Page 1

SS-97028N page 1 of 4

Installation and Operation Instructions for

SELECTRONIC

®

Speed Switches

SS300 Series

SS-97028N

Revised 05-04

Section 20

00-02-0286

Please read the following information before installing. A visual inspection of this product for damage during shipping is recommended before mounting. It is your responsibility to have a qualified person install this unit and make sure it conforms to NEC

and local codes.

GENERAL INFORMATION

BEFORE BEGINNING INSTALLATION OF THIS MURPHY PRODUCT

✔ Disconnect all electrical power to the machine.

✔ Make sure the machine cannot operate during installation.

✔ Follow all safety warnings of the machine manufacturer.

✔ Read and follow all installation instructions.

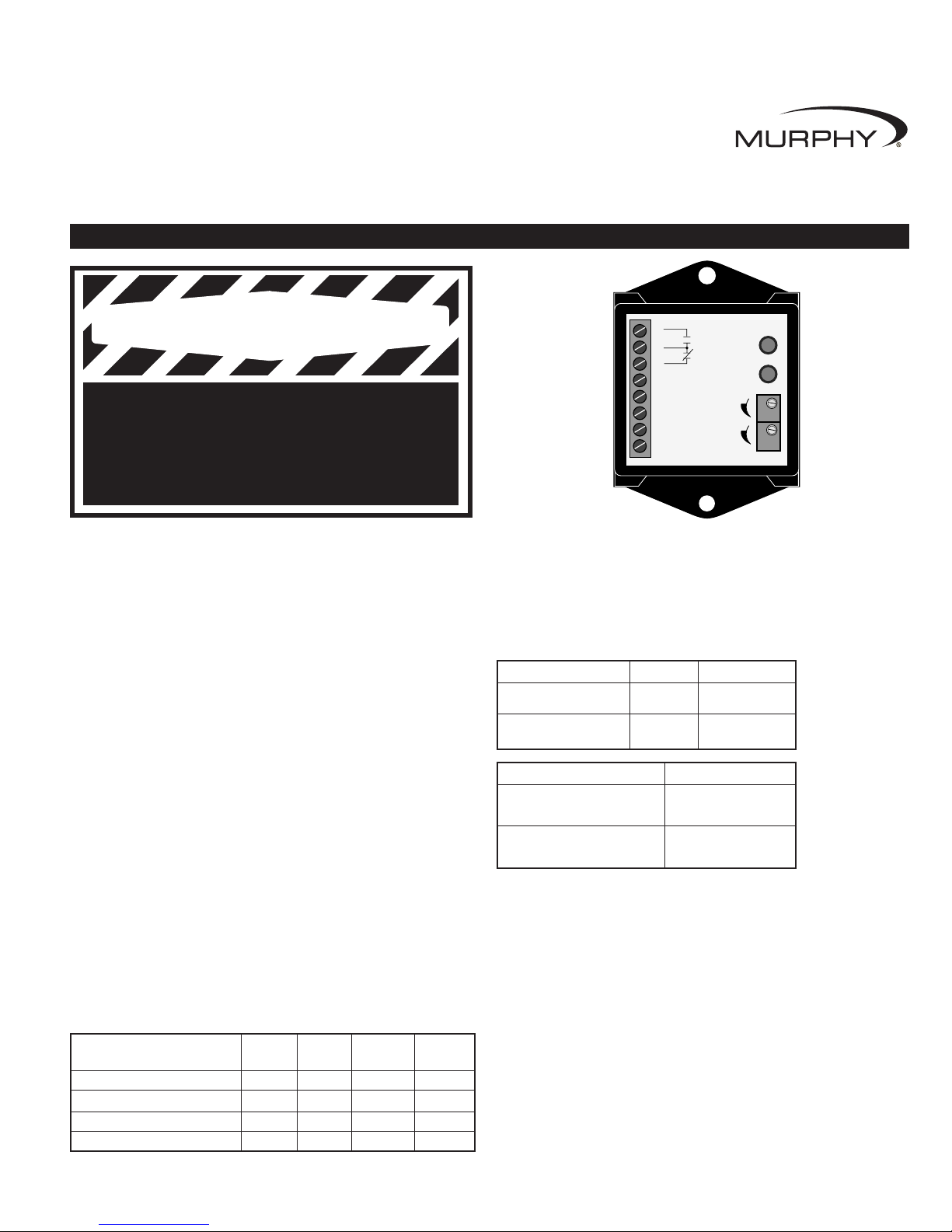

SS300-AD

Description

The SS300 Series are single set point speed switches with SPDT relay dry contact

output. The trip point is set by a potentiometer. An LED indicates when the signal

source is present. A second LED turns on when the trip point is reached. See Table 1

for available models and requirements. An optional time delay is on board to delay

operation of the relay for 2-6 seconds after the set point has been reached.

