Page 1

OS77 Series Single Set Point Switch

Installation and Operation Instructions

OS-98001N

Effective 04-98

Section 20

00-02-0303

Description

The OS77 Series single set point speed switch is a compact, all-electronic,

speed sensing module. It is field adjustable and can be panel mounted via its

trip set point potentiometer.

Standard OS77 models provide a transistor output when tripped. Models with a

relay output are available.

The OS77 is used for protecting the engine from excessive or insufficient operating speeds. As the engine speed reaches the adjustable set point setting, the

OS77 will cause the engine to shutdown.

Models are available with Normally Open or Normally Closed circuit and

available recrank feature which inhibits starter re-engagement until the engine

speed is near zero RPM.

Specifications

Power Supply: Voltage: 7-28 VDC.

Maximum Current: 100 mA.

Frequency Signal:

Voltage, Magnetic Pickup Signal Models

•

Minimum: 1.2 Vrms

•

Maximum: 30 Vrms

Voltage, Distributor Ignition Models

•

Minimum: 6 Vrms

•

Maximum: 30 Vrms

Maximum Current, Magnetic Pickup Signal Models: 0.12 mA

Maximum Current, Distributor Ignition Models: 0.12 mA

Adjustment Range, Magnetic Pickup Signal Models: 1000-10,000 Hz

Adjustment Range, Distributor Ignition Models: 40-400 Hz

Reset Differential, Magnetic Pickup Signal Models

•

Non-recrank model: 10 Hz Differential

•

Recrank model: dropout 54 Hz

Reset Differential, Distributor Ignition Models

•

Non-recrank model: 10 Hz Differential

•

Recrank model: dropout 2.4 Hz

Output:

•

Transistor Sink to Ground Resistive Load: 2 A, 28 VDC

•

Relay Output Models: 5 A, 250 VAC

Adjustment: 270°–turn potentiometer

Temperature Range: -13° to 185°F (-25° to 85°C)

