Page 1

Model MTH6 Tach/Hourmeter Overspeed Switch

Installation and Operation Instructions

MTH-96116N

Revised 04-05

Section 20

(00-02-0778)

Description

Microprocessor-based digital tachometer and hourmeter with a built-in

overspeed switch. This Murphy instrument is highly accurate and dependable. It measures speed and running hours and can give an alarm or shut

down the engine on overspeed.

RPM data for the tachometer and overspeed switch is supplied by a magnetic pickup or a battery charging alternator equipped with a “Tach” terminal (auxiliary AC terminal). The magnetic pickup is installed into the flywheel housing of an internal combustion engine, so that the starter ring gear

acts upon it to generate a voltage pulse each time a gear tooth passes the end

of the magnetic pickup.

Specifications

Power Requirements: 8-40 VDC (12, 24 or 32 VDC system).

Maximum Current:

12 VDC: 0.011 A, backlight Off; 0.025 A, backlight On.

24 VDC: 0.008 A, backlight Off; 0. 015 A, backlight On.

32 VDC: 0.007 A, backlight Off; 0. 010 A, backlight On.

Operating Temperature: -4° to 158°F (-20° to 70°C).

Storage Temperature: -40° to 185°F (-40° to 85°C).

Case: 1018 Polycarbonate/Polyester blend.

Speed Input: 4.5 Vrms minimum.

Input Frequency Range: 25 Hz to 20 kHz.

Overspeed Switch Rating: 2 A, 50 VDC.

Overspeed Range: 0 to 9000 kHz.

Pulses per Revolution: 4 to 255.

Tachometer Range: 0 to 65,535 RPM.

Tachometer Accuracy: ±1% of display reading,

or -2 RPM whichever is greater.

Hourmeter Range: 0 to 99999 hrs.

Hourmeter Resolution: ±0.1 hour to 9999.9; ±1 hour 10,000 and up.

Reset Hourmeter: Ground terminal #5 to reset hours to zero.

Shipping Weight: 14 oz. (435 g).

Shipping Dimensions: 5-1/2 x 5-1/2 x 5-1/2 in. (140 x 140 x 140 mm).

