Murphy LS200N, LS200, L1100 User Manual

LS200, LS200N,

LS200NDVOR Series and

L1 100 Liquid Level Switches

Installation and Operations Manual

00-02-0563

01-11-06

Section 15

In order to consistently bring you the highest quality, full featured products, we reserve the right to change our

specifications and designs at any time. The latest version of this manual can be found at www.fwmurphy.com.

Warranty - A limited warranty on materials and workmanship for one year is given with this FW Murphy product.

A copy of the warranty may be viewed or printed by going to www.fwmurphy.com/support/warranty.htm

CAUTION: LS200 Series parts are not inter change ab le with o ther

Murphy liquid level products. Damage caused by us ing incor rec t

parts is not covered by our Limited Warranty.

Please read the following information before installing. A visual

inspection for damage during shipping is recommended before

mounting.

BEFORE BEGINNING INSTALLATION OF THIS MURPHY

PRODUCT:

• Disconnect all electrical power to the machine.

• Make sure the machine cannot operate during installation.

• Follow all safety warnings of the machine manufacturer.

• Read and follow all installation instructions.

• OBSERVE all pressure and electrical ratings and require-

ments for the devices and the operating environment.

• BE SURE all pressure HAS BEEN REMOVED from the vessel

before opening any pressure connections.

• Please contact FW MURPHY immediately if you have any

questions.

T able of Conte nt s

Product Information................................................................................................................ 1

Features.......................................................................................................................1

LS200...........................................................................................................................1

LS200NDVOR..............................................................................................................2

LS200NDVO ................................................................................................................3

LS200N........................................................................................................................3

Pressure Vessel Installation: LS200, LS200N and L110 0.................................................. 4

Direct Installation into the Wall of the Pressure Vessel................................................4

Installation with a Weld Collar......................................................................................4

Installation Using Murphy External Float Chamber......................................................5

Installation and Adjustment for Pneumatic Models.......................................................5

Trip Cam Operating Lever Orientation.........................................................................6

Replacing and Installing the DVO Assembly....................................................................... 7

Models LS200NDVO & LS200NDVOR ........................................................................7

Electrical ................................................................................................................................10

Replacement Parts................................................................................................................ 10

Accessories........................................................................................................................... 11

15050375: Weld Collar..............................................................................................11

55050617: DVU150/DVU175 Adapter Bushing.........................................................11

15051098: External Float Chamber ..........................................................................12

15051168: CB External Float Chamber ....................................................................12

15000478: Float Shaft Extension..............................................................................13

Specifications................................................................................................................. .......14

All Models...................................................................................................................14

LS200.........................................................................................................................14

LS200NDVOR............................................................................................................14

LS200NDVO ..............................................................................................................14

LS200 N.....................................................................................................................14

L1100.........................................................................................................................14

Approximate Shipping Weights and Dimensions........................................................14

(THIS PAGE INTENTIONALLY LEFT BLANK)

