Page 1

Description

The L129 Series Lube Level Swichgage instrument is a combination lube level indicating gauge with adjustable low and

high limit switches. It provides protection against low oil level or high level

caused by overfill or fuel or water seepage into the crankcase. A 6-3/4 inch

(171 mm) deep sight gauge allows you to check the condition and level of

your oil without shutting down the equipment.

Fingertip adjustable limit switch contacts are adjustable thru 4-7/8 inch (122

mm) range. When the float touches the high or low limit contact, a normally open circuit will close which can activate alarms and/or shutdown the

equipment.

There are two models in the L129 Series: L129 and L129CK1. The L129

model is designed for grounded, low voltage electrical systems. It features a

one-wire-to-ground electrical circuit. The L129CK1 is designed for applications requiring a three-wire, above ground electrical circuit. It features

ungrounded contacts and a conduit hub for electrical wiring connection.

Specifications

Case: Die Cast Aluminum.

Lens: Tempered Glass.

Maximum Working Pressure: 10 psi (68.9 kPa) [0.69 bar].

Process Connection: 1/2 NPT.

Float Material: Brass.

Contact Rating: 2 A @ 30 VAC/DC, pilot duty.

Flow Restrictor Plug

Order Separately

Flow Restrictor Plug restricts oil flow between the

crankcase and the L129 Series. It is typically used on

some mobile applications such as marine and mobile

equipment. Part no. 15050241.

Installation Instructions for

L129 Series Level Swichgage

®

instrument

L-95006N

Revised 06-06

Section 15

00-02-0174

Please read the following information before installing. A visual inspection of this product for

damage during shipping is recommended before mounting.

GENERAL INFORMATION

BEFORE BEGINNING INSTALLATION OF THIS MURPHY PRODUCT

✔✔

Disconnect all electrical power to the machine.

✔✔

Make sure the machine cannot operate during installation.

✔✔

Follow all safety warnings of the machine manufacturer.

✔✔

Read and follow all installation instructions.