The SS300 Series speed switch is intended for installation within a weatherproof

enclosure to protect it from rain, dust, etc.

Overspeed Shutdown

The SS300 Series shuts down the engine if RPM exceeds the pre-set limit.

Speed Sensitive Pull-in/Drop-out

Engage or disengage PTO’s, 4-wheel drives, other switch points, etc. according

to speed of engine being monitored.

Engine and Transmission Alarm/Shutdowns

Oil pressure in some engines and transmissions varies widely between running

and idle speeds. The SS300 Series can select between two pressure switch set

points according to speed of the engine or transmission and thus give maximum

protection to the equipment while at operating RPM and eliminate nuisance

alarms when at idle.

Adjustable Differential Model

The (“AD”) can be adjusted to change the speed range over which the pull-in and

drop-out differential of the relay will operate. A typical application is to insure

that engine speed is above a minimum RPM before applying a load but allows a

drop in speed of several hundred RPM without disconnecting the load.

Table 1: Models Available and Input Signal

Specifications

Power Requirements:

12 VDC (9-16 VDC).

24 VDC (18-30 VDC).

Frequency Signal: Voltage (all models):

• Minimum Input Voltage Signal: 4.5 Vrms.

• Maximum Input Voltage Signal: 50 Vrms.

Reset Differential Magnetic Pickup Signal Models:

•

“Standard Models: 2 Hz Differential.

•

“AD” Models (Adjustable Differential): 650-8900 Hz Adjustable

Reset Differential Alternator Models:

•

“LF” Models (Low Frequency): 2 Hz Differential

•

“AD-LF” Models (Adjustable Differential Low Frequency):

50-1900 Hz Adjustable.

Output: Relay contact, SPDT, resistive load, 6 A, 30 VDC.

Time Delay: When terminal 7 is grounded, the relay operation is delayed for

2-6 seconds after rpm set point is reached.

Adjustment: 20–turn potentiometer(s).

Temperature Range: -4° to 185°F (-20° to 85°C).

Relative Humidity: 0 to 95% Non-condensing.

Case: Black, ABS plastic.

Model Number

Distributor

Ignition

Magnetic

Pickup

Alternator

SS300 (std. model) ✗✗✗

SS300-LF (low frequency) ✗✗✗✗

SS300-AD (adjustable differential) ✗✗✗

SS300-AD-LF (low frq. & Adjst. diff.) ✗✗✗✗

Voltage

12 24

Maximum Current 12V 24V

Pull In 46 mA 46 mA

Pickup only 10.5 mA 16 mA

Frequency Range in Hz Model Number

25-2000 SS300-LF

SS300-AD-LF

625-9000 SS300-AD

SS300

SPEED SWITCH

WARNING

1

2

3

INPUT

4

-BATT

5

+BATT

6

GND. FOR

7

POS. TO

8

LATCH

PICKUP

ENERGIZE

SPEED

ADJ.

