Page 1

Description

The Murphy LM2000 model maintains the crankcase oil level of an engine,

pump or compressor. Adjusted to the correct running-oil-level, the LM2000 will

replenish oil as it is used. An integral, low-level switch will alarm and/or shutdown the equipment if supply oil is lost and the equipment continues to use oil.

Specifications

Crankcase Balance Vent Connection: 1/2 NPTF (top).

Inlet Connection: 1/2 NPTF with removable screen (side).

Outlet Connection: LM2000 3/4 NPTF (bottom).

LM2000S 2 x 3/8 NPTF (side)

1 x 3/4 NPTF (bottom)

Thumb-ValveTMMaterial: Viton.

Snap-switch: SPDT rating 10 A, 125 VAC; 0.5 A, 125 VDC; 10 A, 30 VDC.

Wire leads: 18 AWG x 24 in.(609 mm) length.

Conduit Connection: 1/2 inch conduit (female, top).

Case: Die cast aluminum

Lens: Clear “Frog Eye” non-staining, high impact, high temperature nylon; UV

and heat stabilized.

Dial: High visibility white background with green and white “index” lines

for normal level indication.

Maximum Inlet Pressure: 9.50 psi/25 ft. oil (head pressure).

Maximum Case Pressure: 15 psi (103 kPa).

Maximum Differential: 2 in. (51 mm) between running and stopped.

Maximum Ambient Temperature: 250°F (121°C).

Float: Brass

Flow Rates: SAE 40 motor oil @ 32°F (0°C) with 2 ft. head pressure: 0.5

GPH (1.9 LPH).

NOTE: Friction losses due to piping not considered.

Optional Vent Fittings Kit: 15000954

The 15000943 kit is sold separately. It includes the following items:

Quantity Description

1 Tubing vent (15050202).

1 1/4 x 1/4 NPT Connector (85030447).

Optional Hose Kit:

15000355

Quantity Description

1 1/2 in. (13 mm) I.D. x 3 ft. (914 mm) long hose (89020202)

1 1 in. (25 mm) I.D. x 3 ft. (914 mm) long hose (89020203)

2 1/2 in. (13 mm) worm gear clamp (00003502)

2 1 in. (25 mm) worm gear clamp (00003503)

2 1/2 NPT x 1/2 in. (13 mm) barbed fitting (89080801)

2 3/4 NPT x 1 in. (25 mm) barbed fitting (89081001)

Thumb-Valve™ Operation

As the equipment uses oil, the float falls, providing immediate level compensation. At FULL position, the float holds the valve closed. If the clean oil

supply is depleted and oil level continues to fall, the low level switch will

operate an alarm or equipment shutdown.

Service Parts

(Specify part number)

Description Part Number

Vent Fittings Kit 15000954

Hose Kit 15000355

1/2NPT x 1/2 in. Hose Barbed Fitting 89080801

3/4NPT x 1/2 in. Hose Barbed Fitting 89081001

3/8NPTF x 1/2 in. Hose Barbed Fitting 89080601

Pipe Bracket Kit 15000238

Universal Flange Kit 15010224

LM2000/LM2000S Lube Level Maintainer

Installation Instructions

LM-00011N

Revised 10-03

Section 15

(00-02-0423)

BEFORE BEGINNING INSTALLATION OF THIS MURPHY PRODUCT

✔ Disconnect all electrical power to the machine.

✔ Make sure the machine cannot operate during installation.

✔ Follow all safety warnings of the machine manufacturer.

✔ Read and follow all installation instructions.

Please read the following information before installing. A visual inspection of this product for damage during shipping is

recommended before mounting. CRANKCASE MUST BE DRAINED BEFORE INSTALLATION.

