Page 1

LLS-93096N

®

FRANK W.

MFR.

LLS, LLSB, LLSR, LLSRB Series Models

Effective 03-94

Section 05

Lead Line Pressure Switches

Installation and Operation Instructions

Please read the following information before installing. A visual inspection of this product for damage during shipping is recommended before mounting.

It is your responsibility to have a qualified person install the unit and make sure installation conforms to NEC and local codes.

GENERAL INFORMATION

WARNING

BEFORE BEGINNING INSTALLATION OF THIS MURPHY PRODUCT

✔ Disconnect all electrical power to the machine.

✔ Make sure the machine cannot operate during installation.

✔ Follow all safety warnings of the machine manufacturer.

✔ Read and follow all installation instructions.

LLS Series Pressure Switch

Description

The LLS Series is a pressure switch for applications where viscous liquids

could plug the sensing orifice. LLS and LLSB models have a 2 inch NPT

male connection which attaches directly into the process line. LLSR and

LLSRB models feature a remote sensor connected to the pressure switch by a

length of stainless steel capillary and armor. The snap-acting switch is field

adjustable. The switch is housed in a hard anodized aluminum enclosure.

Optional for LLSR and LLSRB models is a 1 inch NPT x 1 inch NPT (male)

pulsation dampener to minimize damaging pressure pulsation to the switch.

Specifications

• Maximum Ambient Temperature:-10° to +160°F (-23° to +71°C).

• Maximum Process Temperatur e: -40° to +160°F (-40° to +71°C).

• Temperature Compensation: The volumetric expansion and contraction of

the fill may cause a shift of ±3% to ±5% of the set point.

• Switch Enclosure: Aluminum hard anodized (black). NEMA 4, 4x. NEMA 7

and 9 explosion-proof, waterproof and corrosion resistant. Suitable for Class I,

Div. 1, Groups A, B, C, D; Class II, Div. 2, Groups E, F, G.

• Sensor Body: LLS: CRS steel chromate plated; 2 in. NPT connection.

LLSB: Thick wall 304 stainless steel sensor 2 in. NPT pr ocess connection.

LLSR: Remote Sensor; Nickel plated steel, stainless steel capillary.

LLSRB: Remote Sensor; 316 stainless steel housing and capillary.

• Diaphragm Materials:

LLS/LLSB: Ni-SPAN

• Snap-switch Ratings: SPDT (Std.): 15 A @ 125, 250 or 480 V AC

SPDT (Gold): 100 mA @ 125 VAC; 0.250 A @ 6 VDC

DPDT (Std.): 11 A @ 125 or 250 VAC

DPDT (Gold): 100 mA @ 125 VAC; 0.250 A @ 6 VDC

• Trip Point Adjustment: Field-adjusted with screwdriver.

• LLSR/LLSRB Mount: 4-hole bolt pattern; 1/4 in. (6 mm) dia. bolts.

• LLS/LLSB Mount: Direct mount into process (2 in. NPT connection).

• Shipping Weight: LLS/LLSB: 4 lbs. 9 oz. (2.25 kg).

LLSR/LLSRB: 7 lbs. 12 oz. (3.23 kg).

• Shipping Dimensions: LLS/LLSB: 10 x 9-1/4 x 5-3/4 in. (254 x 235 x 146 mm).

LLSR/LLSRB: 15-3/4 x 11 x 5-1/4 in. (400 x 279 x 133 mm).