T/D

DE-ENERGIZE

Page 2

SS-97028N page 2 of 4

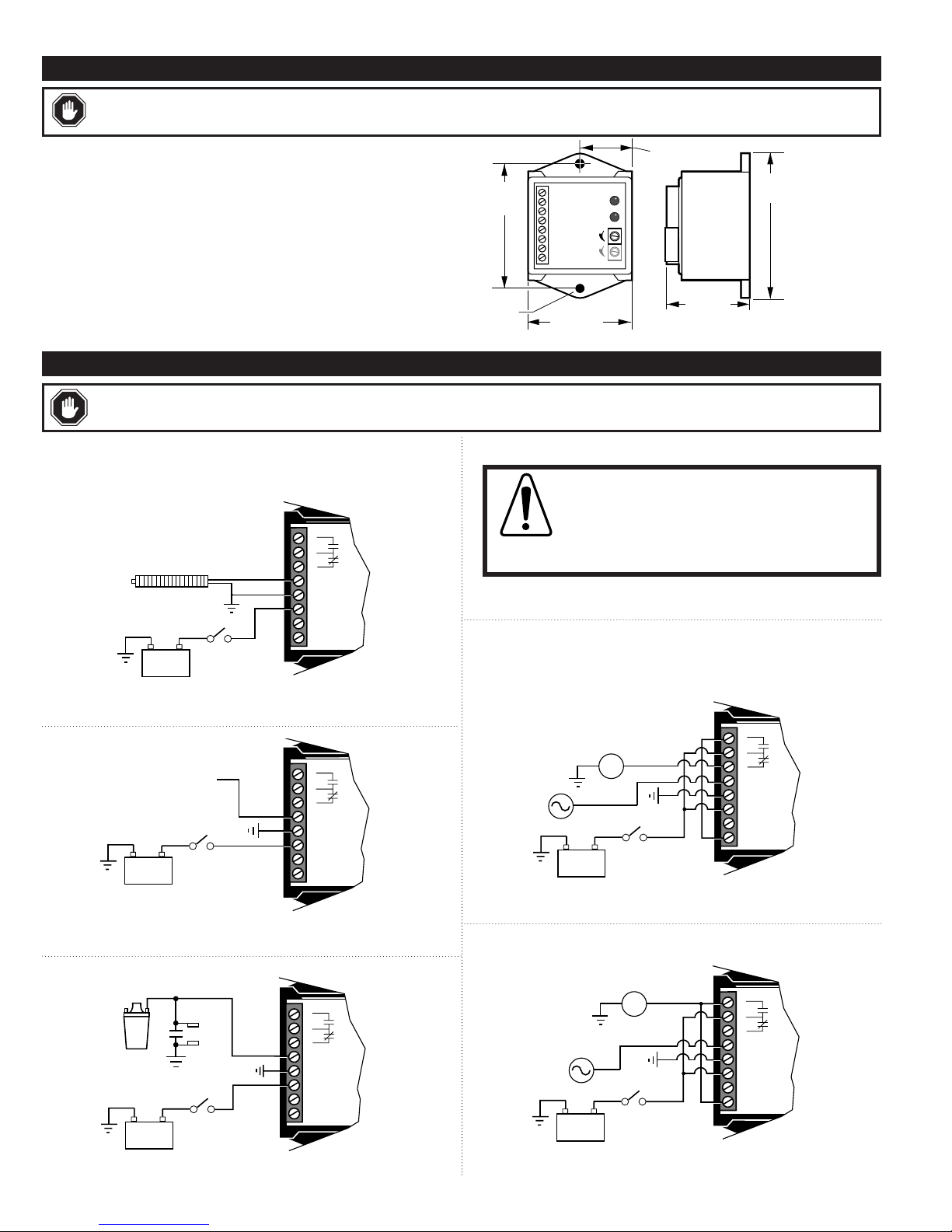

MOUNTING DIMENSIONS

The SS300 Series models can be mounted to a flat surface within

the panel using two #8 screws. Mounting screws are not supplied.

TYPICAL WIRING INSTALLATION

CAUTION:

BEFORE PERFORMING THE WIRING OPERATION TURN THE POWER SOURCE

OFF AND STOP YOUR ENGINE.

CAUTION:

THE SS300 SERIES MODELS ARE INTENDED FOR INSTALLATION WITHIN A WEATHER-

PROOF ENCLOSURE.

Figure 1:

Magnetic Pickup Input

Figure 2:

Alternator Tach., Input

Figure 3:

Distributor Ignition Input

Figure 5:

Energize to Stop Solenoid

CAUTION:

If replacing an SS100 Series

model with an SS300 Series model, note the

significant wiring differences on the SS300

terminals: 5, 6, 7, and 8. Wire your SS300 accordingly.

Figure 4:

Energize to Run Solenoid

Frequency/RPM Input Source

Connect the SS300 Series speed switch to the appropriate frequency/RPM

input source. See Figures 1 thru 3.

