Page 1

MDTM-8907N page 1 of 4

MDTM-8907N

Revised 10-07

Section 10

(00-02-0165)

Description

Murphy's model MDTM89 is an electronic, dual-temperature monitor. It monitors two thermocouples, displays the temperature of the

thermocouple selected, and has adjustable trip points for each input.

A toggle switch provides for selection of the thermocouple to be displayed and/or the temperature trip point to be checked/adjusted. If

either trip point is reached, the associated output “turns on” and can

be used as a control signal, or to initiate alarms and/or shutdown.

Specifications

Power Requirements (Operating Voltages):

MDTM89-A: 100 to 350

††

VDC, CD ignition, negative

ground (FET outputs).

MDTM89-B: 100 to 350

††

VDC, CD ignition, negative or

positive ground (SCR outputs).

MDTM89-C: 12 to 24

†

VDC, negative ground, 15 milliwatts

(FET outputs).

MDTM89-D: 120 VAC (MDTM89-C with 120 V isolation module #IT-1)

(FET outputs.) Model NOT approved by CSA or Factory Mutual.

Power Consumption: CD ignition: 350 µa @ 100V;

120 VAC: 0.6 watts; 24 VDC: 0.5 watts.

Outputs: Model B: output turns on above trip point; output turns off

when power is switched off; two (2) isolated SCR outputs, 0.5 amp

@ 250 VDC.

Models A, C and D: output turns on above trip point; output turns off

below trip point; two (2) isolated FET outputs, 0.5 amp @ 250 VDC.

Ambient Cold Junction Compensation Range:

32 to 122°F (1°C from 0 to 50°C).

Operating Temperature: -4 to 158°F (-20 to 70°C).

Storage Temperature: -40 to 300°F (-40 to 150°C).

Case: Die cast aluminum.

Reset Differential: FET models: Decreases 3 Degrees (°F or °C).

SCR model: turn input power off to reset.

Measurement Range: Monitor Range 0-1999°F or °C (specify “F” or

“C” in part number).

Accuracy: With J-type thermocouple: from 150-1200°F (66°-649°C)

±1.5% of reading. With K-type thermocouple: from 400-2000°F

(204-1076°C) ±1.5% of reading. At calibration temperature.

Laboratory Approvals: CSA

†

and Factory Mutual††approved for

Class I, Division 2, Group D, hazardous locations).

Thermocouple Lead Length: 150 ohm lead resistance affects moni-

tor accuracy less than 1°.

Trip Point Accuracy: ±3°F (±2°C) of reading.

Trip Point Adjustment Range: 0-1999 Degrees.

MDTM89 Interface Capabilities

Model Power Source Rating

LCDT CD Ign., 120 VAC, 12/24 VDC Cl.I, Div.1, Gr.D, Haz. areas

*

S1400 120 VAC or 12/24 VDC Cl.I, Div.1, Gr.D, Haz. areas

*

MARK II and IV CD Ignition, pos. or neg. grnd Cl.I, Div.2, Gr.D, Haz. areas

**

TATTLETALE

®

CD Ign., 120 VAC, 12/24 VDC Non-Hazardous areas

*

An isolation barrier is needed between the MDTM89 and an Annunciator rated for

Class I, Division 1, Group D, Hazardous Areas.

**

When used with approved ignition. Contact Murphy for details.

†

When used with approved ignitions or 12-24 VDC. Contact Murphy for details.

††

Approved for CD ignition, 80–250 VDC.

Instructions for Installation and Operation

Model Series MDTM89,

Dual Temperature SWICHGAGE

®

Please read the following information before installing. A visual inspection before mounting for any damage during shipping is

recommended. General information and installation instructions are intended for all MDTM89 Series models.

GENERAL INFORMATION

BEFORE BEGINNING INSTALLATION OF THIS MURPHY PRODUCT

✔✔

Disconnect all electrical power to the machine.

✔✔

Make sure the machine cannot operate during installation.

✔✔

Follow all safety warnings of the machine manufacturer.

✔✔

Read and follow all installation instructions.

†

††

WARNING

Page 2

MDTM-8907N page 2 of 4

One Thermocouple Only

Even though the MDTM89 is a dual temperature monitor, it will monitor

and display one temperature with equal results.

When monitoring one temperature, always jumper the unused thermocouple terminals on the back of the MDTM89 with a short length of wire.

The unused channel will display approximate ambient temperature.

Open Thermocouple Input

An open thermocouple input forces the monitor into upscale overrange.

The monitor indicates an overrange by displaying the numeral “1” in the

left most digit of the display. An overrange will turn on the trip point output, for the respective thermocouple.

