Page 1

RPS-00092B page 1 of 4

MODEL & PART NUMBERS: DC SOLENOIDS & ACCESSORIES SHIPPING WEIGHT

Model No. Description ozs (kg)

RP2307B 12 VDC, 1 in. (25 mm) stroke, 11 lbf (49 N) pull, 23 lbf (102 N) hold 24 ozs (0.7 kg)

RP2308B 24 VDC, 1 in. (25 mm) stroke, 11 lbf (49 N) pull, 23 lbf (102 N) hold 24 ozs (0.7 kg)

RP2309B 12 VDC, 1-1/2 in. (38 mm) stroke, 14 lbf (62 N) pull, 34 lbf (151 N) hold 48 ozs (1.4 kg)

RP2310B 24VDC, 1-1/2 in. (38 mm) stroke, 14 lbf (62 N) pull, 34 lbf (151 N) hold 48 ozs (1.4 kg)

65-01-0108 Clevis yoke assembly 1 ozs (.03 kg)

65-01-0110 Clevis yoke chain assembly 2 ozs (.04 kg)

40-05-0315 Threaded rod (1-1/2 in.) .05 ozs (.001 kg)

00-00-2457 RPS in-line ball joint .05 ozs (.001 kg)

00-00-2458 RPS 90° ball joint 1 ozs (.03 kg)

