Page 1

00-02-0977

2018-02-23

Section 30

PowerCore

®

Model TEC-10

Installation Manual

Products covered in this document comply with European Council electromagnetic

compatibility directive 2014/30/EU and electrical safety directive 2014/35/EU.

Page 2

In order to consistently bring you the highest quality, full-featured products, we reserve the

right to change our specifications and designs at any time. The latest version of this

manual can be found at enovationcontrols.com.

BEFORE BEGINNING INSTALLATION OF THIS MURPHY

PRODUCT:

• Read and follow all installation instructions.

• Visually inspect this product before installation for

any damage during shipping.

• Disconnect all electrical power to the machine.

Failure to do this before welding can result in

damage to the panel and/or its components.

• It is your responsibility to have a qualified

technician install the unit and make sure the

installation conforms to local codes including, but

not limited to, double insulation and fire

containment.

• Observe all Warnings and Cautions in each

section of these instructions.

• The TEC-10 is designed for use in industrial

environments for monitoring and control which

include engine driven pumps, compressors,

grinders, chippers and rock crushers. Potential

difficulties may exist when ensuring

electromagnetic compatibility in other

environments due to conducted as well as

radiated disturbances.

Contact Enovation Controls Technical Service if you

have any questions or concerns at: +1 918-317-4100.

IMPORTANT! Improper use and operation of electronic

products can be dangerous. It is required that point-ofoperation guarding devices be installed and maintained.

All such devices must meet OSHA and ANSI Machine

safety standards. The manufacturer shall not accept

any responsibility for installation, application or safety of

systems.

Page 3

Table of Contents

Operations Manual Location ................................................. 2

Hardware Installation ............................................................. 2

Inspecting Package Contents ....................................... 2

Tools Needed ............................................................... 2

Installation .................................................................... 3

Dimensions for Installation ................................................... 4

PIN Specifications ................................................................... 6

Accessories ............................................................................. 7

Specifications .......................................................................... 8

Interface ....................................................................... 8

Power Supply ............................................................... 8

Inputs (9) ...................................................................... 8

Outputs (8).................................................................... 8

