Murphy LR579, LR589, LR500, LR589NC User Manual

Unique Anti-Clog Thumb-Valve

™

Regulate Oil Flow From Reservoir to

Keep Lubricator Full

Eliminates Manual Oil Check and

Refill Time

Low-level Shutdown Switch

Reduce Engine and Pump Repairs

Caused By Low Lube Level

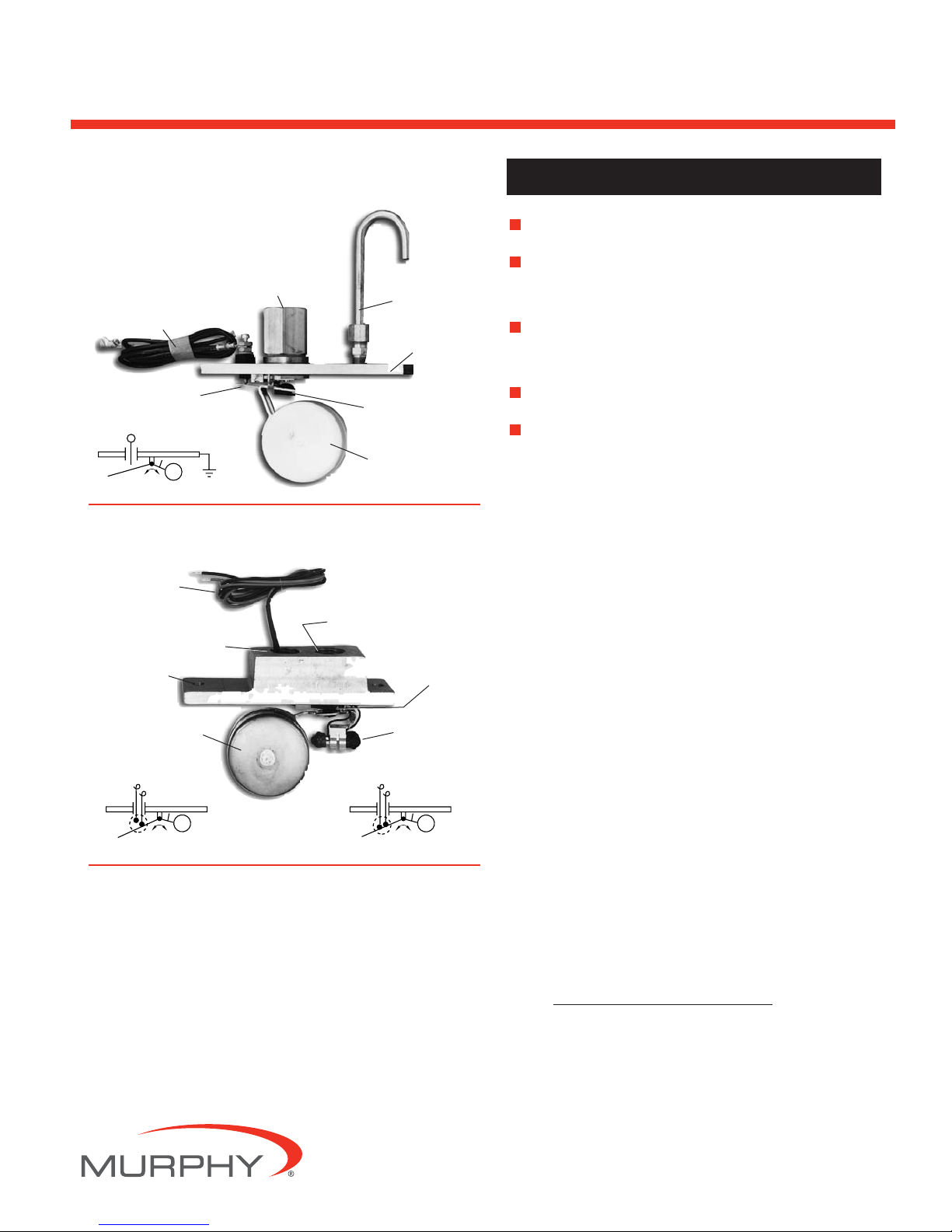

Model LR579

Regulates Lincoln Lubricators

Models LR589 and LR589NC

Regulates Lincoln Lubricators

18 AWG x 24 in.

(1.0 mm

2

x 610 mm)