GENERAL INFORMATION

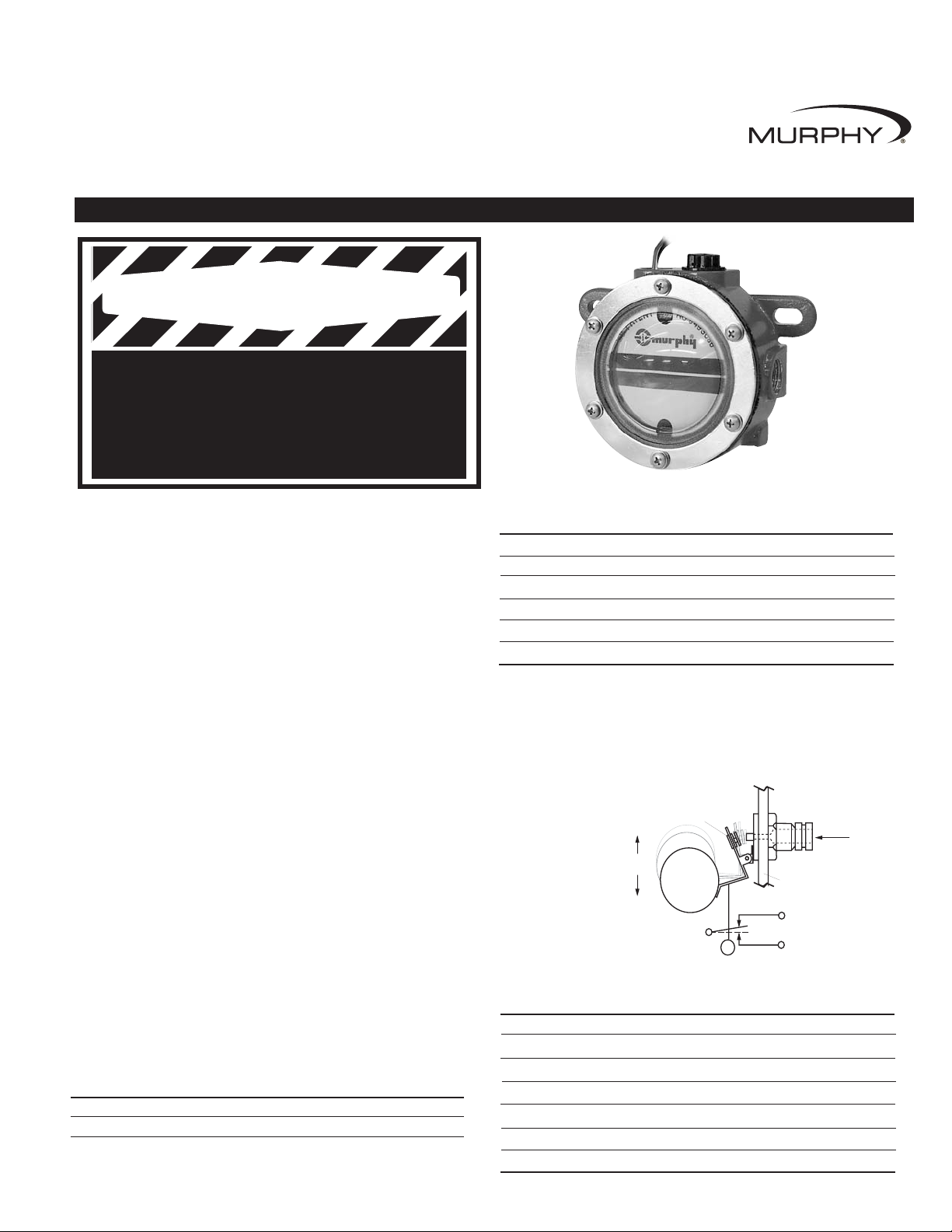

Thumb-ValveTMand

Snap-switch

Schematic

LM-00011N page 1 of 4LM-00011N page 1 of 4

WARNING

Thumb-Valve™

FULL

Float

Action

LOW

COM.

(white)

Low Level Switch

Oil Inlet

LM2000

Case

N.C. (red)

N.O. (black)