Latching Overspeed with Fuel Solenoid

A latching overspeed switch with fuel solenoid application is shown in

Figures 4 and 5. Ignition switch must be turned off to unlatch.

SS300 Series

(all models)

3/16 in. (5 mm)

dia. two places

SPEED

1

2

Magnetic Pickup

+--

Battery

Ignition

Switch

3

4 INPUT

5 – BATT.

6 + BATT.

GND. FOR

7

T/D

POS. TO

8

LATCH

SS300

1-1/32 in.

(26 mm)

2-1/2 in.

(64 mm)

3 in.

(76 mm)

2 in.

(51 mm)

2-1/16 in.

(52 mm)

To Alternator

Tach. Terminal

+--

Battery

--

+

Coil

+--

Battery

Ignition

Switch

Ignition

Switch

1

2

3

4 INPUT

5 – BATT.

6 + BATT.

GND. FOR

7

T/D

POS. TO

8

LATCH

1

2

3

4 INPUT

5 – BATT.

6 + BATT.

GND. FOR

7

T/D

POS. TO

8

LATCH

SPEED

SS300

SPEED

SS300

Speed

Signal

Fuel

Solenoid

Battery

Energize to stop

Solenoid

Speed

Signal

Battery

SPEED

1

2

3

4 INPUT

5 – BATT.

6 + BATT.

GND. FOR

7

T/D

POS. TO

8

Ignition

+--

Switch

LATCH

SS300

SPEED

1

2

3

4 INPUT

5 – BATT.

6 + BATT.

GND. FOR

7

T/D

POS. TO

8

Ignition

+--

Switch

LATCH

SS300

Page 3

SS-97028N page 3 of 4

TYPICAL WIRING INSTALLATION (continued)

Non Latching Overspeed Switch with

Air Shutoff Solenoid

A non-latching overspeed switch with air shutoff solenoid application is

shown in Figure 6. The air shutoff device must be manually reset to

open/run position.

Non Latching Overspeed Switch with

518PH and Fuel Solenoid

A non-latching overspeed switch with an 518PH magnetic switch and a

fuel solenoid is shown in Figure 7.

Dual Set Point Oil Pressure Switch

A dual set point oil pressure switch is shown in Figure 8.

SS300 with AT-67207

Throttle Controller

The SS300 with the AT-67207 throttle control is used to limit speed as

shown in Figure 9. Engine speed is controlled by OPL pressure

SWICHGAGE®setting and the AT-67207 throttle control. The throttle

control moves as long as OPL contact is made. If OPL is calling for an

increase in speed and engine speed exceeds the setting of the SS300, a

slow signal is applied to AT-67207. The throttle control will stop if both

fast and slow signals are applied. Engine speed at a constant load will

not exceed the limit set by the SS300.

SS300-AD with Clutch Engager

The SS300-AD can be applied with a Murphy CO-3 engager (Figure 10).

The circuit is designed to engage a clutch after engine speed has increased

to a preset RPM (Example: 1200 RPM), and disengage clutch when

engine speed has decreased to idle (Example: 600 RPM). The adjustable

differential SS300-AD relay is set to pull in at 1200 RPM and drop out at

600 RPM.

Figure 6

Figure 7

Figure 8

Figure 9

Figure 10

Battery

Air Shutoff

Energized to

Close

Speed

Signal

+--

SS300

4 INPUT

3

2

1

5 – BATT.

6 + BATT.

7

8

SPEED

GND. FOR

T/D

POS. TO

LATCH

Battery

Fuse

Oil

Pressure

Water

Temperature

Fuel

Solenoid

518PH

TATTLETALE

®

Speed

Signal

G

B

NC

SW1

SW2

+--

SS300

4 INPUT

3

2

1

5 – BATT.

6 + BATT.

7

8

SPEED

GND. FOR

T/D

POS. TO

LATCH

Battery

Speed Signal

To alarm or

shutdown

Circuit

On - Off

Switch

N.C.

N.O.

C

+--

SS300

4 INPUT

3

2

1

5 – BATT.

6 + BATT.

7

8

SPEED

GND. FOR

T/D

POS. TO

LATCH

Battery

AT-67207

Battery

Slow

Fast

Speed

Signal

Pressure

SWICHGAGE

®

+--

SS300

4 INPUT

3

2

1

5 – BATT.