Wire with Ring Terminal

18 AWG x 30 in.

(1.0 mm

2

x 762 mm)

Switch Wires

1/2 NPT Conduit

Connection

1/2 NPT Oil Inlet Connection

Tenzalloy Case

Hermetically-Sealed

Mercury Switch

Low Level

Shut-Down Contacts

304 Stainless

Steel Float

304 Stainless Steel Float

1/2 NPT Oil Inlet

Connection

Cane Vent

Pressure-Seal

Thumb-Valve

with Viton

Pressure-Seal

Thumb-Valve

with Viton

Aluminum

Case

Suitable for Class I,

Division 2, Hazardous

Locations

Electrical Diagram

LR589 Electrical Diagram

LR589NC Electrical Diagram

Switch Rating: 2A @ 20 V AC/DC, resistive

Switch Rating: 1A @ 120 V Switch Rating: 1A @ 120 V

LR500 Series

LREG-96121B

Revised 08-02

Catalog Section 15

(00-02-0062)

Oil Level Regulators for Lubricators

Description

The LR500 Series Level Regulators automatically add oil to a

lubricator to maintain the factory recommended level. This

function eliminates the work time necessary for manual checks

and refills.

Each model has a low-level shutdown switch to protect equipment when oil supply is lost. If the lubricator oil level drops

below the minimum operations level, the low-level switch will

operate an alarm and/or shutdown the equipment.

Model LR579 is for Lincoln lubricators. It features an

adjustable low-level shutdown contact.

LR589 is for Lincoln lubricators, and the LR589NC is the normally closed wired version of the LR589.

How to Order

Specify model when ordering.