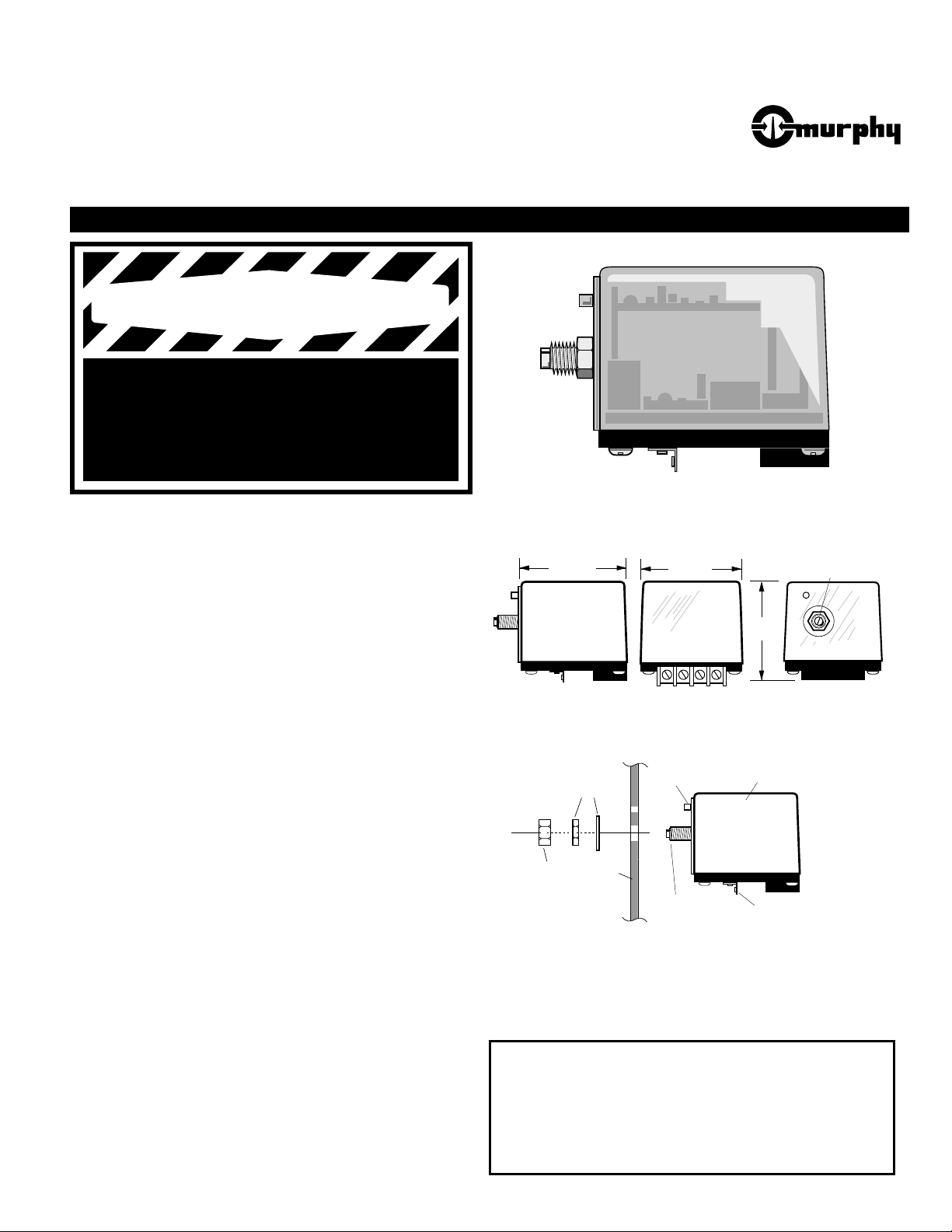

OS77 Module Dimensions

Please read the following information before installing. A visual inspection of this product for damage during shipping is recommended

before mounting. It is your responsibility to have a qualified person install this unit and make sure it conforms to NEC and local codes.

GENERAL INFORMATION

Installation Accessories

Hardware tools and optional equipment needed to install the OS77:

●

Tools as needed for system mounting such as drill and screw driver

●

18 AWG wire for extension and hook up

●

Wire termination tools and ring or spade wire termination.

●

Voltmeter or test lamp for set up and adjustments.

BEFORE BEGINNING INSTALLATION OF THIS MURPHY PRODUCT

✔ Disconnect all electrical power to the machine.

✔ Make sure the machine cannot operate during installation.

✔ Follow all safety warnings of the machine manufacturer.

✔ Read and follow all installation instructions.

OS77 Series

15234

2-1/2 in.

(64 mm)

2-3/8 in.

(60 mm)

2-1/8 in.

(54 mm)

Panel

Mounting

Hardware

Potentiometer

Locknut

Speed Adj.

Potentiometer

Speed Adj.

Potentiometer

Polycarbonate

enclosure

Terminal #5 used for

Relay output models

Positioning

post

Mounting Instructions

The OS77 module is designed to be mounted in a flat panel.

1.

Drill the mounting holes as shown on the template included with the packing.

2.

Insert the module from the back side of the panel (refer to schematic above).

3.

Secure the OS77 module using the mounting hardware included.

Mounting Schematic

FRANK W.

®

MFR.

