Murphy LLSRB, LLSB, LLS, LLSR User Manual

LLS-93096N

®

FRANK W.

MFR.

LLS, LLSB, LLSR, LLSRB Series Models

Effective 03-94

Section 05

Lead Line Pressure Switches

Installation and Operation Instructions

Please read the following information before installing. A visual inspection of this product for damage during shipping is recommended before mounting.

It is your responsibility to have a qualified person install the unit and make sure installation conforms to NEC and local codes.

GENERAL INFORMATION

WARNING

BEFORE BEGINNING INSTALLATION OF THIS MURPHY PRODUCT

✔ Disconnect all electrical power to the machine.

✔ Make sure the machine cannot operate during installation.

✔ Follow all safety warnings of the machine manufacturer.

✔ Read and follow all installation instructions.

LLS Series Pressure Switch

Description

The LLS Series is a pressure switch for applications where viscous liquids

could plug the sensing orifice. LLS and LLSB models have a 2 inch NPT

male connection which attaches directly into the process line. LLSR and

LLSRB models feature a remote sensor connected to the pressure switch by a

length of stainless steel capillary and armor. The snap-acting switch is field

adjustable. The switch is housed in a hard anodized aluminum enclosure.

Optional for LLSR and LLSRB models is a 1 inch NPT x 1 inch NPT (male)

pulsation dampener to minimize damaging pressure pulsation to the switch.

Specifications

• Maximum Ambient Temperature:-10° to +160°F (-23° to +71°C).

• Maximum Process Temperatur e: -40° to +160°F (-40° to +71°C).

• Temperature Compensation: The volumetric expansion and contraction of

the fill may cause a shift of ±3% to ±5% of the set point.

• Switch Enclosure: Aluminum hard anodized (black). NEMA 4, 4x. NEMA 7

and 9 explosion-proof, waterproof and corrosion resistant. Suitable for Class I,

Div. 1, Groups A, B, C, D; Class II, Div. 2, Groups E, F, G.

• Sensor Body: LLS: CRS steel chromate plated; 2 in. NPT connection.

LLSB: Thick wall 304 stainless steel sensor 2 in. NPT pr ocess connection.

LLSR: Remote Sensor; Nickel plated steel, stainless steel capillary.

LLSRB: Remote Sensor; 316 stainless steel housing and capillary.

• Diaphragm Materials:

LLS/LLSB: Ni-SPAN

• Snap-switch Ratings: SPDT (Std.): 15 A @ 125, 250 or 480 V AC

SPDT (Gold): 100 mA @ 125 VAC; 0.250 A @ 6 VDC

DPDT (Std.): 11 A @ 125 or 250 VAC

DPDT (Gold): 100 mA @ 125 VAC; 0.250 A @ 6 VDC

• Trip Point Adjustment: Field-adjusted with screwdriver.

• LLSR/LLSRB Mount: 4-hole bolt pattern; 1/4 in. (6 mm) dia. bolts.

• LLS/LLSB Mount: Direct mount into process (2 in. NPT connection).

• Shipping Weight: LLS/LLSB: 4 lbs. 9 oz. (2.25 kg).

LLSR/LLSRB: 7 lbs. 12 oz. (3.23 kg).

• Shipping Dimensions: LLS/LLSB: 10 x 9-1/4 x 5-3/4 in. (254 x 235 x 146 mm).

LLSR/LLSRB: 15-3/4 x 11 x 5-1/4 in. (400 x 279 x 133 mm).

Sensor Model Selection Table

Base

Model

LLS

LLSB

LLSR

LLSRB

Switch Adjustment Range

psi kPa/MPa

50–450 345 kPa–3.1 MPa 5–45 34 kPa–310 kPa 1500 10.3

100–1750 689 kPa–12 MPa 15–100 103 kPa–689 kPa 2500 17.2

200–2500 13.8 MPa–17.2 MPa 20–150 137 kPa–1.03 MPa 3000 20.6

400–4000 2.8 MPa–27.5 MPa 75–450 517 kPa–3.1 MPa 5000 34.4

50–450 345 kPa–3.1 MPa 5–45 34 kPa–310 kPa 1500 10.3

100–1750 689 kPa–12 MPa 15–100 103 kPa–689 kPa 2500 17.2

200–2500 13.8 MPa–17.2 MPa 20–150 137 kPa–1.03 MPa 3000 20.6

400–4000 2.8 MPa–27.5 MPa 75–450 517 kPa–3.1 MPa 5000 34.4

50–450 345 kPa–3.1 MPa 5–45 34 kPa–310 kPa 1500 10.3

100–1750 689 kPa–12 MPa 15–100 103 kPa–689 kPa 2500 17.2

200–2500 13.8 MPa–17.2 MPa 20–100 137 kPa–689 kPa 3000 20.6

50–450 345 kPa–3.1 MPa 5–45 34 kPa–310 kPa 1500 10.3

100–1750 689 kPa–12 MPa 15–100 103 kPa–689 kPa 2500 17.2

200–2500 13.8 MPa–17.2 MPa 20–150 137 kPa–1.03 MPa 5000 34.4

400–4000 2.8 MPa–27.5 MPa 75–450 517 kPa–3.1 MPa 5000 34.4

Dead Band Approximate

psi kPa/MPa psi MPa

Max System

®

. LLSR/LLSRB: 316L S. Steel–Teflon* coated.

Wetted Parts Materials

CRS steel sensor –chromate plated (yellow)

®

Ni-SPAN

diaphragm.

Thick wall 304 stainless steel sensor housing;

®

Ni-SPAN

standard for direct exposure to H

Remote sensor–Nickel plated steel w/ stainless

steel capillary; Teflon* coated diaphragm.