Sensor Model Selection Table

Base

Model

LLS

LLSB

LLSR

LLSRB

Switch Adjustment Range

psi kPa/MPa

50–450 345 kPa–3.1 MPa 5–45 34 kPa–310 kPa 1500 10.3

100–1750 689 kPa–12 MPa 15–100 103 kPa–689 kPa 2500 17.2

200–2500 13.8 MPa–17.2 MPa 20–150 137 kPa–1.03 MPa 3000 20.6

400–4000 2.8 MPa–27.5 MPa 75–450 517 kPa–3.1 MPa 5000 34.4

50–450 345 kPa–3.1 MPa 5–45 34 kPa–310 kPa 1500 10.3

100–1750 689 kPa–12 MPa 15–100 103 kPa–689 kPa 2500 17.2

200–2500 13.8 MPa–17.2 MPa 20–150 137 kPa–1.03 MPa 3000 20.6

400–4000 2.8 MPa–27.5 MPa 75–450 517 kPa–3.1 MPa 5000 34.4

50–450 345 kPa–3.1 MPa 5–45 34 kPa–310 kPa 1500 10.3

100–1750 689 kPa–12 MPa 15–100 103 kPa–689 kPa 2500 17.2

200–2500 13.8 MPa–17.2 MPa 20–100 137 kPa–689 kPa 3000 20.6

50–450 345 kPa–3.1 MPa 5–45 34 kPa–310 kPa 1500 10.3

100–1750 689 kPa–12 MPa 15–100 103 kPa–689 kPa 2500 17.2

200–2500 13.8 MPa–17.2 MPa 20–150 137 kPa–1.03 MPa 5000 34.4

400–4000 2.8 MPa–27.5 MPa 75–450 517 kPa–3.1 MPa 5000 34.4

Dead Band Approximate

psi kPa/MPa psi MPa

Max System

®

. LLSR/LLSRB: 316L S. Steel–Teflon* coated.

Wetted Parts Materials

CRS steel sensor –chromate plated (yellow)

®

Ni-SPAN

diaphragm.

Thick wall 304 stainless steel sensor housing;

®

Ni-SPAN

standard for direct exposure to H

Remote sensor–Nickel plated steel w/ stainless

steel capillary; Teflon* coated diaphragm.

Remote sensor–AISI 316 stainless steel housing;

stainless steel capillary and armor; AISI 316L

stainless steel Teflon* coated diaphragm.

diaphragm. Meets NACE MR-01-75

S.