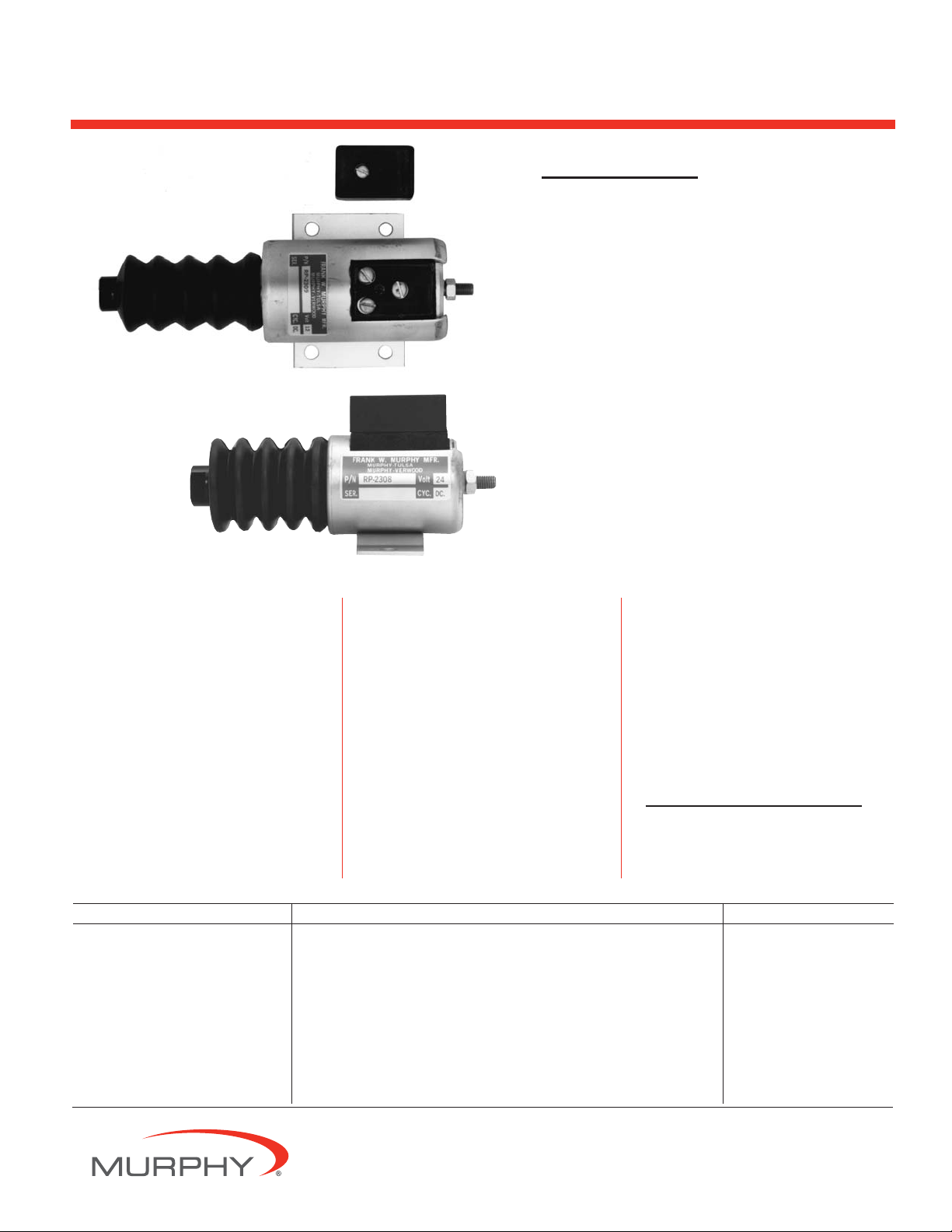

RP Series

■

One Solenoid For Pull/Push Operation

■

No Internal Switches

■

Reduce Coil Burnout

■

Boost Reliability

■

Reduce Adjustments

■

High Force–Small Size

■

Can Be Used With Most Engines

Start Systems

■

SD85 Solenoid Drive Time Delay

Available To Greatly Reduce Possibility

Of Coil Burnout And Facilitate Low

Current Piloted Operation.

RP2307B & RP2308B

RP2309B & RP2310B

RPS-00092B

Revised 11-03

Catalog Section 40

(00-02-0107)

Pull/Push DC Solenoids for

Diesel Engines

Description

Murphy push/pull DC Solenoids

provide single unit versatility for engine

applications, such as shutdown.

A choice of two models and two

voltages is available. All models come

complete with return spring and rubber

seal boot. See the next page for

specifications and options.

Basic Models

Models RP2307B and RP2308B give a

full one inch (25 mm) stroke at 11

pounds (49 N) and hold up to 23 pounds

(102 N) at full voltage, continuous duty.

They will operate at any stroke less than

maximum; refer to the chart shown on

page 2.

Models RP2309B and RP2310B can

pull 14 pounds (62 N) with a one-and-ahalf inch (38 mm) stroke. They hold up

to 34 pounds (151 N) at full voltage,

continuous duty. See the chart on page 2

for holding force at any stroke less than

maximum.

SD85 Solenoid Drive

Time Delay

Using the SD85 ensures the energize

coil is only powered for 1-2 seconds

with each operation. If the plunger does

not seat in that time, it is highly

unlikely it will seat. The hold coil is

energized as long as the signal to the

SD85 is active. This insures long life of

the RP solenoid.