Page 2

LM-00011N page 2 of 4

TYPICAL INSTALLATION

DIMENSIONS

LM2000

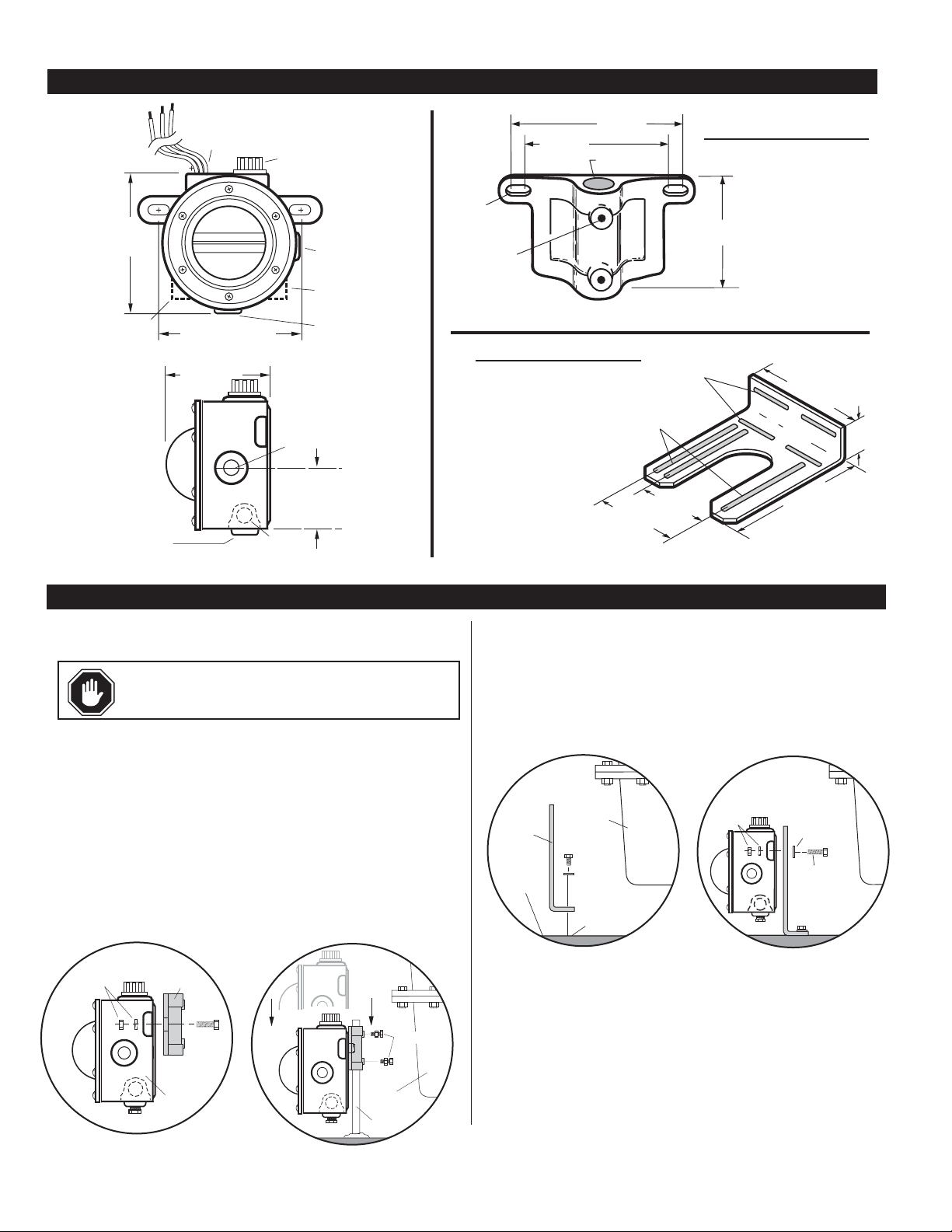

Mounting the LM2000

NOTE: Mount the LM2000 as close as possible to the crankcase.

The following instructions are based on the usage of the pipe and universal

mounting brackets shown above.

Pipe Bracket Mounting (15000238)

1. Mount a nominal 1/2 inch (13 mm) diameter pipe to the base of the engine.

2. Install the pipe bracket to the LM2000 using two 1/4-20 UNC x 1 inch

bolts, nuts and lock washers supplied. See Figure 1A.

3. Slip the LM2000 onto the pipe and install the two adjustment bolts. Each

bolt consists of a 1/4-20 UNC x 1 in. bolt, nuts and lock washers. See

Figure 1B. DO NOT tighten the adjustment screws too tightly because

you will have to adjust the LM2000 later in the installation process.

Mounting with Universal Bracket (15000370)

The universal bracket has two mounting methods: base mounting or

pan mounting.

Base Mounting

1. Install the universal bracket to the base as shown in Figure 2A using two

flat washers and two 5/16 inch dia. bolts or others as necessary.

2. Mount the LM2000 to the universal bracket using two 1/4-20 UNC x 1-

1/4 inch (32 mm) bolts, nuts and lock washers supplied (Figure 2B).

DO NOT tighten the adjustment screws too tightly. You will have to

adjust the LM2000 later in the installation process.

Figure 1B

LM2000

Pipe

Bracket

Lock Washer

and Nut

Bolt

Pipe

Crankcase

Adjustment

Bolts

Figure 1A

Figure 2B

Crankcase

Base

Universal

Bracket

Threaded

hole

Adjustment

Bolts

Flat

Washer

Lock Washer

and Nut

Figure 2A

15000238

Pipe Bracket Kit

15010224

Universal Flange Kit

Additional Hardware

Supplied

(2) 1/4-20 x 7/8 inch

(22 mm) screws

(2) 1/4-20 x 1 inch

(25 mm) screws

(4) 1/4-20 hex nuts

(4) 1/4 inch (6 mm) dia.

split washer

Additional Hardware

Supplied

(2) 1/4-20 x 1/4 inch

(32 mm) bolts

(4) 1/4 inch dia. flat washer

(2) 1/4-20 hex nuts

(2) 5/16-18 x 1/4 inch

(32 mm) bolts

(4) 5/16 dia. flat washer

(2) 5/16-18 hex nuts

CAUTION:

Excessive vibration can cause over-

fill. Be sure mounting brackets are supported.