Product Information

Features

• Designed for harsh gas compressor scrubber applications

• 304 stainless steel float operates in 0.5 specific gravity and heavier fluids

• LS200 series rated for 2000 psi (13.8 MPa) [138 bar] working pressure

• Electric and pneumatic models available

• Improved design provides better snap action and dependability with reduced

number of moving parts

• All models screw directly into the vessel or can be mounted via external float

chamber

• Nickel plated body to provide enhanced corrosion protection

• Improved float connection thread design provides a more secure connection

• Listed for Class I, Div. 1, Grp. C & D locations

• Canadian Registration Number OF1476.2

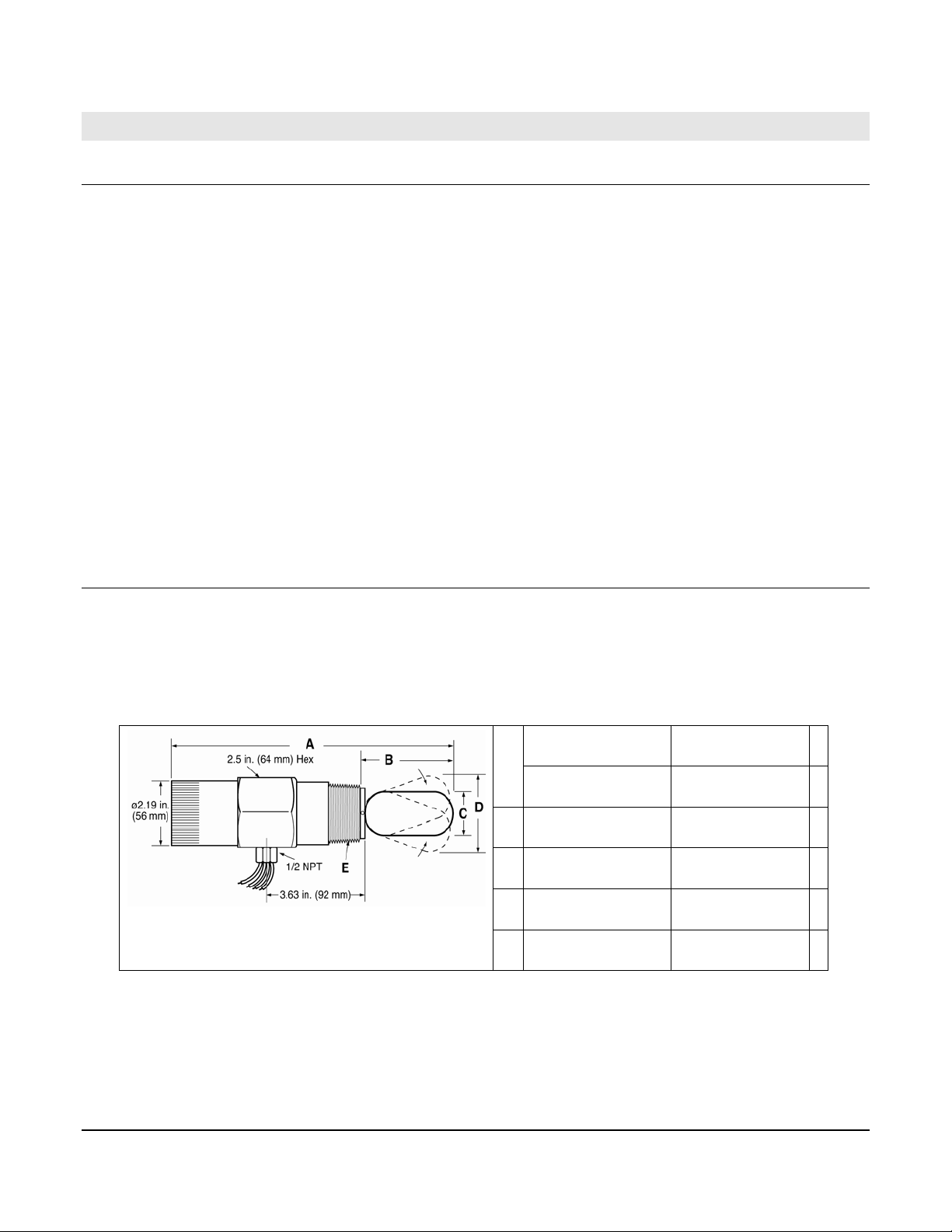

LS200

LS200 Liquid Level Switches with 2” NPT mounting are float activated to operate an electrical

SPDT snap switch (optional DPDT on some models) for alarm or shutdown of an engine or

electric motor. The LS200 connects via a thread-o-let directly into the vessel wall and can be

used with a weld collar (P/N 15050375) or Murphy external float chamber. L1100 models

(1-1/2” NPT) are also available.

LS200 L1100

A

10.16 in. (258 mm) 11 in. (279 mm)

B

3.44 in. (87 mm) 3.50 in. (189 mm)

C

1.75 in. (44 mm) 1.56 in. (40 mm)

D

2.80 in. (71 mm) 3.4 in. (71 mm)