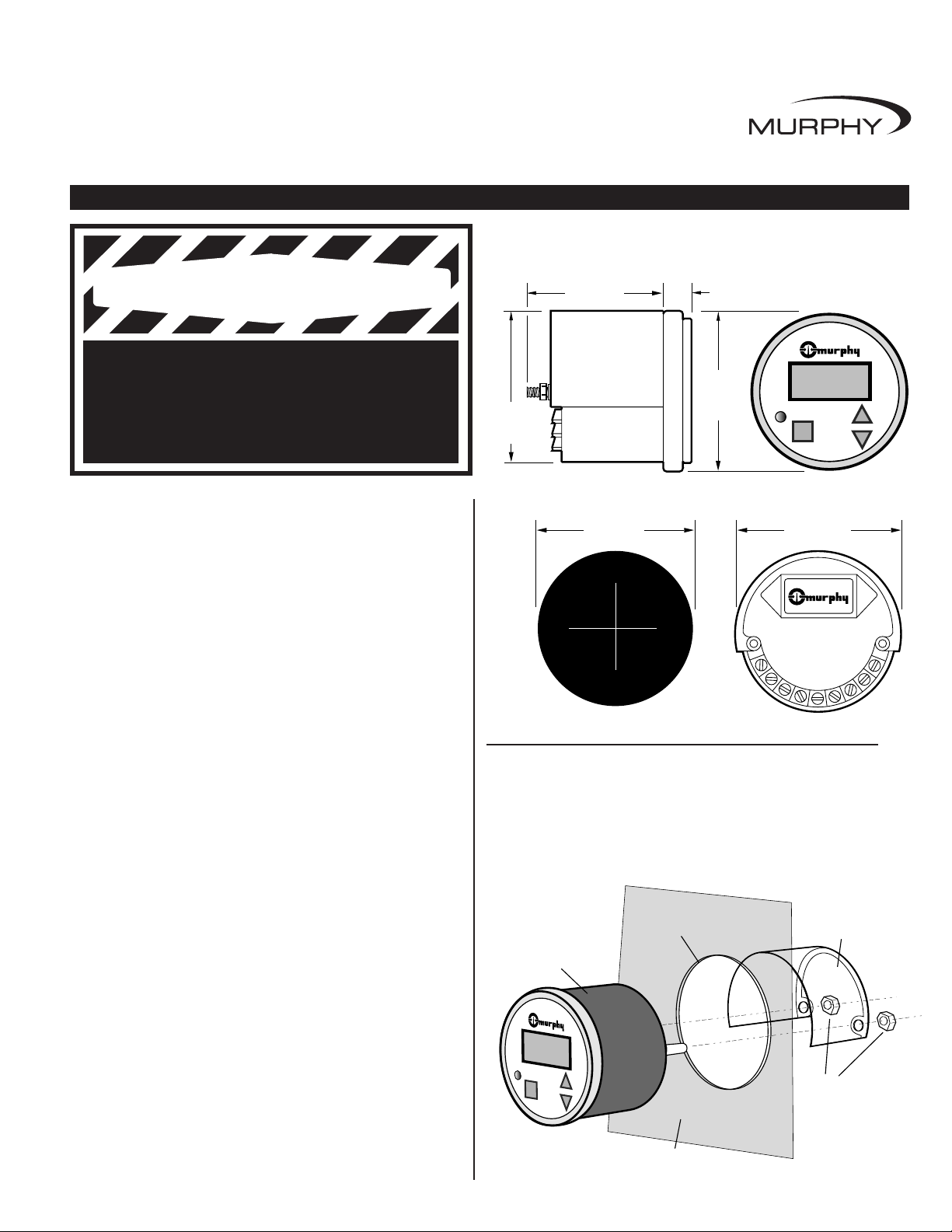

MTH6 Mounting Schematic

To mount the MTH6 to your panel, a 3-3/8 in. (86 mm) diameter mounting hole is required. Remove the mounting bracket and lock nuts (provided with the unit).

Insert the MTH6 module from the front of the panel, see schematic below.

Replace mounting bracket and secure in place with the lock nuts.

Please read the following information before installing. A visual inspection of this product for damage during shipping is recommended

before mounting. It is your responsibility to have a qualified person install this unit.

GENERAL INFORMATION

BEFORE BEGINNING INSTALLATION OF THIS MURPHY PRODUCT

✔✔

Disconnect all electrical power to the machine.

✔✔

Make sure the machine cannot operate during installation.

✔✔

Follow all safety warnings of the machine manufacturer.

✔✔

Read and follow all installation instructions.

Dimensions

Side View

Front View

Back View

Mounting Hole

MTH-96116N page 1 of 2

WARNING

3-33/64 in.

(89 mm)

Diameter

3-1/8 in.

(79 mm)

Mounting

Bracket

15/32 in.

(12 mm)

3-5/8 in.

(92 mm)

Diameter

FRANK W.

SETPOINT

MTH6

ENTER

®

MFR.

MTH6 Module

SETPOINT

(86 mm) Dia.

F

R

A

N

K

W

.

®

M

F

R

.

MTH6

E

N

T

E

R

3-3/8 in.

Mounting Hole

Panel

3-9/16 in.

(90 mm)

FRANK W.

MFR.

1

2

3

4

6

5

Mounting

Bracket

Nuts to

Secure

Mounting

(provided)