4-5/8 in.

(117 mm)

3/8 NPTF

LM2000S

Oil Outlet

Connection

3/4 NPTF

1/2 in. Electrical

Female Conduit

Connection

4-1/2 to 5-3/16 in.

(114 to 132 mm)

2-7/8 in.

(73 mm)

3/8 NPTF

LM2000S

Crankcase

Balance Vent

1/2 NPTF

Oil Inlet

Connection

1/2 NPTF

3/8 NPTF

LM2000S

Oil Outlet

Connection

3/4 NPTF

Oil Inlet

Connection

1/2 NPTF

C

L

2-1/4 in.

(57 mm)

4-1/2 in.

(114 mm)

9/32 x 5/8 in.

(7 x 16 mm)

2 places

1/4-20 NC

2 places

5-3/16 in.

(132 mm)

Hole 7/8 in.

(22 mm) dia.

Slot, 29/64 in. (14 mm)

x 2-3/8 in. (60 mm)

4 places

Slot, 29/64 in. (14 mm)

x 4-3/8 in. (111 mm)

3 places

4-1/2 in.

(114 mm)

5-3/16 in.

(132 mm)

2-1/2 in.

(63.5 mm)

6-11/16 in.

(170 mm)

1-3/4 in.

(44 mm)

7-1/2 in.

(191 mm)

Page 3

Crankcase (Oil Pan) Mounting

1. Install the universal bracket to the crankcase using the existing crankcase bolts

(Figure 3A). Crankcase bolt diameter must be no larger than 7/16 inch (11 mm).

NOTE: Check clearance between crankcase and mounting bracket

before installing the mounting bracket. If space between the crankcase

and mounting bracket does not allow installation and access to the

adjustment bolts advance to Step 3.

2. Mount the LM2000 to the universal bracket using two 1/4-20 UNC x 1-

1/4 inch bolts, nuts and lock washers supplied. DO NOT tighten the

adjustment bolts too tight. You will have to adjust the LM2000 later in the

installation process.

3. If space between the crankcase and mounting bracket is narrow, install the uni-

versal mounting bracket to the LM2000 before installing to the crankcase oil pan.

Connecting Fittings and Hoses

The following instructions are based on the Murphy optional hose kit

described on page 1. If you did not order the optional hose kit, use the

list designation as a guide to the required materials.

1. Install the LM2000 fittings in their proper locations. NOTE: Apply a

sealant such as Teflon®, to all threaded

connections.

2. Attach the 1 inch (25 mm) diam-

eter, flexible monitoring hose

to the crankcase and the monitoring port on the LM2000.

See Figure 4. CAUTION:

The hose must slope slightly

downward from the LM2000

and MUST NOT have any

droops or low spots.

NOTE: If the drain plug on the

crankcase is used for the connection, we

recommend installation of a tee to allow

draining of the crankcase for service.

3. Install the 1/2 inch (13 mm) I.D. x 3 ft. (914 mm) hose to the vent connec-

tion on the LM2000 and to the vent connection on the crankcase. See

Figure 4. The vent connection on the crankcase must be well above

the regulated oil level. All hoses must be clear of obstructions, valleys,

or dips that could create liquid traps, or gas/air pockets. The vent and

crankcase connections should be as straight as possible.

BEFORE CONTINUING, VERIFY THAT ALL HOSE CLAMPS ARE TIGHT.

4. Fill the crankcase to the proper oil level. With the engine running and

warm, loosen the mounting bracket adjustment bolts and adjust the

LM2000 so that the oil level in the sight gauge is aligned with the white

“index line” on the dial (Figure 4). Tighten the adjustment bolts securely.

Connecting the LM2000 to an Oil Supply Tank

1. Remove the plug from the oil inlet connection. Be sure the removable screen,

inside the connection, is clear of debris. Install the oil inlet connection.

2. Connect a 1/2 inch I.D. (13 mm) or larger hose

to the oil inlet fitting on the LM2000 and to the

shutoff valve on the oil supply tank. See

Figure 5. Recommended minimum

height above the LM2000 is 2 ft.

(0.6m); maximum 25 ft.

(7.7m). The hose must

maintain a downward

slope and not have low

spots or droops.

Maximum head pressure

rating is 9.50 psi or 25 ft

oil (head pressure).

3. Before filling the supply

tank with oil, be sure the

tank is clean and dry and

the shutoff valve is closed.