2

* Teflon–DuPont Trademark

1

Page 2

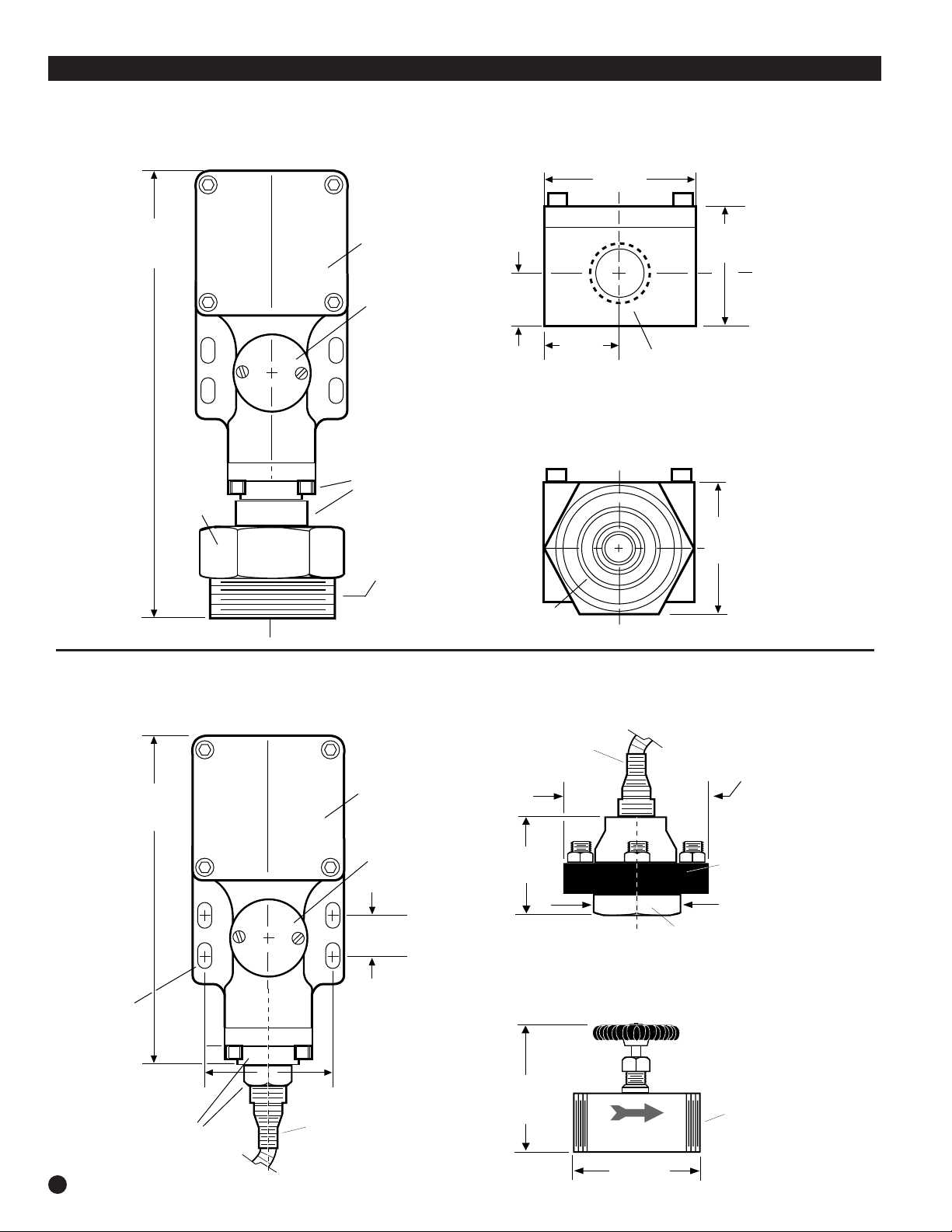

DIMENSIONS

Diaphragm

9-1/4 in.

(235 mm)

MAX.

3 in.

(76 mm)

3/4-14 NPT

Conduit Inlet

7/8 in.

(22 mm)

1-1/2 in.

(38 mm)

2-9/64 in.

(54 mm)

2 in. NPT

Process

Connection

2-1/2 in.

(64 mm)

MAX.

6-1/2 in.

(165 mm)

MAX.

Transmitting

tube, 5 feet

(1.524 m) std.

3/4 in.

(19 mm)

2-1/2 in.

(64 mm)

17/64 x 1/2 in.

(7 x 13 mm)

mounting holes

(4 places)

Sensor

Body

Switch

Enclosure

Switch

Enclosure

Sensor

Body

1 in. NPT (male)

Process Connection

2 places

2-7/8 in.

(73 mm)

LLSR models:

3-3/4 in. (95 mm) dia.

LLSRB models:

3-7/8 in. (98 mm) dia.

1-13/16 in.

(46 mm)

3-7/8 in.

(98 mm)

3-1/2 in.

(89 mm)

Transmitting tube

FLOW

Switch

Trip Point

Adjustment

Panel

1 in. NPT (female) Connection

Switch

Trip Point

Adjustment

Panel

Do NOT Tamper with

these Sealed

Connections

Do NOT Tamper with

these Sealed

Connections

LLS and LLSB Models

Complete Unit

Front View

Switch Enclosure

Top View

Sensor Enclosure

End View

2

Switch Enclosure

Front View

LLSR and LLSRB Models

Sensor Enclosure

Front View

Pulsation Dampener

PD8187 Option

Page 3

Provision for

Case Ground

N.O. N.C. COM.

Terminal

Block(s)

Customer

Wiring

NC NO C NC NO C

3/4 in.-14 NPT

Conduit Inlet

NC

C

NO

P

NC

C

NO

P

NC

C

NO

INSTALLING THE LLS SERIES PRESSURE SWITCH

2 in. NPT

Use Wrech Flats to

Screw the LLS

Into the Process

Do NOT Tamper with

This Connection

Do NOT Tamper with

these Sealed Connections

Lead line tee

Wrench Flats

WARNING: PERFORM THE INSTALLATION WITH POWER SOURCE “OFF”. NEVER EXCEED RATED PRESSURE RANGE FOR THE UNIT.