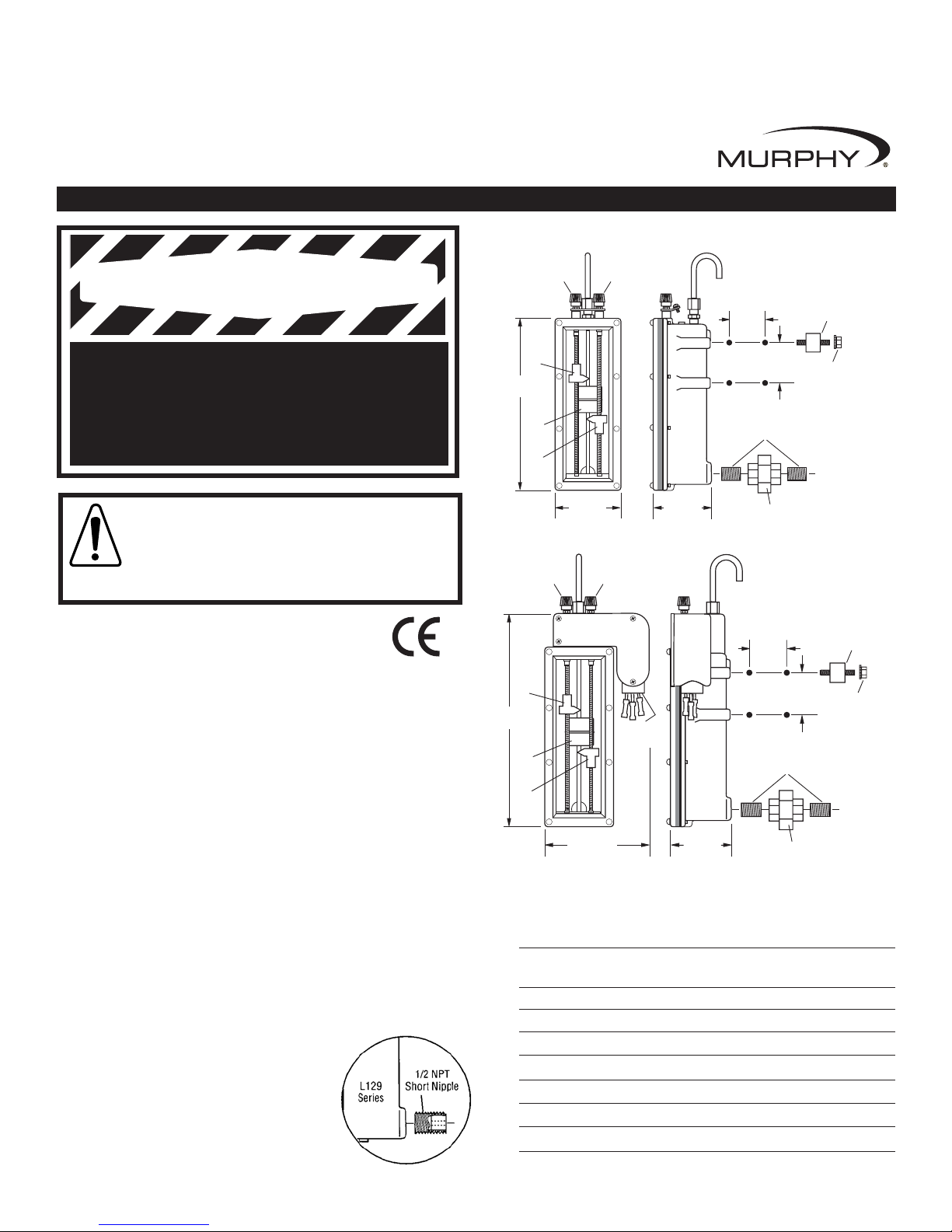

L129CK1

Dimensions

*

L129

CAUTION:

Certain danger to human and to equipment

such as applied in a mobile or marine application may occur if

some equipment is stopped without pre-warning. It is therefore,

recommended that monitored functions be limited to alarm

only or to alarm before shutdown in such applications.

Repair Kits

Specify part number.

L129

15000888 Full Repair Kit (less castings and glass assÕy) fo r date

code T2 and later.

15000480 Bezel, Glass and Gasket Set for date code W7 and later

15000485 Glass and Gasket Set for all date codes

15050241 Restrictor plug for all date codes

L129CK1

15000480 Bezel, Glass and Gasket Set for date code W7 and later

15000485 Glass and Gasket Set for all date codes

15050241 Restrictor plug for all date codes

L-95006N page 1 of 2

*Complete with EMC Council directive 89/336/EEC regarding electromagnetic compatibility.

High Level

Adjust

Low Level

Adjust

WARNING

-

-

-

-

Adjust

2-31/64 in.

(63 mm)

++

High

Contact

++

8 in.

(203 mm)

Float

++

Low

Contact

++

3-3/16 in.

(81 mm)

High Level

Adjust

Low Level

1-1/2 in.

(38 mm)

2 in.

(51 mm)

1/2 NPT Closed Nipple

(2 supplied)

1/2 NPT Union

(1 supplied)

Shock Mount

(2 supplied)

Keps nut

(2 supplied)

High

Contact

9-55/64 in.

(250 mm)

Float

Low

Contact

+ +

+ +

+ +

+

4-55/64 in.

(123 mm)

+

1/2 NPT

Conduit

-

-

-

-

2-31/64 in.

(63 mm)

1-1/2 in.

(38 mm)

2 in.

(51 mm)

1/2 NPT Closed Nipple

(2 supplied)

1/2 NPT Union

(1 supplied)

Shock Mount

(2 supplied)

Keps nut

(2 supplied)

Page 2

INSTALLATION and OPERATION

NOTE: Read all instructions before beginning installation.