WARNING

Page 2

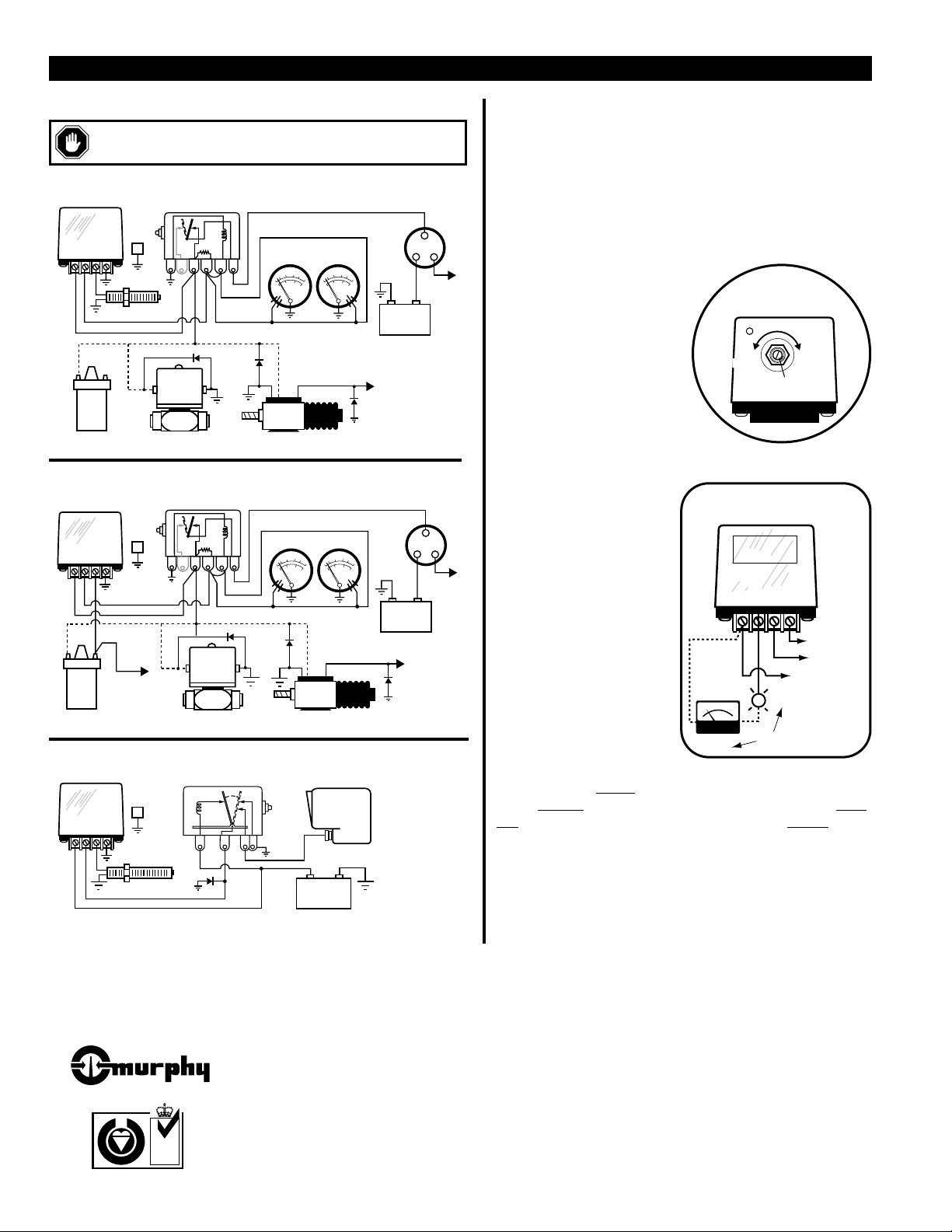

Setting the OS77 Series

The OS77 Series module must be fully installed and properly wired before

attempting any of adjustment steps. These adjustment steps must be performed before the fine tuning can be accomplished and should be performed

for first time setup of the OS77.

Note for relay output models only (OS77R): The following instructions

assume terminal 5 is grounded. Relay contacts are between terminals 2& 5.

1

. Turn the “SPEED ADJ. ” potentiometer

fully clockwise (Detail 1).

2

. Remove the wire from terminal #2 of

the OS77 terminal block (Detail 2).

3

. Start engine and run at the highest

RPM desired. This is the RPM at

which the engine should be shutdown if exceeded.

4

. Connect a Voltmeter or a test light

between terminals #1 (positive+) and

terminal #2 (negative) of the OS77 terminal block. You should read no voltage

or the test lamp will be OFF.

5

. Slowly turn the “SPEED ADJ. ”

pot counter-clockwise and stop

the INSTANT the battery voltage is indicated on the meter

or the test light comes ON.

6

. Slowly turn “SPEED ADJ.”

pot clockwise about 1/8 of an

inch. Now, tighten the locknut

(bigger nut) on the SPEED

ADJ. pot without disturbing

the setting.

7

. Re-connect the wire to terminal

#2 on the OS77 terminal block.

This reconnects the SPEED

shutdown circuitry.

NOTE: If further adjustment (fine tuning) is needed: Turning the SPEED

ADJ. pot clockwise, RAISES

the shutdown point. This allows the engine to

run at a HIGHER

RPM. Turning the SPEED ADJ. counter-clockwise LOW-

ERS the shutdown point. This will shutdown the engine at a LOWER RPM.