MDTM89 Wiring and Adjustment

Instructions

A. Using Thermocouple Extension Wire

1. After thermocouple installation, connect the thermocouple leads to

the MDTM89 according to the instructions.

IMPORTANT: Use correct wire for the thermocouple selected.

USE ONLY THERMOCOUPLE EXTENSION WIRE.

2. If the thermocouple leads are not long enough you will need to use

shielded thermocouple extension wire. The thermocouple extension

wires, from your thermocouple lead wires to the terminals of the

MDTM89, must be of the same material as the thermocouple lead

wires. (See Table 1.)

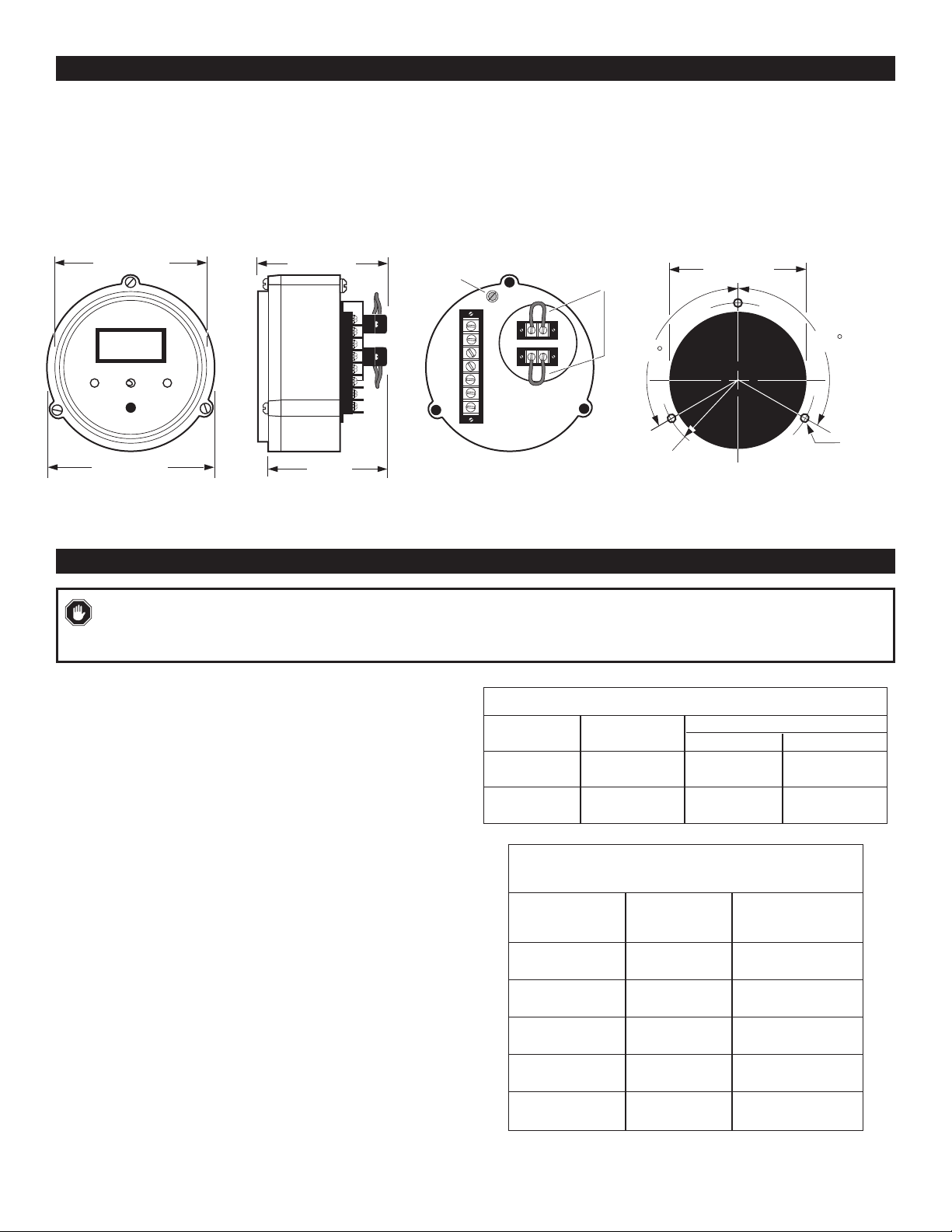

Mount the MDTM89 temperature SWICHGAGE

®

in a place where it

will be protected from rain and splashing water. A minimum distance of

12 in. (305 mm) from any ignition coils or coil leads should be maintained. The MDTM89 flush mount case is intended for mounting in a flat

panel .032 in. (1 mm) to .125 in. (3 mm) thick.