LR579

LR589

LR589NC

Warranty

A limited warranty on materials and workmanship is given with this FW

Murphy product. A copy of the warranty may be viewed or printed by

going to www.fwmurphy.com/support/warranty.htm

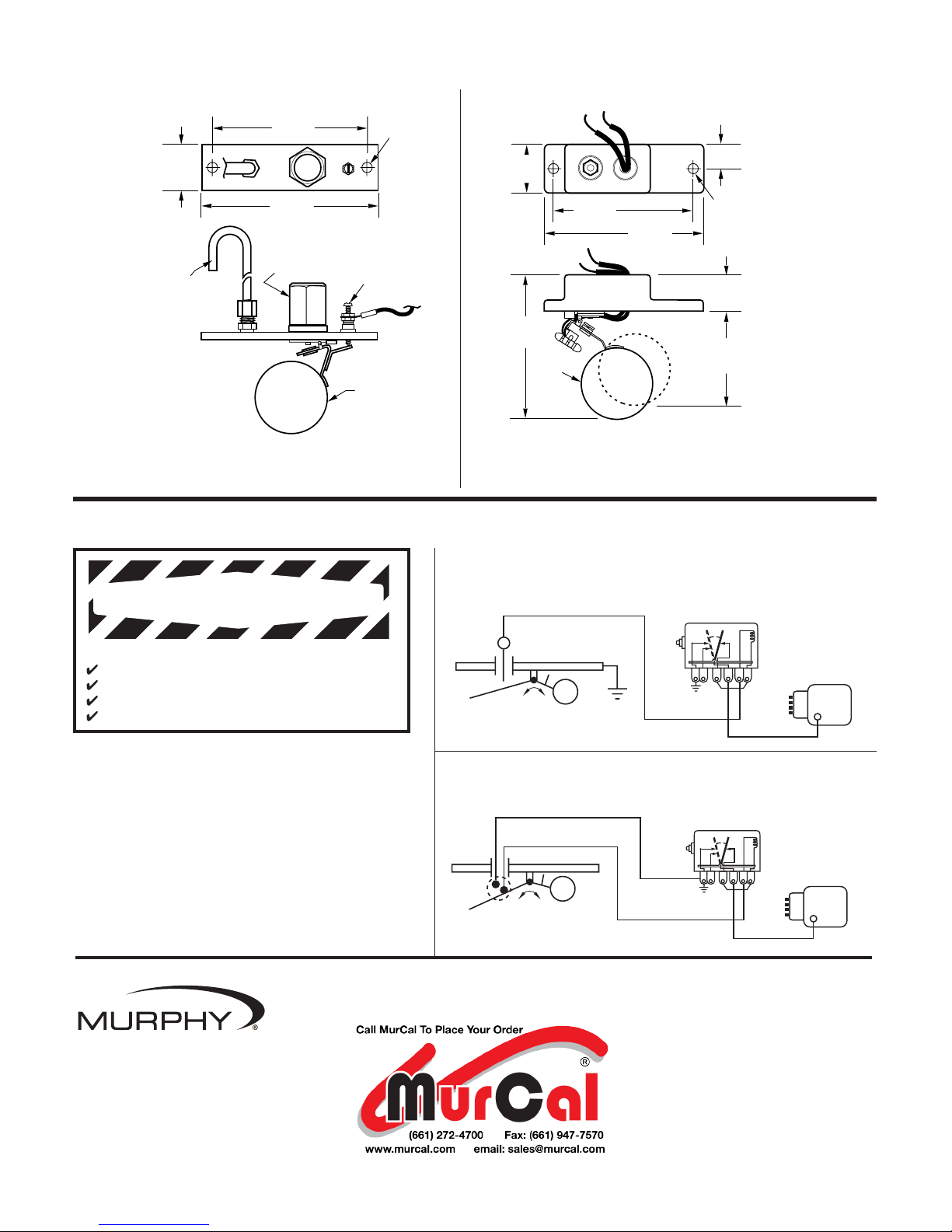

Dimensions

Before beginning installation of this Murphy product:

Disconnect ALL electrical power to the machine.

Make sure the machine CANNOT operate during installation.

Follow all safety warnings of the machine manufacturer.

Read and follow all installation instructions.

1. Remove the cover on a vacant cell of the lubricator

(DO NOT install in bays next to crank arm).

2. Bolt the level regulator in place, using the bolts that

held the cover.

3. Connect the flex hose from the oil reservoir to the oil

inlet at the level regulator. Oil reservoir must be at

least two feet (0.61 meters) above the level regulator.

4. Wire switch for alarm and/or shutdown. One switch

can be used to shut-down all equipment supplied by a

common oil reservoir.

1-1/2 in.

Installation

Typical Wiring for LR579

CN985RL / 985RL975RL

Typical Wiring for LR589

Shipping Weight: 13 oz. (368 g).

Shipping Dimensions:4-3/4 x 4-3/4 x 3-1/4 in.

(121 x 121 x 83 mm).

Shipping Weight: 12 oz. (340 g).

Shipping Dimensions:4-3/4 x 4-3/4 x 2-3/4 in.

(121 x 121 x 70 mm)

LREG-96121B page 2 of 2

Printed in U.S.A.

(38 mm)

Vent Tube

1/4 inch (6 mm)

Copper

4-7/16 in.

(113 mm)

5 in.

(127 mm)

1 Inch

Hex

9/32 in.

(7 mm)

diameter

2-places

Contact

Adjustment

Screw

Float

1-1/2 in.

(38 mm)

4-1/16 in.

(103 mm)

Float

4-7/16 in.

(113 mm)

5-1/16 in.

(129 mm)

3/4 in.

(19 mm)

9/32 in.

(7 mm)

diameter

2-places

1-1/8 in.

(29 mm)

Switch Operating Point

2-1/2 in.

(64 mm)

WARNING

Murphy MS2100

Magnetic Switch

4

6 2 3

1

Murphy MS2100

Magnetic Switch

1

6 2 3

5

4

5

CD Ignition

CD Ignition

Loading...

Loading...