Warranty

A two year limited warranty on materials and workmanship is

provided with this Murphy product. Details are available on

request and are packed with each unit.

HOOK UP AND ADJUSTMENTS

1234

5

OS77

++–

–

B

Battery

To Starter

To

Starter

Key Switch

Pressure

Temp.

Rack Puller

Hold coil

Fuel Valve

Ignition Coil

Pickup

518PH/518APH

I

S

1234

OS77

+–

Battery

Pickup

169PH Magnetic Switch

1234

OS77

+

–

To Starter

Rack Puller

Hold coil

Fuel Valve

Ignition Coil

To Distributor

Ignition

R

G

NO NC

SW1

SW2

B

+–

B

Battery

To

Starter

Key Switch

Pressure

Temp.

518PH/518APH

I

S

R

G

NO NC

SW1

SW2

B

SB GC

*

Applies to 518APH model.

***

Applies to Relay output models only. B+ can be

switched on Relay output models if desired.

**

Always use shielded cable.

**

*

**

*

5

5

***

***

***

OS77 Module

Front View

Speed Adj.

Potentiometer

RaiseLower

Detail 1

OS77D Model Typical Wiring Diagram

(Negative Ground Only)

OS77I Typical Wiring Diagram

(Distributor Ignition Applications)

OS77I Typical Wiring Diagram

(For Shutting Down Magneto Ignitions)

Wiring the OS77 Series

Detail 2

WARNING: BEFORE WIRING THE OS77 MAKE SURE THE

POWER SOURCE IS OFF AND EQUIPMENT IS STOPPED.

To Pickup

To Battery–

To Battery +

Light

Meter

OR

+

--

1234

OS77 Module

Back View

Printed in U.S.A.

®

FRANK W.

MFR.

■ FRANK W. MURPHY SOUTHERN DIVISION

P.O. Box 1819; Rosenberg, Texas 77471; USA

tel. (281) 342-0297 fax (281) 341-6006

e-mail sales@fwmurphy.com

■ FRANK W. MURPHY, LTD.

Church Rd.; Laverstock, Salisbury SP1 1QZ; U.K.

tel. +44 1722 410055 fax +44 1722 410088

e-mail sales@fwmurphy.co.uk

http://www.fwmurphy.co.uk

■ FRANK W. MURPHY FRANCE

tel. +33 1 30 762626 fax +33 1 30 763989

■ MURPHY DE MEXICO, S.A. DE C.V.

Blvd. Antonio Rocha Cordero 300, Fracción del Aguaje

San Luis Potosí, S.L.P.; México 78384

tel. +52-48-206264 fax +52-48-206336

e-mail murmexsl@sanluis.podernet.com.mx

■ FRANK W. MURPHY PTE., LTD.

No. 2 Tuas South Street 2,

Sprintecs Bldg., #02-01/02

Singapore 638042

tel. +65 863-1398 fax +65 863-0208

e-mail fwmsales@fwmurphy.com.sg

In order to consistently bring you the highest quality, full featured products, we reserve the right to change our specifications and designs at any time.

■ MURPHY SWITCH OF CALIFORNIA

41343 12th Street West

Palmdale, California 93551-1442; USA

tel. (661) 272-4700 fax (661) 947-7570

e-mail sales@murphyswitch.com

http://www.murphyswitch.com

■ MACQUARRIE CORPORATION

1620 Hume Highway;

Campbellfield, Vic 3061; Australia

tel. +61 3 9358-5555 fax +61 3 9358-5558

e-mail murphy@macquarrie.com.au

FRANK W. MURPHY MANUFACTURER P.O. Box 470248; Tulsa, Oklahoma 74147; USA tel. (918) 627-3550 fax (918) 664-6146 e-mail sales@fwmurphy.com http://www.fwmurphy.com

BSI

R

E

G

I

S

T

E

R

E

D

F

I

R

M

FM 28221

FM 29422

USA–ISO 9001

UK–ISO 9002

NATIONAL

ACCREDITATION

OF CERTIFICATION

BODIES

Since 1939

Loading...

Loading...