Warranty

A limited warranty on materials and workmanship

is given with this FW Murphy product. A copy of

the warranty may be viewed or printed by going

to www

.fwmurphy.com/support/warranty.htm

Page 2

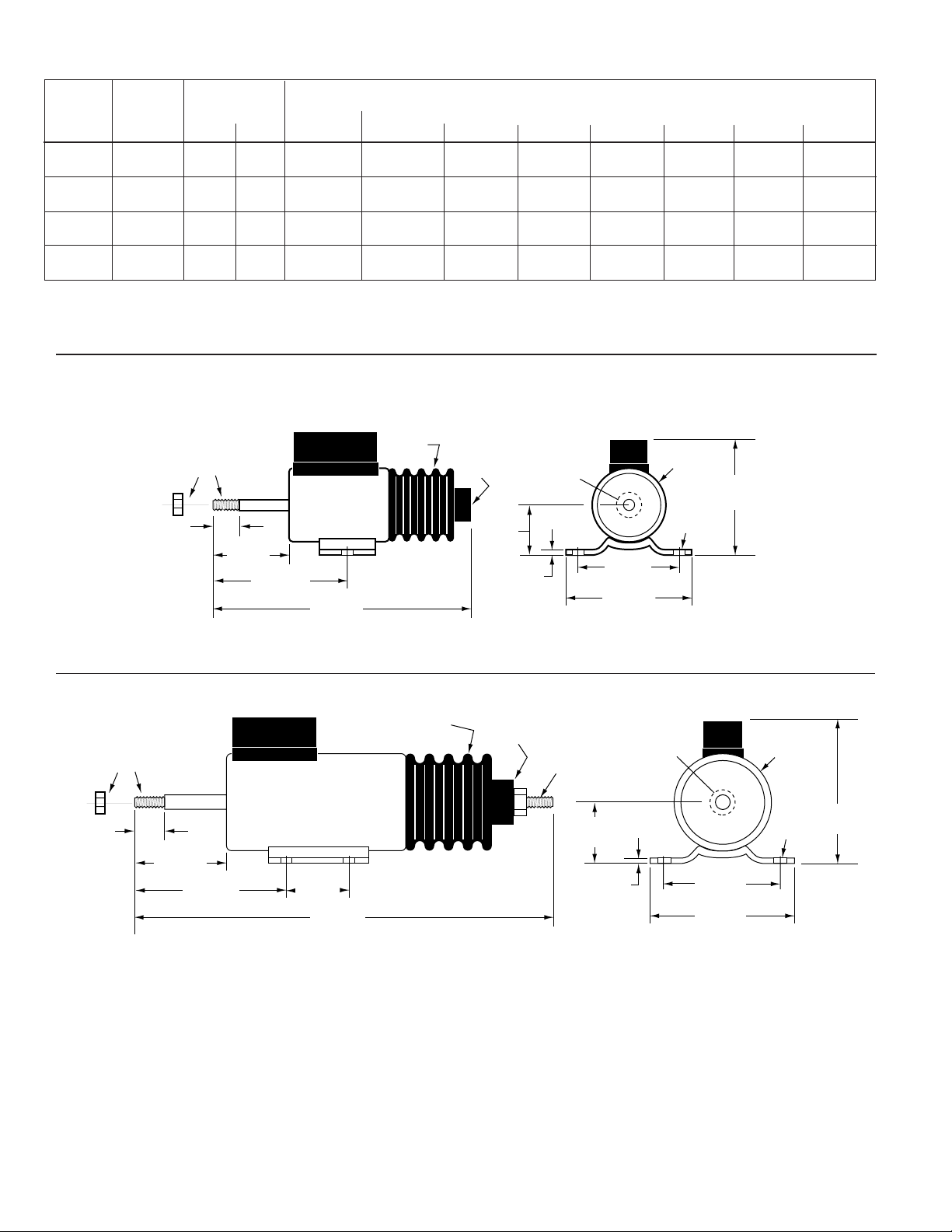

RP2307B and RP2308B

RP2309B and RP2310B

Solenoid Dimensions

Solenoid Shown with Plunger Seated (Coil Energized)

Solenoid Shown with Plunger Seated (Coil Energized)

†

A stud with nut is supplied, loose.

1-1/2 in. (38 mm)—1/4-28

part number: 40-01-0055

Solenoid

Model

Number

Maximum

Stroke

In. (mm)

Power in Watts

Seated Inrush

Force* in Pounds [Kilograms] at 100% Voltage**

Stroke in Inches (Millimeters)

Hold 1/8(3) 1/4(6) 1/2(13) 3/4(19) 1 (25) 1-1/4 (32) 1-1/2 (38)

Continuous

RP2307B 1 (25) 18 624

25 [11.34] 22 [9.98] 21 [9.53] 17 [7.71] 14 [6.35] 10 [4.54] — —

<13> [5.90] <12> [5.44] <11> [4.99] <10> [4.54] <8> [3.63] <6> [2.72] — —

RP2308B 1 (25) 12 696

27 [12.25] 25 [11.34] 23 [10.43] 19 [8.62] 15 [6.80] 11 [4.99] — —

<15> [6.80] <14> [6.35] <13> [5.90] <12> [5.44] <9> [4.08] <7> [3.18] — —

RP2309B 1-1/2 (38) 18 1029

32 [14.52] 30 [13.61] 27 [12.25] 22 [9.98] 18 [8.16] 13 [5.90] 8 [3.63] 6 [2.72]

<19> [8.62] <18> [8.16] <16> [7.26] <14> [6.35] <11> [4.99] <9> [4.08] <6> [2.72] <4> [1.81]

RP2310B 1-1/2 (38) 12 960

35 [15.88] 34 [15.42] 31 [14.06] 26 [11.79] 22 [9.98] 17 [7.71] 12 [5.44] 7 [3.18]

<20> [9.07] <19> [8.62] <17> [7.71] <15> [6.80] <12> [5.44] <9> [4.08] <7> [3.18] <4> [1.81]

*Forces shown are without return spring. Forces shown < > are with return spring. Forces shown in [ ] are in kilograms.

**To determine the operating current, divide the power (watts) indicated in the above table by the applied voltage.

Solenoids will operate at any stroke less than maximum.

†

A stud with nut is supplied, loose.

1-1/2 in. (38 mm)—1/4-28

part number: 40-01-0055

Watts Power/Cold Force in Pounds at 100% Voltage/Inches Stroke

RPS-00092B page 2 of 4

Note 1. Typical operating temperature for single 15 second operation of the energize coil is less than:

140°F(60°C) ± 10°F (6°C) for 1 in. (25 mm) Stroke Solenoids (70°F/21°C Rise above ambient)

120°F(49°C) ± 10°F (6°C) 1-1/2 in. (38 mm) Stroke Solenoids (50°F/10°C Rise above ambient)

See CAUTION statement on next page and note maximum housing temperature is 185°F (85°C).

Note 2. The energize-coil should not be activated for more than 15 seconds.