®

9

8

7

Page 2

MTH-96116N page 2 of 2

WIRING AND OPERATION

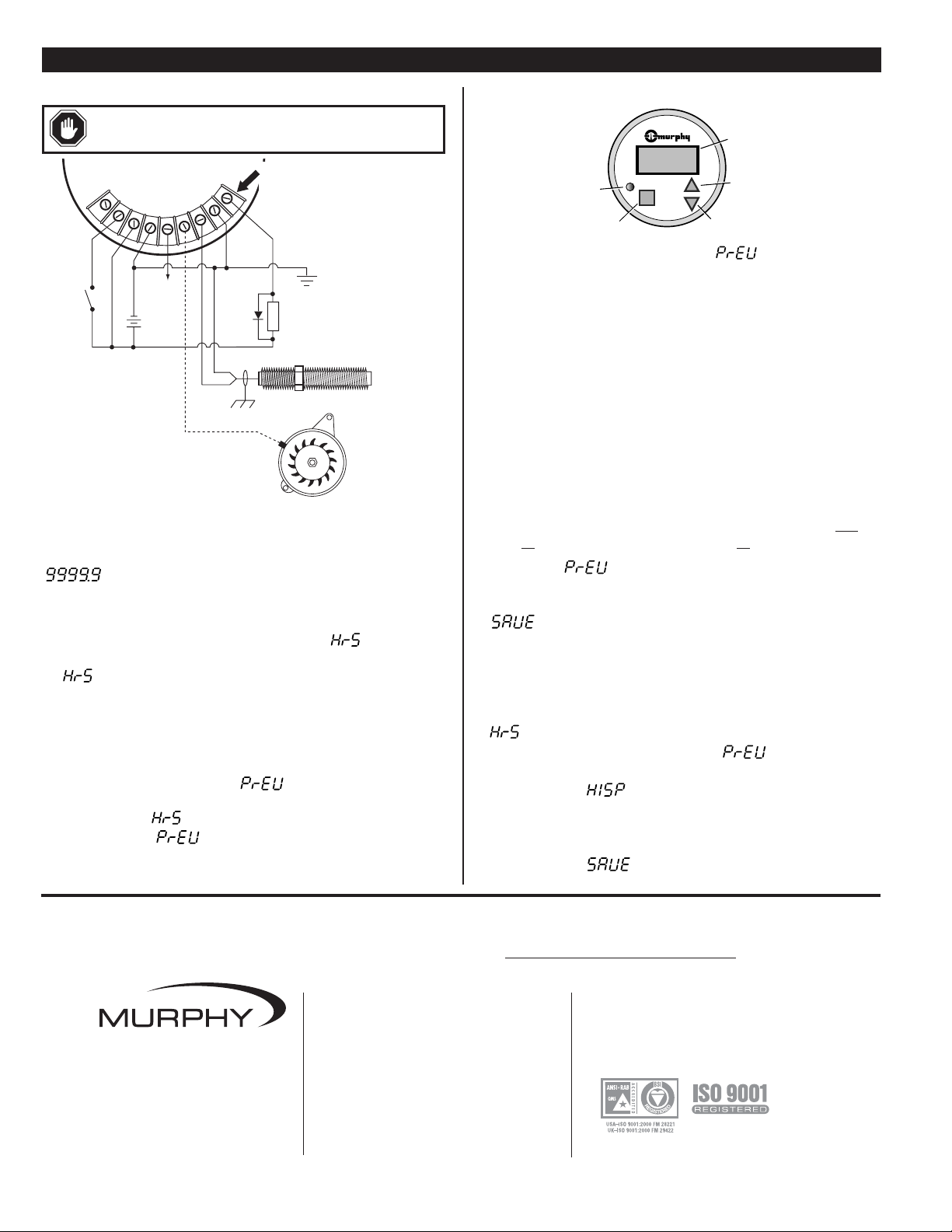

Wiring the MTH6

Refer to Typical Wiring Diagram, below.

Operation Sequence and Adjustments

When power is applied, the MTH6 performs an LCD test displaying

counting down to zero within 3 seconds. The MTH6 will perform

a normal scan, and will begin to monitor engine RPM. When the unit is in

Normal Scan, it displays RPM. The display is updated internally every second.

Viewing the Elapsed Time Hours

( )

1.

To view the elapsed hours, press

ENTER

(■■) while in Normal Scan.

2.

will be displayed followed by elapsed hours.

3.

To clear/reset to zero, apply a momentary ground to terminal #5. The hourmeter cannot be reset when a speed signal is present (normal operation).

NOTE: When speed input is present the first digit and decimal point will

flash. Decimal point will NOT appear after 10,000 hours have elapsed.

Pulses Per Revolution

( )

Calibration

1.

To view the current pulses per engine revolution, press

ENTER

(■■) while

in Normal Scan. will be displayed followed by the running hours.

2.

Press

ENTER

(■■). will be displayed followed by the present number

of pulses per revolution. The factory setting is 60. Unit will display input frequency with this setting.

3.

To calculate the pulses per engine revolution ( ) follow the instructions:

Magnetic Pickup: Determine the number of teeth on the engine’s flywheel.

The number of teeth is equal to the number of pulses per engine revolution.

Battery Charging Alternator: Multiply the ratio of alternator to engine

pulley diameter, times, the number of poles of the alternator divided by 2

to determine the correct pulses per engine revolution.