Communications ........................................................... 8

Mating Connectors ....................................................... 8

Physical / Environmental .............................................. 8

Page 4

Section 30 00-02-0977

2018-02-23 - 1 -

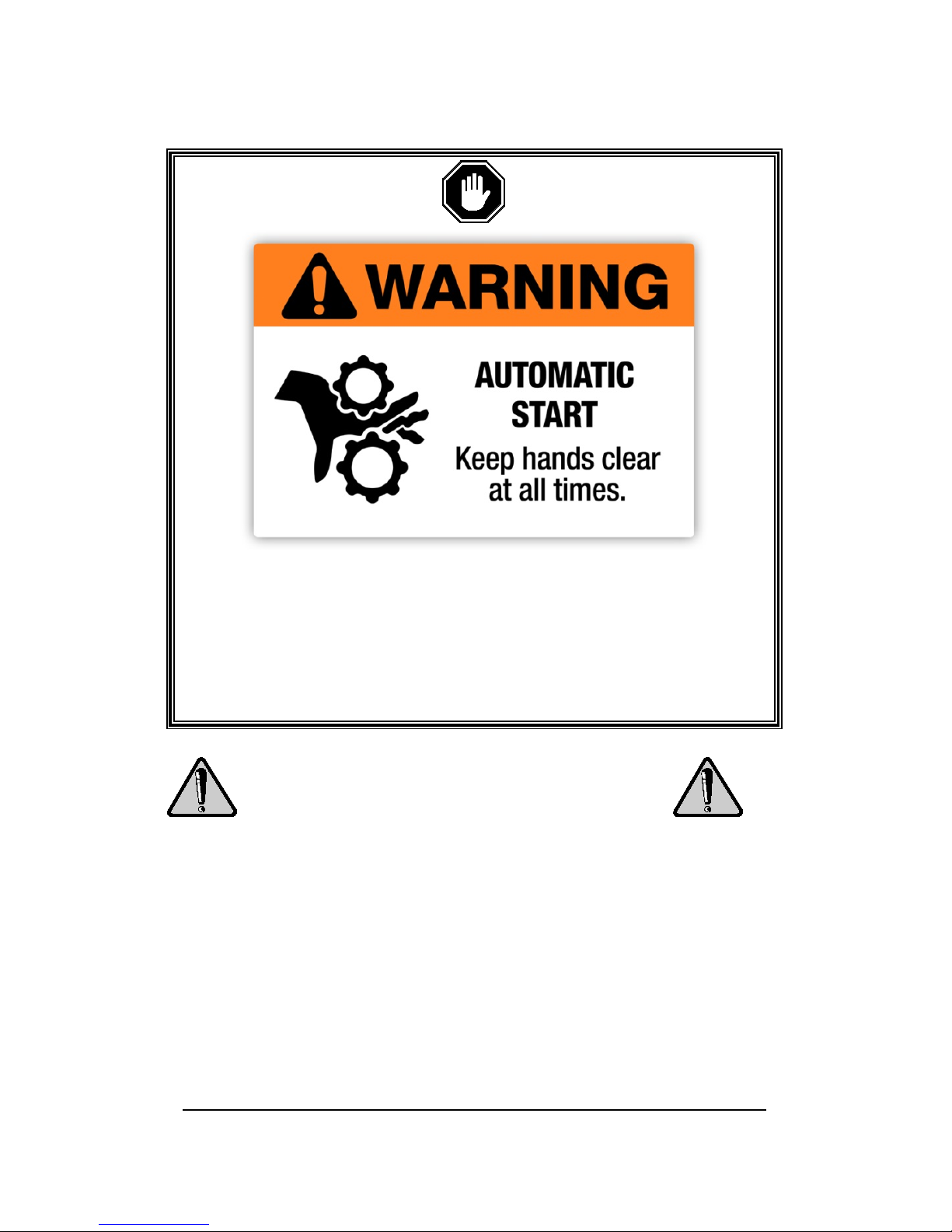

The TEC-10 can be set as an AutoStart Controller.

Please be cognizant at all times of hands and other

objects that are in close proximity to the machine(s)

being controlled as they may commence operation

suddenly and without warning.

LENS CLEANING PROCEDURES

The lens on the TEC-10 is composed of Polycarbonate

materials. Use only mild soap and water to clean the

lens/display window. Evidence of improper cleaning

techniques or chemicals includes cracks, smear marks,

scratches, or fogged/hazy lenses.

Page 5

Section 30 00-02-0977

2018-02-23 - 2 -

Operations Manual Location

After installation, please review the TEC-10 Operations Manual

prior to placing the controller into service. In order to access the

TEC-10 Operation Manual, please visit:

support.enovationcontrols.com

Then search for TEC-10. Download the latest manual by clicking

the link under the Manuals section of the page.

Hardware Installation

Inspecting Package Contents

Before attempting to install the product, it is recommended that

you ensure all parts are accounted for and inspect each item for

damage (which sometimes occurs during shipping). The items

included in the box are:

TEC-10 Controller kit – P/N 40-70-0495 includes:

• TEC-10 Control Panel

• Mounting Kit:

o 4 Shockmount Isolators

o 4 ¼ x 20 Hex Keps Nuts

• TEC-10 Installation Manual – P/N 00-02-0977

Tools Needed

Use a 9/32 or 7.5mm drill bit to make the approximately sized

0.28125” or 7.5mm mounting holes.

Use a 7/16” or 11mm torque wrench for shockmount nut

installation.

Page 6

Section 30 00-02-0977

2018-02-23 - 3 -

Installation

Preparing the Enclosed Panel

Determine the location of the TEC-10 Panel on the customersupplied mounting bracket or plate. The suitability of the location

is subject to investigation by the local authority having jurisdiction

at the time of the installation.

Recommended torque for tightening both the shockmounts into

the panel and the nuts on the shockmounts is 78 inch-pounds or

8.8 Nm (Newton Meters). Although thread lock is not required,

only blue polycarbonate compatible thread lock should be used

for the TEC-10 mounting screws.

Page 7

Section 30 00-02-0977

2018-02-23 - 4 -

Dimensions for Installation

Front Inches

[mm]

Side View

Page 8

Section 30 00-02-0977

2018-02-23 - 5 -

Back View

Page 9

Section 30 00-02-0977

2018-02-23 - 6 -

PIN Specifications

PIN

21 Pin Connector (A)

PIN

31 Pin Connector (B)

A

Unavailable

1

Unavailable

B

Battery (positive)

2

Unavailable

C

Unavailable

3

Unavailable

D

Relay 1, +DC (10A), Default Setting: Crank

4

Unavailable

E

Battery (negative)

5

Unavailable

F

J1939 CAN Shield

6

Unavailable

G

Relay 2, +DC (10A), Default Setting: ECU

Enable

7

Unavailable

H

Unavailable

8

Unavailable

J

Alternator Excite Output, +DC (1A)