Remote sensor–AISI 316 stainless steel housing;

stainless steel capillary and armor; AISI 316L

stainless steel Teflon* coated diaphragm.

diaphragm. Meets NACE MR-01-75

S.

2

* Teflon–DuPont Trademark

1

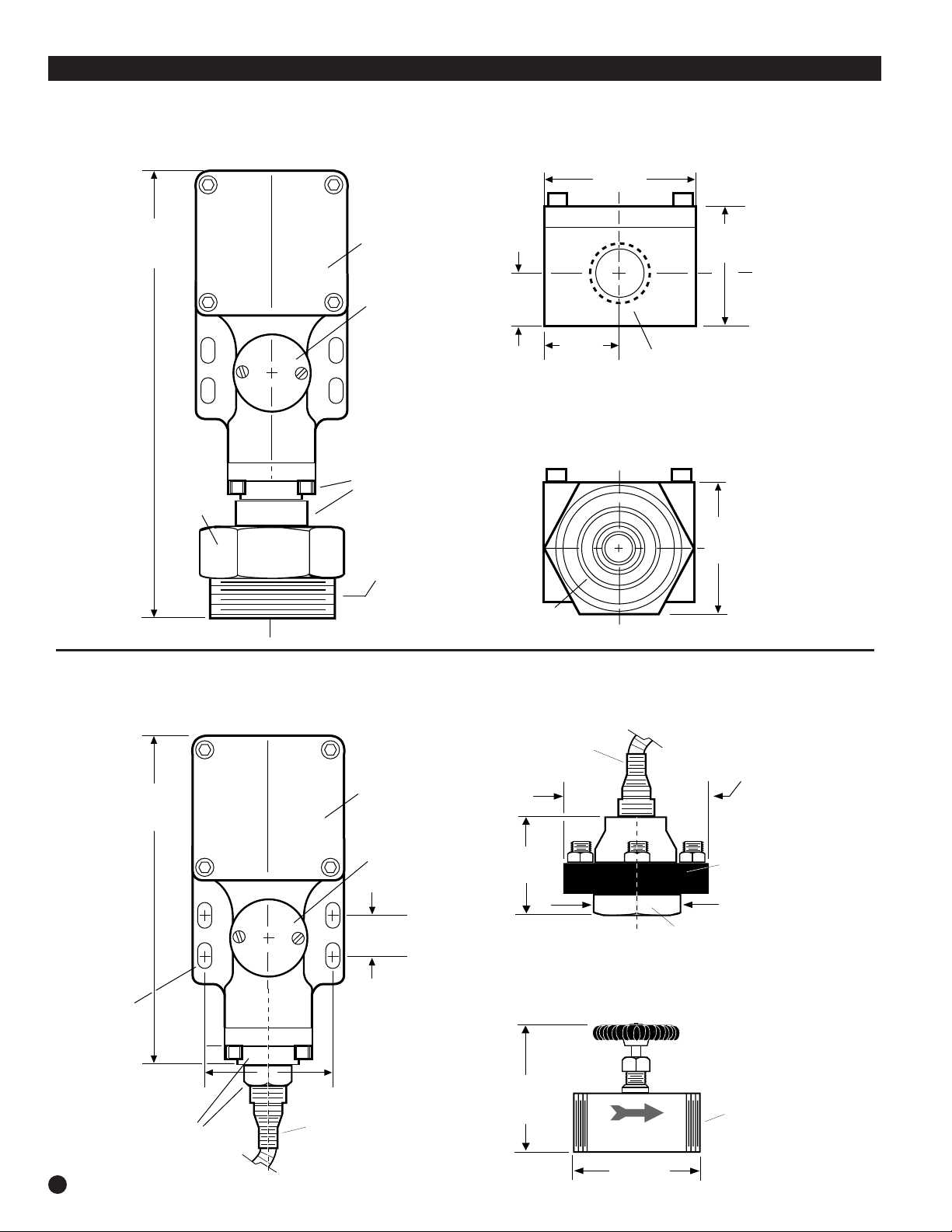

DIMENSIONS

Diaphragm

9-1/4 in.

(235 mm)

MAX.

3 in.

(76 mm)

3/4-14 NPT

Conduit Inlet

7/8 in.

(22 mm)

1-1/2 in.

(38 mm)

2-9/64 in.

(54 mm)

2 in. NPT

Process

Connection

2-1/2 in.

(64 mm)

MAX.

6-1/2 in.

(165 mm)

MAX.

Transmitting

tube, 5 feet

(1.524 m) std.

3/4 in.

(19 mm)

2-1/2 in.

(64 mm)

17/64 x 1/2 in.

(7 x 13 mm)

mounting holes

(4 places)

Sensor

Body

Switch

Enclosure

Switch

Enclosure

Sensor

Body

1 in. NPT (male)

Process Connection

2 places

2-7/8 in.

(73 mm)

LLSR models:

3-3/4 in. (95 mm) dia.

LLSRB models:

3-7/8 in. (98 mm) dia.

1-13/16 in.

(46 mm)

3-7/8 in.

(98 mm)

3-1/2 in.

(89 mm)

Transmitting tube

FLOW

Switch

Trip Point

Adjustment

Panel

1 in. NPT (female) Connection

Switch

Trip Point

Adjustment

Panel

Do NOT Tamper with

these Sealed

Connections

Do NOT Tamper with

these Sealed

Connections

LLS and LLSB Models

Complete Unit

Front View

Switch Enclosure

Top View

Sensor Enclosure

End View

2

Switch Enclosure

Front View

LLSR and LLSRB Models

Sensor Enclosure

Front View

Pulsation Dampener

PD8187 Option

Loading...

Loading...