When the number of pulses per revolution is unknown, follow this procedure:

1. Set the pulses per revolution on the MTH6 to “60”.

2. Run the engine at a constant speed and measure the actual RPM using a hand-

held tachometer or any means which measures actual RPM.

3. Read the RPM displayed on the MTH6 (this is the frequency in hertz caused by

the engine speed).

4. Multiply the RPM reading on the MTH by 60, then divide by the actual RPM

read by the handheld device. Set this resulting number as the pulses per revolution

on the MTH6.

NOTE: If pulses per revolution are not a whole number, for example: 21.5, a

setting of 21 will read slightly high and a setting of 22 will read slightly low.

4.

To change the setting first remove the input signal. Press

UP

(▲▲) to

increase the value. Press

DOWN

(▼▼) to decrease the value.

5.

Once the number of pulses per revolution is set, press

ENTER

(■■) to save.

is displayed indicating that the new number is saved.

6.

Connect the input signal back in place (refer to typical wiring diagram at left).

Overspeed Set Point (HISP) Calibration

1.

To view the current Overspeed set point, press

ENTER

(■■) while the

MTH6 is in Normal Scan.

2.

will be displayed followed by the amount of elapsed hours.

3.

Press

ENTER

(■■) with elapsed time visible. will be displayed fol-

lowed by the number of pulses per revolution.

4.

Press

ENTER

(■■). will be displayed followed by the overspeed set

point previously entered. Factory setting is 1500.

5.

Press

UP

(▲▲), to increase the overspeed setting. Press

DOWN

(▼▼) to

decrease the setting.

6.

Press

ENTER

(■■), will be displayed indicating that the new value

is now saved.

WARNING:

Disconnect All Power before performing

wiring operation. Keep power leads away from input leads.

MTH6 Back View

MTH6 Module Detail

Warranty

A limited warranty on materials and workmanship is given with this FW Murphy product.

A copy of the warranty may be viewed or printed by going to www.fwmurphy.com/support/warranty.htm

INDUSTRIAL PANEL DIVISION

P.O. Box 470248

Tulsa, Oklahoma 74147 USA

+1 918 317 4100 fax +1 918 317 4266

e-mail sales@fwmurphy.com

MURPHY DE MEXICO, S.A. DE C.V.

Blvd. Antonio Rocha Cordero 300, Fracción del Aguaje

San Luis Potosí, S.L.P.; México 78384

+52 444 8206264 fax +52 444 8206336

Villahermosa Office +52 993 3162117

e-mail ventas@murphymex.com.mx

www.murphymex.com.mx

FRANK W. MURPHY, LTD.

Church Rd.; Laverstock, Salisbury SP1 1QZ; U.K.

+44 1722 410055 fax +44 1722 410088

e-mail sales@fwmurphy.co.uk

www.fwmurphy.co.uk

In order to consistently bring you the highest quality, full featured products, we reserve the right to change our specifications and designs at any time.

FW Murphy

P.O. Box 470248

Tulsa, Oklahoma 74147 USA

+1 918 317 4100 fax +1 918 317 4266

e-mail sales@fwmurphy.com

www.fwmurphy.com

Printed in U.S.A.

®

FRANK W.

MFR.

Display

1

2

3

4

Display

Light

Switch

NOTE 1: Apply momentary ground to reset

hours to zero.

NOTE 2: When using the MTH6 with inductive

loads, we recommend installing a

suppression diode across all coils.

NOTE 3: Terminals 4 and 8 may be grounded

on negative ground power supply.

NOTE 4: Alternator must be equipped with a

tach terminal (auxiliary AC terminal).

Note 1

--

Supply

8-40 Vdc

+

See

8

7

6

5

Shield

Grd.

CAUTION: Connecting full battery

potential to terminal 9 can cause damage

9

to the SWICHGAGE

is rated for 300 mA continuous.

Circuit grounds out at set point.

See Note 3

See

Note 2

Tachometer

terminal

See Note 4

Overspeed Load 2 A, 50 Vdc

(example: 518PH TATTLETALE®

magnetic switches; SAH MINI-SIREN®;

TL7 Flashing Alarms)

Magnetic Pickup

Alternator

®

. Shutdown circuit

Overspeed

Set Point

LED (light)

Enter or

Aknowledge

SETPOINT

ENTER

MTH6

Up

Down

Loading...

Loading...