LS200

E

2 NPT 1-1/2 NPT

Section 15 00-02-0563

01-11-06 - 1 -

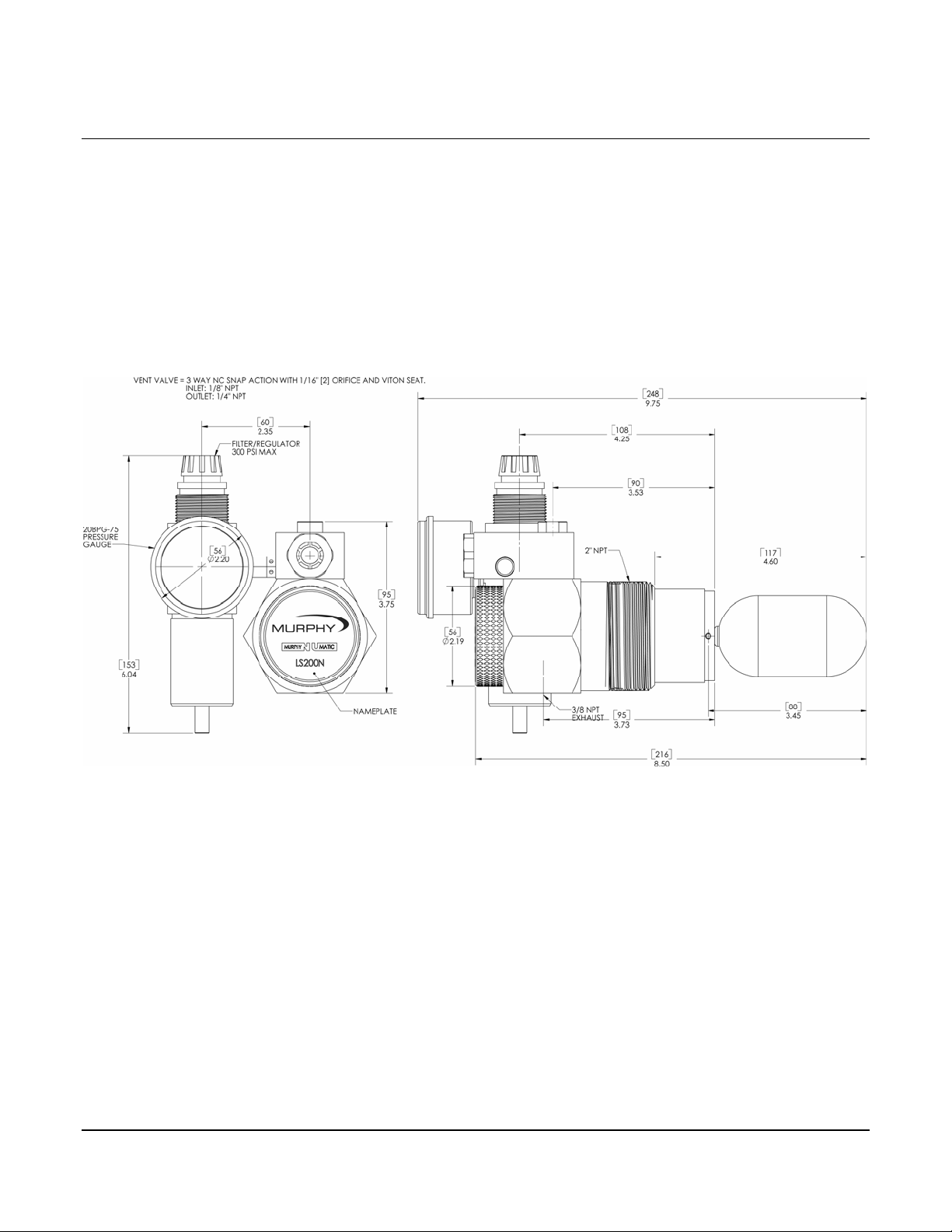

LS200NDVOR

LS200NDVOR is a float-activated, pneumatic-vent level device used to operate dump valves

or similar devices.

The LS200NDVOR provides a 2” NPT mounting with a pneumatic snap action output for

interfacing with pneumatic devices such as our Murphy pneumatic dump valve or with other

pneumatic instrumentation.

Pneumatic media devices require clean, dry, instrument quality air or gas. This unit is supplied

with a pressure regulator, filter and Murphy 20BPG pressure gage for improved system life and

trouble-free operation.

LS200NDVOR pneumatic level switch with dump valve operator, pressure regulator and

gage

Section 15 00-02-0563

01-11-06 - 2 -

Loading...

Loading...