USE WRENCH ON SHANK TO TIGHTEN/LOOSEN CONNECTIONS. DO NOT TWIST THE ENCLOSURE WHEN SCREWING THE LLS INTO THE

PROCESS – THIS WILL DAMAGE INTERNAL COMPONENTS, FILLED MECHANISM AND THE SEALS. DO NOT OVERTIGHTEN THE UNIT.

Connecting the LLS and LLSB Series

To install the LLS and LLSB Series,

a vertical mounting is recommended.

Figure 1

1. The unit threads directly into a 2 in. 11-1/2 NPT tee on the lead line.

CAUTION: DO NOT TAMPER WITH OR BREAK SEALED CONNEC-

TIONS. APPLY PIPE SEALANT TO PROCESS CONNECTION THREADS.

2. Tighten the bottom housing to the lead line tee using ONLY the

transmitter wrench flats (see figure 1).

3. Check for leakage on any of the connections. Make sure that the

installation conforms with local and other applicable codes.

Connecting the LLSR and LLSRB Series

For mounting the switch enclosure refer to “Dimensions” on page 2.

The following instructions are based on the usage of a PD8187 Pulsation

Dampener option shown in Figure 2 (at right.)

1. Install sensor/pulsation dampener into pressure source connection.

CAUTION: THE PD8187 PULSATION DAMPENER IS NOT INTENDED

AS A SHUTOFF VALVE. APPLY PIPE SEALANT TO THE THREADS.

2. Loosen the eight housing bolts until the bottom housing is free to turn.

CAUTION: WHEN LOOSING THE EIGHT HOUSING BOLTS, MAKE

SURE NOT TO UNSCREW THE GREEN DIAPHRAGM CAPSULE.

3. Tighten the bottom housing to the pulsation dampener connection.

4. Tighten the eight housing bolts to 25±3 foot lbs. Stagger the tighten-

ing to assure even clamping.

5. Route capillary away from heat source (exhaust manifold). Excess

capillary should be carefully coiled and secured (do NOT cut it).

Figure 2

Housing

Bolts

Wrench

Flats

1 in. NPT

Transmitting Tubing

(capillary)

Diaphragm

Body

Pulsation

Dampener

(optional)

Lead Line Tee

WARNING: PERFORM THE WIRING OPERATION WITH THE POWER SOURCE “OFF”. MAKE SURE VOLTAGE AND CURRENT REQUIRE-

MENTS ARE WITHIN THE LLS RATINGS. BEFORE WIRING THE UNIT DETERMINE VOLTAGE AND POLARITY FOR THE APPLICATION.

IF THE UNIT IS USED IN HAZARDOUS AREAS, MAKE THE AREA SAFE BEFORE REMOVING THE SNAP-SWITCH(ES) COVER.

If switch trip point needs to be adjusted, see page 4.

LLS Series Hook-up (all models)

To wire the LLS Series, use proper the electrical conduit.

1. A 3/4''-14 NPT inlet connection for conduit installation is provided

at the top end of the switch enclosure (see opposite page–

“Dimensions” for location).

NOTE: The plastic plug (supplied) is to protect the conduit inlet threads

and must be removed before wiring the unit.

2. Using a 3/16 in. hex wrench, unscrew the 4 hex-cap screws.

Now proceed to remove the square cover to reveal snap-switch(es).

3. To wire the unit, refer to the typical wiring drawing (Figure 3) and

to the Schematic (shown at right). Wire the LLS Series switch(es)

with 60°/75°C (140°/167°F) insulated wire.

4. A terminal (inside the switch enclosure) is provided for case or

equipment grounding, refer to Figure 3 for location.

5. After completing wiring, replace the switch cover and make sure it

is tightly secured before applying power to the system.

WIRING THE LLS SERIES PRESSURE SWITCH

Schematic

SPDT DPDT

Figure 3

SPDT

DPDT

3

Page 4

ADJUSTING THE TRIP POINT

To increase

set point

To decrease

set point

Adjustment

Wheel

Switch Trip Point

Adjustment Cover

or Round Cover

Snap-switch(es) Cover

or Square Cover

Do NOT remove until

the area is made

NON-HAZARDOUS

Screwdriver

®

FRANK W.