Also, be sure all hoses and clamps are tight. Fill the tank with CLEAN

oil.

4. After oil supply tank is full, open the shutoff valve.

Next, make the proper electrical connections for the application.

(See Snap-switch ratings and schematic on page 1.)

Switch Test

To test the shutdown or alarm functions perform the following:

NOTE: Installations with closed vent systems can only be tested with

the engine off.

1. Unscrew the vent fittings.

2. Using a long narrow shank screw driver, gently insert until contact is

felt with float arm. Gently push the float arm down.

3. Verify proper switch operation

LM-00011N page 3 of 4

TYPICAL INSTALLATION

Figure 3B

Crankcase

Universal

Bracket

Crankcase

Bolt

Note Clearance

before mounting

Adjustment

Bolt

Flat

Washer

Lock washer

and Nut

Figure 3A

Oil Inlet

Hose

Oil Supply

Tank

Figure 5

Viewing

Lens

Monitoring Hose

Crankcase

Oil Level

Running

Engine

Vent

Hose

Oil Inlet

Hose

Figure 4

WARNING: Overfill condition can be caused by excessive

inlet pressure and/or improper “vent to crankcase” installation.

Page 4

OPERATING RANGE OF THE SNAP-SWITCH

LM2000 Typical Installation Shown with FSV Series Valves

Figure 6

Figure 6 shows the LM2000 dial and the operating range of the switch.

If level is within the designated zones the switch will activate.

The switch activates approximately 1/4 in. (6 mm) from the bottom of the

low zone. The dial in Figure 6 shows that if level continues to drop into

the low-low zone, a shutdown will occur.

NOTE: Color zones on dial face show approximate normal operating

zones. Actual conditions may vary depending upon operating characteristics of the engine. Placement of the LM2000 according to the above

instructions will compensate for these conditions.

Warranty

A limited warranty on materials and workmanship is given with this FW Murphy product.

A copy of the warranty may be viewed or printed by going to www

.fwmurphy.com/support/warranty.htm

WARNING:

Perform this installation using appropriate

protection. Trapped air and hot oil may cause burns.

LM2000 Typical Installation

LM-00011N page 4 of 4

CONTROL SYSTEMS & SERVICES DIVISION

P.O. Box 1819; Rosenberg, Texas 77471; USA

+1 281 633 4500 fax +1 281 633 4588

e-mail sales@fwmurphy.com

MURPHY DE MEXICO, S.A. DE C.V.

Blvd. Antonio Rocha Cordero 300, Fracción del Aguaje

San Luis Potosí, S.L.P.; México 78384

+52 444 8206264 fax +52 444 8206336

Villahermosa Office +52 993 3162117

e-mail ventas@murphymex.com.mx

www.murphymex.com.mx

FRANK W. MURPHY, LTD.

Church Rd.; Laverstock, Salisbury SP1 1QZ; U.K.

+44 1722 410055 fax +44 1722 410088

e-mail sales@fwmurphy.co.uk

www.fwmurphy.co.uk

MURPHY SWITCH OF CALIFORNIA

41343 12th Street West

Palmdale, California 93551-1442; USA

+1 661 272 4700 fax +1 661 947 7570

e-mail sales@murphyswitch.com

www.murphyswitch.com

In order to consistently bring you the highest quality, full featured products, we reserve the right to change our specifications and designs at any time.

MACQUARRIE CORPORATION

1620 Hume Highway

Campbellfield, Vic 3061; Australia

+61 3 9358 5555 fax +61 3 9358 5558

e-mail murphy@macquarrie.com.au

FW Murphy

P.O. Box 470248

Tulsa, Oklahoma 74147 USA

+1 918 317 4100

fax +1 918 317 4266

e-mail sales@fwmurphy.com

www.fwmurphy.com

R

E

G

I

S

T

E

R

E

D

USA–ISO 9001:2000 FM 28221

UK–ISO 9001:2000 FM 29422

Printed in U.S.A.

CRANKCASE

Electrical Conduit

wire to switch circuits

Oil Outlet

For vented crankcase use the

plastic vent plug or optional

vent tube kit (15000954).

For sealed systems, vent must be

piped back to crankcase,

above oil level.

LM2000

Oil Level Maintainer

Oil

Inlet

CLEAN Oil Supply Tank.

Height above LM recommended

2 ft. (0.6m) minimum and 25 ft

(7.7m) maximum.

Shutoff

Valve

Approx. Normal levels

in feet of head.

25’

Normal

10’

3/4 in.

(19 mm)

1/4 in.

(6 mm)

Operating Range

4’

Low Zone

Shutdown

Loading...

Loading...