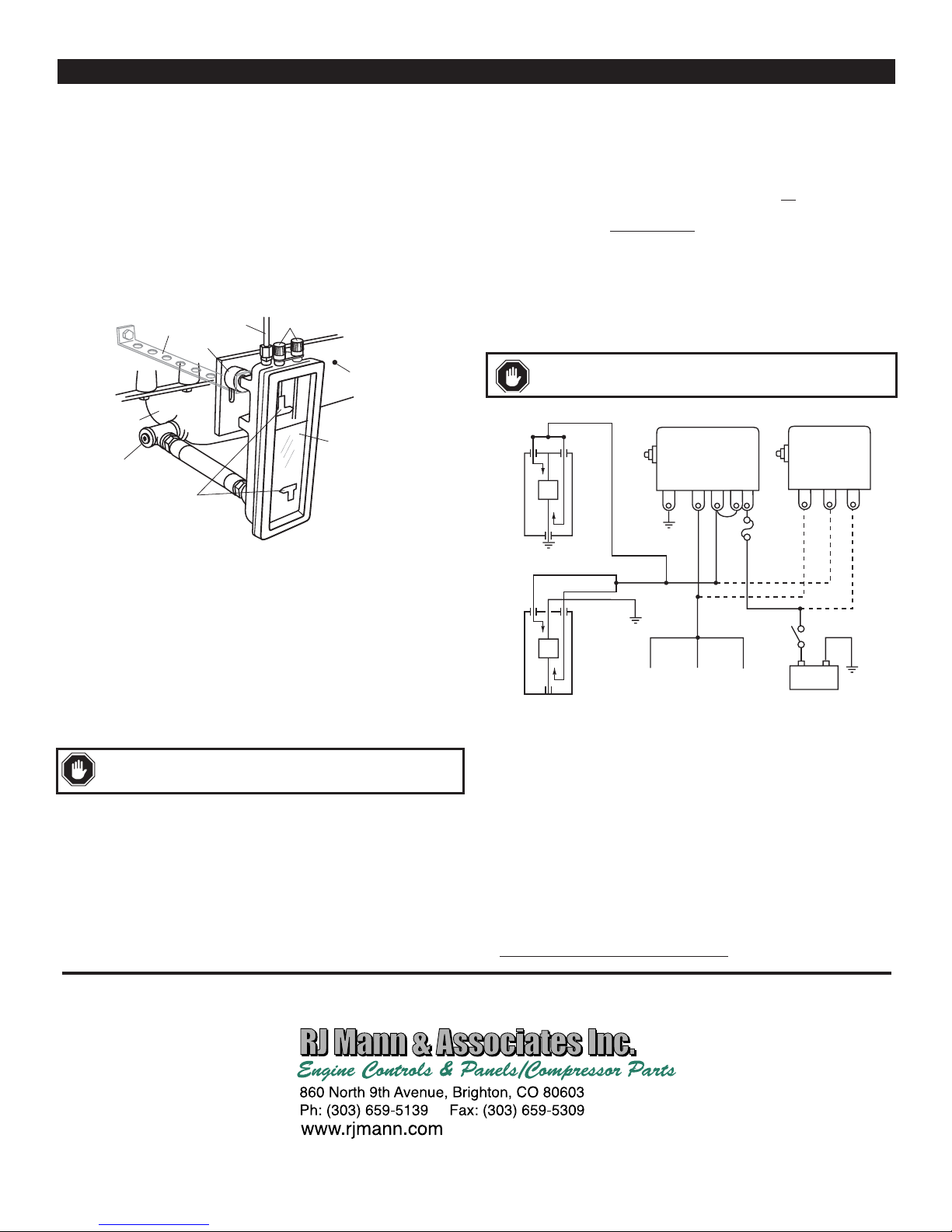

Mounting

1.

Determine which side of the engine to mount the L129. This will normally be the

side of the engine from which it is started. Weld a slotted mounting plate to the

engine skid or attach the mounting plate to the crankcase. If a mounting plate is

not used, a support strap is recommended (see Typical Installation below).

2.