First, cut a 4-

3

/4 in. (121 mm) diameter hole and three

1

/4 in. (6 mm)

diameter fastening holes as shown below. Insert the SWICHGAGE

®

from the back side of the panel. Using the three 10-24 screws, included

with the SWICHGAGE

®

, secure to the panel.

Mounting Hole Pattern

JJxWhite/Iron Red/Constantan

KKxYellow/Chromel Red/Alumel

Table 1. Thermocouple Extension Wire Color Code

Thermocouple

Type

Thermocouple

Extension Wire

Color Code/Material

Positive Lead Negative Lead

14 .07 .146

16 .137 .230

18 .222 .374

20 .357 .586

24 .878 1.490

Table 2. Thermocouple Extension Wire Loop

Resistance in Ohms per Foot at 68°F

Size

AWG No.

Type “J” Type “K”

Thermocouple lead length: 150 ohm lead resistance affects monitor accuracy less than 1°.

Back View

Side View

Front View

MOUNTING DIMENSIONS

WIRING AND ADJUSTMENT INFORMATION

CAUTION:

Perform the wiring operation with the power source “OFF”. Make sure the voltage and current requirements are

within the SWICHGAGE®ratings. Keep all high voltage wiring, such as spark plug wires away from THERMOCOUPLES

AND EXTENSION WIRING. Before wiring determine the voltage and polarity for the application.

4-3/4 in.

(121 mm)

5-1/2 in.

(140 mm)

4-1/4 in.

(108 mm)

4 in.

(102 mm)

Screw for

Equipment Ground

Remove Jumper(s)

to Install

Thermocouple

TC1

TC2

4-3/4 in.

(121 mm)

120

120

2-39/64 in. radius

(66 mm)

1/4 in.

(6 mm)

typical

diameter

Page 3

MDTM-8907N page 3 of 4

3. When connecting the thermocouple extension wire to your thermocouple leads, twist the wire connections, then install wire nuts,

such as ceramic type, which have no metal insert.

DO NOT SOLDER.

To prevent problems of interference from electrical noise, DO NOT

route thermocouple wires in the same conduit or within 12 inches

(304 mm) of ignition wires or alternating current conductors.

Metallic-overbraided, thermocouple wire is recommended. It provides electrical shielding as well as protection against wear and

abrasion.

B. Connecting Thermocouple Wires (ungrounded thermocouple)

1. Remove factory installed jumpers or shunts from TC1 and TC2

terminals before connecting thermocouple(s).

2. Connect the thermocouple leads to the thermocouples. Observe

lead polarity. See Table 1 for thermocouple extension lead color

code and thermocouple polarity.

NOTE: Before continuing to the next step, decide which thermocouple

is to be identified as TC1 and which is to be identified as TC2.

A wire marker should be installed on each end of the thermocouple lead to identify TC1 and TC2.

3. Connect the positive lead of thermocouple TC1 to the positive (+)

terminal of terminal strip TC1.

4. Connect the negative lead of thermocouple TC1 to the negative (-)

terminal of terminal strip TC1.

5. Connect the positive lead of thermocouple TC2 to the positive (+)

terminal of terminal strip TC2.

6. Connect the negative lead of thermocouple TC2 to the negative (-)

terminal of terminal strip TC2.

C. Connecting Output Wires

Wire the SWICHGAGE

®

trip point outputs as shown in the typical

wiring diagrams on the back of this page.

D. Connecting Power Wires

1. Determine the voltage and the polarity of the input power before

attempting to connect the power leads to the MDTM89.

2. On CD ignitions, connect the shutdown lead to the MDTM89

ignition input as shown in the diagrams below.

Operation Test

NOTE: Perform the Operation Test after the MDTM89 is installed and wired

appropriately.

1. a. Rotate the trip point potentiometers TC1 and TC2 clockwise until an

audible click is heard or detente is felt. These are 12-turn

potentiometers.

b. Start the engine or power up the monitor.

2. a. Set the display selector switch to the TC1 position to display the TC1

temperature.

b. Next depress and hold the “Push to Read” trip point push button to

display the TP1 setting.

c. Rotate the TC1 trip point potentiometer counterclockwise until the

display reading is equal to the temperature reading observed in

step 2. a.

d. Trip point TP1 will turn on and trip the shutdown device or alarm;

verify by observation.

e. Rotate the trip point potentiometer TC1 clockwise several turns to

turn off TP1.

f. Reset alarm or shutdown device.