Longer energize-coil activation times will damage the solenoid.

Note 3. Allow minimum 15 minutes for cooling between activations of energize-coil to avoid damaging the

solenoid. (Depends on length of time energize coil is energized.)

Note 4. The energize-coil must fully seat the plunger to allow the hold-coil to function properly.

1/4-28 Shaft w/nut

shown installed

(is supplied loose)

1/2 in.

(13 mm)

1-19/32 in.

(40 mm)

2-13/16 in.

(72 mm)

5 in.

(127 mm)

Boot

Internal

1/4-28

(25 mm)

†

1 in.

3/32 in.

(2 mm)

NOTE: Remove

or pierce decal

to install shaft.

2 in.

(51 mm)

2-1/2 in.

(64 mm)

1-5/8 in.

Diameter

2-7/16 in.

(62 mm)

9/32 in.

(7 mm)

1/4-28 Shaft w/nut

shown installed

(is supplied loose)

21/32 in.

(17 mm)

2-1/16 in.

(52 mm)

3-9/32 in.

(83 mm)

1-1/2 in.

(38 mm)

7-7/32 in.

(184 mm)

Boot

Internal

1/4-28

†

Shown with

stud and nut

installed.

1-1/8 in.

(28 mm)

Remove or

pierce decal

to install shaft.

3/32 in.

(2 mm)

2 in.

(51 mm)

Diameter

9/32 in.

(7 mm)

2-1/2 in.

(64 mm)

3-1/8 in.

(79 mm)

2-7/8 in.

(73 mm)

Page 3

RPS-00092B page 3 of 4

Mechanical Installation

1. Bolt the solenoid securely to the mounting bracket.

2. Connect linkage and check for binding. Plunger should move

freely throughout the complete stroke and be allowed to

“bottom” at the internal stop of the solenoid.

DO NOT MOUNT WITH BOOT DOWN.

DO NOT APPLY ANY GREASE OR LUBRICATION TO PARTS.

IMPORTANT: If the plunger does not seat, it will release

prematurely when shifted to the “holding” mode of operation.

Readjust linkage to lengthen the plunger stroke. Adjust the yoke

in increments of 1/2 turn until plunger will remain in hold

position.

Electrical Installation

1. Refer to the diagrams above for typical electric wiring.

2. Use minimum 10 AWG [65/0.3 mm (4.5 mm)] wire size, as

noted in the wiring diagrams. A smaller wire will reduce the

current available and thus the pulling force. Wire length must

be kept to a minimum.

Operation

The solenoid coil is connected to the existing engine starter

system or an equivalent circuit. A SD85 is recommended. At

starting, both the Energize and Hold-in coils are energized. In

the run mode, the Hold-in coil is continuously energized while

the Energize coil has to be disconnected, reducing the heating

effect and power consumption and avoiding damage to the

device.

NOTE: Coils that burn out due to improper electrical hookup,

misadjustment or improper operation are not covered by Murphy

factory warranty.

NOTE: A cool down period of 15 minutes minimum should be

allowed between energized pull in cycles.

*Wires must be minimum 10 AWG (65/0.3 mm [4.5 mm]) to develop full force.

*Wires must be minimum 10 AWG (65/0.3 mm [4.5 mm]) to develop full force.

Typical Wiring Diagrams

CAUTION: The solenoid housing is hot to the

touch. A temperature rise to 185°F (85°C) is

permissible.

Typical time-delayed shutdown using a 760A magnetic switch

(SD85 is optional)

NOTE: In either application if the starter

hangs, on starters with integral solenoids, the

energize coil remains energized.

CAUTION: On certain starter solenoids/contactor relays,

current can feed back through the energize terminal

from the hold coil and provide a parallel path to ground

through the device connected to the energize terminal.

Typical time-delayed shutdown using a 518PH magnetic switch

(SD85 is optional)

20P-F 20T-F

®

SWICHGAGE

Instruments

Typical Closed Loop™ Circuit

Emergency

Stop

TATTLETALE

G NC

518PH

®

SW

SW

B

1

2

In-Line

Fuse

Existing

Start

System

OFF

ON

Turn OFF for

Emergency Stop

IG

Start Key

Switch

B

ST

*

10 AWG

Starter

Motor

12345

10 AWG

ON OFF

Fuel Lever

12345

SD85

10 AWG

SD85

*

*

N.O.

Starter Contactor

Relay

N.O.

10 AWG

10 AWG

*

Energize

*

Hold

Battery

RP2300 Series

Solenoid

Battery

Key Switch

OFF: No power.

ON: Power to hold coil of

fuel solenoid.