9

Analog Input 3, Default Setting: Not Used

K

Unavailable

10

Unavailable

L

Unavailable

11

Unavailable

M

Unavailable

12

Unavailable

N

Unavailable

13

Digital Output 1, +DC, (1A), Default Setting: Not in

Auto)

P

Unavailable

14

Digital Input 3, Default Setting: Dual Contact Stop,

B-

R

Digital Output 3, -DC, (1A), Default Setting:

Throttle Decrease)

15

Unavailable

S

Digital Output 4, -DC, (1A), Default Setting:

Throttle Increase

16

Unavailable

T

Frequency Input

17

Relay 3 Common (RLY 3 Defaulted to Not Used)

10A Max

U

J1939 CAN Low (includes terminating resistor,

Default to ON)

18

Relay 3 NC (RLY 3 Defaulted to Not Used) 10A

Max

V

J1939 CAN High, (includes terminating

resistor, Default to ON)

19

Relay 3 NO (RLY 3 Defaulted to Not Used) 10A

Max

W

Analog Input 2, Default Setting: Not Used

20

Digital Input 5, Default Setting: Low Lube Oil Level

B-

X

Analog Input 1, Default Setting: Not Used

21

Digital Input 1, Default Setting: Not Used

NOTE: Wiring of this device must

meet all applicable electrical codes.

22

Unavailable

23

Digital Input 2, Default Setting: Dual Contact Start,

B-

24

Digital Output 2, +DC, (1A), Default Setting: Engine

Running)

25

Unavailable

26

Battery (negative)

27

Unavailable

28

Unavailable

29

Digital Input 4, Default Setting: Low Coolant Level,

B-

30

RS485 (positive)

31

RS485 (negative)

Page 10

Section 30 00-02-0977

2018-02-23 - 7 -

Accessories

Part

Number

Description

40000602

Engine Harness, 21 Position Connector 10’ Whip

Harness (3m approx.)

40000603

I/O Harness, 31 Position Connector 10’ Whip

Harness (3m approx.)

40000479

Deutsch Connector Kit, 21-pin and 31-pin, Panel

Connector Kit

40000531

Deutsch Connector Kit, 21-pin, Panel Connector

Kit, Engine Only

78700046

Deutsch Connector Kit, 31-pin, Panel Connector

Kit, I/O Only

40051073

Replacement Fuse Door

40051143

Replacement Fuse Door Pad

40000601

Replacement Shock Mount Kit

40000636

Replacement Key Set

40000625

TEC-10 Programming Kit

Page 11

Section 30 00-02-0977

2018-02-23 - 8 -

Specifications

Interface

Display:

Monochrome HR-TFT with backlight

2.7” / 68 mm, WQVGA (400 x 240 pixels)

Languages: English, Spanish, German, French, Italian

(3) LEDs: Green (mode), Yellow (warning) and Red (shutdown)

Operator Controls:

(11) Raised silicone keypads, tactile feedback

(1) Rotary key switch, power on/off

(1) Push switch (red), engine stop

Power Supply

Operating Voltage: 8-32 VDC, reverse battery polarity and load-dump protected

Cranking Power Holdup: 0 VDC up to 50mS (also good for brownout / blackout

instances)

Current Consumption:

Power on in stopped state; 117 mA at 12 VDC.

Power on in standby mode; 52 mA at 12 VDC

Inputs (9)

(5) Digital: configurable (active on High, Low, Open)

(3) Analog: configurable (4-20 mA, 0-5V, resistive or digital ground)

(1) Frequency: supporting:

Magnetic Pickup (30 Hz – 10 kHz, 2.0 VAC – 120 VAC) and

Engine Alternator (30 Hz – 10 kHz, 4.5 VRMS – 90 VRMS)

Outputs (8)

(2) Relay: switched +DC, 10A

(1) Relay: Form C (dry / volt-free), 10A

(2) Low-side FET: (-DC), 1A

(2) High-side FET: (+DC), 1A

(1) Dedicated Alternator Excitation: +DC, 1A

Communications

(1) CAN: J1939

(1) RS485: Modbus RTU

Mating Connectors

21 Position, Deutsch HDP26-24-21SE

31 Position, Deutsch HDP26-24-31SE

Physical / Environmental

Enclosure material: Polycarbonate

Dimensions (WxHxD): 9.59 x 7.34 x 5.20 in. (243.48 x 186.5 x 132.23 mm)

Weight: 4 lbs (1.8 kg)

IP Rating: IP67

Operating and Storage Temperature: -40° to +85° C (-40° to 185° F)

Vibration: 7.86 G

rms

(5-2000 Hz), 3-axes random

Shock: ±50G, 3-axes

Page 12

Loading...

Loading...