Install the shockmounts in the threaded holes provided in the mounting bosses on

the rear of the L129. NOTE: We recommend using the shockmounts provided

to minimize “contact bounce” resulting in improper operation.

3.

Attach the L129 to the mounting plate as shown below but do not tighten TOO

TIGHT since you will have to adjust the L129 later in the installation process.

Typical Installation

Crankcase

Tee

Customer Supplied

Support Strap

Shockmount

High and Low

Contacts

Vent

Contact Adjustment Knobs

Mounting

Plate

Sight

Glass

L129 vent back to the crankcase. If you do not do this, the L129 will indicate

high level with a pressurized crankcase and a low level with a vacuum crankcase.

In extreme cases a pressurized system will blow oil out the vent tube or in vacuum crankcases can suck oil out of the L129.

To vent the L129 back to the crankcase, install a 1/4 inch (6 mm) O.D.

or larger tubing (copper or flexible) from the L129 vent fitting to a point in the

crankcase above the full oil level or in the fill pipe that is not

restricted by baffles, filters or other obstructions. If connecting directly into the crankcase, be

sure the entry point is clear of oil splash

4.

Refill the crankcase to proper oil level. With the engine running and warm, loosen

that can plug the tube opening.

the L129 from the mounting bracket and adjust the L129 so that the oil level shows

approximately midway or above in the sight glass. Tighten shockmount nuts.

Wiring

Follow appropriate wiring for the alarm or engine shutdown system you are using.

Diagrams below are shown with the float in the “full” position.

CAUTION:

disconnected. Observe all contact ratings and voltages.

HI LOW

perform all wiring connections with the battery

Magnetic Switches

117PH

C S

L129

518PH

G NC

SW1 SW2

B

B

Connecting Hoses and Fittings

1.

DRAIN THE CRANKCASE. If the crankcase does not have an auxiliary plug or

connection, connect the L129 to the crankcase drain plug connection. This connection will n

fiber washer. NOTE: If the drain plug on the crankcase is used for the connection,

we recommend installation of a tee to allow draining of the crankcase for service.

2.

Flexible hose or rigid pipe can be used to attach the L129 to the engine

crankcase. Flexible hose is to be 1/2 in. (13 mm) I.D. minimum and made of

quality material. Use of flexible hose will allow you to adjust the height of the

L129 to properly reflect the oil level in the crankcase. Also, a swivel connection

on one end of the hose will assist in properly aligning the L129.

Rigid pipe is to be 1/2 inch pipe. If the length of the pipe is relatively short, no

additional support for the L129

pipe union is provided in the installation kit.

Attach the hose or pipe from the L129 process connection (1/2 NPT) to the

crankcase.

3.

For vented crankcases, install the tube fitting and copper cane provided in the

installation kit into the top of the L129. Venting to atmosphere will allow the oil

level to rise in the L129 to the same level as in the crankcase, (the pressure/vacuum in the L129 and the crankcase must be equal). If the crankcase develops a

positive (pressure) or negative (vacuum) pressure, you MUST connect the

ormally be a straight (parallel) thread which seals with a copper or

WARNING: If both flexible hose and shockmounts are used, a

gr ound wi r e must be added between the L129 and the engine.

may be needed, although it is recommended. A

HI

BLACK

LOW

RED

WHITE

COM.

L129CK1

_

Rack Pull

Solenoid

Fuel

Valve

Ignition

Coil

+

Battery

Contact Rating: 2 A @ 30 VAC/DC, pilot duty.

Operation Test

The following test is to be performed after the L129 has been installed and the

crankcase has been filled to the proper oil level.

1.

With equipment running, turn the high and low adjust knobs one at a time until

they “make” contact with the float. When contact is made the alarm or shutdown

circuit should actuate.

2.

Return high and low adjustment knobs to the proper contact position before

operating equipment.

Warranty

A limited warranty on materials and workmanship is given with this FW

Murphy product. A copy of the warranty may be viewed or printed by going

to www.fwmurphy.com/support/warranty.htm

L-95006N page 2 of 2

Loading...

Loading...