3. a. Set the display selector switch to the TC2 position to display the TC2

temperature.

b. Next, depress and hold the “Push to Read” trip point push button to

display the TP2 setting.

c. Rotate the TC2 trip point potentiometer counterclockwise until the

display reading is equal to the temperature reading observed in

step 3.-a.

d. Trip point TP2 will turn on and trip the shutdown device or alarm;

verify by observation.

e. Rotate trip point potentiometer TC2 clockwise several turns to turn

off TP2.

f. Reset alarm or shutdown device.

A

C

D

12 turn

potentiometers

DETAIL

B

Face Plate Diagram

A

. Trip point/display

toggle switch.

B

. Readout digital

display.

C

. Trip point

potentiometers.

D

. Push to read trip

point button.

WIRING AND ADJUSTMENT INFORMATION

TRIP POINT ADJUSTMENT INFORMATION

Trip Point Adjustments

1. Power up the temperature monitor by turning on power or by

starting engine.

2. Set the display selector switch to the TC1 position.

3. Depress the “Push to Read” trip point push button to read trip point.

4. Rotate the trip point potentiometer TC1 until the display indicates

the desired trip point temperature for TC1.

5. Set the display selector switch to TC2 position.

6. Depress the “Push to Read” trip point push button to read the

trip point.

7. Rotate the trip point potentiometer TC2 until the display indicates

the desired trip point temperature for TC2.

CAUTION:

The use of non thermocouple wire will cause

inaccurate temperature sensing and erratic operation.

Page 4

MDTM-8907N page 4 of 4

Load

12/24 VDC Power

120 VAC Power

Option NOT approved by

CSA or Factory Mutual

Typical TTD Hook-up

CD Ignition—Negative Ground

TYPICAL WIRING DIAGRAMS

Warranty

A limited warranty on materials and workmanship is given with this FW Murphy product.

A copy of the warranty may be viewed or printed by going to www.fwmurphy.com/support/warranty.htm

In order to consistently bring you the highest quality, full featured products, we reserve the right to change our specifications and designs at any time.

CONTROL SYSTEMS & SERVICES DIVISION

P.O. Box 1819

Rosenberg, Texas 77471 USA

Phone: 281.633.4500 Fax: 281.633.4588

E-mail: sales@fwmurphy.com

Web site: www.fwmurphy.com

FRANK W. MURPHY, LTD

Church Rd Laverstock

Salisbury SP1 1QZ UK

Phone: +44.1722.41005 Fax: +44.1722.410088

E-mail: sales@fwmurphy.co.uk

Web site: www.fwmurphy.co.uk

COMPUTRONIC CONTROLS, LTD

41 - 43 Railway Terrance Nechells

Birmingham B7 5NG UK

Phone: +44.1213.278500 Fax: +44.1213.278501

E-mail: info@computroniccontrols.com

Web site: www.computroniccontrols.com

FW MURPHY INSTRUMENTS (HANGZHOU) CO. LTD

77 23rd Street

Hangzhou Economic & Technological Development Area

Hangzhou, Zhejiang, 310018, China

Phone: +86.571.8684.8886 Fax: +86.571.8684.8878

FW MURPHY

P.O. Box 470248

Tulsa, Oklahoma 74147 USA

+1.918.317.4100 Fax: +1.918.317.4266

E-mail: sales@fwmurphy.com

INDUSTRIAL PANEL DIVISION

Fax: 918.317.4124

E-mail: ipdsales@fwmurphy.com

MURPHY POWER IGNITION

Web site: www.murphy-pi.com

www.

fwmurphy

.com

Printed in U.S.A. 0889795

Power

Source

12/24

VDC

Load

Power

Source

12/24

NC

NEG

TC1

TC2

TP1

TP2

Thermocouple

TC1 Input

See Table 1 for

wire color code.

Thermocouple

TC2 Input

See Table 1 for

wire color code.

120 VAC/24 VDC

Isolation

Module

H

ISOLATION

120 VAC 24 VDC

MODULE

N

Load

Power

Source

Load

Power

Source

12/24

NC

NEG

Thermocouple

TC1 Input

See Table 1 for

wire color code.

TC1

TC2

TP1

TP2

Thermocouple

TC2 Input

See Table 1 for

wire color code.

100-150 VDC

150-350 VDC

Load

Power

Source

CD

Ignition

Load

Source

Power

Negative

Ground

100-150

150-350

NEG

Thermocouple

TC1 Input

See Table 1 for

wire color code.

TC1

TC2

TP1

TP2

Thermocouple

TC2 Input

See Table 1 for

wire color code.

TPI

Loading...

Loading...