU –

3 NEG 90-300vdc

4 POS 90-300vdc

NO

TB2

1234

TB1

®

307PHCD

TATTLETALE

Pressure Overspeed Level

1 23

1G23 1G23

+

SW

ALT 2

ALT 1

GRD

65-02-0155

Adapter

Package

®

1 23456

+–

1G23

Frame Ground

Connect to

Good Engine

Ground

CD Ignition

90-350 VDC

+

C

NC

1234

SWICHGAGE

TB2

1 NO

2 C

3 NC

4 +Overspeed SCR

5 –Overspeed SCR

6

Reset Hourmeter

7

–

567

–

Emergency

Stop Switch

®

SWICHGAGE

SHD30

TB2

1 NO

+

C

NC

1234

2 C

3 NC

4 +Overspeed SCR

5 –Overspeed SCR

6

Reset Hourmeter

7

–

567

TB1

1 MPU +

5-120Vrms

2 MPU –

3 NEG 90-300vdc

4 POS 90-300vdc

NO

TB2

1234

TB1

307PHCD

TATTLETALE

Pressure Overspeed Level

1 23

1G23 1G23 1G23

+

–

SW

ALT 2

ALT 1

GRD

65-02-0127

Adapter

Package

®

1 23456

Emergency

Stop Switch

Frame Ground

Connect to

Good Engine

Ground

CD Ignition

+–

90-350 VDC

Page 4

SHD3-97051N 4 of 4

Resetting the Run Hours

To reset the Run hours to zero, place a jumper between terminals #6 and #7

(7-point terminal block). Press and hold the Reset Relay Read

Hours key on

the SHD30 models faceplate for 5 seconds. The Run Hours will be reset to

zero.

Presetting the Run Hours

To preset the run hours first you must reset the run hours (see the above

paragraph). After resetting the hours continue to hold the Reset

Relay Read

Hours

key for another 5 seconds. The run hours will flash 3 times. At this

point the hours can be preset in hours using the up/down keys to increase or

decrease the hours. When the desired preset run hours is reached, continue

holding the Reset Relay Read Hours key for another 5 seconds. The run

hours will flash 3 times indicating the run hours value has been saved.

Pulses Per Revolution Adjustments

The SHD30 models measures RPM based on the number of pulses per engine

revolution. Pulses can come from either an ignition or a magnetic pickup. For

an ignition, the number of pulses per revolution is determined by the number

of cylinders and cycles, refer to Table 2.

For magnetic pickup, the number of pulses per revolution is simply the number of teeth on the gear. To adjust the pulses per revolution do the following:

1.

Press and hold the Reset

Relay Read Hours key. Run hours will be dis-

played. Continue to hold the Reset Relay Read Hours

key.

2.

Press the DOWN key and hold for 5 seconds. The current pulses per revolution value will flash indicating that it now can be changed.

3.

Continue to hold the Reset Relay Read Hours key. Use the UP/DOWN

keys to increase and decrease the number of pulses per revolution. Once

the desired value is displayed, continue holding Reset Relay key for 5

seconds, the display will flash 3 times indicating that the new value is

saved (the display MUST flash 3 times for the new value to be saved).

Overspeed Set Point Adjustments

To adjust the overspeed set point perform the following steps:

1.

Press and hold the Reset Relay Read

Hours key. Run hours will be dis-

played. Continue to hold the Reset

Relay Read Hours key.

2.

Press the UP key and hold for 5 seconds. The current overspeed set point

value will flash indicating that it now can be changed.

3.

Continue to hold the Reset Relay Read Hours key. Use the UP/DOWN keys

to increase and decrease the value of overspeed set point. Once the desired

value is displayed, continue holding the Reset

Relay Read Hours key for 5

seconds, the display will flash 3 times indicating that the new value is saved

(the display MUST flash 3 times for the new value to be saved).

Operation Sequence

When the SHD30 models receive a tach signal, it begins displaying RPM.

When the RPM reading is flashing, it means that the overspeed setting has

been tripped (see Overspeed Output Tripped, below).