START: Power to energize

coil of fuel solenoid.

20P

SWICHGAGE

Instruments

START

20T

®

760A

Time-Delay

Before Shutdown

NO BNC

SG

Starter

Starter Contactor

Relay

10 AWG

10 AWG

*

*

Energize

Hold

Motor

RP2300 Series

Solenoid

*

10 AWG

ON OFF

Fuel Lever

Page 4

RPS-00092B page 4 of 4

RPS Linkage Parts and Assemblies

Threaded Rod

(40-05-0315)

RPS 90° Ball Joint

(00-00-2458)

RPS In-Line Ball Joint (00-00-2457)

SD85: Solenoid Drive Time Delay

The SD85 is used when the solenoid is duty cycled for short time

periods such as 2-position throttle operation. It also provides

enhanced operational control for normal on-off applications. The

SD85 activates both coils of the solenoid for a short time then deenergizes the Energize-coil. The Hold-in coil remains energized.

SD85: Specifications

Input Voltage 8 to 30 VDC

Current Ratings:

40 ma standby (quiescent) 8 to 30 VDC

75 Amps Pull-in @12 VDC

1 Amps Hold @ 12 VDC

37.5 Amps Pull-in @ 24 VDC

0.5 Amps Hold @ 24 VDC

Terminal #3 2 Amps Maximum

Terminal #5 112.5 Amps Maximum during Pull-in

Control

Switch

(continuous HOLD

power to #2 and

temporary PULL

power to #4)

SD85 Terminal Block

Clevis Yoke Bead Chain Assemblies

65-01-0110

12 inch

(300 mm)

Chain

7/8 in.

(22 mm)

5/8 in.

(16 mm)

2 in.

(51 mm)

1/16 x 3/8

Cotter Pin

1/16 in.

(2 mm)

diameter

1/4-28

Thread

1/4 in. (6 mm) diameter

Clevis Yoke

Clevis Yoke Assembly

65-01-0108

Accessories

2-3/16 in.

(56 mm)

2-1/4 in.

(57 mm)

2-1/2 in. (64 mm)

Mounting Holes

3 in. (76 mm)

Mounting Holes

3/16 in. (5 mm)

diameter 2-places

NOTE: Wires designated 10 ga. must be

at least 10 AWG [65/0.3 mm (4.5 mm)] to

develop full force.

CONTROL SYSTEMS & SERVICES DIVISION

P.O. Box 1819; Rosenberg, Texas 77471; USA

+1 281 633 4500 fax +1 281 633 4588

e-mail sales@fwmurphy.com

MURPHY DE MEXICO, S.A. DE C.V.

Blvd. Antonio Rocha Cordero 300, Fracción del Aguaje

San Luis Potosí, S.L.P.; México 78384

+52 444 8206264 fax +52 444 8206336

Villahermosa Office +52 993 3162117

e-mail ventas@murphymex.com.mx

www.murphymex.com.mx

FRANK W. MURPHY, LTD.

Church Rd.; Laverstock, Salisbury SP1 1QZ; U.K.

+44 1722 410055 fax +44 1722 410088

e-mail sales@fwmurphy.co.uk

www.fwmurphy.co.uk

MURPHY SWITCH OF CALIFORNIA

41343 12th Street West

Palmdale, California 93551-1442; USA

+1 661 272 4700 fax +1 661 947 7570

e-mail sales@murphyswitch.com

www.murphyswitch.com

In order to consistently bring you the highest quality, full featured products, we reserve the right to change our specifications and designs at any time.

MACQUARRIE CORPORATION

1620 Hume Highway

Campbellfield, Vic 3061; Australia

+61 3 9358 5555 fax +61 3 9358 5558

e-mail murphy@macquarrie.com.au

FW Murphy

P.O. Box 470248

Tulsa, Oklahoma 74147 USA

+1 918 317 4100

fax +1 918 317 4266

e-mail sales@fwmurphy.com

www.fwmurphy.com

R

E

G

I

S

T

E

R

E

D

USA–ISO 9001:2000 FM 28221

UK–ISO 9001:2000 FM 29422

Printed in U.S.A.

1-1/2 in.

3/8 in.

(9 mm)

3/8 in.

(9 mm)

(38 mm)

1/4-28 Threads

1/4-28

Threads

1-1/4 in.

(32 mm)

2 in.

(51 mm)

1/4-28 Threads

1-1/4 in.

(32 mm)

10 ga.

Ground

Solenoid

Hold

1 2 3

10 ga.

Energize

10 ga.

12-24 VDC

4 5

NC

B

10 ga.

TATTLETALE®

Option

Loading...

Loading...