MFR.

CAUTION:

ADJUSTMENT OF THE TRIP POINT VARIES ACCORDINGLY TO THE APPLICATION AND MUST BE PERFORMED BY A QUALIFIED PERSON.

REMEMBER THAT THE FIELD-ADJUSTABLE TRIP POINT MAY HAVE BEEN FACTORY SET TO YOUR SPECIFICATIONS.

LLS Series Trip Point Adjustment

if necessary (all models)

NOTICE: If trip point is not specified, the switch will be set at approximately 50% of full scale. To perform trip point re-adjustments, a test

stand with variable pressure source, a test light, and a pressure gauge

®

(such as our OPLG or OPLFG MURPHYGAGE

) may be used.

To Reset for Rising Pressure

1. Locate and remove the Switch Trip Point Adjustment cover

(round) to reveal the Adjustment Wheel, (see figure 4).

WARNING:

INSTALLATION SIGHT UNTIL THE AREA IS MADE NON-HAZARDOUS.

2. After area is made non-hazardous, proceed to remove the square

cover to reveal the snap-switch(es).

3. Connect test light to (COM) and (N.C.) terminals. The light

should turn “ON”. Gradually increase the pressure until the light

turns“OFF”. Observe the trip point pressure reading.

4. With a screwdriver, turn the adjustment wheel to the desired setting.

Repeat step 4 until the light turns “OFF” at the desired pressure.

DO NOT REMOVE SNAP-SWITCH COVER AT THE

Figure 4

To Reset for Falling Pressure

Follow step 1 and step 2 (above), then:

3. Connect test light to (COM) and (N.O.) terminals. The light

should stay “OFF”. Gradually increase the pressure until the

light turns“ON”. Observe the trip point pressure reading.

4. With a screwdriver, turn the adjustment wheel to the desired setting.

Repeat step 4 until the light turns “OFF” at the desired pressure.

Replace the adjustment and the switch covers securely.

A two year limited warranty on materials and workmanship is provided with this Murphy product. Details are

In order to consistently bring you the highest quality, full featured products, we reserve the right to change our specifications and designs at any time.

■ Frank W. Murphy Manufacturer

P.O. Box 470248; Tulsa, Oklahoma 74147; USA

tel. (918) 627-3550 fax (918) 664-6146

e-mail fwmurphy@ionet.net

■ Frank W. Murphy Southern Division

P.O. Box 1819; Rosenberg, Texas 77471; USA

tel. (281) 342-0297 fax (281) 341-6006

e-mail murphysd@intertex.net

Printed in U.S.A.

Since 1939

available on request and are packed with each unit.

■ Frank W. Murphy, Ltd.

Church Rd.; Laverstock, Salisbury SP1 1QZ; U.K.

tel. +44 1722 410055 fax +44 1722 410088 tlx 477088

e-mail sales@fwmurphy.co.uk

■ Frank W. Murphy Pte., Ltd.

26 Siglap Drive; Republic of Singapore 456153

tel. +65 241-3166 fax +65 241-8382

e-mail fwmsales@fwmurphy.com.sg

■ Murphek Pty., Ltd.

1620 Hume Highway; Campbellfield, Vic 3061; Australia

tel. +61 3 9358-5555 fax +61 3 9358-5558

WARRANTY

■ Murphy de México, S.A. de C.V.

Blvd. Antonio Rocha Cordero 300, Fracción del Aguaje

San Luis Potosí, S.L.P.; México 78384

tel. +52-48-206264 fax +52-48-206336

e-mail murmexsl@sanluis.podernet.com.mx

■ Murphy Switch of California

P.O. Box 900788; Palmdale, California 93590; USA

tel. (805) 272-4700 fax (805) 947-7570

e-mail sales@murphyswitch.com

■ Frank W. Murphy France

tel. +33 1 30 762626 fax +33 1 30 763989

4

Loading...

Loading...