Run Hours Display

To display the run hours, press Reset Relay Read Hours key. The run hours will

be displayed for 5 seconds before returning to RPM.

To configure the SHD30 models to automatically toggle between displaying

rpm and run hours, press the Reset

Relay Read Hours key twice quickly. The

display will toggle between displaying rpm for 6 seconds, and run hours for 2

seconds. The setting is saved and the display will toggle every time the unit is

powered up. Press the Reset Relay Read Hours

key twice again to return to the

rpm display.

Overspeed Set Point Display

To display the overspeed set point, press the UP

key. The current overspeed

set point will be displayed for 5 seconds before returning to RPM.

Overspeed Output Tripped

When RPM exceeds the overspeed setting, the normally open SCR output trips

and latches, and the normally closed relay output opens. To reset the relay output, press the Reset Relay Read Hours key after the RPM has fallen below

overspeed set point. The current through the SCR must be broken to allow the

SCR to reset in addition to pressing the Reset

Relay Read Hours key.

Pulses Per Revolution Display

To display the pulses per revolution, press the DOWN key. Current pulses per

revolution will be displayed for 5 seconds before returning to RPM.

Replacing the Backup Batteries

Backup batteries are provided to allow display of the run hours and for resetting

the overspeed relay after power is lost. To replace the batteries, first disconnect

the terminal block plugs and remove the SHD30 models from the panel.

Remove the 3 small screws located on the back of the SHD30 models and

VERY CAREFULLY remove the circuit board. Replace the existing batteries

with new ones (see specifications). Replace the circuit board and the screws.

Remount the SHD30 models on the panel.

CALIBRATING AND OPERATING THE SHD30

Cylinders Cycles Pulses

121

222

241

323

424

442

525

Cylinders Cycles Pulses

626

643

828

844

10 4 5

12 4 6

16 4 8

Table 2:

Cylinders, Cycles, Pulses Per Revolution

NOTE:

Divide the number of cylinders by 2 for split capacitor ignitions.

Multiply the number of cylinders by 2 for throw away spark ignitions.

Warranty

A limited warranty on materials and workmanship is given with this FW

Murphy product. A copy of the warranty may be viewed or printed by going

to www.fwmurphy.com/support/warranty.htm

CONTROL SYSTEMS & SERVICES DIVISION

P.O. Box 1819; Rosenberg, Texas 77471; USA

+1 281 633 4500 fax +1 281 633 4588

e-mail sales@fwmurphy.com

MURPHY DE MEXICO, S.A. DE C.V.

Blvd. Antonio Rocha Cordero 300, Fracción del Aguaje

San Luis Potosí, S.L.P.; México 78384

+52 444 8206264 fax +52 444 8206336

Villahermosa Office +52 993 3162117

e-mail ventas@murphymex.com.mx

www.murphymex.com.mx

FRANK W. MURPHY, LTD.

Church Rd.; Laverstock, Salisbury SP1 1QZ; U.K.

+44 1722 410055 fax +44 1722 410088

e-mail sales@fwmurphy.co.uk

www.fwmurphy.co.uk

MURPHY SWITCH OF CALIFORNIA

41343 12th Street West

Palmdale, California 93551-1442; USA

+1 661 272 4700 fax +1 661 947 7570

e-mail sales@murphyswitch.com

www.murphyswitch.com

In order to consistently bring you the highest quality, full featured products, we reserve the right to change our specifications and designs at any time.

MACQUARRIE CORPORATION

1620 Hume Highway

Campbellfield, Vic 3061; Australia

+61 3 9358 5555 fax +61 3 9358 5558

e-mail murphy@macquarrie.com.au

FW Murphy

P.O. Box 470248

Tulsa, Oklahoma 74147 USA

+1 918 317 4100

fax +1 918 317 4266

e-mail sales@fwmurphy.com

www.fwmurphy.com

R

E

G

I

S

T

E

R

E

D

USA–ISO 9001:2000 FM 28221

UK–ISO 9001:2000 FM 29422

Printed in U.S.A.

Loading...

Loading...