6 + BATT.

7

8

SPEED

GND. FOR

T/D

POS. TO

LATCH

Battery

CO-3

Common

Disengage

Engage

1

2

3

4

5

Speed

Signal

+--

SS300

4 INPUT

3

2

1

5 – BATT.

6 + BATT.

7

8

SPEED

GND. FOR

T/D

POS. TO

LATCH

CAUTION:

If replacing an SS100 Series

model with an SS300 Series model, note the

significant wiring differences on the SS300

terminals: 5, 6, 7, and 8. Wire your SS300 accordingly.

Page 4

SS-97028N page 4 of 4

SPEED SETTING ADJUSTMENT

For Models SS300 and SS300-LF

NOTE: The adjustment control(s) is a 20-turn potentiometer(s) and

have no stops when the extreme settings are reached. Always turn a

full 20 turns.

1. Make sure the PICKUP LED light is “ON”. The PICKUP LED will

be flashing for a low frequency (under 30 Hz) and will remain “ON”

for a higher frequency.

2. Turn the SPEED ADJUST pot fully clockwise 20 turns (Figure 13).

3. Run the engine at the desired RPM and adjust the SPEED ADJUST pot

counterclockwise until the ENERGIZE LED comes “ON” and the

relay has transferred (Figure 13).

For Models SS300-AD and SS300-AD-LF

1. Make sure the PICKUP LED light is “ON”. The PICKUP LED will be

flashing for low frequency (under 30 Hz) and will remain “ON” for a

high frequency.

2. Turn the SPEED ADJUST pot fully clockwise 20 turns (Figure 14).

3. Turn the DE-ENERGIZE pot fully counterclockwise 20 turns.

4. Run the engine at the desired RPM and adjust the SPEED ADJUST pot

counterclockwise until the ENERGIZE LED comes “ON” and relay

has transferred.

5. Reduce the engine speed to the desired drop out point.

6. Adjust the DE-ENERGIZE pot clockwise until the ENERGIZE LED

goes “OFF” and the relay has dropped out (Figure 14).

ENERGIZE

SPEED

PICKUP

LED

Lights

20 turn

potentiometers

SPEED

ADJ.

DE-ENERGIZE

Figure 13

Figure 14

CONTROL SYSTEMS & SERVICES DIVISION

P.O. Box 1819; Rosenberg, Texas 77471; USA

+1 281 633 4500 fax +1 281 633 4588

e-mail sales@fwmurphy.com

MURPHY DE MEXICO, S.A. DE C.V.

Blvd. Antonio Rocha Cordero 300, Fracción del Aguaje

San Luis Potosí, S.L.P.; México 78384

+52 444 8206264 fax +52 444 8206336

Villahermosa Office +52 993 3162117

e-mail ventas@murphymex.com.mx

www.murphymex.com.mx

FRANK W. MURPHY, LTD.

Church Rd.; Laverstock, Salisbury SP1 1QZ; U.K.

+44 1722 410055 fax +44 1722 410088

e-mail sales@fwmurphy.co.uk

www.fwmurphy.co.uk

MURPHY SWITCH OF CALIFORNIA

41343 12th Street West

Palmdale, California 93551-1442; USA

+1 661 272 4700 fax +1 661 947 7570

e-mail sales@murphyswitch.com

www.murphyswitch.com

In order to consistently bring you the highest quality, full featured products, we reserve the right to change our specifications and designs at any time.

MACQUARRIE CORPORATION

1620 Hume Highway

Campbellfield, Vic 3061; Australia

+61 3 9358 5555 fax +61 3 9358 5558

e-mail murphy@macquarrie.com.au

FW Murphy

P.O. Box 470248

Tulsa, Oklahoma 74147 USA

+1 918 317 4100

fax +1 918 317 4266

e-mail sales@fwmurphy.com

www.fwmurphy.com

R

E

G

I

S

T

E

R

E

D

USA–ISO 9001:2000 FM 28221

UK–ISO 9001:2000 FM 29422

Printed in U.S.A.

Warranty

A limited warranty on materials and workmanship is given with this FW Murphy product.

A copy of the warranty may be viewed or printed by going to www.fwmurphy.com/support/warranty.htm

Loading...

Loading...